Elevator apparatus

A technology for elevators and guiding devices, which can be used in textile cables, transportation and packaging, textiles and papermaking, etc., and can solve problems such as inability to stabilize traction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

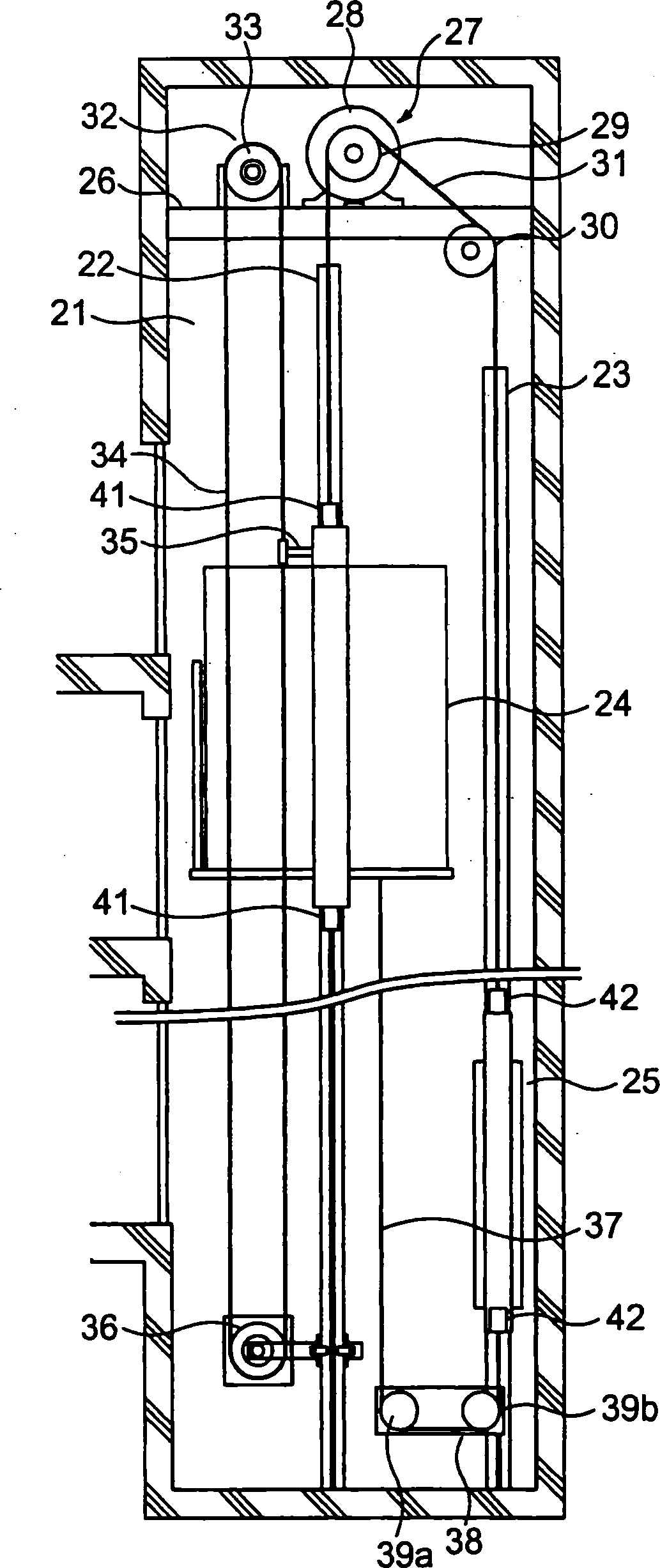

[0013] figure 1 It is a configuration diagram showing the elevator apparatus (machine-room-less elevator) according to Embodiment 1 of the present invention. In the drawing, a pair of car guide rails 22 and a pair of counterweight guide rails 23 are provided in a hoistway 21 . The car 24 moves up and down in the hoistway 21 along the car guide rail 22 . The counterweight 25 moves up and down in the hoistway 21 along the counterweight guide rail 23 .

