Patents

Literature

63results about How to "Shorten batching time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Reducing the telogenic behavior of hydrocarbon-containing surfactants in aqueous dispersion fluoromonomer polymerization

ActiveUS9074025B2Reduce telogenic behaviorReduce impactOrganic-compounds/hydrides/coordination-complexes catalystsFibre treatmentPolymer scienceFluoropolymer

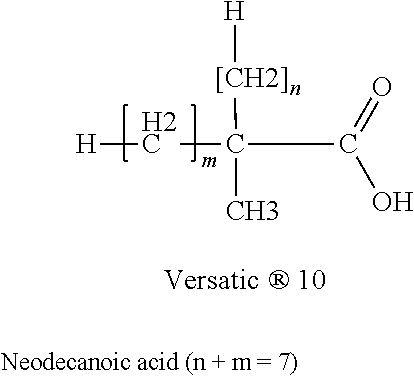

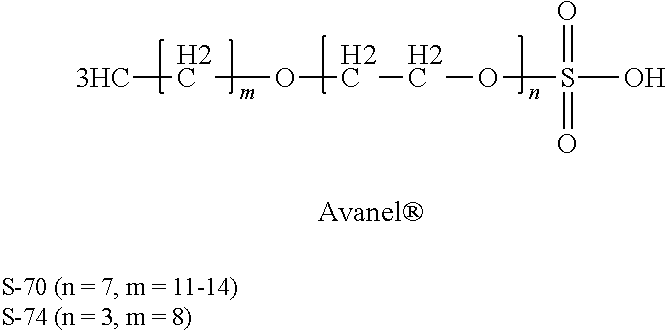

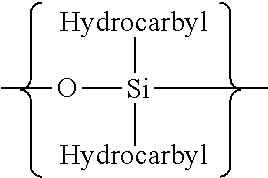

A polymerization process is provided, comprising polymerizing fluoromonomer in an aqueous medium to form a dispersion of fluoropolymer particles in the aqueous medium, said polymerizing being carried out in the presence of (i) polymerization initiator, and (ii) hydrocarbon-containing surfactant stabilizing the dispersion of fluoropolymer particles, the hydrocarbon-containing surfactant being passivated to reduce its the telogenic behavior.

Owner:THE CHEMOURS CO FC LLC

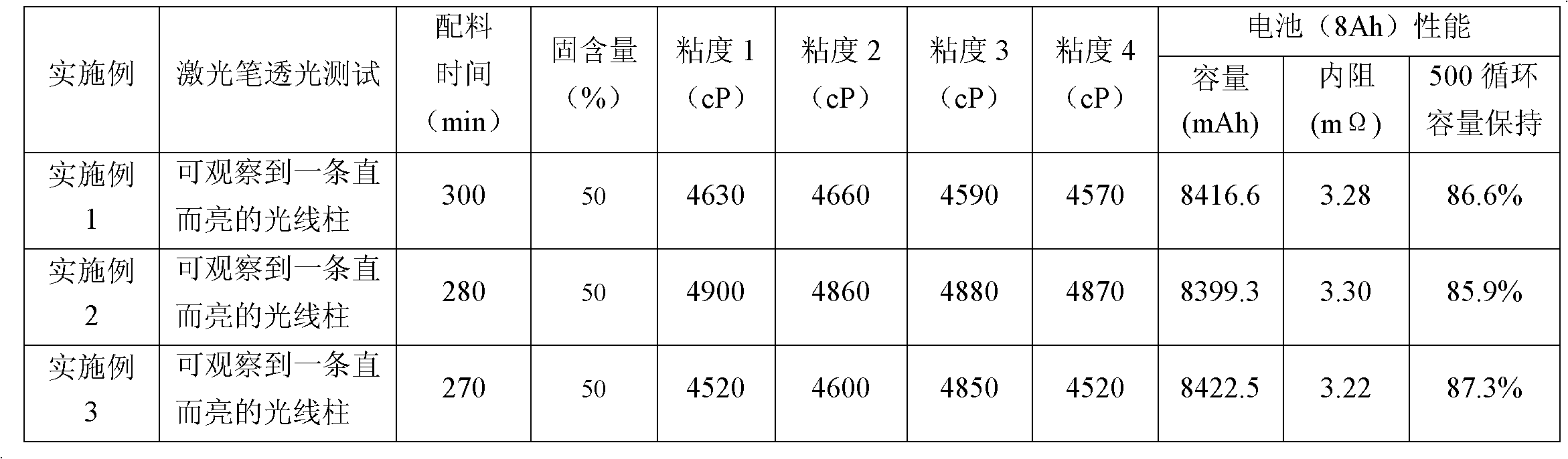

Preparation process of lithium ion battery negative paste, lithium ion battery negative pole plate and lithium ion battery

ActiveCN108305987AEvenly dispersedQuality improvementElectrode manufacturing processesElectrode carriers/collectorsPhysical chemistrySodium-ion battery

The invention belongs to the technical field of a lithium ion battery, and relates to a preparation process of lithium ion battery negative paste, a lithium ion battery negative pole plate and a lithium ion battery. The preparation process of the lithium ion battery negative paste comprises the following steps of (a) mixing a negative active substance, a conductive additive, a dispersion agent anda thickening agent in a dried way to obtain mixed powder; (b) adding a solvent, performing uniform mixing to obtain primary paste with solid content being 67-69wt%; (c) adding the solvent again, performing uniform mixing to obtain secondary paste with solid content being 58-62wt%; (d) adding the solvent again, performing uniform mixing to obtain third paste with solid content being 54-56wt%; and(e) adding a binding agent into the third paste, and performing uniform mixing to obtain the lithium ion battery negative paste. The process is simple and is easy to operate, the preparation time canbe remarkably prepared, the equipment utilization ratio is improved, meanwhile, the mixing is uniform, and the dispersion performance, the consistency and the fineness of the paste are improved.

Owner:BEIJING NAT BATTERY TECH

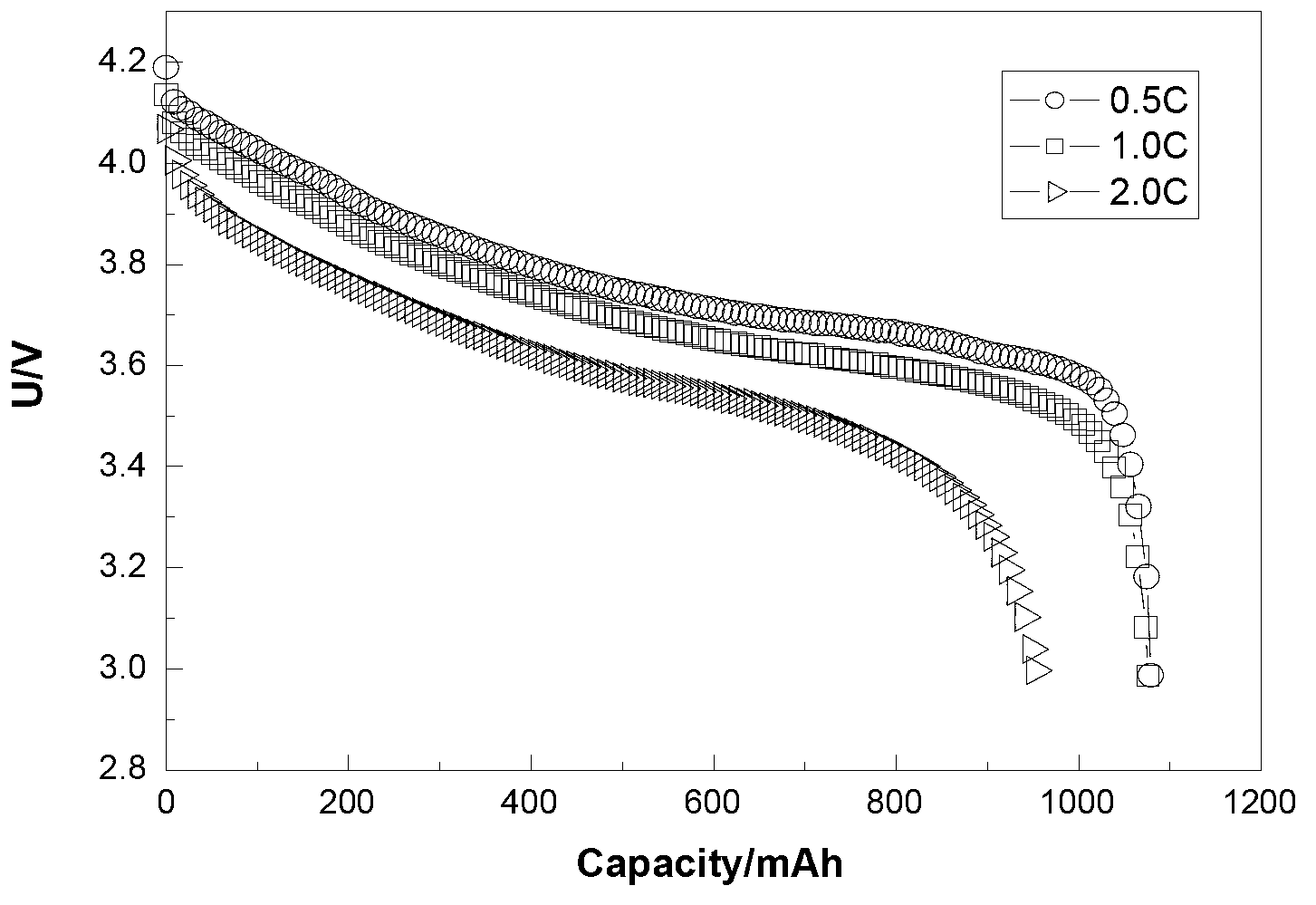

Quick-charging polymer lithium ion battery based on carbon-based nanometer materials

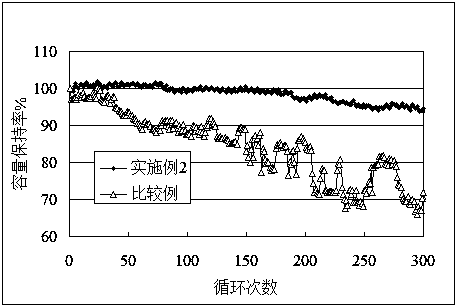

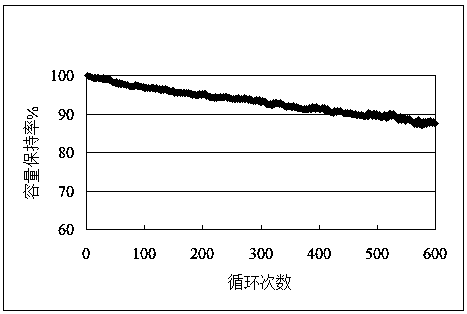

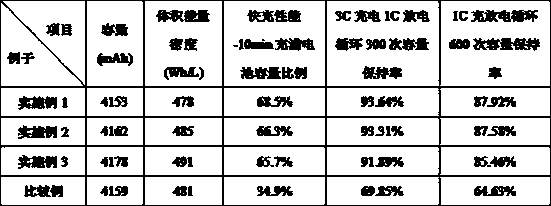

ActiveCN108269973AWell mixedShorten batching timeCell electrodesSecondary cellsCarbon based nanomaterialsMass ratio

