Process flow of single-track double-end dragger with flying saw

A technological process and tractor technology, which is applied in the technological process field of the single-track band flying saw double-head tractor, can solve the problems of not being able to meet various specifications of users, not being able to automatically unload, increasing waste, etc., so as to reduce resources and manpower. Loss, traction process stability, effect of reducing life problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

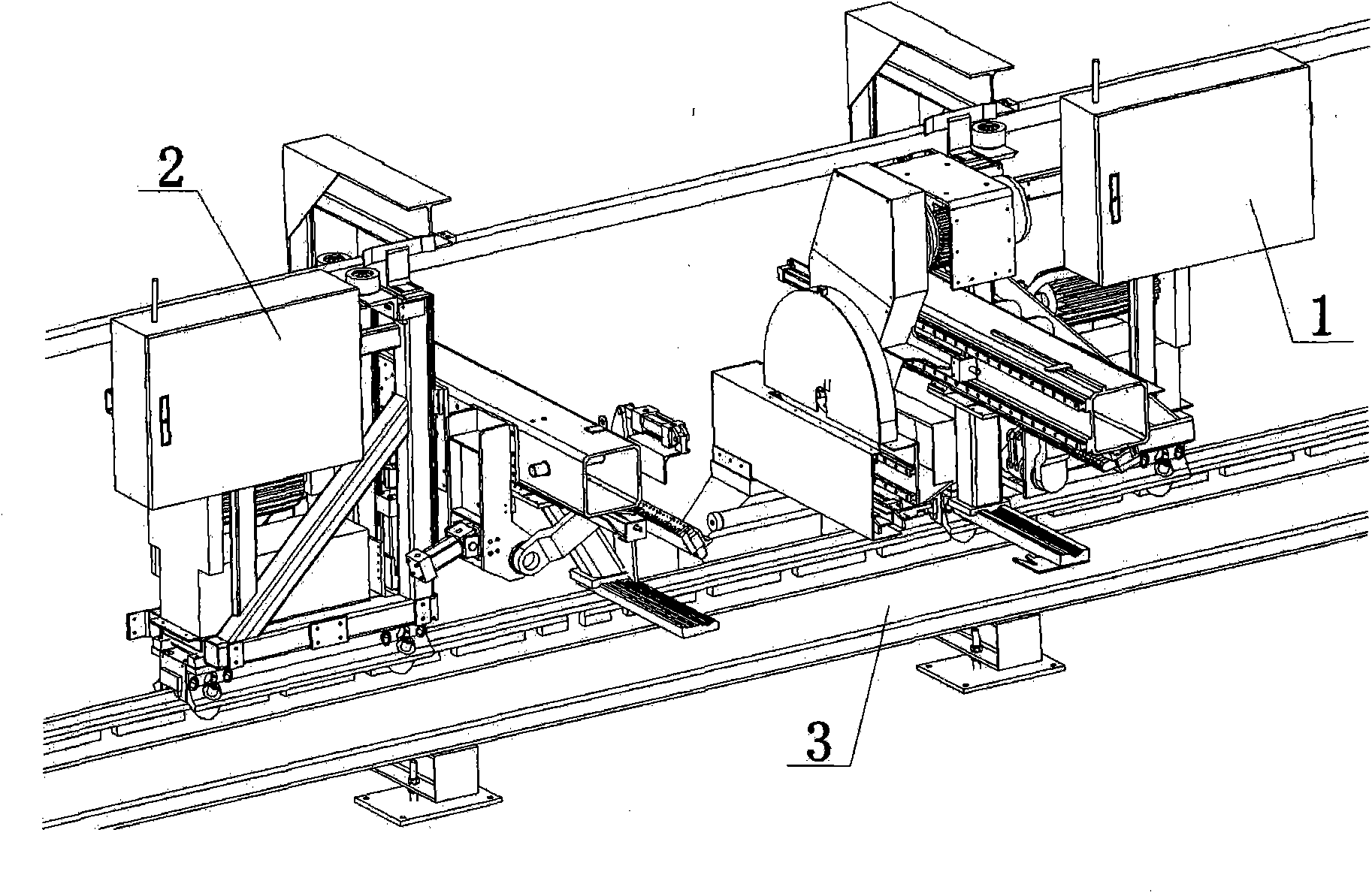

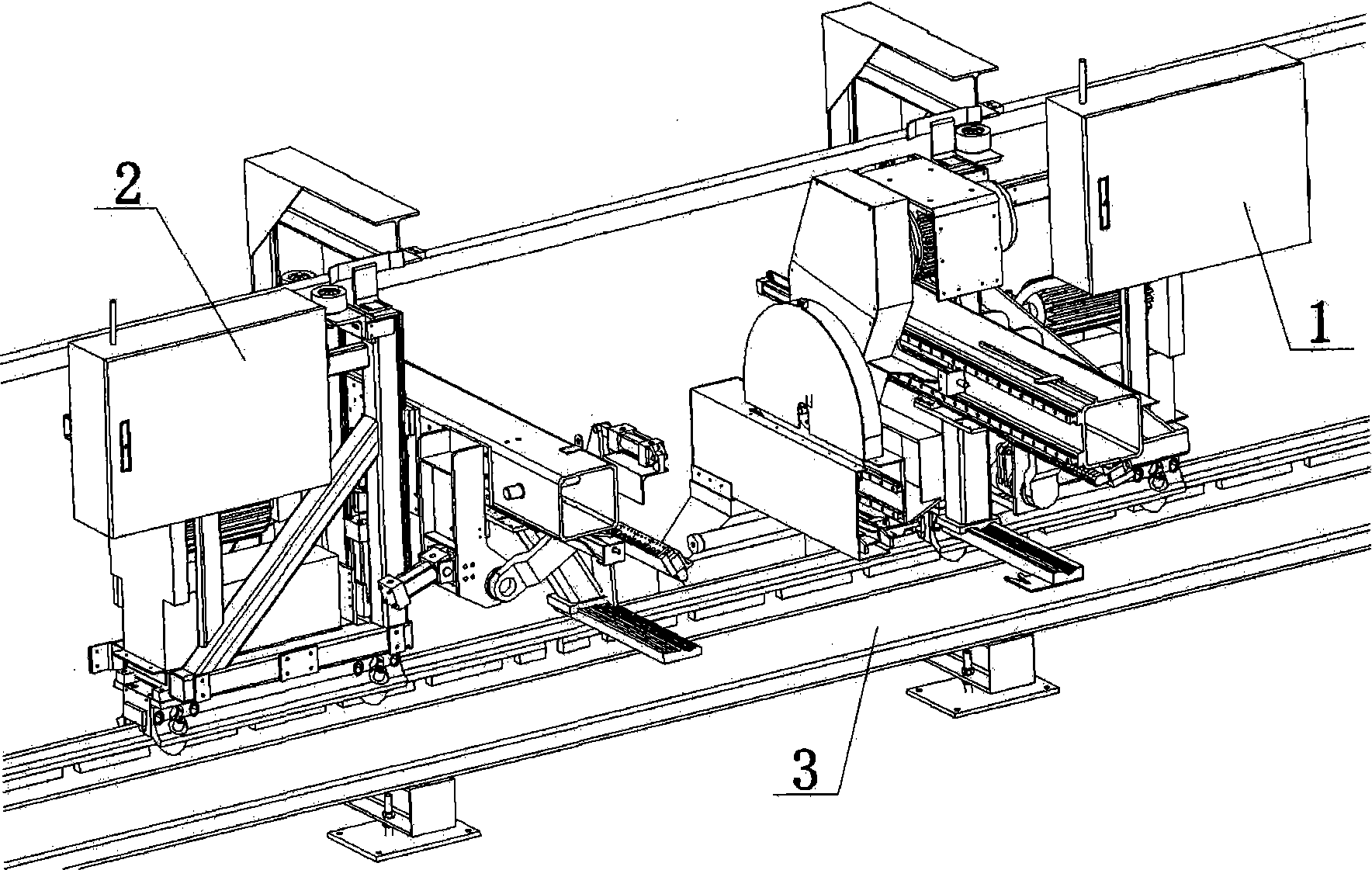

[0021] The specific implementation manners of the present invention will be described in further detail below in conjunction with the accompanying drawings.

[0022] Referring to accompanying drawing, technological process of the present invention is:

[0023] 1) The P1 traction head clamps the profile at the discharge port of the extruder and pulls it away from the discharge port;

[0024] 2) When the P1 traction head meets the P2 traction head, the P2 traction head clamps the profile, and the P1 traction head and the P2 traction head maintain the same speed and jointly pull the profile;

[0025] 3) The P1 traction head releases the profile and quickly returns to the discharge port of the extruder;

[0026] 4) The P2 traction head continues to pull the profile until the extruder stops when it enters the non-extrusion cycle;

[0027] 5) When the non-extrusion cycle ends, the P2 tractor head continues to pull the profile, and the profile parking mark or welding mark is output...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com