Patents

Literature

132results about How to "Stable traction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

INTEGRATED PROPULSION & STEERING For Battery Electric Vehicles (BEV), Hybrid Electric Vehicles (HEV), Fuel Cell Electric Vehicles (FCEV), AV (Autonomous Vehicles); Electric Trucks, Buses and Semi-Trailers

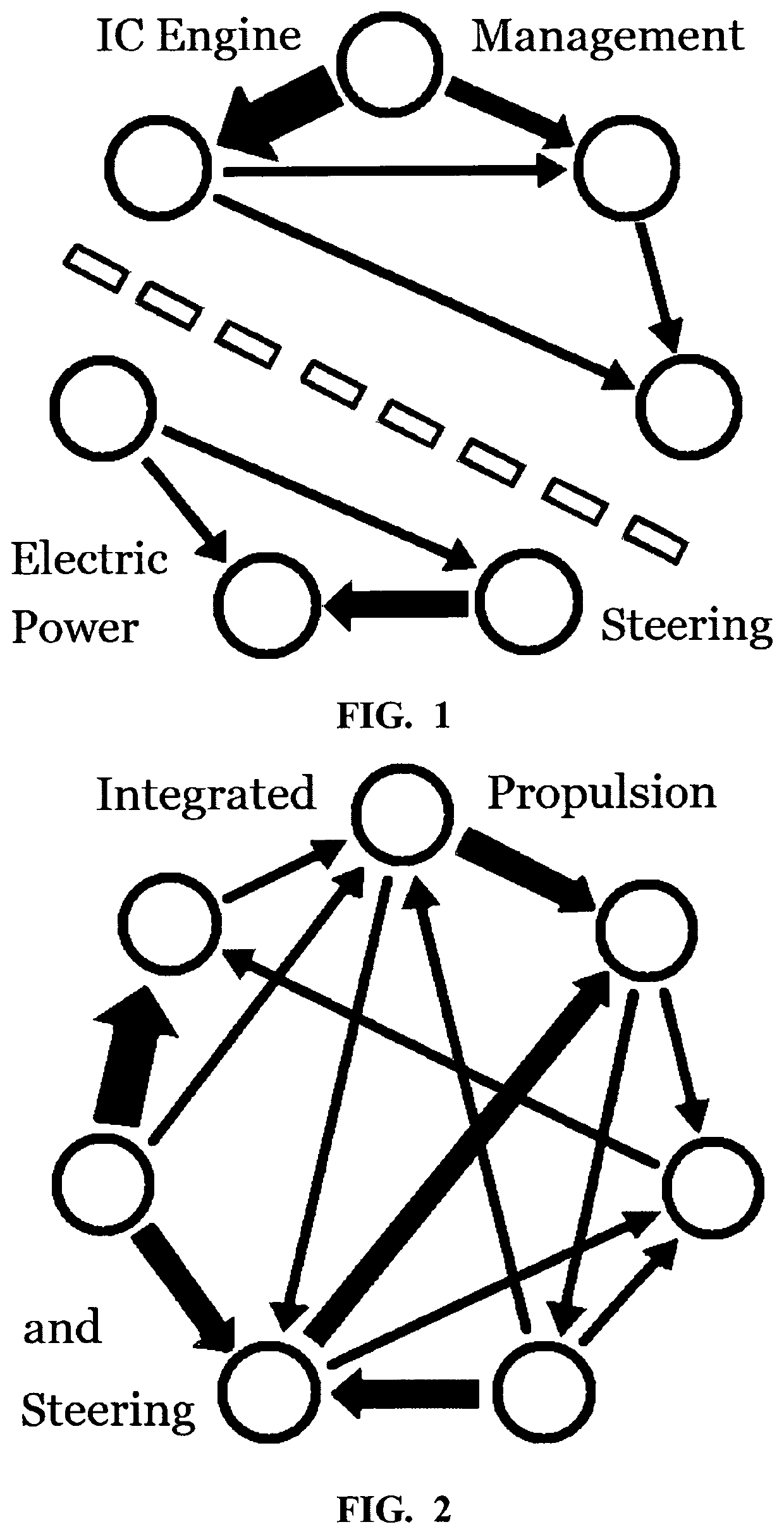

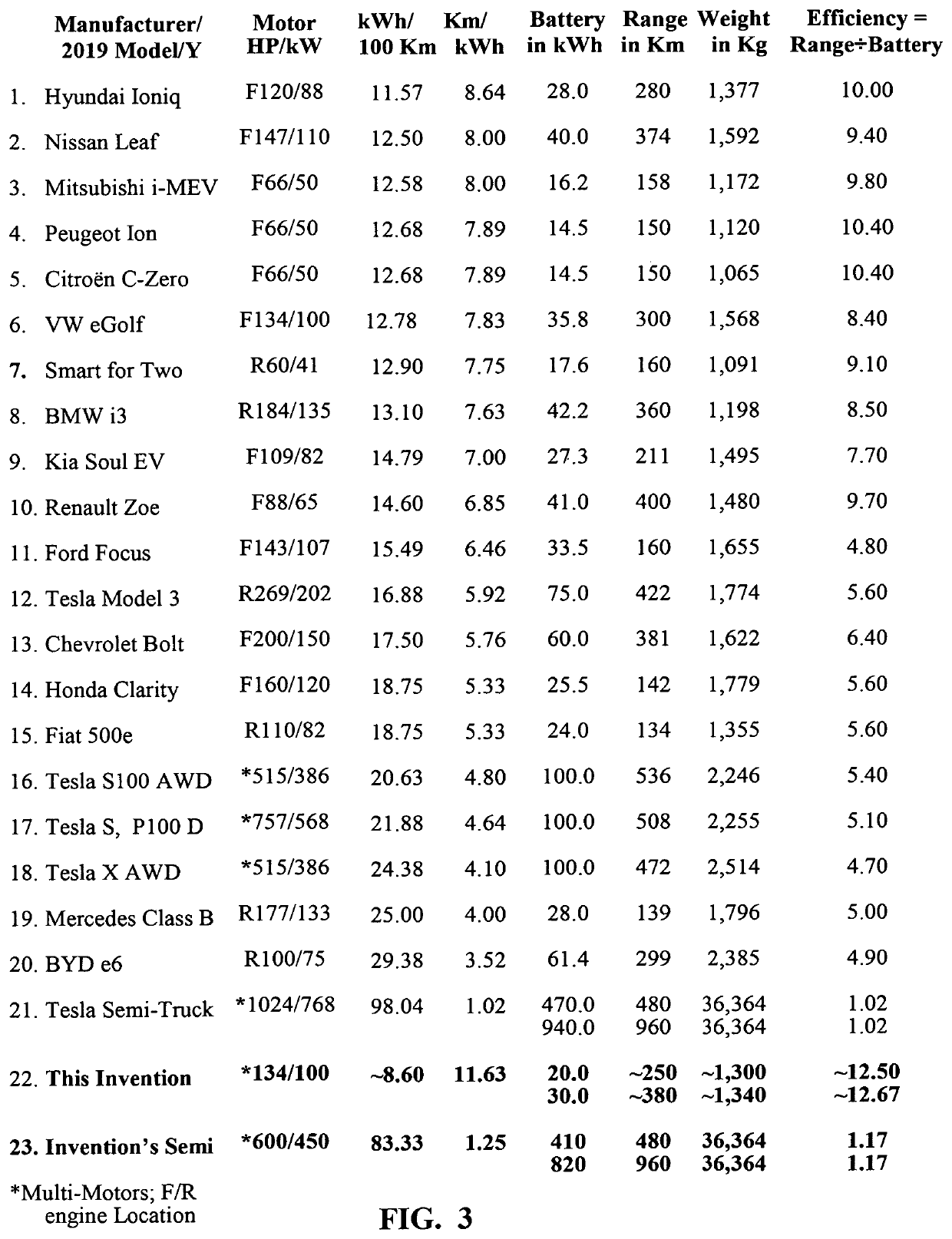

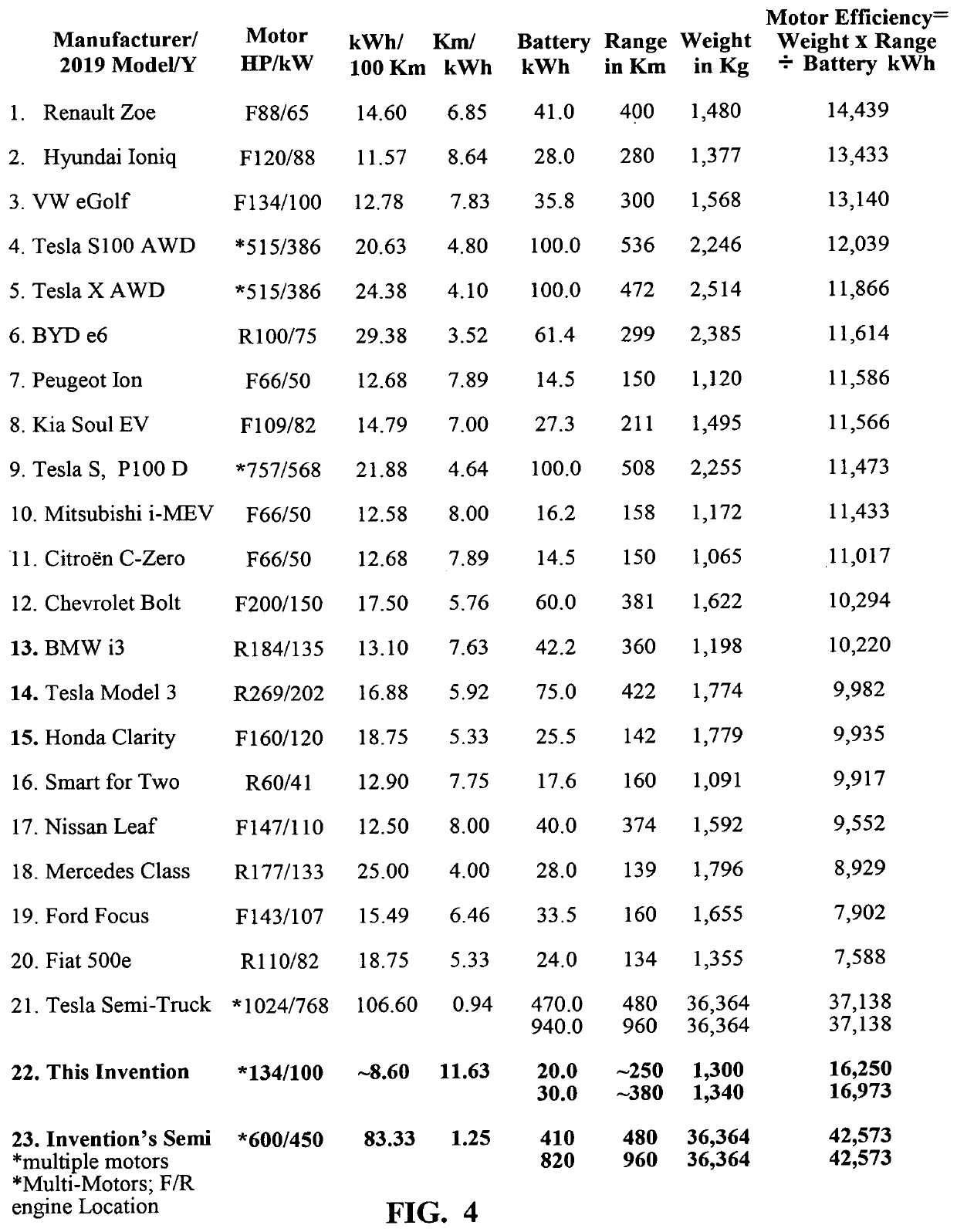

InactiveUS20190351895A1Stable tractionEasy to operateHybrid vehiclesVehicle sub-unit featuresEngineeringActuator

A vehicle, integrated all-wheel propulsion and steering system with plurality of propulsion and steering power sources, designed with enumerate specifications are coupled to, and de-coupled from a final drive of the vehicle propulsion system. A controller receives input-signals from the driver steering-wheel sensor; computes a set of reactions to the plurality of steering-actuators, wherein feedback-mechanism with each wheel-position sensor, the controller secures each wheel in its computed angle. In different speed and load conditions, the controller is programmed to compute a desired power demand then couple to the final drive[s] the propulsion power source[s] that is designed to do-the-job with the least energy consumption. When the vehicle changes speed and load, the controller couples a different power source[s], and de-couples the previous power source[s] to meet the power demand. In turning-modes, whilst positioning every wheel in its computed position, the controller computes the different distances the left and the right wheels of the vehicle have to travel, wherein the controller moves-up the propulsion power sources velocity to the wheels opposite to the turn to make a perfect turn without EPS assistance.