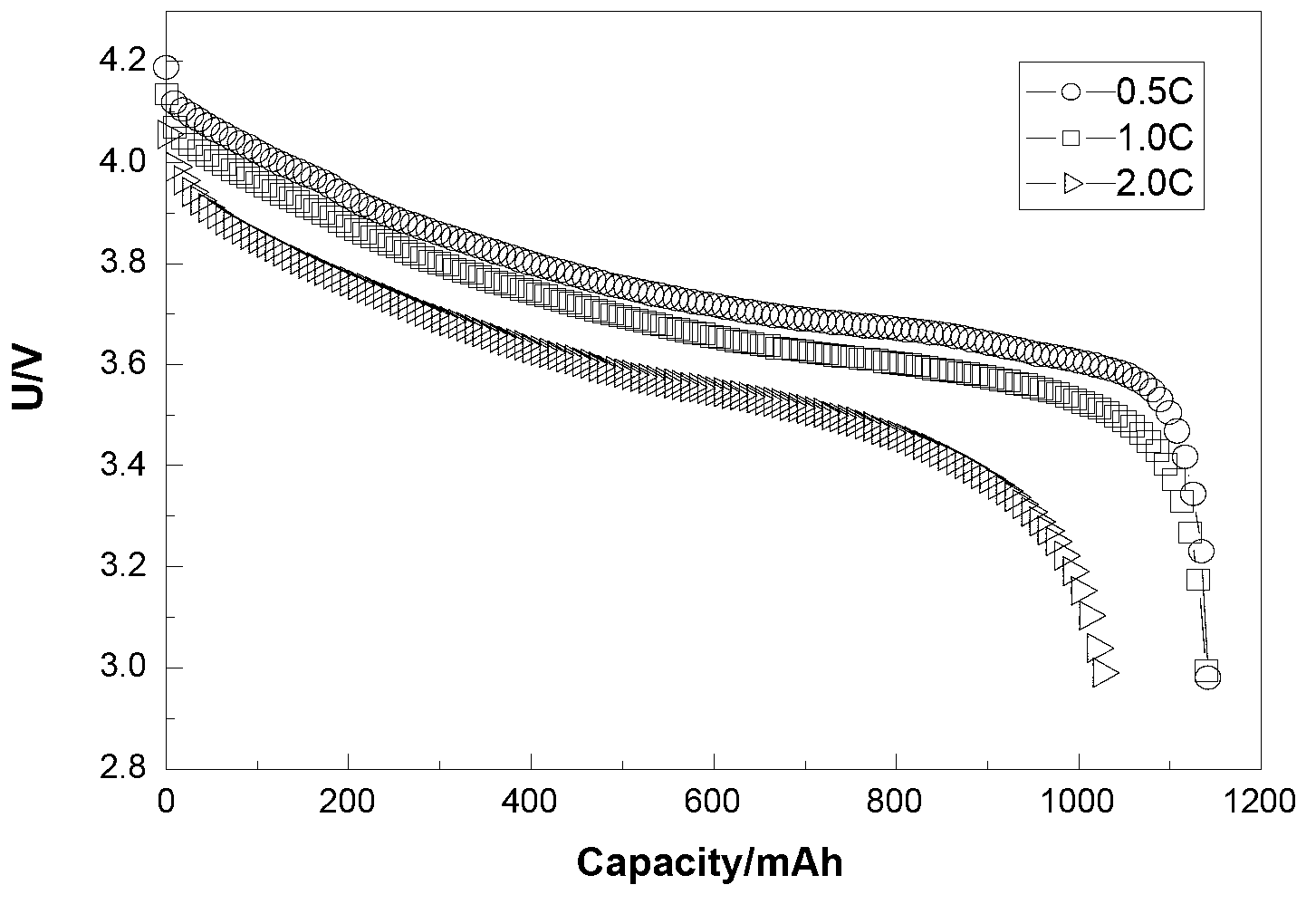

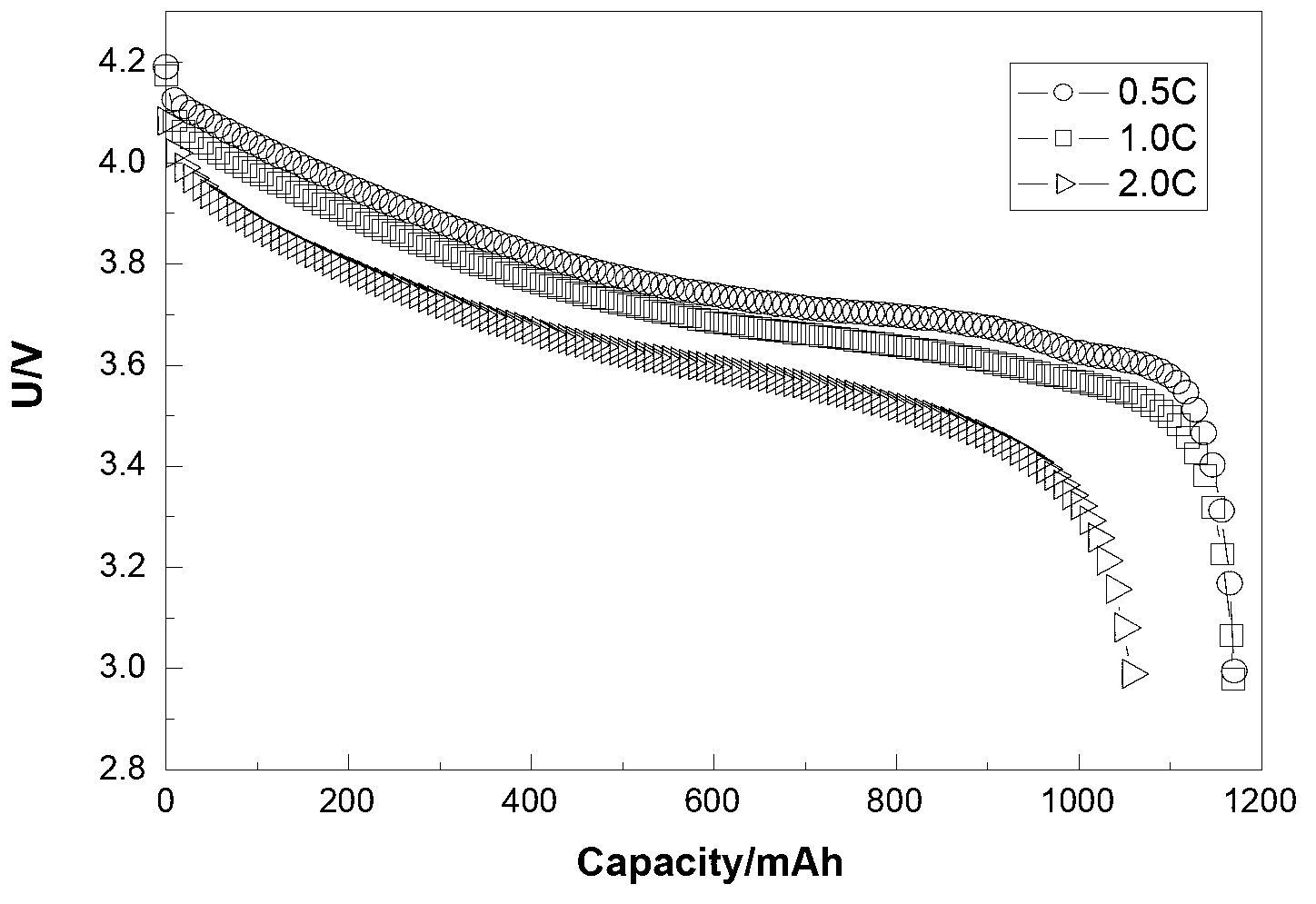

The invention discloses a quick-charging polymer lithium ion battery based on carbon-based nanometer materials. An anode sheet of the battery is prepared by mixing anode active substances, carbon-based nanometer material graphene / carbon nanotube compound conductive agents, conductive graphene and PVDF according to a certain mass ratio, adopting an NMP as a solvent, conducting pulping by means ofa sand mill with zirconium beads and a vacuum high-speed blender and then coating aluminum foil with obtained pulp. A cathode sheet is prepared by mixing cathode active substances, carbon-based nanometer material graphene / carbon nanotube compound conductive agents, nanoscale conductive carbon black, CMC and SBR according to a certain mass ratio, adopting deionized water as a solvent, conducting pulping and coating a copper foil current collector with obtained pulp. The anode sheet and the cathode sheet are wound with a partition membrane, packaged, injected with liquid, formed by a high-temperature fixture and subjected to air exhaust, volume distribution and the like, and then the quick-charging polymer lithium ion battery is obtained. The volume energy density of the battery is 460 Wh / Lor above, the battery capacity can be charged to 60% or above within 10 min, and the battery has excellent 3C charging performance, great 1C discharging fast-charge cycling performance and remarkable1C charge-discharge cycling performance.

Owner:江西格林德能源有限公司

Process for the manufacture of a grease composition

ActiveUS20130157907A1Vent time shortenedEfficient preparationTransportation and packagingMixingComposition processSlurry

Processes for the manufacture of metal complex grease compositions are provided. In one embodiment, the process comprises: preparing a slurry comprising a base oil, water, a metal base and a complexing agent, wherein the weight ratio of water:solid in the slurry is in the range of from 0.15:1 to 1.5:1; applying shear to the slurry; adding a C10-C24 saturated or unsaturated fatty acid or derivative thereof to effect a saponification reaction; removing water from the saponified product; heating the saponified product at a temperature in the range of from 190 to 230° C.; and subsequently cooling the product to a temperature in the range of from 200 to 150° C. to form the metal complex grease composition.

Owner:SHELL USA INC

Combination type full dummy brightness transferring aluminum-plating paper coating and preparing method thereof

ActiveCN101408015AThere will be no phenomenon such as uneven extinctionSimplify the batching processCoatings with pigmentsCoatingsAcrylic resinThermoplastic polyurethane

The invention relates to combination type total matte luster shift aluminum-plated paper paint and a preparation method thereof. The combination type total matte luster shift aluminum-plated paper paint consists of double coating type total matte luster shift aluminum-plated paper paint and separating paint used together with the aluminum-plated paper paint, the double coating type total matte luster shift aluminum-plated paper paint adopts the following components and contents (weight percentage) as raw materials: 6 to 8 percent of solid thermoplastic acrylic resin, 4 to 5 percent of thermoplastic polyurethane resin, 4 to 5 percent of chlorovinyl ether, 0 to 2 percent of nitrocotton, 0.5 to 1 percent of dye, 0.05 to 0.1 percent of auxiliary agent and 80 to 82 percent of solvent. Compared with the prior art, the invention has the following advantages: the batching procedure is simple, the delustering degree is high, the total matte effect of aluminum foil can be reached, and the difficulty that the shift aluminum-plated paper can not be made like matte aluminium-foil paper is solved; the difficulty of the fold foil break of the aluminium-foil card paper is overcome, the cost is lowered; the made products have better printing adaptability and good binding property with paper, aluminum plating luster is soft and simple but elegant, the aluminum plating fastness is good, and the application range is wide.

Owner:SHANGHAI WEIKAI CHEM

Anti-flaming anti-corrosion modified unsaturated polyester resin (UPR) glass fiber reinforced plastic grating

The invention discloses an anti-flaming anti-corrosion modified unsaturated polyester resin (UPR) glass fiber reinforced plastic grating which is prepared from, by weight, 50-150 parts of UPR, 20-60 parts of vinylite, 5-15 parts of epoxy resin, 2-5 parts of expandable graphite, 1-4 parts of aluminum hydroxide, 3-9 parts of magnesium hydrate, 2-6 parts of talcum powder, 1-4 parts of quartz powder, 2-5 parts of ceramic powder, 3-5 parts of glass fiber, 1-4 parts of benzotriazole, 1-6 parts of a BYK-W940 wetting dispersant, 2-8 parts of a BYK-W985 wetting dispersant, 1-4 parts of ammonium polyphosphate, 3-9 parts of a BYK-S6665 adding agent, 1-4 parts of a BYK-S740 adding agent, 1-5 parts of an KH-560 silane coupling agent, 2-5 parts of a curing agent and 3-6 parts of an accelerant. The anti-flaming anti-corrosion modified UPR glass fiber reinforced plastic grating has excellent anti-corrosion and anti-flaming properties.

