Patents

Literature

110results about How to "Improve batching efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

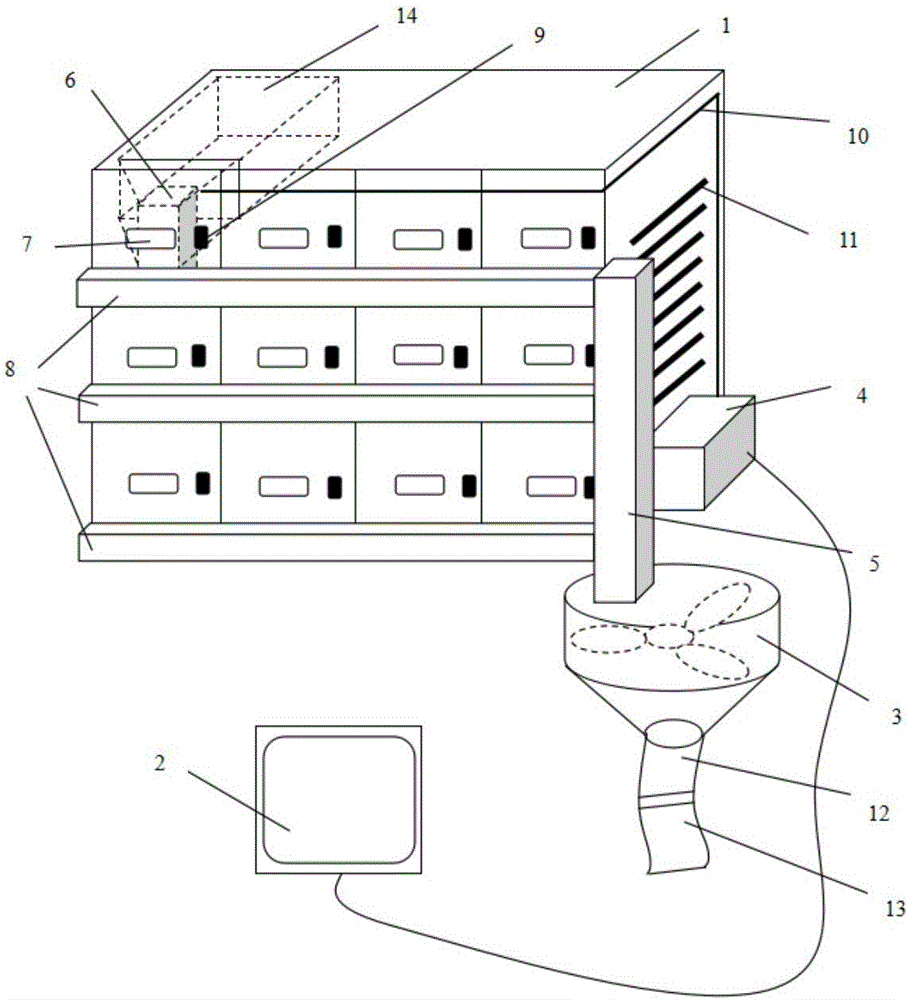

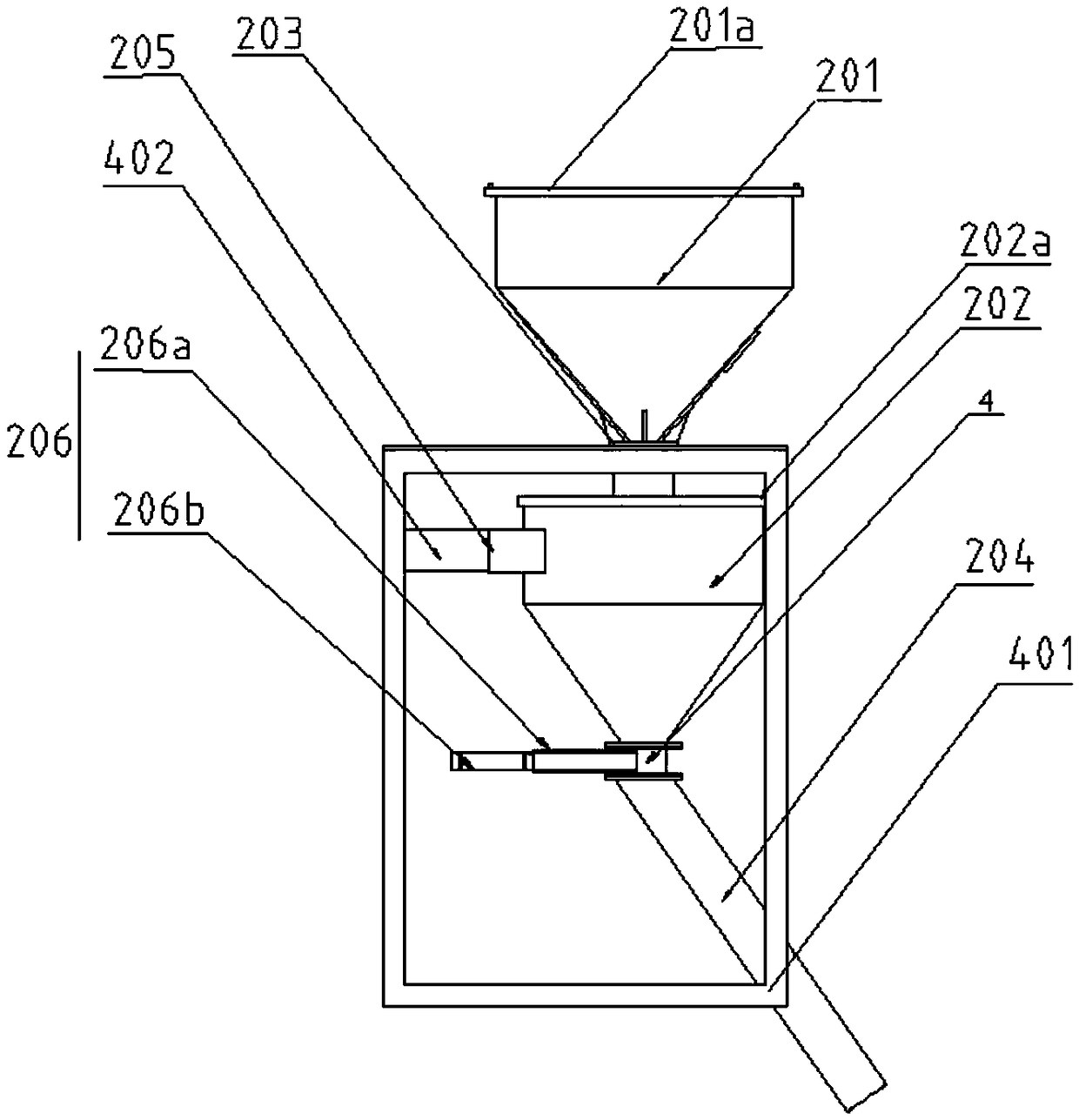

Batching device for smelting

InactiveCN107138098AAccurate ingredientsImprove batching efficiencyMixer accessoriesLoading/unloadingEngineeringSmelting

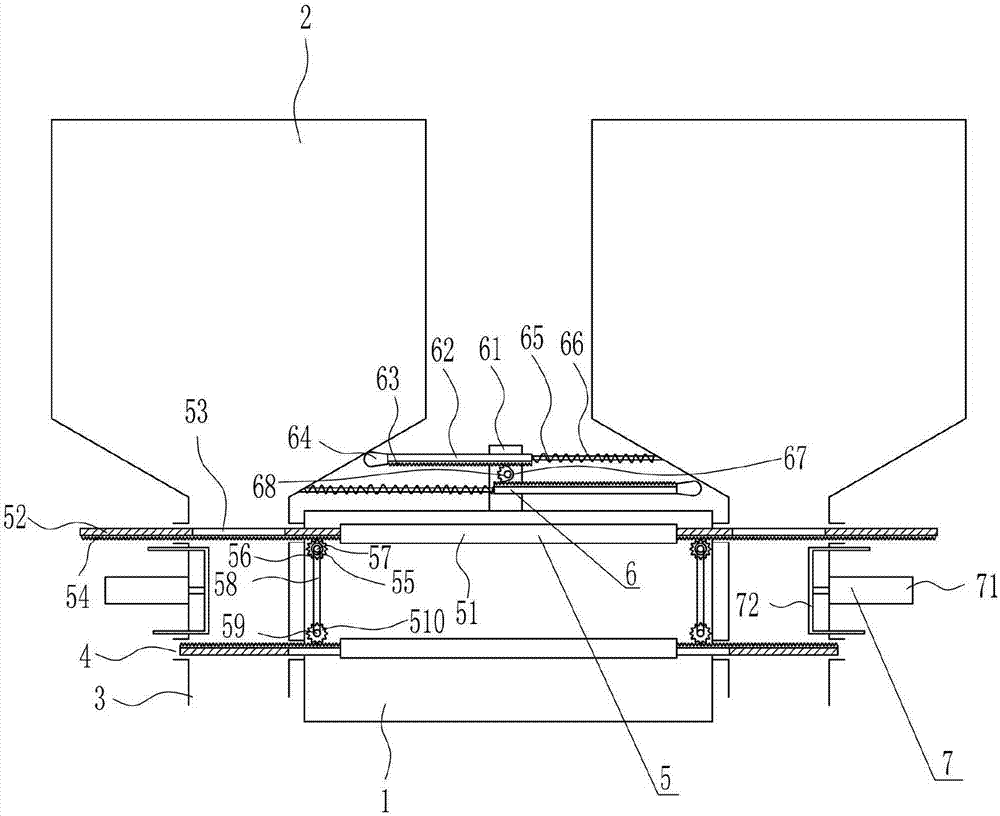

The invention relates to batching equipment, in particular to a batching device for smelting. Technically, the invention aims to provide a batching device for smelting with the characteristics of no need for manual batching, accurate batching and high batching efficiency. In order to solve the technical problem, the batching device for smelting provided by the invention comprises a mounting plate and the like. Blanking hoppers are symmetrically arranged on the left side and right side above the mounting plate, the bottoms of the blanking hoppers are connected to blanking pipes, two blanking pipes are both located on the left side and right side of the mounting plate, the upper sides and lower sides of the blanking pipes are both equipped with sliding chutes, the front side of the mounting plate is provided with a quantitation apparatus, a beat apparatus is arranged above the quantitation apparatus, and adjustment apparatuses are mounted outside the blanking pipes. The batching device for smelting provided by the invention reaches the effects of no need for manual batching, accurate batching and high batching efficiency.

Owner:雷海涛

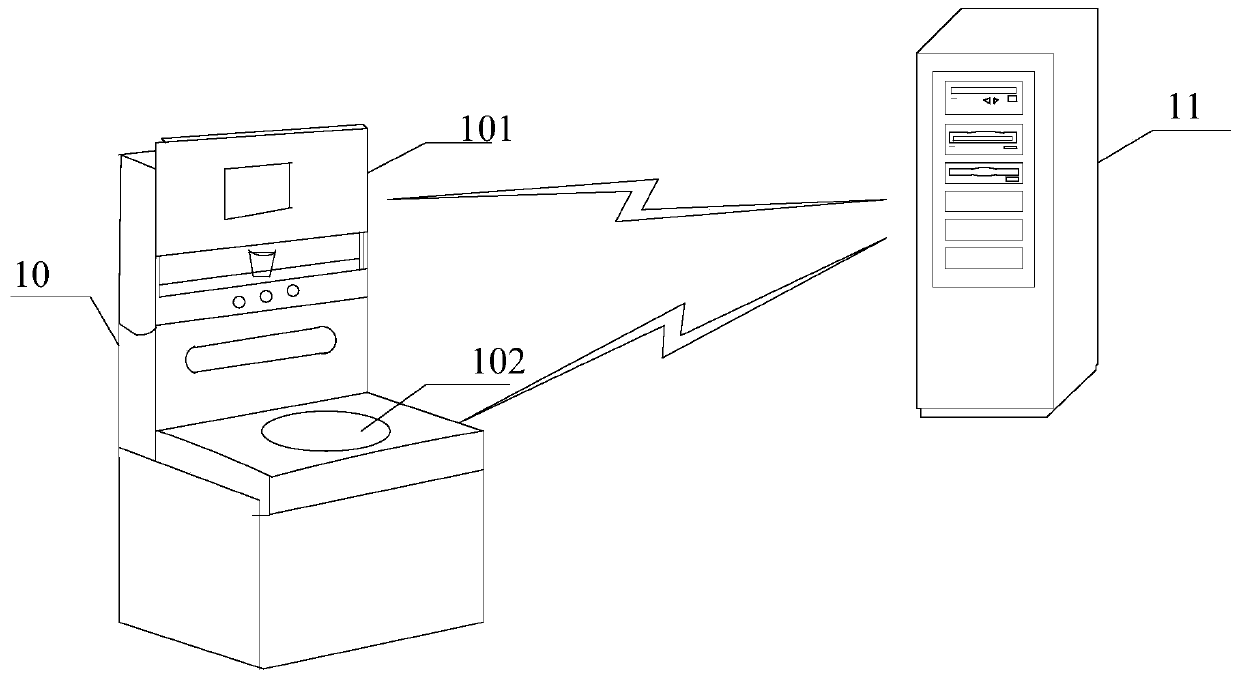

Digital menu, and ingredient method and ingredient system based on digital menu

ActiveCN104932319AOptimizing the batching processImprove batching efficiencyProgramme control in sequence/logic controllersSystem structureDigitization

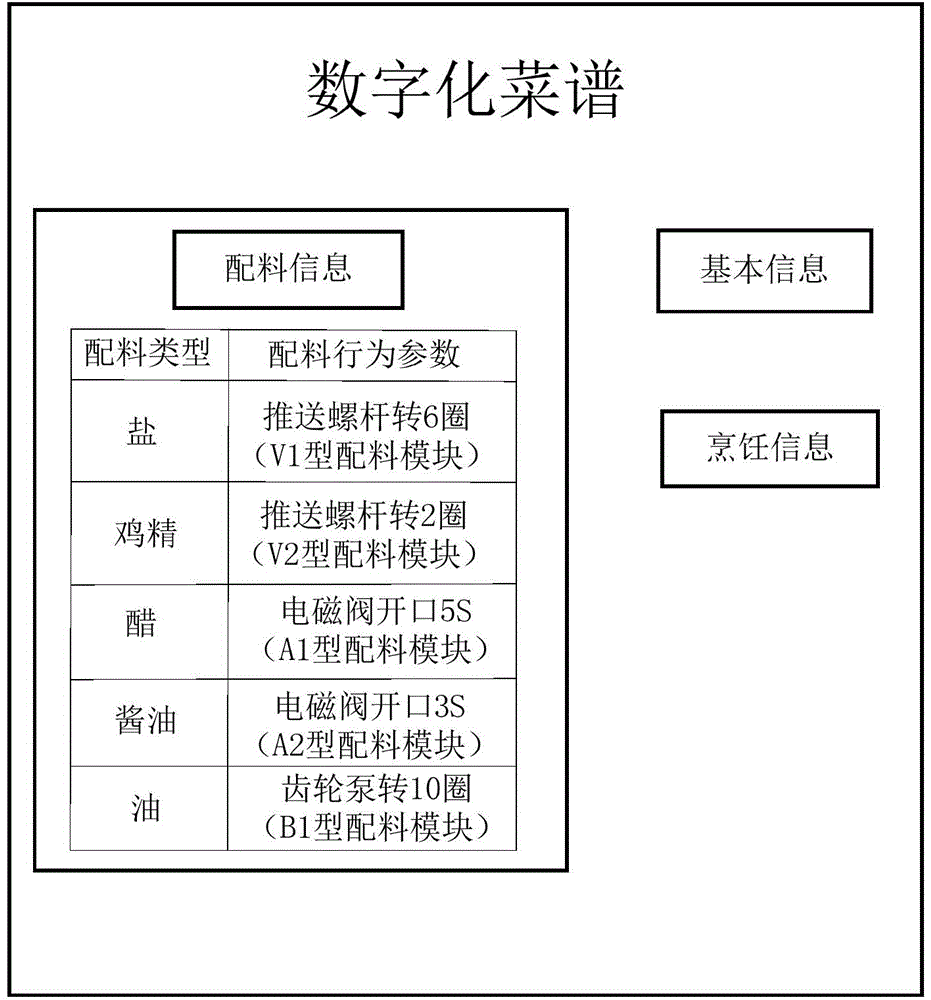

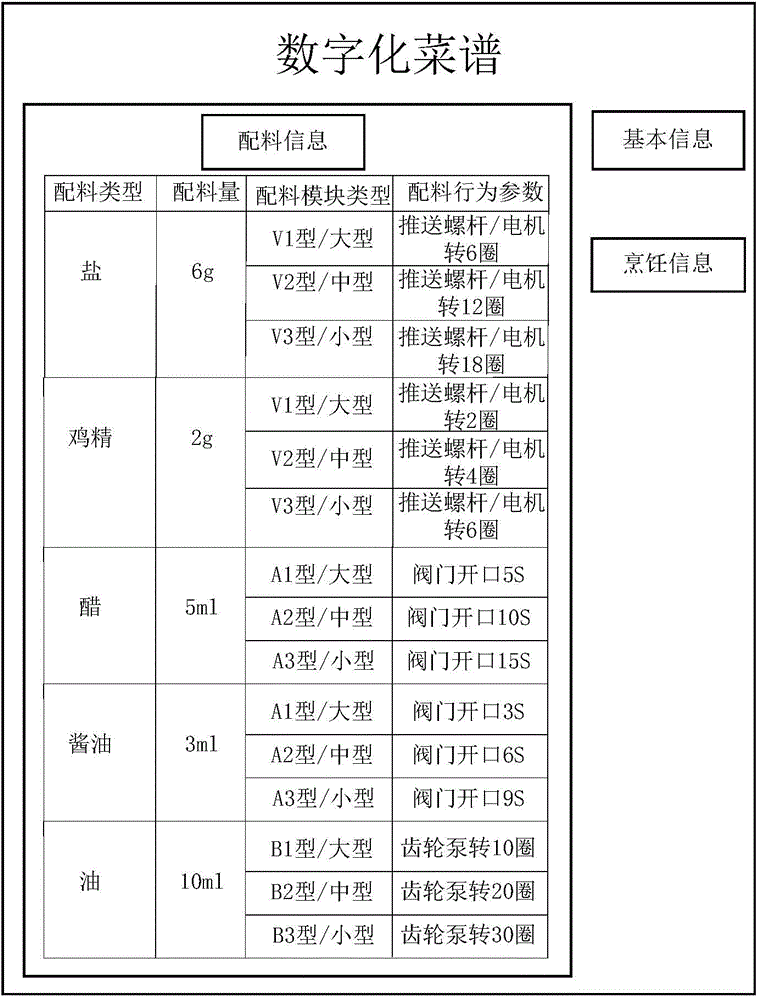

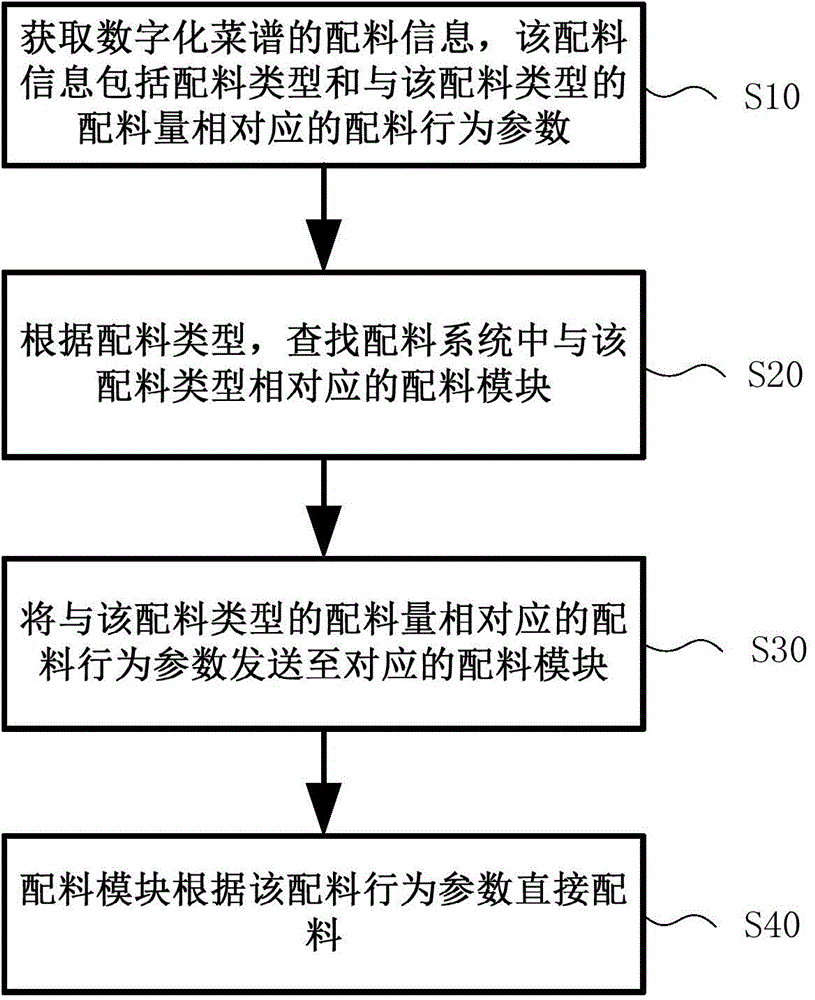

The invention provides a digital menu, and an ingredient method and an ingredient system based on a digital menu. The digital menu includes ingredient information. The ingredient information includes ingredient types, and ingredient behavioral parameters that correspond to the ingredient types and can be directly conducted by ingredient modules in the ingredient system. The ingredient method includes the steps: obtaining the ingredient types and the ingredient behavioral parameters that are included in the digital menu; according to the ingredient types, searching in the ingredient system the ingredient modules that correspond to the ingredient types; sending the ingredient behavioral parameters that correspond to the quantity of ingredients of the ingredient types to the corresponding ingredient modules; and the ingredient modules directly distributing ingredients according to the ingredient behavioral parameters. People can directly obtain the ingredient behavioral parameters from the digital menu and choose ingredients on the basis of the ingredient behavioral parameters instead of choosing ingredients after converting the volume, mass and the like of needed ingredients into the ingredient behavioral parameters. The principles are ingenious, the ingredient selecting precision is high, the system structure is simplified, and the cost is low.

Owner:珠海优特智厨科技有限公司

Intelligent automated traditional Chinese herbal medicine dispensing system

ActiveCN106709258AReduce dispensing timeReduce waiting time in lineRotating receptacle mixersTransportation and packagingControl systemMedical prescription

The invention discloses an intelligent automated traditional Chinese herbal medicine dispensing system. The system comprises a medicine containing system, a medicine extraction system and a control system. Starting from the prescription made by a doctor, the QR code identification technology and the computer input technology are used for the two-way information collection, a central processor of the control device is used to make the analysis to drive a medicine discharge switch and a weighing device in the medicine extraction device to generate a series of work responses, accumulation and instantaneous flow statistic are done, at last the medicine is mixed and then packed, the medicine discharge error is reduced, the mixing precision and the efficiency is enhanced. According to the intelligent automated traditional Chinese herbal medicine dispensing system, after the doctor gives out the prescription, what remains in the procedure is only pushing a button once, thus the medicine extraction time spent by the medical personnel is shortened, the queuing time of the patients is shortened, the cost is low, and therefore the system is applicable to the promotion and use.

