Vehicle-mounted movable tilting sealing tank device

A vehicle-mounted technology for moving and sealing cans, applied in packaging, transportation, packaging, containers, etc., can solve the problems of abnormal driving, inconvenient unloading, poor flexibility, etc., to achieve high flexibility, convenient unloading, and avoid idle waste. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

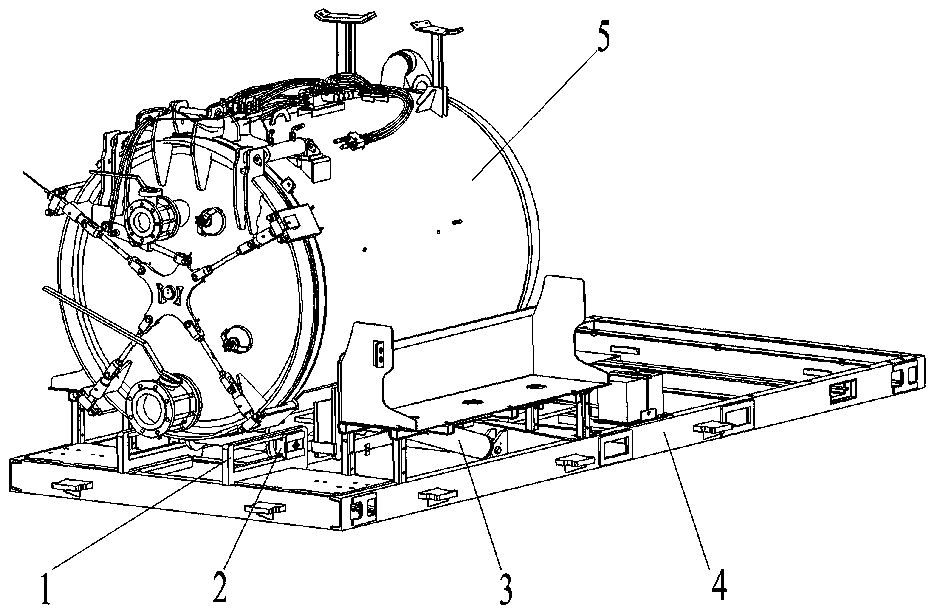

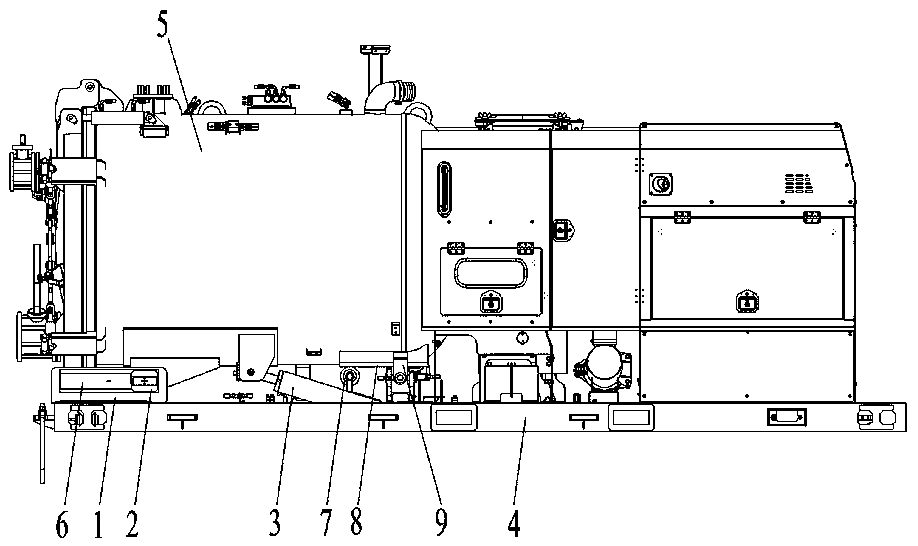

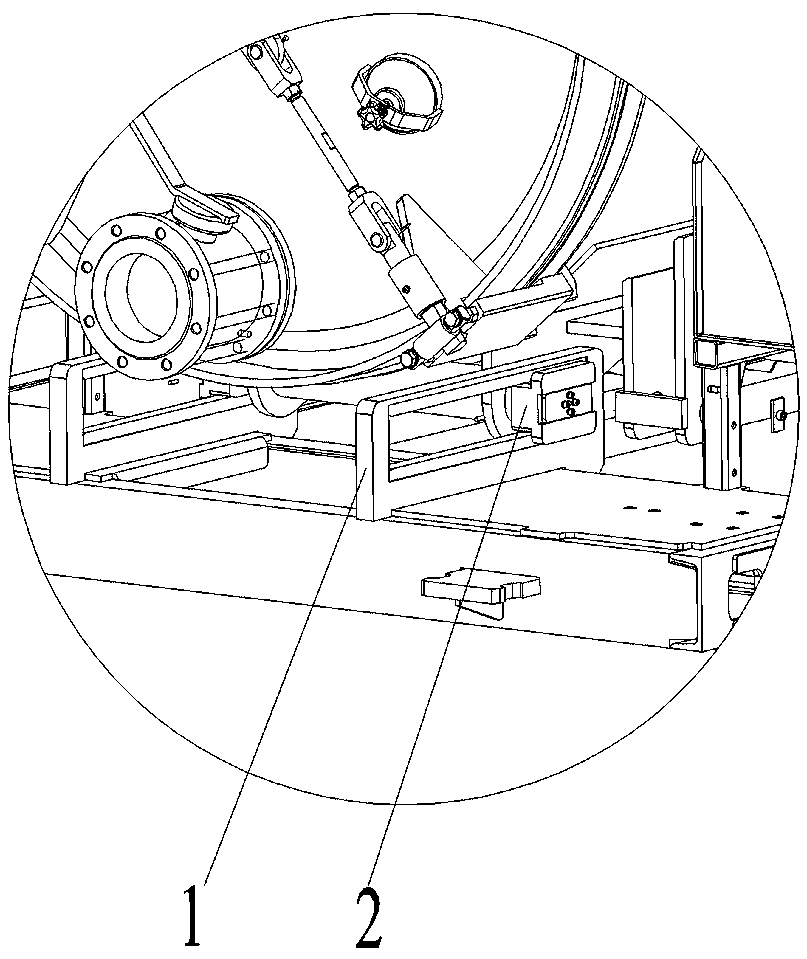

[0030] A vehicle-mountable mobile tipping seal tank device, including a support base 4, a seal tank 5, a preset number of drive cylinders 3 (the number of drive cylinders 3 in this embodiment is 2), and a power supply for the drive cylinder 3 Power station, a preset number of limit wheels 7 (in this embodiment, the number of limit wheels 7 is 1) and a horizontal sliding assembly fixed on the rear end of the top surface of the support chassis 4; the power station is fixed on the support bottom by bolts or welding On the frame 4, the power station includes an engine, a hydraulic pump, a hydraulic valve, etc.; the horizontal sliding assembly includes a sliding body that can slide back and forth above the supporting chassis 4, and the sliding direction of the sliding body is parallel to the central axis of the sealed tank, so The rear portion of the bottom end of the airtight tank 5 is hinged with the sliding body, and the spacer wheel 7 is rotatably fixed on the support chassis 4 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com