Roller-type plastic pipe traction machine

A technology for plastic pipes and tractors, which is applied in the field of roller-type plastic pipe tractors, can solve problems such as easily damaged plastic pipes, and achieve the effect of promoting high-quality and high-efficiency processing and production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

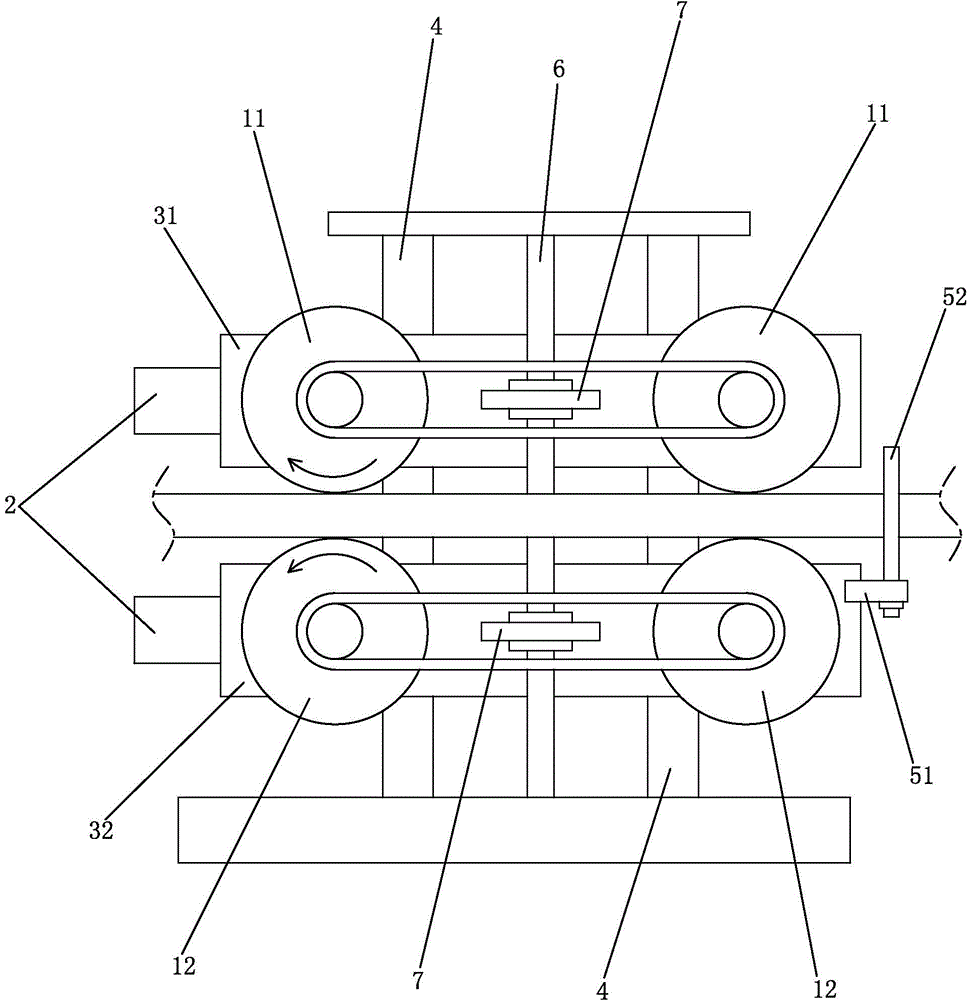

[0013] refer to figure 1 , a roller-type plastic pipe hauler of the present invention includes two roller sets horizontally arranged on both sides of the body, and the roller sets are longitudinally provided with upper rollers 11 and lower rollers 12 for cooperating with each other to roll and pull plastic pipes, located at The upper roller 11 and the lower roller 12 on the pipe outlet side of the tractor are connected with the motor 2, and the upper roller 11 and the lower roller 12 are respectively installed on the upper frame 31 and the lower frame 32 which can be adjusted in height separately, and the upper frame 31 and the lower frame The frame 32 adjusts the positions of the upper roller 11 and the lower roller 12 respectively, so that plastic pipes of different types and sizes are simultaneously coordinated with the rolling, and the two roller groups drive the plastic pipes at the same time, so that the plastic pipes are evenly stressed and pulled straight at a constant ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com