Supercritical composite electroplating drill bit machining device based on swept cathodes and use method

A mobile cathode and composite electroplating technology, which is applied to the plating of superimposed layers, electrodes, electrolytic components, etc., can solve the problems of increasing the cost of power consumption and energy consumption, unable to achieve mass production, and high production costs, and achieve energy saving. wasteful effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] In order to make the technical solutions of the present invention clearer and clearer to those skilled in the art, the present invention will be further described in detail below in conjunction with the examples and accompanying drawings, but the embodiments of the present invention are not limited thereto.

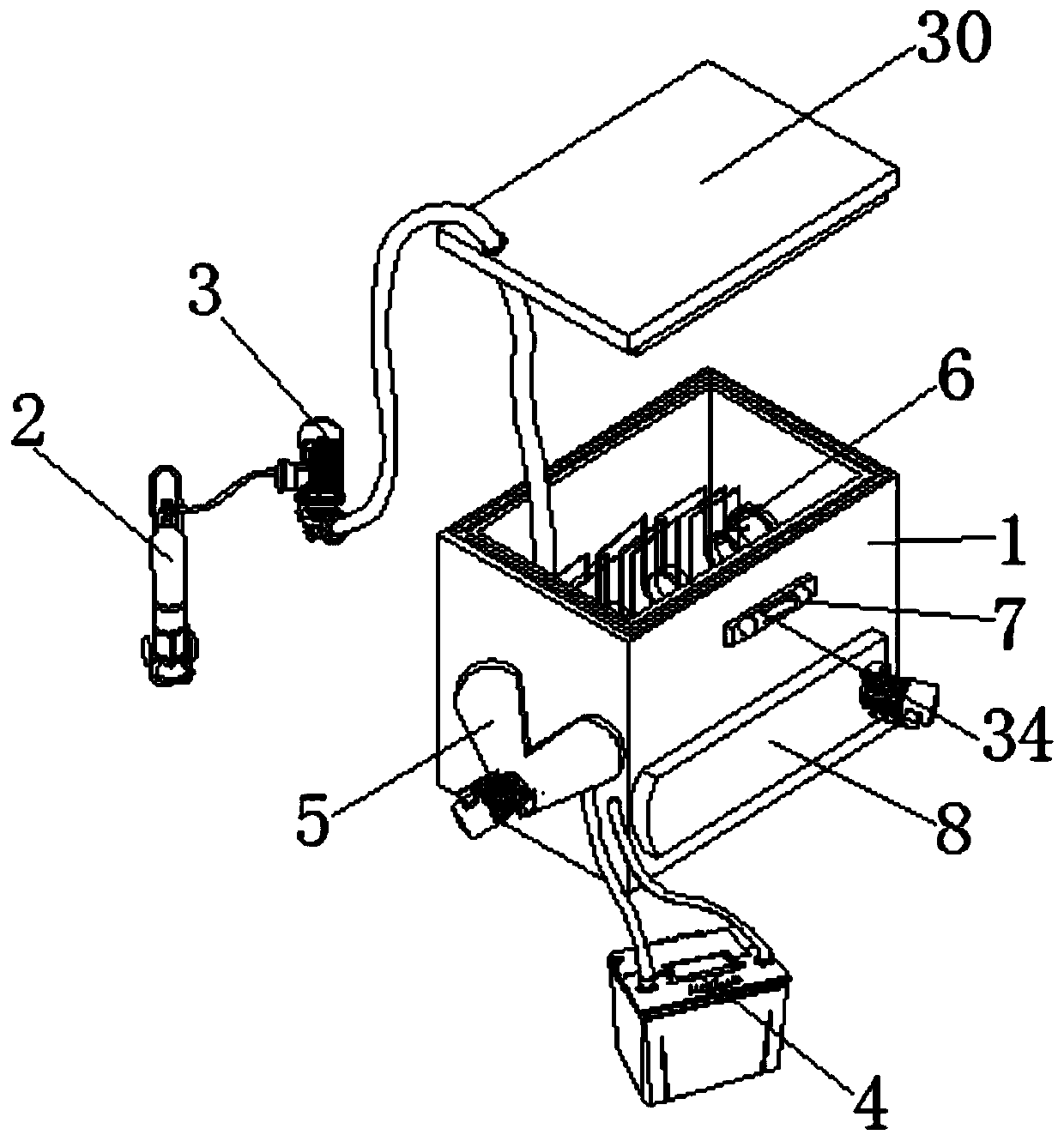

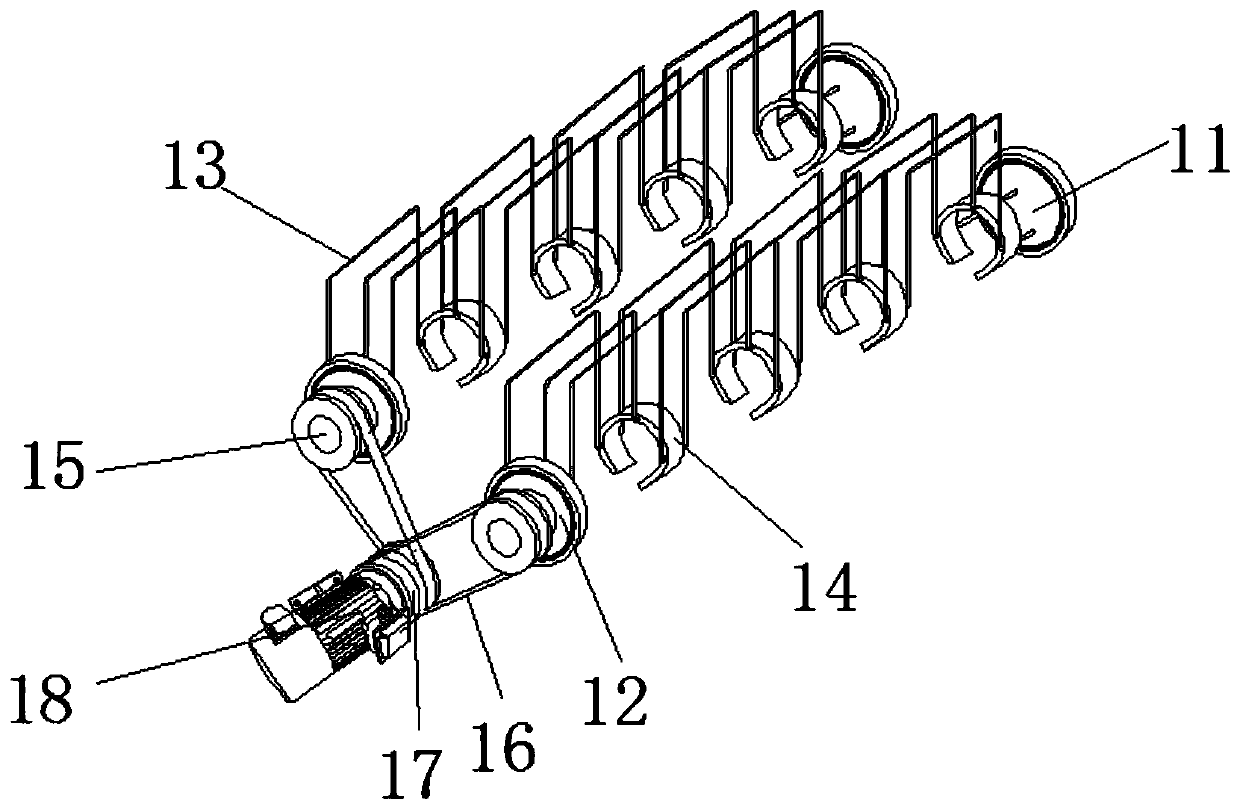

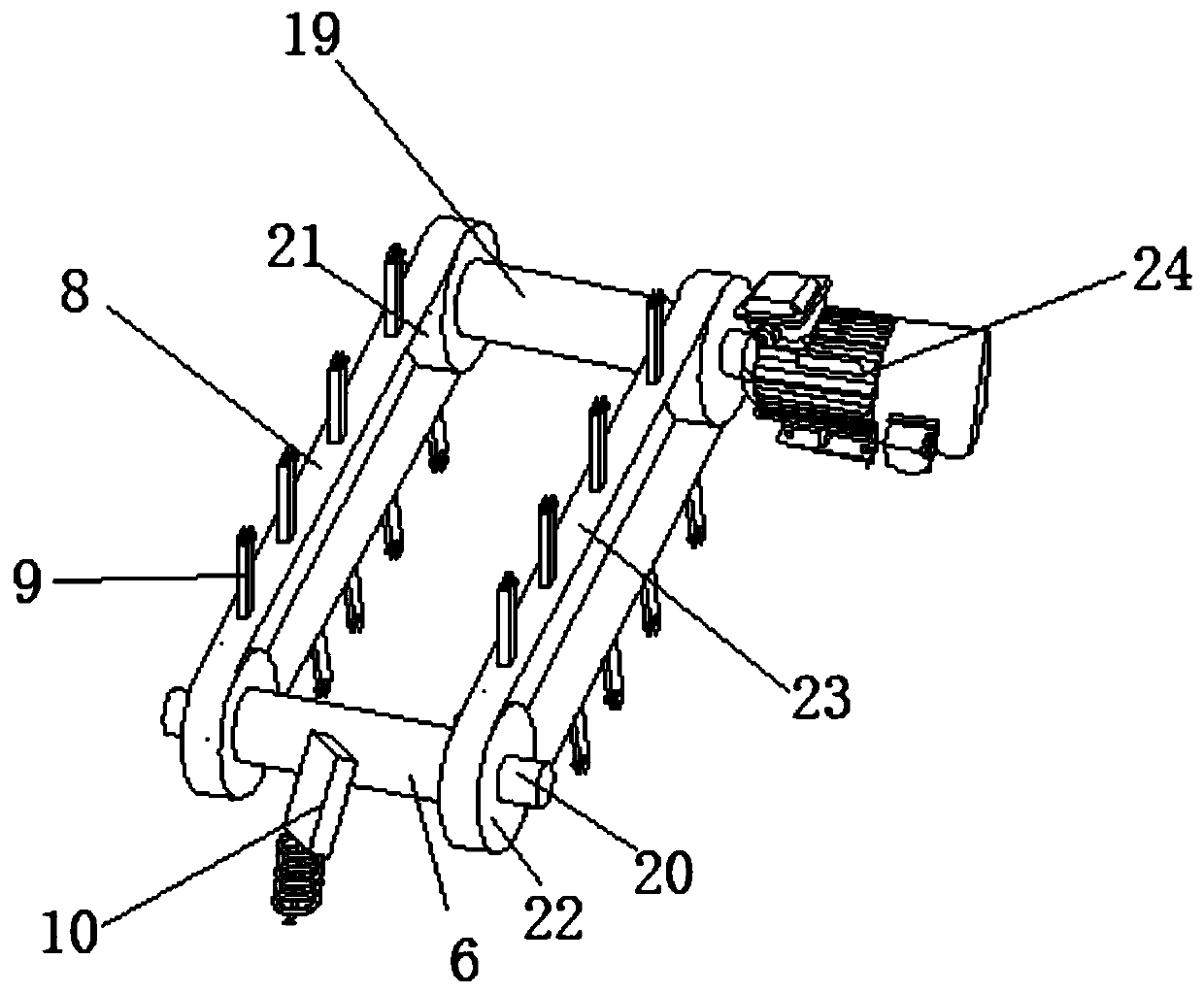

[0037] In this example, if figure 1 As shown, it includes a reaction tank 1, a carbon dioxide gas cylinder 2, a high-pressure pump 3 and a DC power supply assembly 4. The outlet end of the carbon dioxide gas cylinder 2 is connected to one end of the high-pressure pump 3 through a hose, and the other end of the high-pressure pump 3 is connected to the reaction tank through a hose. The bottom of the pool 1 is connected, and the reaction pool 1 is provided with an anode assembly driving mechanism 5, and the anode assembly 6 located inside the reaction pool 1 is driven by the anode assembly driving mechanism 5, and the reaction pool 1 is provided with an electric heatin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com