[0014] A machine table (support beam) 26 is fixed to an upper portion in the hoistway 21 . A driving device (tractor) 27 that generates a driving force for raising and lowering the car 24 and the counterweight 25 is supported on the machine table 26 . The driving device 27 has: a driving device main body 28 including a motor and a brake; and a driving sheave 29 rotated by the driving device main body 28 . A rotatable deflector wheel 30 is installed on the machine table 26 .

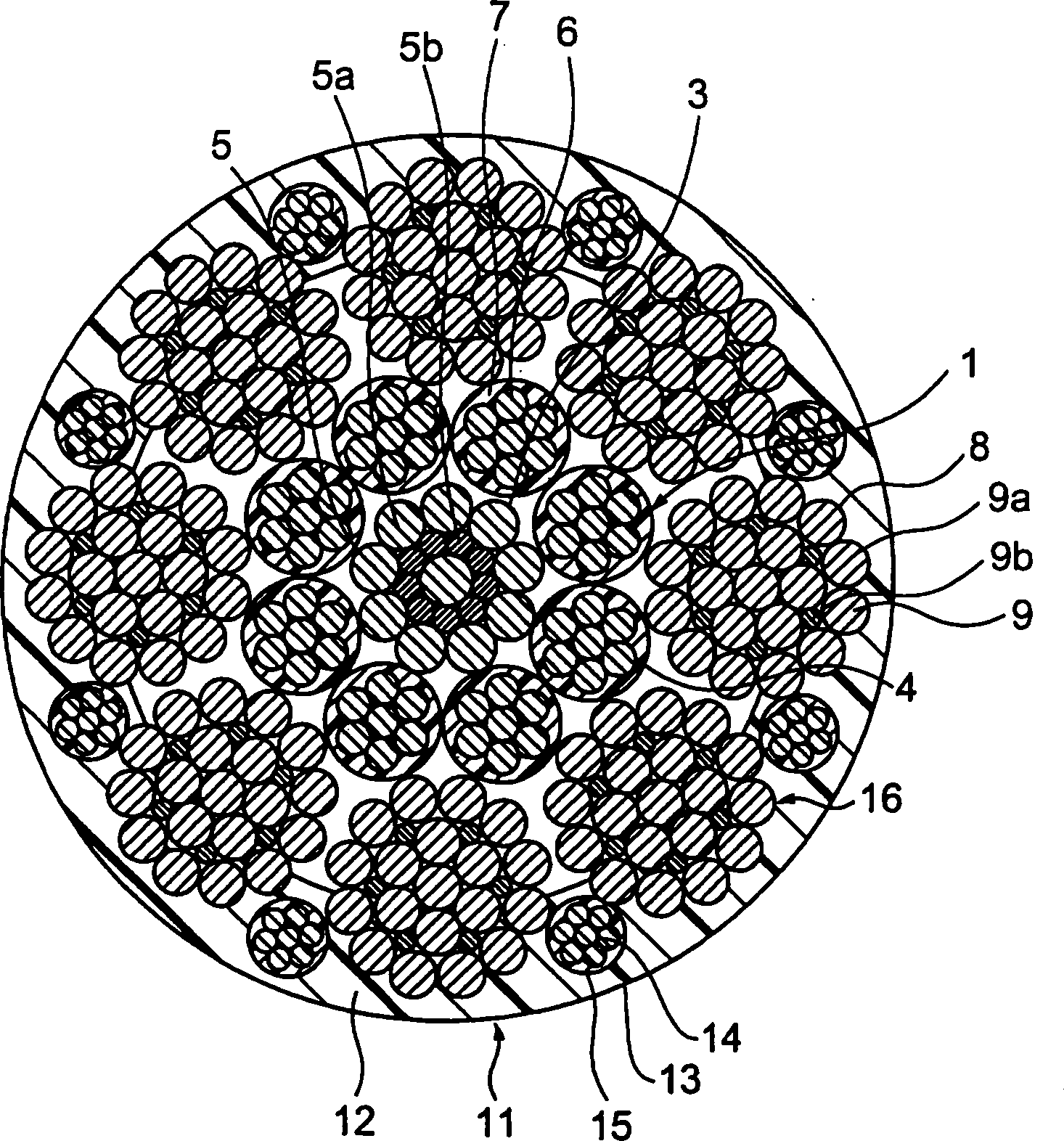

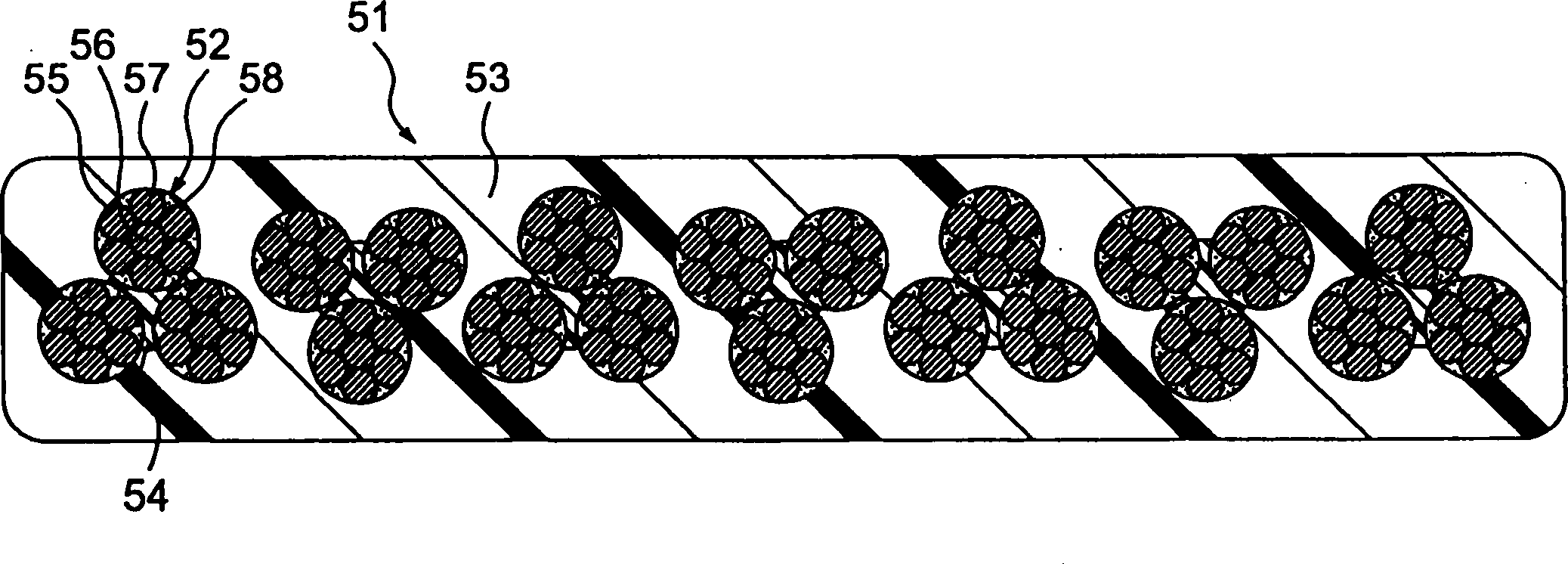

[0015] A plurality of (only one is shown in the f...

Embodiment approach 2

[0044] Next, Figure 4 It is a configuration diagram showing an elevator apparatus according to Embodiment 2 of the present invention. In the figure, a counterweight balancing chain 43 is suspended between the car 24 and the counterweight 25 . The counterweight balance chain 43 has: a car-side end connected to the lower part of the car 24 ; and a counterweight-side end connected to the lower part of the counterweight 25 . Other structures are the same as those in Embodiment 1.

[0045] In this way, when the lifting stroke of the car 24 is short, the counterweight balance chain 43 can be used instead of the counterweight rope 37, and the same effect as that of the first embodiment can be obtained.

[0046] In addition, Whisperflex (registered trademark) or the like may be used instead of the counterweight rope 37 and the counterweight balance chain 43 .

[0047] In addition, in the above example, the driving device 27 is arranged in the upper part of the hoistway 21, but the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com