Owner:WUTONG AROMA CHEM CO LTD

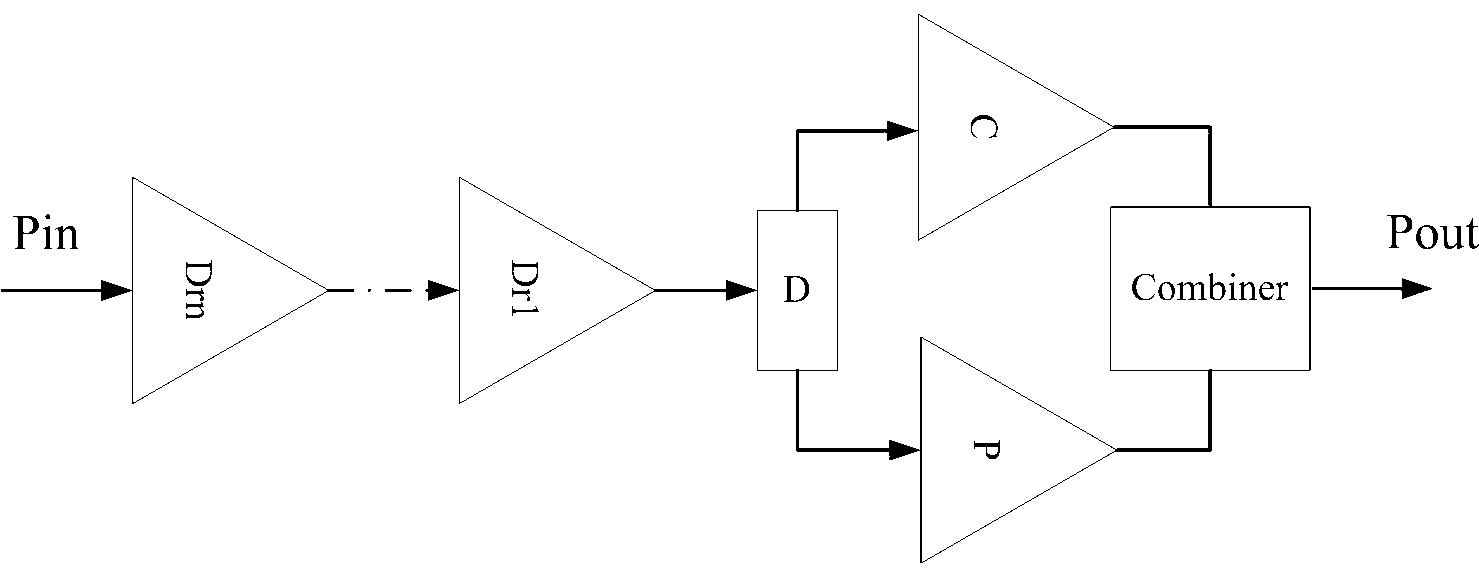

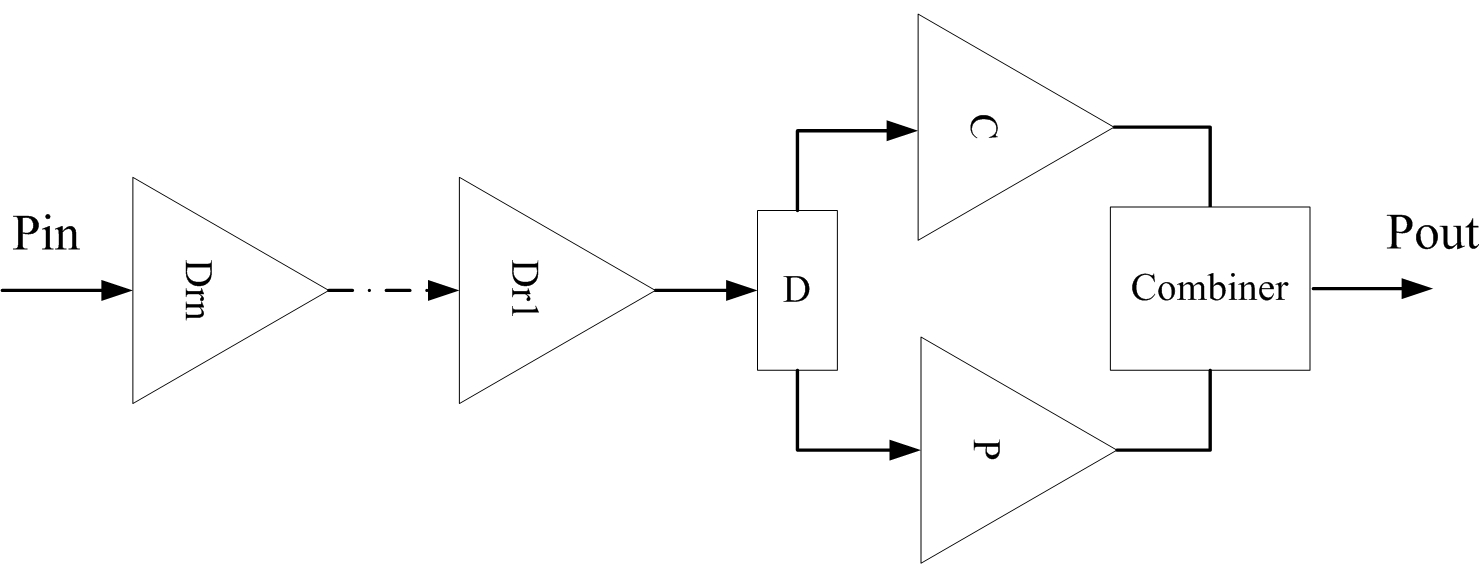

Doherty power amplifier and implementation method thereof

InactiveCN102761310AAvoid the disadvantages of early turn-onReduce power consumptionGated amplifiersAmplifier modifications to raise efficiencyAudio power amplifierCarrier signal

Owner:ZTE CORP

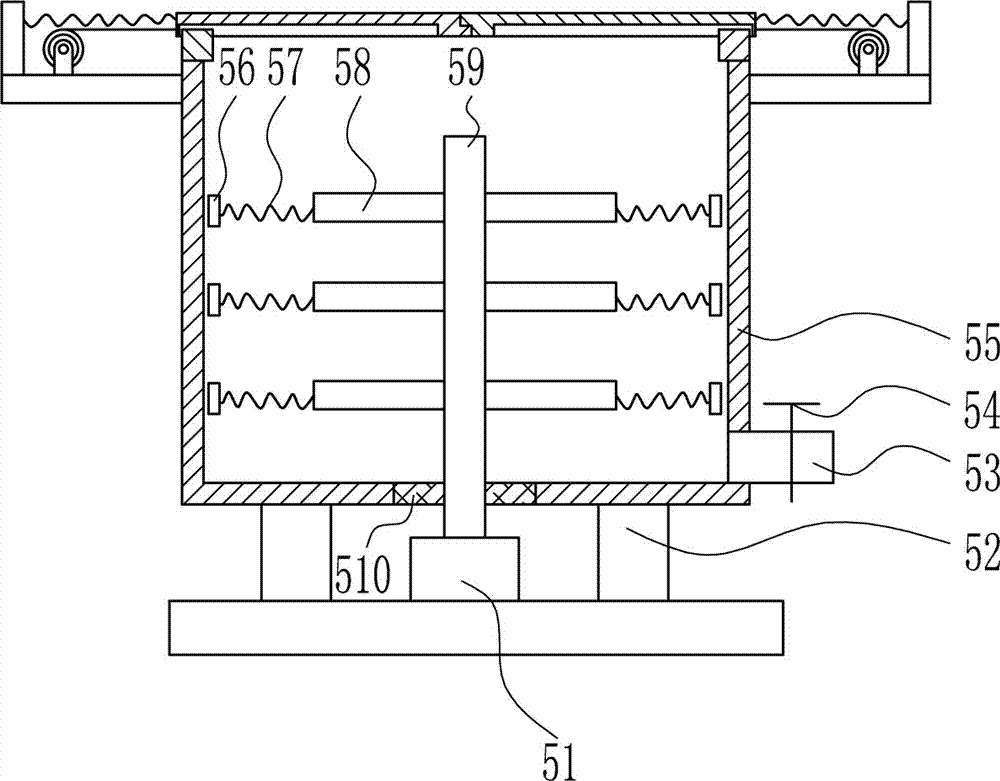

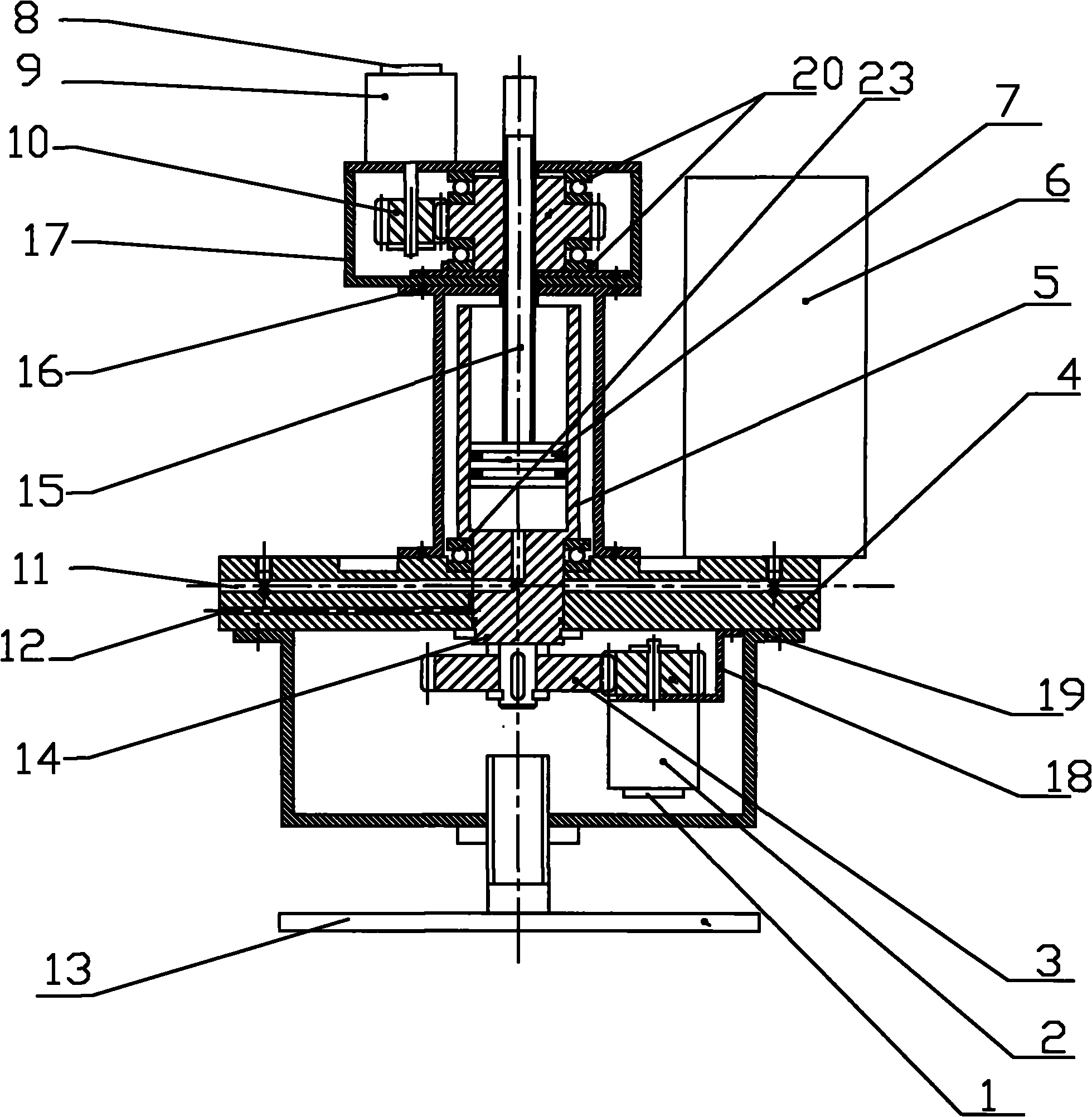

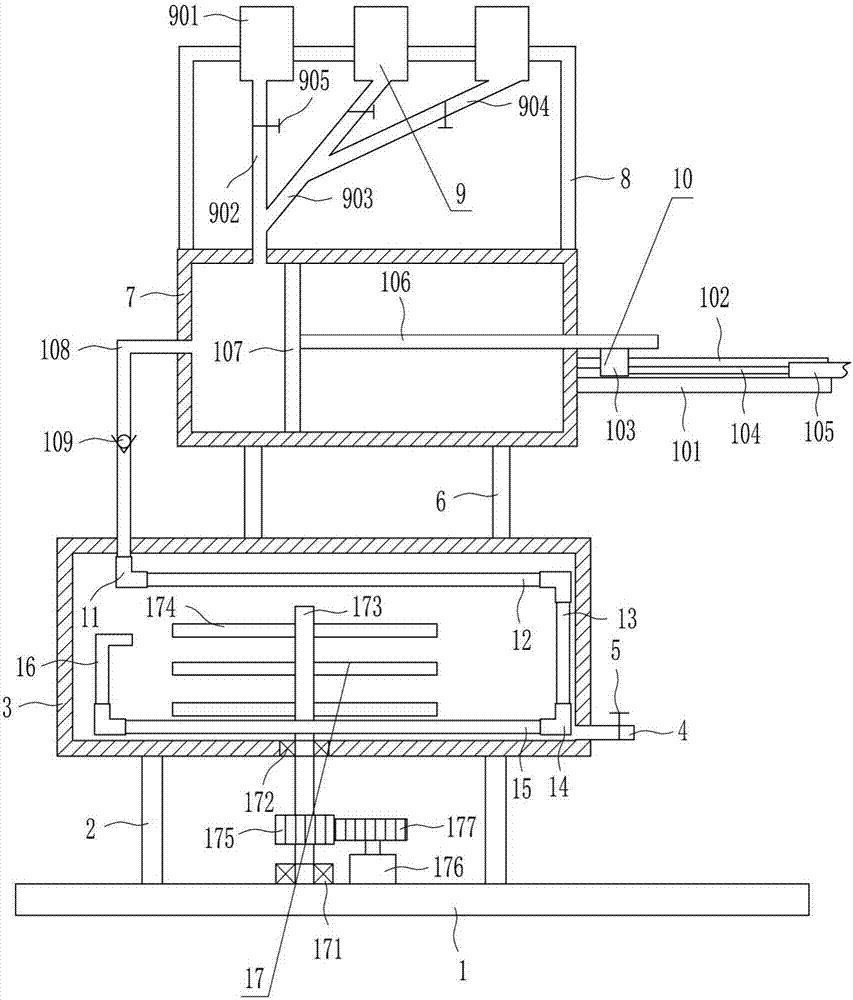

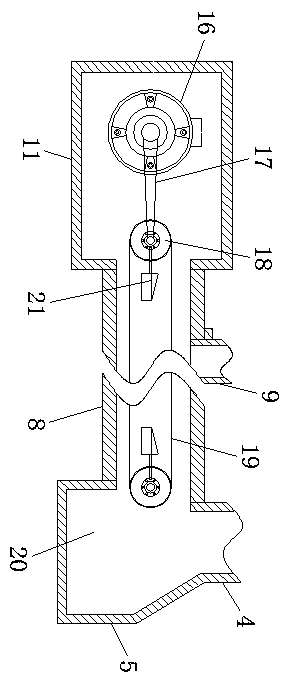

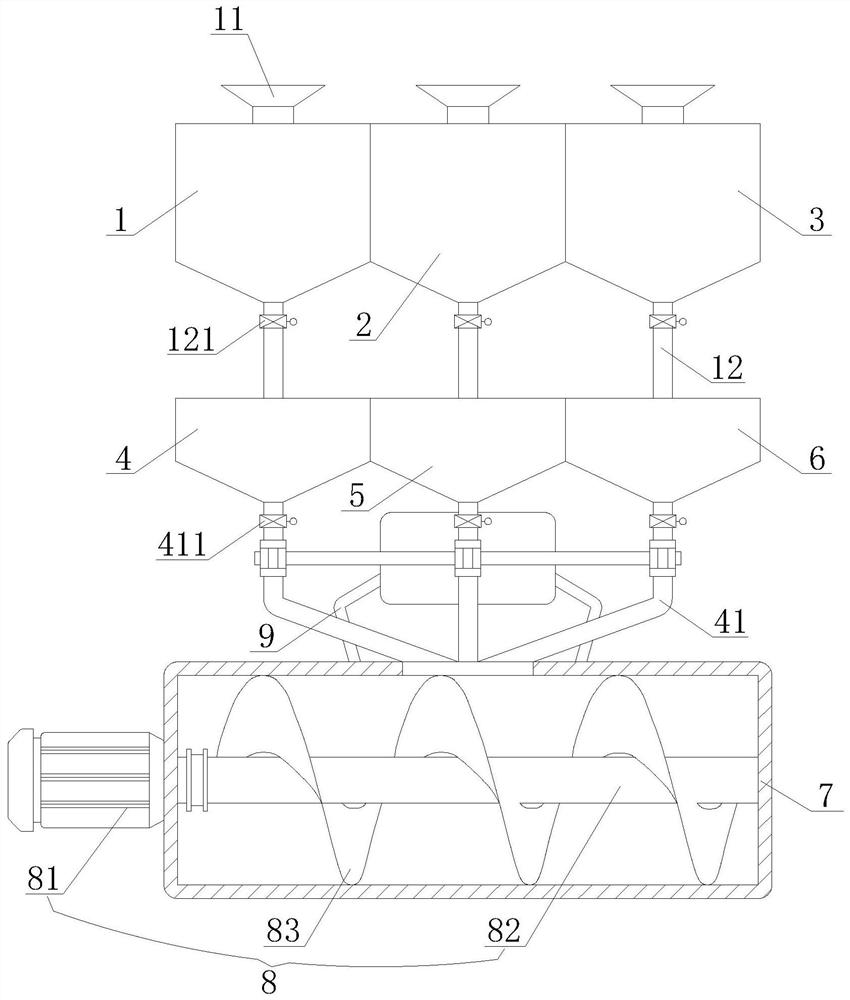

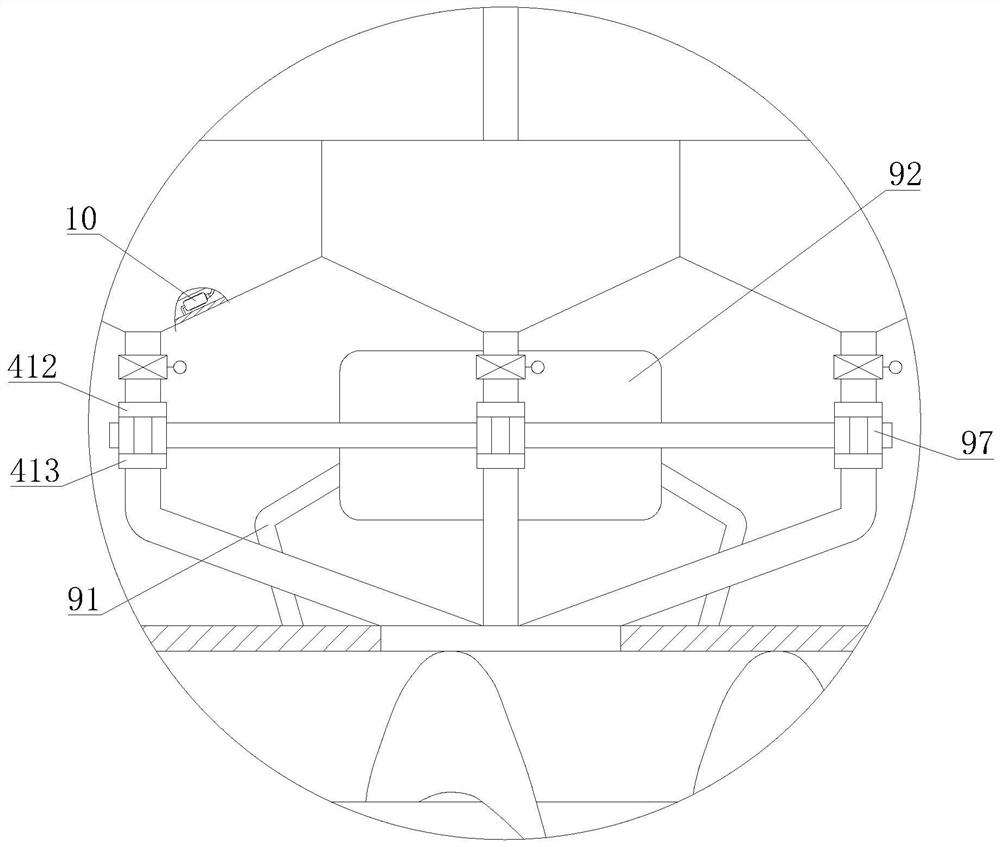

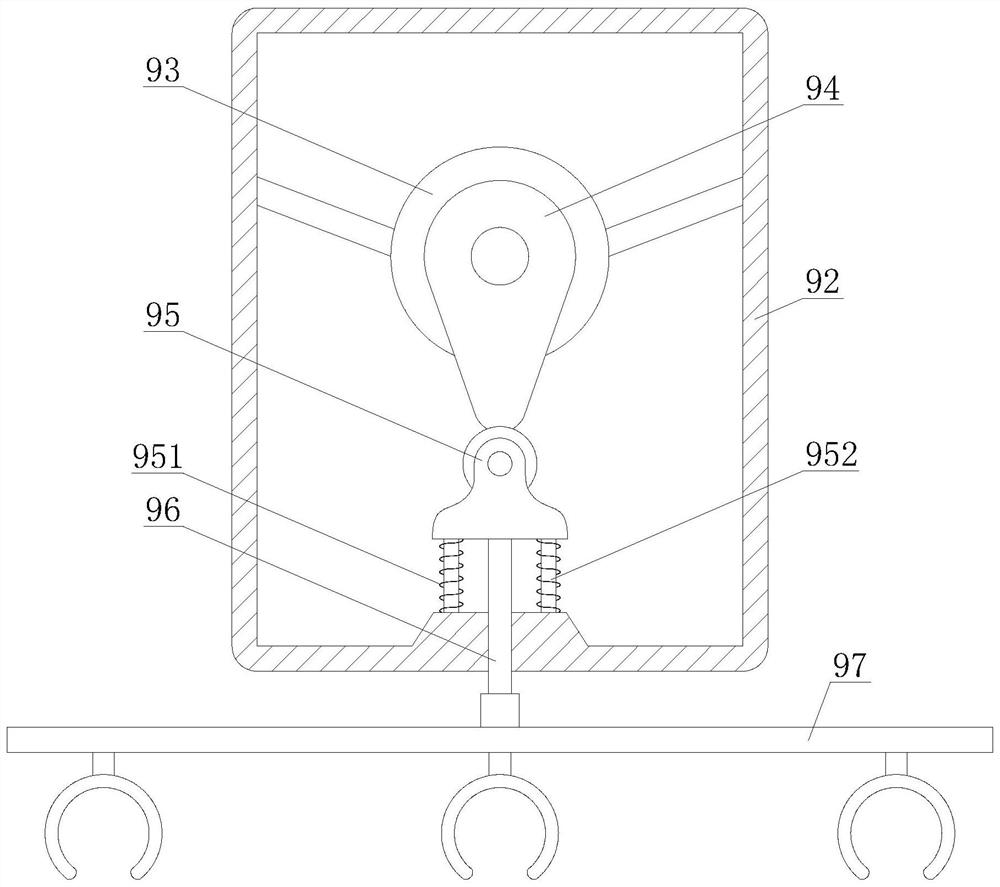

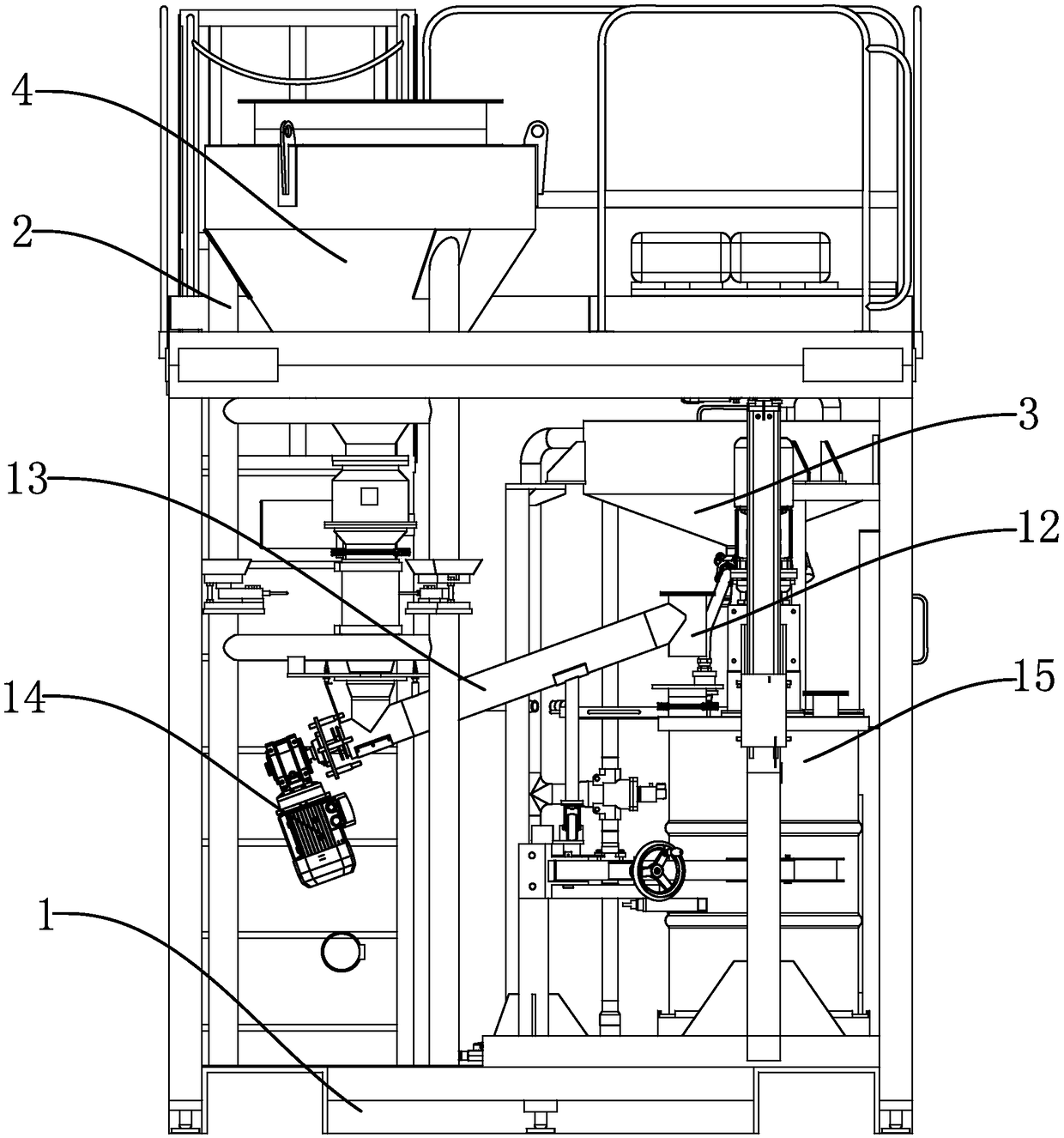

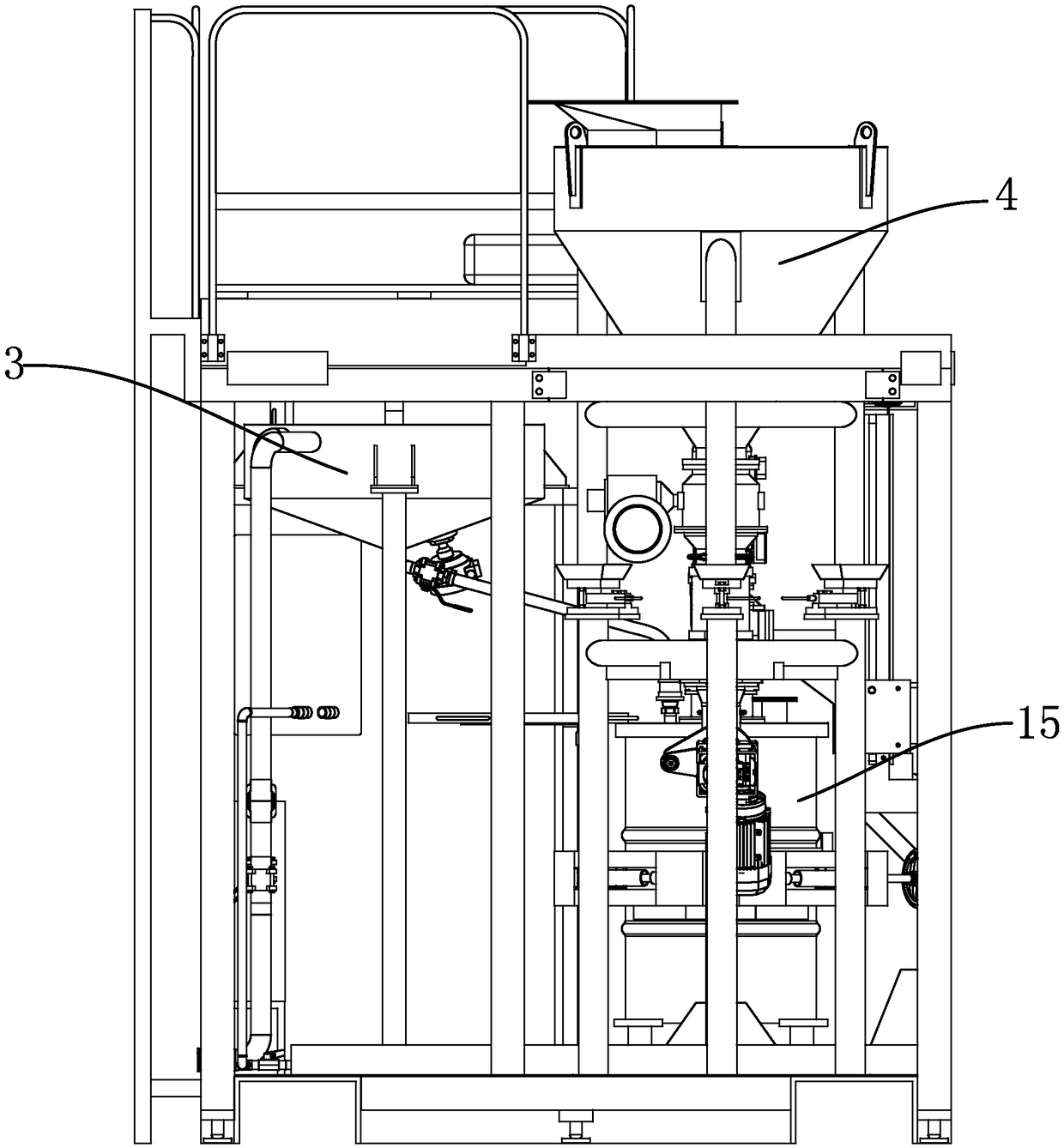

Proportioning device for manufacturing brake pad

InactiveCN106925164AImprove batching efficiencyImprovement ingredientsRotary stirring mixersTransportation and packagingEngineeringMechanical engineering

The invention relates to a proportioning device and in particular relates to a proportioning device for manufacturing a brake pad. The invention aims to provide the proportioning device for manufacturing the brake pad. The device can stir automatically, proportions in section, and is time- and labor-saving and high in proportioning efficiency. In order to solve the technical problem, the invention provides the proportioning device for manufacturing the brake pad. The proportioning device for manufacturing the brake pad comprises a bottom plate, a collecting frame, a left and right moving mechanism, a swinging mechanism, a stirring mechanism and a feeding mechanism and the like, wherein the collecting frame is arranged on the left side of the top of the bottom plate, the left and right moving mechanism is mounted in the middle of the top of the bottom plate, the top of the left and right moving mechanism is connected to the stirring mechanism, the top of the stirring mechanism is connected to the feeding mechanism, a left rack is mounted on the top of the bottom plate, the top end of the left rack is connected to the top plate, and a blanking mechanism is arranged on the top plate. The device performs blanking in sections by matching the blanking mechanism with the left and right moving mechanism, and the proportioning efficiency of a brake pad raw material is increased by means of the stirring mechanism.