Owner:NINGGUO CITY OF CAPE COMPOSITE MATERIAL LIMITED

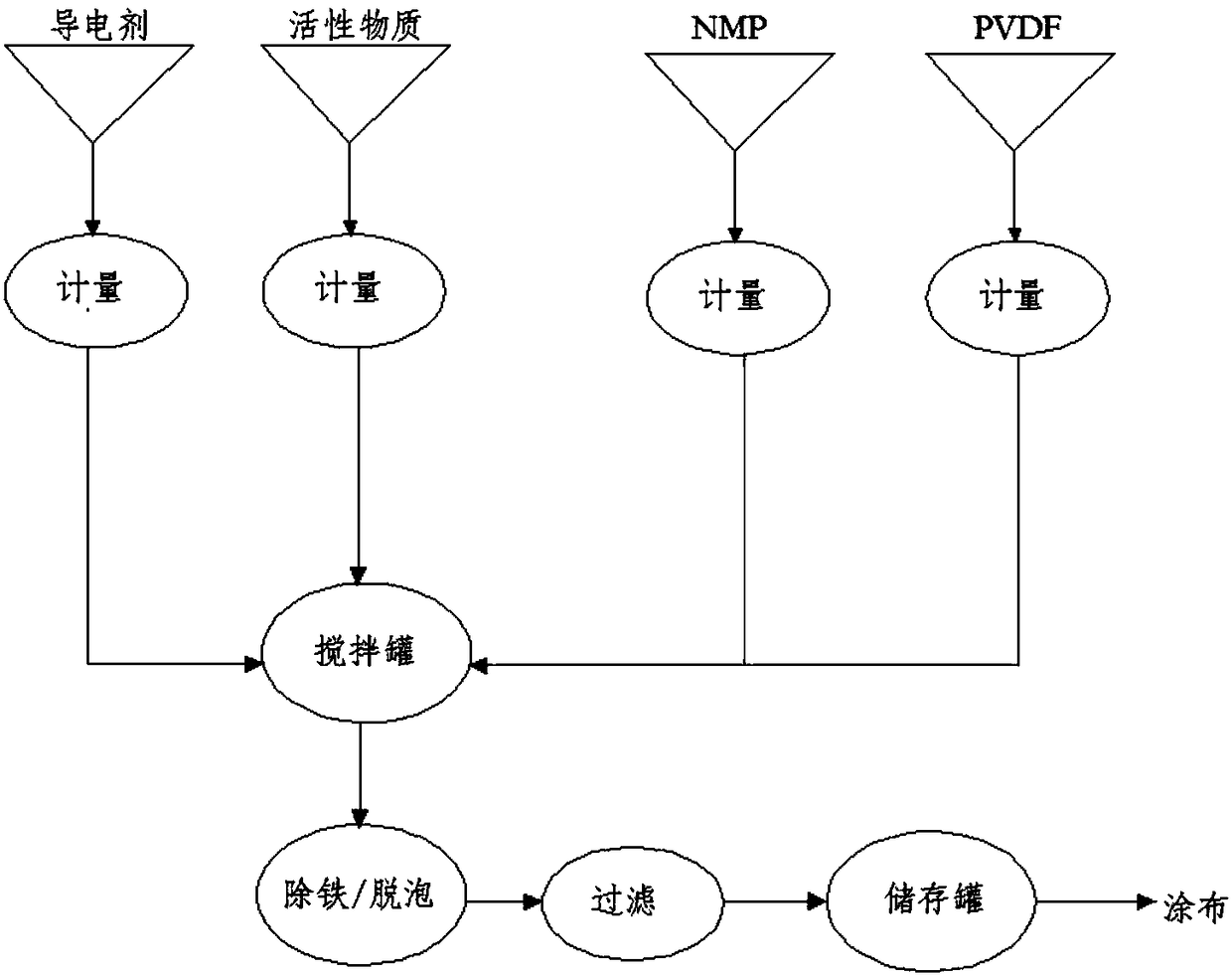

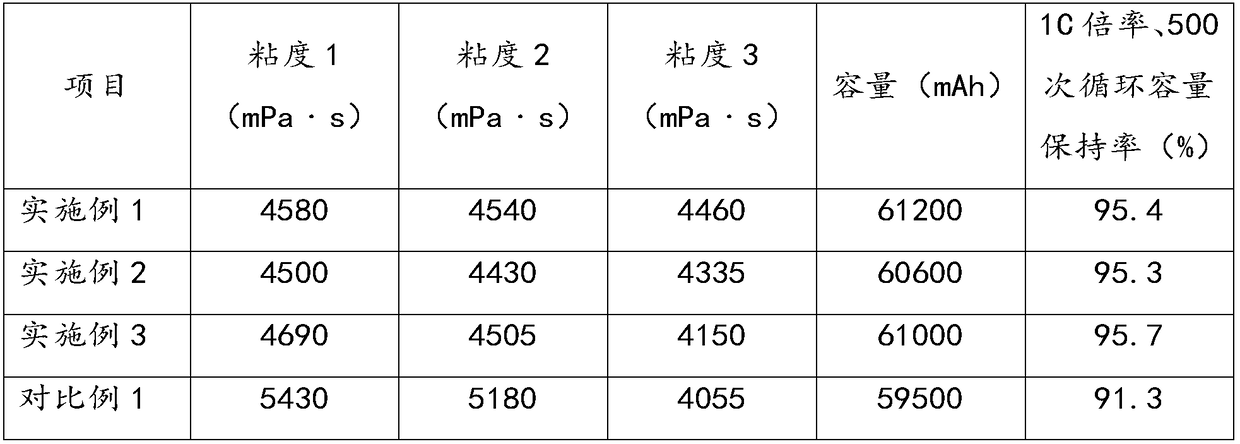

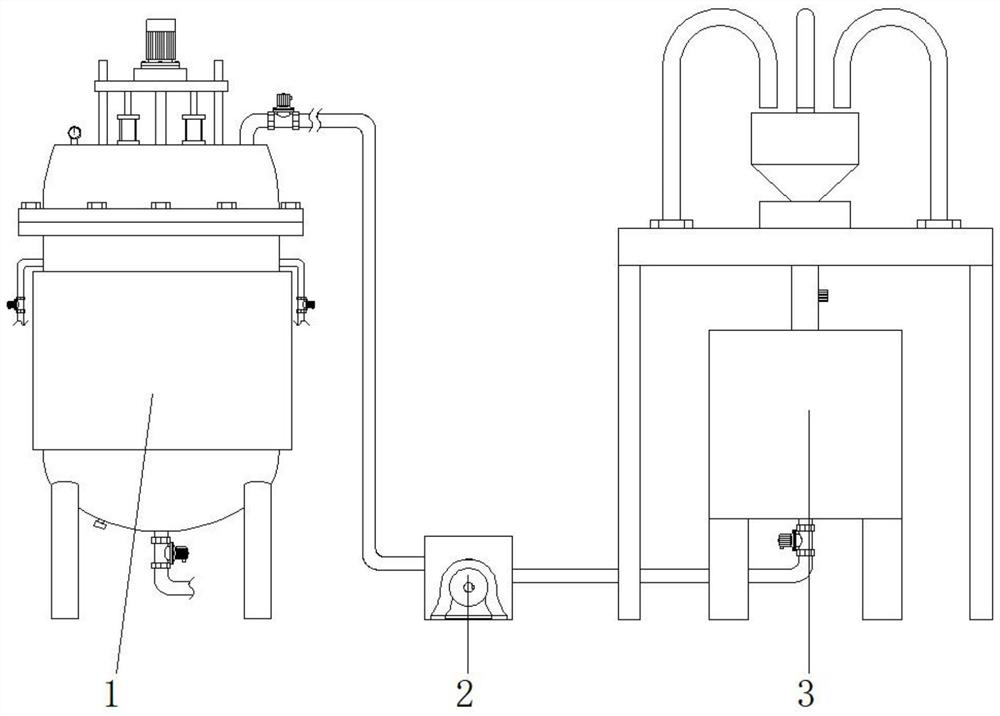

Burdening technology for slurry used by nanometer ferrous phosphate lithium ion battery

The invention relates to a burdening technology for slurry used by a nanometer ferrous phosphate lithium ion battery. Nanometer ferrous phosphate lithium ion, conductive agent, binder and N-methyl pyrrolidone are prepared into primary slurry; the primary slurry is stirred and dispersed for 60-90 minutes in a reciprocating mode between a stirring pot and a dispersion machine to obtain the slurry used by the nanometer ferrous phosphate lithium ion battery; and the linear velocity of the dispersion machine is 35-45m / s. The slurry prepared with the burdening technology disclosed by the invention can be evenly dispersed. The viscosity of the slurry slightly changes with the extending of placing time, and performance is stable. The lithium ion battery prepared by the slurry has the advantages of excellent electrochemistry performance, high retention rate of capacity-grading volumes and low resistance.

Owner:HUNAN FENGYUAN YESHINE KINGCO NEW ENERGY

Carbon-free low mirabilite plate glass

The invention discloses a carbon-free low mirabilite plate glass. The carbon-free low mirabilite plate glass is prepared from batches for forming sodium calcium silicate plate glass, the content of carbon powder in the batches is 0, and the addition amount of mirabilite in the batches is calculated by using the weight proportion of sodium oxide generated by mirabilite in total sodium oxide in finished glass of 2.0-2.5wt.%. The discharge amount of SO2, S and CO2 in the production process is reduced in order to protect the environment.

Owner:中国建材桐城新能源材料有限公司

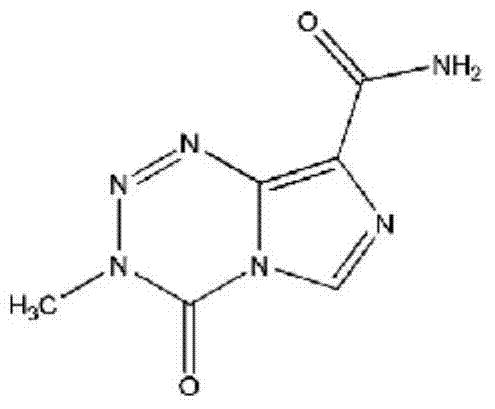

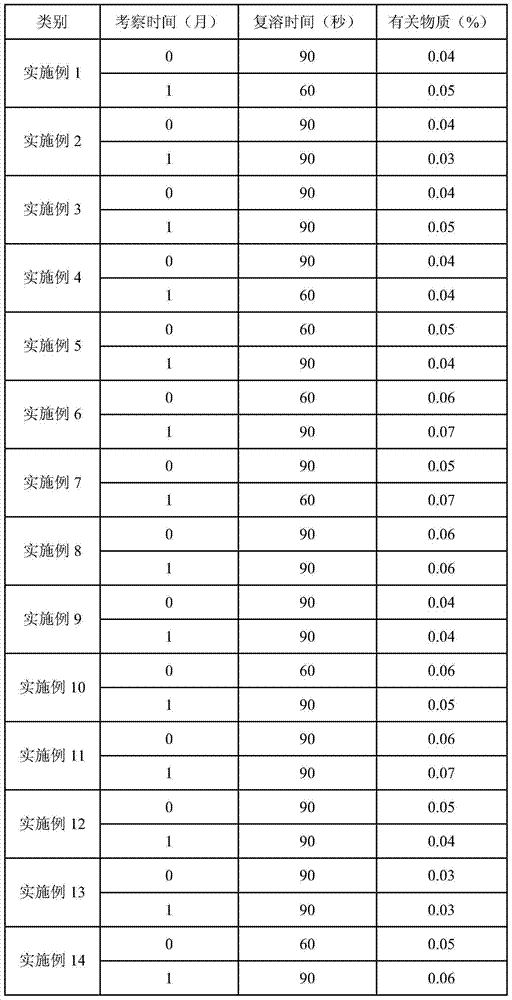

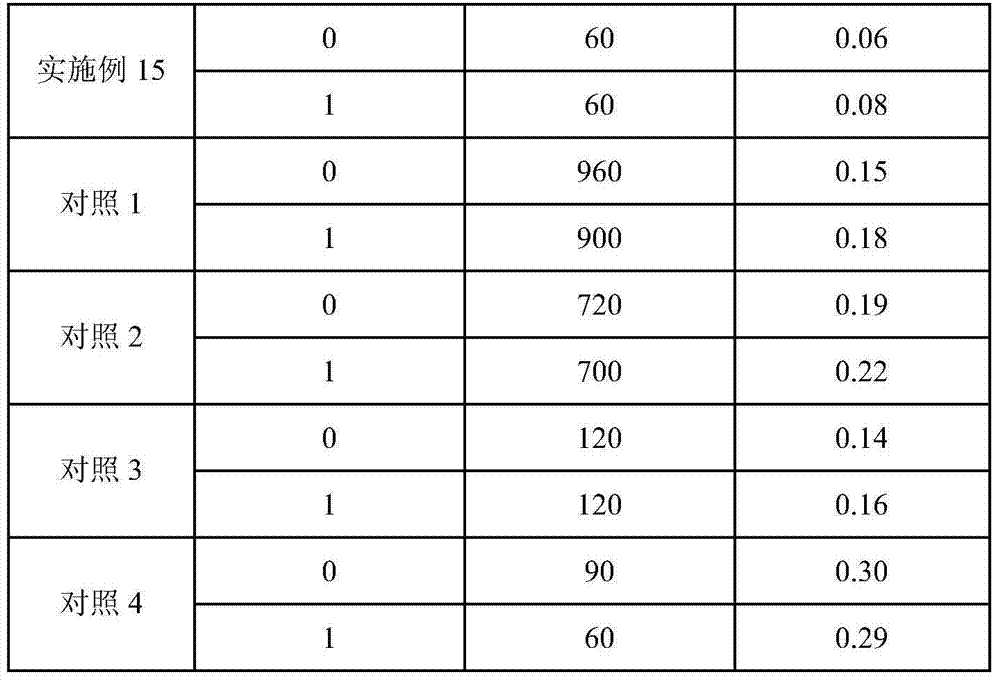

Temozolomide lyophilized powder preparation and preparation method thereof

ActiveCN104721155AReduce adverse reactionsLow toxicityOrganic active ingredientsPowder deliveryDissolutionBULK ACTIVE INGREDIENT

The invention belongs to the technical field of pharmaceutical preparations and specifically relates to a temozolomide lyophilized powder preparation. The temozolomide lyophilized powder preparation comprises an active ingredient of temozolomide or a pharmaceutically acceptable salt thereof, and a solution before lyophilization further contains an excipient, a wetting agent, a buffer agent, an osmotic pressure regulating agent, a pH regulating agent, water for injection and an organic solvent, wherein the organic solvent is selected from one or any combination of ethanol, acetone, isopropanol, n-propanol, butanone, sec-butyl alcohol and methanol, and is preferably ethanol. The temozolomide lyophilized powder preparation provided by the invention has the advantages of stable quality, high re-dissolution speed and a small residual amount of the organic solvent. The invention further provides a method for preparing the preparation. The process provided by the invention is simple and convenient in preparation process and easy to control production links, the organic solvent accounts for a relatively small part of total volume of material liquid, the pollution to production equipment and environment caused by the organic solvent is reduced, and thus the method is suitable for large-scale production.

