Carbon preheatable feed proportioning system

A batching system and heating system technology, which is applied in the field of carbon preheatable batching systems, can solve the problems of lowering production efficiency, restricting the production of carbon blocks in carbon factories, and taking a lot of time, so as to improve workshop production capacity and reduce dry mixing time. , the effect of reducing the batching time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited by the embodiments.

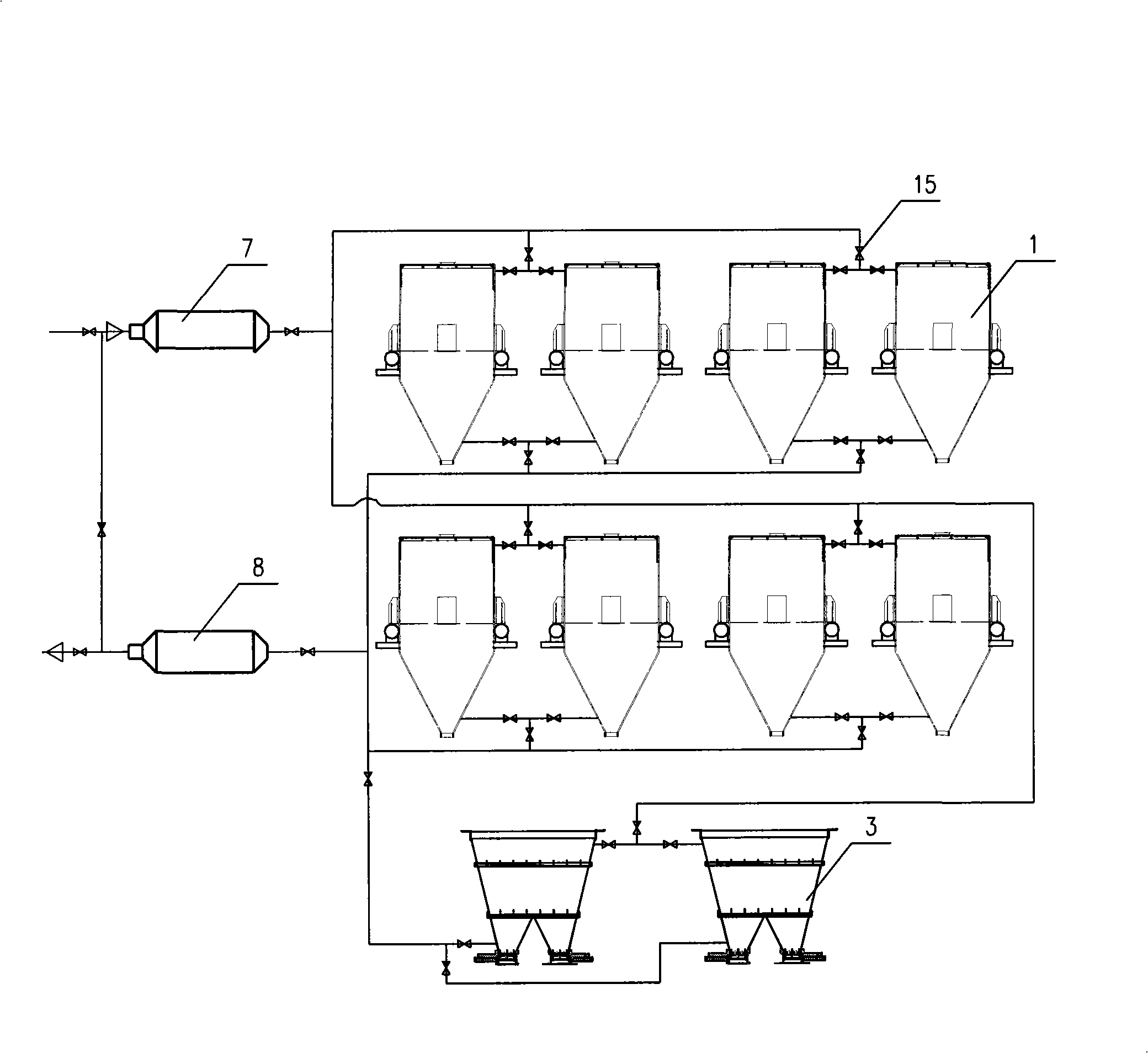

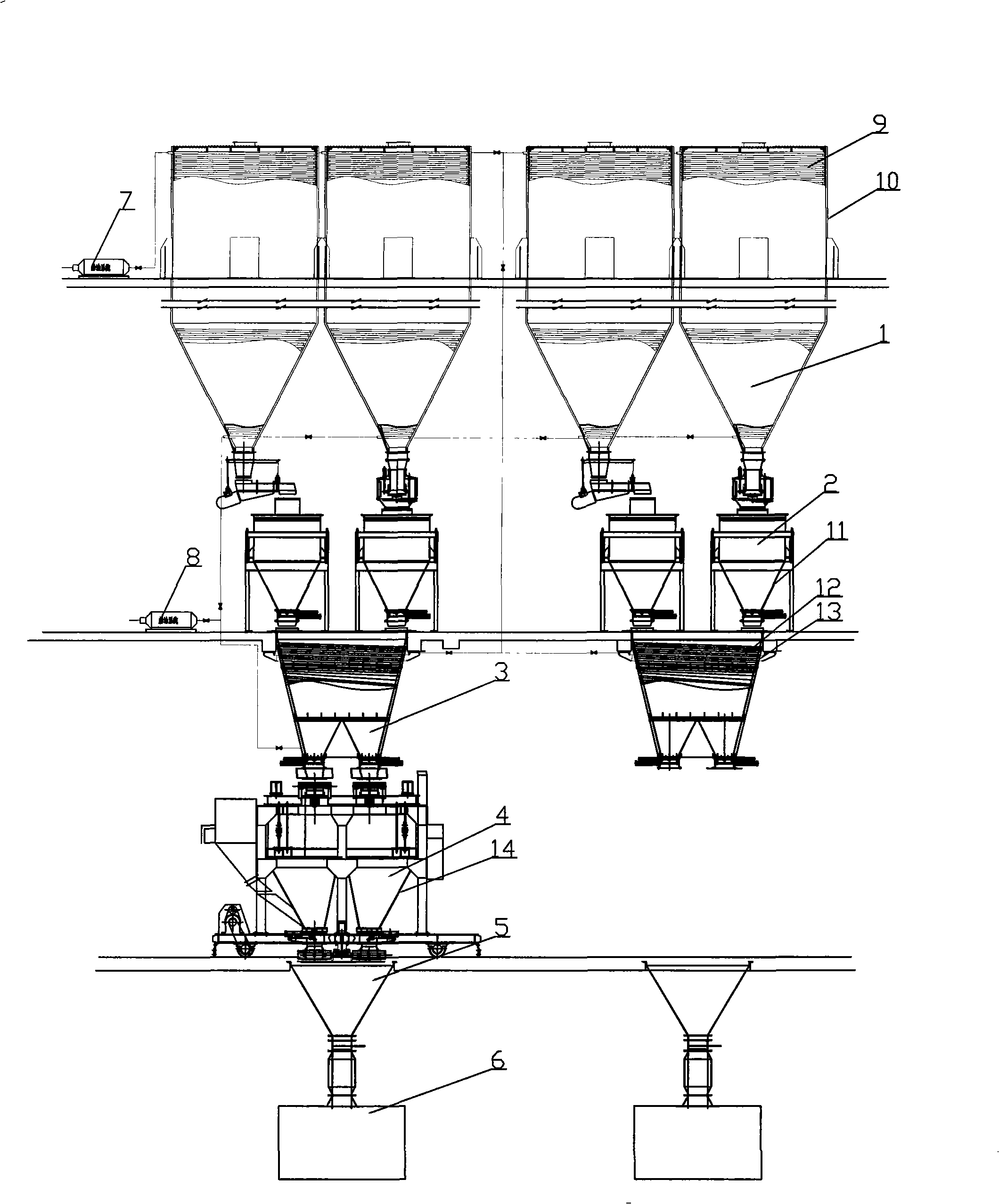

[0025] Such as figure 1 with figure 2 Shown: the structure of the carbon preheating batching system of the present invention is as follows: it includes a batching bin 1, a collection hopper 3, a batching scale 2, a batching car 4 and a kneading pot 6, wherein a set of batching bin 1, collection hopper 3 is added The fully closed circulation heat conduction oil heating system for heating with batching scale 2 realizes the preheating of raw materials. The batching scale insulation layer 11, the batching truck 4 outer wall is provided with the batching truck insulation layer 14;

[0026] The fully closed cycle heat transfer oil heating system consists of an oil supply system 7, an oil discharge system 8, a heating pipeline and a gate valve 15. The oil supply system...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com