Owner:BEN ARI JACOB

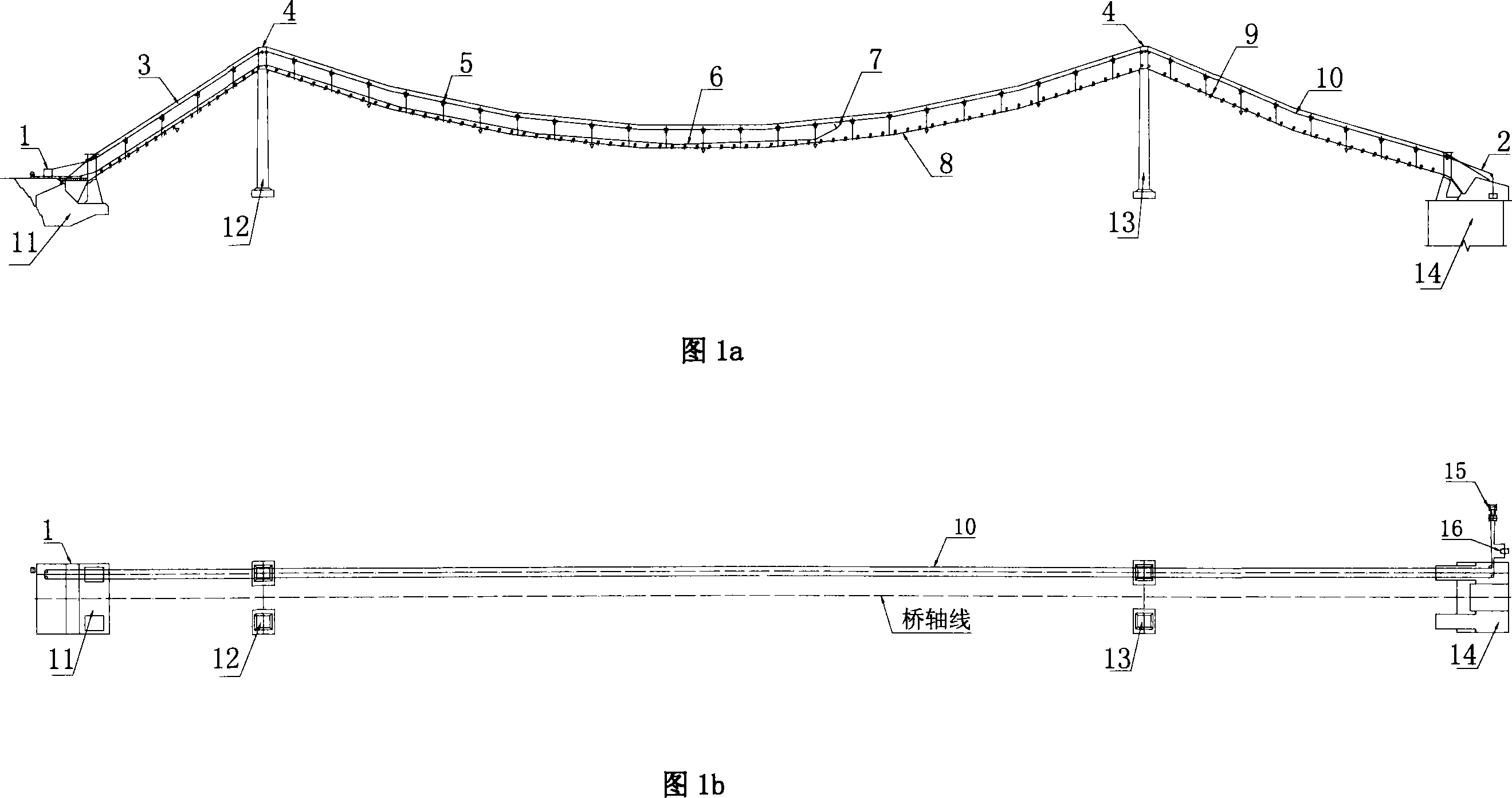

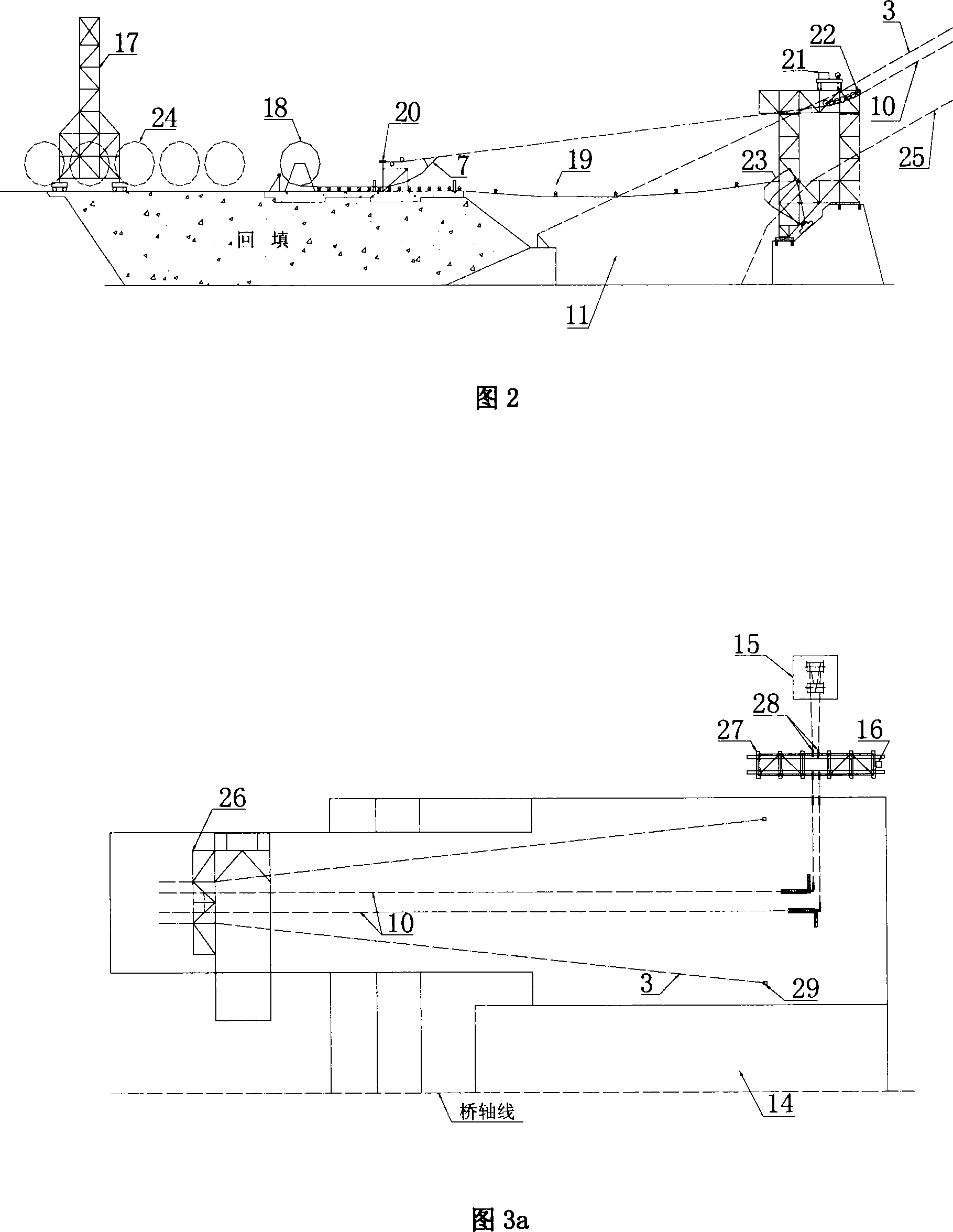

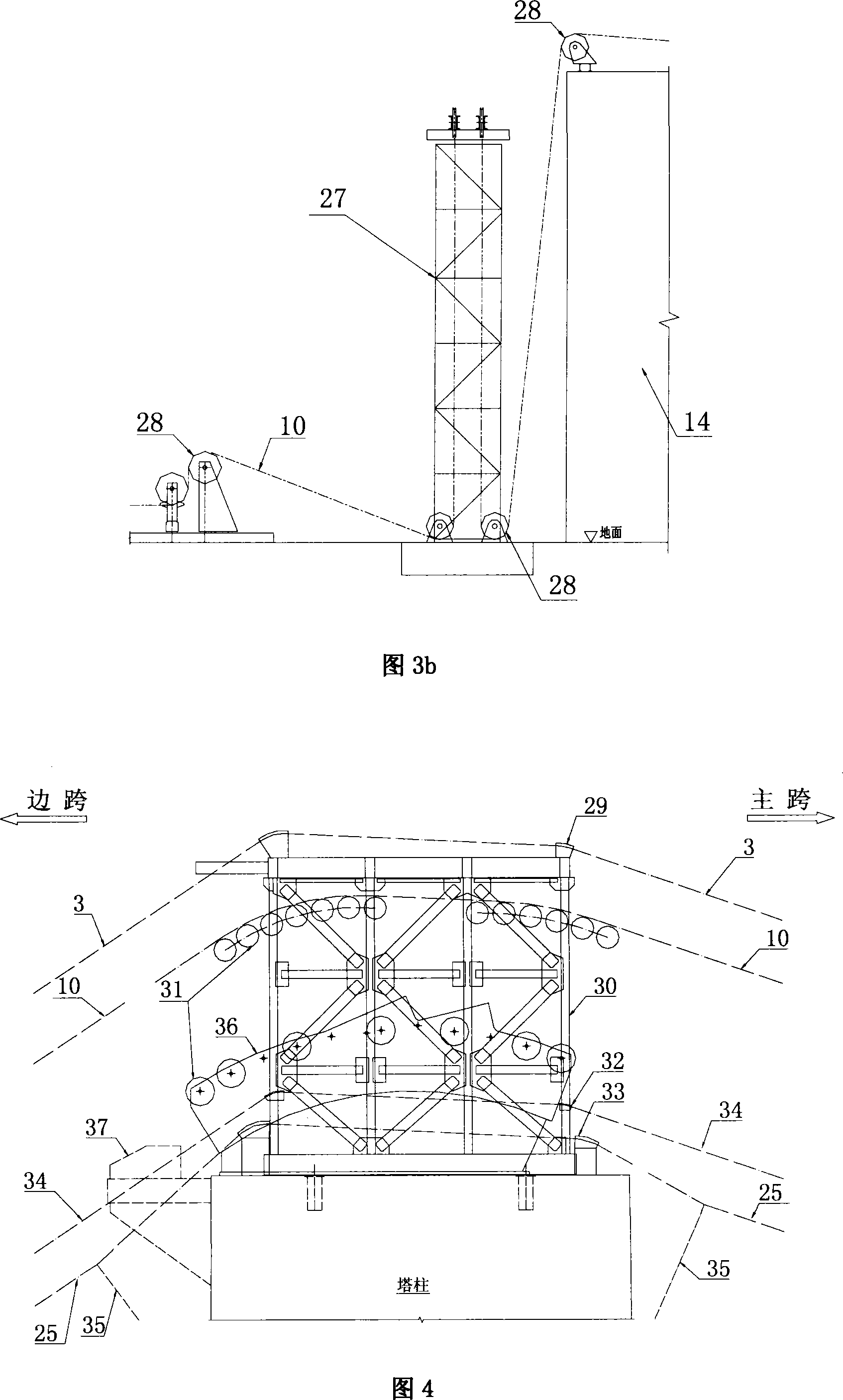

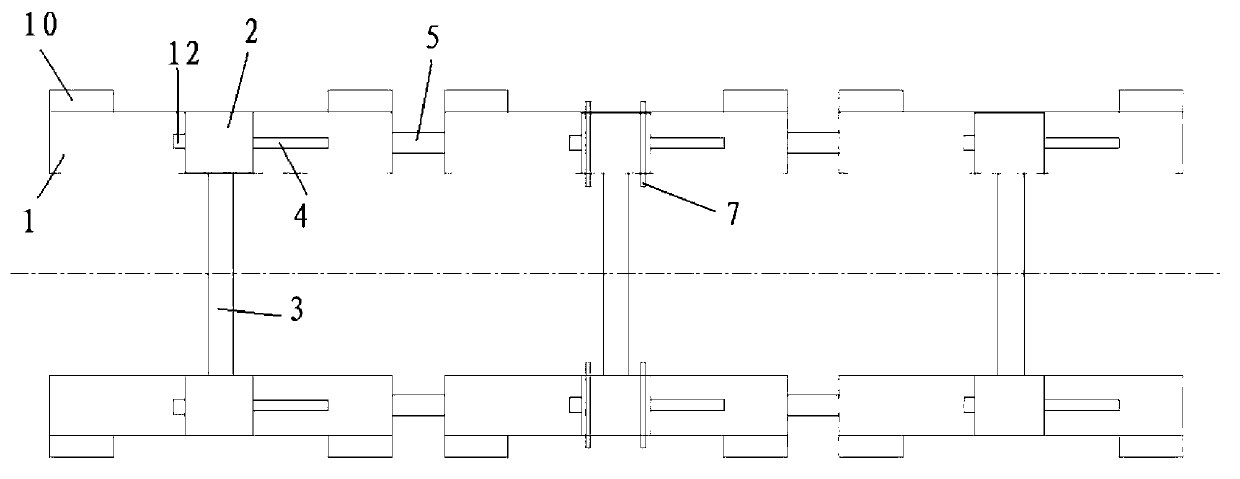

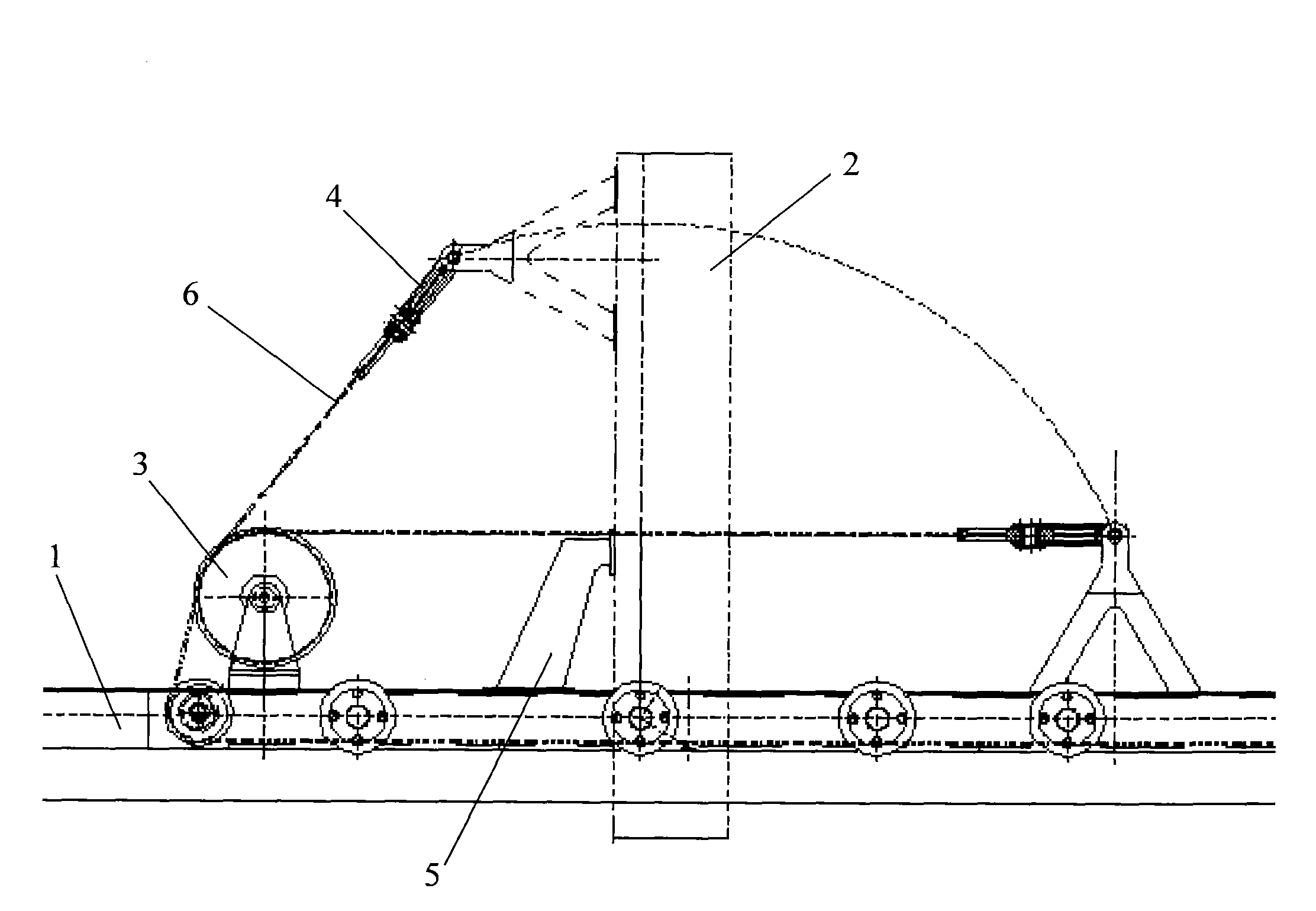

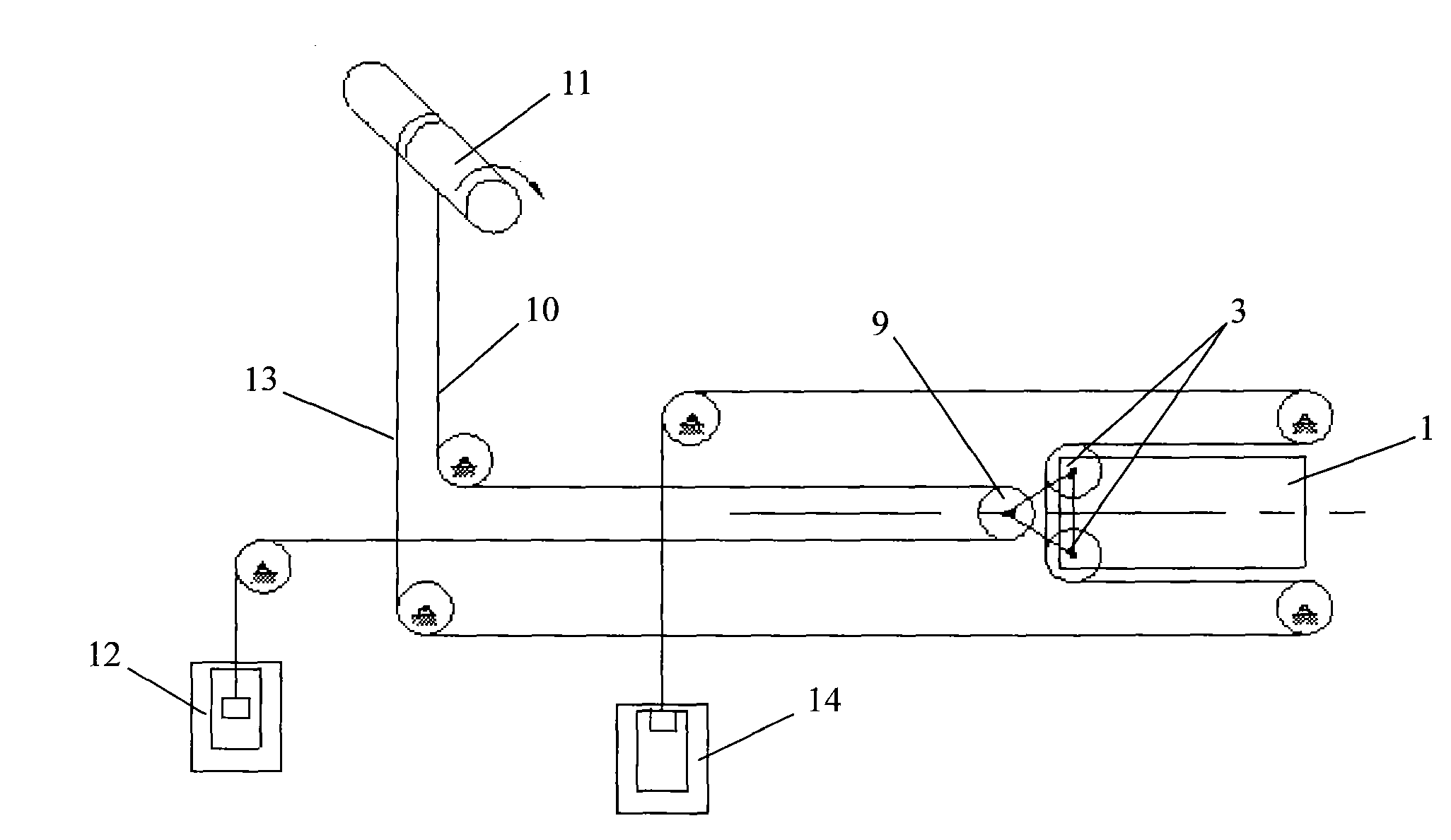

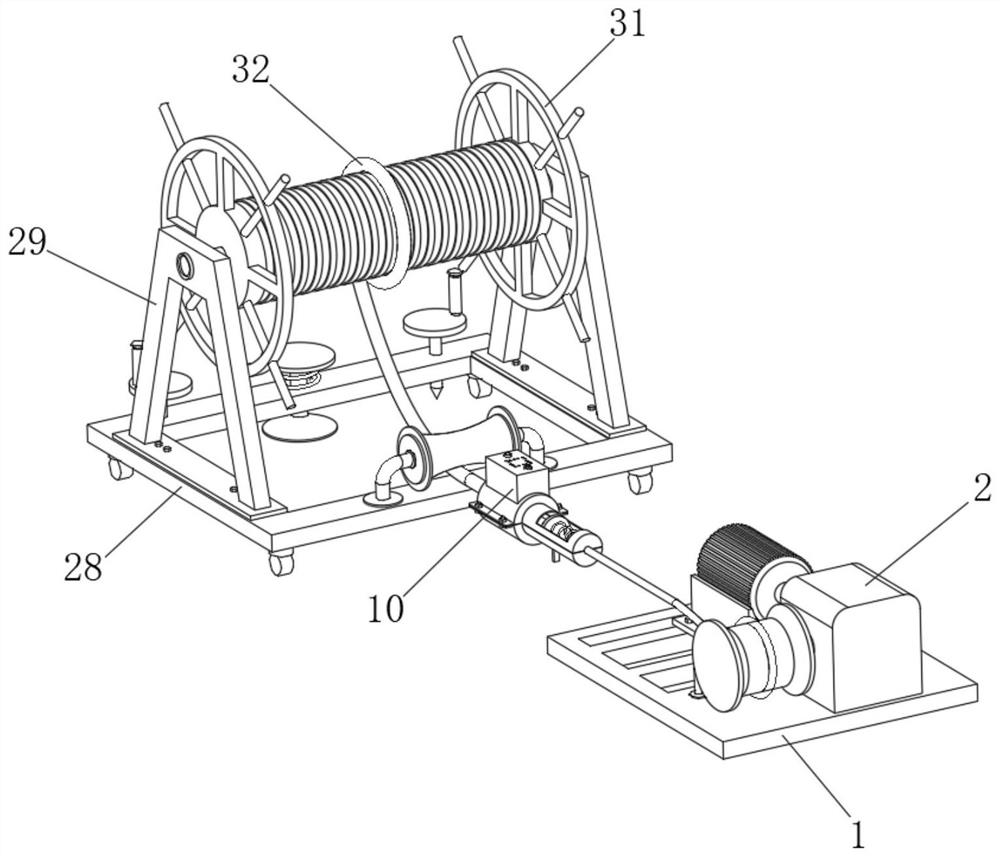

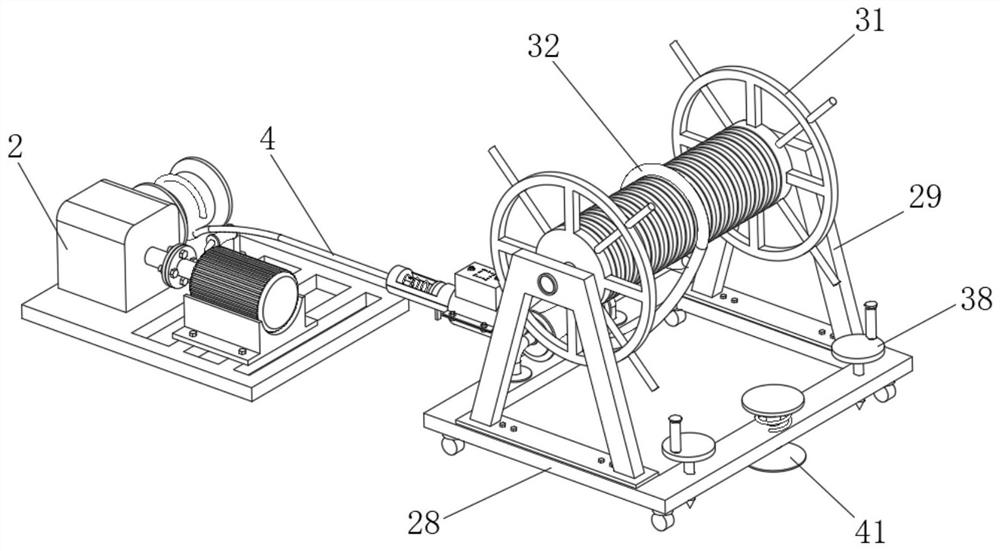

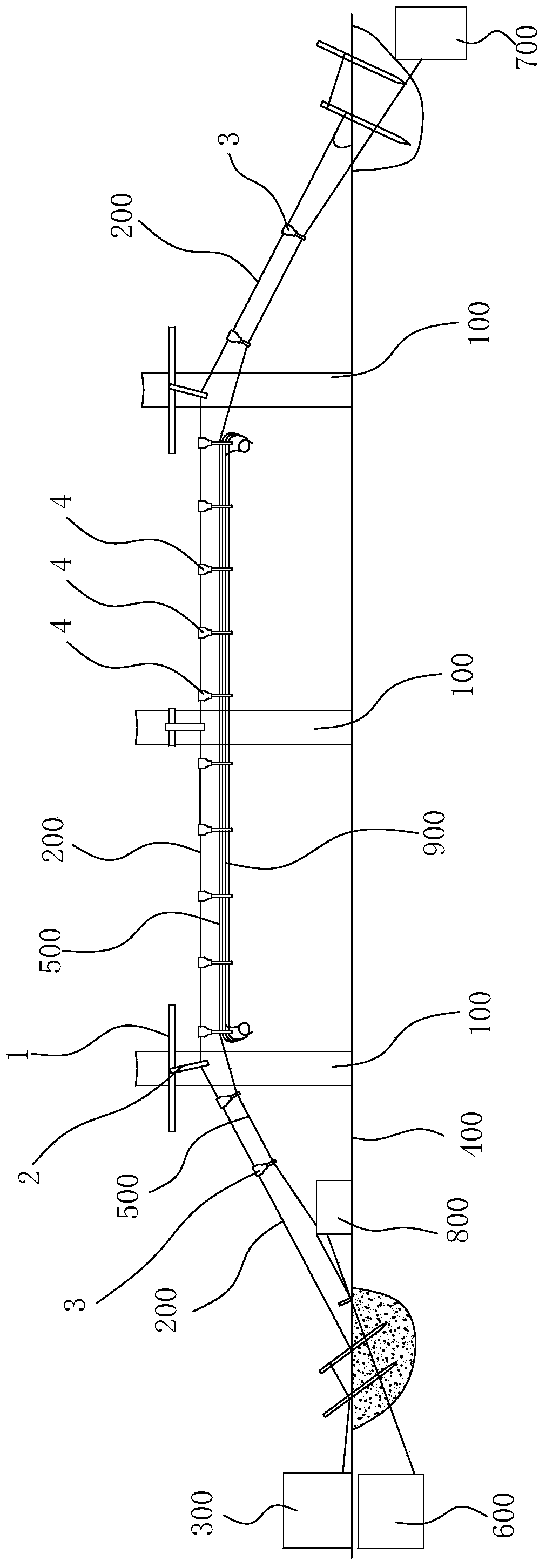

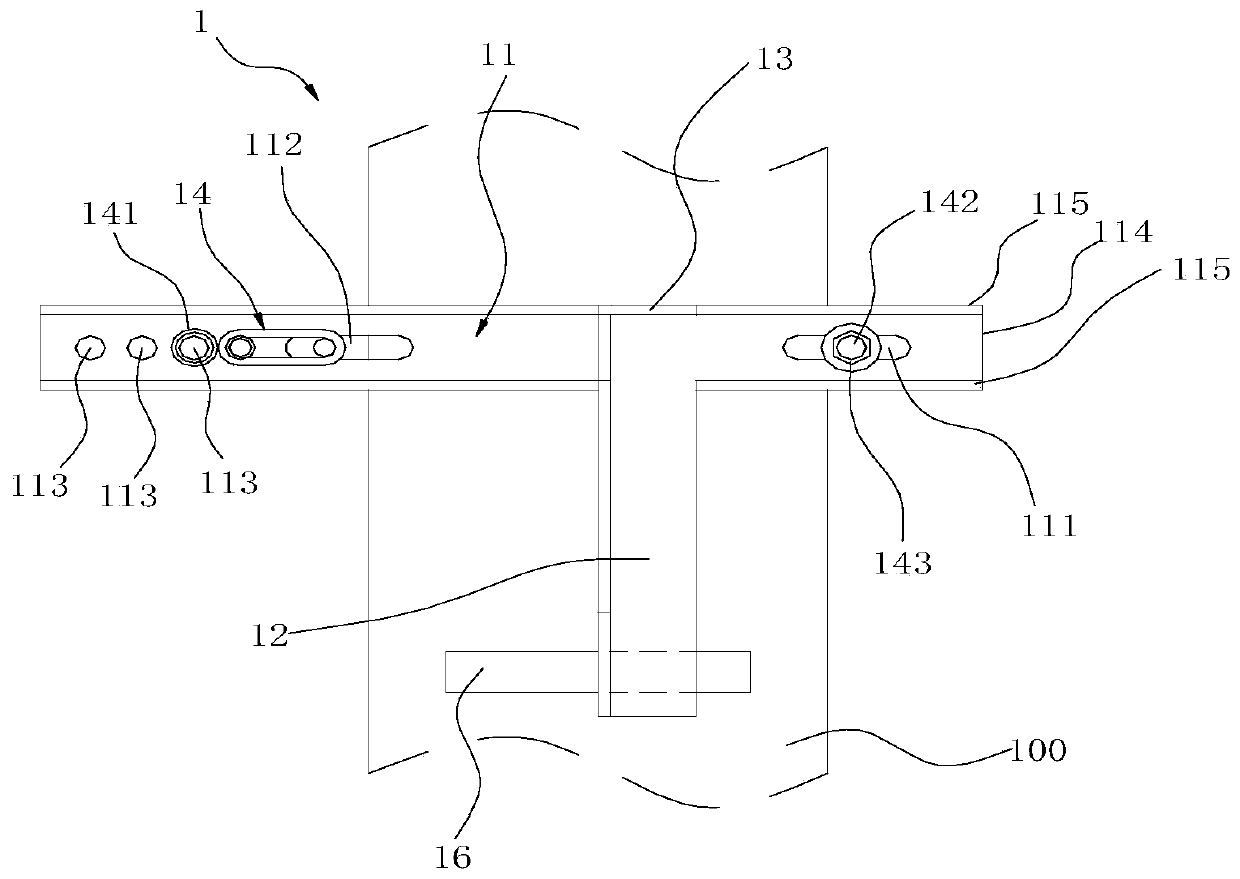

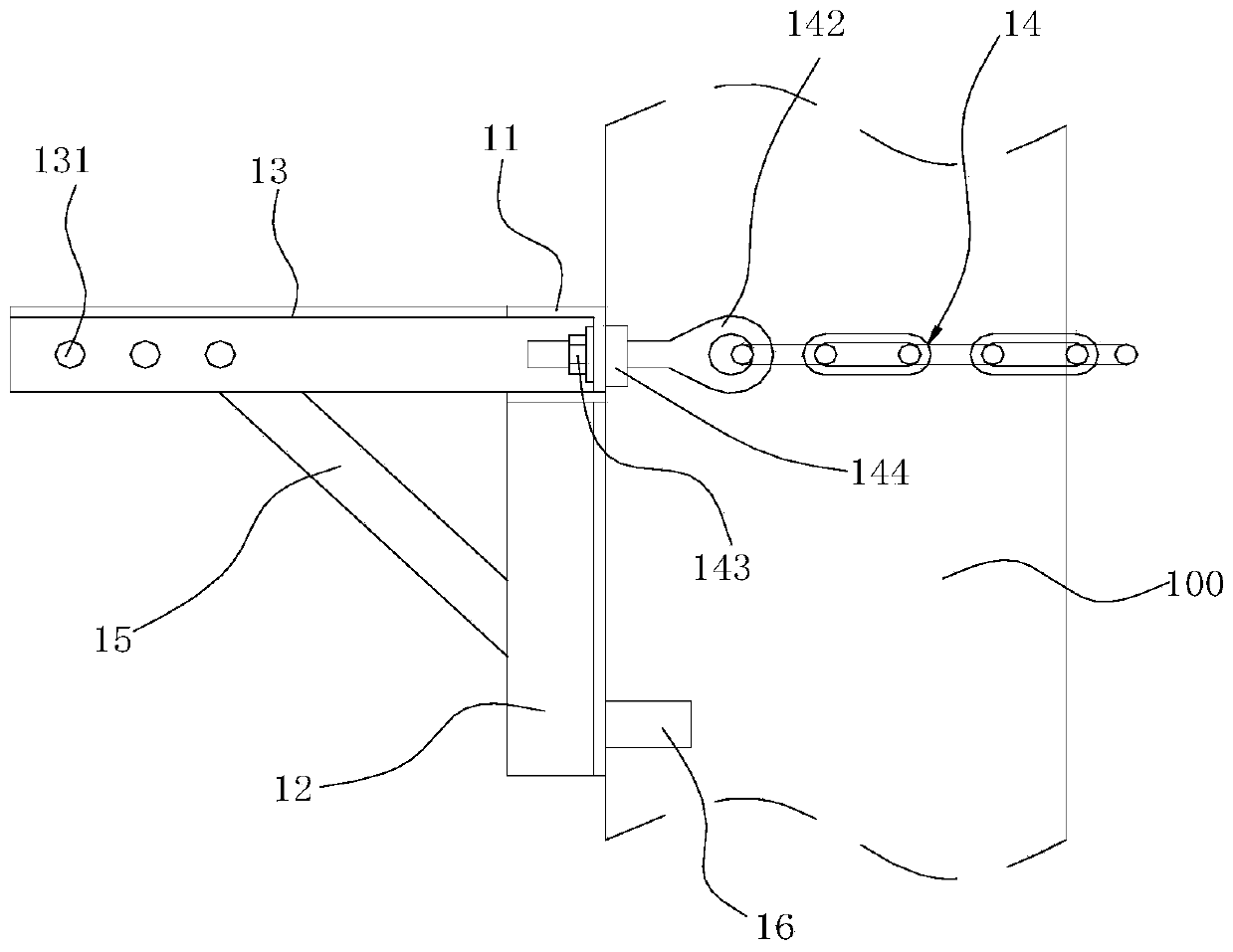

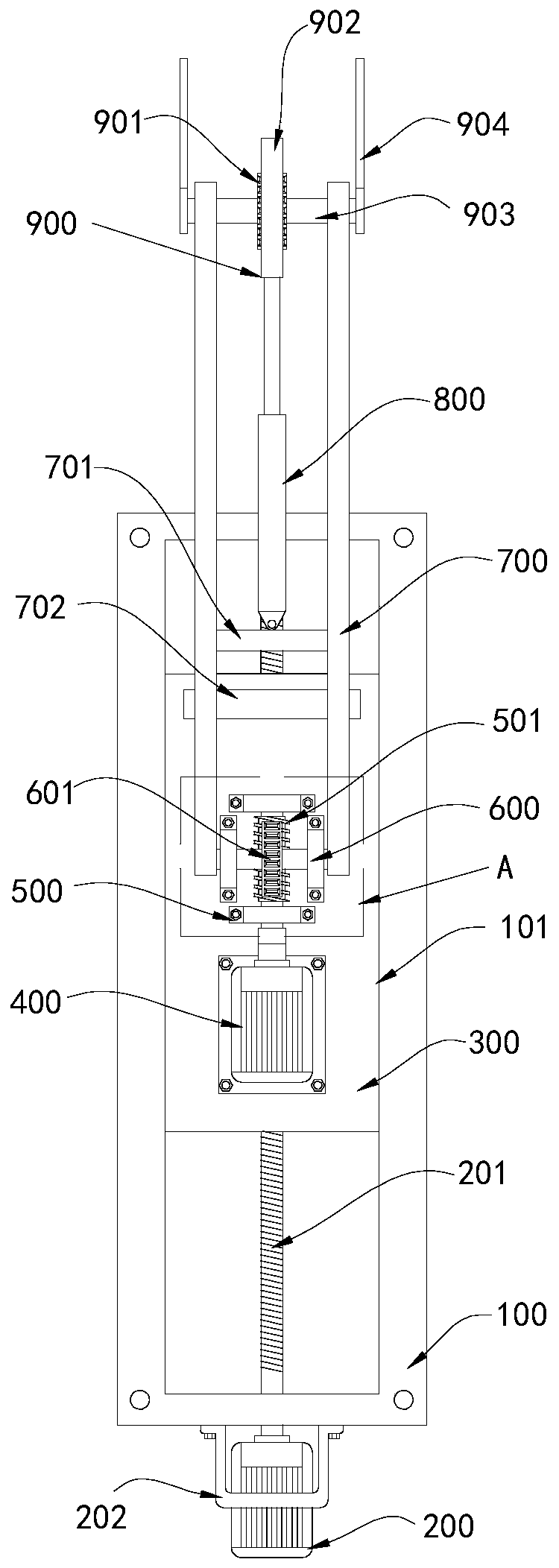

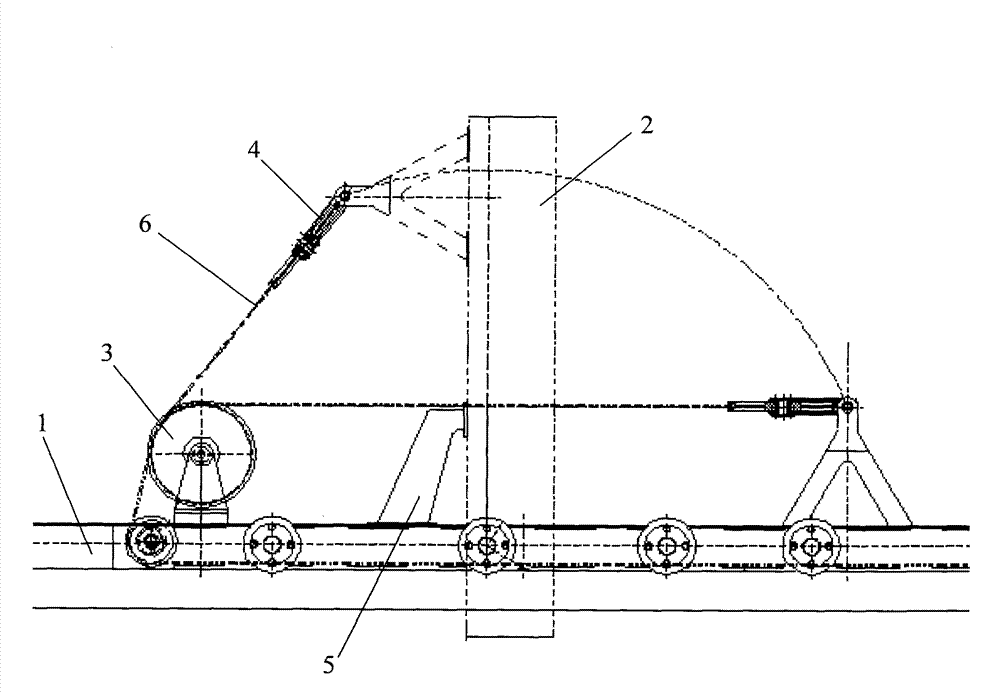

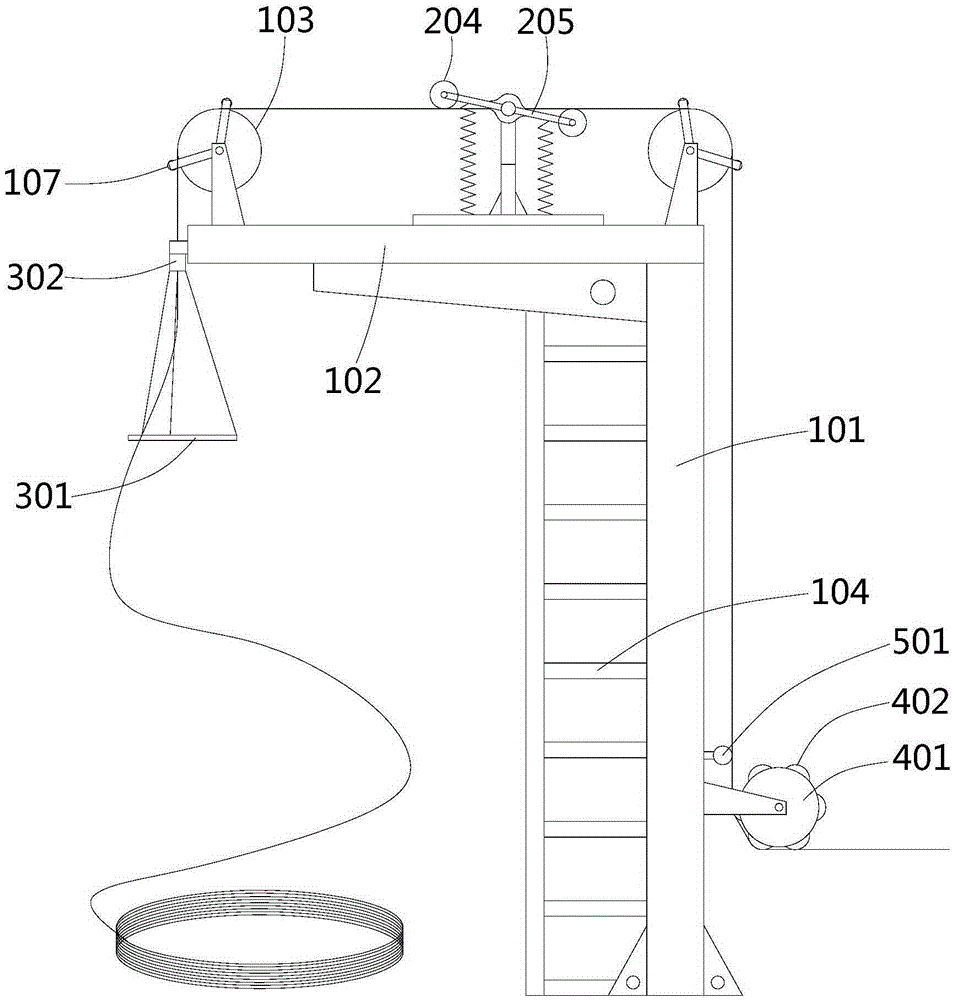

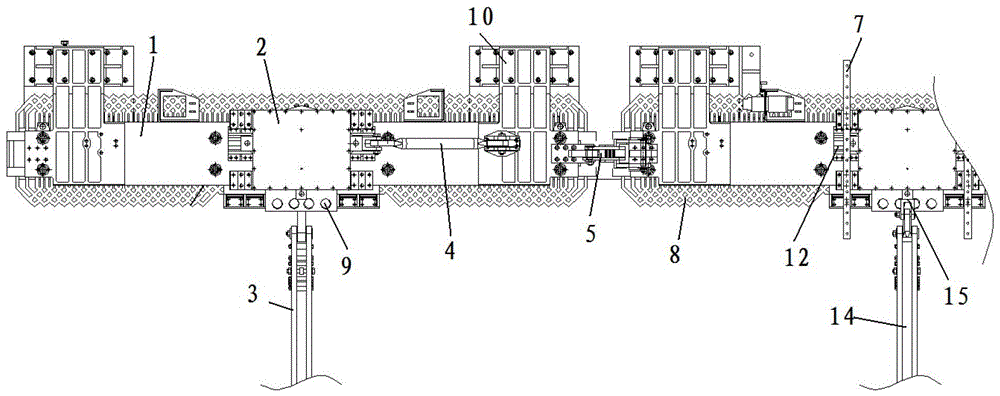

Erection of gantry type small-cycle traction system on large-span suspension bridge main cable

ActiveCN101177931AStable tractionImprove erection qualityBridge erection/assemblyTraction systemTraveling block

The utility model relates to a gantry type small circulation traction system for a main cable erection of a large-span suspension bridge, which belongs to the technical field of bridge superstructure construction. Set up a cable storage area behind the A anchorage, and install a 60-ton gantry crane and a cable-laying bracket; set up a traction cable revolving wheel behind this anchorage; set up a 25-ton main traction hoist and a balance weight bracket on the side of the B anchorage. The traction cable is connected by a puller at Anchor Anchor, bypasses the hoist drum at B Anchor Anchor, and is inserted through the balance weight bracket and each steering block to form a ring-shaped endless cable. Make a horizontal circular motion to form an independent small circular traction system. The small circulation system has the advantages of high power, large traction force, high construction efficiency and low cost.

