Liquid phase fluorination reaction device

A liquid-phase fluorination and reaction device technology, which is applied in organic chemistry, halogen substitution preparation, etc., can solve the problems of inconspicuous catalytic effect, slow reaction speed, poor mass transfer and heat transfer effects, etc., to improve mass transfer effect, The effect of reducing the volume and speeding up the reaction speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

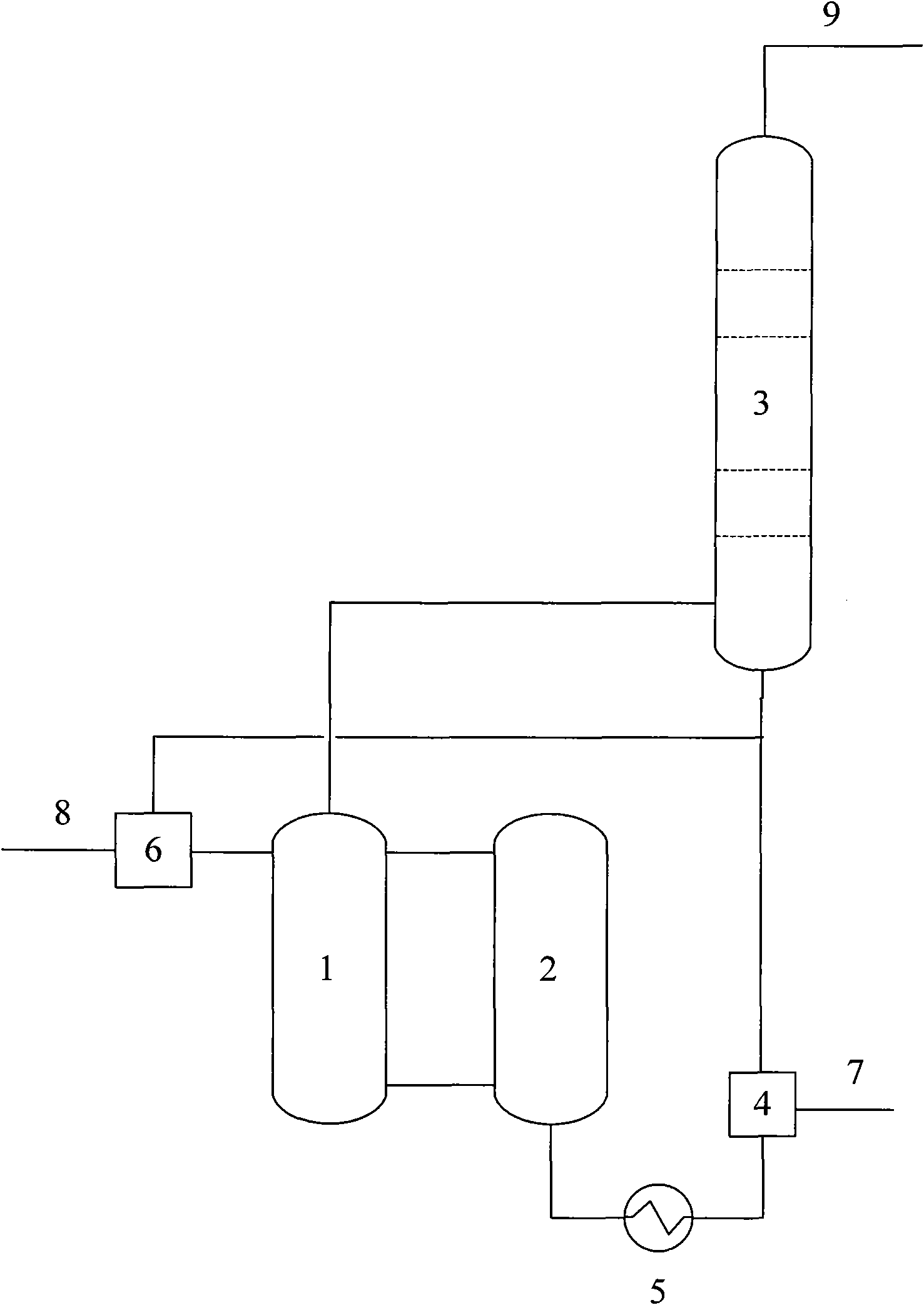

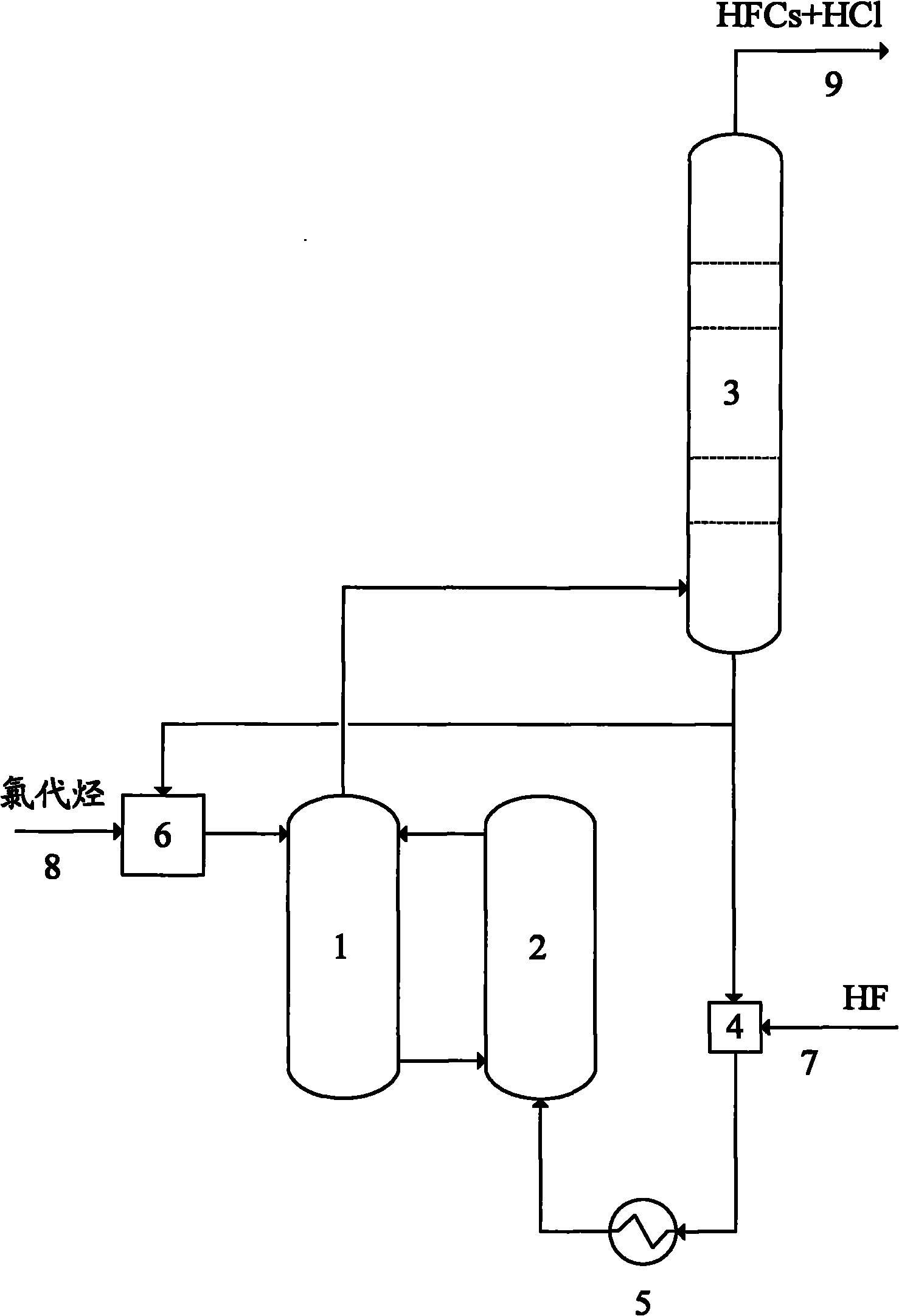

[0022] Refer to attached figure 1 , 3 The present invention is further described in detail.

[0023] First the SbCl 5The liquid phase fluorination catalyst is added to the liquid phase fluorination reactor; fresh HF enters the high temperature from the bottom feed port after being preheated by the HF feed mixer (4) and the HF preheater (5) through the HF feed pipe (7). Reaction zone (2), and enters low-temperature reaction zone (1) from the upper outlet of high-temperature reaction zone (2), HF enters reflux tower (3) by the top outlet of low-temperature reaction zone (1), as reflux tower A part of the bottom fraction of (3) is circulated to the high-temperature reaction zone (2) through the HF feed mixer (4), and another part is circulated to the low-temperature reaction zone (1) through the chlorinated hydrocarbon feed mixer (6). By controlling the outlet temperature of the HF preheater (5) and the flow rate of HF, the temperature of the low-temperature reaction zone (1) ...

