Hawthorn fruit drying device with charging machine

A drying device and feeding machine technology, applied in the fields of application, food processing, food science, etc., can solve the problems of easy wear of aluminum profiles and sprockets, inconvenient replacement and maintenance, short service life, etc., to achieve low cost, The structure is simple and the effect of reducing the noise in use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

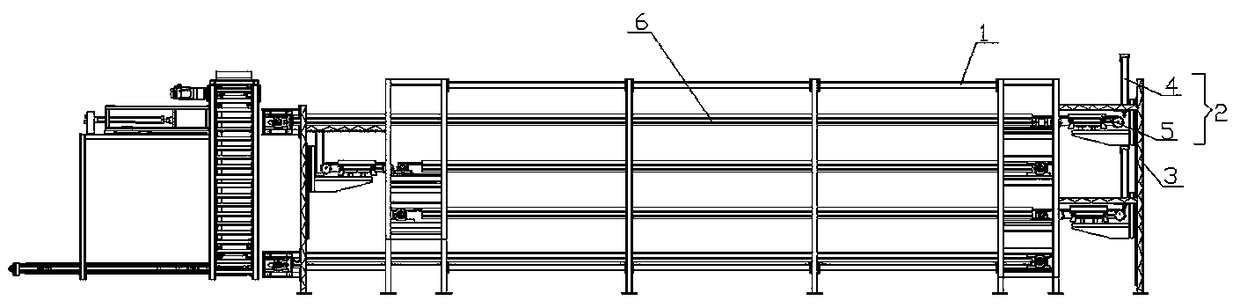

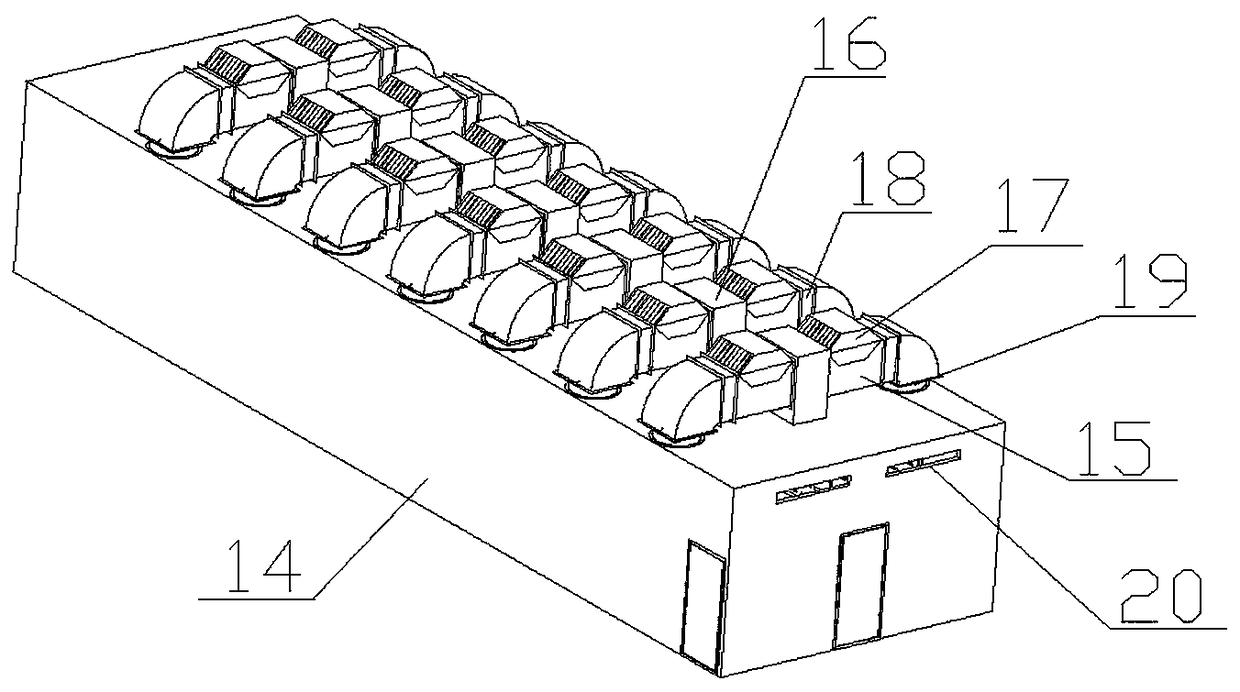

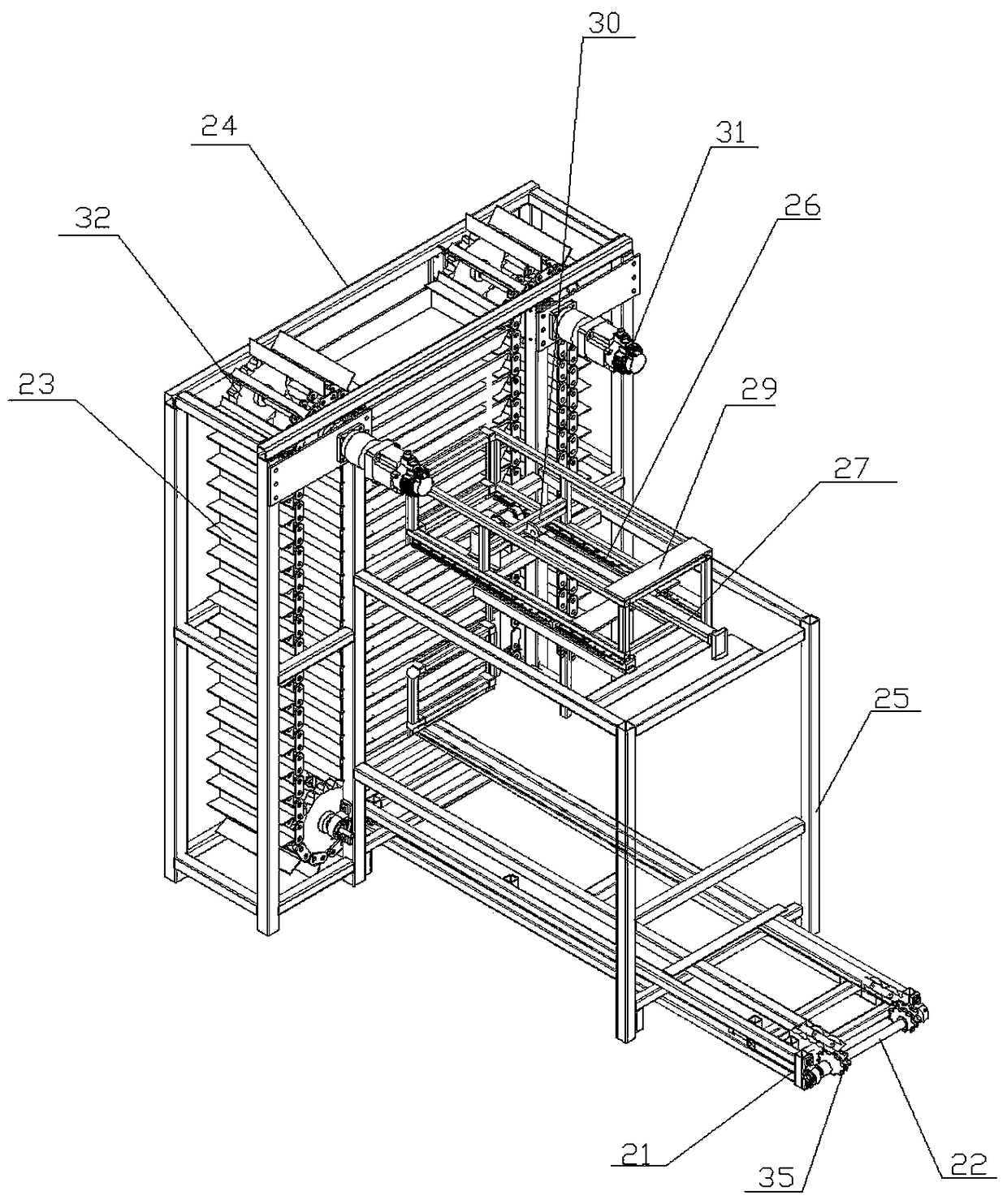

[0047] Such as Figure 1-15 As shown, a hawthorn drying device with a feeding machine includes a drying room 14, a feeding machine located outside the drying room 14, several heat transfer systems arranged in parallel above the drying room 14 and located at the drying room 14. The conveying device inside the drying room 14; the top of one end of the drying room 14 is provided with a feed port 20, and the bottom is provided with a discharge port; The conveying part at the bottom, the lifting part located at the inner end of the conveying part and the pushing part located at the outside of the lifting part; The air inlet 19 of the wet blower 16 faces down and communicates with the inside of the drying room 14, and the air outlets on both sides of the humid exhaust blower 16 are respectively provided with air ducts 15 connected to the air outlets of the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com