Owner:CHINA RAILWAY MAJOR BRIDGE ENG GRP CO LTD

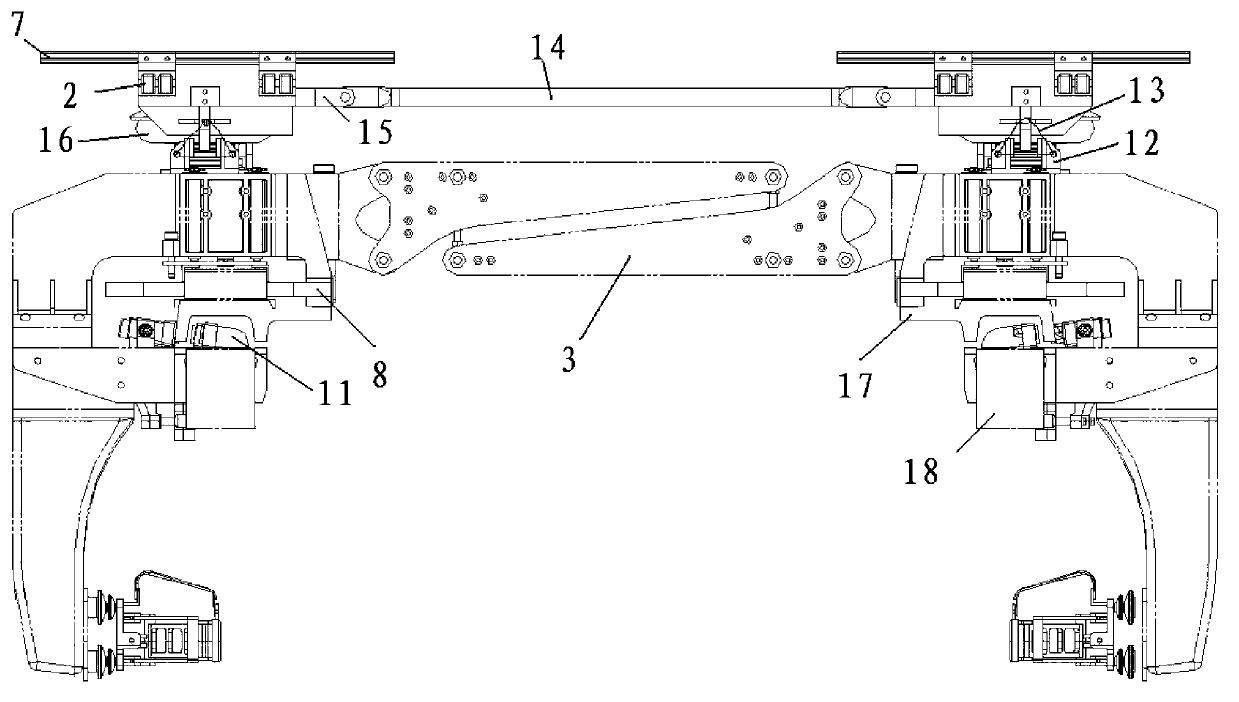

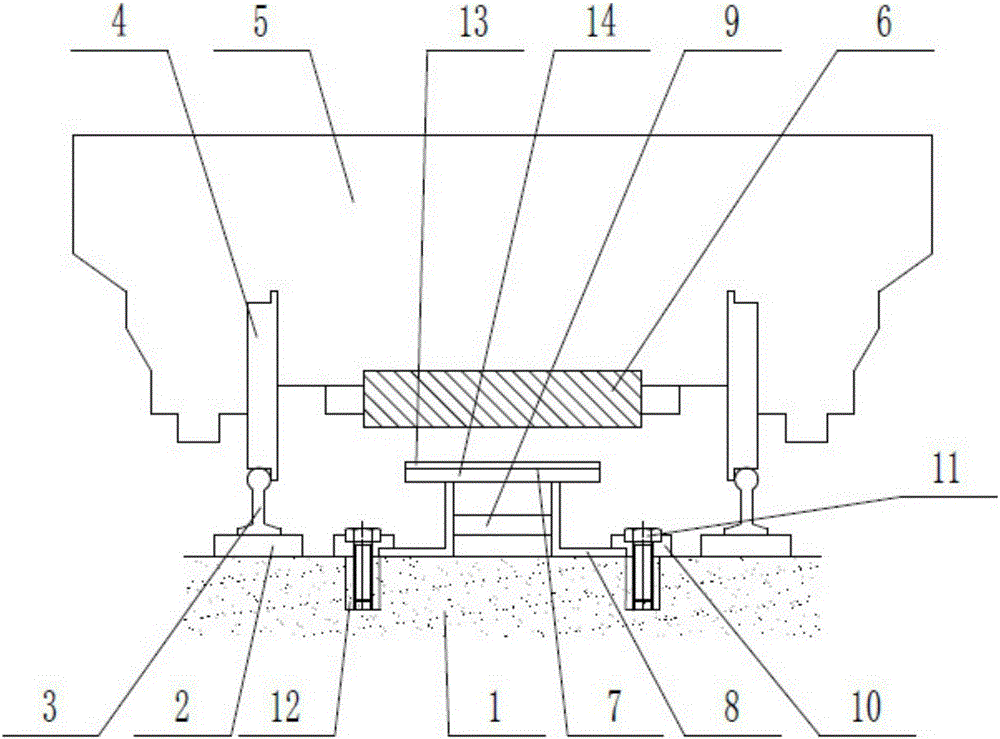

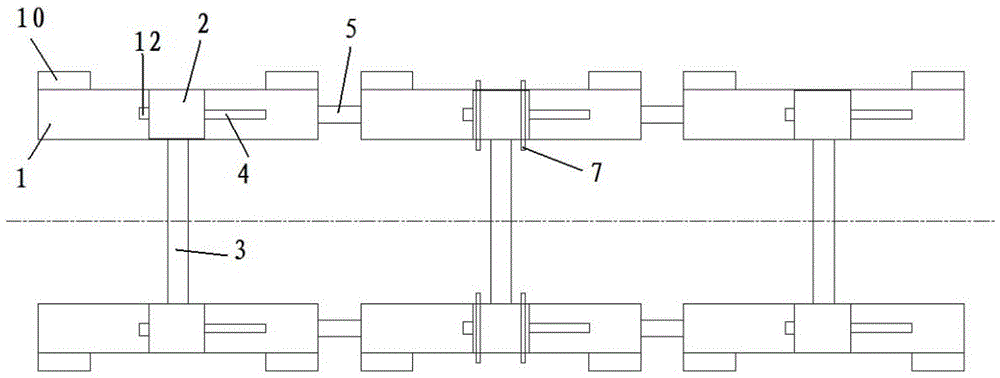

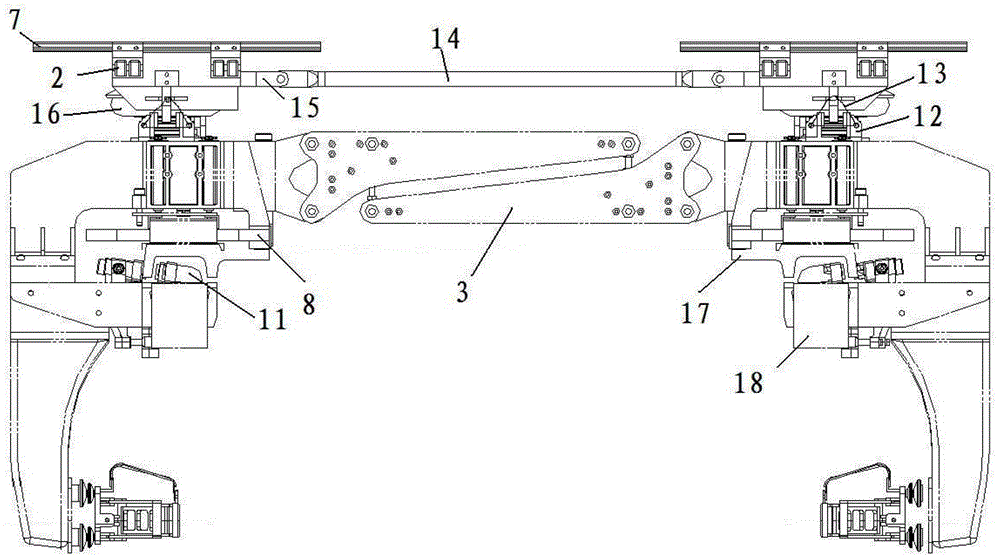

Walking mechanism for middle/low-speed maglev vehicles

The invention relates to the technical field of walking mechanisms for maglev vehicles, and particularly relates to a walking mechanism for middle / low-speed maglev vehicles. The walking mechanism for middle / low-speed maglev vehicles comprises at least two end part suspension frames and at least an intermediate suspension frame, each suspension frame comprises two longitudinal beams, sliding tables, air springs, a transverse draw bar and an anti-side-rolling draw bar, wherein the two longitudinal beams are arranged in a left and right mode, the sliding tables and the air springs are arranged in the middle of the longitudinal beams, each longitudinal beam is provided with a sliding table, the sliding table is fixedly supported on the longitudinal beam through the air spring, the sliding tables are connected through the transverse draw bar, the longitudinal beams are connected through the anti-side-rolling draw bar, the transverse draw bar and the anti-side-rolling draw bar are located in the middle of the suspension frame, the sliding tables of the intermediate suspension frame are provided with a linear guide rail extending along the transverse direction, the sliding tables of the intermediate suspension frame are connected with a train body through the linear guide rail, and the sliding tables and the longitudinal beams are connected through traction bars. The walking mechanism disclosed by the invention has the beneficial effects that as a method that the sliding tables are arranged in the middle of the suspension frames and a linear bearing replaces a swing bolster and a Z-shaped traction bar is adopted, the structure of the walking mechanism is simplified, and the walking mechanism is convenient to maintain.

Owner:常州西南交通大学轨道交通研究院 +1

PET (polyester) high-speed spinning finish oil

InactiveCN102115978AImprove the lubrication effectStable coefficient of frictionFibre typesPolyesterPolyethylene glycol

The invention discloses PET (polyester) high-speed spinning finish oil, which comprises the following components in parts by weight: 66-74 parts of smoothing agent, 10-14 parts of emulsifier, 4-8 parts of antistatic agent, 6-10 parts of tow collecting agent and 3-5 parts of additive, wherein the smoothing agent comprises phosphate, polyacrylic ester, and any one or a mixture of plant oil, animal oil, mineral oil and synthetic ester oil, the emulsifier comprises an alkyl ether type surfactant, castor oil polyoxyethylene ether and polyoxyethylene ether laurate, the antistatic agent comprises the cationic surfactant of an ammonium salt and octadecanol phosphate potassium salt, the tow collecting agent comprises polyethylene glycol laurate diester, propylene glycol and rubber pyrolysis oil, and the additive comprises talcum powder, fatty alcohol, fatty acid and acrylic acid. By means of the design disclosed by the invention, the frictional factor is more stable and the oil film strength and the oil flash point are both higher.

Owner:吴江市良燕纺织助剂厂

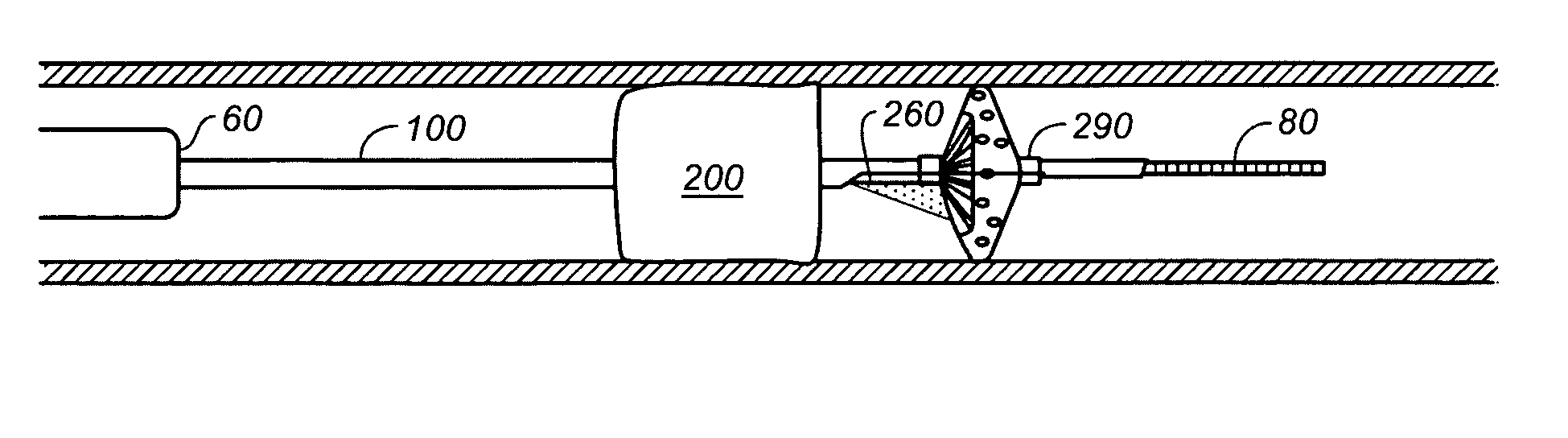

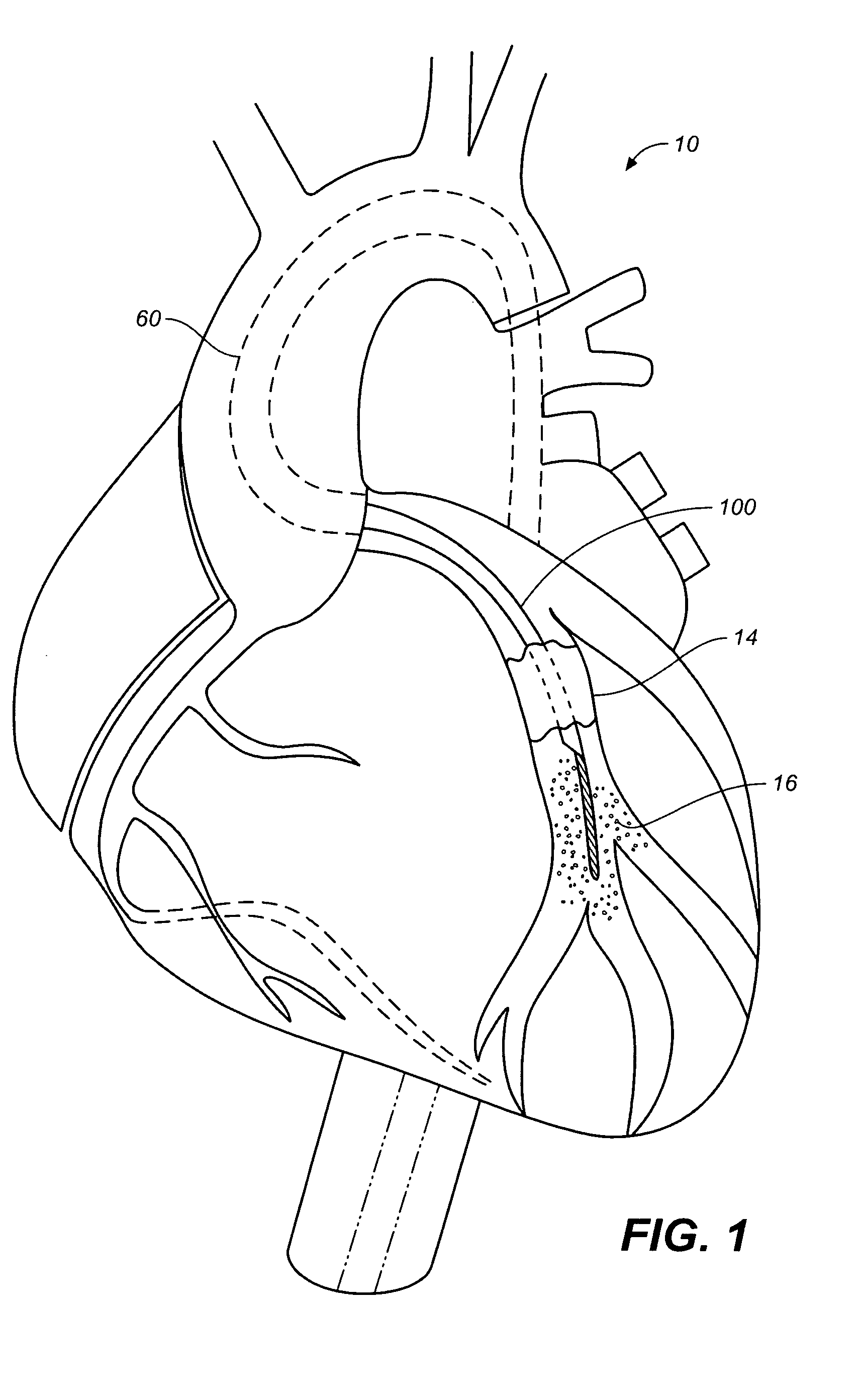

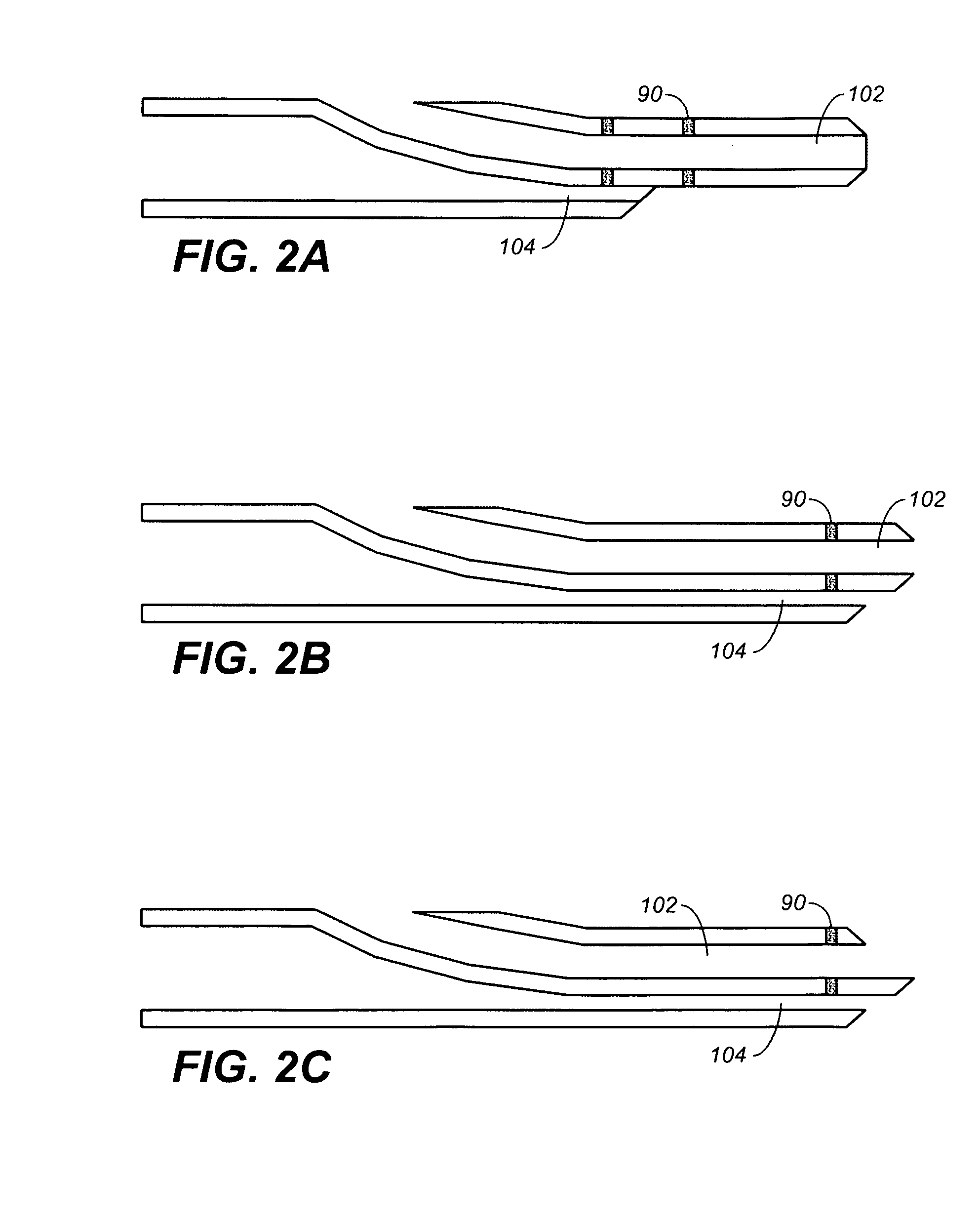

Integrated device for ischemic treatment

InactiveUS20090287166A1Stable tractionLow profileGuide needlesBalloon catheterReperfusion injuryKidney

A system and method in accordance with the present invention provides a infusion catheter that is flexible, has such a smooth traction and a low profile to minimize break up of the obstruction when crossing it, can access distal vasculature quickly, is easy to use and readily to be implemented in the conventional PCI. Another object is to provide a method that can be performed within a short period of time and employs the catheter described herein to infuse a therapeutic agent distally to the obstruction before it is removed as a means of reducing reperfusion injury, protecting distal vasculature and microcirculation, preserving myocytes, reducing infarct size and ischemic damages in the heart, brain, lung, liver, kidney and limb. Another object is to provide complementary feature options to the infusion catheter and the aspiration catheter to improve the speed and quality of the vessel clearance.

Owner:CNATEK

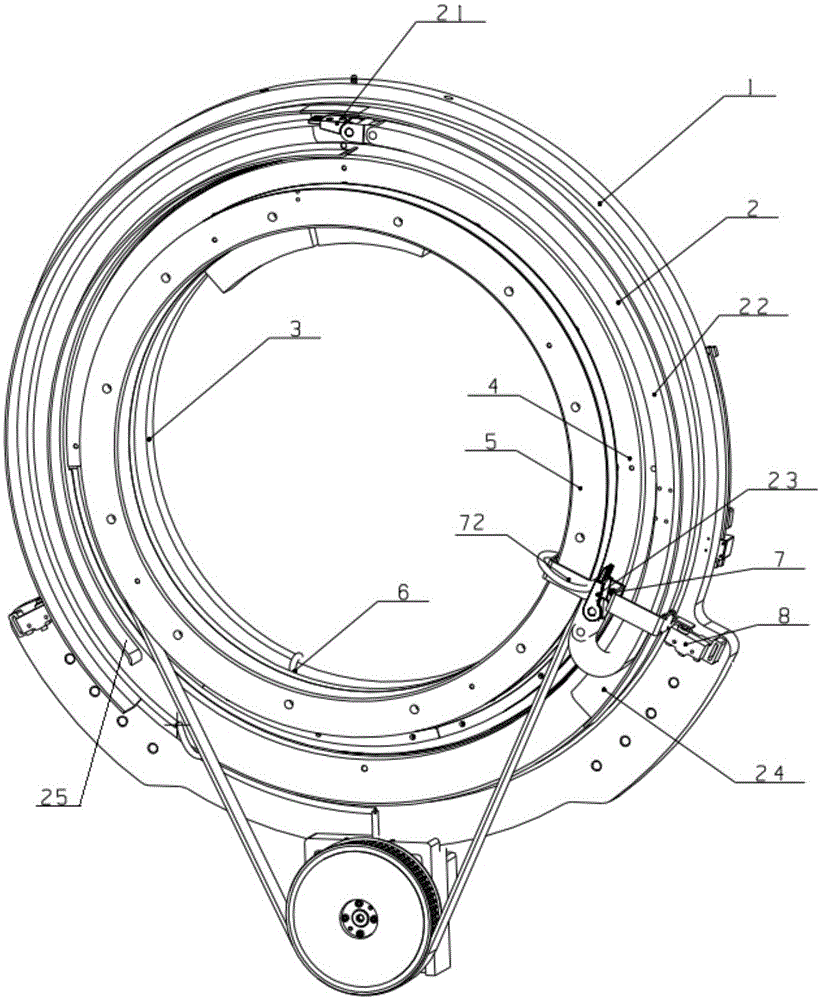

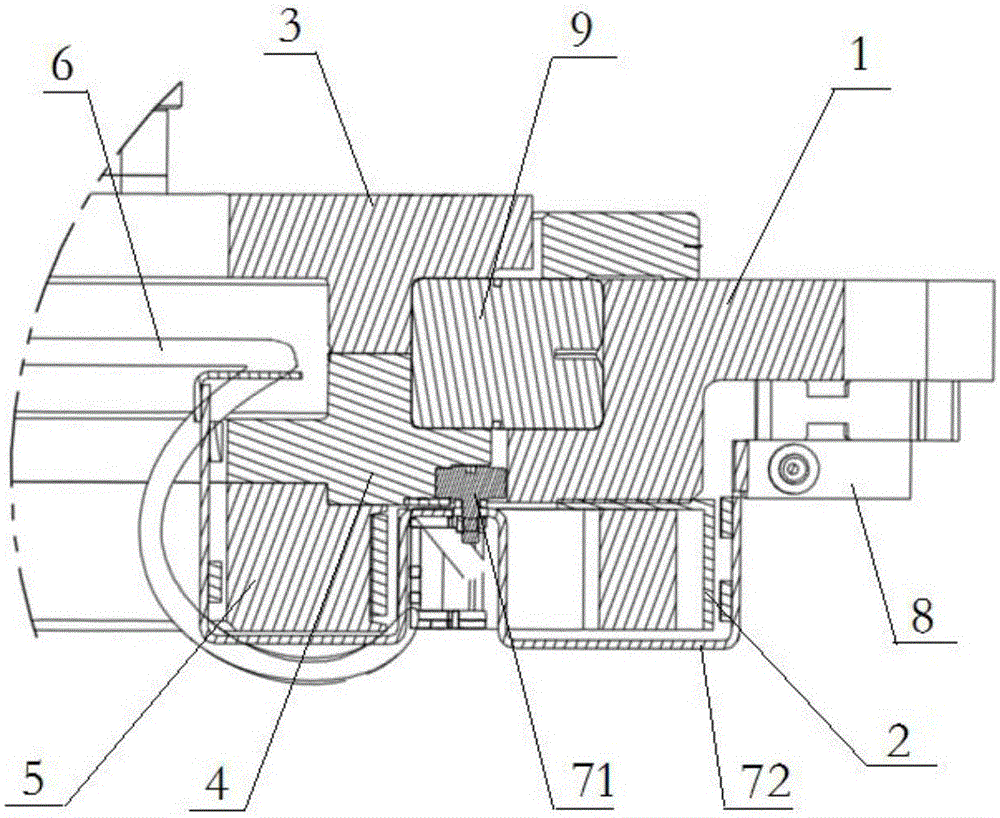

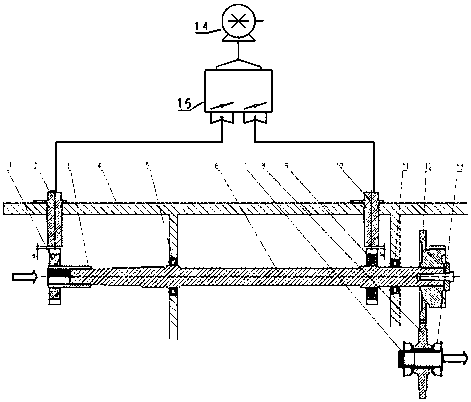

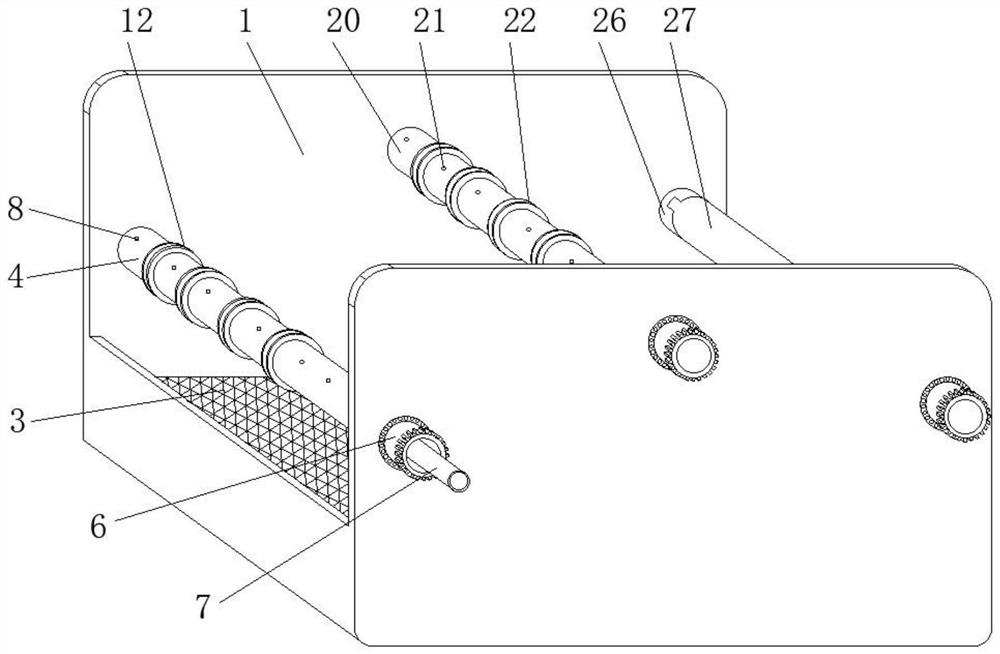

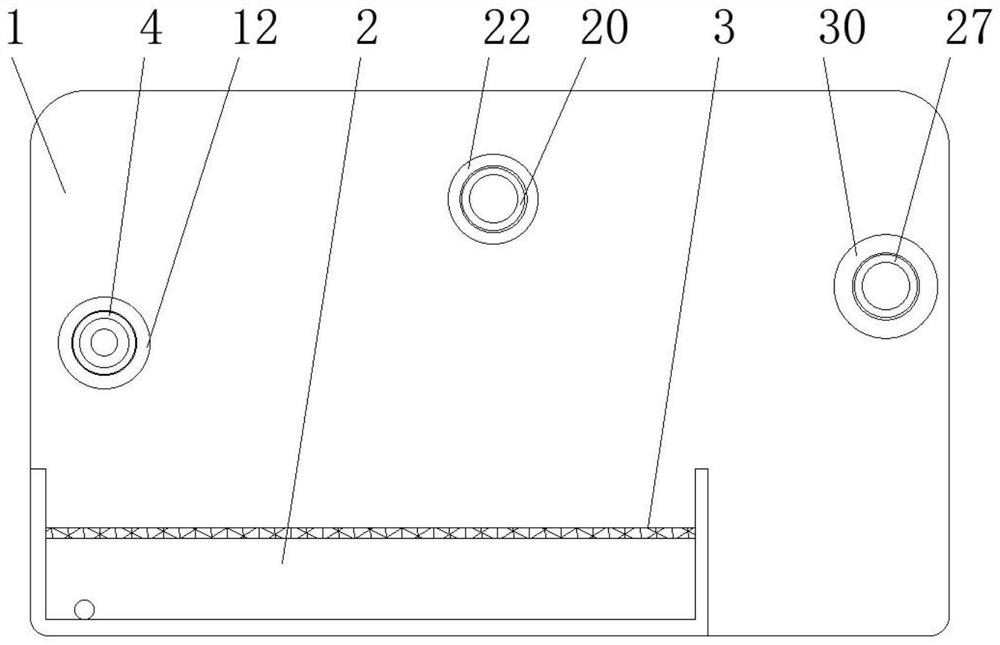

Wiring device for rotating scanning of cone beam CT machine

ActiveCN105125233AShorten the axial widthSimple structureComputerised tomographsTomographyControl theoryFlange

The invention discloses a wiring device for rotating scanning of a cone beam CT machine. The wiring device comprises a rack, a rotating part, a drag chain and a follower, wherein the rack is vertically arranged on the base of the CT machine; a pivotal bearing is arranged in the rack; the rotating part comprises a rotating disk, a flange and a synchronous pulley; the rotating disk and the flange are connected in a manner that the inner ring of the pivotal bearing is clamped by bolts; the synchronous pulley and the outer side wall of the flange are connected by bolts, and is connected with a belt pulley; the fixed end of the drag chain is arranged at the right upper end of the rack; the movable end of the drag chain is movably arranged on the side wall of the rack; the follower comprises a servo roller and a servo bent board connected with the servo roller; the servo roller is movably arranged in the space between the flange and the rack; the servo bent board is arranged on the surface of the rotating part in a bridge manner, and is tightly and fixedly connected with the movable end of the drag chain. The wiring device is compact in structure, safe and reliable in working, and cables are smoothly pulled.