Owner:刘世荣

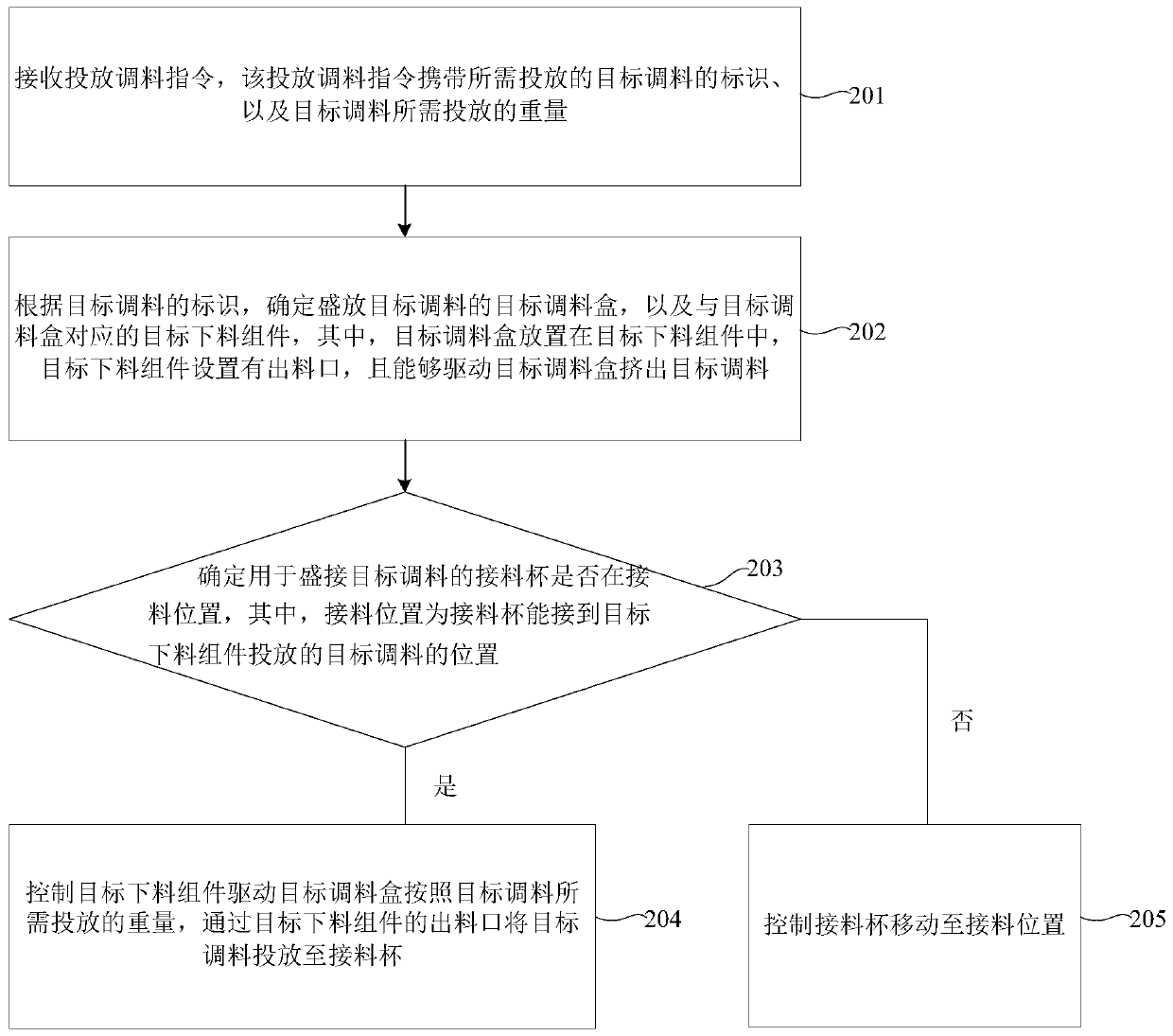

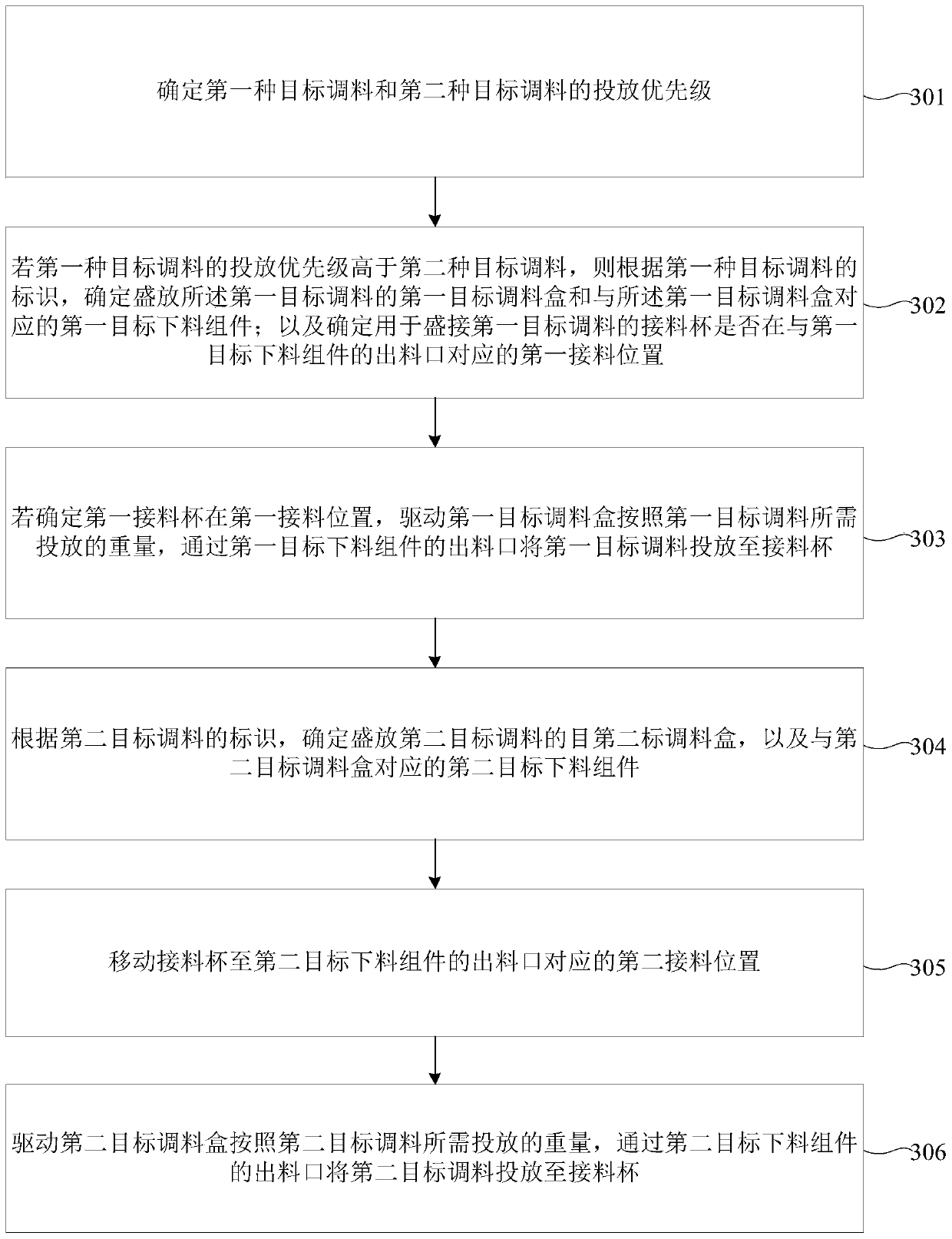

Seasoning putting method, proportioning machine and storage medium

InactiveCN109730556AAvoid Misplaced Seasoning SituationsImprove accuracyKitchen equipmentComputer science

The invention relates to the technical field of intelligent cooking and discloses a seasoning putting method, a proportioning machine and a storage medium for increasing the proportioning precision and the proportioning efficiency of the proportioning machine as well as the executing effect of a cooking task. The method comprises the following steps: receiving a seasoning inputting command which carries an identifier of a target seasoning needed to be input and the weight of the target seasoning needed to be input; determining a target seasoning box for holding the target seasoning according to the identifier of the target seasoning and a target discharging assembly corresponding to the target seasoning box; determining whether a seasoning receiving cup for holding the target seasoning isin a seasoning receiving position or not; and if so, controlling the target discharging assembly to drive the target seasoning box to input the target seasoning to the seasoning receiving cup throughthe discharge port of the target discharging assembly according to the weight of the target seasoning needed to be input.

Owner:ZHUHAI YOUTE SMART KITCHEN TECH CO LTD

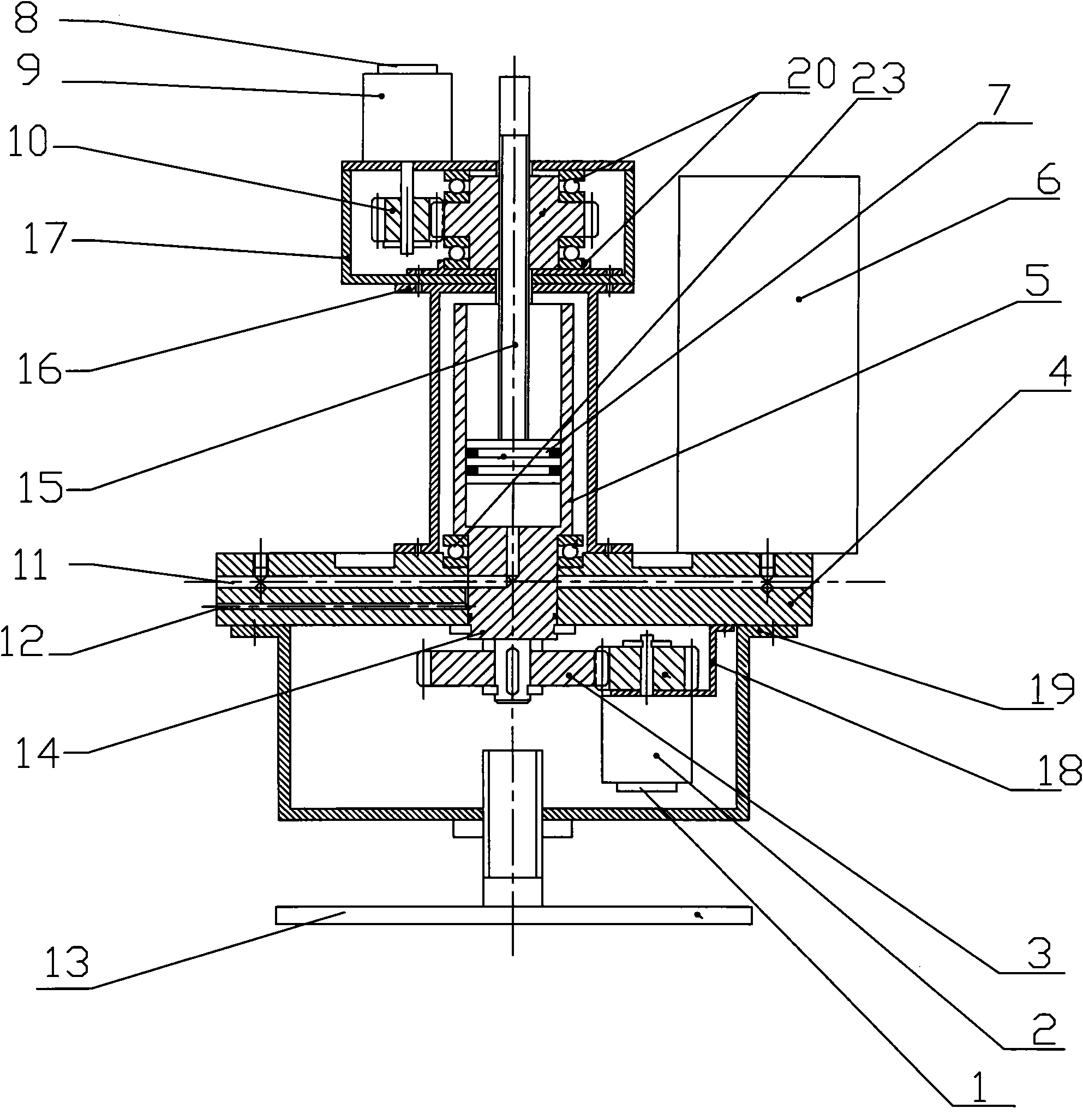

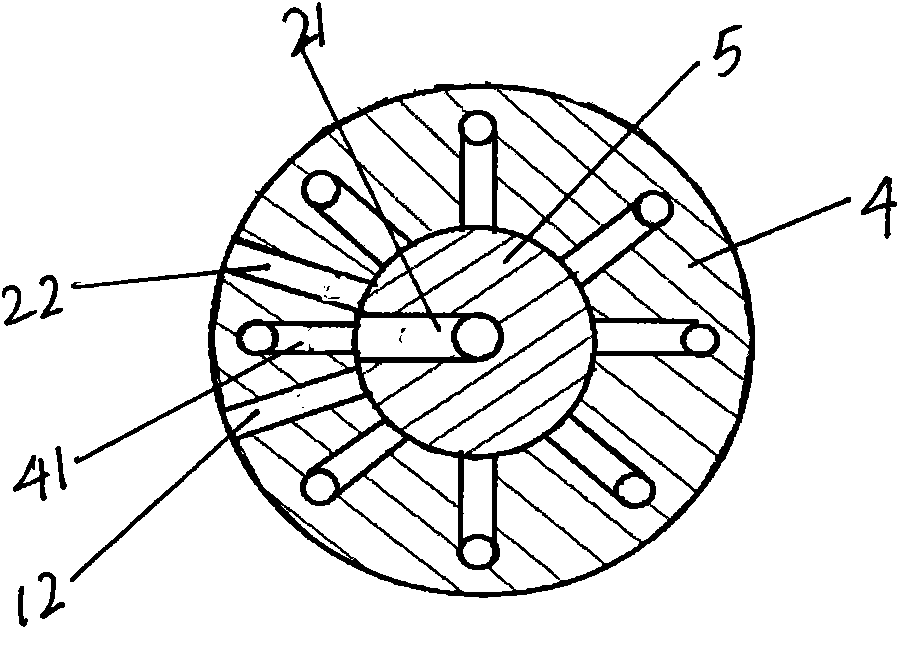

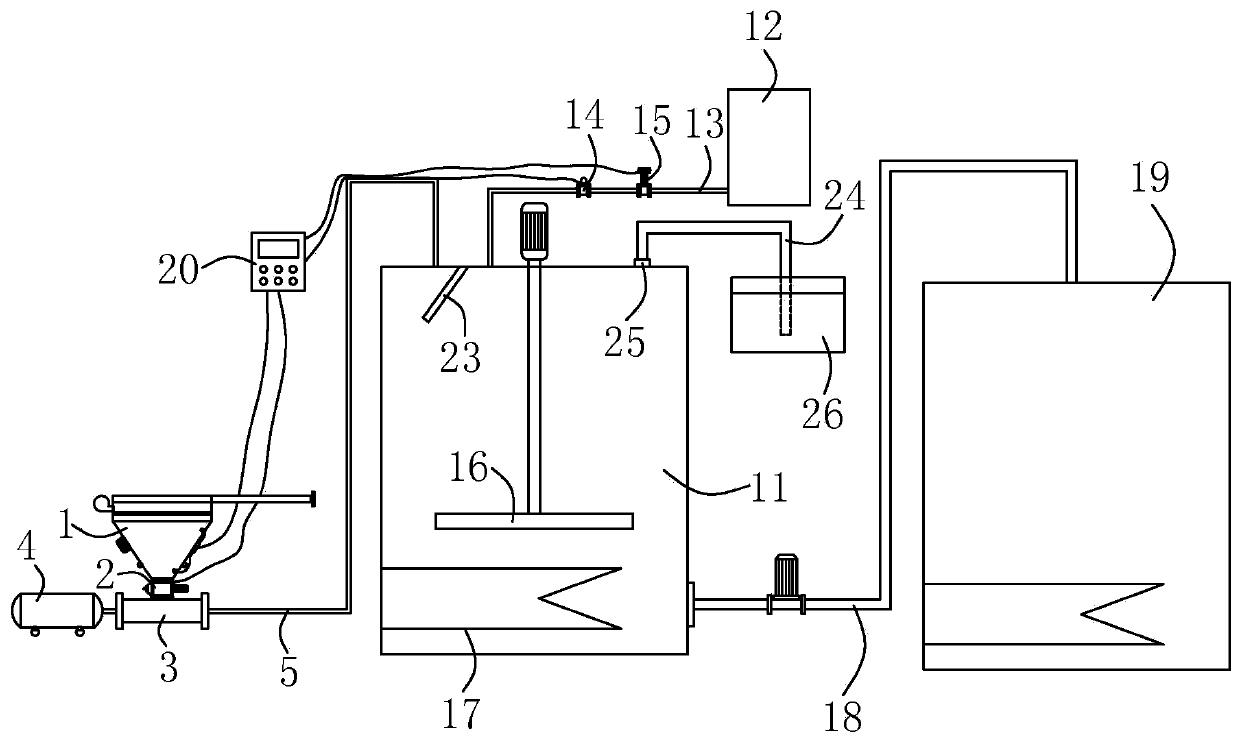

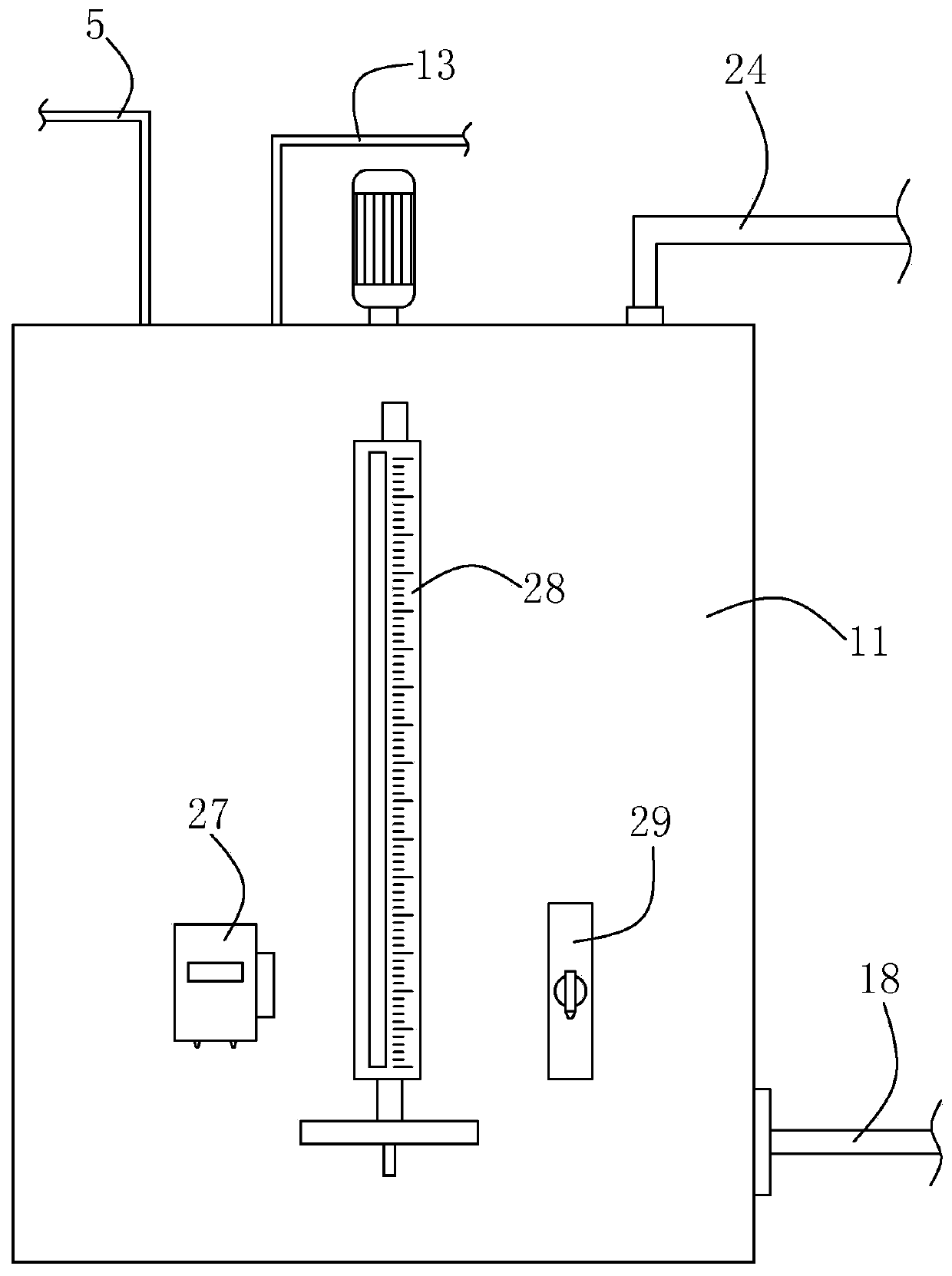

Automatic seasoning system

The invention discloses an automatic seasoning system, which comprises a first drive motor, a first gear transmission pair, a tray, a metering cylinder, a storage tank, a piston, a second drive motor, and a second gear transmission pair. A driving gear of the first gear transmission pair is connected with an output shaft of the first drive motor; an internal thread is arranged in a driven gear of the first gear transmission pair; an external thread is arranged at the upper end of a piston rod; the upper end of the piston rod which is provided with the external thread is inserted into the driven gear of the first gear transmission pair to form a screw transmission pair; the piston is fixedly arranged at the lower end of the piston rod and arranged in the metering cylinder; the end part of the metering cylinder is provided with a syringe which is arranged on the tray; the syringe is connected with a rotating shaft of the driven gear in the second gear transmission pair; a driving gear of the second gear transmission pair is connected with an output shaft of the second drive motor; the tray is provided with a feed channel, a discharge channel and an air inlet passage; the feed channel which is arranged on the tray is communicated with the storage tank; the syringe is provided with a suction channel which can be communicated with the feed channel and the discharge channel; and the tray is arranged on a base. The automatic seasoning system has the advantages of simple use and maintenance, high reliability, simple control and high distribution efficiency.

Owner:广州奥特佳数控系统有限公司

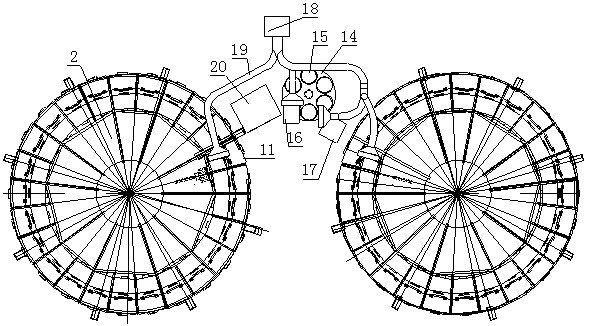

Automatic distribution system

ActiveCN102600756AEnsure safetyDoes not affect normal rotationMixer accessoriesDistribution systemElectric control

The invention discloses an automatic distribution system, which is characterized by comprising two distribution rotary wheel mechanisms arranged in parallel, a storage rotary wheel mechanism, a dust collection mechanism, an electric control system and the like. The automatic distribution system has the advantages of convenience and high speed in use, long service life, low implementing cost, capabilities of increasing distribution efficiency and reducing labor intensity and the like.

