Explosion composite induction plate device for linear motor rails

A technology of linear motors and induction plates, applied in the field of rail transit, can solve problems such as low bonding strength of composite induction plates, delamination and cracking, and inoperability of linear motor rail vehicles, so as to achieve difficult delamination and cracking, low manufacturing cost, and composite high intensity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

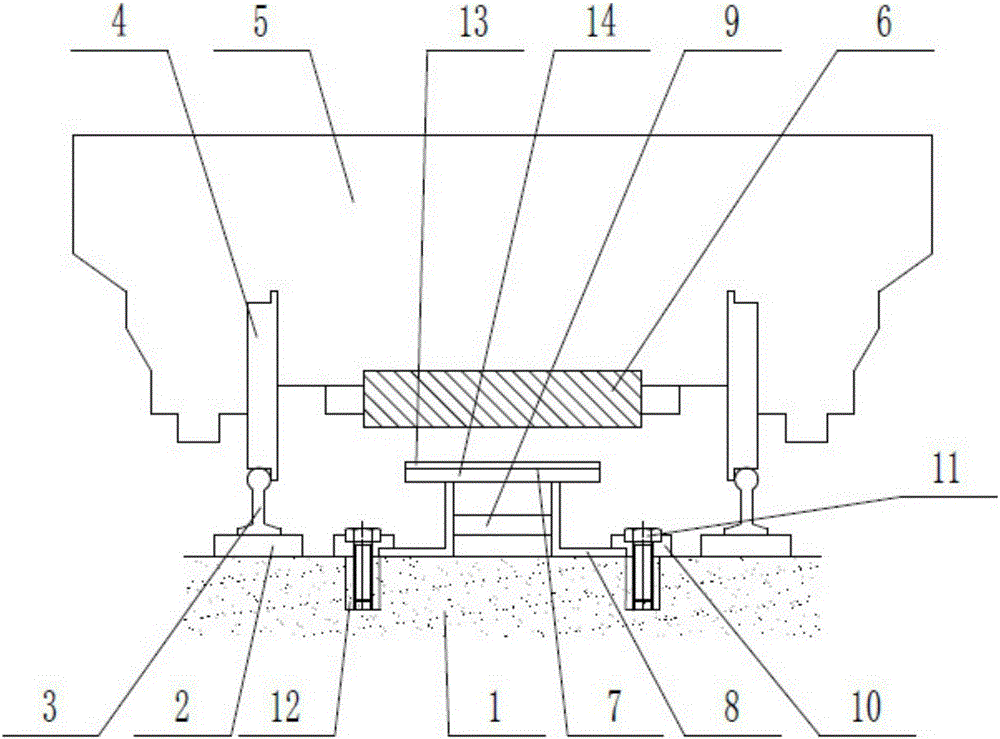

[0021] This embodiment includes ballast bed 1, sleeper 2, rail 3, rail wheel 4, locomotive 5, linear motor 6, explosive composite induction plate 7, angle steel 8, rib plate 9, pressure seat 10, fixing bolt 11, bolt sleeve 12, The sleepers 2 are densely laid on the track bed 1, the rails 3 are symmetrically installed on both sides of the sleeper 2, the locomotive 5 is set on the rail 3 through the rail wheels 4, a linear motor 6 is arranged directly below the locomotive 5, and a linear motor 6 is arranged directly below the linear motor 6. Explosion composite induction plate 7. Explosion composite induction plate 7 includes upper pure aluminum plate 13 and lower base steel plate 14. Explosion composite induction plate 7 has a width of 360mm. The model of the pure aluminum plate 13 is pure aluminum 1050, and its thickness is 7mm. The model of the base steel plate 14 is Q235B, and its thickness is 25 mm. Angle steels 3 are symmetrically connected under the explosive composite i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com