Owner:SUZHOU INST OF BIOMEDICAL ENG & TECH CHINESE ACADEMY OF SCI

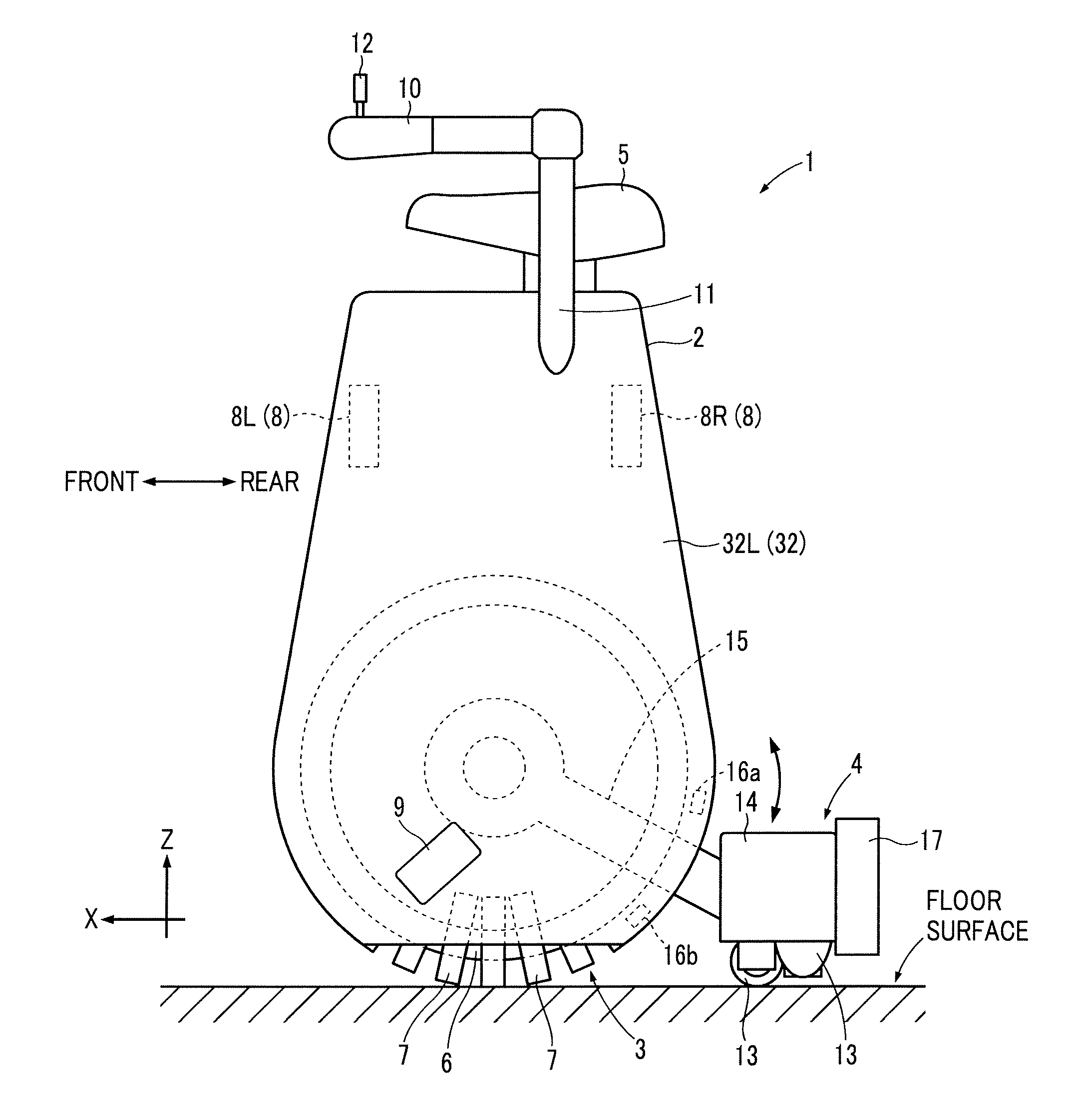

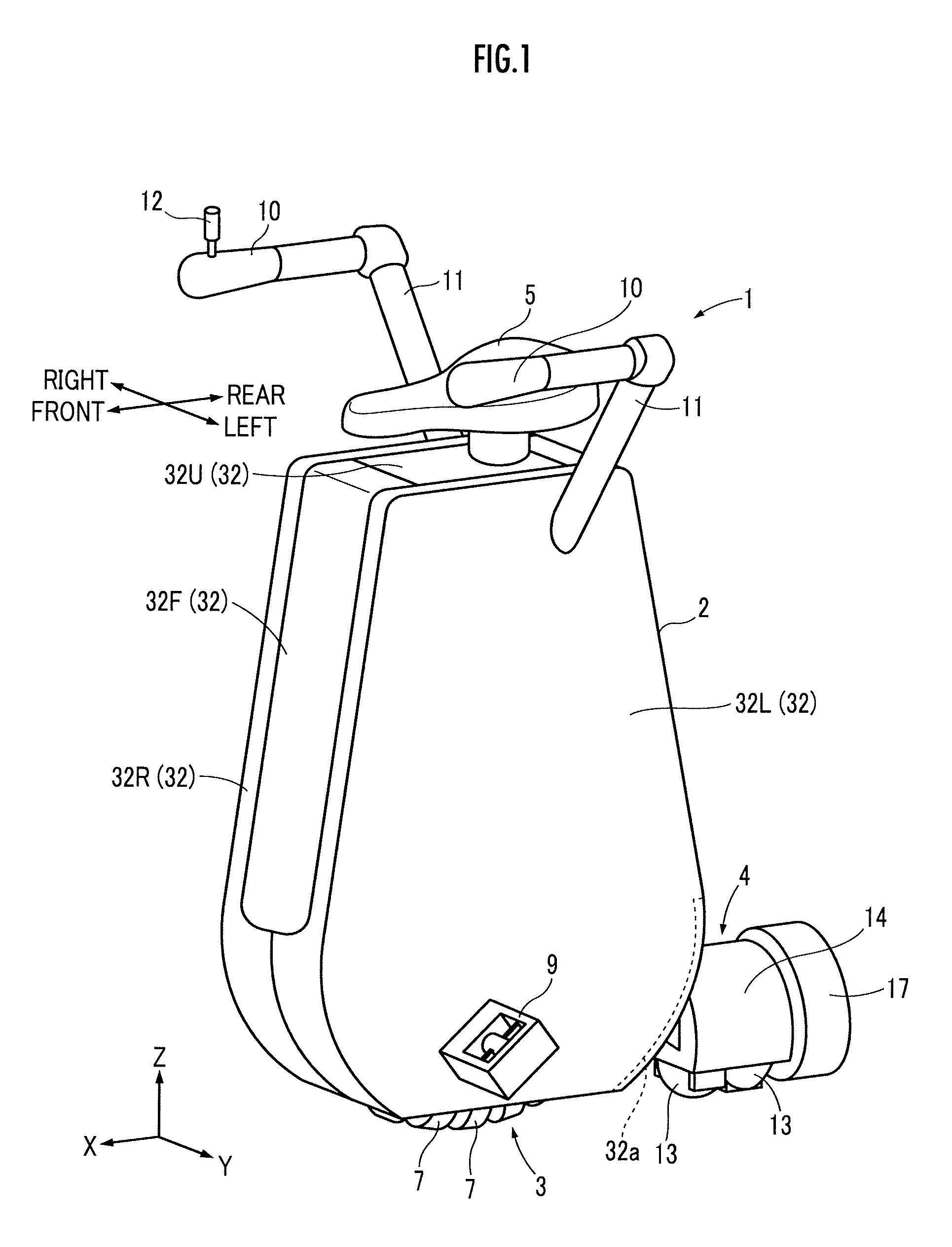

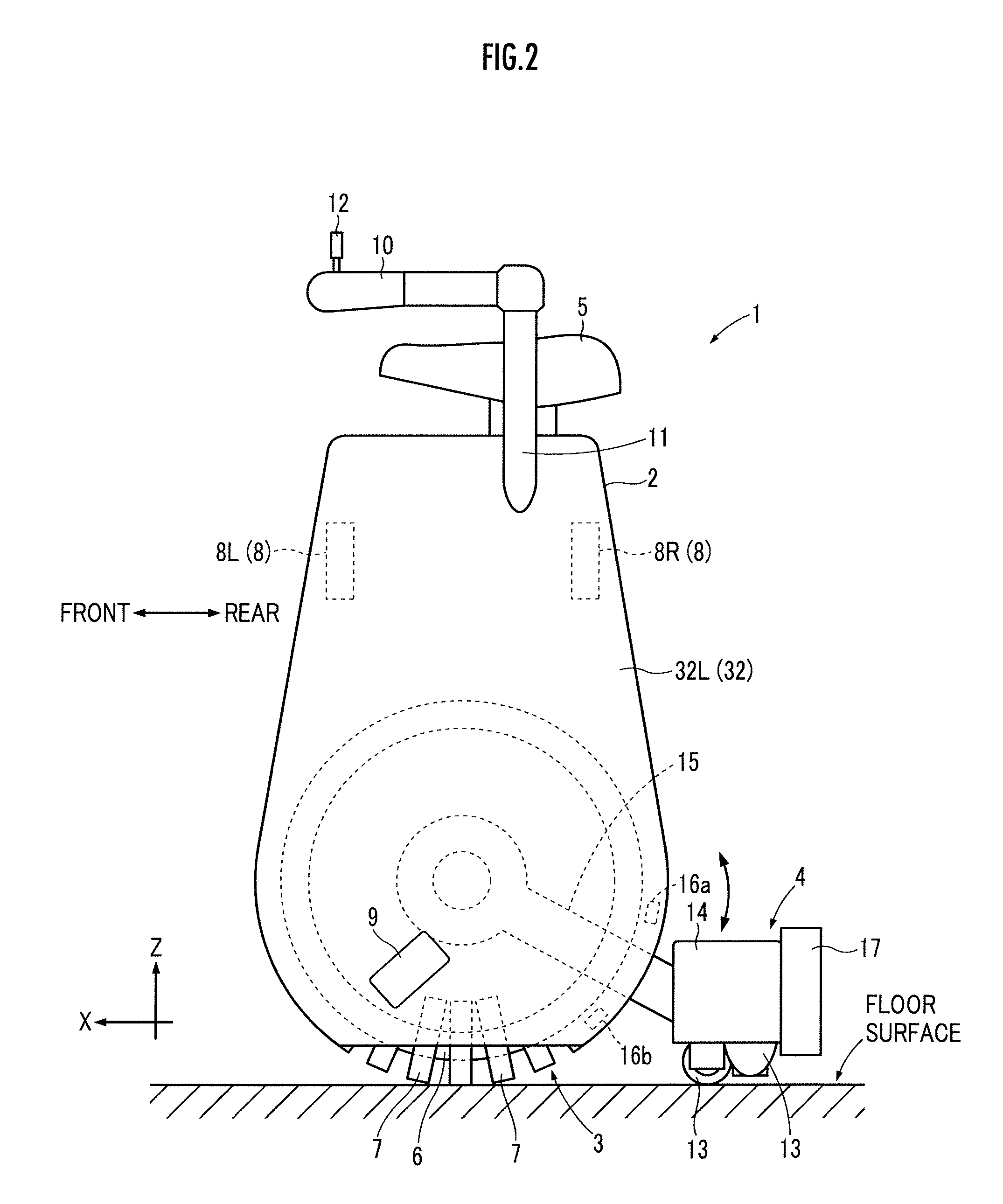

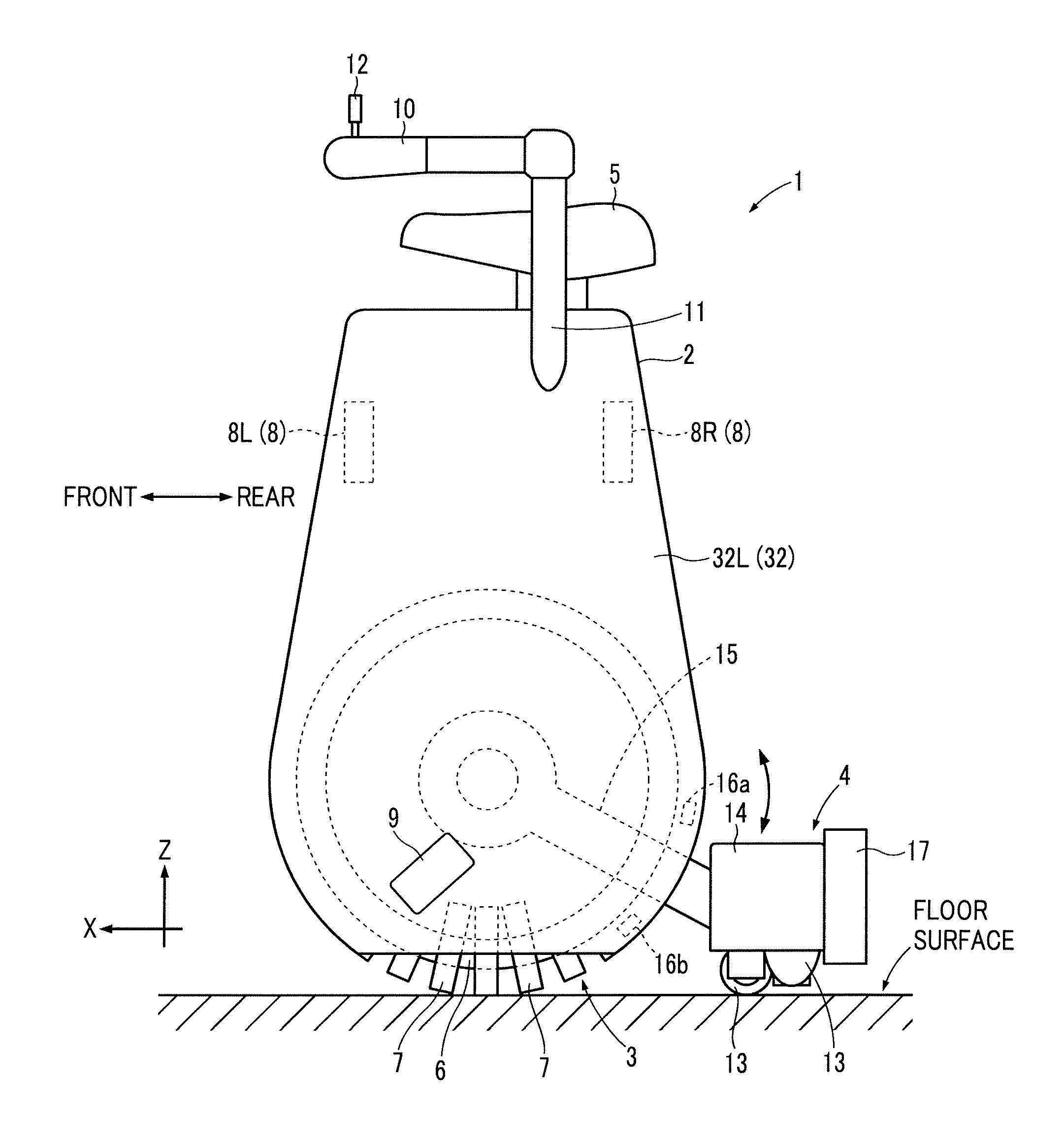

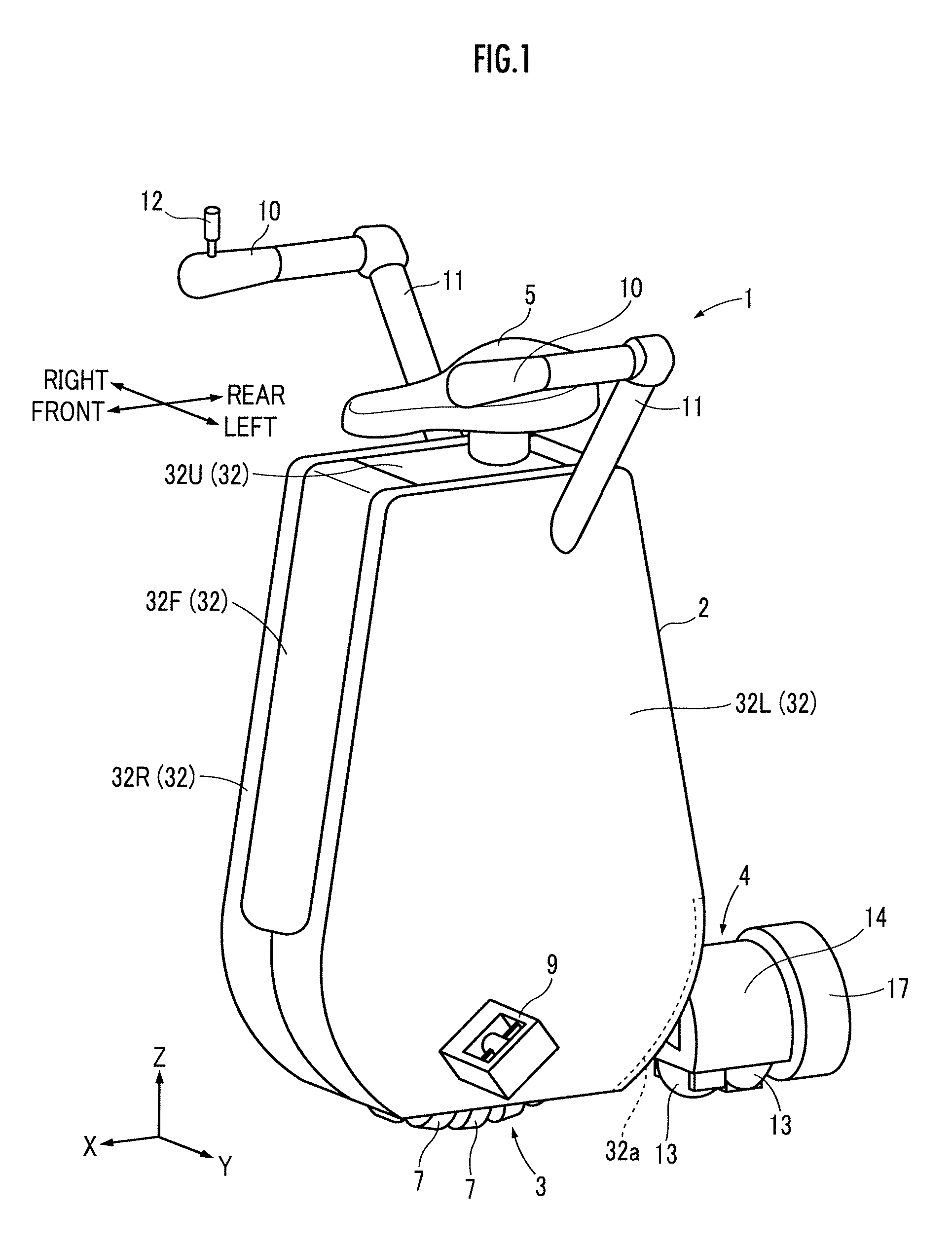

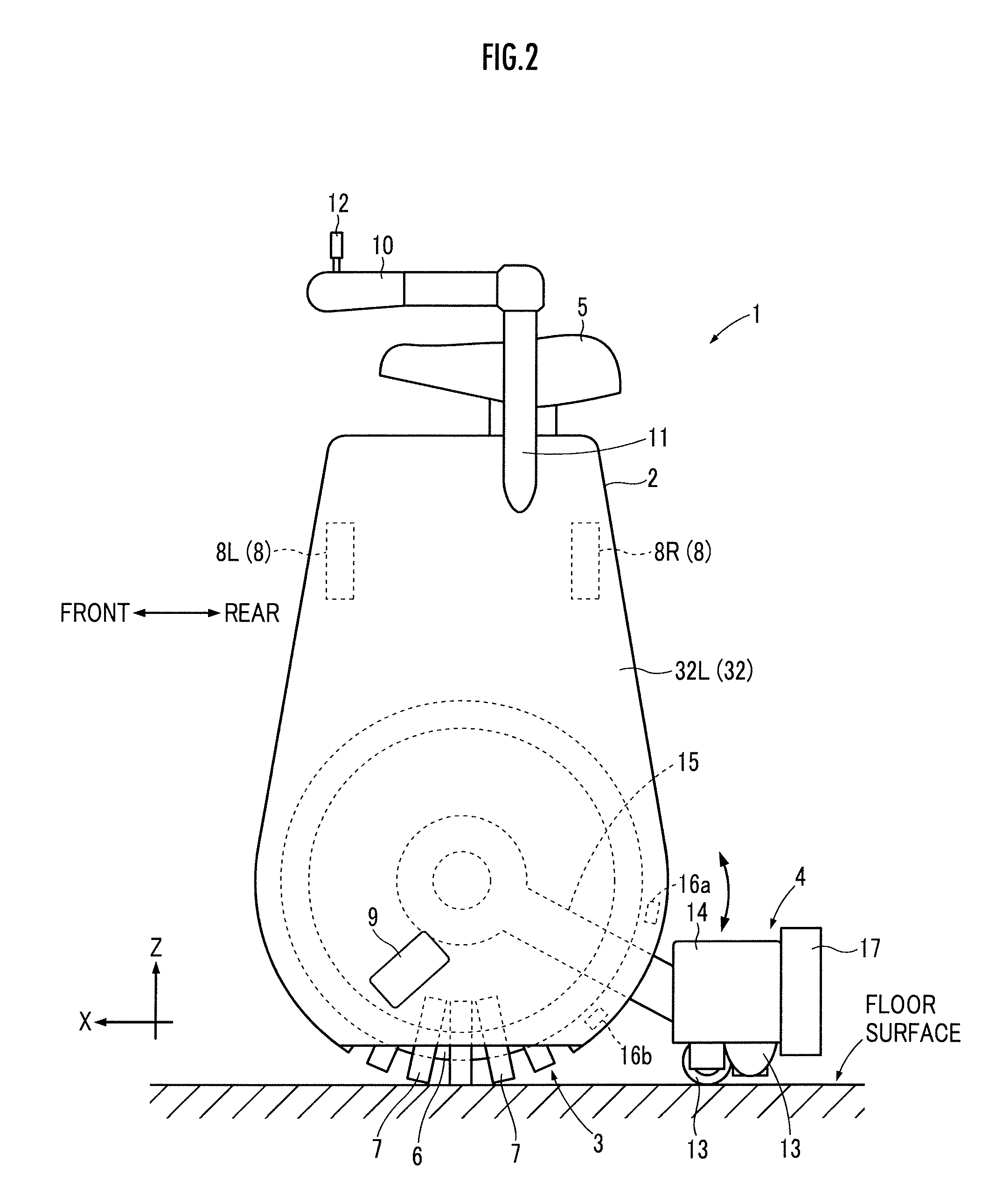

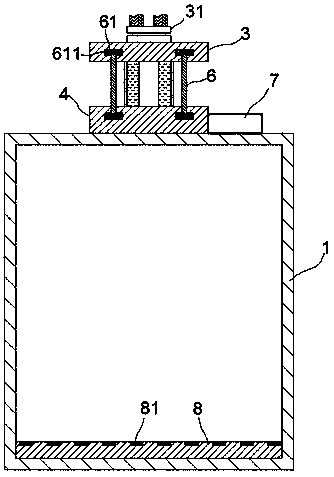

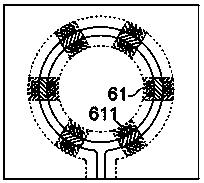

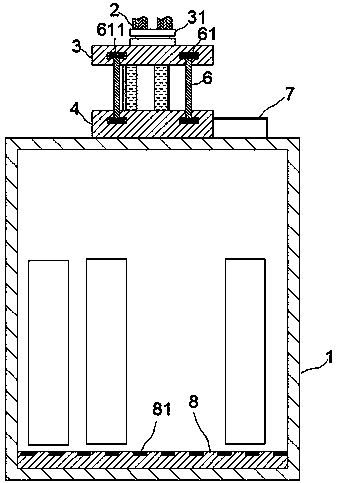

Omnidirectional vehicle

ActiveUS20130133959A1Prevent substanceAvoid mixingUnicyclesCycle standsGround contactOmnidirectional vehicle

An omnidirectional vehicle 1 includes: a main wheel 3 which is able to be driven in all directions; a base 2 which supports the main wheel 3; and a sub wheel 4 which is connected to the base 2 via an arm 15 and is grounded at a position apart from the ground contact point of the main wheel 3. The sub wheel 4 is attached so as to circularly move about the center of rotation of the main wheel 3.