Owner:重庆诺信包装制品有限公司

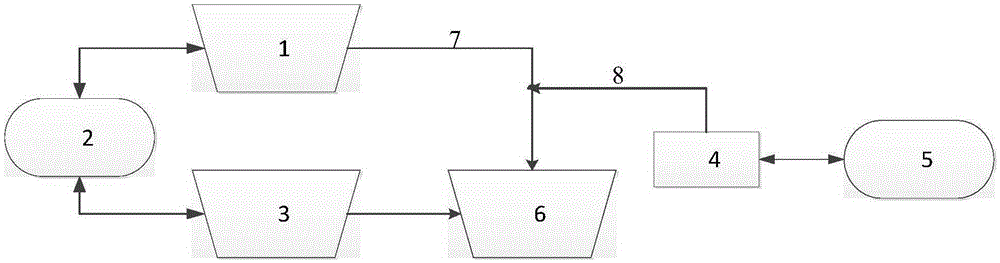

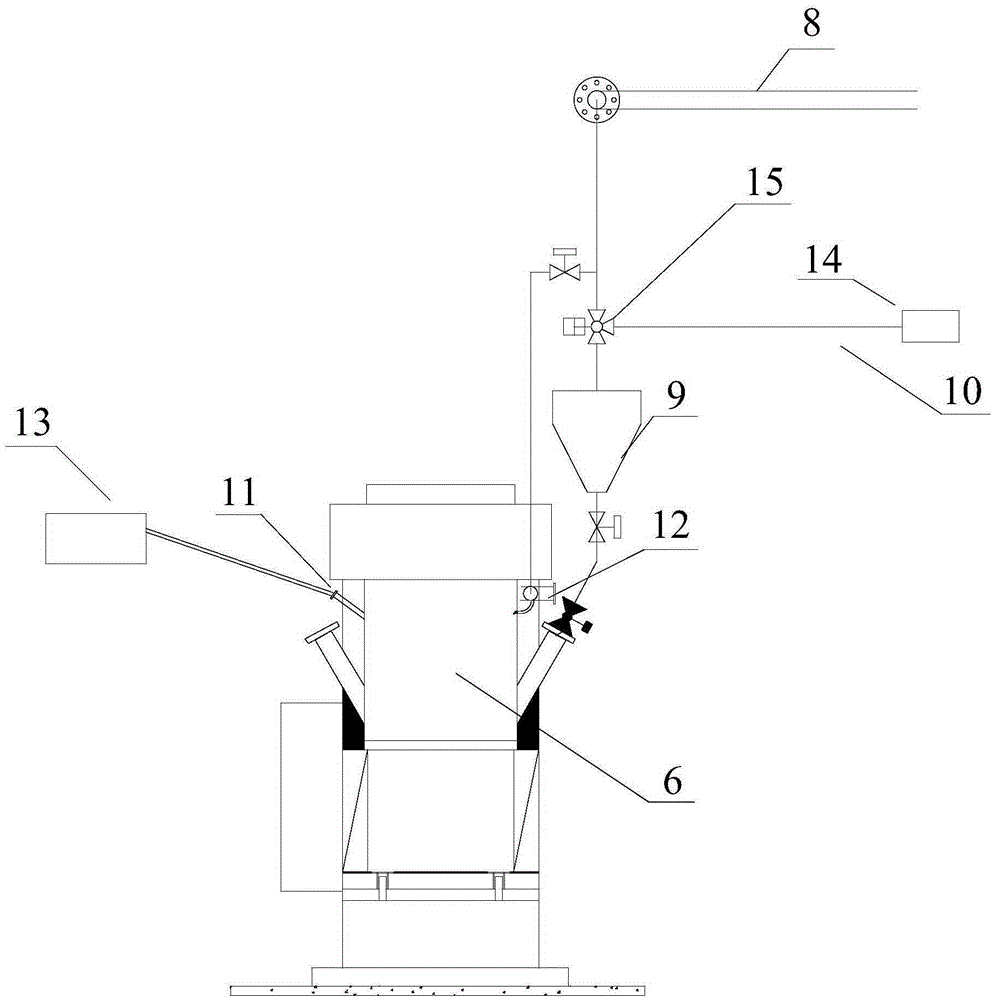

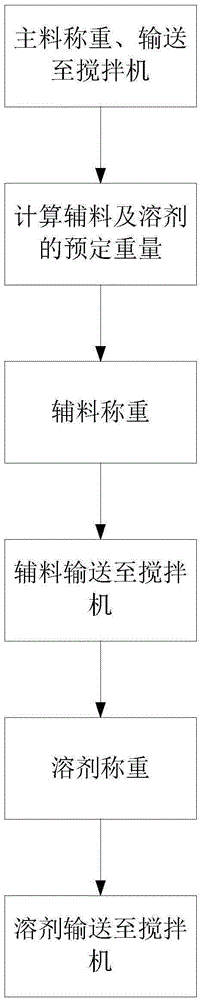

Batching system and control method thereof

ActiveCN105289405ASolve the problem of manual weighingNo human intervention requiredMixer accessoriesBatch operationSemi automatic

The invention provides a batching system, comprising a stirrer, a main ingredient weighing device, a main ingredient delivery device, an auxiliary material weighing device, an auxiliary material delivery device, a solvent weighing device, a solvent delivery device, a powder controller, and a solvent controller, wherein the main ingredient weighing device is communicated with the stirrer; the main ingredient delivery device is communicated with the main ingredient weighing device and the stirrer; the auxiliary material delivery device is communicated with the auxiliary material weighing device and the stirrer; the solvent delivery device is communicated with the solvent weighing device and the stirrer; the powder controller is connected with the main ingredient weighing device and the auxiliary material weighing device in a communicating manner; the solvent controller is connected with the solvent weighing device and the powder controller in a communication manner. The batching system provided by the invention is capable of automatically completing the rectification batching operation and remarkably improving the batching efficiency and batching accuracy. The problems that feed amount of main ingredients is large and multiple operators assist to operate are solved; the problem of manual weighing of the main ingredients and auxiliary materials is solved; the problem of solvent semi-automatic loading is solved; the problems that raw materials are polluted in a blending process and 5S of a workshop environment are solved. The invention also provides the control method of the batching system.

Owner:CONTEMPORARY AMPEREX TECH CO

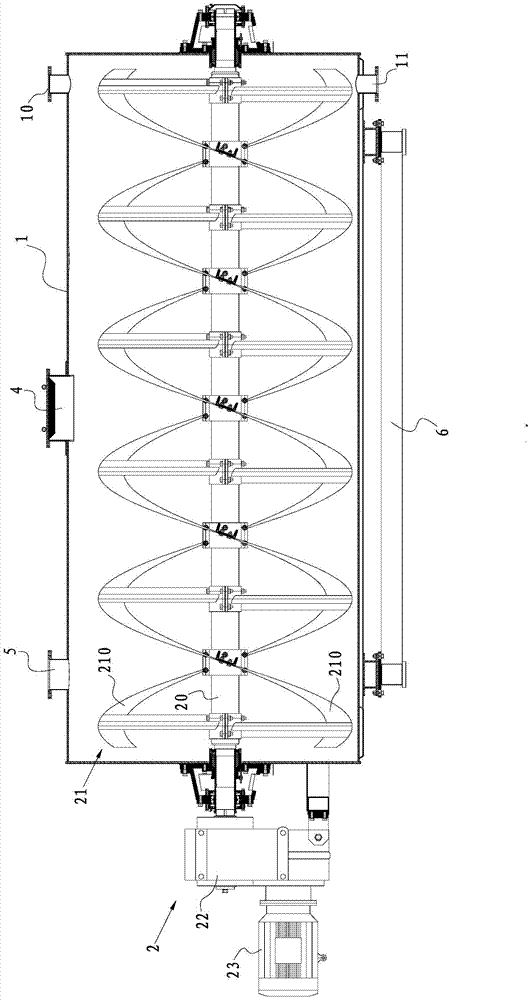

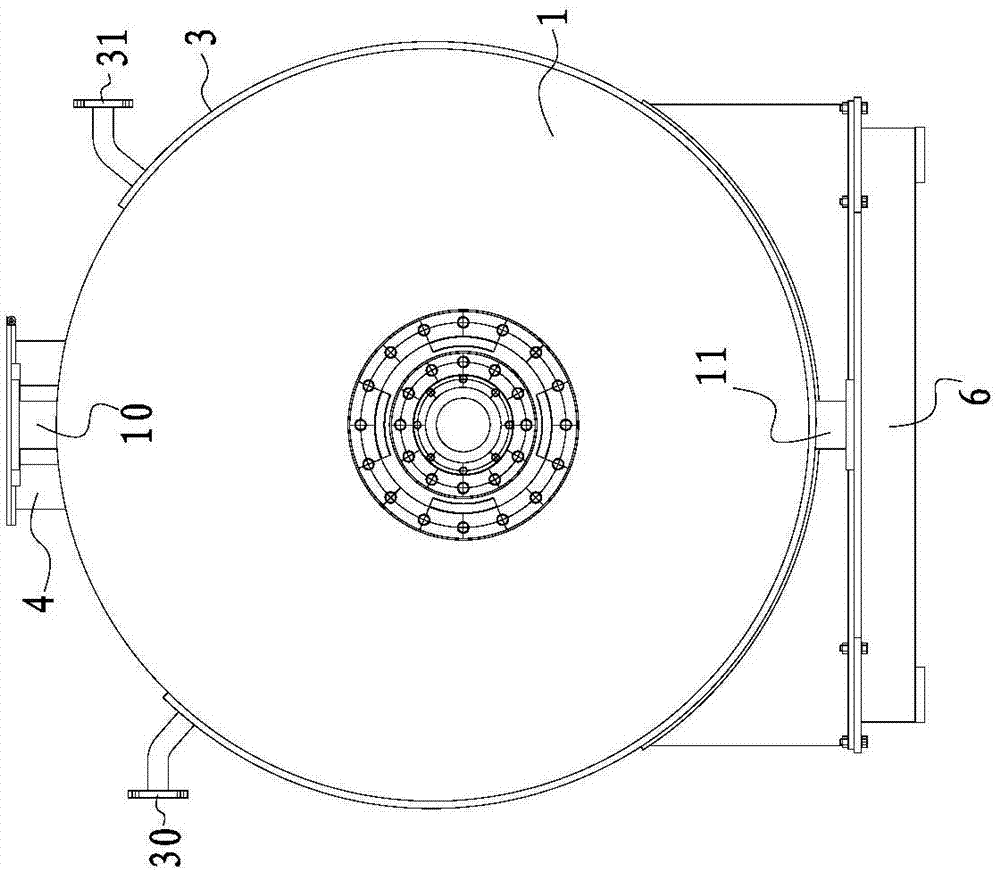

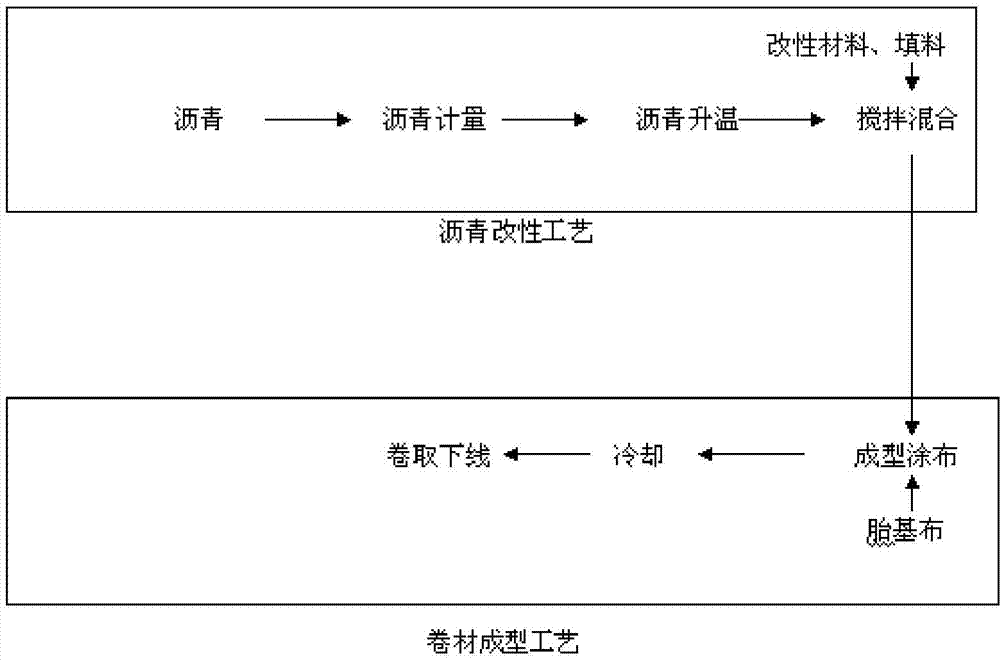

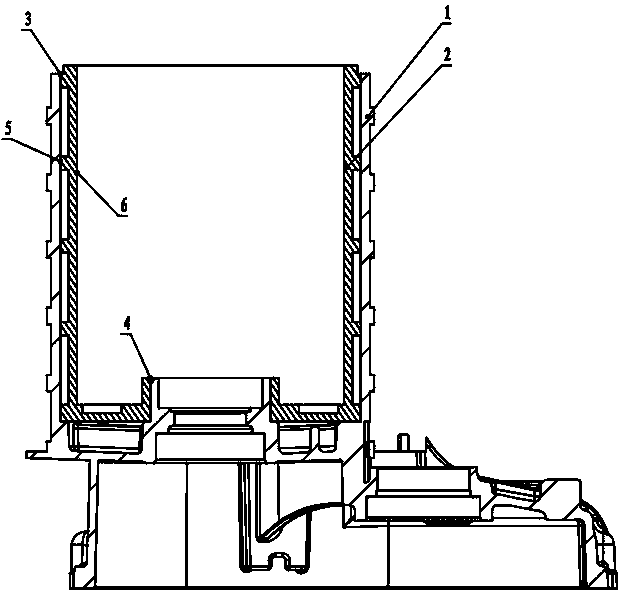

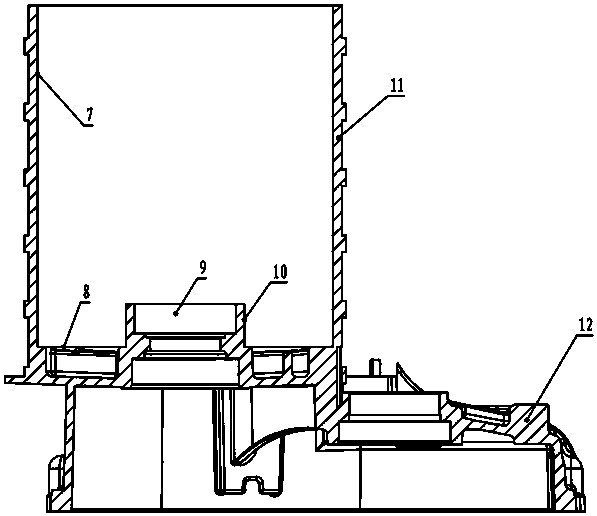

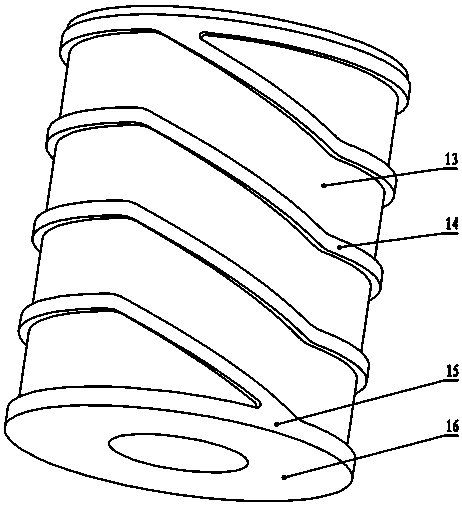

Material proportioning device for preparation of modified-asphalt waterproof coil material

InactiveCN103801208AReduce unevennessGuaranteed qualityRotary stirring mixersBituminous waterproofingEngineering

The invention relates to a material proportioning device for the preparation of a modified-asphalt waterproof coil material. The material proportioning device comprises a material proportioning tank which is provided with a charging opening and a discharging opening, and a stirring device, wherein the stirring device comprises a driving motor, a stirring shaft which is driven to rotate by the driving motor, and a stirring paddle which is arranged on the stirring shaft. The material proportioning device is characterized in that the material proportioning tank is arranged in a manner of extending along the horizontal direction, the stirring shaft is arranged in the material proportioning tank along the extending direction of the material proportioning tank, and the stirring paddle comprises a plurality of spiral belts which are spirally wound on the stirring shaft along the extending direction of the stirring shaft. According to the material proportioning device disclosed by the invention, the phenomenon that the proportioned materials are non-uniform caused due to the sedimentation of the proportioned materials can be reduced effectively, meanwhile, the material proportioning tank can be fully used, the material proportioning efficiency is increased, and the material proportioning quality is guaranteed; in addition, the material proportioning device is simple in structure and low in cost.

Owner:中建材苏州防水研究院有限公司

Batching apparatus for cultural medium book and periodical printing

InactiveCN106964294AIngredients are fastImprove batching efficiencyTransportation and packagingMixer accessoriesMechanical engineeringPigment

The invention relates to a batching apparatus for book and periodical printing, in particular to a batching apparatus for cultural medium book and periodical printing and aims to provide a batching apparatus which can save time and effort and improve the batching speed and batching efficiency and is used for cultural medium book and periodical printing. For solving the technical problem, the batching apparatus for cultural medium book and periodical printing comprises a base plate, first supporting plates, a first box body, a first liquid outlet pipe, a first valve, a second supporting plate and the like. The top of the base plate is vertically connected with two first supporting plates, the two first supporting plates are bilaterally symmetric, the first box body is connected between the tops of the two first supporting plates, and the lower portion of the right side of the first box body is connected with the first liquid outlet pipe. The batching apparatus performs preliminary pigment mixing through a first blanking device, performs secondary pigment mixing through a second blanking device and accordingly can perform rapid batching.

Owner:湖州风雷文化传媒股份有限公司

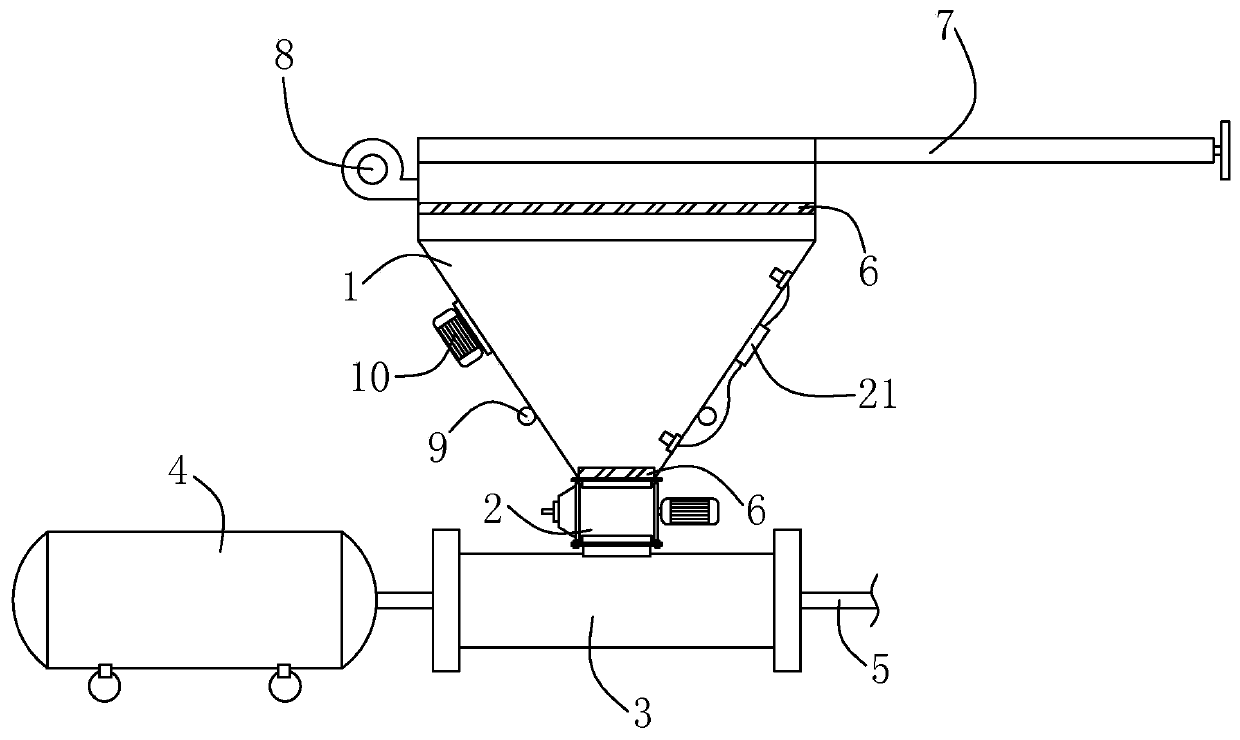

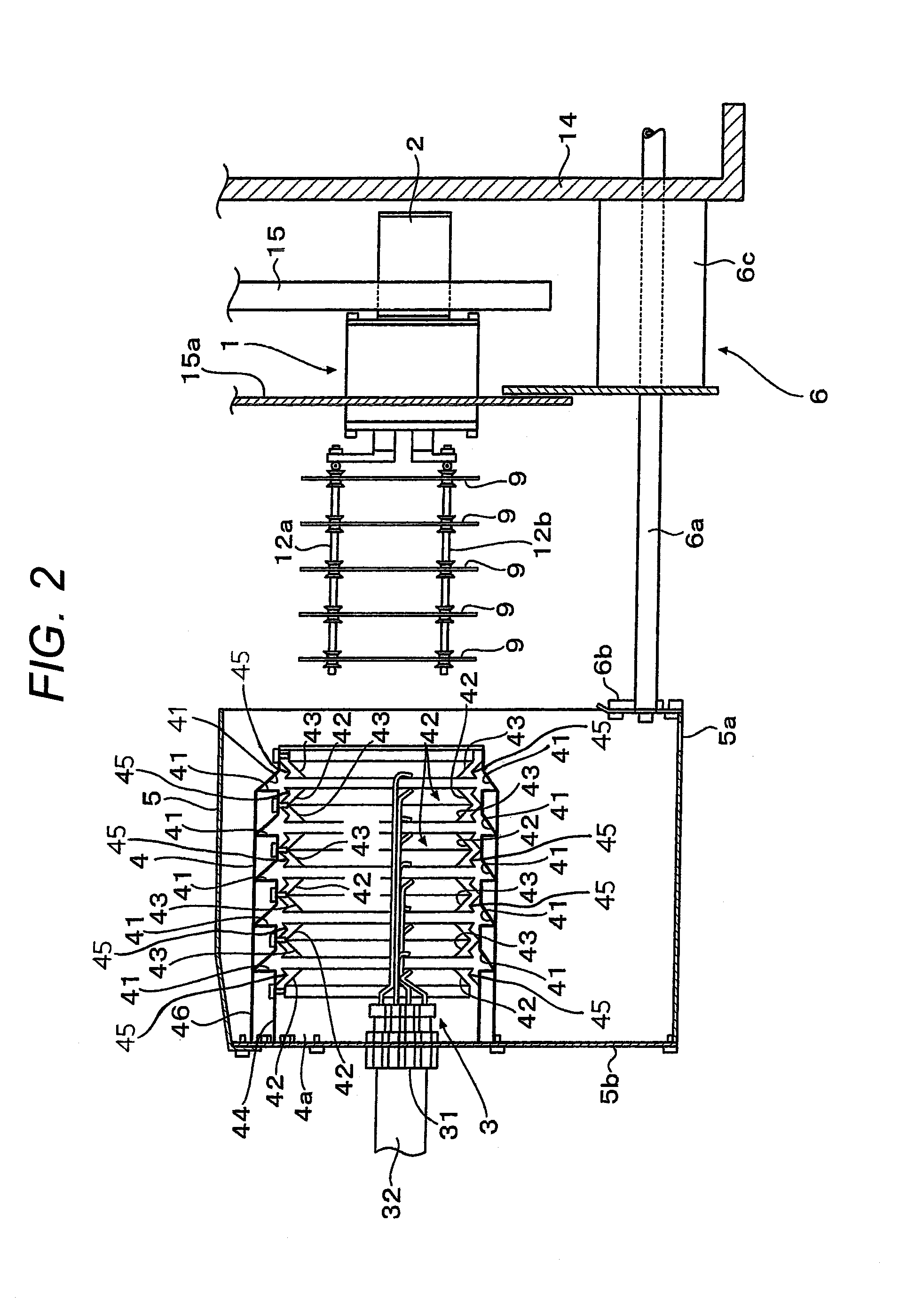

Urea solution continuous online batching system and solid feeding assembly thereof

PendingCN111468007AAccurate measurementLow costRotary stirring mixersTransportation and packagingFlue gasProcess engineering

The invention discloses a urea solution continuous online batching system and a solid feeding assembly thereof, and belongs to the technical field of flue gas denitrification reducing agent systems. The solid feeding assembly comprises a hopper and a feeding amount detector, wherein the outlet side of the hopper is connected with a rotary feeder, and the side, away from the hopper, of the rotary feeder is fixedly connected with a gas-solid mixer. The invention further provides the urea solution continuous online batching system which comprises a batching tank, the solid feeding assembly is fixedly connected to the batching tank, and a liquid feeding assembly is further communicated to the batching tank. A stirring piece and a heating piece are arranged in the batching tank. Quantitative conveying and accurate metering can be conducted on solid materials, water is synchronously conveyed into the batching tank in proportion, continuous online batching of a urea solution can be achieved,immediate batching and immediate use are achieved, the device cost can be reduced, the batching efficiency can be improved, and the occupied area of the device can be reduced.

