Novel cable traction frame

A new type of cable pulling technology, which is applied in the transportation of filamentous materials, thin material handling, transportation and packaging, etc. effect, ensure the tension force, reduce the effect of jitter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

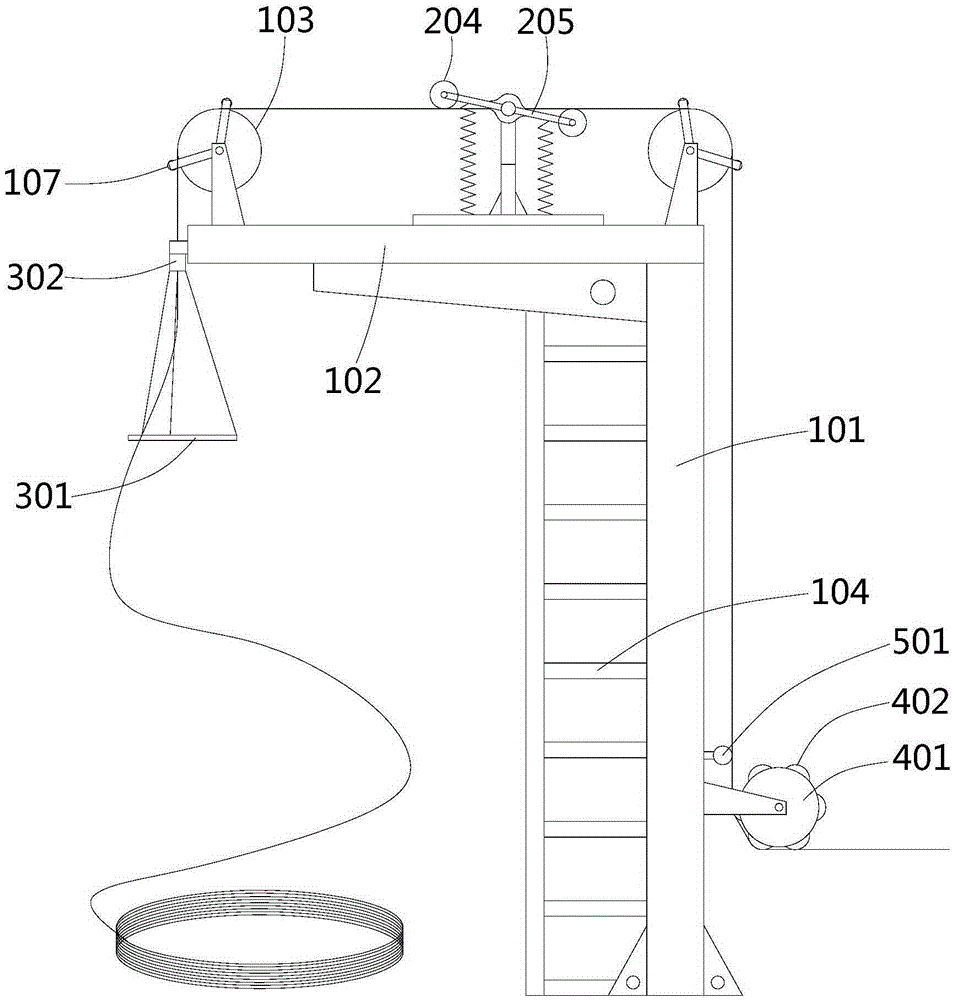

[0050] This embodiment provides a novel cable traction frame, and the novel cable traction frame includes a frame body. The frame body includes a column 101 and a cantilever beam 102. One end of the cantilever beam 102 is fixedly connected to the column 101. The end of the cantilever beam 102 away from the column 101 is provided with a rotation limiting traction device. Two ends of the cantilever beam 102 are oppositely arranged. traction wheel 103.

