Claw-type rotatable dynamic balance base cap clamping vice

A technology of rotational balance and dynamic balance, which is applied in the vise field, can solve problems such as difficult vise clamping smoothly, affecting clamping stability and precision, and achieves the effect of increasing practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The features and advantages of the present invention will be described in detail below with reference to the accompanying drawings.

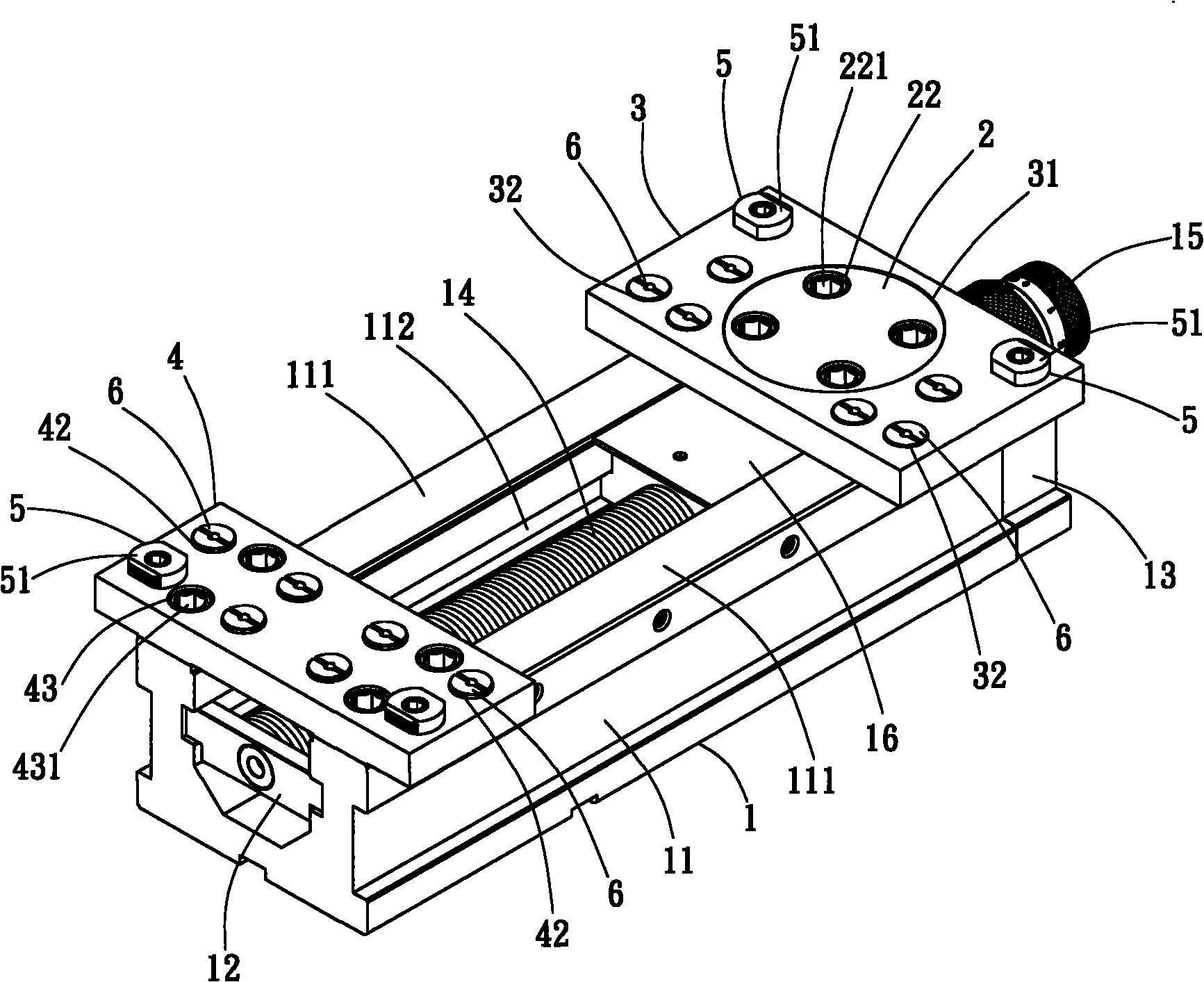

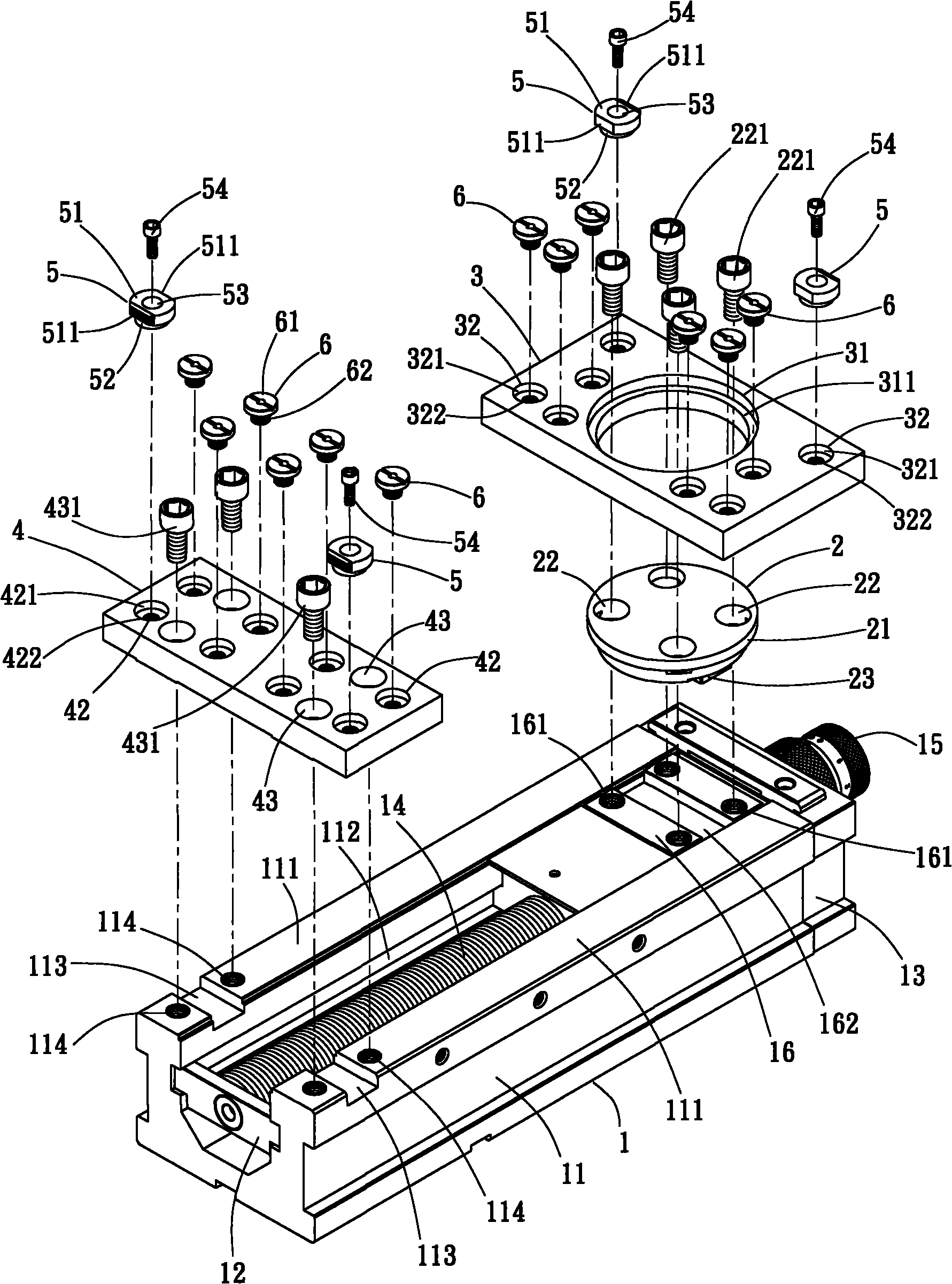

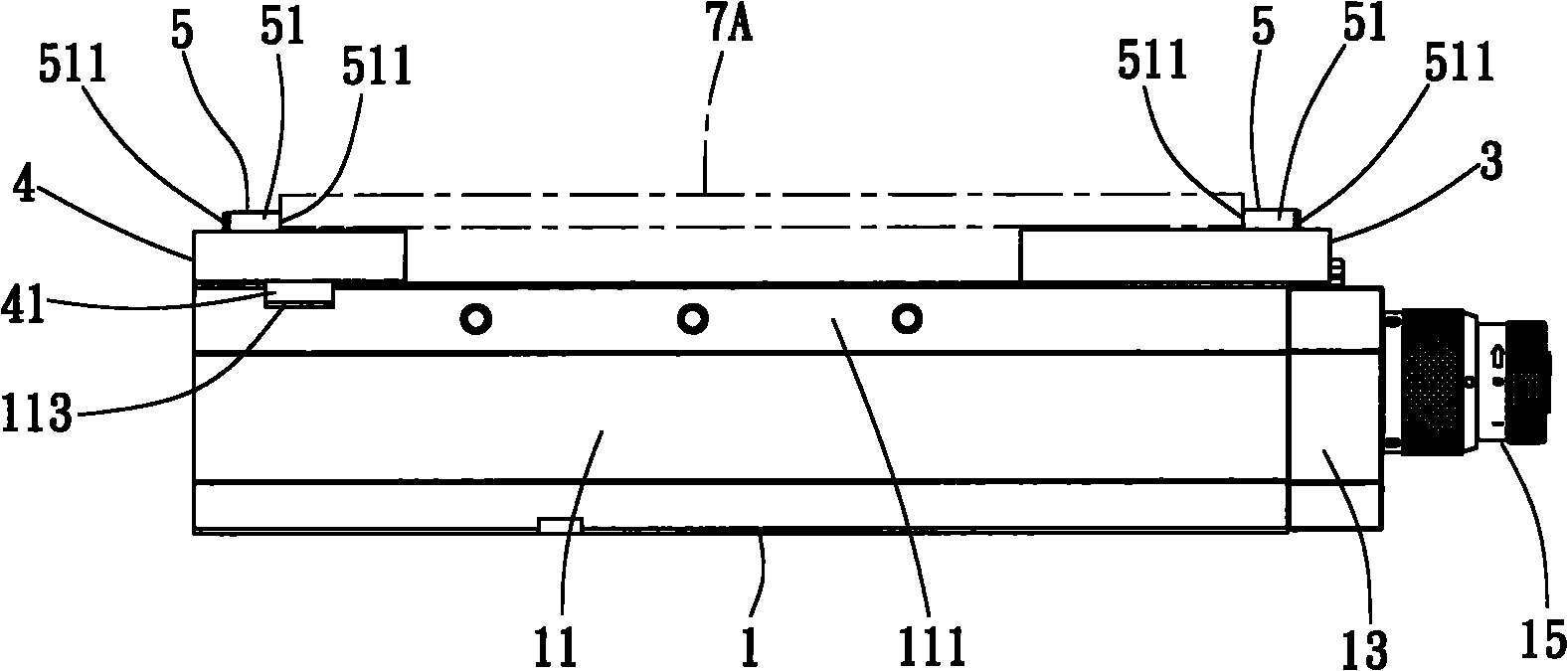

[0029] Such as figure 1 and figure 2 As shown, the claw-type rotatable rotary balance jaw clamping vise of the present invention, its preferred embodiment includes a vise body 1, a fulcrum 2, a dynamic balance jaw 3, a fixed jaw 4 and two or more clamps Claw 5 consisting of:

[0030] Vise body 1, such as figure 1 and figure 2 As shown, it includes a base 11, the base 11 is provided with two parallel slide rails 111, an accommodating chamber 112 is formed between the two slide rails 111, and a positioning groove 113 is provided at the proximal end of the slide rails 111 And one or more second fixing parts 114, the second fixing parts 114 can be screw holes. And the front end of this accommodating chamber 112 is combined with front axle seat 12, and rear end is combined with rear axle seat 13, is provided with rotatable screw rod 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com