Owner:上海鲁源控制设备有限公司

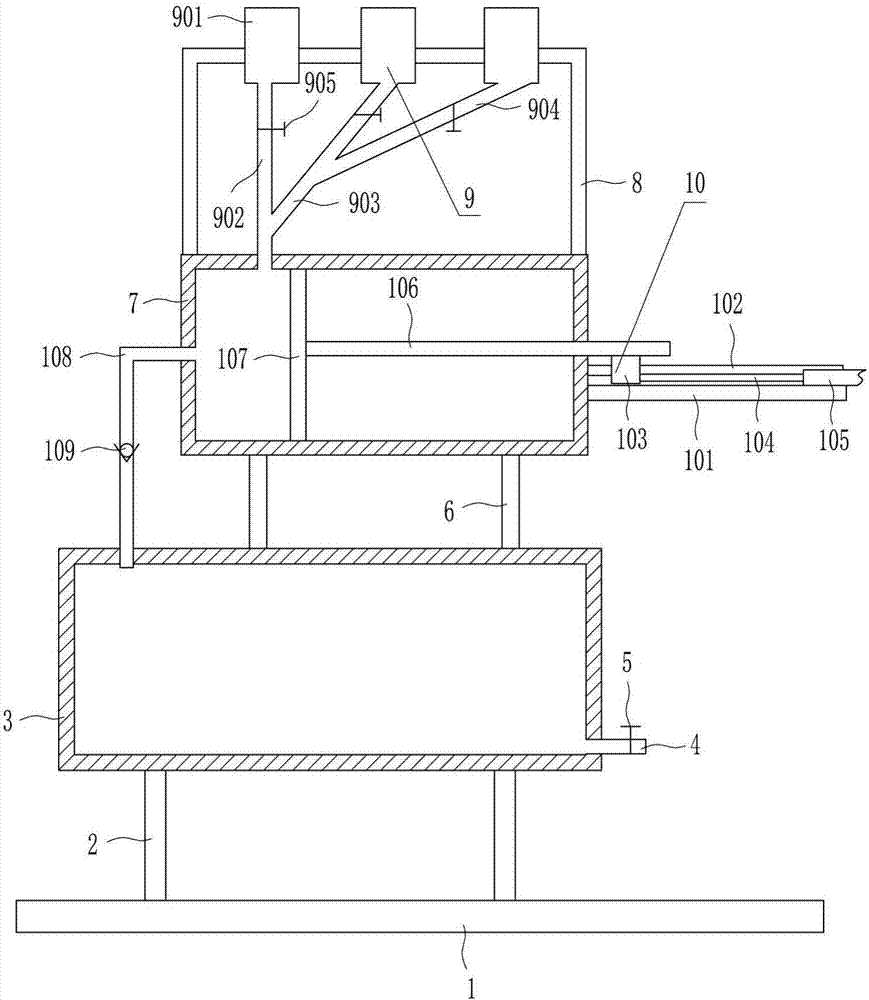

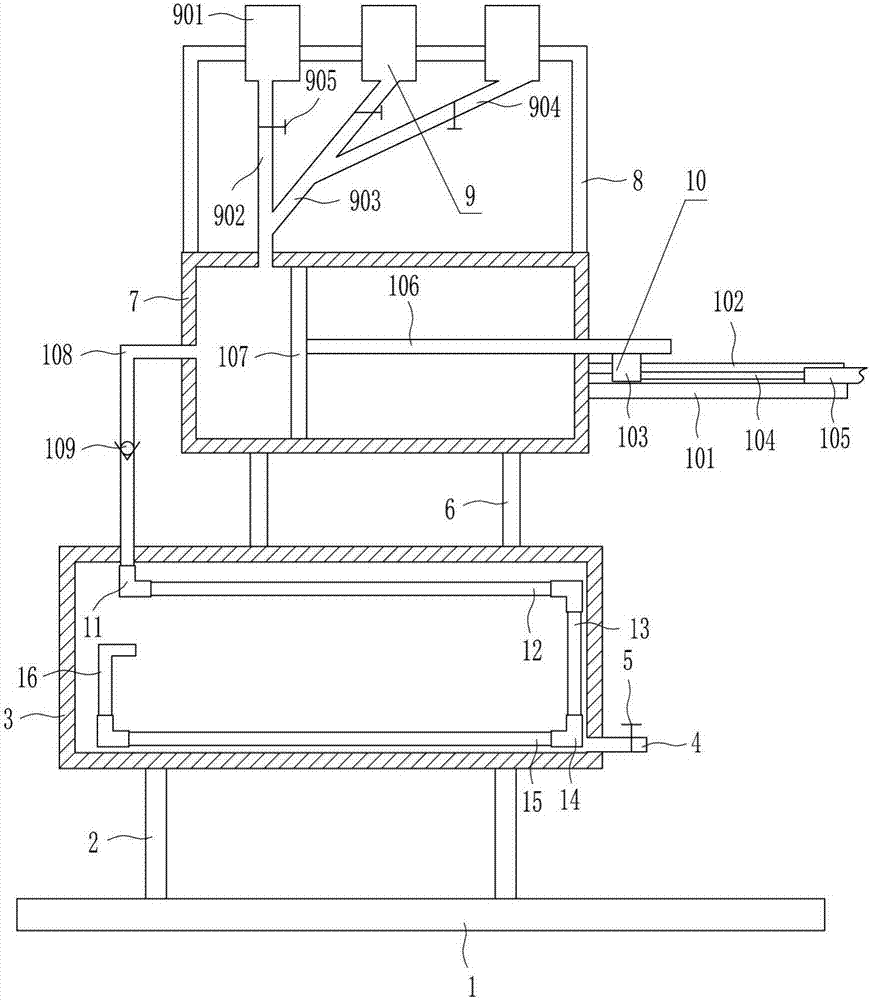

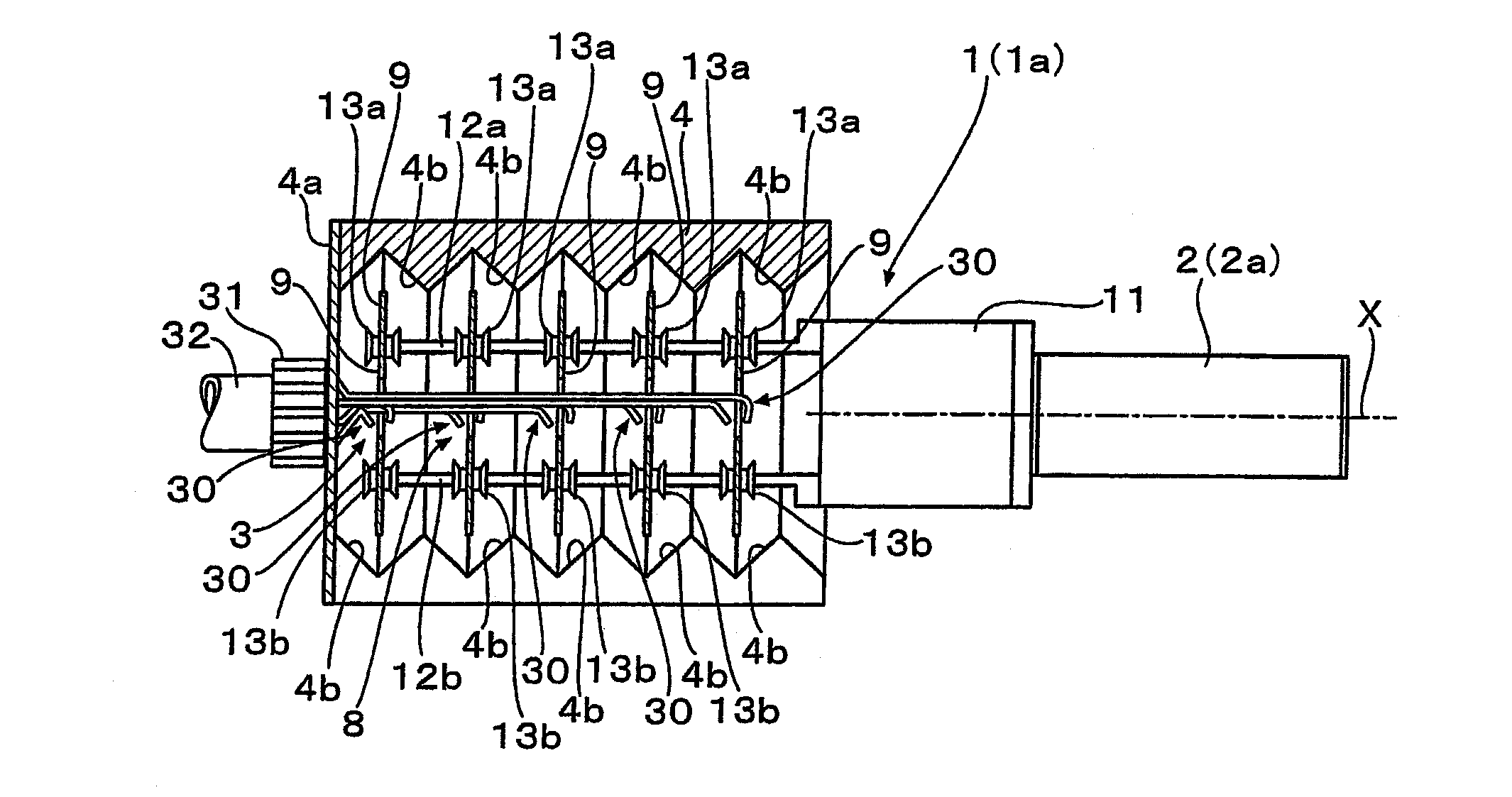

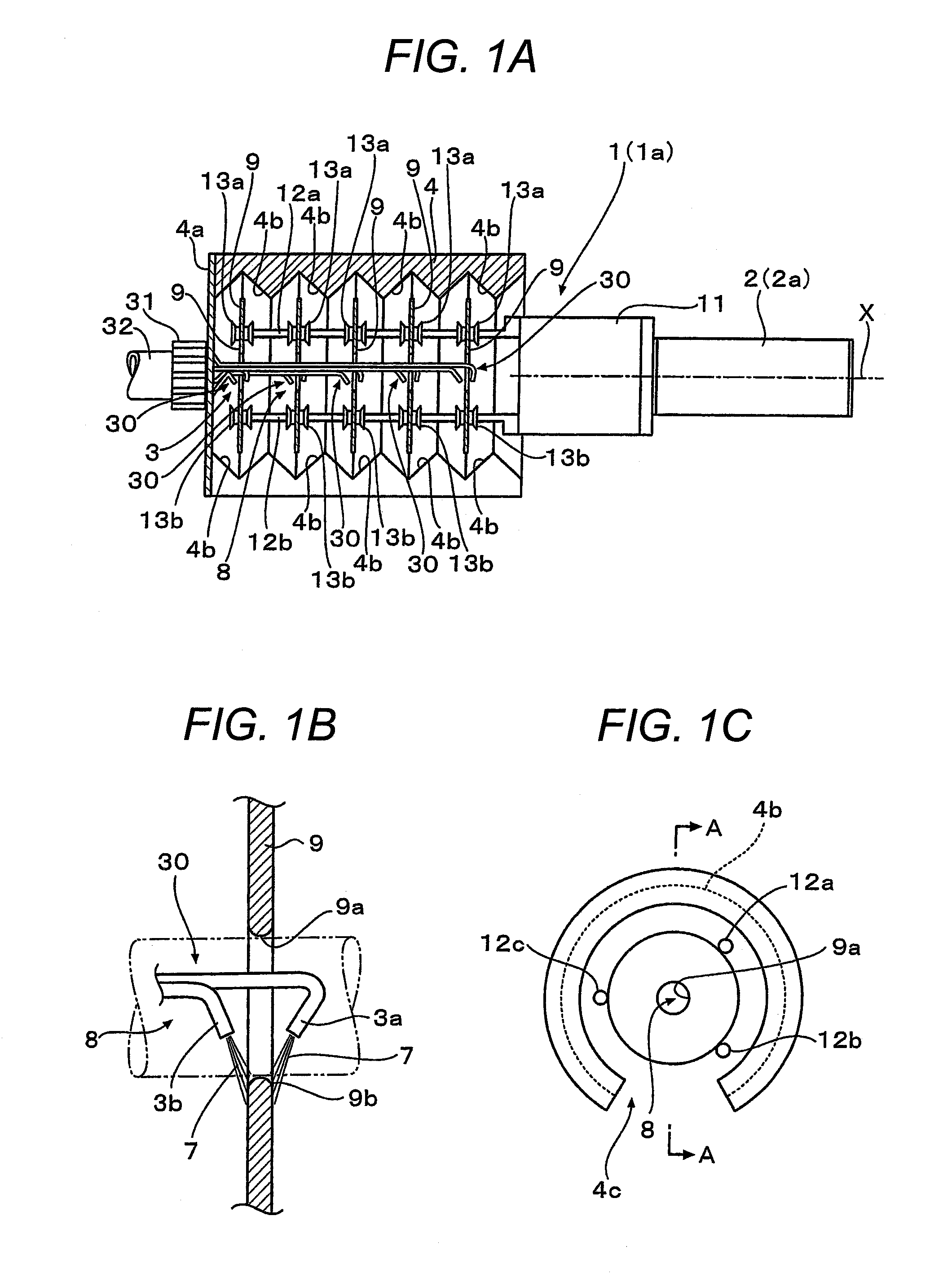

Disc drying device and disc drying method

InactiveUS20100319210A1Easy to unloadImprove batching efficiencyDrying using combination processesDrying solid materials with heatWater flowMiniaturization

The present invention provides a disc drying device and a disc drying method that allow simultaneous and quick drying of plural discs by a batch process and realize miniaturization of the device. In the present invention, plural discs arranged along a single axis are simultaneously chucked at outer peripheries thereof so that central openings of the discs internally form a space; plural nozzles are disposed in the space so as to supply hot water from inner peripheral surfaces of two sides of each of the discs to heat the discs with the hot water; and the discs are simultaneously rotated to thereby move the hot water from inner peripheries to outer peripheries of the discs and discharge the hot water outwardly of the outer peripheries by centrifugal force. The discharged hot water flows through valley grooves provided in inner wall surfaces of a water receiving cover to the lower side of the discs to be discharged to the outside.

Owner:HITACHI HIGH-TECH CORP

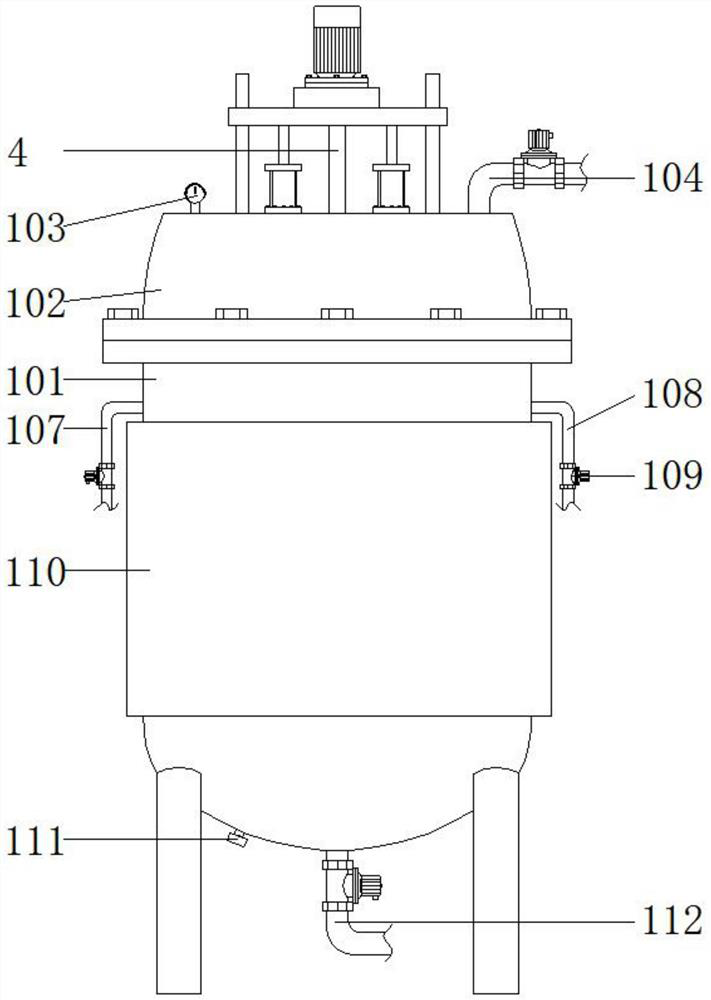

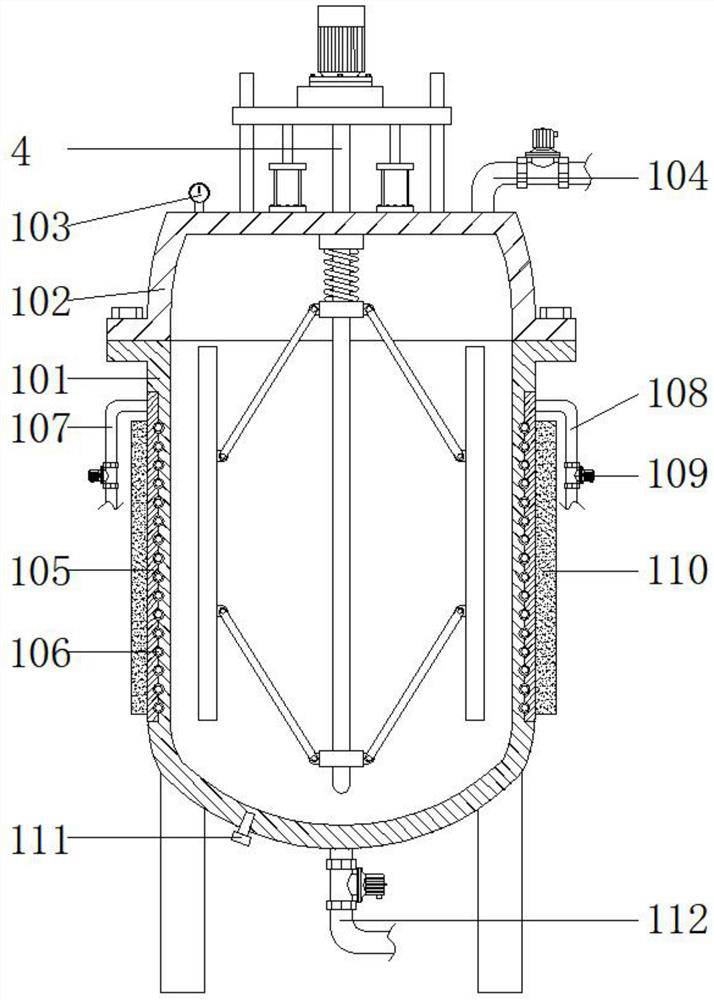

Lactic acid bacteria fermentation device

InactiveCN112481090AEasy to cleanEnsure proper temperatureBioreactor/fermenter combinationsBiological substance pretreatmentsBiotechnologyLactic acid bacterium

The invention discloses a lactic acid bacteria fermentation device, and relates to the technical field of food production. The lactic acid bacteria fermentation device comprises a fermentation mechanism and a batching mechanism, the fermentation mechanism and the batching mechanism are connected through an infusion pump, the batching mechanism can carry out automatic batching, the fermentation mechanism comprises a fermentation tank body, a stirring and cleaning part is fixedly installed at the top of the fermentation tank body, the stirring and cleaning part comprises a fermentation tank cover, fixed guide columns are fixedly connected with the four corners of the top of the fermentation tank cover correspondingly, a lifting plate is slidably connected between the fixed guide columns, anda telescopic air cylinder is further fixedly mounted at the top of the fermentation tank cover. Through the arrangement of the stirring and cleaning part, when the fermentation mechanism completes fermentation, the stirring and cleaning part can be used for stirring yoghourt during fermentation, and meanwhile, after fermentation is completed, the stirring and cleaning part can be used for cleaning the interior of the fermentation tank body, so that the fermentation mechanism is convenient to clean.

Owner:清远一生自然生物研究院有限公司 +1

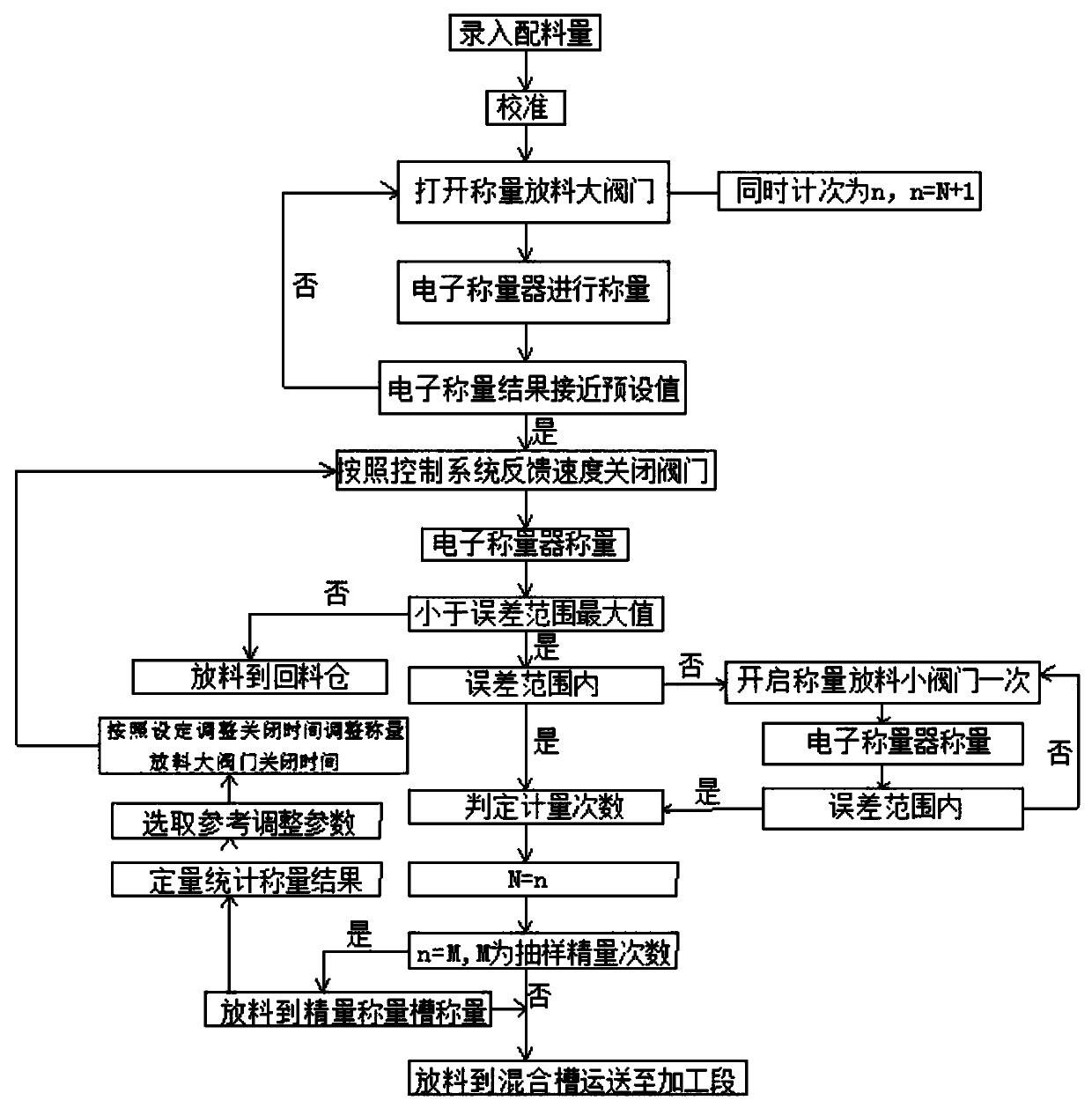

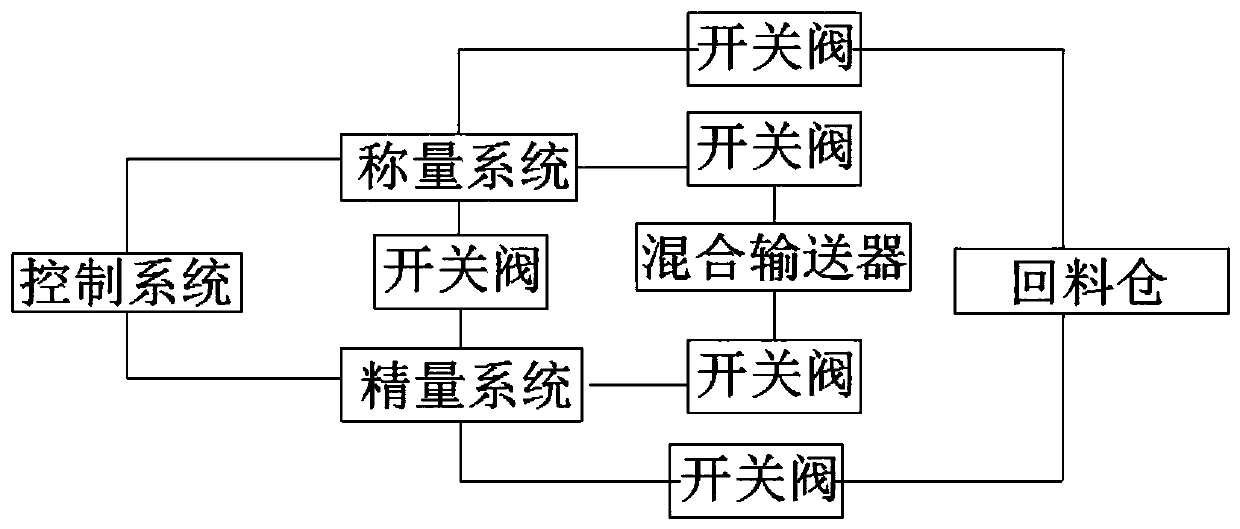

Material preparing control method and material preparing control system

InactiveCN110585984AReduce weighing timeLose weightTransportation and packagingMixer accessoriesControl systemEngineering

The invention discloses a material preparing control method. According to the method, material discharge and primary weighing are performed, a program closes a material discharge valve when a materialpreparing amount preset value is approached so as to achieve the precise control of the material discharge amount, and the closing speed of a switch valve is controlled through sampling precise weighing statistical analysis so as to improve the precision of the weighing, such that the proportion of the process comprising repeated valve closing and then weighing can be reduced. According to the present invention, with the method and the system, the material discharge process at a weighting preset amount approaching point is controlled by controlling the closing speed of the switch valve so asto substantially reduce the weighing time and improve the material preparing efficiency; the precise weighing is performed through interval sampling, and the opening / closing speed is adjusted according to the statistical result, such that the opening / closing speed of the switch valve can be automatically adjusted; and the material preparing precision is gradually adjusted according to the statistical result so as to substantially reduce the repeated material discharging and weighing processes in the weighing process, such that the proportion of the one-time weighing meeting the error requirement can be increased, and the material preparing efficiency is improved.

