Walking mechanism for middle/low-speed maglev vehicles

A traveling mechanism and magnetic levitation technology, applied in railway car body parts, bogies, transportation and packaging, etc., can solve problems such as the lack of effective suppression of over-nodding motion, the lack of anti-detachment device for the sliding table mechanism, and the reduction of the vehicle floor height. , to achieve the effect of convenient daily maintenance, space reduction and weight reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

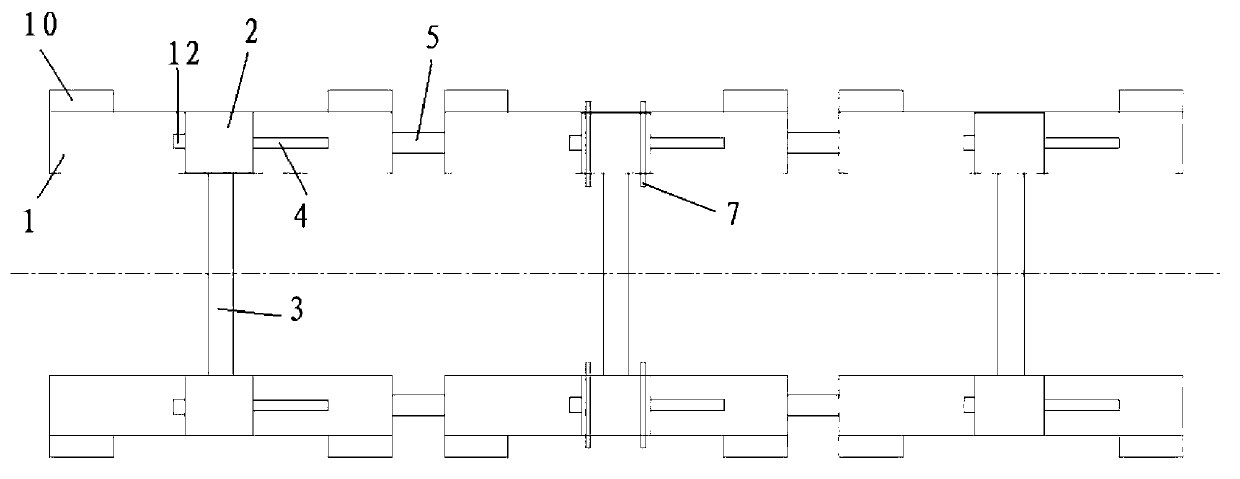

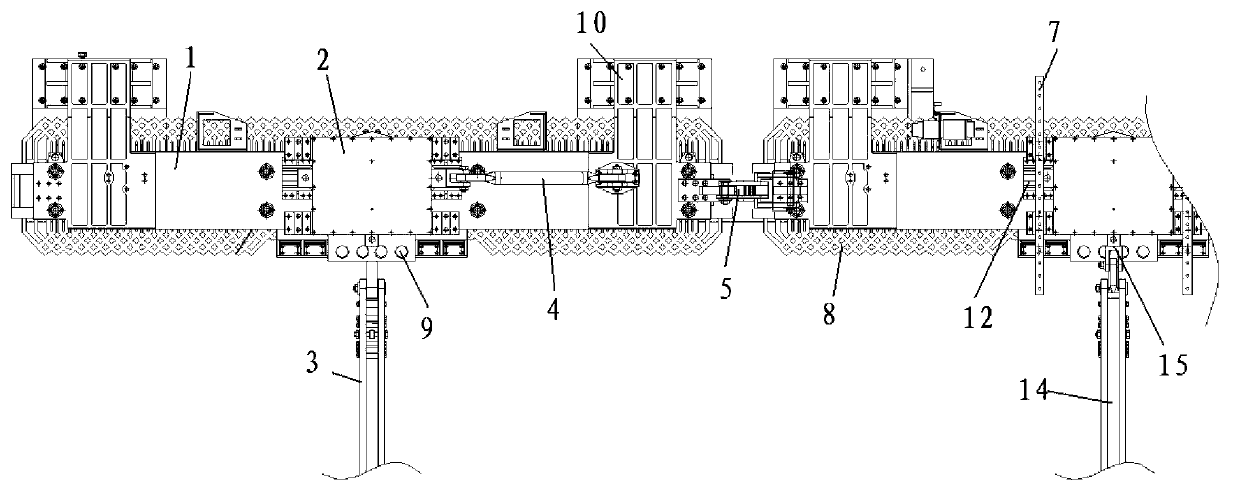

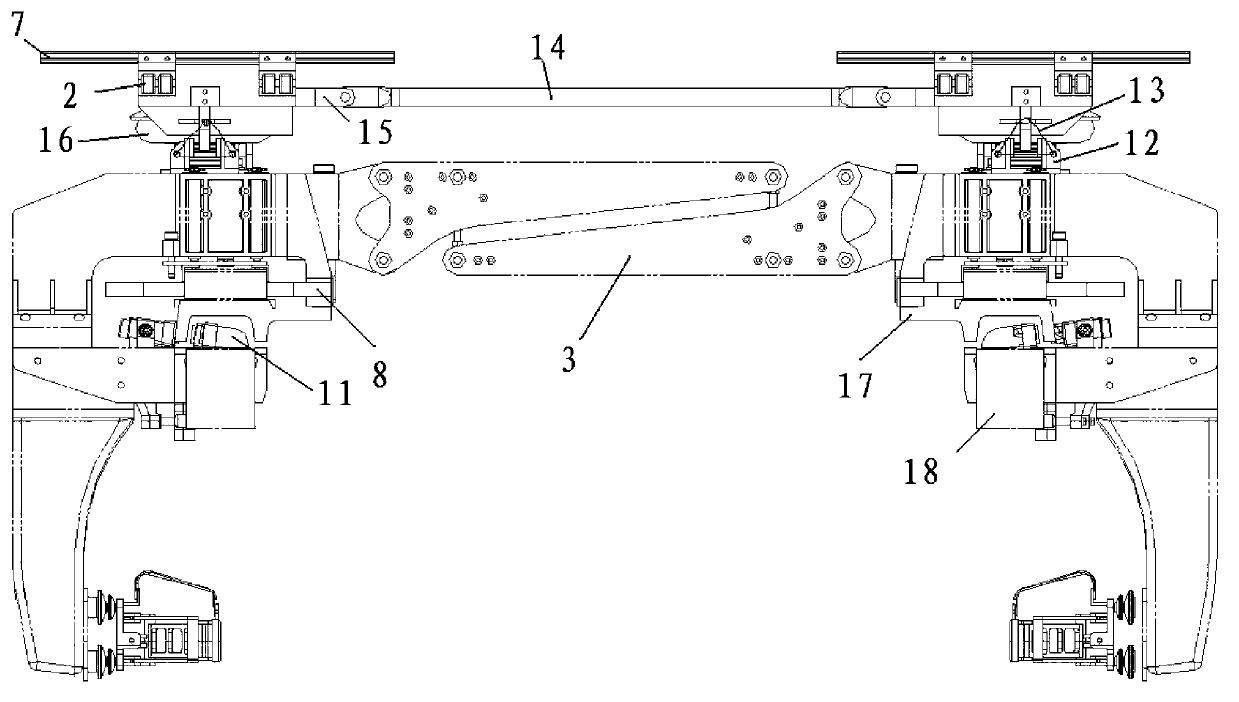

[0023] Such as figure 1 , 2 As shown in and 3, a running mechanism of a medium-low speed maglev vehicle includes at least two end suspension frames and at least one intermediate suspension frame, the end suspension frames are arranged on the front and rear sides of the middle suspension frame, and the end suspension frames and the middle suspension frame Suspension frame all comprises two longitudinal beams 1, slide table 2, air spring 16, transverse tie rod 14 and anti-rolling tie bar 3 that are arranged on the left and right, slide table 2 and air spring 16 all are positioned at the middle position of longitudinal beam 1, each longitudinal beam A sliding table 2 is set on the beam 1, and the sliding table 2 is fixedly supported on the longitudinal beam 1 by an air spring 16. The sliding tables 2 are connected by transverse tie rods 14, and the ends of the transverse tie rods 14 pass through the tie rods arranged inside the sliding table 2. The seat 15 is hinged with the sli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com