Owner:HONDA MOTOR CO LTD

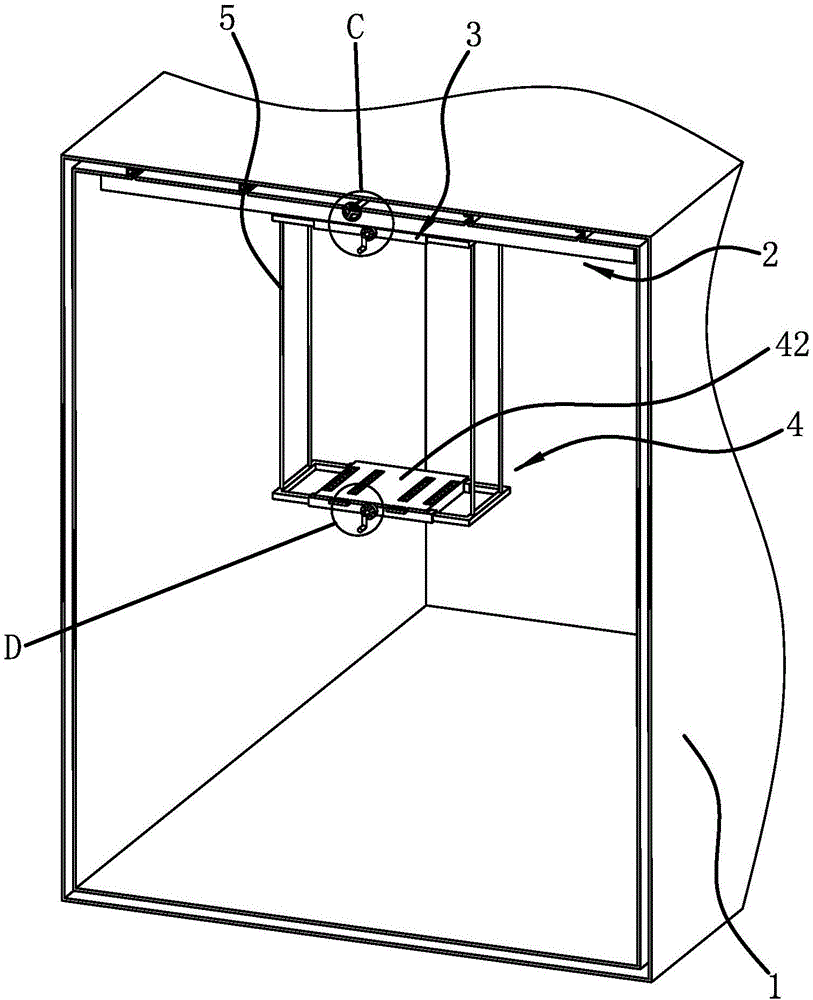

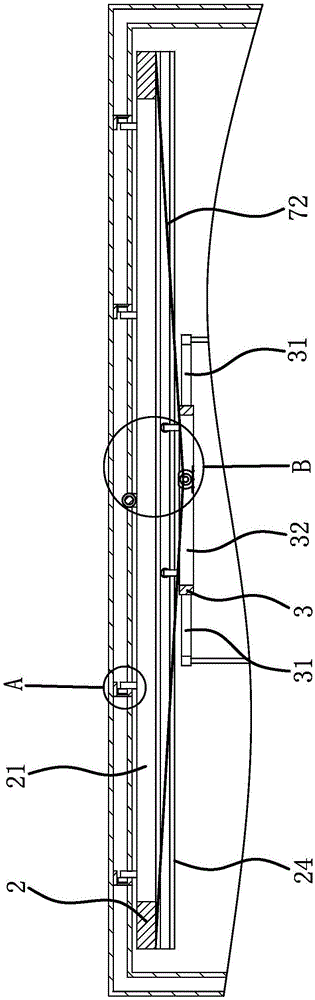

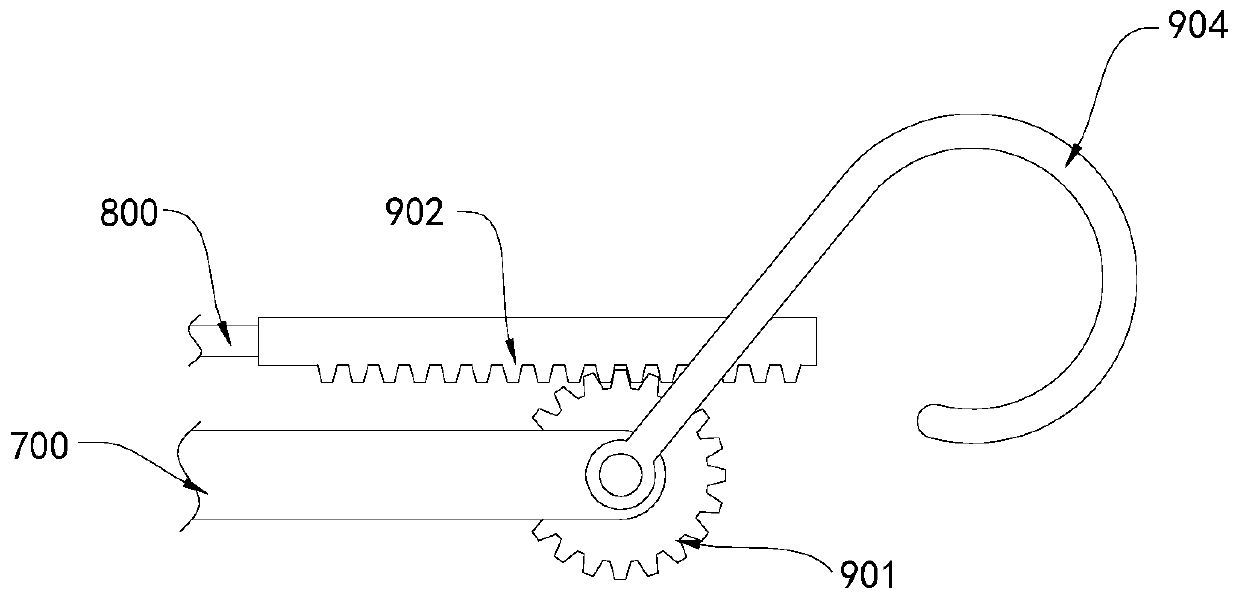

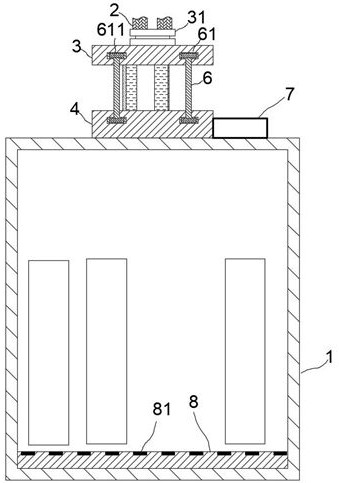

Cargo movement structure of freight car

ActiveCN106740378AImprove applicabilityStable tractionVehicles with cranesTransportation itemsEngineeringTruck

The invention provides a cargo movement structure of a freight car, and belongs to the technical field of freight cars. The problem that cargos in an existing freight car are difficult to move and stack is solved. According to the cargo movement structure, the freight car includes a carriage, the cargo movement structure includes a longitudinal moving frame, a transverse moving frame and a lifting frame, the longitudinal moving frame is in sliding connection with the top surface of the carriage, the transverse moving frame is in sliding connection with the longitudinal moving frame, two pairs of upper adjusting rods are inserted in the transverse moving frame in a sliding mode, two pairs of lower adjusting rods are inserted in the lifting frame in a sliding mode, four inhaul cables are connected with the transverse moving frame and fixed connected with the four lower adjusting rods, the lifting frame includes a disk body, the disk body is provided with a number of installation grooves, jacking blocks and air bags are arranged in the installation grooves, and the jacking blocks are rotatably connected with a number of balls. The cargo movement structure can make the cargos more convenient to move and stack in the carriage, and more labor is saved.

Owner:SHENZHEN XINNING MODERN LOGISTICS

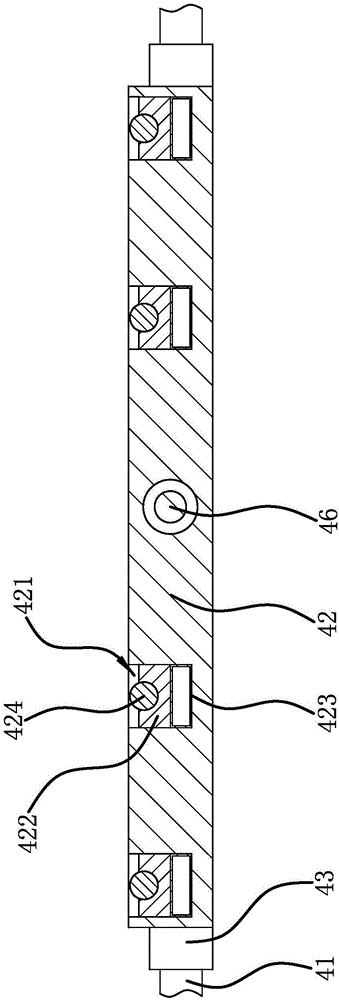

Explosion composite induction plate device for linear motor rails

InactiveCN105196889AImprove stabilityGuaranteed uptimePropulsion systemsElectric propulsionElectric machineEngineering

The invention belongs to the technical field of rail traffic, and provides an explosion composite induction plate device for linear motor rails. The device comprises a rail bed, sleepers, a linear motor, an explosion composite induction plate, press seats, fixing bolts and bolt sleeves, wherein the sleepers are laid on the rail bed in a close-packed manner; steel rails are symmetrically arranged on two sides of the sleepers; a locomotive is arranged on the steel rails by virtue of rail wheels, and the linear motor is arranged right under the locomotive; the explosion composite induction plate is arranged right under the linear motor and comprises an upper pure aluminum plate and a lower substrate steel sheet; steel angles are symmetrically connected to the lower side of the explosion composite induction plate, and rib plates are fixed among the steel angles; one side of each steel angle is pressed below the respective press seat; the press seats are fixed on the rail bed by virtue of the fixing bolts and the bolt sleeves; and the bolt sleeves are pre-buried on the rail bed. The device can be used for effectively solving the problems that a composite induction plate is low in binding strength and easily causes operation failure of a linear motor rail vehicle due to the occurrence of delamination splitting.

Owner:成都佰世成科技有限公司

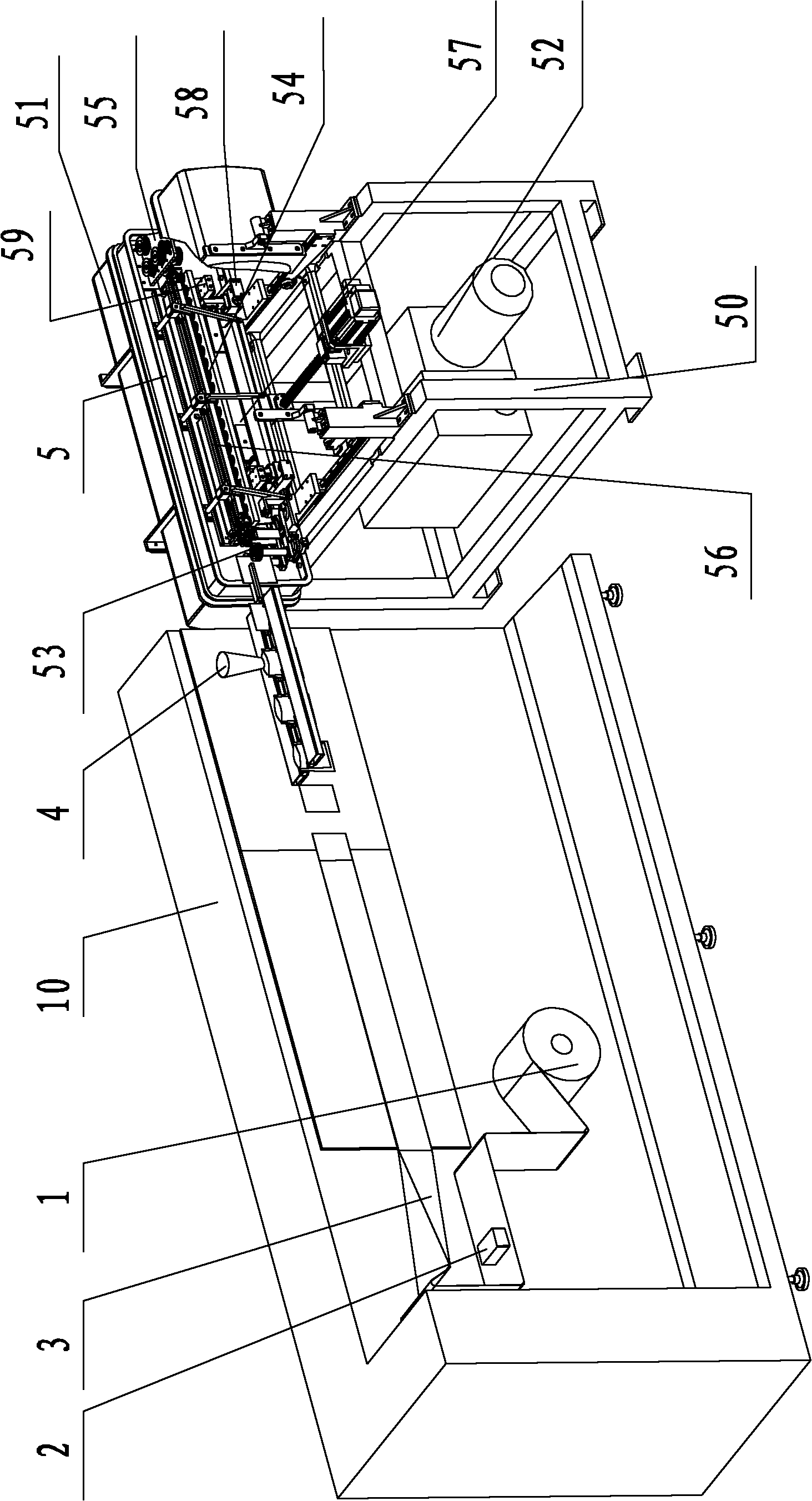

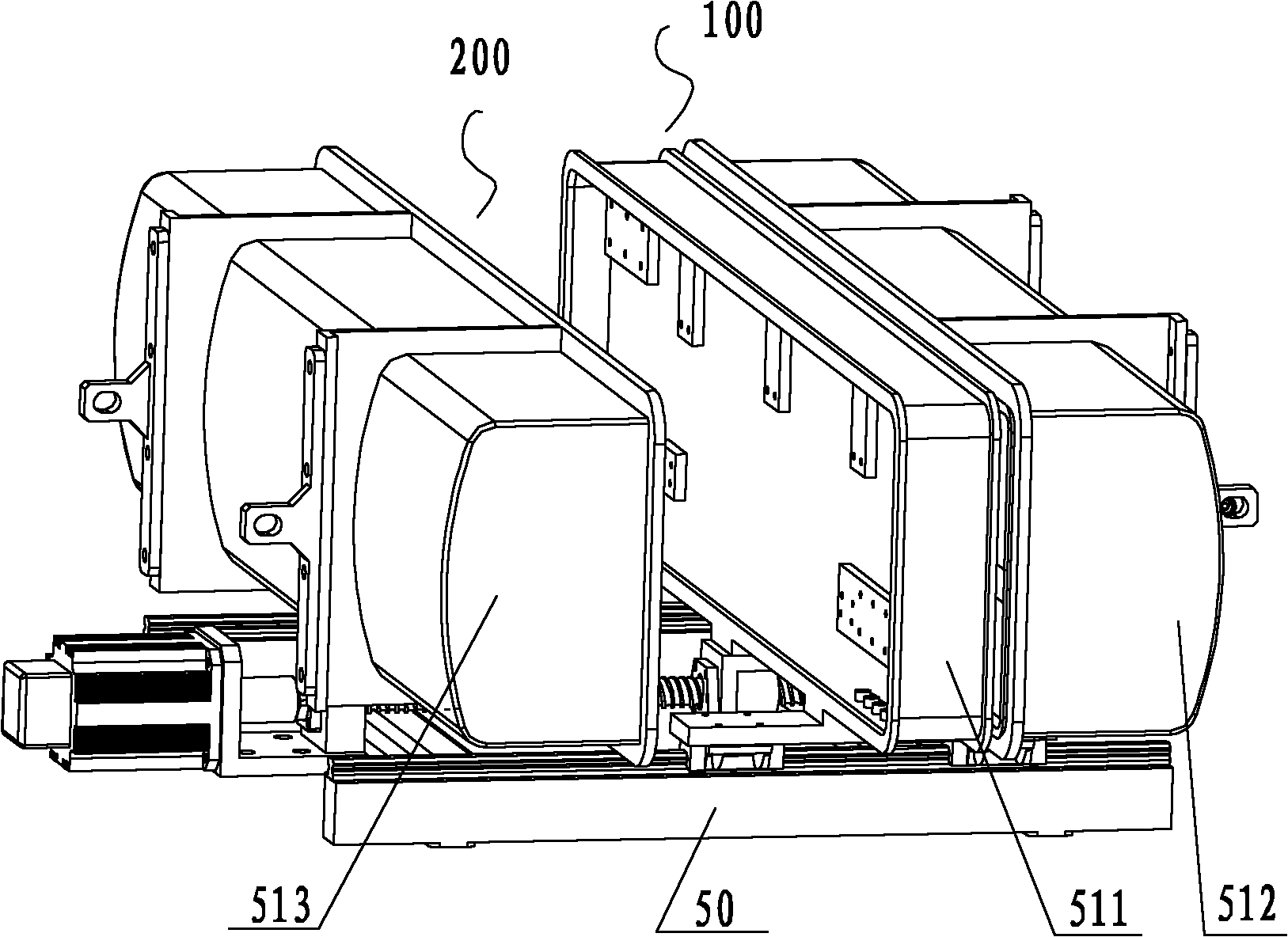

Underwater fuel conveying trolley and tipping-over device for pressurized water reactor

ActiveCN102097140AImplement the tipping actionSimple designNuclear energy generationReactor fuel elementsPressurized water reactorEngineering

The invention relates to an underwater fuel conveying system for a pressurized water reactor, in particular to an underwater fuel conveying trolley and tipping-over device for a pressurized water reactor. The underwater fuel conveying trolley comprises a trolley capable of running stably inside a fuel conveying pipeline, the trolley is provided with a fuel basket capable of rotating along a fixedshaft alternatively in a horizontal direction and a vertical direction, two sides of the frame of the trolley are provided with steel wire rope leading sheaves, the fuel basket is provided with tipping-over leading sheaves capable of swinging around a pivot, a tipping-over steel wire rope rounds the tipping-over leading sheaves on the fuel basket and the tipping-over leading sheaves on two sides of the trolley, one end of each tipping-over steel wire rope is connected with a winding drum, and the other end of each tipping-over steel wire rope is connected with a counter weight. The underwaterfuel conveying trolley has the advantages of simple structure, convenience for debugging and long service life.

Owner:SHANGHAI NUCLEAR ENG RES & DESIGN INST CO LTD

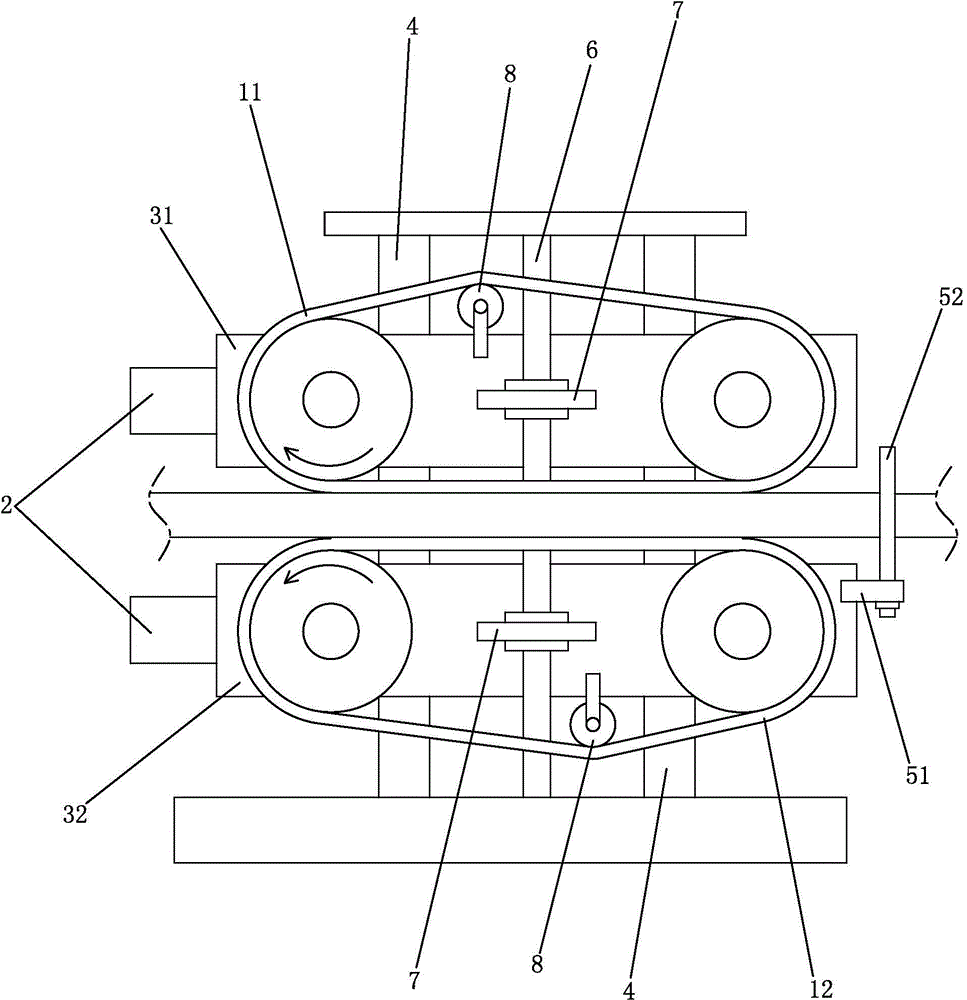

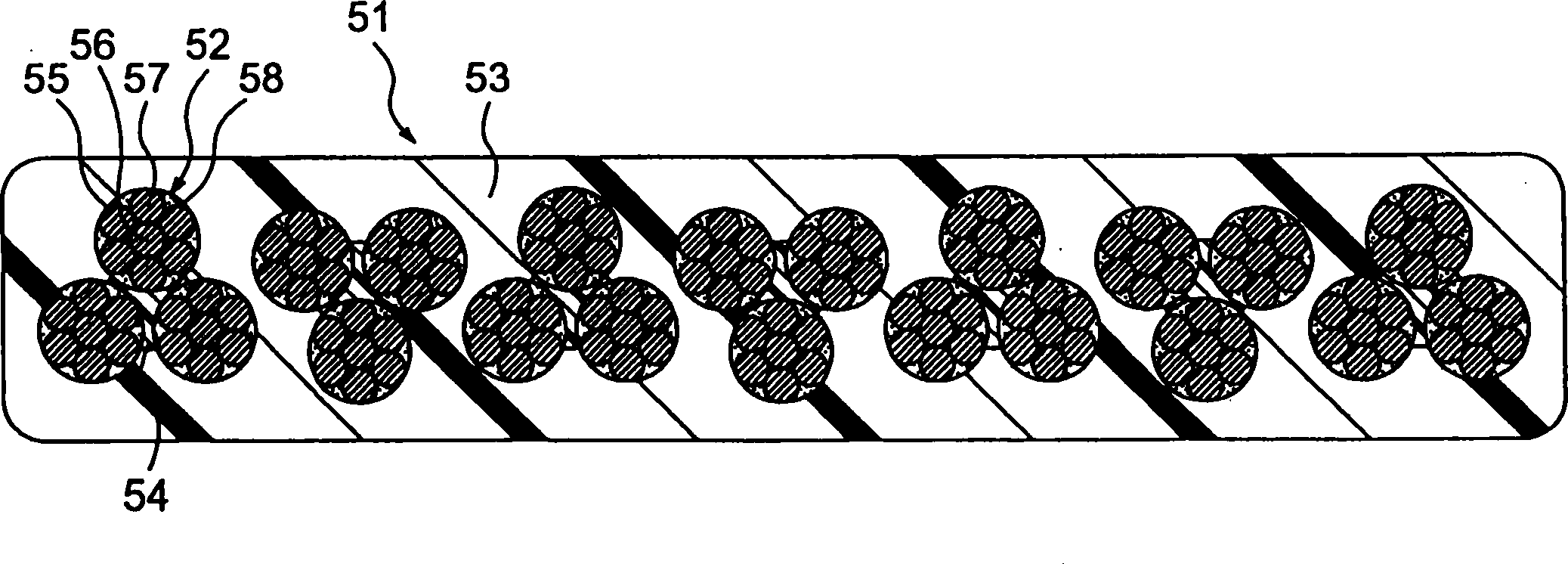

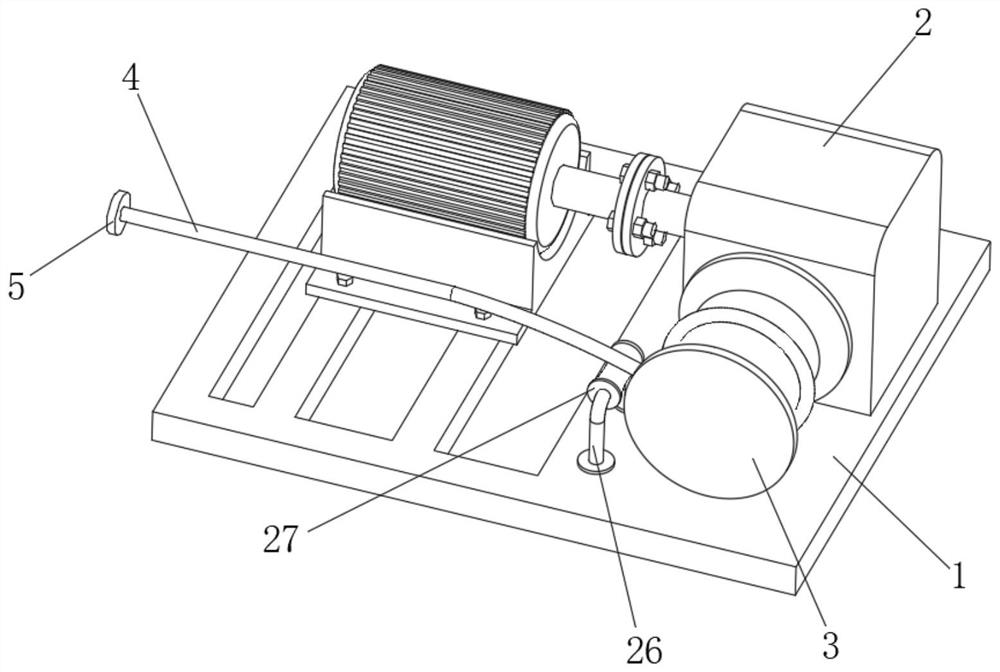

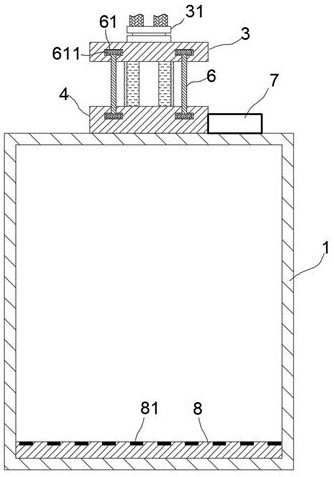

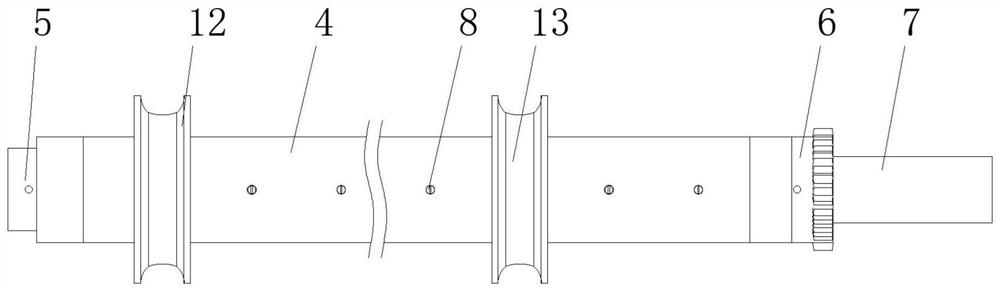

Crawler type plastic pipe tractor

InactiveCN104129056AHigh-quality and efficient processing and productionStable tractionTubular articlesEngineeringMechanical engineering

The invention discloses a crawler type plastic pipe tractor, which includes an upper crawler belt and a lower crawler belt that are disposed horizontally and driven by belt pulleys. The upper crawler belt and the lower crawler belt are respectively mounted on an upper rack and a lower rack with individually adjustable height correspondingly, and the belt pulleys of the upper crawler belt and the lower crawler belt are connected to a motor. The product provided by the invention can adapt to a variety of plastic pipes, can pull plastic pipes smoothly under uniform stress, and promote the realization of high quality and high efficiency production of plastic pipes.