Owner:QILU PHARMA HAINAN

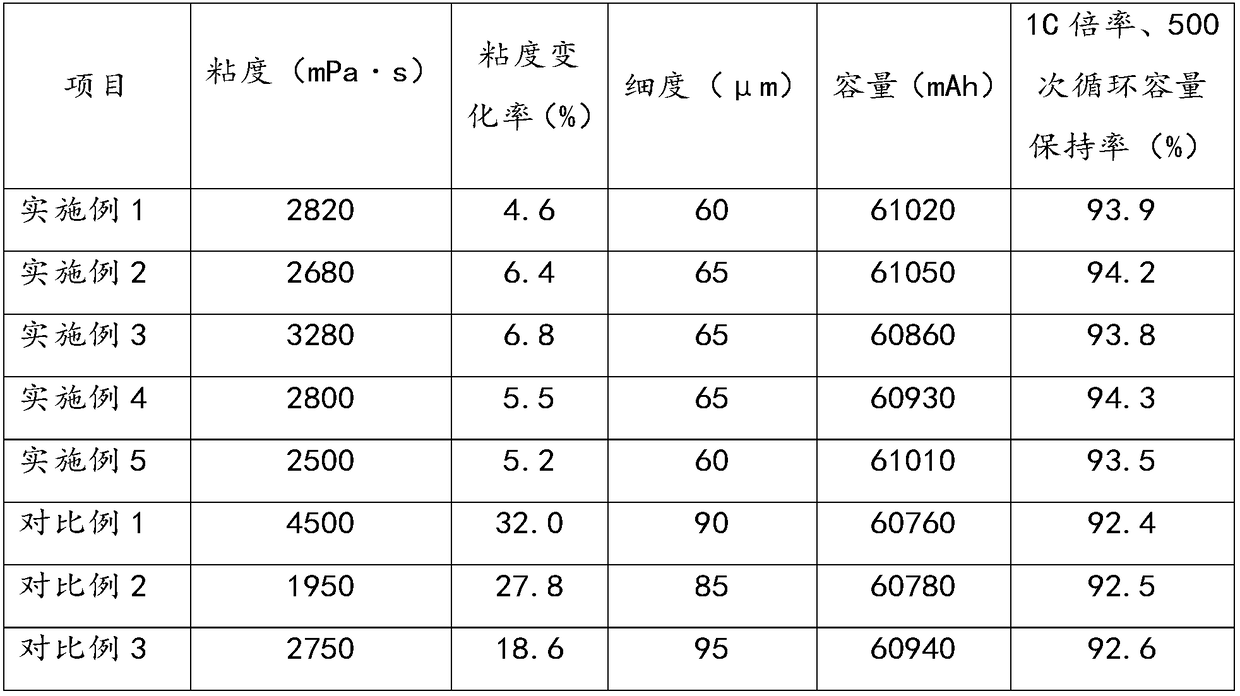

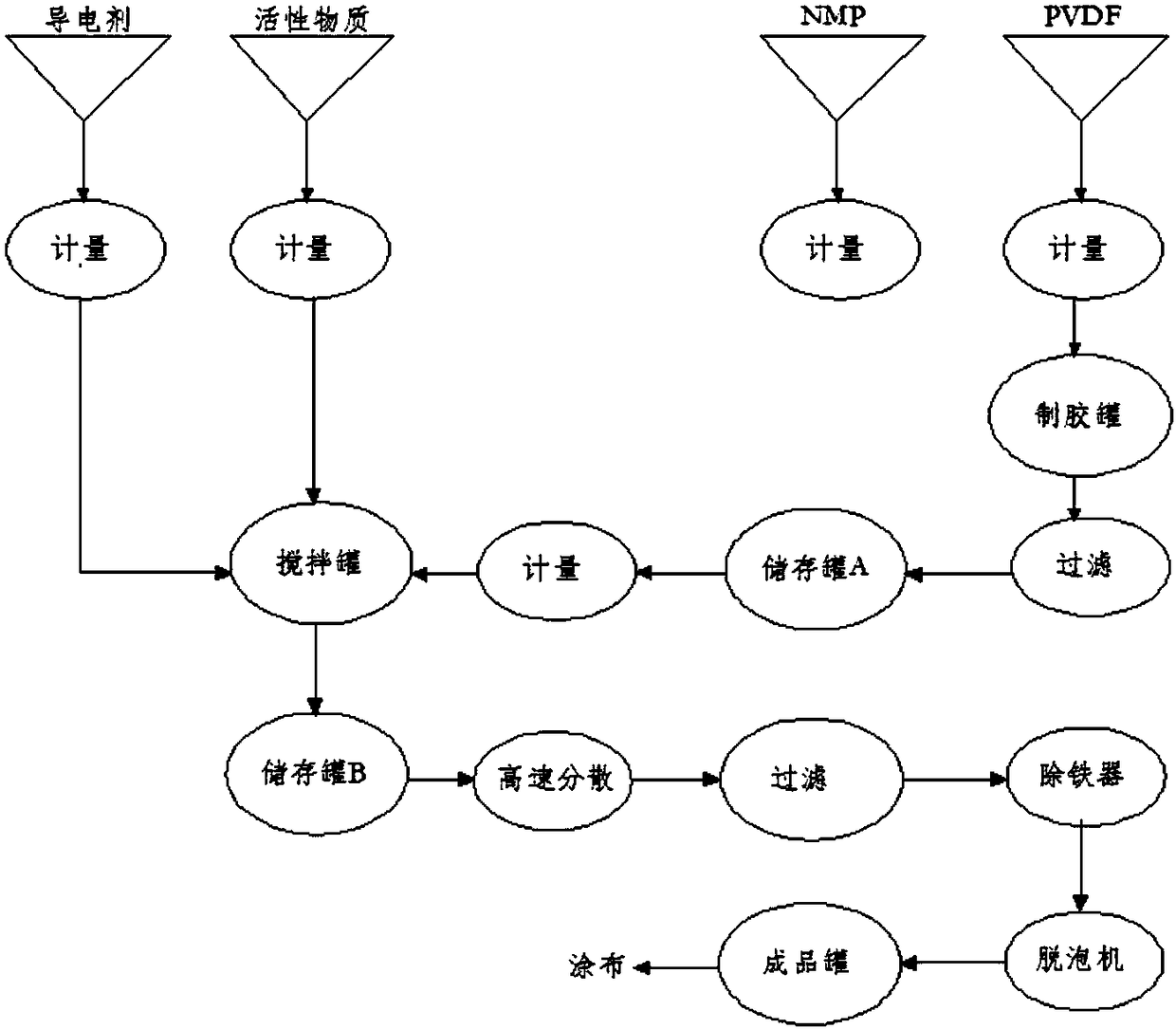

Preparation method of lithium ion battery cathode paste, lithium ion battery cathode plate and lithium ion battery

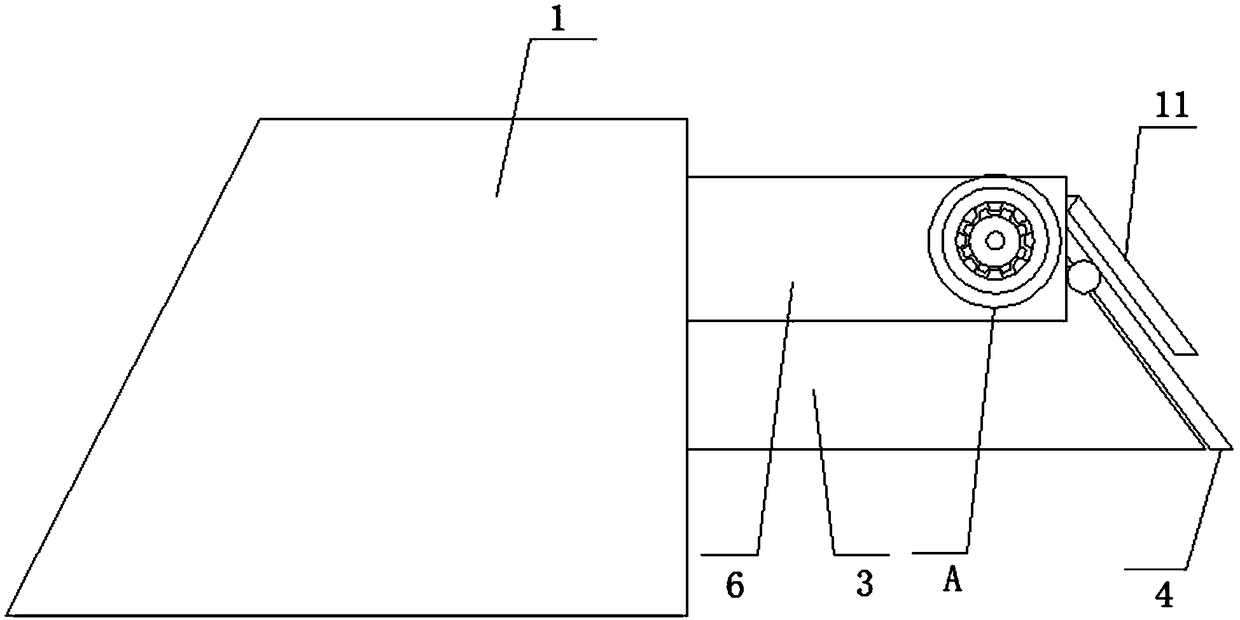

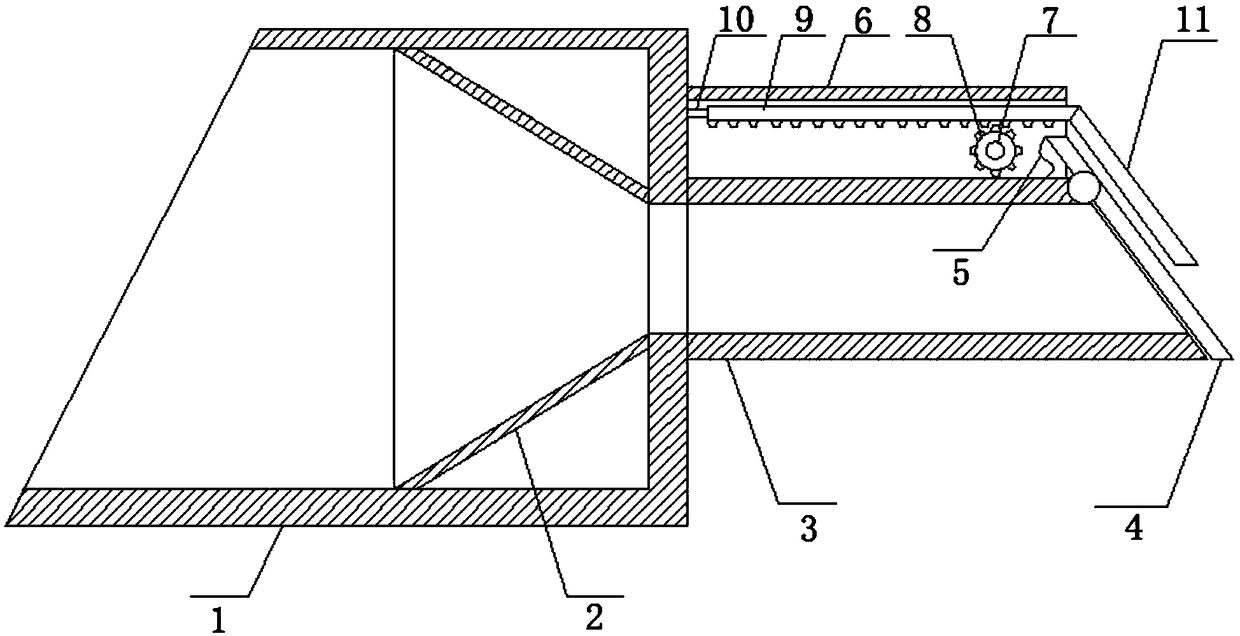

InactiveCN108281616AShorten batching timeIncrease productivityElectrode manufacturing processesSecondary cellsSolventElectrical battery

The invention belongs to the technical field of lithium ion batteries, and relates to a preparation method of lithium ion battery cathode paste, a lithium ion battery cathode plate and a lithium ion battery. The preparation method of the lithium ion battery cathode paste comprises the following steps: adding a solvent and a bonding agent into a glue preparation tank, and evenly mixing to obtain aglue solution; sending the glue solution into a storage tank A for storing; adding the glue solution, a conductive agent and active materials into a mixing tank, and evenly mixing to obtain paste to be treated; sending the paste to be treated to a storage tank B for storing; sending the paste to be treated to a high speed dispersion system for treating so as to obtain the lithium ion battery cathode paste. The preparation method provided by the invention is simple in process and easy to operate, can remarkably reduce the blending time, and increases the production efficiency and the equipmentutilization rate; furthermore, the paste is evenly mixed and is good in dispersity and consistency.