Owner:无锡大拇指机电科技有限公司

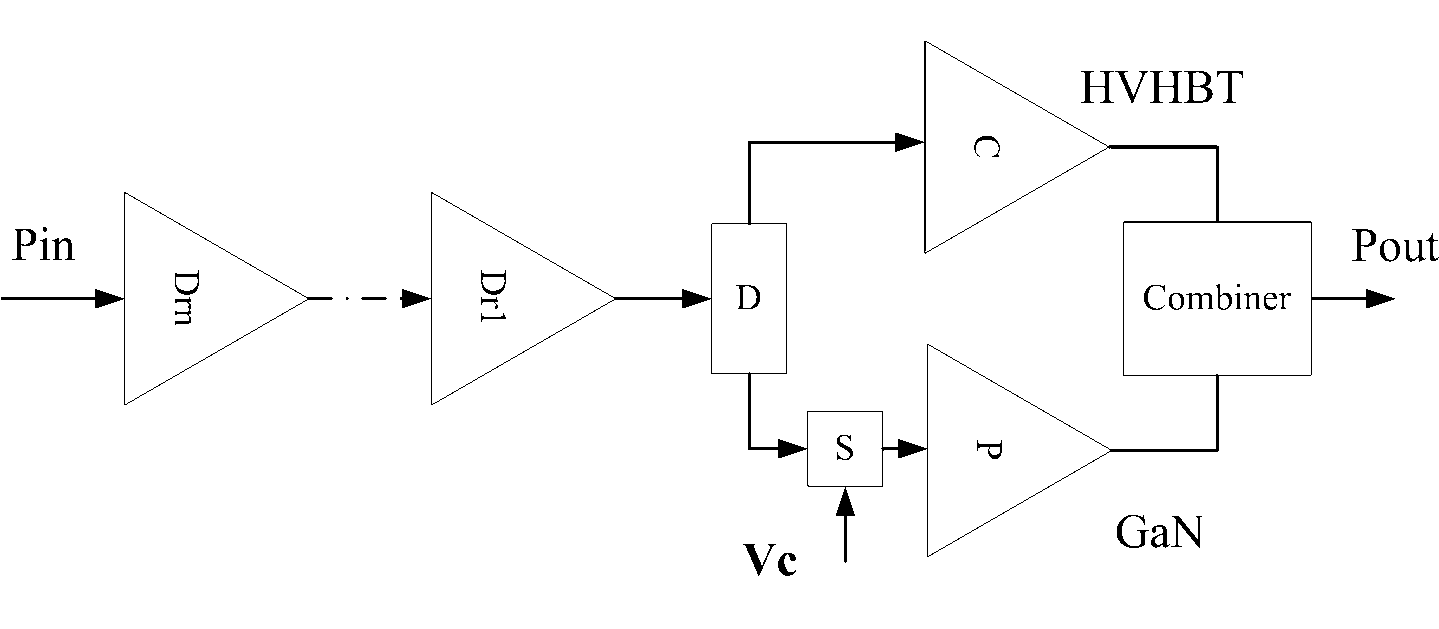

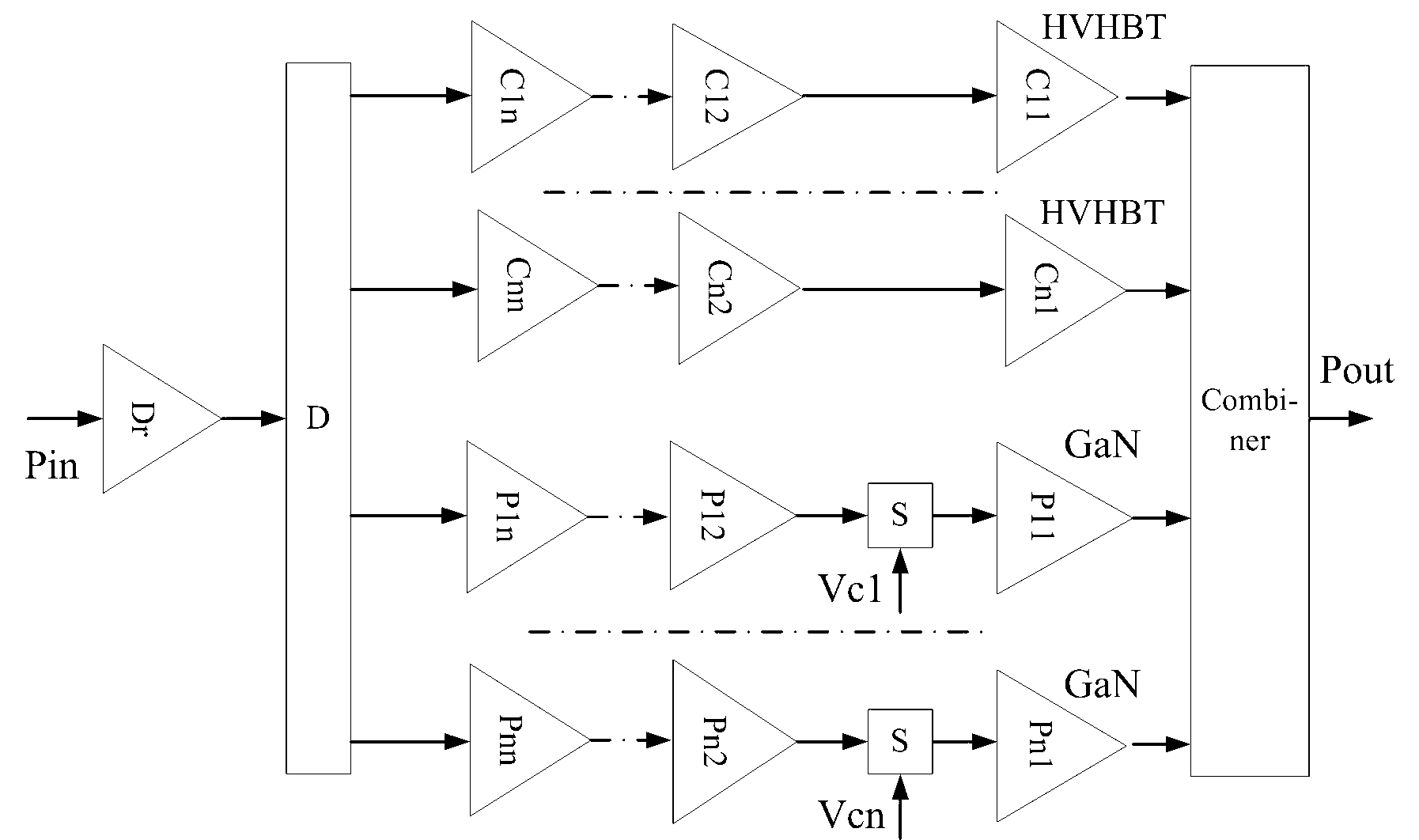

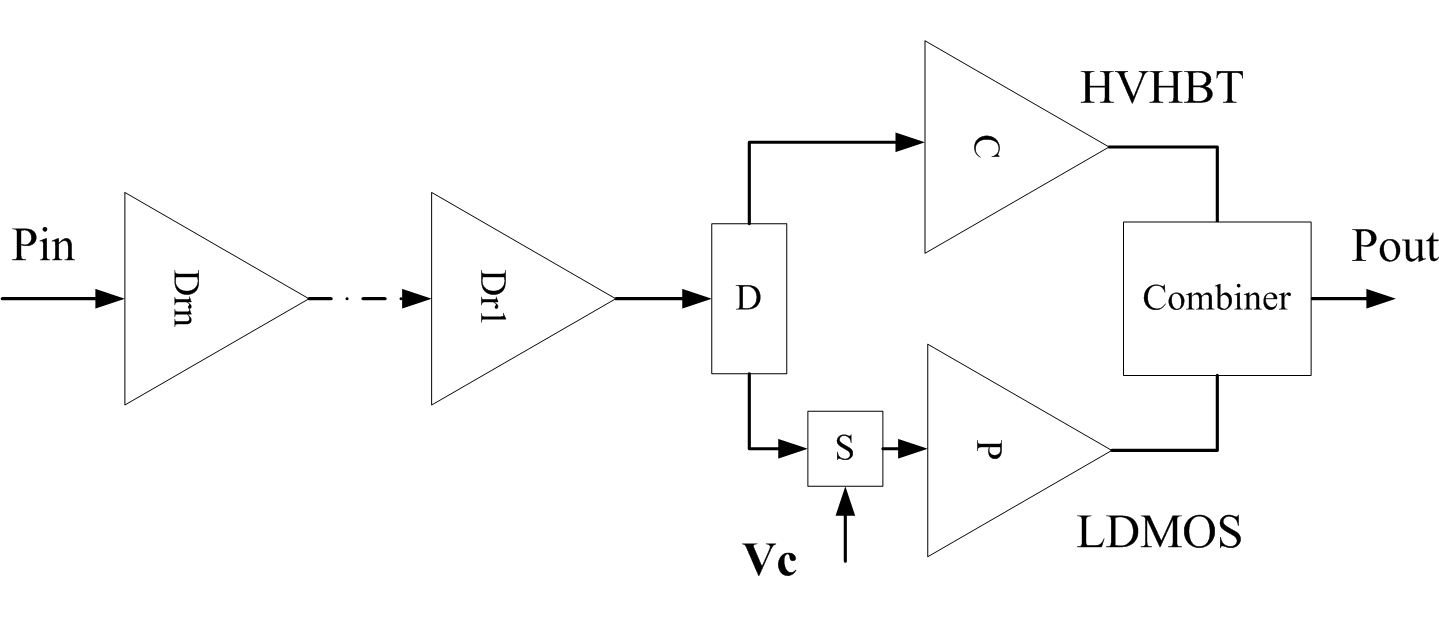

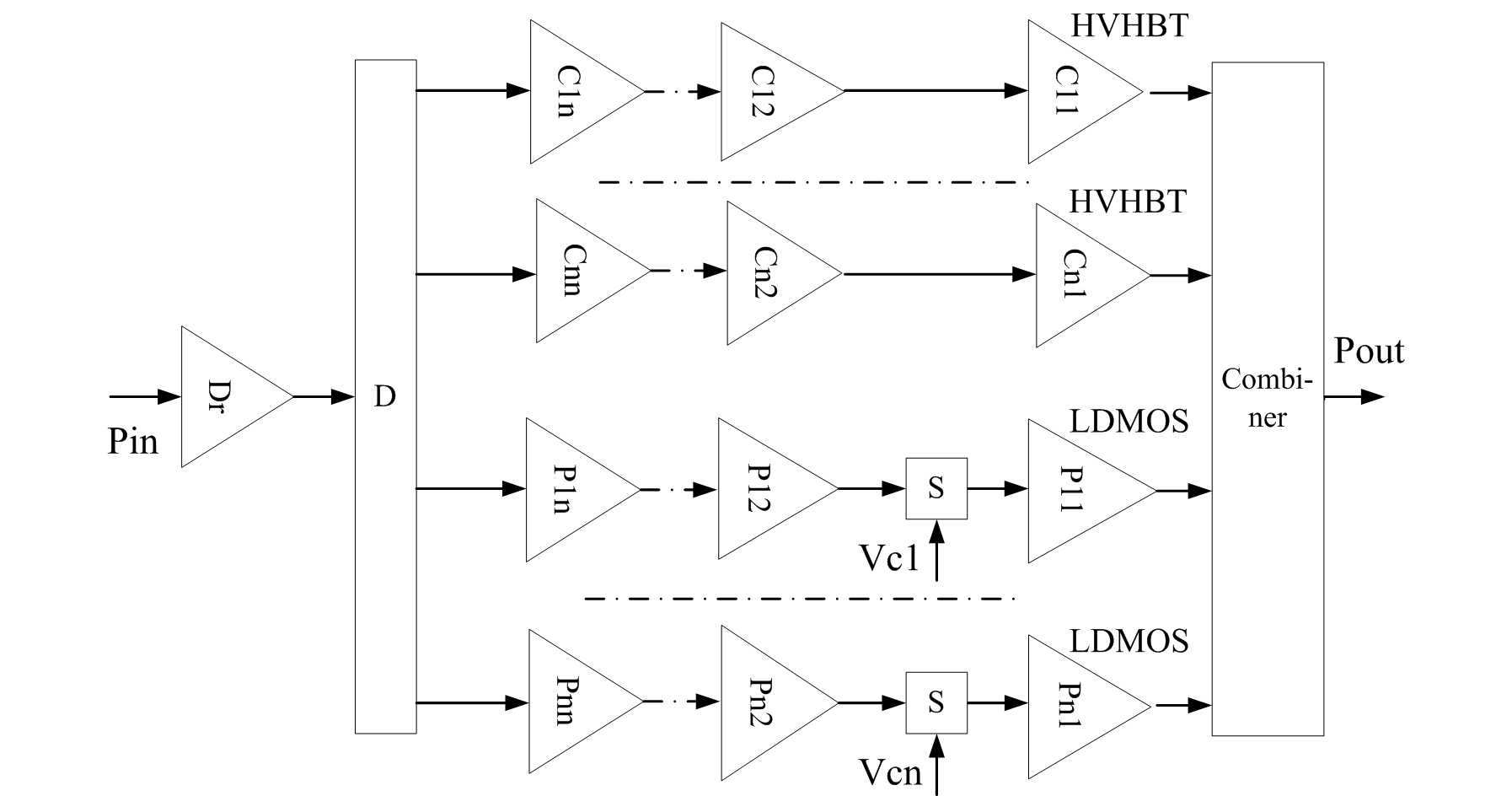

Multi-combination power amplifier and realizing method thereof

InactiveCN102185568AAvoid the disadvantages of early turn-onReduce power consumptionHigh frequency amplifiersGated amplifiersLDMOSAudio power amplifier

The invention discloses a multi-combination power amplifier and a realizing method thereof. A peak amplification branch circuit of a Doherty power amplifier comprises a radio frequency switch; the radio frequency switch is used for controlling the conduction of final peak power amplification in the peak amplification branch circuit; the final carrier power amplification of a carrier amplification branch circuit of the power amplifier adopts an HVHBT (High-Voltage Heterojunction Bipolar Transistor) device; and the final peak power amplification of the peak amplification branch circuit of the power amplifier adopts an LDMOS (Laterally Diffused Metal Oxide Semiconductor) device. By adopting the invention, the peak power consumption increase when the peak amplifier is conducted in advance is prevented, and the efficiency of the whole power amplification is improved.

Owner:ZTE CORP

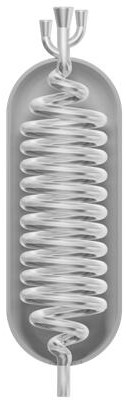

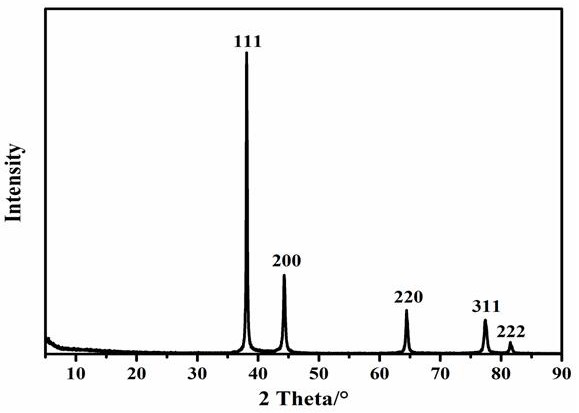

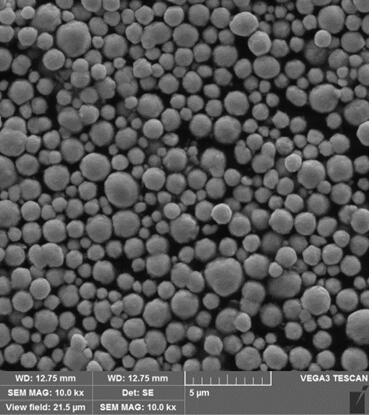

Method for preparing silver powder through space confinement method

ActiveCN112276108AControl dispersionControl shapeTransportation and packagingMetal-working apparatusSlurryMaterials science

The invention discloses a method for preparing silver powder by a space confinement method, which is characterized by using a spiral reactor, adding double reducing agents, stirring is not needed, andthe silver powder is prepared by an ultrasonic parallel flow mode. and filtering, washing, emulsifying, drying and crushing the obtained silver slurry to obtain the silver powder. The temperature ofthe reduction reaction does not need to be controlled in the whole reaction process, and a new thought is provided for silver powder preparation. The silver powder prepared through the method has extremely high dispersity, single-particle dispersion of the silver powder can be achieved, the tap density is larger than 6.0g / cm<3>, the apparent density is larger than 3.3g / cm<3>, and wide market popularization prospects are achieved. The dispersity of the silver powder can be improved by replacing stirring with ultrasonic waves, the soft agglomerated silver powder is dispersed in the reaction process, the wall sticking phenomenon of the silver powder in a reaction kettle can be reduced through the spiral reactor, and in the use process, the reactor is convenient to clean and is not prone to blockage.

Owner:西安宏星电子浆料科技股份有限公司

Color masterbatch automatic feeding equipment and feeding process

PendingCN109110505ACentralized processingImplement closed inputLarge containersBulk conveyorsVacuum pumpingMasterbatch

The invention discloses color masterbatch automatic feeding equipment and a feeding process, the equipment comprises a feedstock feeding device, a weight-increasing type feeding device, a gathering device and a control device, wherein the feedstock feeding device adopts a vacuum pumping mode to carry out feeding and supplementing, the weight-increasing type feeding device distributes materials tothe same material distribution point through mutually independent weighting warehouses arranged in a ring, so that the feeding efficiency is increased. The weighting mode of the weighting warehouse isthat an industrial control computer controls an opening amount of an outlet valve according to an input material addition amount to make the material fall from the storage bin into the weighing warehouse in a fast-adding-slow-supplying manner, and the weighing is more accurate. The equipment can realize material centered processing, closed input, and prevention of dust and feedstock pollution ofthe workshops. In order to ensure the continuity and reliability of the system operation, the system adopts the industrial control computer, a MES system device connected with the industrial control computer and interacting with the industrial control computer and a human-computer interface, which reduces manual participation and greatly improves the quality of products.

Owner:JIANGSU KINGFA SCI & TECH ADVANCED MATERIALS CO LTD +1

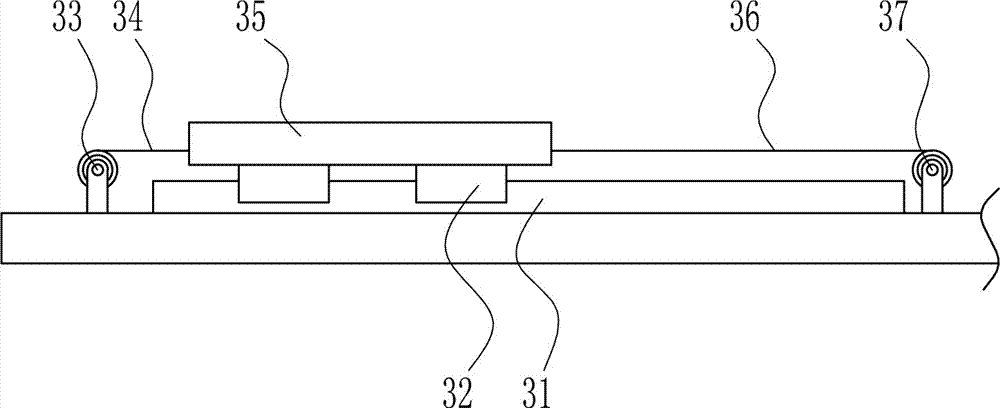

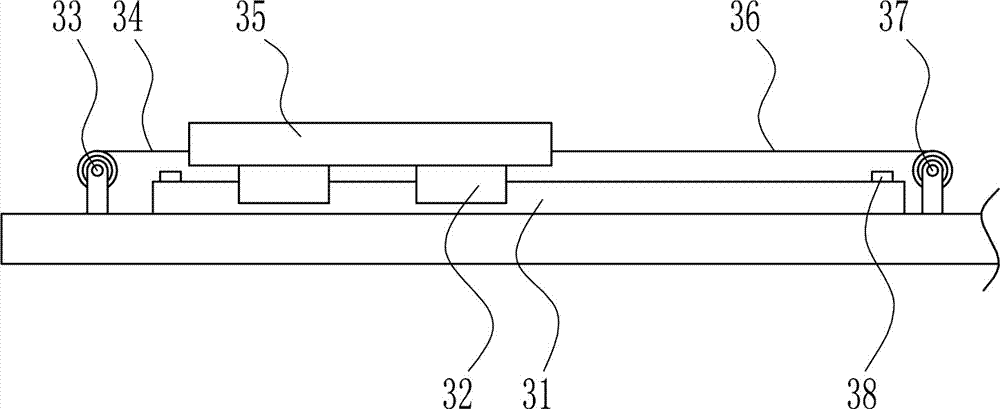

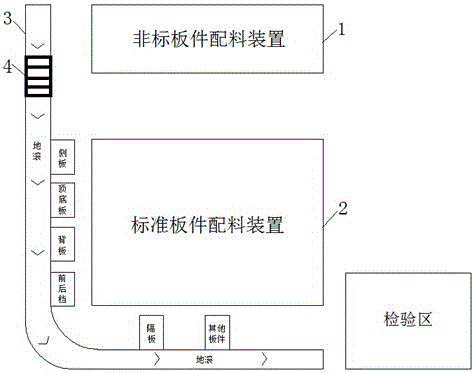

Dosing method for novel kitchen cabinet casing plate dosing system

ActiveCN105678356AImprove batching efficiencyReduce multiple handlingCo-operative working arrangementsStorage devicesEngineeringStandard plate

The invention relates to a dosing method for a novel kitchen cabinet casing plate dosing system. The kitchen cabinet casing plate dosing system comprises a non-standard plate dosing device, a standard plate dosing device, a ground roll arranged along the periphery of the non-standard plate dosing device and the periphery of the standard plate dosing device, and a plurality of dosing carts arranged above the ground roll and in sliding fit with the ground roll. According to the technical scheme of the invention, the defects in the prior art can be solved. Meanwhile, the system is high in kitchen cabinet casing plate dosing efficiency, and high in dosing accuracy. Therefore, the smooth operation of the entire kitchen cabinet manufacturing process can be ensured.

Owner:合肥志邦家居有限公司

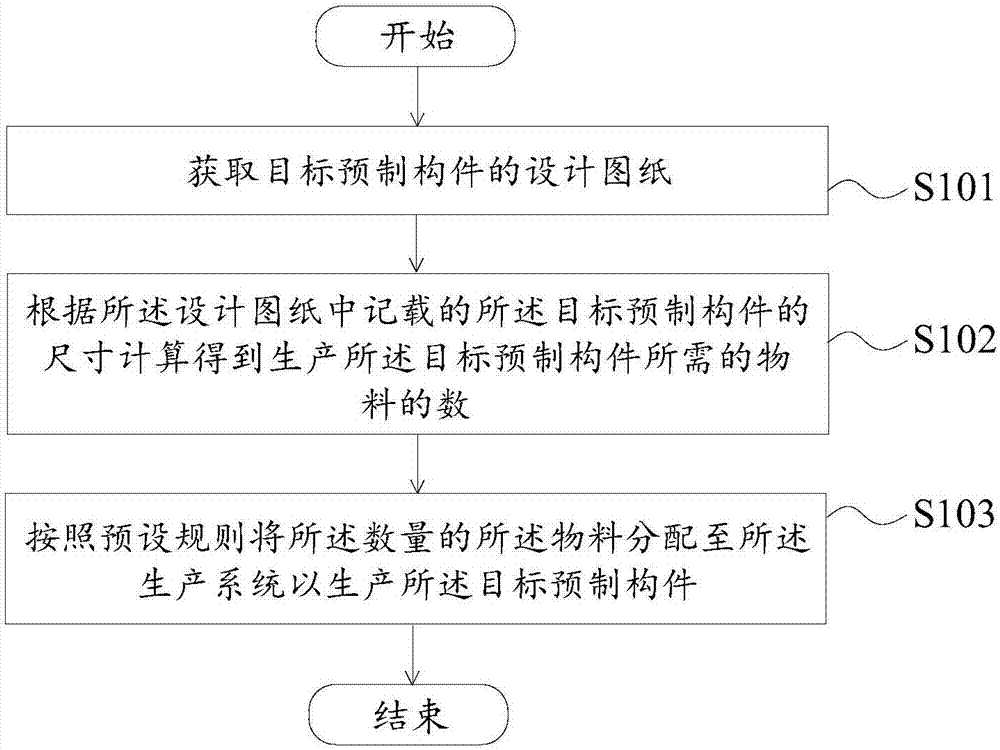

Automatic batching method and device

InactiveCN107443556AImprove batching efficiencyImprove accuracyFeeding arrangmentsManufacturing engineering

The invention provides an automatic batching method and device. The automatic batching method and device are applied to a production system for producing prefabricated parts. The prefabricated parts are used for assembling of a prefabricated building. The automatic batching method comprises the steps that a design drawing of a target prefabricated part is obtained; the number of materials required by production of the target prefabricated part is obtained through calculation according to the size, recorded in the design drawing, of the target prefabricated part; the quantitative materials are distributed to the production system according to the preset rule so as to produce the target prefabricated part. By means of the design, automatic batching of the production system can be achieved, the production efficiency is improved, and the batching error rate is reduced.

Owner:HEZHOU UNIV

Motor and speed reducer integrated case and casting and welding method thereof

InactiveCN108539897AHigh degree of integrationLow costManufacturing dynamo-electric machinesSupports/enclosures/casingsWater channelReduction drive

The invention discloses a motor and speed reducer integrated case and a casting and welding method thereof. The case comprises an outer case body and an inner case body, wherein the outer case body comprises a motor case body and a speed reducer case body which are integrally formed through high-pressure casting; the inner case body is nested in the motor case body, a spiral water channel rib is arranged on the outer surface of the inner case body, and spaces of the spiral water channel rib form a spiral water channel by being matched with an outer wall of the inner case body and the inner wall of the motor case body. According to the motor and speed reducer integrated case, the integration degree is increased, end covers are reduced, the cost is reduced, the axial space is compressed, andthe NVH characteristic of a system is improved. According to the casting and welding method, the complexity of a manufacturing process is reduced through high-pressure casting, the batch efficiency is high, the wall thickness of the case is reduced, structures of process holes are omitted, and the radial space is compressed.