Embodiment 2

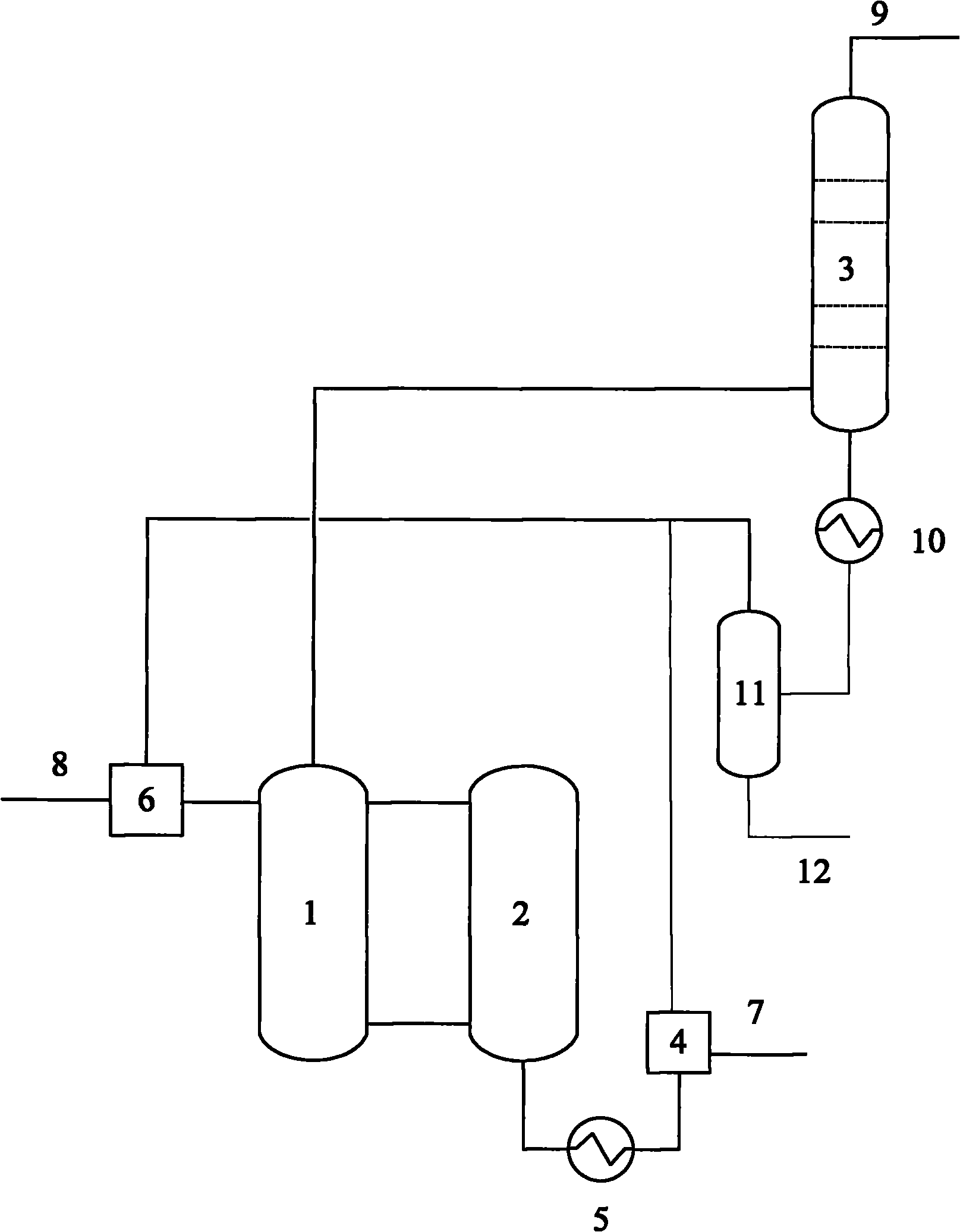

[0027] Refer to attached figure 2 , 4 The present invention is further described in detail.

[0028] First the SbCl 5 The liquid phase fluorination catalyst is added to the liquid phase fluorination reactor; fresh HF enters the high temperature from the bottom feed port after being preheated by the HF feed mixer (4) and the HF preheater (5) through the HF feed pipe (7). Reaction zone (2), and enters low-temperature reaction zone (1) from the upper outlet of high-temperature reaction zone (2), HF enters reflux tower (3) by the top outlet of low-temperature reaction zone (1), as reflux tower The bottom fraction of (3) enters the phase separator (11) after being cooled by the cooler (10), a part is circulated to the high temperature reaction zone (2) through the HF feed mixer (4), and the other part is mixed through the chlorinated hydrocarbon feed The device (6) is recycled to the low temperature reaction zone (1). By controlling the outlet temperature of the HF preheater (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com