Owner:河南国能电池有限公司

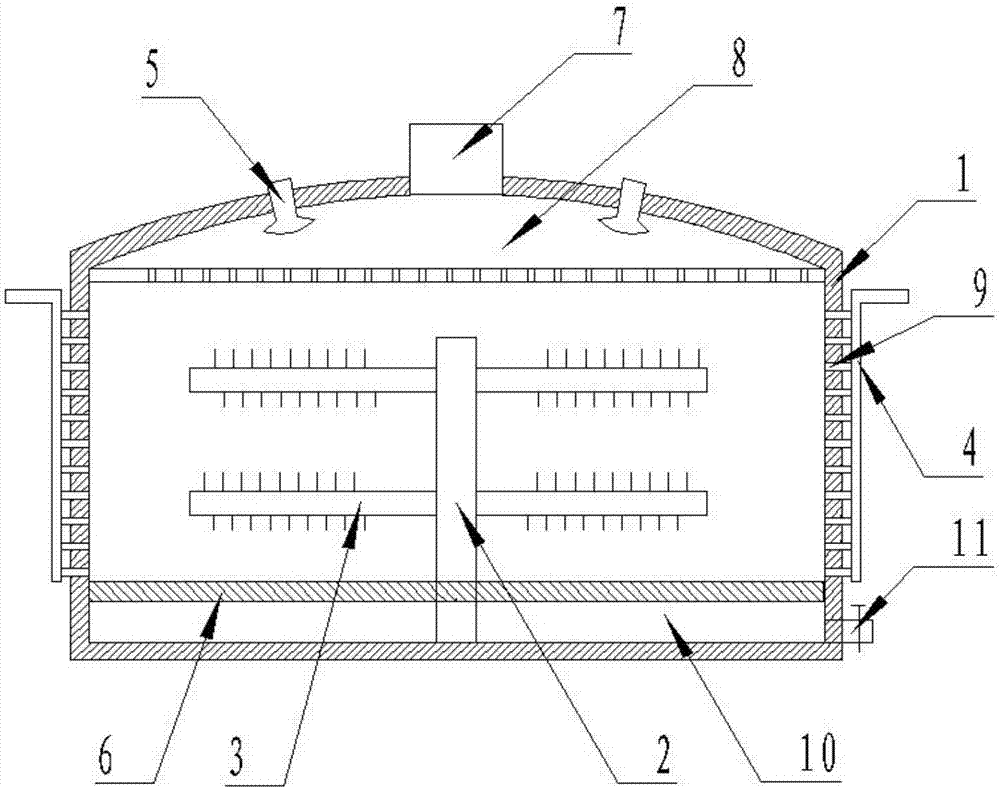

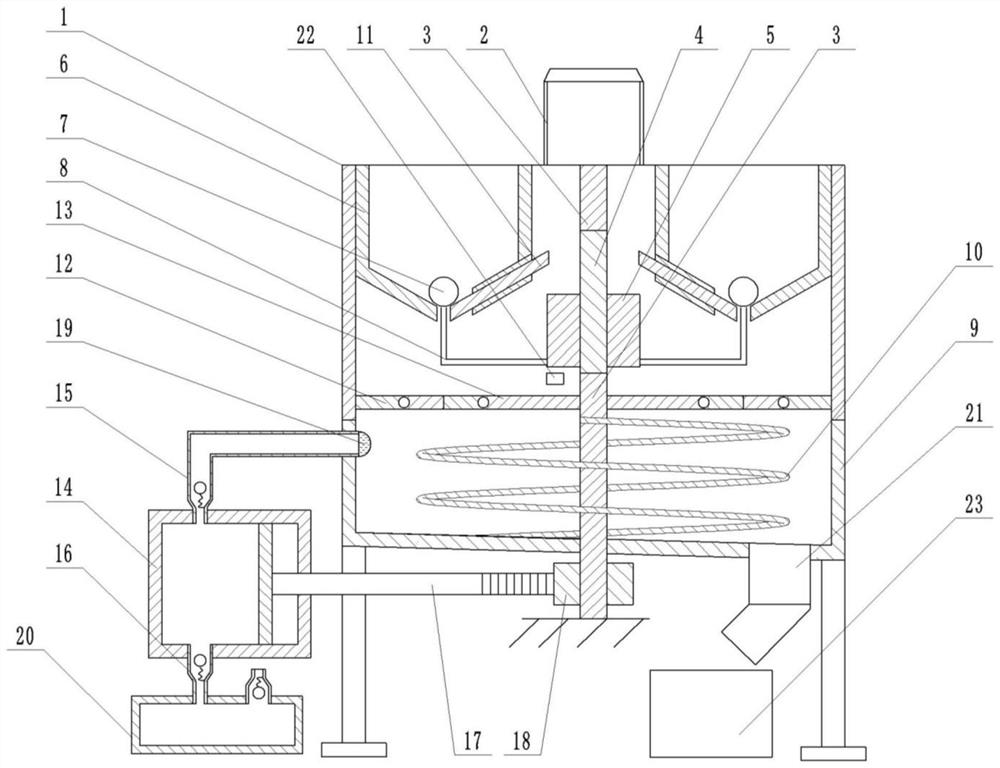

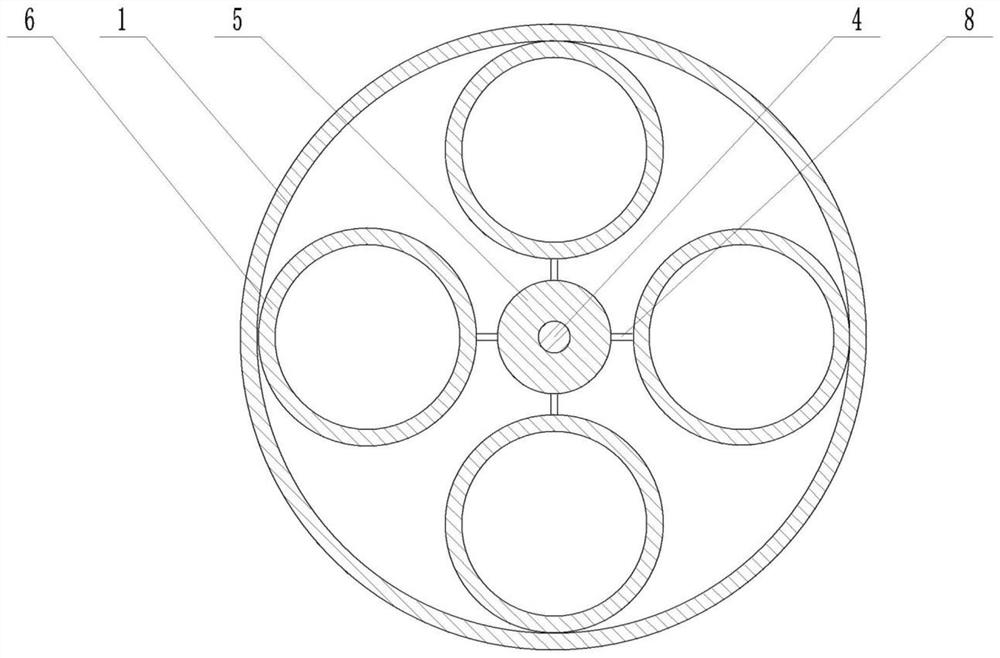

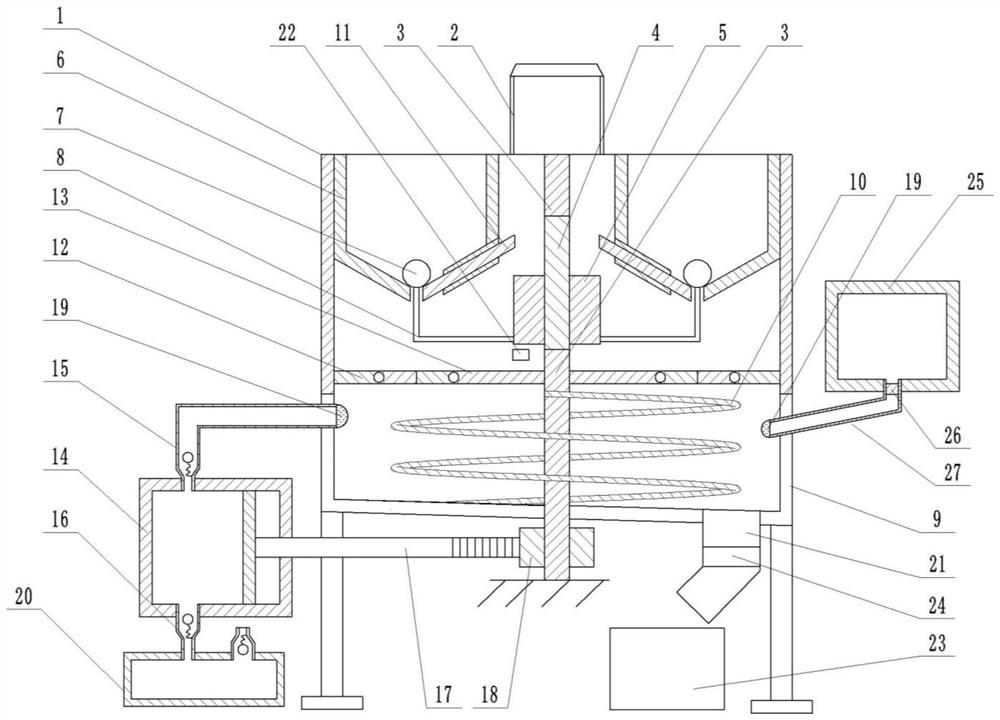

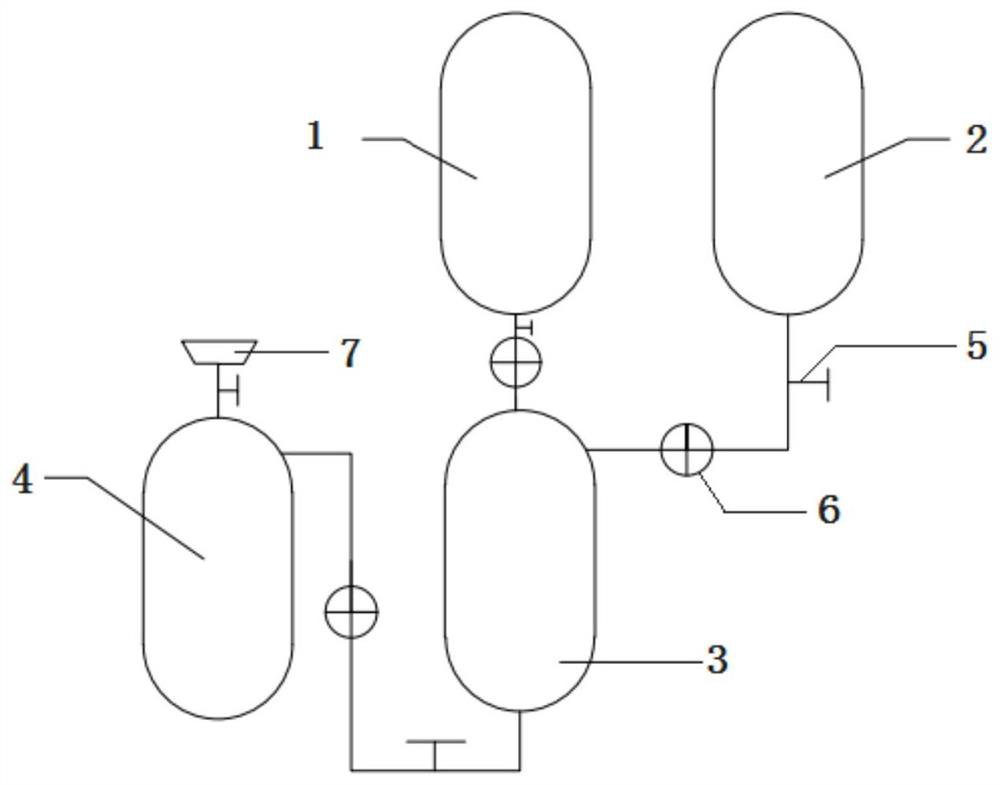

Lactic acid bacteria fermentation device

InactiveCN112481090AEasy to cleanEnsure proper temperatureBioreactor/fermenter combinationsBiological substance pretreatmentsBiotechnologyLactic acid bacterium

The invention discloses a lactic acid bacteria fermentation device, and relates to the technical field of food production. The lactic acid bacteria fermentation device comprises a fermentation mechanism and a batching mechanism, the fermentation mechanism and the batching mechanism are connected through an infusion pump, the batching mechanism can carry out automatic batching, the fermentation mechanism comprises a fermentation tank body, a stirring and cleaning part is fixedly installed at the top of the fermentation tank body, the stirring and cleaning part comprises a fermentation tank cover, fixed guide columns are fixedly connected with the four corners of the top of the fermentation tank cover correspondingly, a lifting plate is slidably connected between the fixed guide columns, anda telescopic air cylinder is further fixedly mounted at the top of the fermentation tank cover. Through the arrangement of the stirring and cleaning part, when the fermentation mechanism completes fermentation, the stirring and cleaning part can be used for stirring yoghourt during fermentation, and meanwhile, after fermentation is completed, the stirring and cleaning part can be used for cleaning the interior of the fermentation tank body, so that the fermentation mechanism is convenient to clean.

Owner:清远一生自然生物研究院有限公司 +1

Ionic liquid modified bar code carbon strip back coating and preparation method thereof

InactiveCN108485358ASolve heat resistanceFix stability issuesFireproof paintsThermographyOrganic solventDouble bond

The invention relates to an ionic liquid modified bar code carbon strip back coating which is prepared from the following raw materials in parts by weight: 10-50 parts of an acrylic monomer, 0.5-2 parts of a silane coupling agent, 0.5-3 parts of an ionic liquid containing double bonds; 15-30 parts of organic silicon, 13-73.5 parts of an organic solvent and 0.5-2 parts of a catalyst. The inventionprovides the ionic liquid modified bar code carbon strip back coating and a preparation process. By means of block polymerization, the ionic liquid containing double bonds is introduced into a high molecular chain of the polyacrylate back coating, and the high molecular back coating with low resistivity is coated with a bar code carbon strip, so that static electricity generated and accumulated onthe carbon strip are reduced effectively, and therefore, the printing using quality of the back coating is guaranteed.