Owner:HEFEI JUYI POWER SYST CO LTD

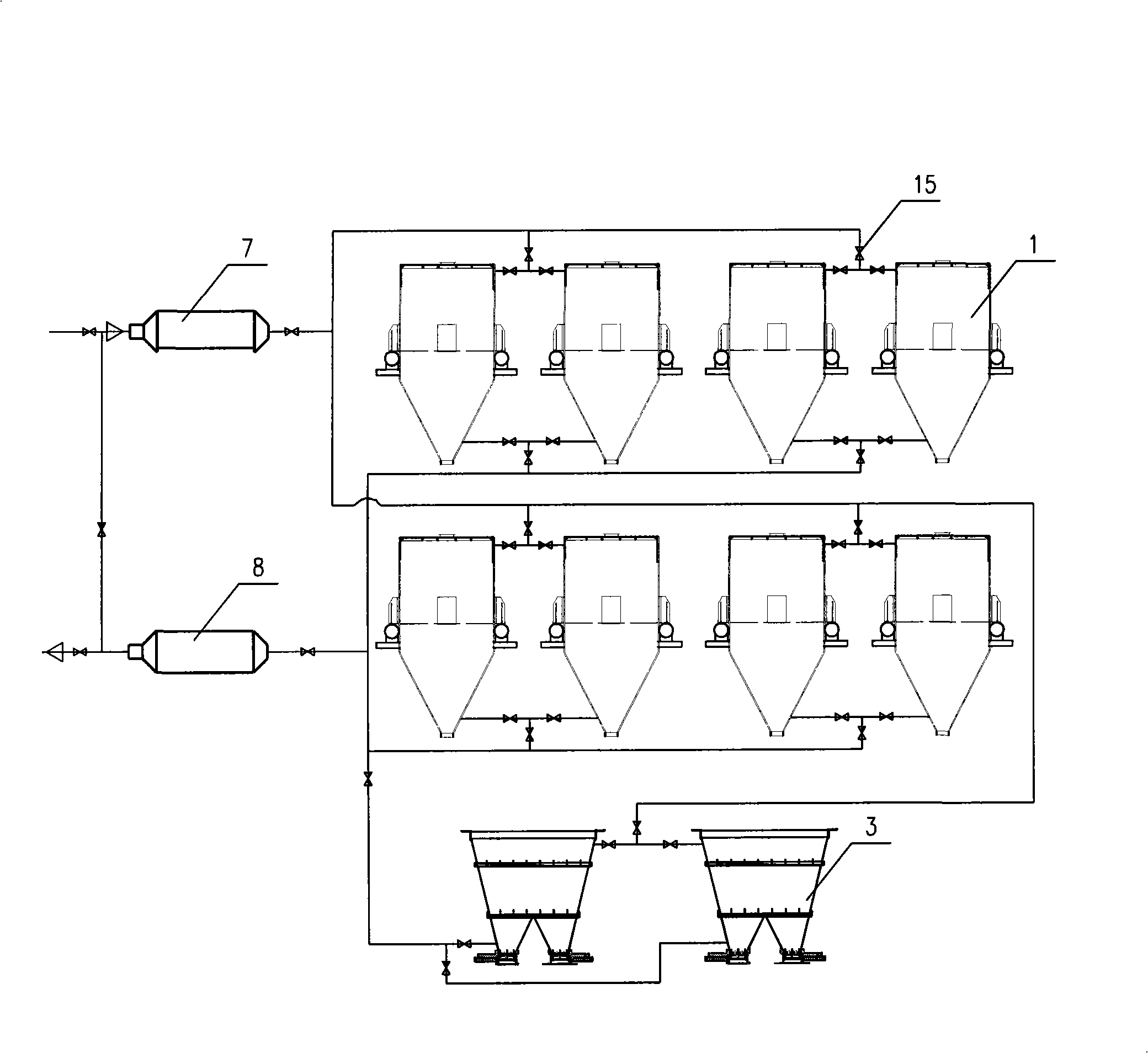

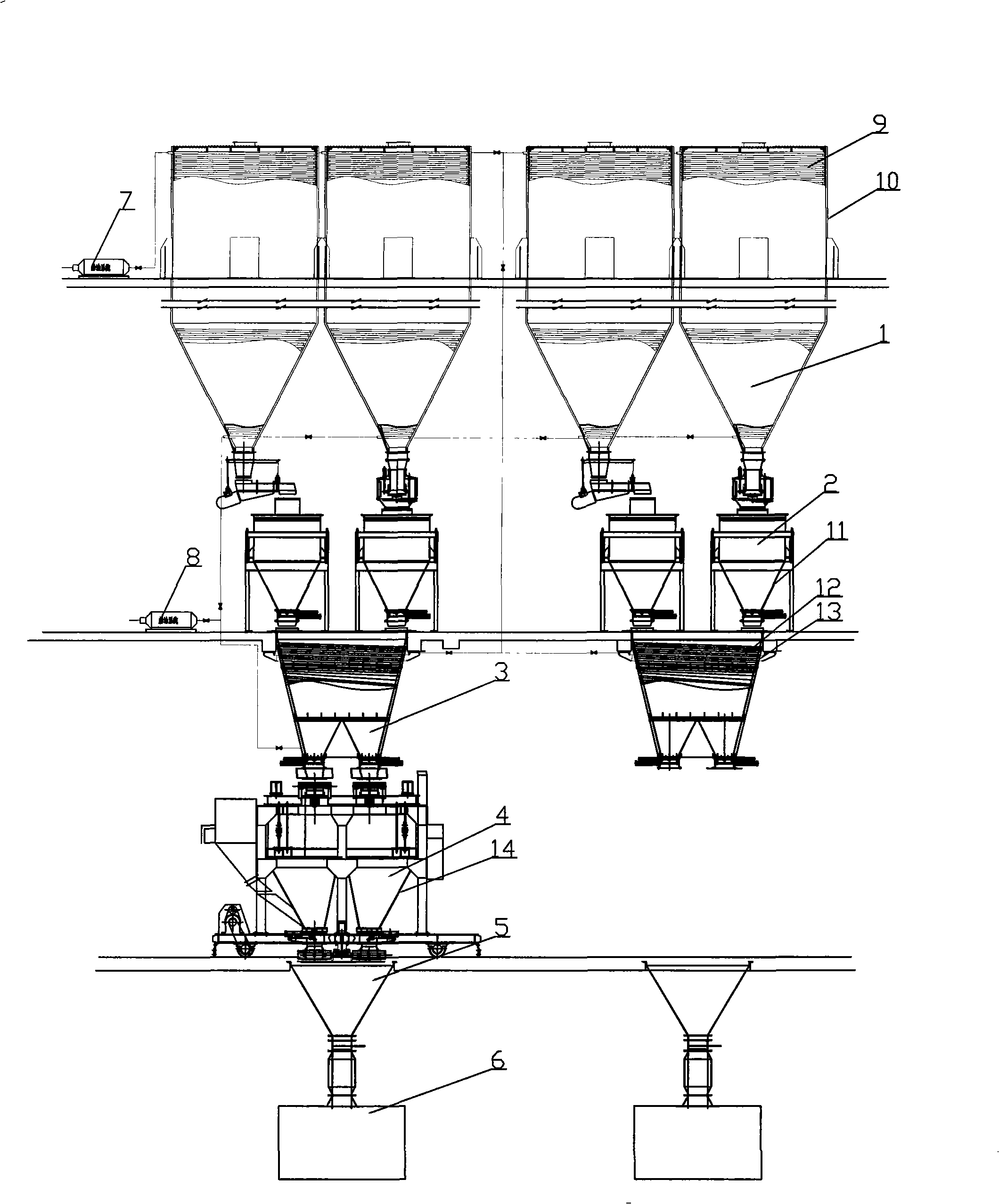

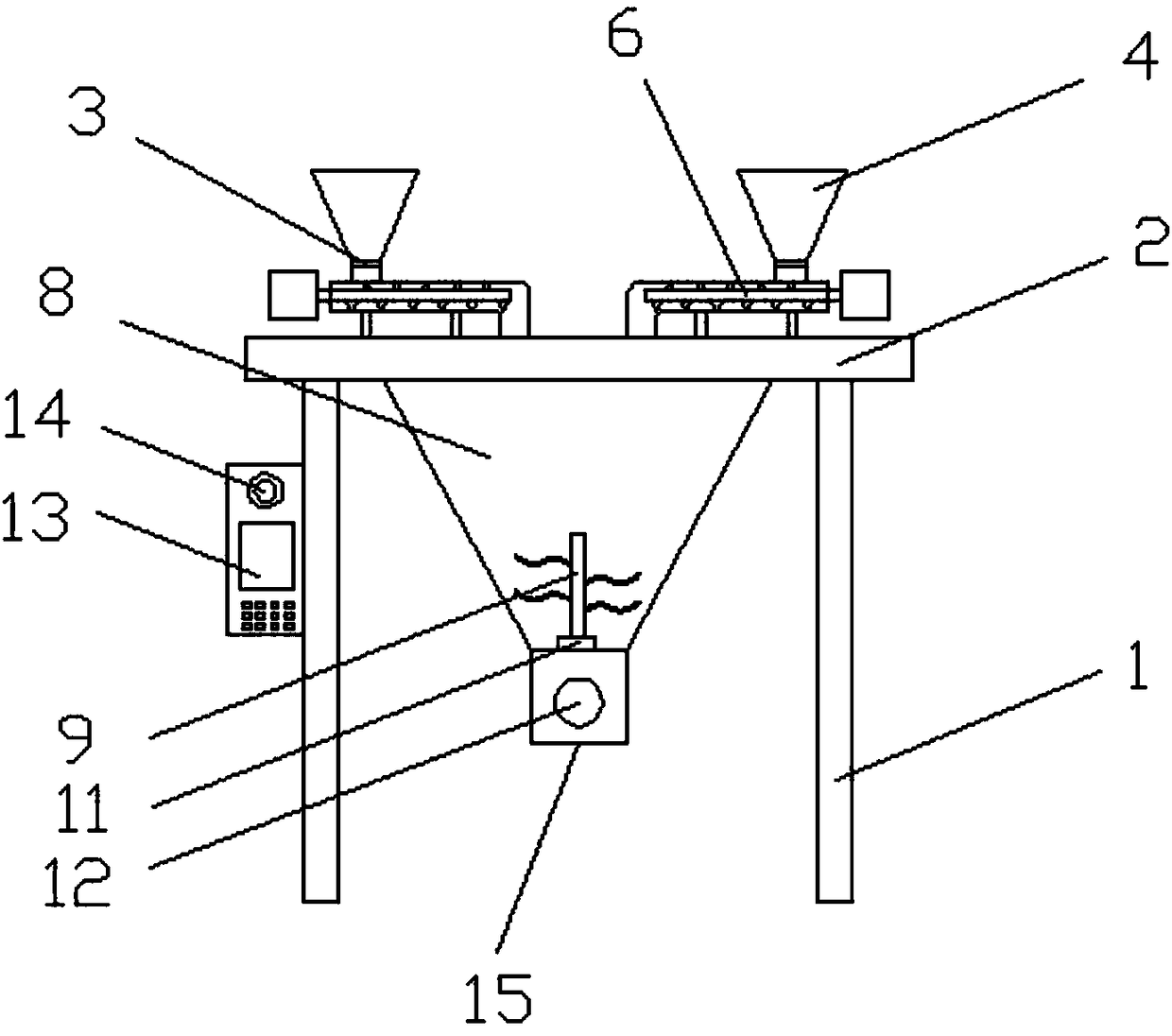

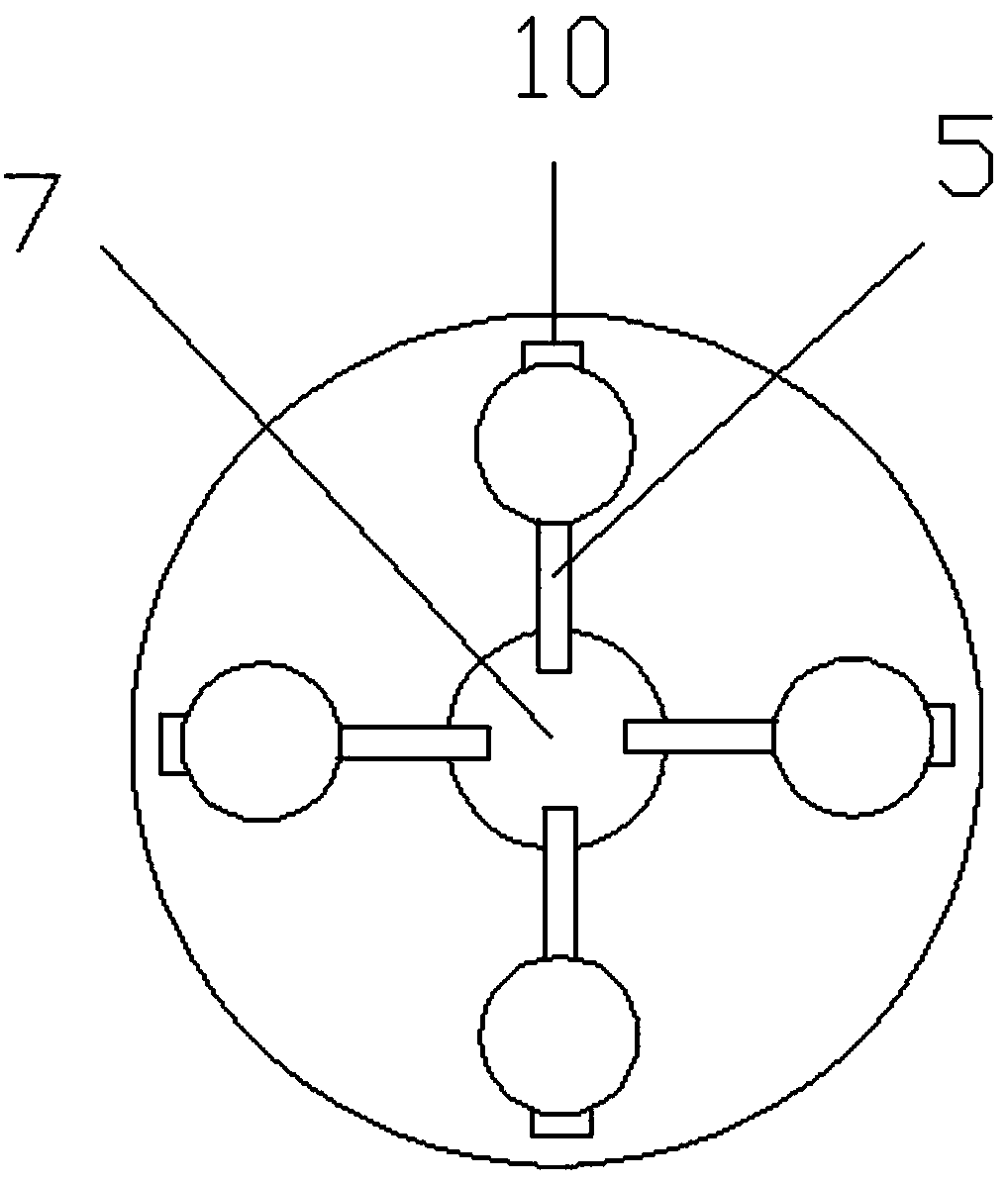

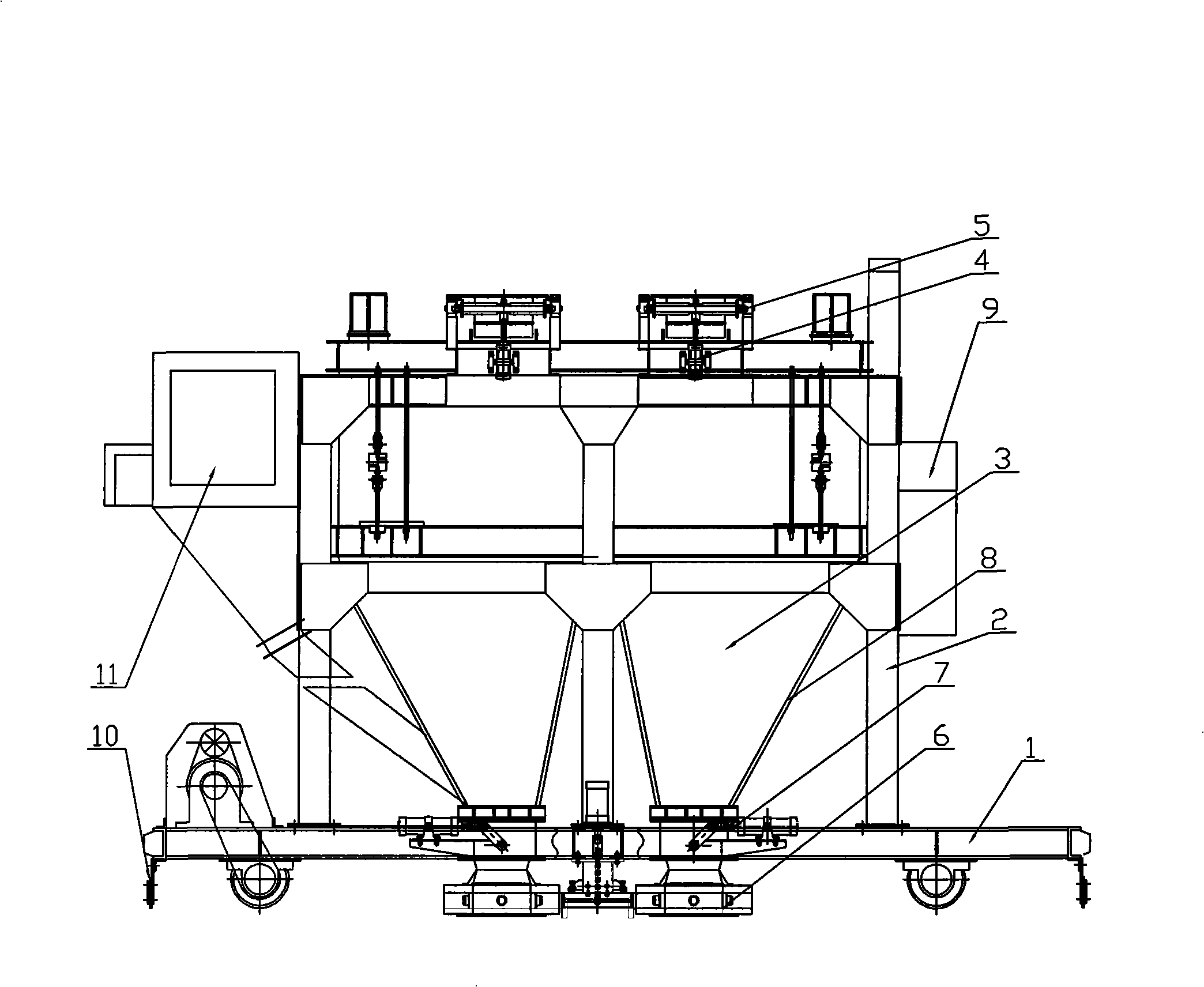

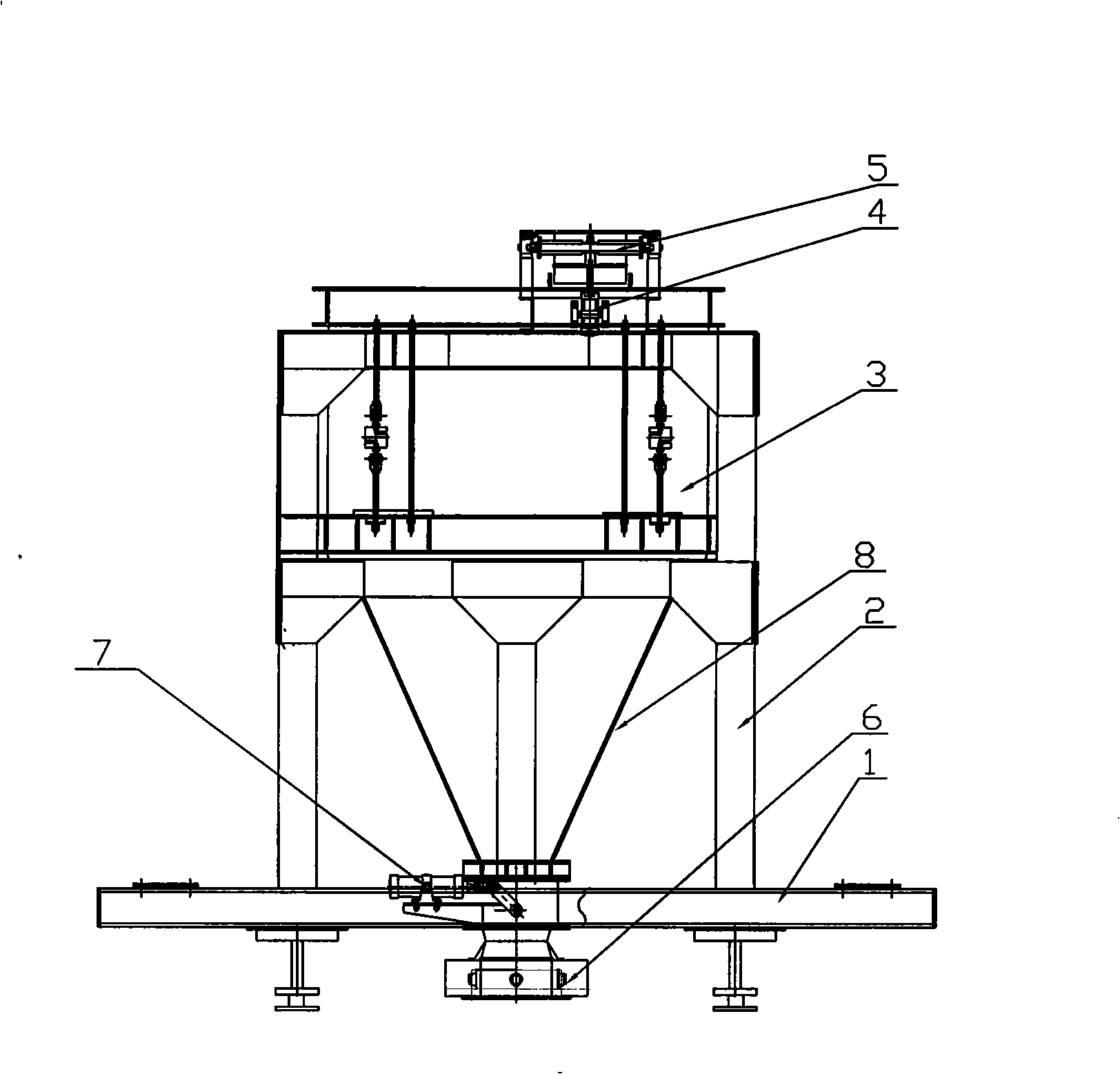

Carbon preheatable feed proportioning system

InactiveCN101348247ARealize fully enclosed productionRaise the preheat temperatureProcess engineeringTruck

The invention discloses a carbon material proportioning system, particularly relating to a carbon preheating and heat preservation material proportioning system. The new system comprises a preheating system, a proportioning bin, a batch scale, a batch truck, a collection hopper and a pugging pot feeding hopper, etc., wherein the preheating system can realize the preheating and heat preservation of materials by pipeline systems arranged in the proportioning bin and the collection hopper, the full closing production can be realized by a precise para position system arranged on the truck, so that the material proportioning time is greatly saved, and the material proportioning efficiency is improved; the materials are preheated, so that the dry mixing time of the materials is greatly saved, and the production capacity of a workshop is improved.

Owner:SHENYANG ALUMINIUM MAGNESIUM INSTITUTE

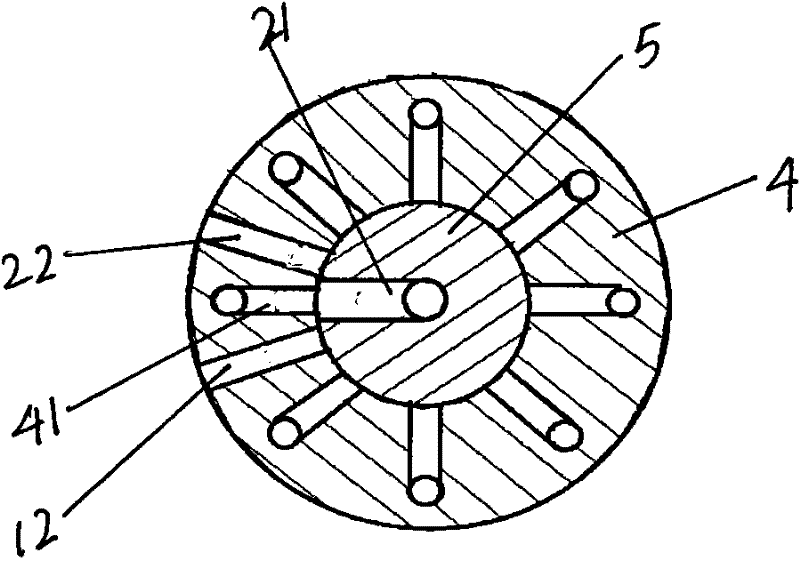

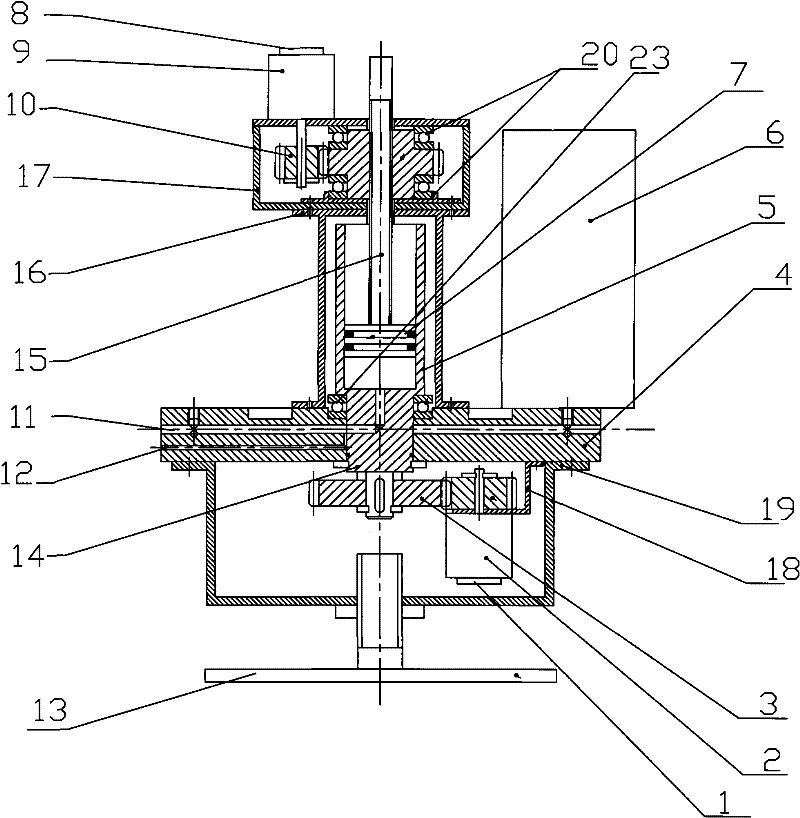

Material blending device for hazel grouse rapid reproduction feed

InactiveCN108065427AQuality assurancePrecise control of batching speedFeeding-stuffEngineeringDrive motor

The present invention discloses a material blending device for hazel grouse rapid reproduction feed. The material blending device for the hazel grouse rapid reproduction feed comprises weighing sensors, weighing material hoppers, screw feeders and a material blending workbench. The material blending workbench has a round structure, the bottom part of the material blending workbench is provided with three support columns at an equal interval arrangement in a same circumferential direction, a material blending through-hole is arranged at the center place of the material blending workbench, a material mixing hopper is arranged below the material blending through-hole and is welded at the bottom part of the material blending workbench, the screw feeders are arranged on the upper side of the material blending workbench, screw material pushing rods are arranged inside the screw feeders and connected with driving motors, and the weighing material hoppers are arranged on the screw feeders andprovided with the weighing sensors. The weighing sensors and a controller are used to drive rotations of the motors and can realize on-demand proportioning by the weighing material hoppers, the screwfeeders precisely control material blending speed, and each screw feeder independently controls operations, thereby improving weighing accuracy and material blending efficiency, and ensuring feed quality.

Owner:天津市华野生态养殖有限公司

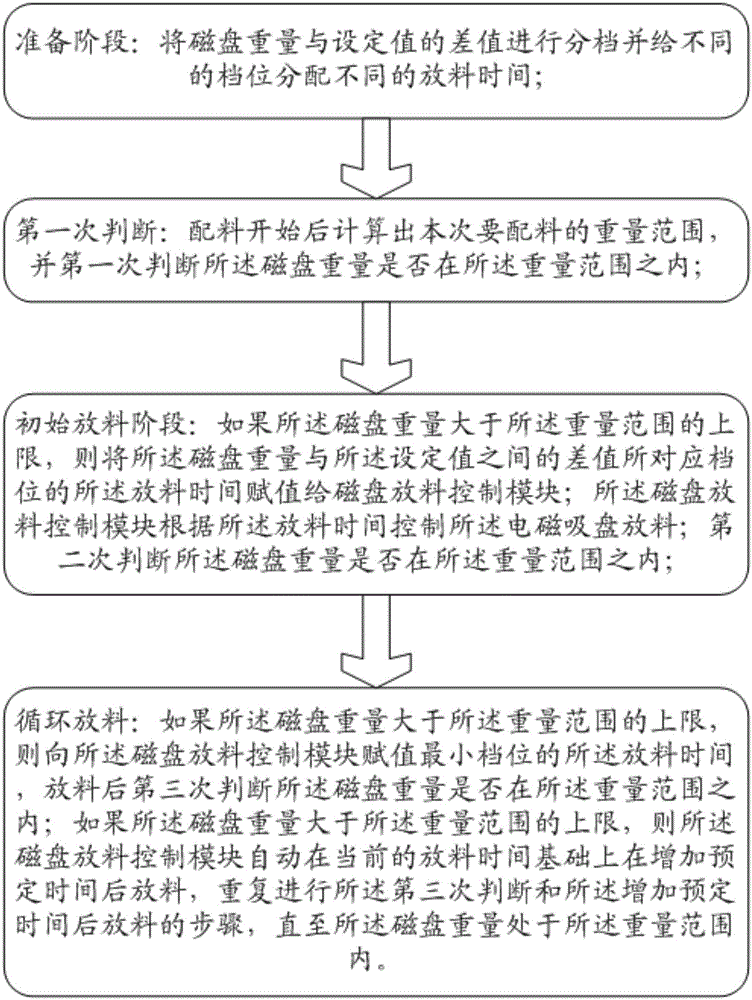

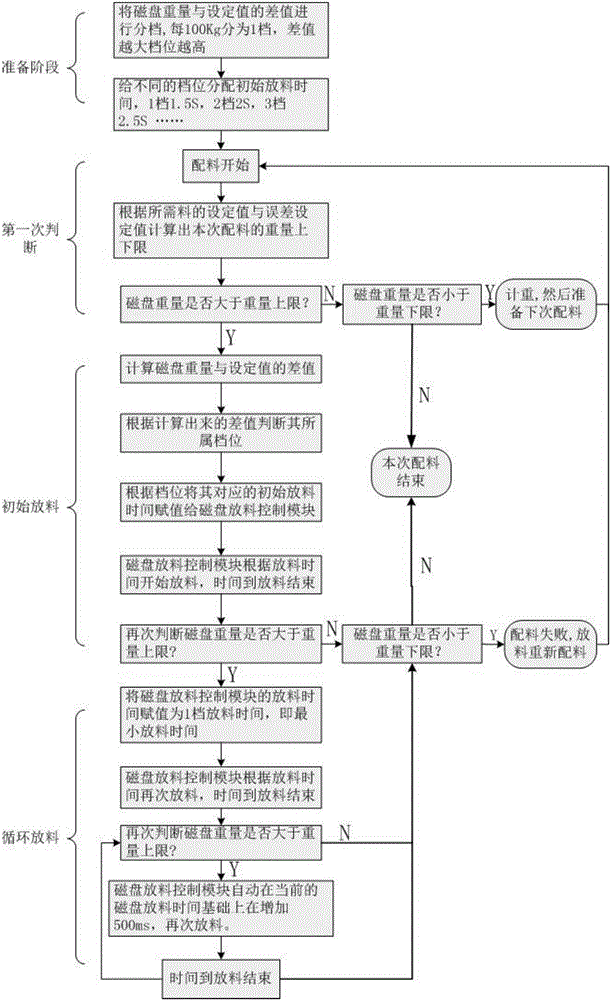

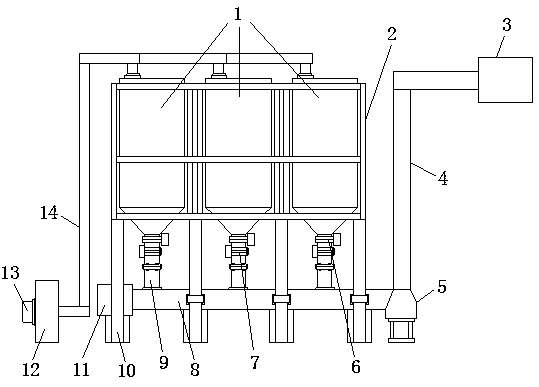

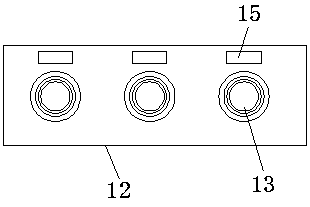

Burdening method based on electromagnetic chuck

ActiveCN106292508AShorten the timeImprove batching efficiencyProgramme control in sequence/logic controllersPreparation stageEnvironmental geology

The invention provides a burdening method based on an electromagnetic chuck. The method comprises the following steps: a preparation stage, primary judgment, initial feeding and circulating discharging. The invention aims at providing the burdening method based on the electromagnetic chuck. The burdening method is capable of realizing rapid and accurate burdening of the electromagnetic chuck.