Owner:YIYANG PLASTIC PROD

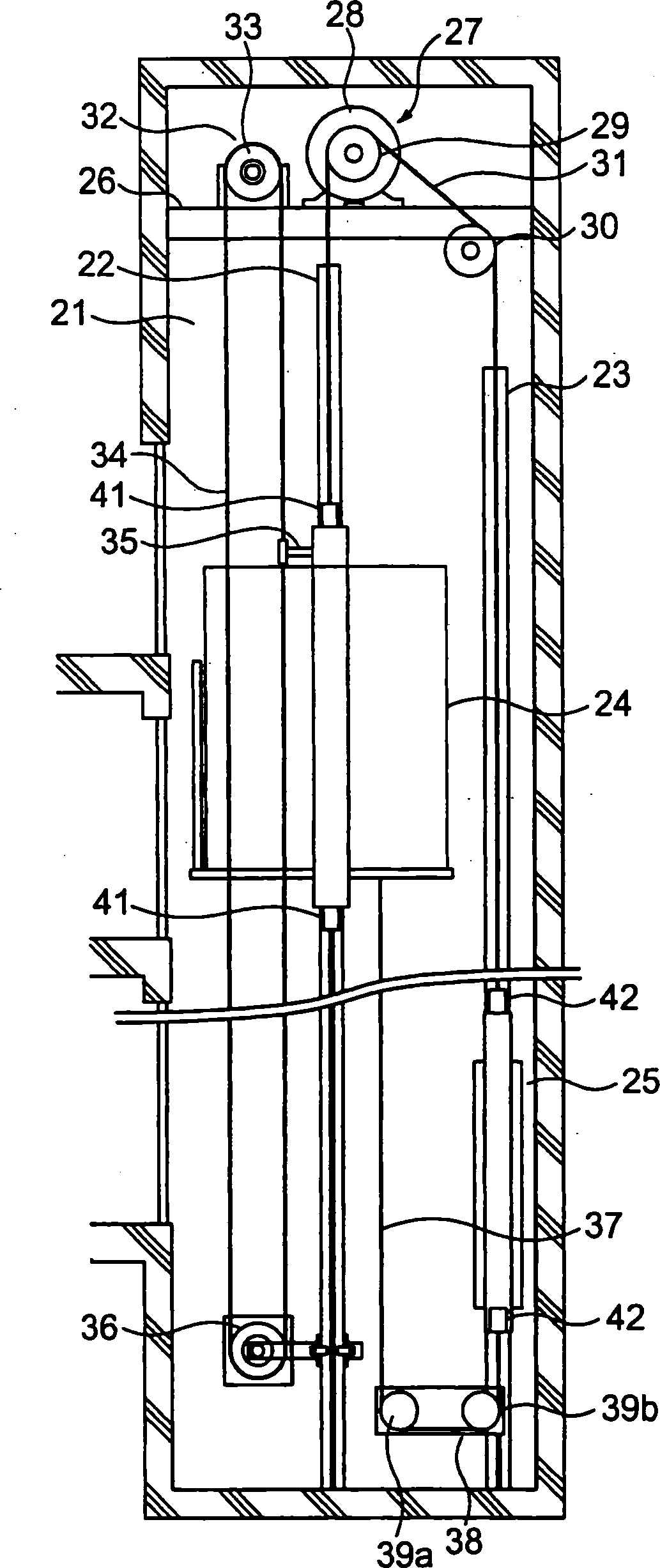

Elevator apparatus

In an elevator apparatus, an elevator car is suspended in an elevator shaft by a main rope. The car is provided with a car guide device engaging with a car guide rail. A speed regulator sheave is provided at the upper part of the elevator shaft. A speed regulator rope is passed over the speed regulator sheave. The speed regulator rope is circulated as the car is lifted and lowered. A resin-coated rope, having on its outer periphery a coating body of a resin material, is used as the main rope and the speed regulator rope. A non-lubricated guide device is used as the car guide device.

Owner:MITSUBISHI ELECTRIC CORP

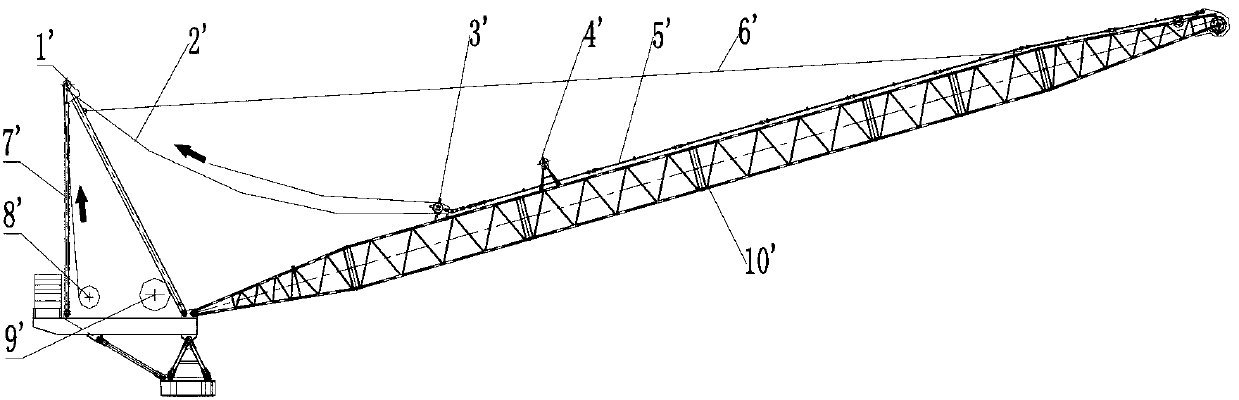

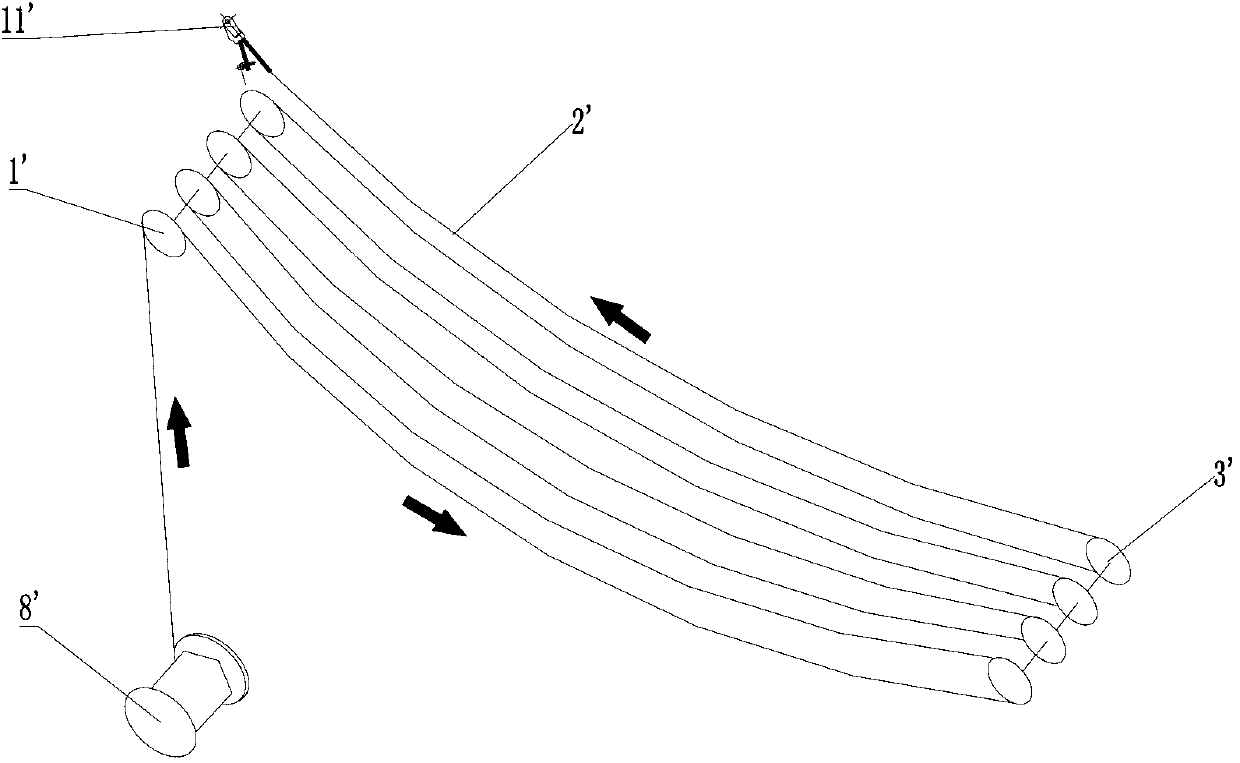

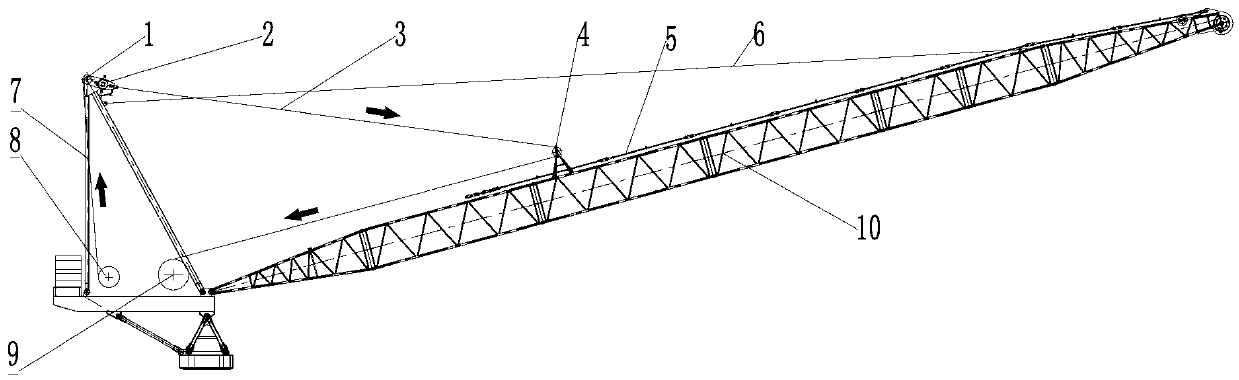

Tower crane with luffing boom and mounting method for variable-amplitude pull rod of tower crane

The invention provides a tower crane with a luffing boom and a mounting method for a variable-amplitude pull rod of the tower crane. The tower crane with a luffing boom comprises an A-shaped frame, a boom frame, an A-shaped frame fixed pulley block, a variable-amplitude pull rod movable pulley block, a variable-amplitude drum and a variable-amplitude rope, wherein one end of the boom frame is articulated with the A-shaped frame, the A-shaped frame fixed pulley block is arranged at the top end of the A-shaped frame; the variable-amplitude rope is threaded and wound on the variable-amplitude pull rod movable pulley block and the A-shaped frame fixed pulley block, one end of the variable-amplitude rope is wound to the variable-amplitude drum and the other end of the variable-amplitude rope is fixed at the end fixing point of the variable-amplitude rope on the A-shaped frame; and the tower crane with the luffing boom further comprises at least two traction ropes, and each of the traction ropes is connected at intervals on a pulley frame of the variable-amplitude pull rod movable pulley block and connected with a traction mechanism. Based on the technical scheme provided by the invention, the balance of the movable pulley block during traction is guaranteed by at least two traction ropes to prevent the twisting of the mounted variable-amplitude rope caused by the inclination of the movable pulley block, so that the traction process is smooth and safe.

Owner:ZOOMLION HEAVY IND CO LTD

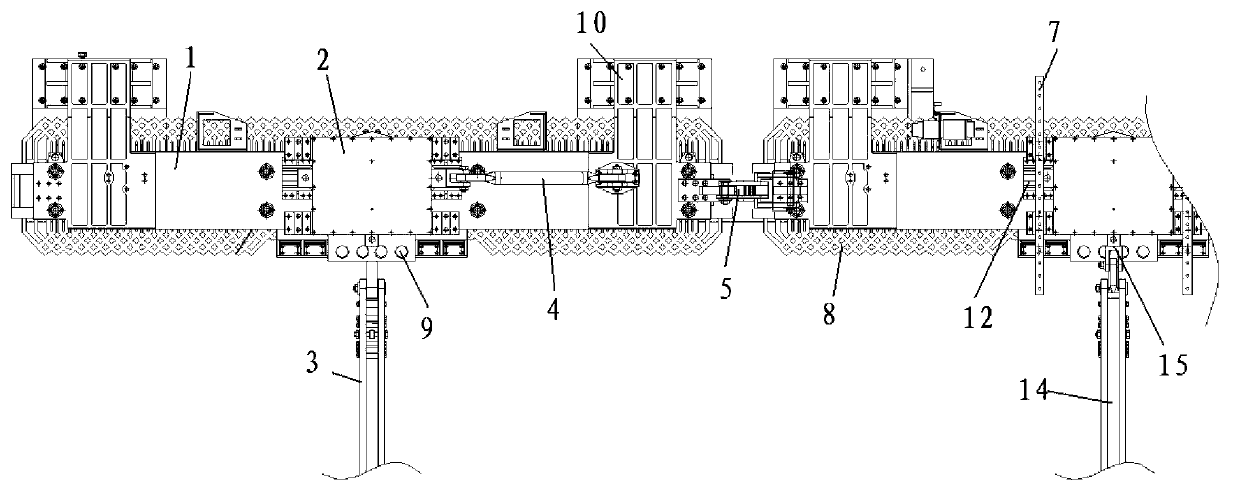

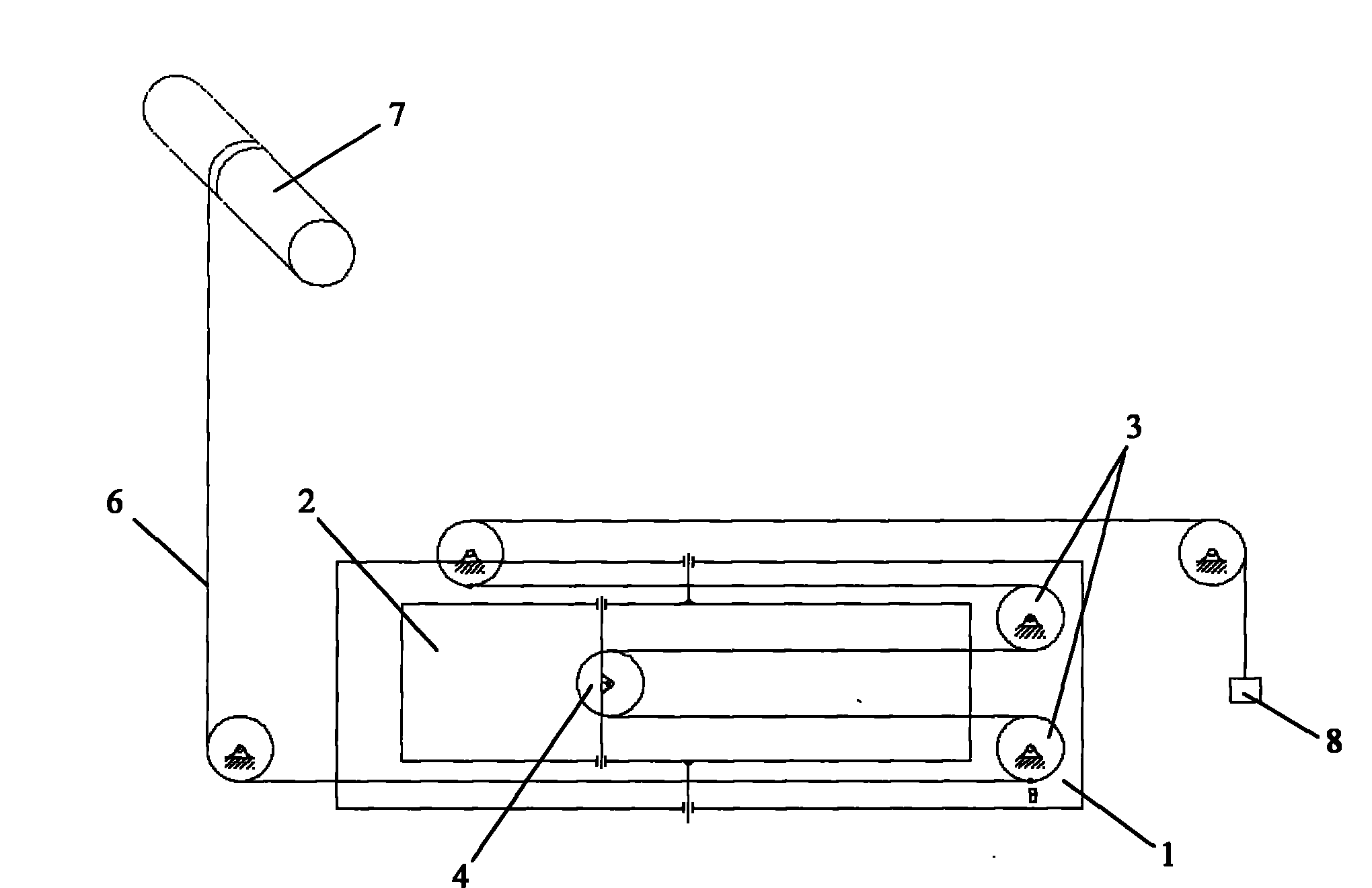

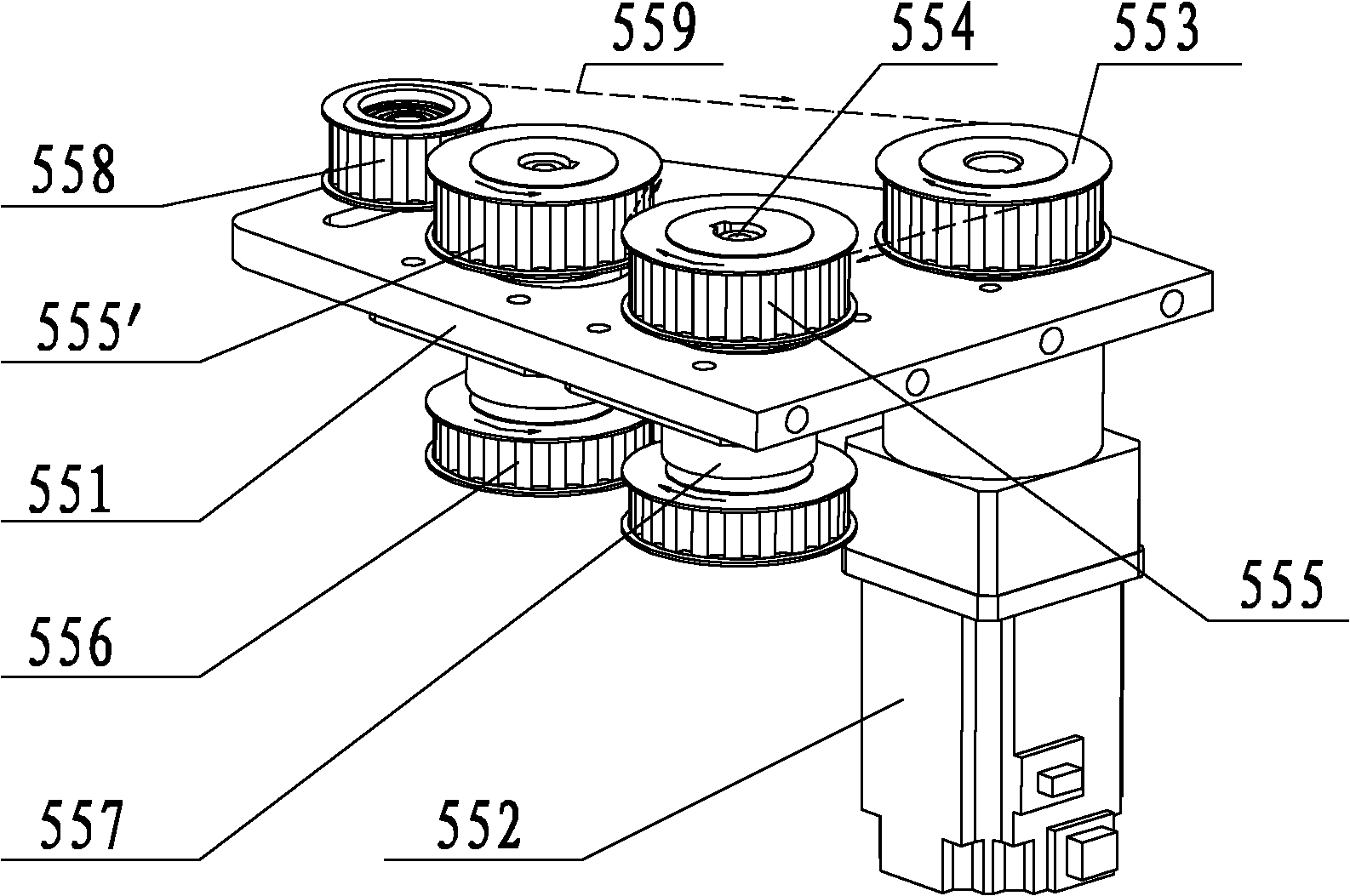

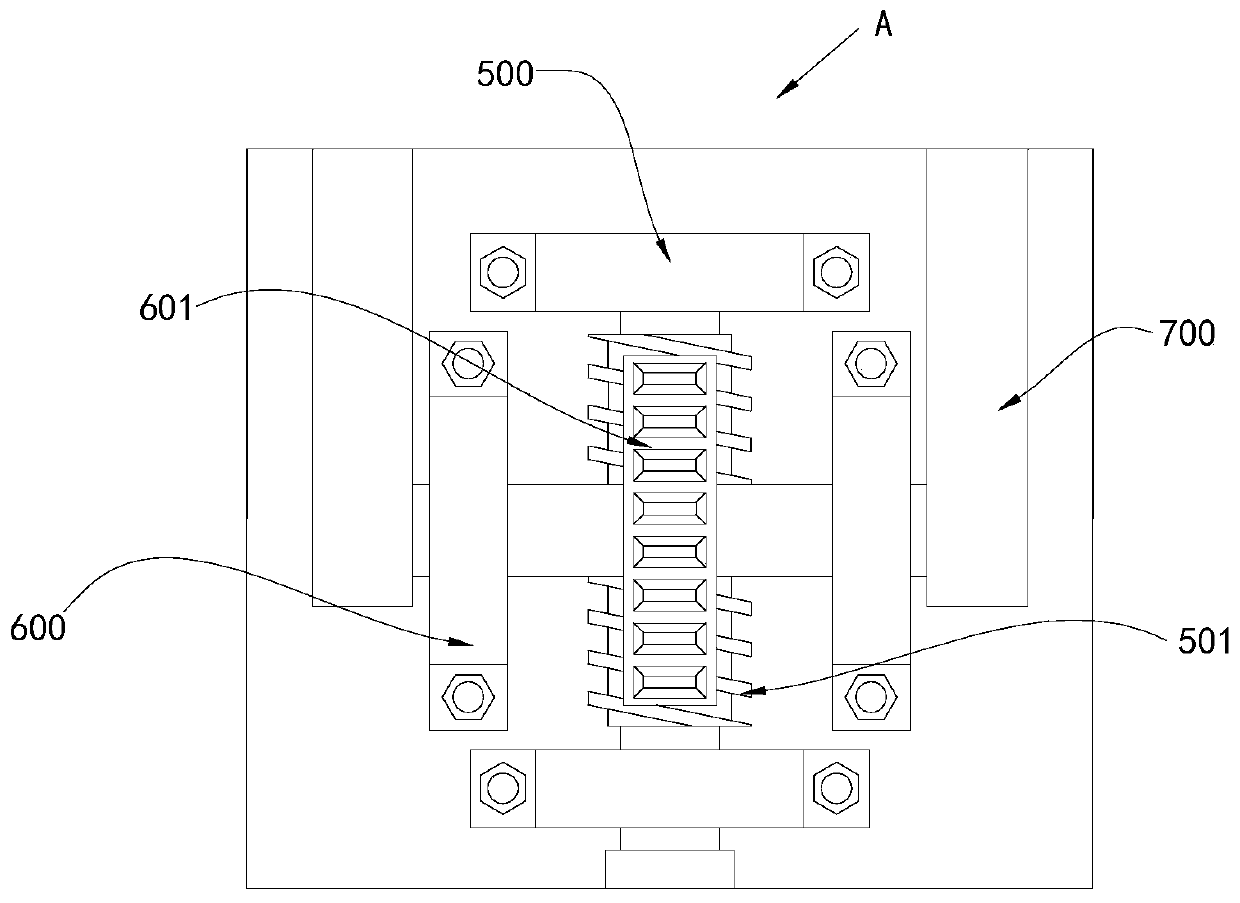

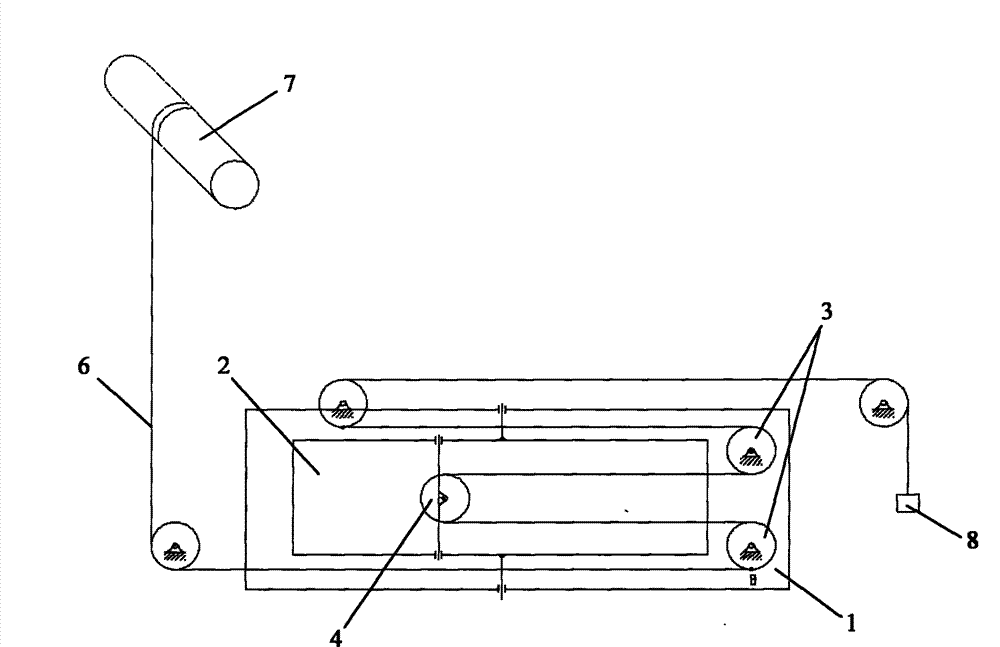

Traction mechanism for full-automatic vacuum packing machine

InactiveCN101973409AReasonable structureStable tractionPackaging under vacuum/special atmosphereWrapper twisting/gatheringVacuum packDrive shaft

The invention discloses a traction mechanism for a full-automatic vacuum packing machine. The full-automatic vacuum packing machine comprises a vacuum reciprocating mechanism and traction mechanisms. The vacuum reciprocating mechanism comprises a main box body capable of moving left and right and fixed side box bodies positioned on the left and right sides of the main box body, wherein the main box body moves left and right can be combined with one side box body at the same time to form a vacuum chamber, and the other side box body forms an open packing station. The number of the traction mechanisms is two sets; and each set of traction mechanism comprises a motor mounting plate, a driving motor, a driving traction wheel, two drive shafts, two driven traction wheels, two bag clasping traction wheels, a rear tensioning wheel and a double-side synchronous belt. The motor mounting plate is arranged on the main box body; the driving motor, the two drive shafts and the rear tensioning wheel are all arranged on the motor mounting plate; the driving traction wheel is arranged on the output shaft of the driving motor; the two driven traction wheels and the two bag clasping traction wheels are arranged on the upper and lower ends of the drive shafts in pair respectively; and the two bag clasping traction wheels rotate in opposite directions through the double-side synchronous belt.

Owner:上海嘉迪机械有限公司

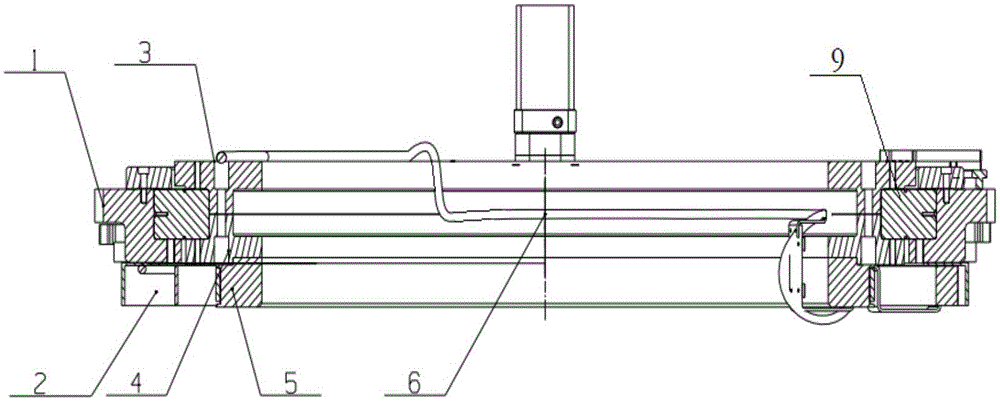

Torque detecting device and detecting method used in tractor gearbox inner cavity

PendingCN107607234ASmooth tractionEliminate frustrationWork measurementTorque measurementMoment of inertiaEngine power

The invention discloses a torque detecting device and a detecting method used in a tractor gearbox inner cavity. The torque detecting device comprises main and auxiliary box signal disks, main and auxiliary box detecting sensor, a main box signal disk spline sleeve, a gearbox case, front and rear bearings, a flexible signal shaft, a power output shaft 7, a power output drive gear, a power output driven gear, a power output shaft bearing, a controller, and the like. The torque detecting device consisting of the above components is installed inside a tractor gearbox, performs measurement and feedback of the torque and the rotation speed through a detection system and a sensor analysis system to monitor the change of the working rotation speed and the torque of the tractor in real time, can effectively control the reasonable range of the rotation speed difference and the size range of the inertia moment during a matching and gear-shifting process, can accurately calculate the power outputof the engine and the rotation speed of the tractor to achieve real-time monitoring of the output power of the tractor, can effectively adjust the reasonable gear-shifting timing of the tractor, canimprove the gear-shifting quality of the power gear-shifting of the tractor, and can ensure the constant power output of the engine.