Owner:HENAN UNIV OF SCI & TECH

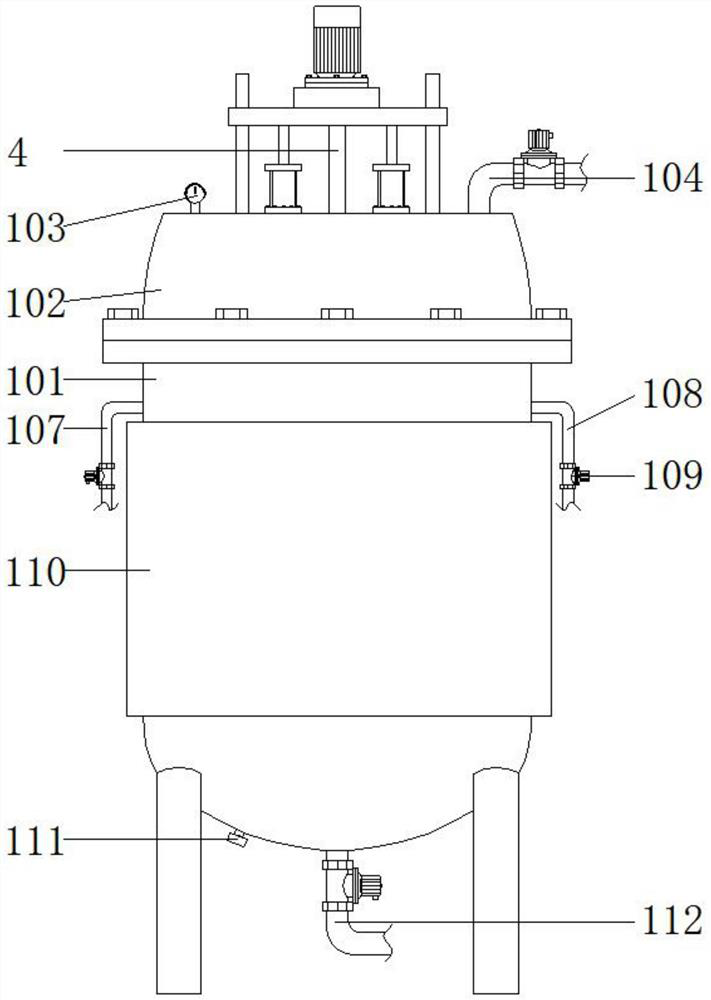

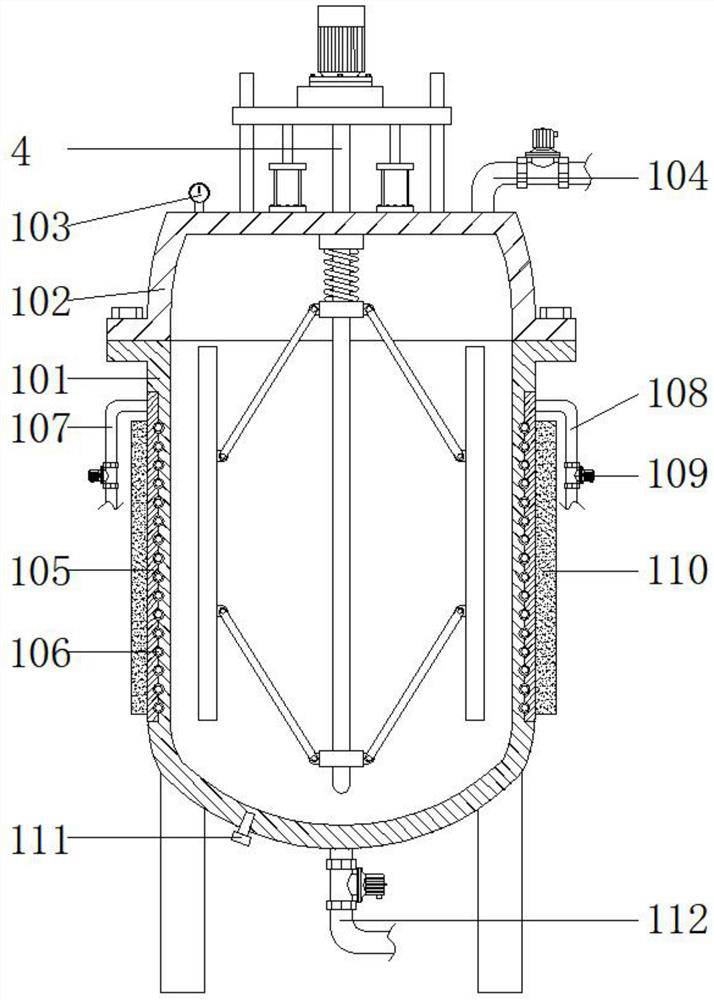

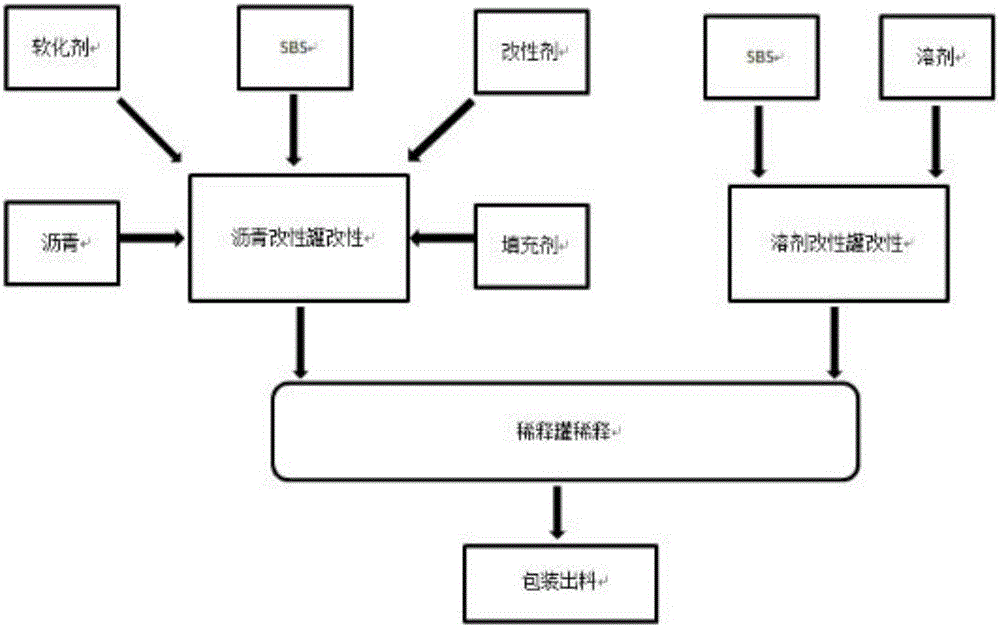

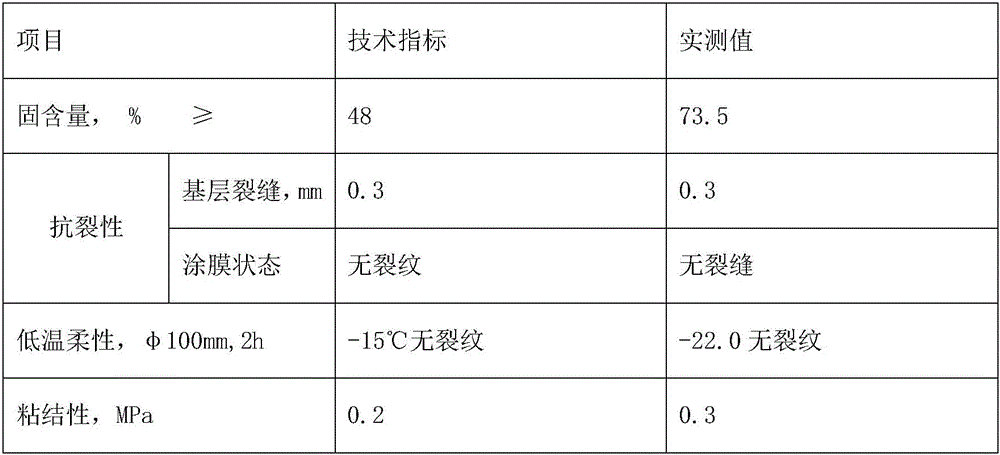

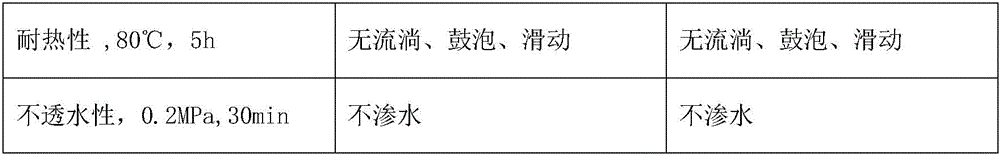

Low-VOC (volatile organic compound)-content low-temperature-resistant solvent type rubber asphalt waterproof paint and preparation method thereof

ActiveCN106634604AReduce temperature sensitivityReduce evaporation rateBituminous coatingsBituminous waterproofingHeat losses

The invention relates to low-VOC (volatile organic compound)-content low-temperature-resistant solvent type rubber asphalt waterproof paint, which is prepared from the following raw materials in parts by weight: 90 to 110 parts of asphalt, 5 to 15 parts of softening agents, 10 to 30 parts of SBS, 0 to 3 parts of modifiers, 20 to 40 parts of filling agents and 60 to 80 parts of solvents. The invention also provides a preparation method of the low-VOC-content low-temperature-resistant solvent type rubber asphalt waterproof paint. The low-temperature-resistant performance of a product provided by the invention is obviously improved; the product application range is improved; the product VOC content is reduced; the environment-friendly application effect of the product is obviously improved; the product proportioning time is shortened; the product proportioning temperature is lowered; the heat loss in the product temperature reduction process is reduced; the energy is saved; the emission is reduced; meanwhile, the defects of low dissolution dispersion speed of a high modifier addition of asphalt paint and easy polymerization in long-time modification can be solved; the defect of obvious reduction of performance after the dilution of modified asphalt by a solvent is overcome.

Owner:JINZHOU DONGFANG YUHONG BUILDING MATERIALS

Lithium ion battery anode water-based formula and processing technology

InactiveCN104733692AShorten batching timeIncrease profitNon-aqueous electrolyte accumulator electrodesWater basedAdhesive

The invention relates to a lithium ion battery anode water-based formula and a processing technology, and aims at providing a lithium ion battery anode water-based formula and a processing technology, which are short in material preparing time, high in equipment utilization rate and low in manufacture cost. According to the key point of the technical scheme, the lithium ion battery anode comprises the following raw materials in parts by weight; 1.0 to 1.5 parts of an adhesive, 0.5 to 1.0 part of a thickening agent, 0.0 to 1.5 parts of a defoaming agent, 0.0 to 0.5 part of a surface tension removal agent, 45.0 to 50.0 part of anode active substance, 0.5 to 1.0 part of a conducting agent and 46.0 to 55.0 parts of a solvent. By adopting the lithium ion battery anode water-based formula and the processing technology, the problems of the existing lithium ion battery anode that the material preparing time is long, the equipment utilization rate is low and the production cost is high can be solved, the material preparing time of the anode can be shortened to be less than 5 hours, the equipment utilization rate is increased, and the production cost is reduced.

Owner:河南新太行电源股份有限公司

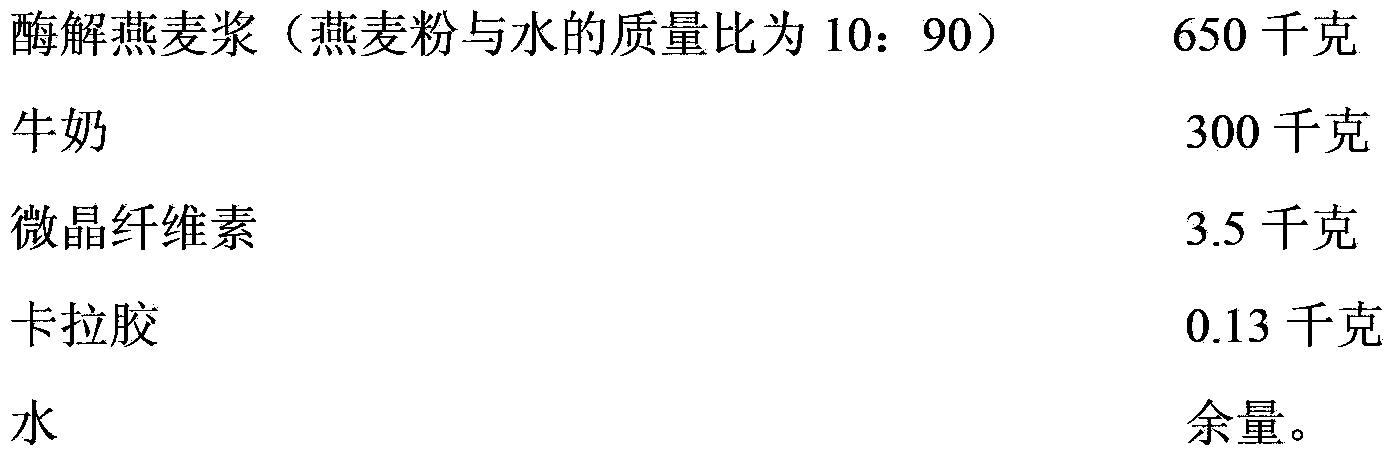

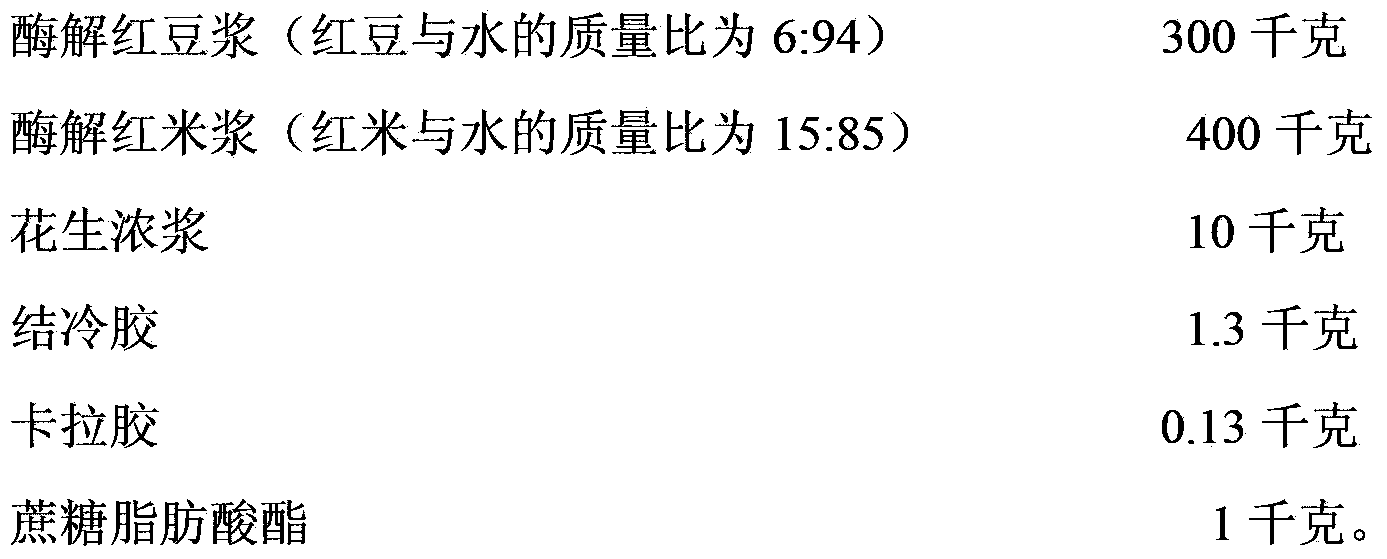

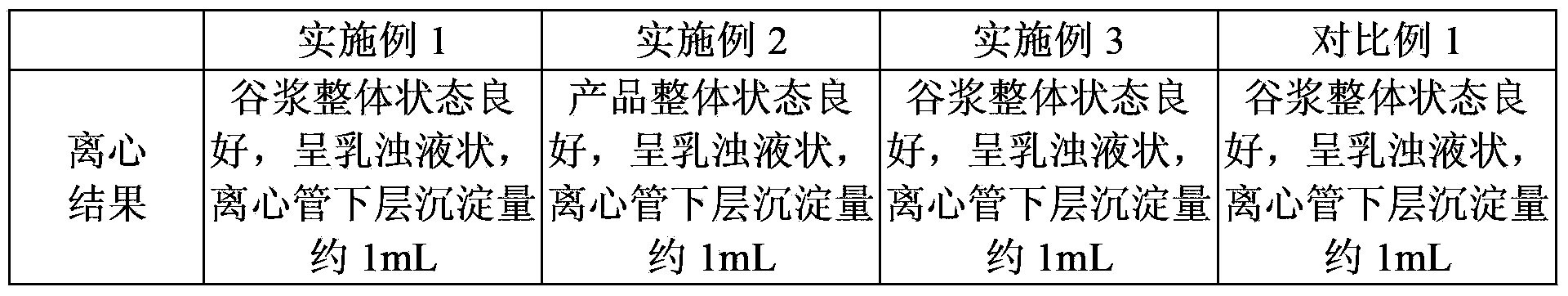

Grain pulp using high-temperature alpha-amylase and preparation method thereof

InactiveCN104336183AImprove utilization efficiencyShorten batching timeMilk preparationFood preparationEnzymatic hydrolysisFood safety

The invention relates to a grain pulp using high-temperature alpha-amylase and a preparation method thereof. The preparation method of the grain pulp using high-temperature alpha-amylase comprises the following steps: adding high-temperature alpha-amylase, and performing enzymatic hydrolysis. The invention provides a grain pulp product by using the above method. The provided preparation method comprises the following advantages that 1) material feeding time during a normal production can be saved, energy utilization efficiency is increased; and 2)starch enables full enzymatic hydrolysis under 80-85 DEG C by employing the high-temperature alpha-amylase, inactivation can be carried out under disinfection condition of 137 DEG / 4s, enzyme residue can not be generated, so that food safety can not be influenced.