Owner:NINGXIA KOCEL MOLD

Dispensing device for cement production and feeding structure thereof

InactiveCN110843133AAvoid errorsAvoid the situationMixing operation control apparatusIngredients proportioning apparatusProcess engineeringMechanical engineering

The invention discloses a dispensing device for cement production and a feeding structure thereof. The dispensing device comprises a plurality of ash cans, an ash conveying pipe is arranged below theash cans, the ash cans communicate with the ash conveying pipe through connecting pipes, and a feeding pipe is arranged at the upper right side of the ash conveying pipe and connected with the ash conveying pipe through an adapter box. The interior of the ash conveying pipe communicates with the feeding pipe through a cavity in the adapter box, the end, away from the adapter box, of the feeding pipe is provided with a negative-pressure supplying machine, conveying rollers are installed at the left and right ends inside the ash conveying pipe respectively, a conveying belt is installed on the conveying rollers at the left and right sides, and a power tank is connected to the left end of the ash conveying pipe. According to the dispensing device, since the ash cans loaded with different aggregates are utilized for separate supplying, during supplying, an electromagnetic flowmeter precisely controls the feeding amount, and the situation of errors existing in manual weighing and low efficiency is avoided. The aggregates which are fed in proportion are supplied into stirring equipment through the negative pressure supplying machine, automatic and accurate work control is achieved in thewhole process, and the dispensing efficiency is greatly improved.

Owner:常德金江水泥有限公司

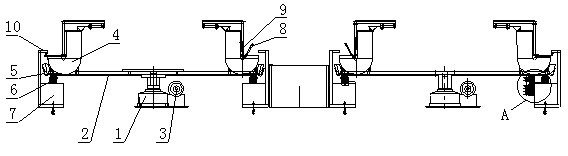

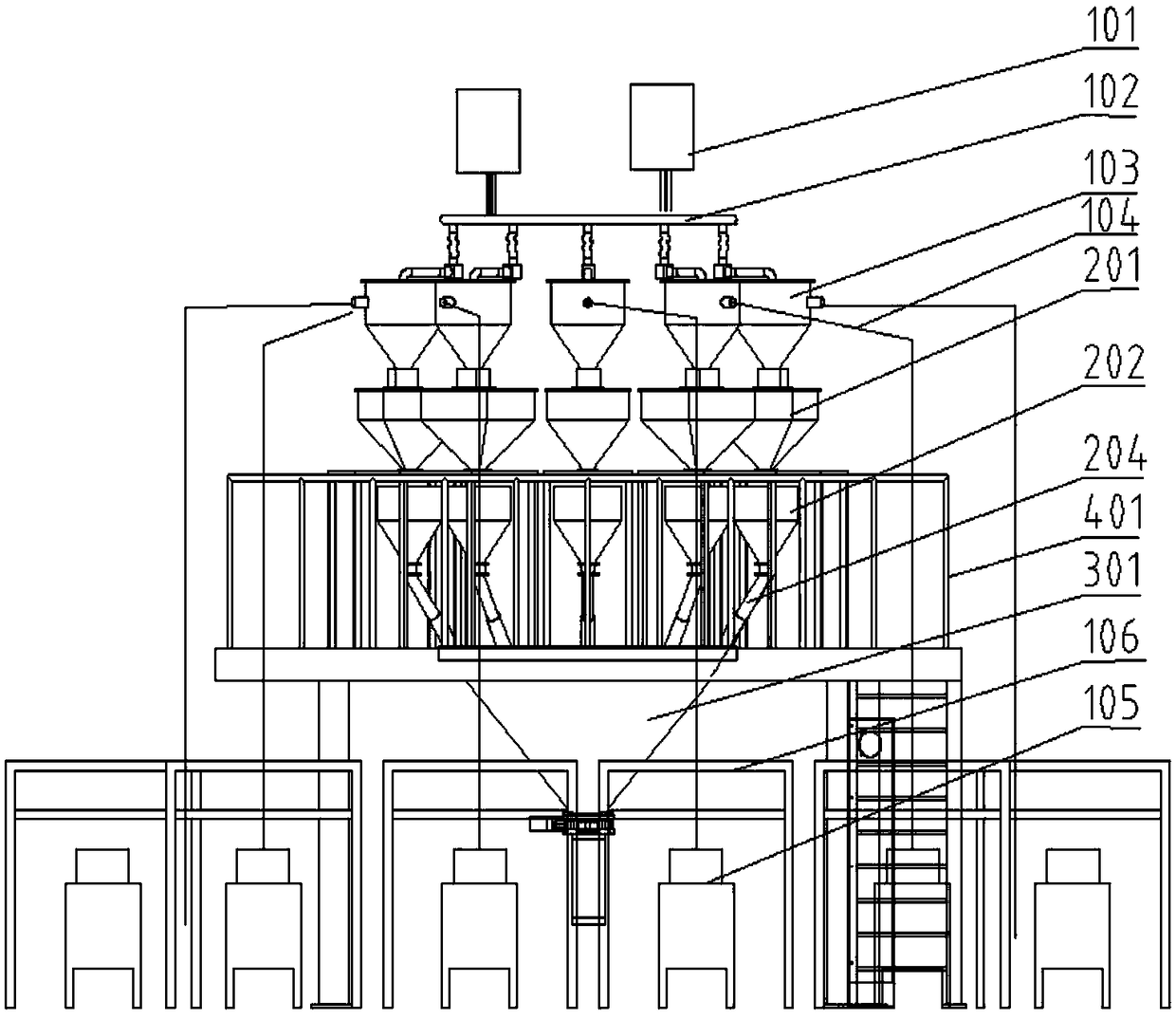

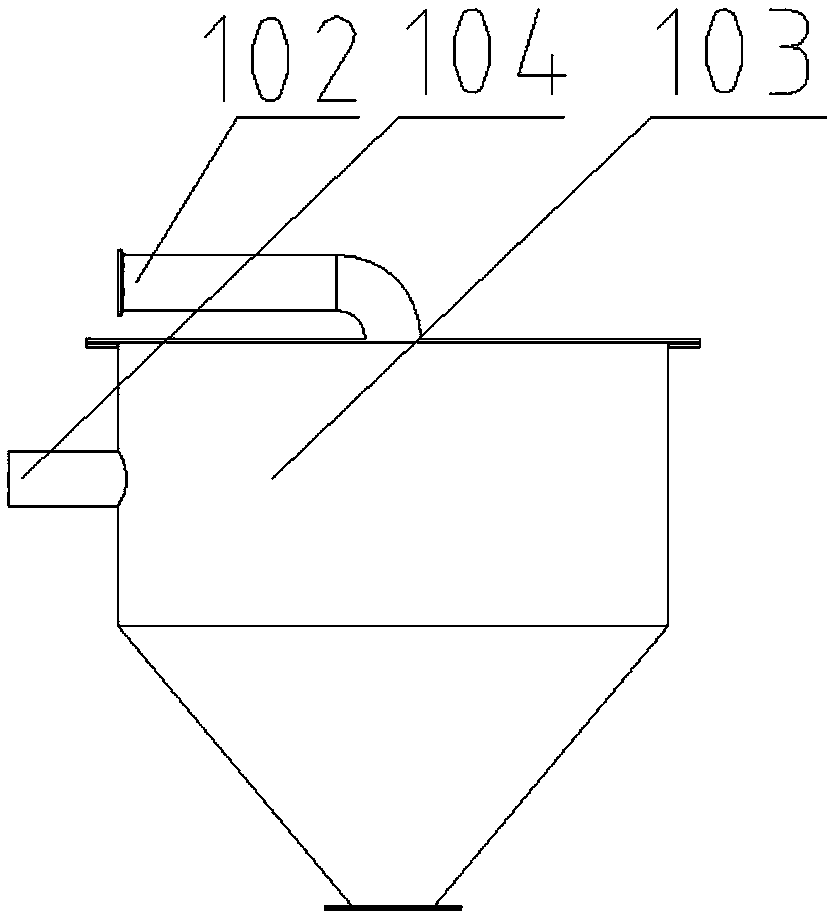

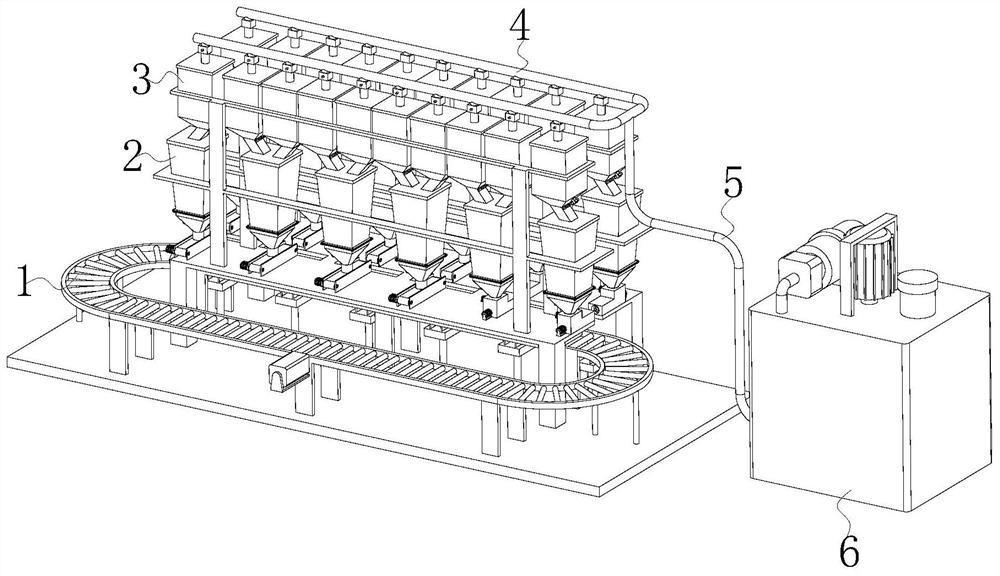

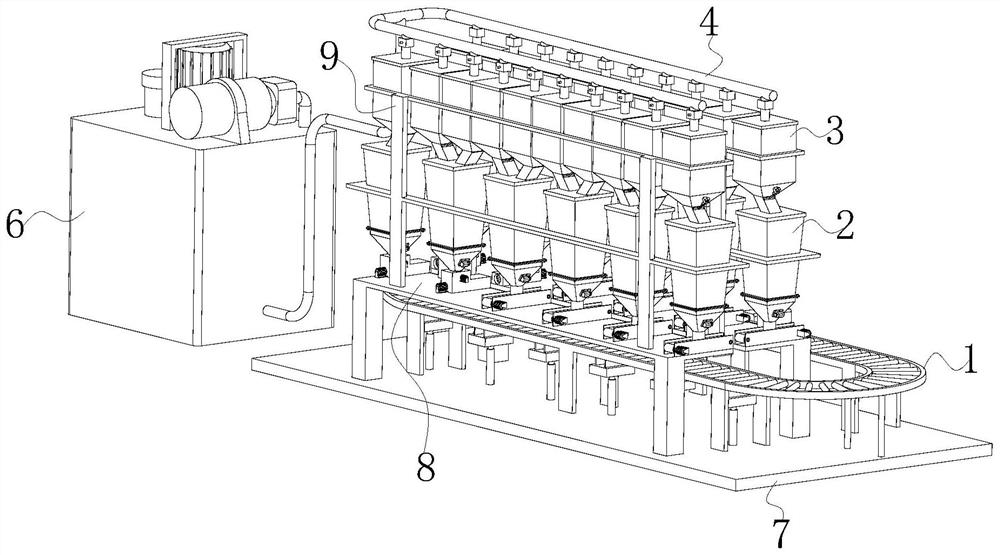

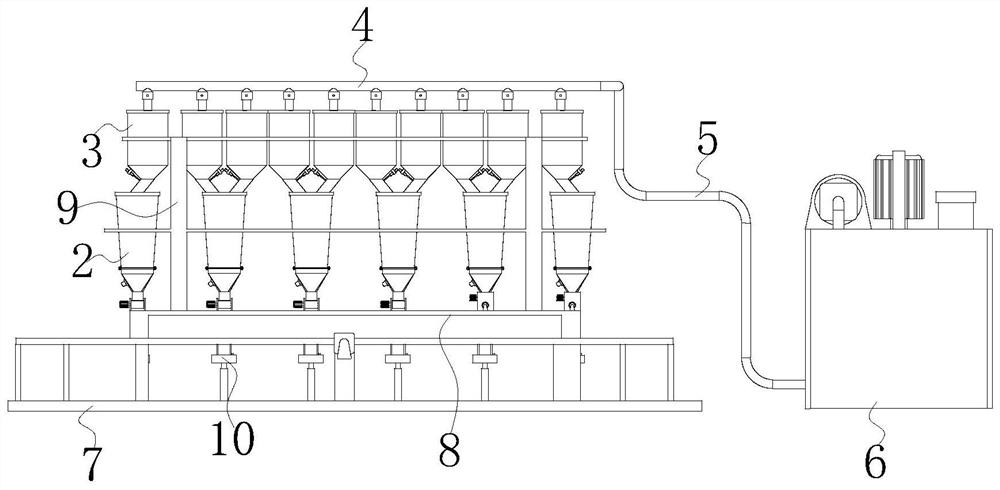

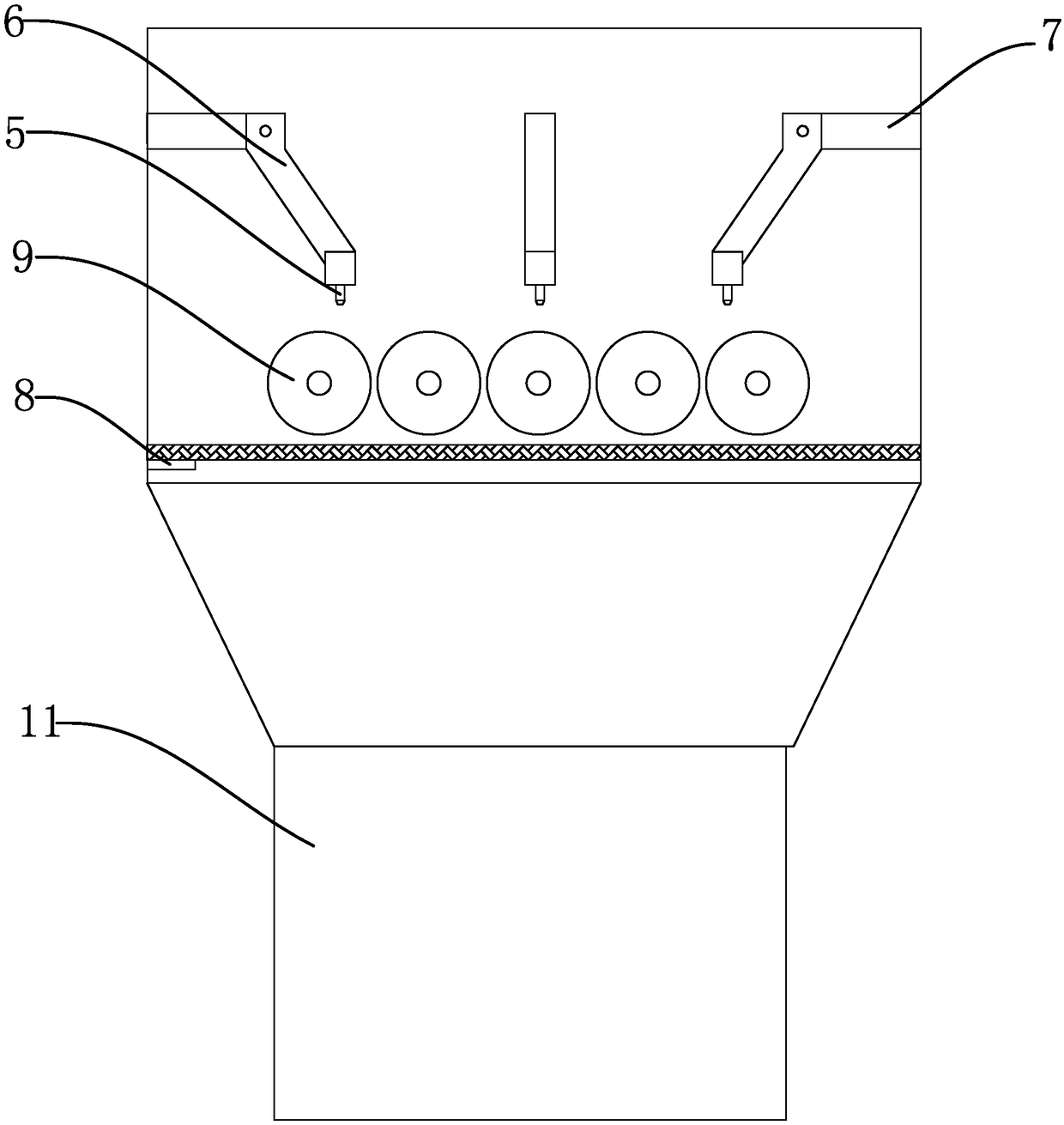

Automatic batching technological process and automatic batching machine

The invention discloses an automatic batching technological process and further discloses an automatic batching machine. The automatic batching machine comprises a conveying mechanism, feeding hoppers, storage hoppers and a negative pressure feeding mechanism, the conveying mechanism is integrally arranged in a rounded rectangle shape, and the two sets of feeding hoppers are symmetrically arranged on the two sides of the upper portion of one long side edge of the conveying mechanism; each set of feeding hoppers is composed of a plurality of feeding hoppers arranged in parallel in the conveying direction of the conveying mechanism, and meanwhile a plurality of storage hoppers are further arranged above each set of feeding hoppers in parallel in the conveying direction of the conveying mechanism; and the feeding hoppers and the storage hoppers are fixedly connected to the inner side of a mounting frame. According to the automatic batching machine, through the arrangement of the feeding hoppers, the storage hoppers, a weighing device, a discharging auxiliary device, a hydraulic cylinder and an infrared distance measuring sensor, when the batching machine is used, the automation degree is high, the production efficiency is effectively improved, meanwhile, the batching variety of the batching machine is rich, and the practicability is high.

Owner:江门市新会区发达运动用品有限公司

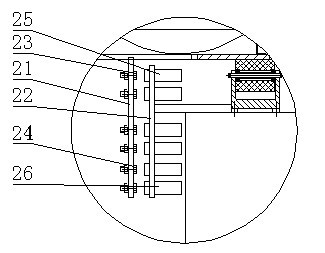

Batching device for seasoning powder bag production, and implementation method thereof

InactiveCN112263925AAvoid ingredient interruptionsImprove batching efficiencyRotary stirring mixersTransportation and packagingProcess engineeringBLENDER/MIXER

The invention discloses a batching device for seasoning powder bag production, and an implementation method thereof, belonging to the technical field of seasoning powder bag production. The batching device comprises a storage tank A, a storage tank B and a storage tank C, wherein the storage tank A, the storage tank B and the storage tank C are connected with a weighing chamber A, a weighing chamber B and a weighing chamber C through guide pipes correspondingly; discharging pipes are arranged at the lower ends of the weighing chamber A, the weighing chamber B and the weighing chamber C, discharging valves are installed on the discharging pipes, and the weighing chamber A, the weighing chamber B and the weighing chamber C are connected with a stirring tank through the discharging pipes; a stirring mechanism is installed on the stirring tank; and a shaking mechanism is installed at the upper end of the stirring tank and shakes the discharging pipes. According to the batching device for seasoning powder bag production and the implementation method of the batching device, ingredients of seasoning powder bags are accurate in batching and good in mixing effect, the discharging pipes areshaken through the shaking mechanism, so no raw material is left in the discharging pipes, batching interruption caused by the fact that the discharging pipes are blocked by the raw materials can be effectively avoided, and batching efficiency can be improved.

Owner:HEXIAN COUNTY JILONGSHAN CONDIMENT

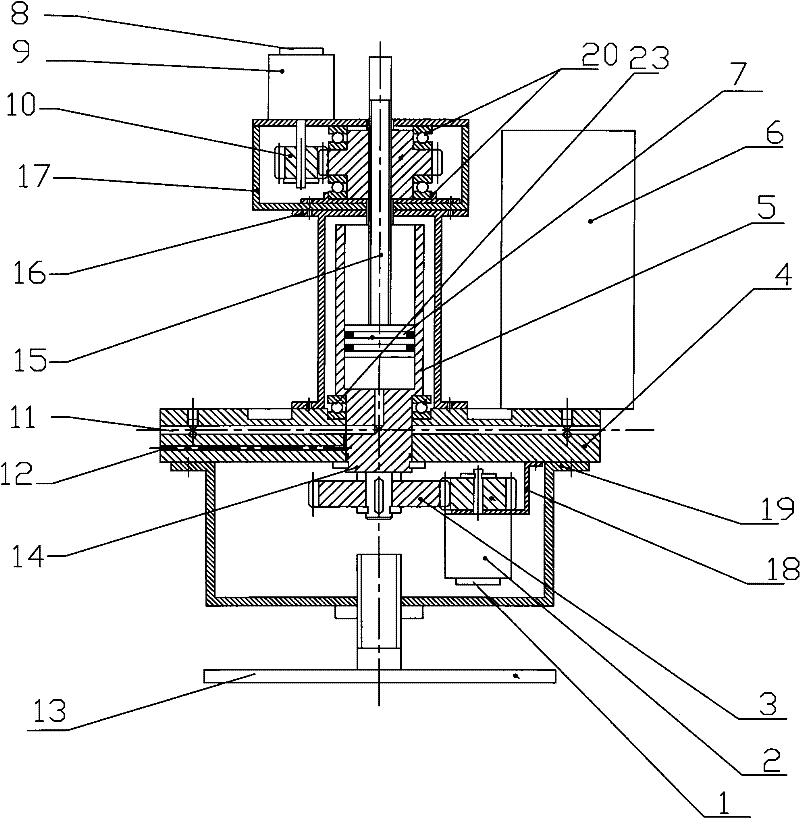

Automatic seasoning system

InactiveCN101843455BOvercome precisionSolve the problem of automatic and accurate batchingKitchen equipmentDrive motorEngineering

The invention discloses an automatic seasoning system, which comprises a first drive motor, a first gear transmission pair, a tray, a metering cylinder, a storage tank, a piston, a second drive motor, a second gear transmission pair, a charging channel, a discharging channel, a base, a syringe, and a piston rod. A driving gear of the first gear transmission pair is connected with an output shaft of the first drive motor; an internal thread is arranged in a driven gear of the second gear transmission pair; an external thread is arranged at the upper end of a piston rod; the upper end of the piston rod which is provided with the external thread is inserted into the driven gear of the seond gear transmission pair to form a screw transmission pair; the piston is fixedly arranged at the lower end of the piston rod and arranged in the metering cylinder; the end part of the metering cylinder is provided with a syringe which is arranged on the tray; the syringe is connected with a rotating shaft of the driven gear in the first gear transmission pair; a driving gear of the second gear transmission pair is connected with an output shaft of the second drive motor; the tray is provided with a feed channel, a discharge channel and an air inlet passage; the feed channel which is arranged on the tray is communicated with the storage tank; the syringe is provided with a suction channel which can be communicated with the feed channel and the discharge channel; and the tray is arranged on a base. The automatic seasoning system has the advantages of simple use and maintenance, high reliability, simple control and high distribution efficiency.

Owner:广州奥特佳数控系统有限公司

Carbon environmental protecting type burden charging carriage

InactiveCN101347962AImprove environmental performanceReduce the chance of errorMixing operation control apparatusMixer accessoriesInsulation layerEngineering

The invention relates to a carbon environmentally-friendly burden charging carriage which comprises a platform trolley, a fixed support, a collection storage hopper, a feeding opening and a discharge opening. An insulation layer is arranged on the outer wall of collection storage hopper. The feeding and discharge openings are provided with a feeding pushing device and a discharge pushing device. A positioning sensor is respectively arranged at the two ends of the platform trolley; a dust catcher and a control box are arranged at the outer side of the fixed support. The dust collecting mouth of the dust catcher is communicated with the feeding and discharge openings. The invention realizes the wholly confined production of the feeding and discharge of the trolley,. Therefore, the secondary pollution is reduced, the eco-friendly effects of blending are greatly increased, and the probability of incorrect blending and blending time are reduced, thus improving the blending efficiency; at the same time, the insulation layer arranged on the outer wall of the collection storage hopper can reduce the heat loss of raw materials to the minimum, thus increasing the wet ability of the combination of the raw materials and liquid asphalt.

Owner:SHENYANG ALUMINIUM MAGNESIUM INSTITUTE

Material allocation mechanism of material allocation device

The invention provides a material allocation mechanism of a material allocation device, and belongs to the technical field of machinery. The problem that material allocation quality is low in the prior art is solved. The material allocation mechanism of the material allocation device comprises a base and a machine frame fixed on the base, the material allocation mechanism is arranged on the machine frame and comprises a material allocation hopper, a feeding port is formed in the top of the material allocation hopper, and a feeding structure is arranged at the feeding port; the feeding structure comprises a plurality of feeding pipes and a plurality of material storage boxes, the feeding pipes communicate with the material storage boxes in a one-to-one corresponding manner, and the materialstorage boxes are fixed on the machine frame, and the feeding pipes are connected with material spray heads; an electromagnetic valve I and a metering valve are further arranged on each feeding pipe,the material spray heads are fixed on swing arms, and mounting frames are further fixed in the material allocation hopper; and rotating shafts are arranged at the upper ends of the swinging arms, therotating shafts are hinged to the mounting frame, motors 7 are further fixed on the mounting frame, and output shafts of the motors 7 are connected with the rotating shafts. The material allocation mechanism of the material allocation device has the advantage of improving material allocation quality.

Owner:海宁市冲达机械设计有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com