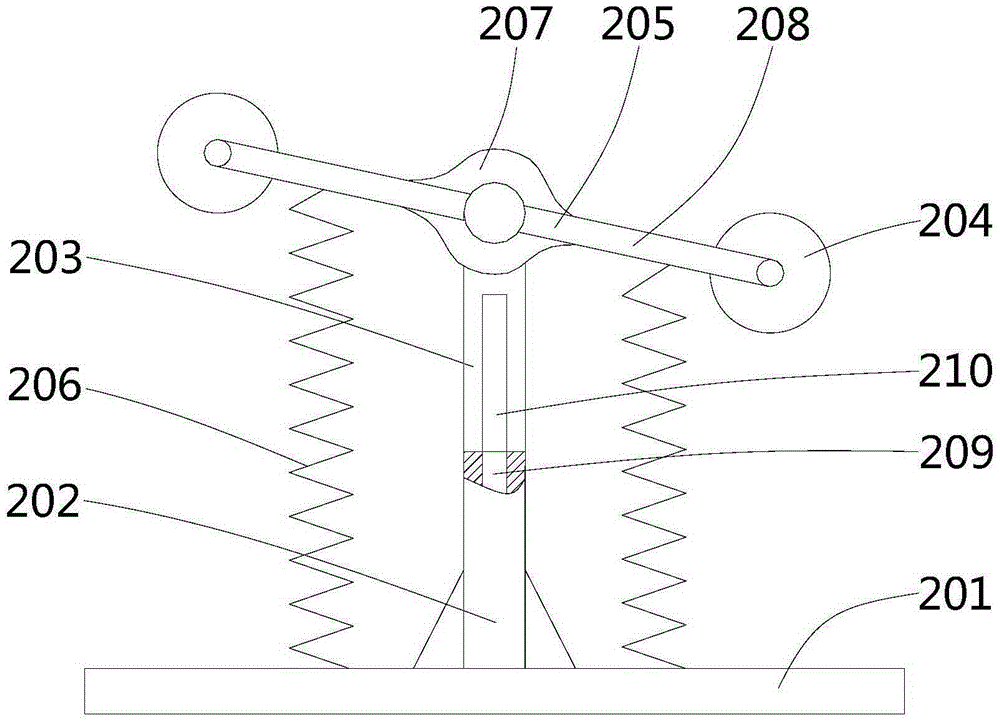

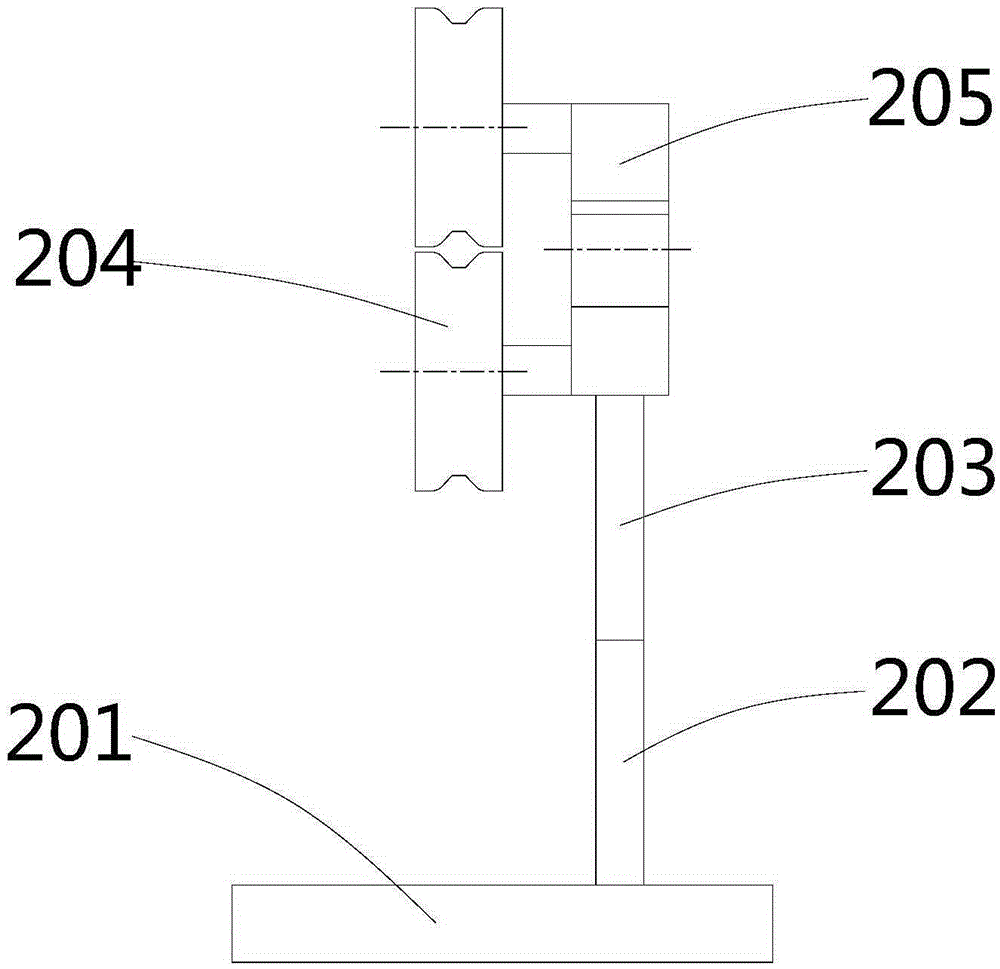

[0051] The cantilever beam 102 is provided with a tensioning mechanism between the two traction wheels 103. The tensioning mechanism includes a fixed base 201, a first pole 202, a second pole 203 and two tensioning wheels 204. The fixed base 201 is fixed on the cantilever The upper end surface of the beam 102, the lower end of the first pole 202 is fixed on the fixed seat 201, the bottom of the second pole 203 can slide on the first pole 202, the upper end of the second pole 203 and the middle part of the connecting rod 205 Rota...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com