Owner:INNER MONGOLIA YILI INDUSTRIAL GROUP CO LTD

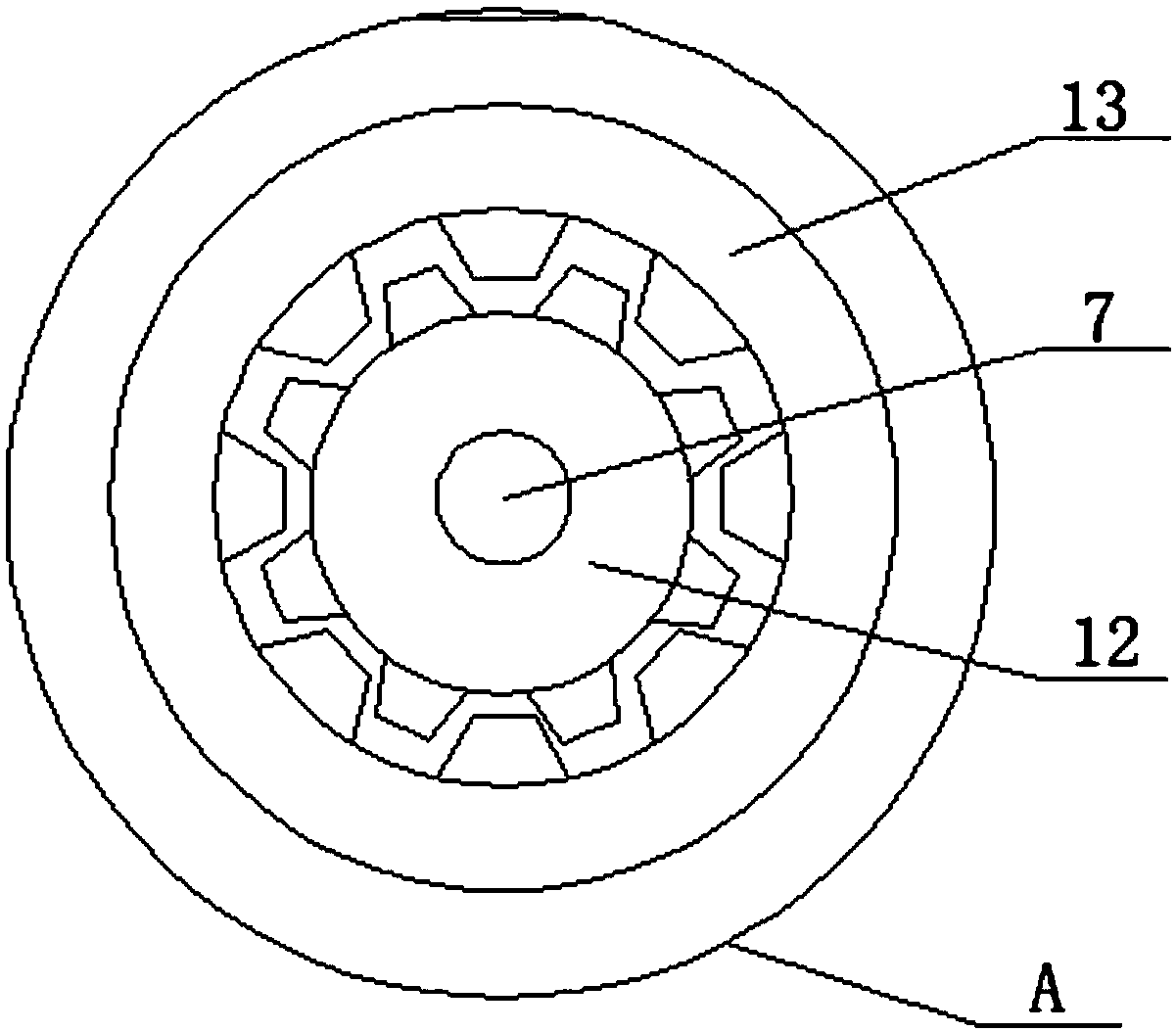

Biological dispensing equipment

InactiveCN107418885AImprove uniformityImprove production efficiencyBioreactor/fermenter combinationsBiological substance pretreatmentsPulp and paper industryBiological materials

The invention relates to a biological batching equipment, which includes a stirring cylinder, a stirring shaft, a stirring rod, a water spray pipe, a blowing pipe and a filter sieve body. The top of the stirring cylinder is provided with a decomposing enzyme inlet. A blowpipe is provided, and the blowpipe communicates with the inside of the mixing cylinder, and a fermentation gas mixing chamber is arranged on the top of the mixing cylinder, and the fermentation gas mixing chamber communicates with the inside of the mixing cylinder, and the filter sieve body is arranged at the lower part of the mixing cylinder , the bottom of the mixing cylinder is provided with a stirring shaft, the stirring shaft is provided with stirring rods in the left and right directions, and a water spray port is provided on both sides of the stirring cylinder, and the water spray port communicates with the water spray pipe. The invention has the advantages of simple structure, simple operation and good uniformity of preparing biological materials.

