Anti-static film and polaroid attaching device

A technology for attaching polarizers and anti-static films, which is applied in the direction of film/sheet-shaped adhesives, optics, optical components, etc., can solve problems such as electrostatic breakdown of display panels, and eliminate hidden dangers of electrostatic breakdown of products. Avoid equipment idle waste, the effect of a wide range of equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

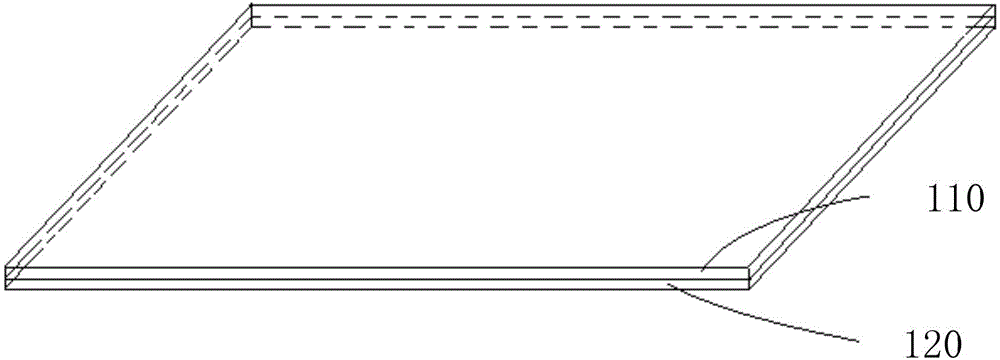

[0024] figure 2 It is a schematic diagram of an antistatic film provided in an embodiment of the present invention. The antistatic film includes an electrostatic treatment layer 110 and an adhesive layer 120 disposed on one side of the electrostatic treatment layer 110. The electrostatic treatment layer 110 is used to remove static electricity. .

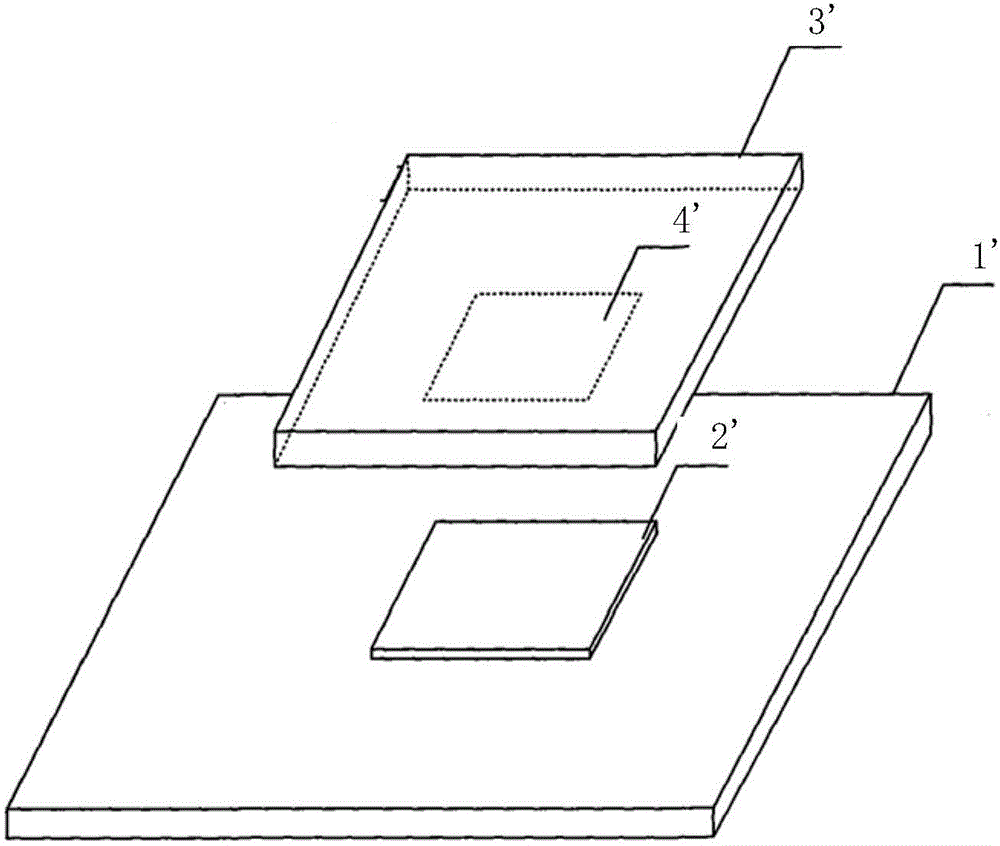

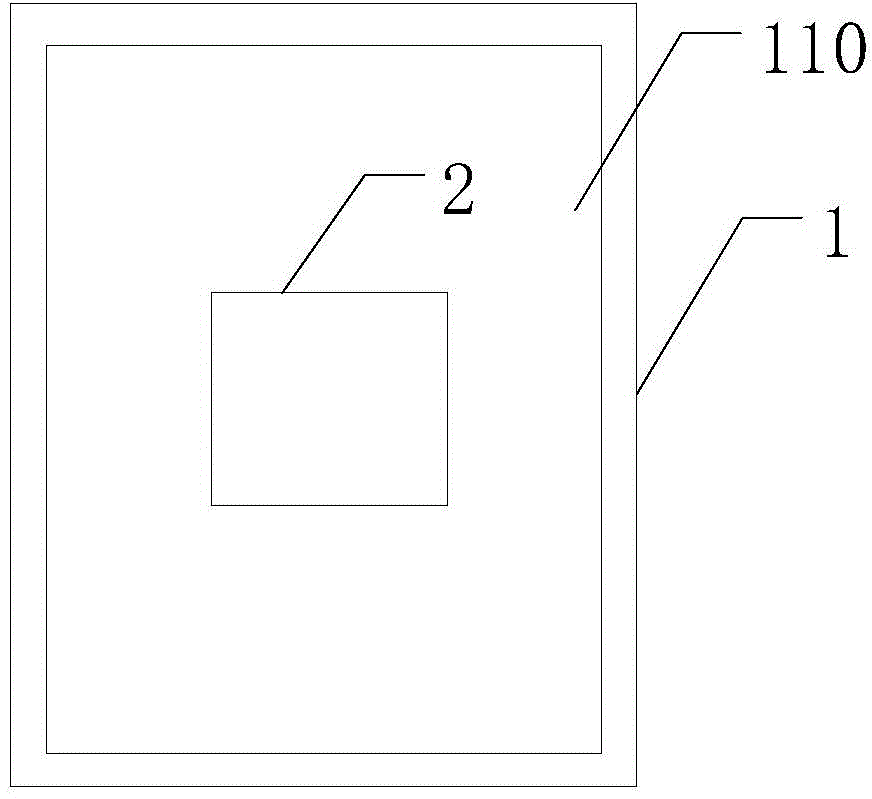

[0025] The above-mentioned antistatic film can be used on polarizer attaching equipment, such as image 3 As shown, after the antistatic film is attached to the carrying platform of the polarizer attaching device, the electrostatic treatment layer 110 is adhered to the surface of the carrying platform through the adhesive lay...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com