Owner:FIRST TRACTOR

Cable threading traction device for building electrical engineering

ActiveCN112803305AReduce damage rateExtended service lifeFilament handlingApparatus for laying cablesElectric machineryStructural engineering

The invention relates to the technical field of cable traction devices, and discloses a cable threading traction device for building electrical engineering. Through arrangement of a heating motor, a heating wire and the like, a heat shrink tube is shrunk, and a cable leather sheath is wrapped and thickened so that subsequent traction is facilitated, and damage to the cable leather sheath by adopting a traditional net sleeve mode is avoided; through the arrangement of a winching machine, a pull disc and the like, the pull disc drives an upper shell and a lower shell to move towards one side, through the arrangement of semicircular holes, the upper shell and the lower shell drive the cable leather sheath to move towards one side of the winching machine, then the purpose of damage-free traction is achieved, and through the arrangement of a control rod and the like, stable traction can be achieved, and the cable leather sheath is prevented from being separated during traction due to the too thin cable leather sheath; and through the arrangement of a fixing cone, a suction cup and the like, distinguished reinforcement is achieved according to different geologies, and a situation that a pay-off rack slides accidentally in the traction process and accidents are generated is avoided.

Owner:HUANGGANG POWER SUPPLY COMPANY HUBEI ELECTRIC POWER

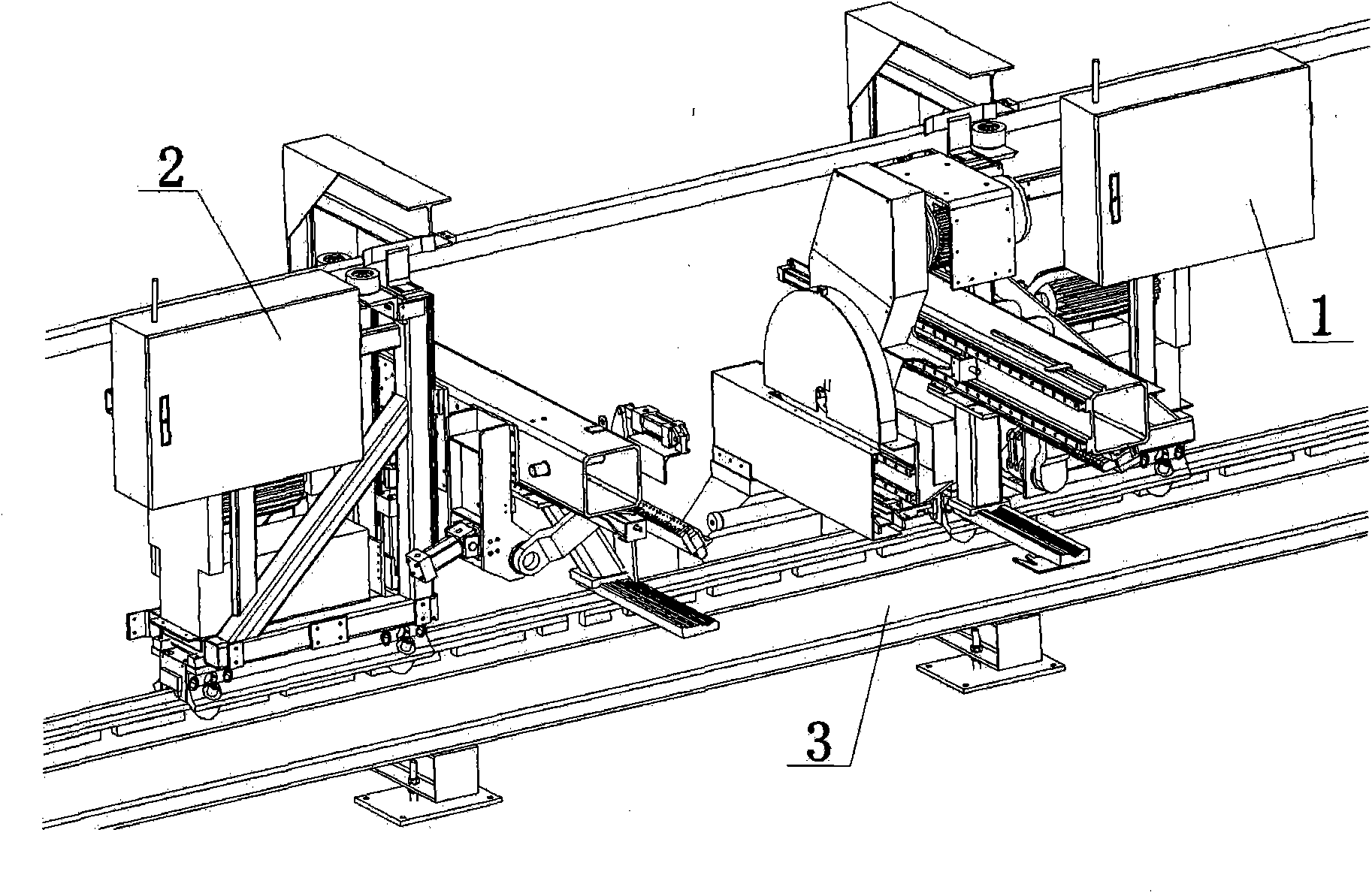

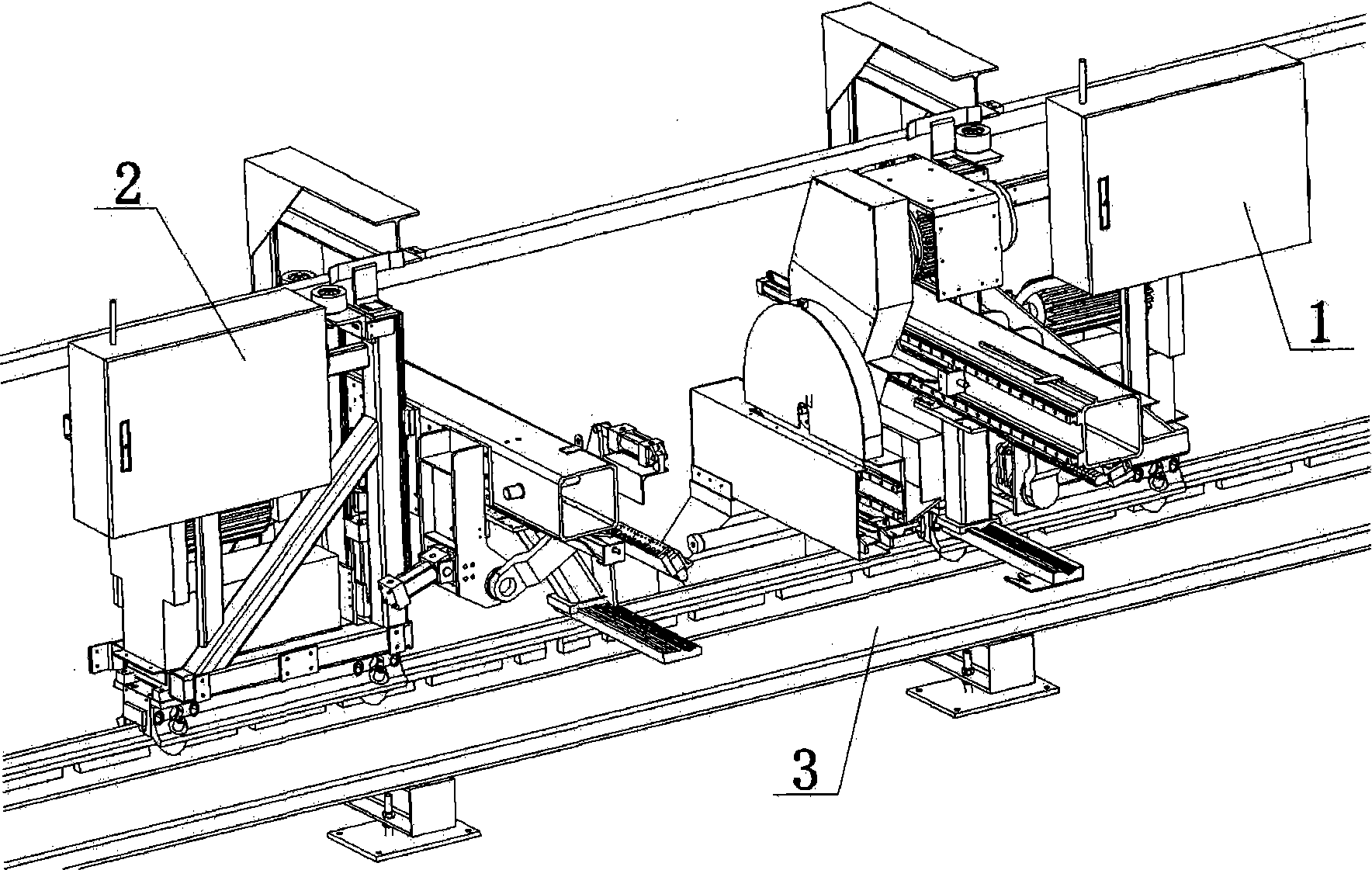

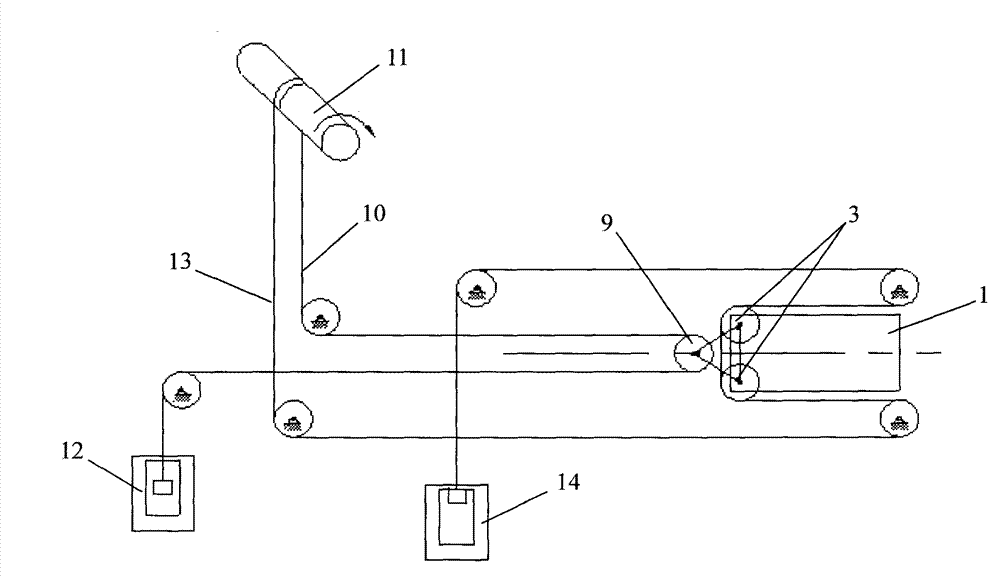

Process flow of single-track double-end dragger with flying saw

The invention discloses a process flow of a single-track double-end dragger with a flying saw, and aims to provide a process flow of a dragger which can cut automatically, meet requirements of multiple specifications and save labors and resources. The process flow comprises the following steps that: a P1 drawing head clamps sections at a discharge hole of an extruder; when the sections are drawn to meet a P2 drawing head, the P2 drawing head clamps the sections, and the two drawing heads draw the sections together at the same speed; the P1 drawing head loosens the sections and returns to the discharge hole of the extruder; the P2 drawing head continues to draw the sections and stops drawing until the extruder enters the non-extrusion period, and continues to draw the sections when the non-extrusion period ends; a detector on the P1 drawing head detects stopping marks, the P1 drawing head clamps the sections to cut the sections completely, the P2 drawing head draws the sections to reach the discharging position and unloads the sections, and moves to the P1 drawing head at the high speed; and the step is repeated when the two drawing heads meet each other. The process flow is mainly used for drawing products automatically after the products are produced by manufacturers of extruded sections.

Owner:梁伙有

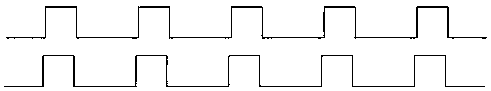

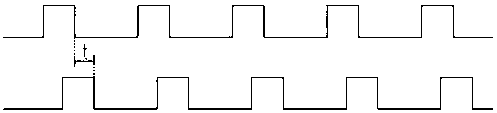

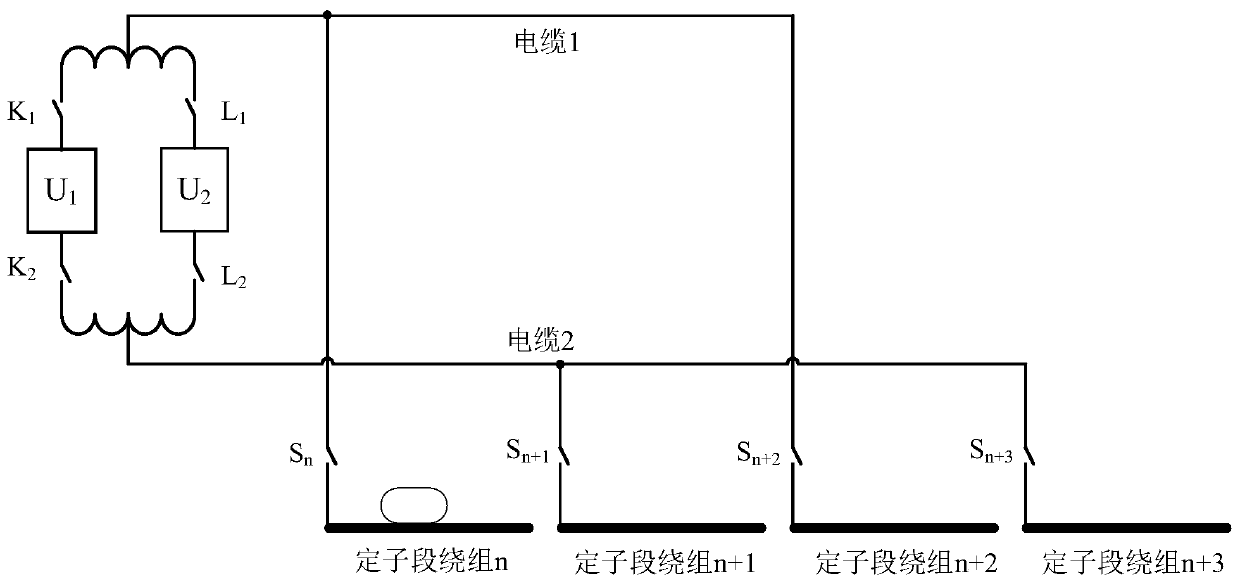

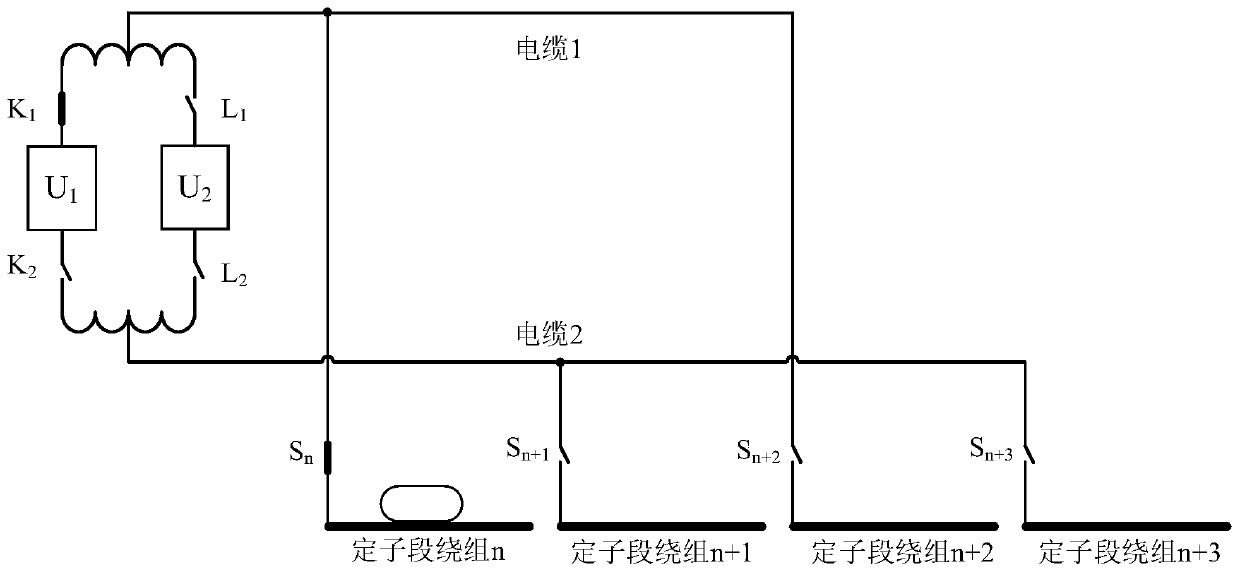

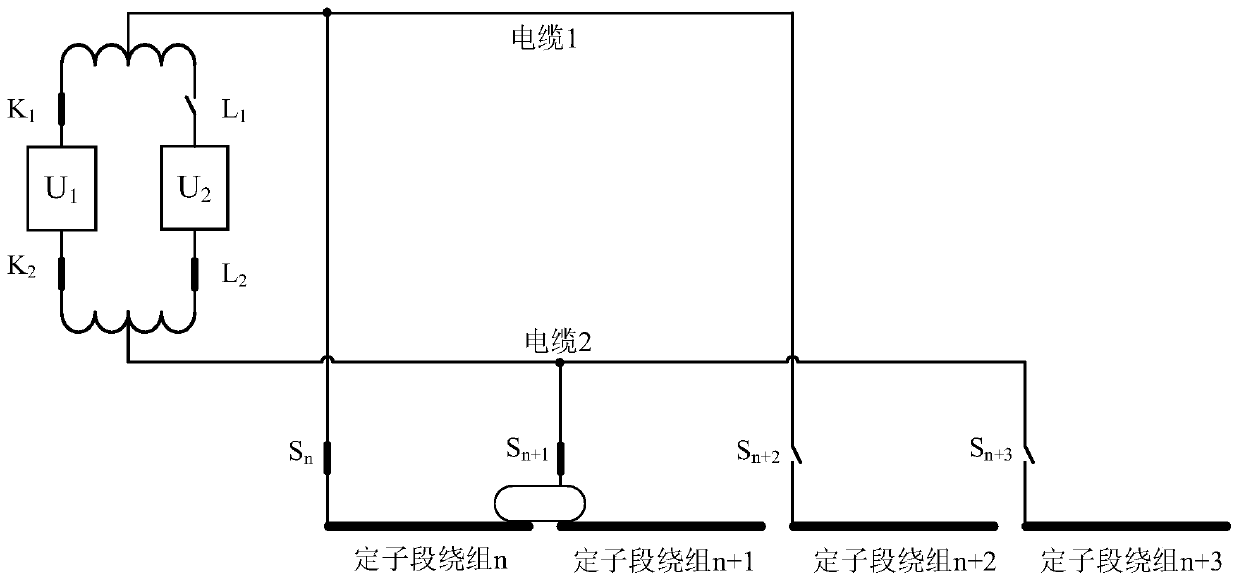

Step changing method for stator segment winding of medium speed magnetic suspension train long stator linear synchronous motor

The present invention discloses a step changing method for a stator segment winding of a medium speed magnetic suspension train long stator linear synchronous motor. The step changing system for the stator segment winding of the medium speed magnetic suspension train long stator linear synchronous motor comprises: a main converter unit U1, an auxiliary converter U2, two sets of feeder cables, anda row of long stator linear synchronous motor stator segment winding placed in the middle of the track. The main converter unit U1 is a large-capacity converter that satisfies power output requirements in state of traction acceleration etc.; the auxiliary converter unit U2 has a smaller capacity than the main converter unit U1, and is used for current regulation of a next stator segment winding during step changing process. When the train runs on a stator segment winding n, the main converter unit U1 participates in power supply. When the train is in state of changing step from the stator segment winding n to a stator segment winding n+1, the stator segment winding n is supplied by the main converter unit U1, and the stator segment winding n+1 is supplied in parallel by the main converterunit U1 and the auxiliary converter unit U2. When the train fully enters the stator segment winding n+1, only the main converter unit U1 supplies power.

Owner:INST OF ELECTRICAL ENG CHINESE ACAD OF SCI

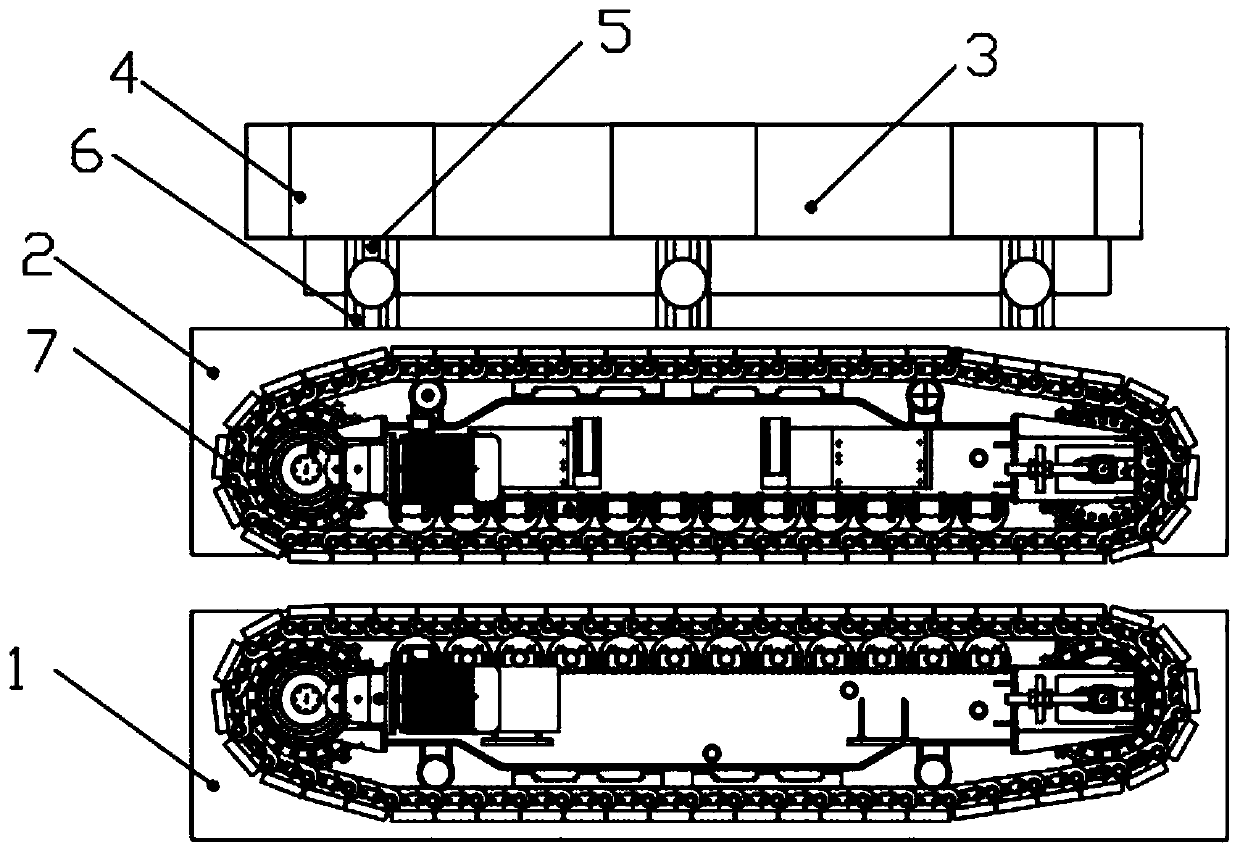

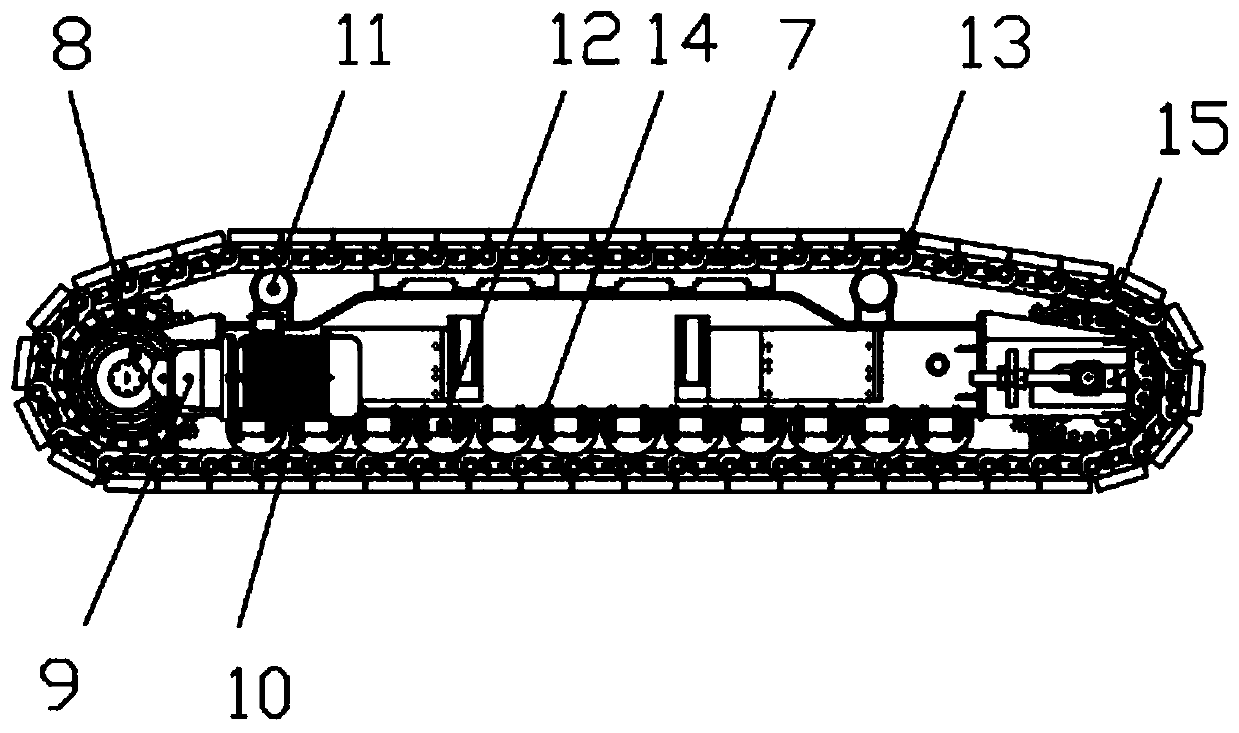

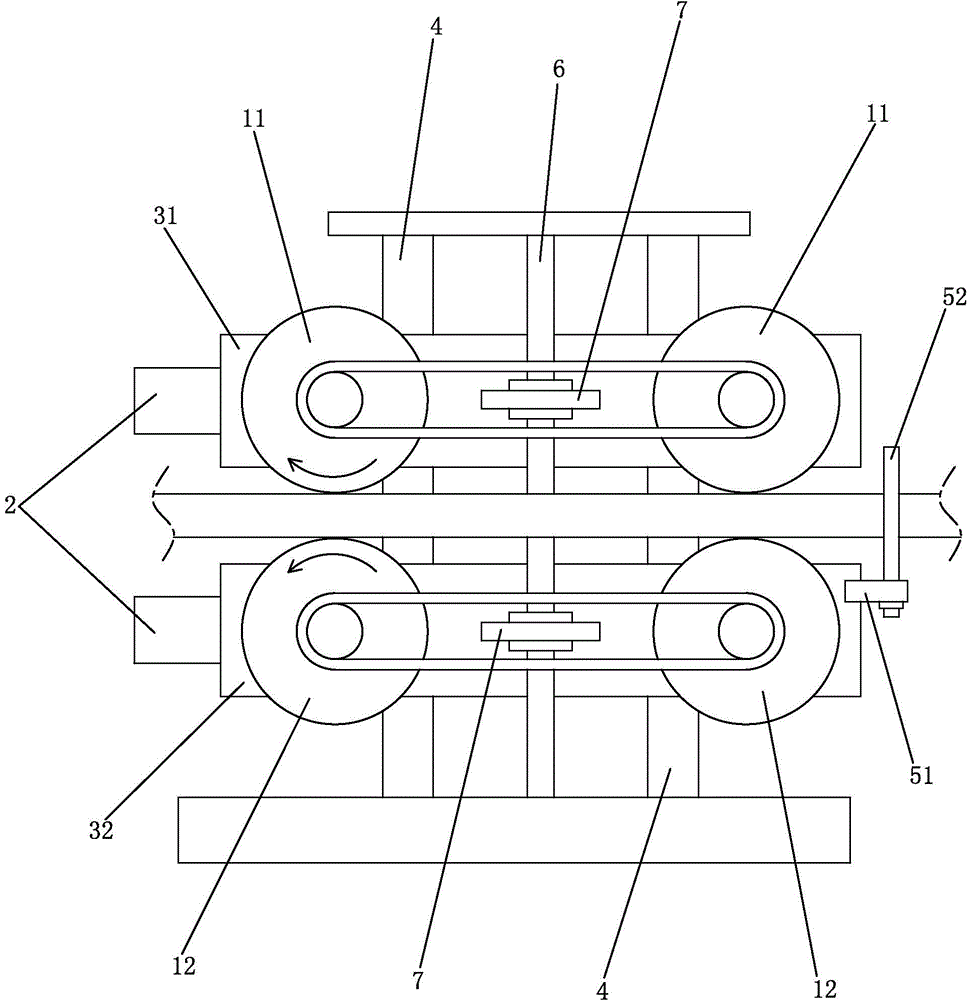

Two crawler type tractor

PendingCN110697495AGuaranteed tensionIncrease contact surfaceFilament handlingMarine engineeringStructural engineering

The invention discloses a two crawler type tractor. The two crawler type tractor comprises an upper moving frame, a lower fixing frame and a traction mechanism, wherein a plurality of slide rails arearranged on one side of the upper moving frame, the same ends of the plurality of the slide rails are all connected with a top frame, a plurality of oil cylinders are installed on the top frame, the bottom of each oil cylinder is connected with a telescopic rod, and each telescopic rod is connected into the slide rail on the corresponding position, and connected with the upper moving frame. The two crawler type tractor can solve the problems that a slipping phenomenon is easily caused in the traction process of a submarine cable due to the fact that most crawler belts used by an existing crawler type tractor are flat belts, the existing crawler type tractor is lack of a mechanism for adjusting the distance between each two adjacent crawler belts, and therefore the distance between each twoadjacent crawler belts is inconvenient to adjust; the existing crawler type tractor is lack of an abutting and limiting component when each two adjacent crawler belts clamp the submarine cable, and therefore slip is easily caused in traction; and all assemblies of a traction mechanism of the existing tractor need customized production, and therefore cost is high, and procurement is troublesome.

