Underwater fuel conveying trolley and tipping-over device for pressurized water reactor

A technology for transporting trolleys and tipping devices, which is applied in the fields of reactor fuel elements, reactors, and greenhouse gas reduction, etc., can solve the problems of difficult installation, commissioning and maintenance, limited diameter of pipeline equipment, complicated design, etc., so as to avoid inspection and maintenance work, Simple structure, convenient installation and adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

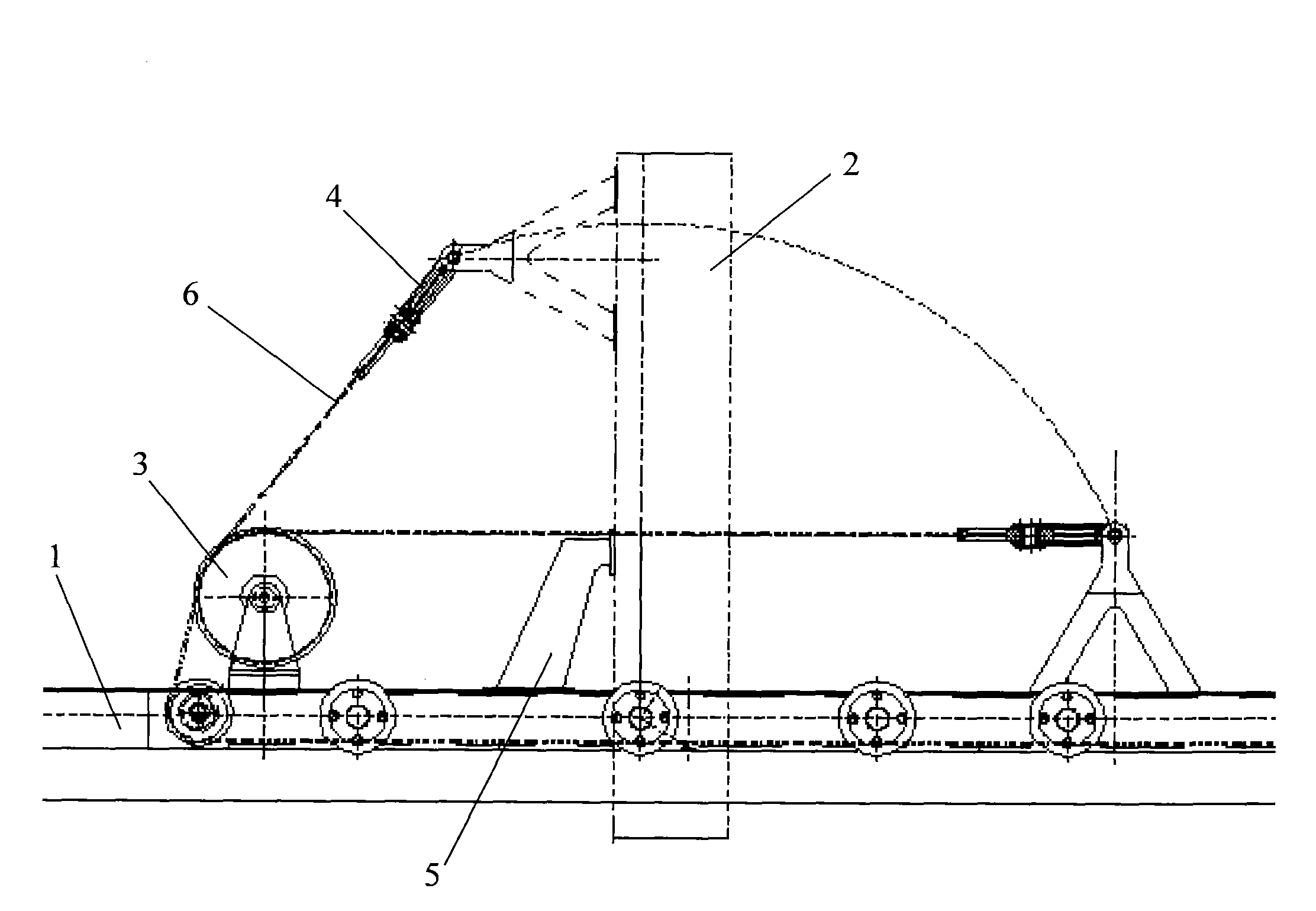

[0021] Such as figure 1 As shown, the pressurized water reactor fuel underwater transport trolley 1 provided by the present invention is provided with a fuel basket 2 that can rotate between the horizontal and vertical directions along a fixed axis, and the trolley 1 is provided with a vertical support block 5 for the fuel basket , when the fuel basket 2 reaches the vertical position, it is close to the vertical support block 5 . Under the premise that the transport trolley can pass through the transport pipeline smoothly and maintain a gap of more than 12.7mm with the transport pipeline equipment, the two sides of the frame of the trolley 1 are provided with wire rope guide pulleys 3, and the fuel basket 3 is provided with a swing around the fulcrum. The tipping guide pulley 4 and the tipping wire rope 6 go around the tipping guide pulley 4 on the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com