Owner:HEFEI SMARTER TECH GROUP CORP

Automatic bypass cable conveying system

PendingCN111276904AAvoid stampedeAvoid layingSuspension arrangements for electric cablesApparatus for overhead lines/cablesClassical mechanicsTraction cord

The invention relates to an automatic bypass cable conveying system. The system comprises an electric pole, a track, a traction assembly and a cable supporting assembly. A supporting assembly is arranged on the electric pole. The supporting assembly is connected with a hanging assembly. The rail is arranged to be of a rope structure. The hanging rod is arranged on the hanging assembly after beingtightened. Two ends of the track are respectively connected with the first pay-off rack and the ground. The plurality of traction assemblies are connected with the traction rope and are arranged on the rail in a sliding manner. Two ends of the traction rope are respectively connected with the second pay-off rack and the lead rack. A traction machine capable of pulling the traction rope to move isfurther arranged on one side of the second pay-off rack. The cable supporting assemblies are connected with the traction rope and arranged on the rail in a sliding mode, each cable supporting assemblyis provided with a first fixing position for fixing the traction rope and a second fixing position for supporting the bypass cable, and the bypass cable is not pulled in the conveying process. The automatic bypass cable conveying system is simple in structure and convenient to convey.

Owner:GUANGDONG POWER GRID CO LTD +1

Shore end traction device for intelligent ship docking

ActiveCN110816753AReasonable structural designStable tractionTowing/pushing equipmentElectric machinerySlide plate

The invention discloses a shore end traction device for intelligent ship docking. The traction device is reasonable in structural design, a second motor is driven to drive a turbine worm to drive a traction arm to swing by taking one end as an origin, an electric push rod drives the traction device to hook a traction ring on the shore side, a first motor is driven to drive a sliding plate to moveon a lead screw so as to achieve stable traction, stable traction under the condition of unmanned operation can be achieved, the traction device is more convenient, and the traction device can be adjusted according to the distance between the ship body and the shore, so that the practicability is high. The traction device is used in the technical field of intelligent ship docking.

Owner:WUHAN UNIV OF TECH

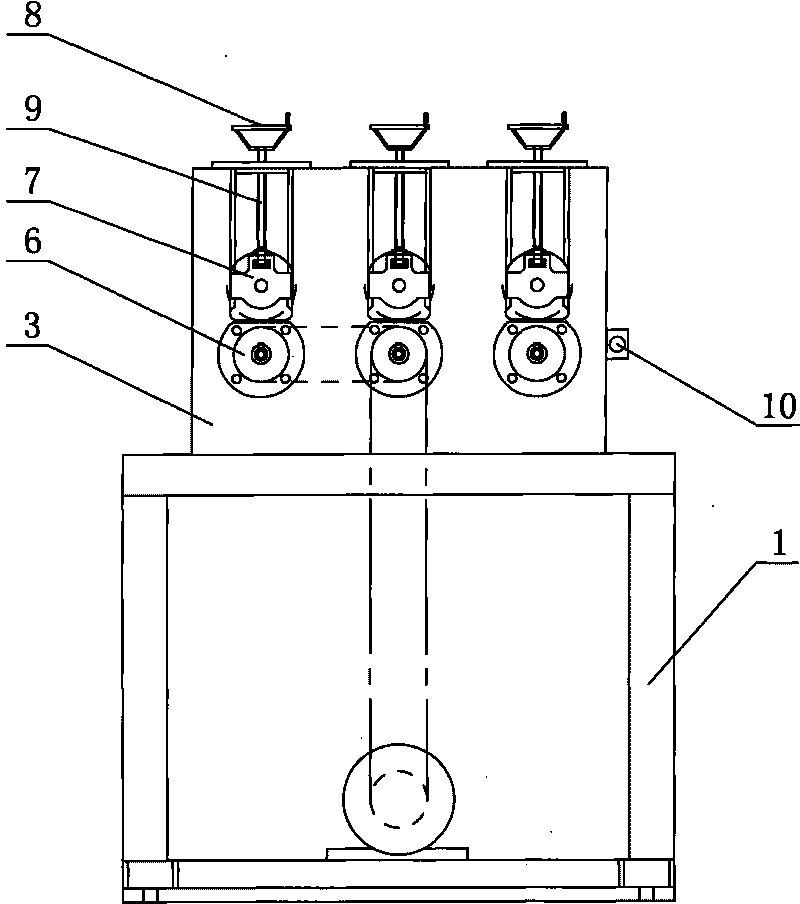

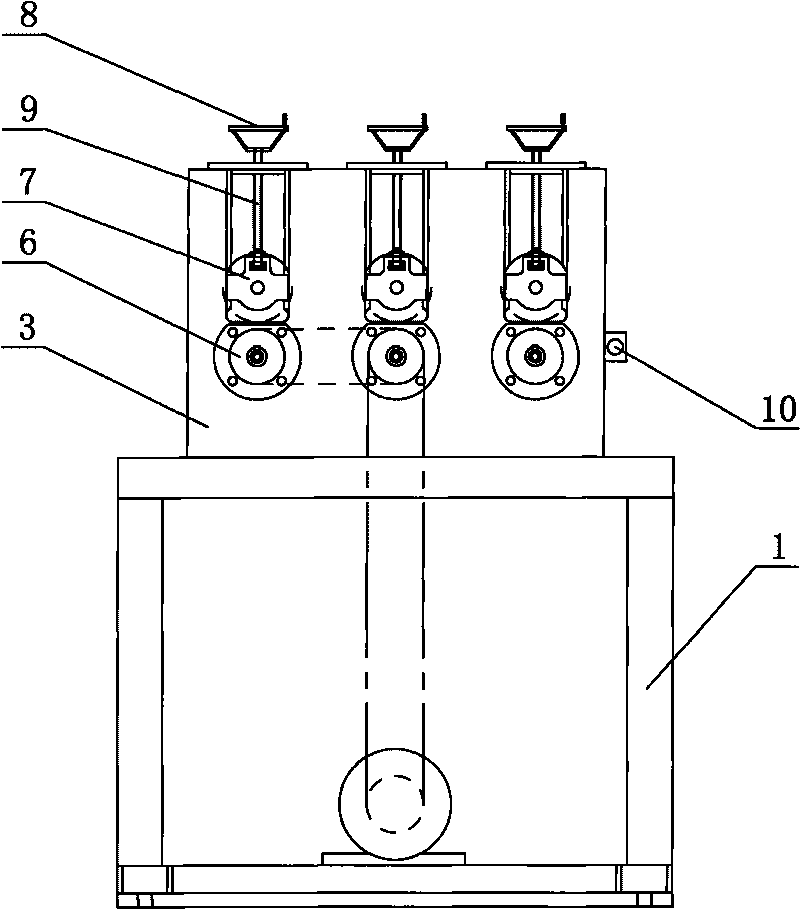

Multi-roller seal tractor

InactiveCN101758001AUniform thicknessStable tractionLiquid surface applicatorsCoatingsEngineeringScrew thread

The invention discloses a multi-roller seal tractor capable of steady traction, comprising a frame, an electric motor arranged on the frame, and a pair of wallboards arranged on the frame, wherein one side near a feeding port on the wallboard is provided with a gluing device and the wallboard is provided with three traction devices with the same structure which comprises a pair of upper, lower rollers, a shaft end of the lower roller is arranged inside a bearing support on the wallboard, the shaft end of the upper roller is arranged inside a movable bearing support which is movably arranged on the wallboard and is movably connected with one end of a lead screw, the other end of the lead screw is movably connected with a handwheel, the lead screw is also in threaded connection with the wallboards, two traction devices near a discharging port is in transmission connection with each other, and the electric motor is in transmission connection with one of the two traction devices. The multi-roller seal tractor is suitable for the gluing and traction of seal.

Owner:张家港市欣达机械制造有限公司

Underwater fuel conveying trolley and tipping-over device for pressurized water reactor

ActiveCN102097140BImplement the tipping actionSimple designNuclear energy generationReactor fuel elementsPressurized water reactorEngineering

Owner:SHANGHAI NUCLEAR ENG RES & DESIGN INST CO LTD

elevator

Owner:烟台祥润电梯有限公司

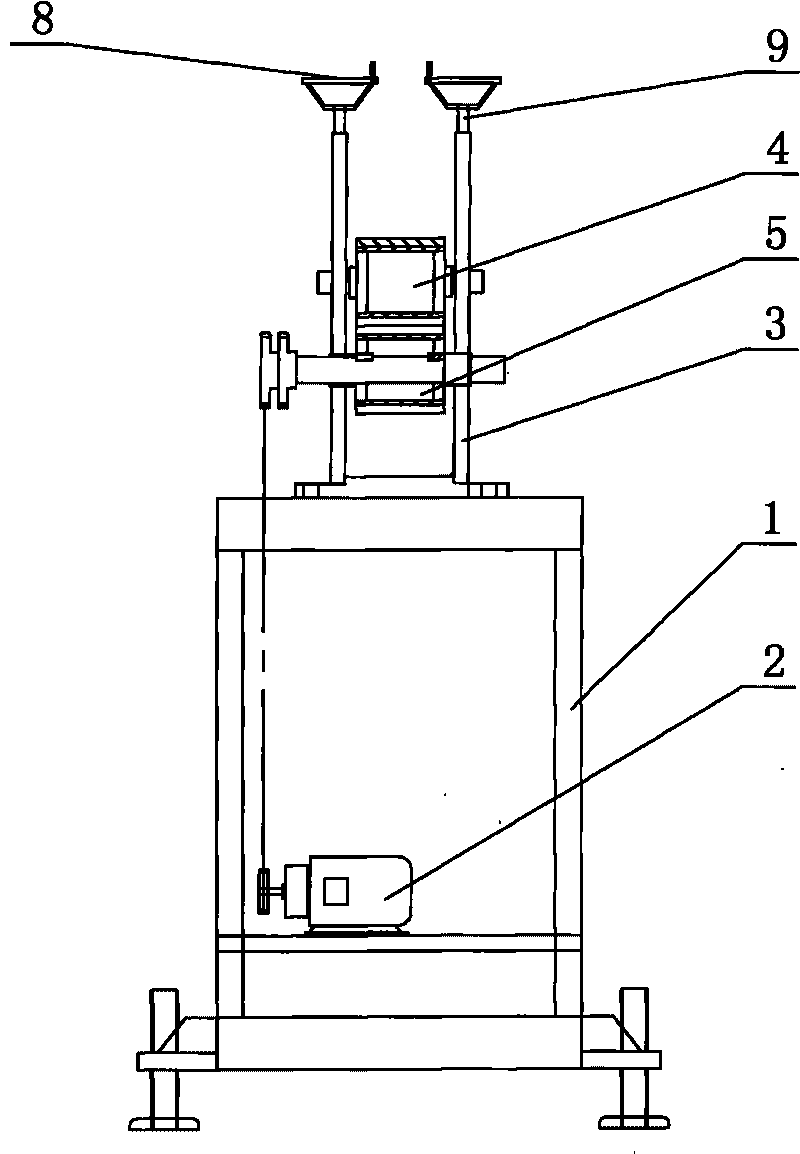

Roller-type plastic pipe traction machine

InactiveCN104085097AHigh-quality and efficient processing and productionStable tractionEngineeringMechanical engineering

The invention discloses a roller-type plastic pipe traction machine. The roller-type plastic pipe traction machine comprises two horizontal roller groups, and each roller group is longitudinally provided with upper rollers and lower rollers, which are matched with each other to drag a plastic pipe in a rolling manner, the upper rollers and the lower rollers on a pipe outlet side of the traction machine are respectively connected with a motor, the upper rollers and the lower rollers are installed on an upper frame and a lower frame, respectively, and the heights of the upper frame and the lower frame can be independently adjusted. The roller-type plastic pipe traction machine is suitable for different plastic pipes, the plastic pipes can be stably dragged in a uniform stress manner and the high-quality high-efficiency processing production of the plastic pipes can be promoted.

Owner:YIYANG PLASTIC PROD

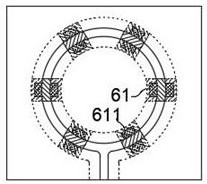

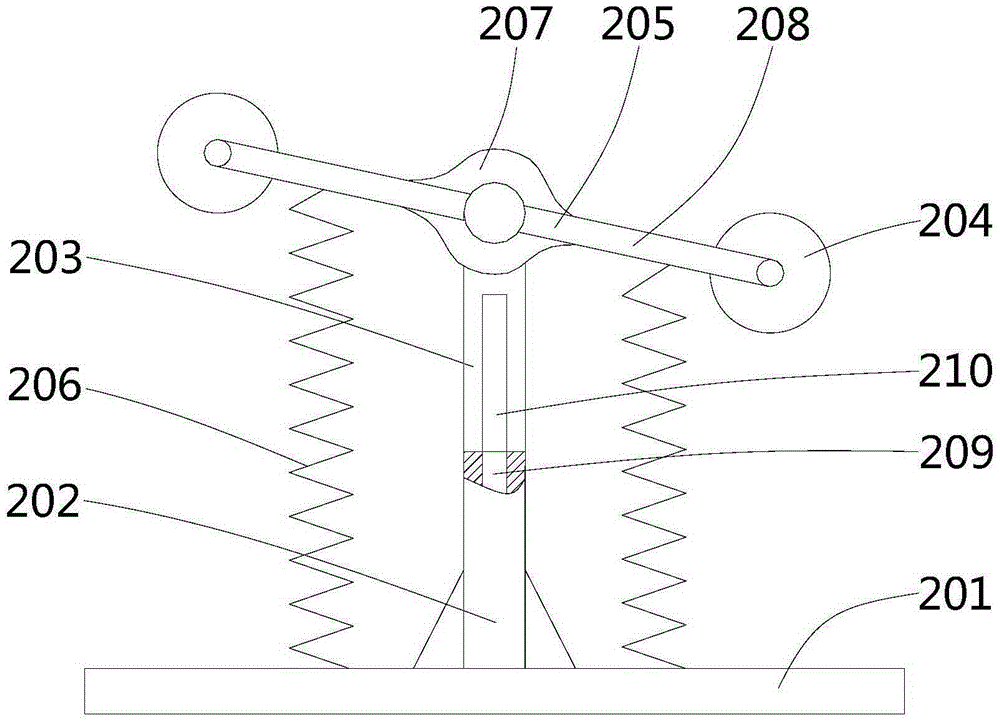

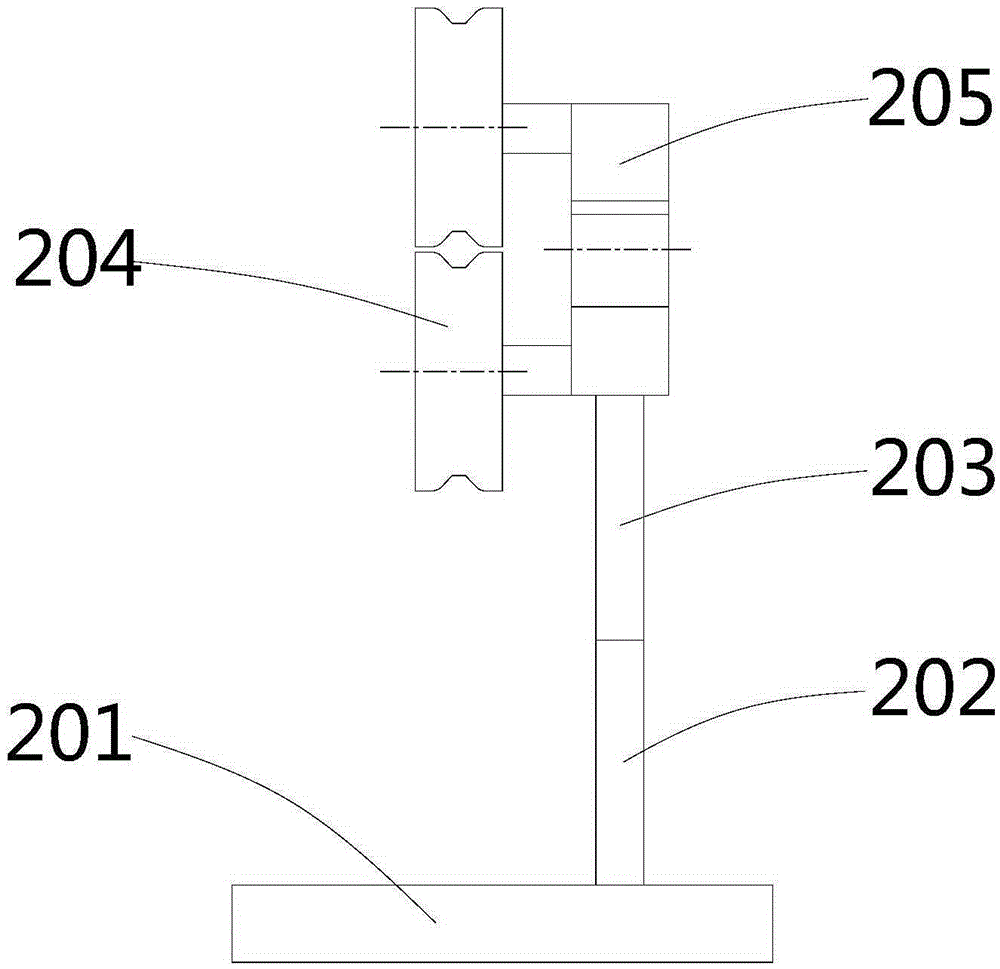

Novel cable traction frame

The invention provides a novel cable traction frame, and belongs to the field of cable traction equipment. The novel cable traction frame comprises a frame body, wherein the frame body comprises an upright column and a cantilever beam; a rotation limitation traction device is arranged on the cantilever beam; two traction wheels are arranged at the two ends of the cantilever beam; a tightening mechanism is arranged on the cantilever beam and at a position between the two traction wheels; the tightening mechanism comprises a fixing seat, a first support rod, a second support rod and two tensioning wheels; the lower part of the second support rod can slide on the first support rod; the upper end of the second support rod is rotatably connected with the middle part of a connecting rod; a spring is arranged at each of the two ends of the connecting rod; a planetary traction device is arranged on the side, far from the cantilever beam, of the upright column; the planetary traction device comprises a center wheel and at least three planet wheels. According to the novel cable traction frame, provided by the invention, all the devices are connected in series to form the traction system of cables, and all the devices cooperate well with each other, therefore the traction tensile force of cables is greater, shaking is greatly reduced, the traction rate is increased, and the machining efficiency is further improved.

Owner:江苏永达电力金具有限公司

Running mechanism of medium and low speed maglev vehicle

The invention relates to the technical field of walking mechanisms for maglev vehicles, and particularly relates to a walking mechanism for middle / low-speed maglev vehicles. The walking mechanism for middle / low-speed maglev vehicles comprises at least two end part suspension frames and at least an intermediate suspension frame, each suspension frame comprises two longitudinal beams, sliding tables, air springs, a transverse draw bar and an anti-side-rolling draw bar, wherein the two longitudinal beams are arranged in a left and right mode, the sliding tables and the air springs are arranged in the middle of the longitudinal beams, each longitudinal beam is provided with a sliding table, the sliding table is fixedly supported on the longitudinal beam through the air spring, the sliding tables are connected through the transverse draw bar, the longitudinal beams are connected through the anti-side-rolling draw bar, the transverse draw bar and the anti-side-rolling draw bar are located in the middle of the suspension frame, the sliding tables of the intermediate suspension frame are provided with a linear guide rail extending along the transverse direction, the sliding tables of the intermediate suspension frame are connected with a train body through the linear guide rail, and the sliding tables and the longitudinal beams are connected through traction bars. The walking mechanism disclosed by the invention has the beneficial effects that as a method that the sliding tables are arranged in the middle of the suspension frames and a linear bearing replaces a swing bolster and a Z-shaped traction bar is adopted, the structure of the walking mechanism is simplified, and the walking mechanism is convenient to maintain.

Owner:常州西南交通大学轨道交通研究院 +1

Textile thread traction device with textile thread breakage avoiding function

PendingCN112591552AAvoid breakingStable deliveryFilament handlingLiquid/gas/vapor textile treatmentStructural engineeringMechanical engineering

The invention discloses a textile thread traction device with a textile thread breakage avoiding function. The device comprises a fixed frame, a tensioning shaft and a front mounting frame, wherein awater tank is arranged at the bottom of the inner side of the fixed frame, a partition plate is mounted on the top face of the water tank, a conveying shaft is arranged at the upper left corner of thefixed frame, an end socket is arranged on the edge of the end of the conveying shaft, limiting rings are arranged on the outer side of the conveying shaft, connecting pipes are connected to the innersides of the limiting rings, connecting ropes are connected to the upper middle portions of the connecting pipes, the tensioning shaft is arranged on the upper side of the middle of the fixed frame,the front mounting frame is arranged below the right side of the tensioning shaft, and an inner ring plate is arranged at the inner side of each clamping plate. According to the textile thread traction device with the textile thread breakage avoiding function, breakage of textile threads can be avoided, stable delivery of the textile threads is guaranteed, stable winding can be guaranteed, the textile threads can be conveniently arranged, integration can be conducted, disassembling and assembling are facilitated, and the working efficiency can be guaranteed.

Owner:福建新华源纺织集团有限公司

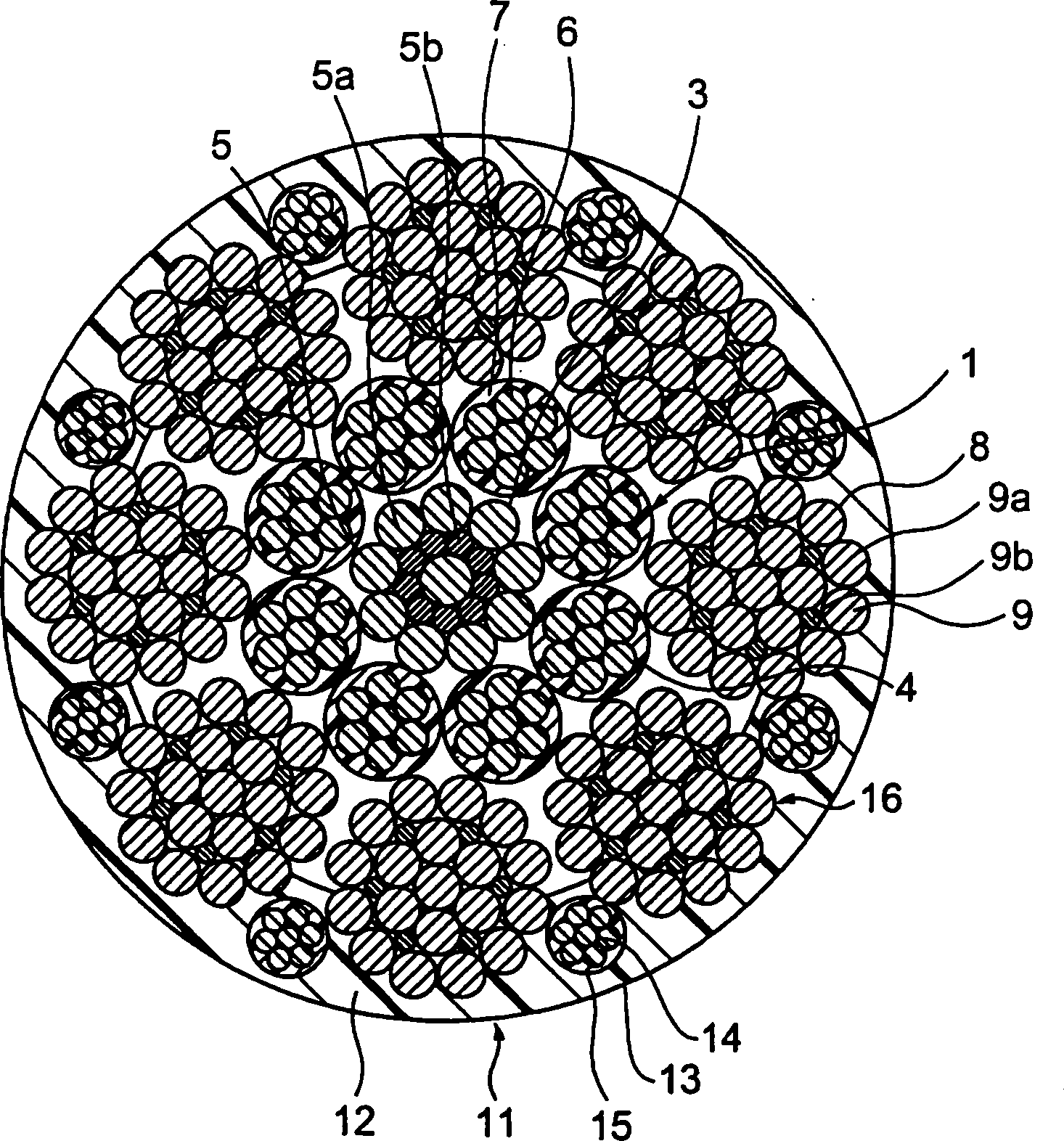

Omnidirectional vehicle

An omnidirectional vehicle 1 includes: a main wheel 3 which is able to be driven in all directions; a base 2 which supports the main wheel 3; and a sub wheel 4 which is connected to the base 2 via an arm 15 and is grounded at a position apart from the ground contact point of the main wheel 3. The sub wheel 4 is attached so as to circularly move about the center of rotation of the main wheel 3.

Owner:HONDA MOTOR CO LTD

Elevator

The invention relates to an elevator. The elevator comprises a lift car, sliding rails, a traction machine, traction ropes and a counterweight structure, wherein the lift car is connected with the traction ropes through a regulating device; the regulating device comprises an upper support plate and a lower support plate, regulating sliding grooves are formed in the opposite surfaces of the upper support plate and the lower support plate, the upper supply plate and the lower support plate are connected through regulating rods, and sliding heads at the two ends of each regulating rod are arranged in the regulating sliding grooves in the upper support plate and the lower support plate in a sliding manner; electromagnetic columns are embedded in the sliding heads; in the same regulating sliding groove, the magnetic force of the electromagnetic columns in the adjacent sliding heads is repellent; and a pedal is arranged on the inner bottom surface of the lift car, and pressure-sensitive pieces are arranged into an array on the surface of the pedal at equal intervals. The elevator is novel in structure and unique in principle and can intelligently regulate the traction positions of the traction ropes according to the distribution condition of passengers in the lift car, so that the uniform stress of each traction rope is ensured, the stable lifting of the lift car is promoted, the safety of the elevator is effectively improved, and the working efficiency is increased.

Owner:烟台祥润电梯有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com