Owner:李兴龙

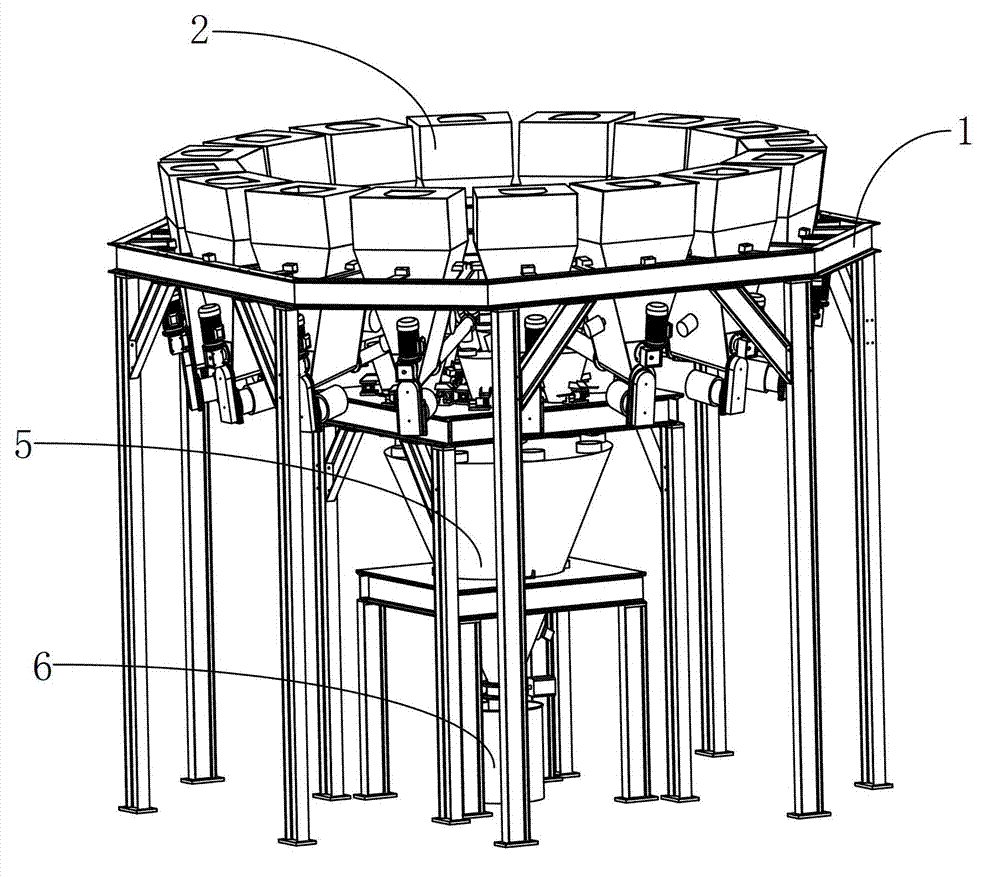

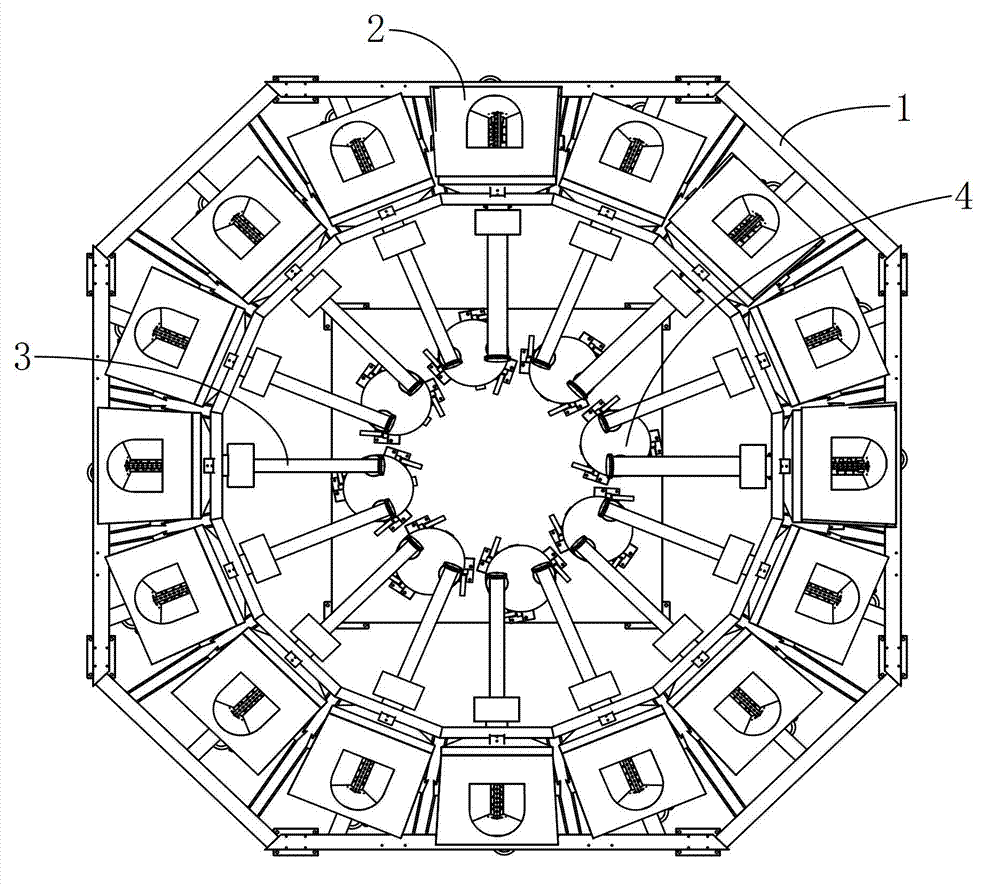

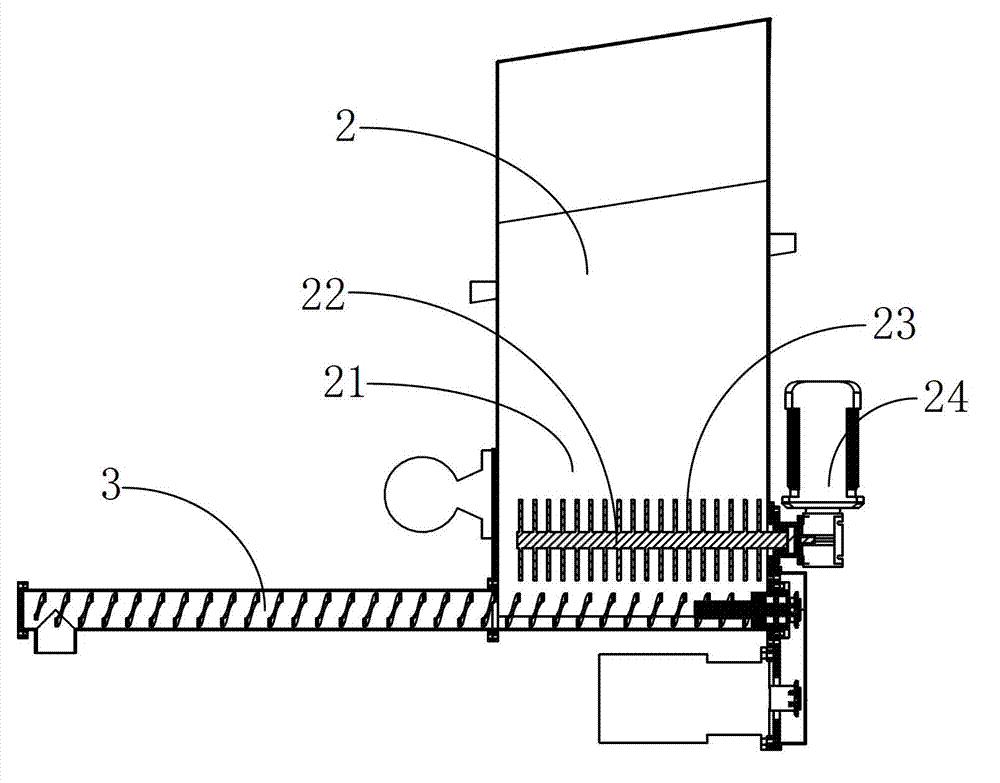

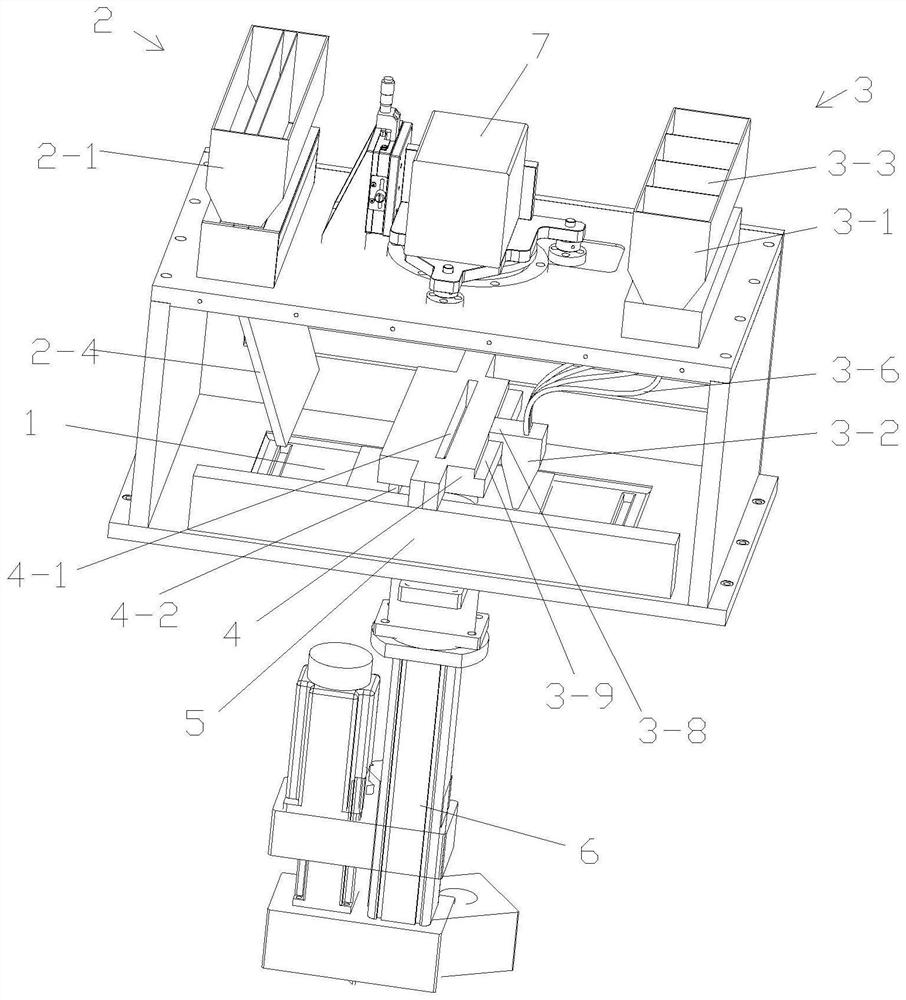

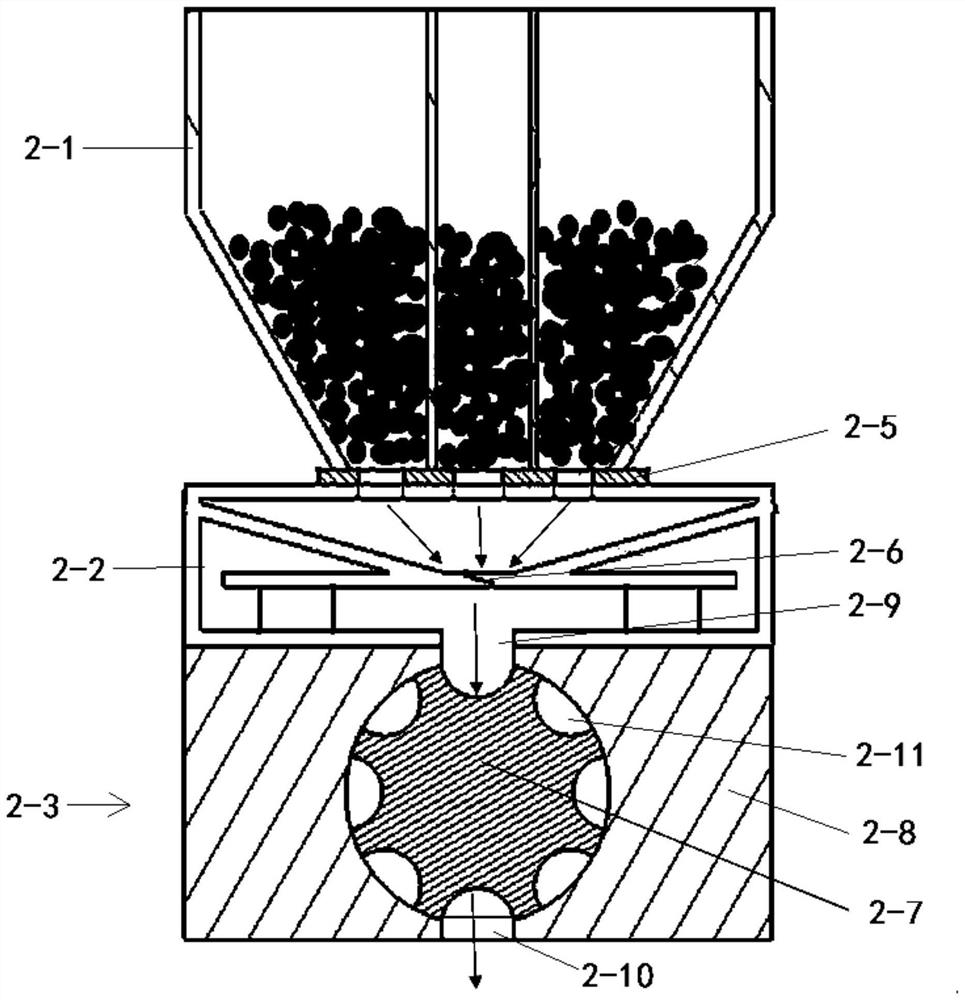

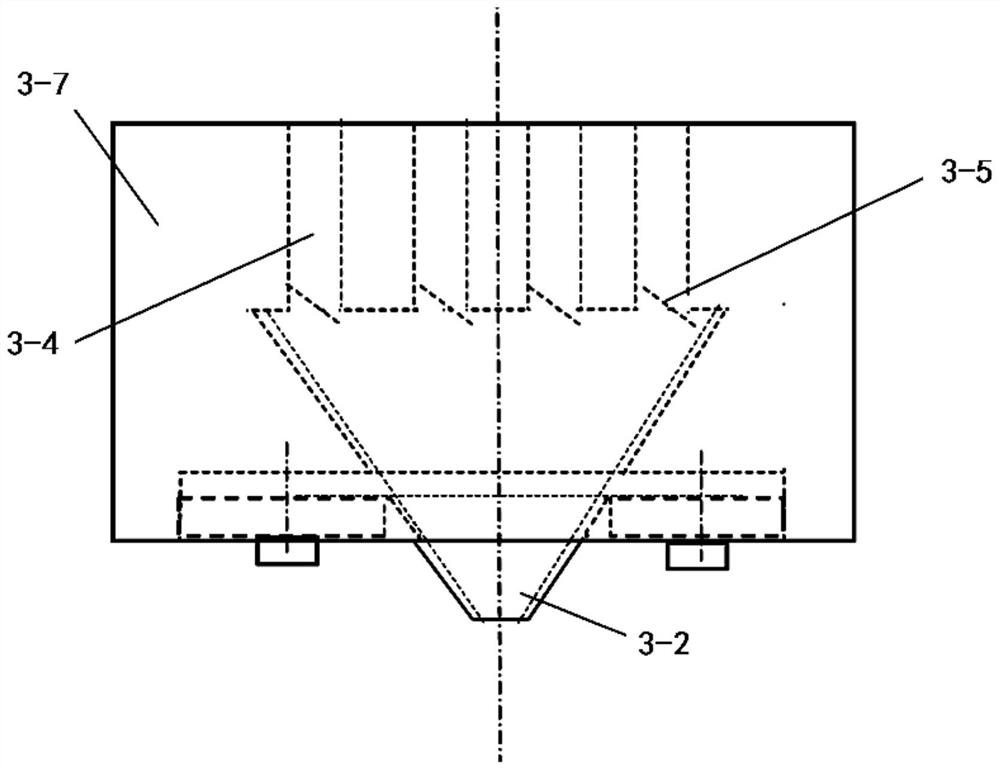

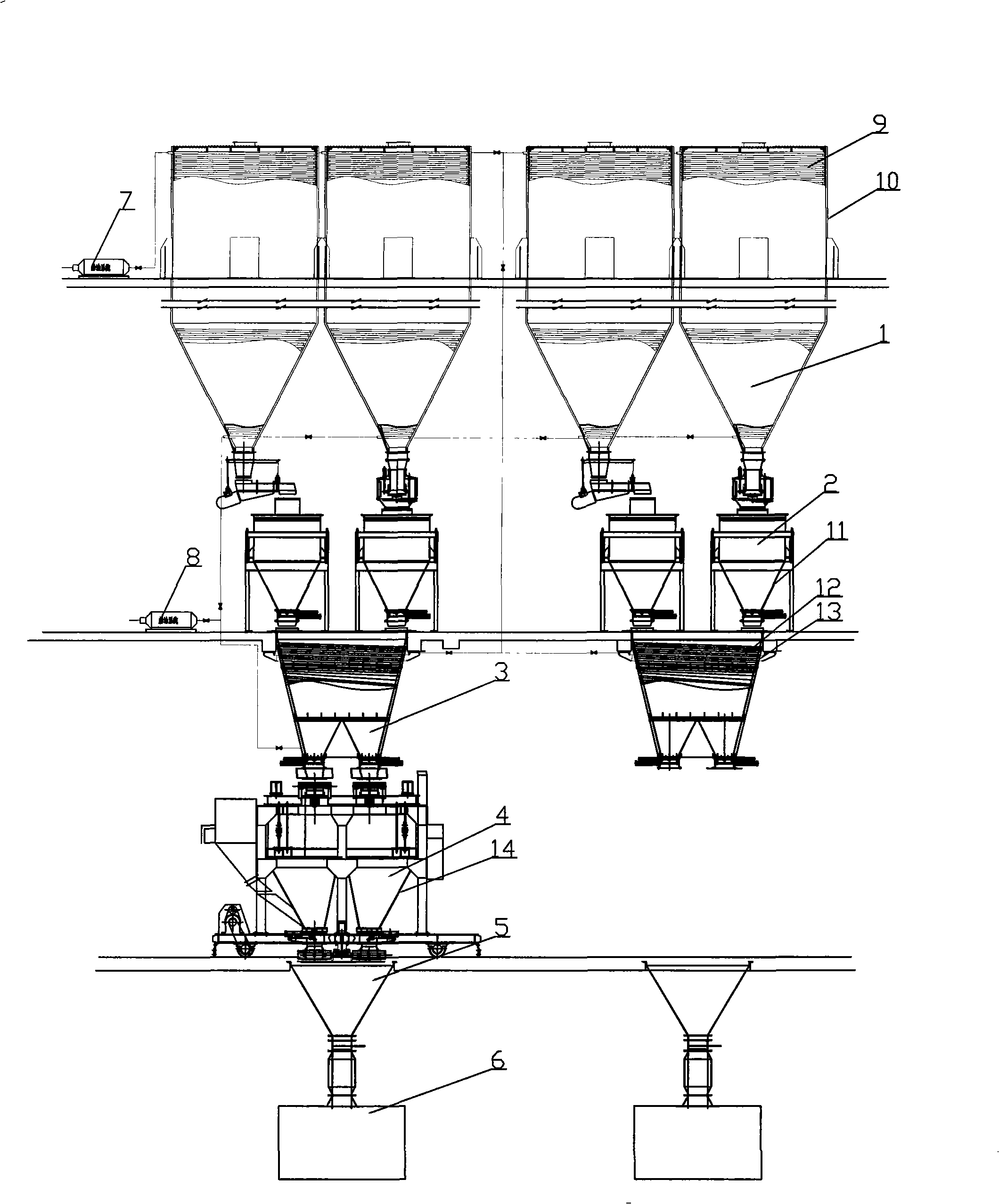

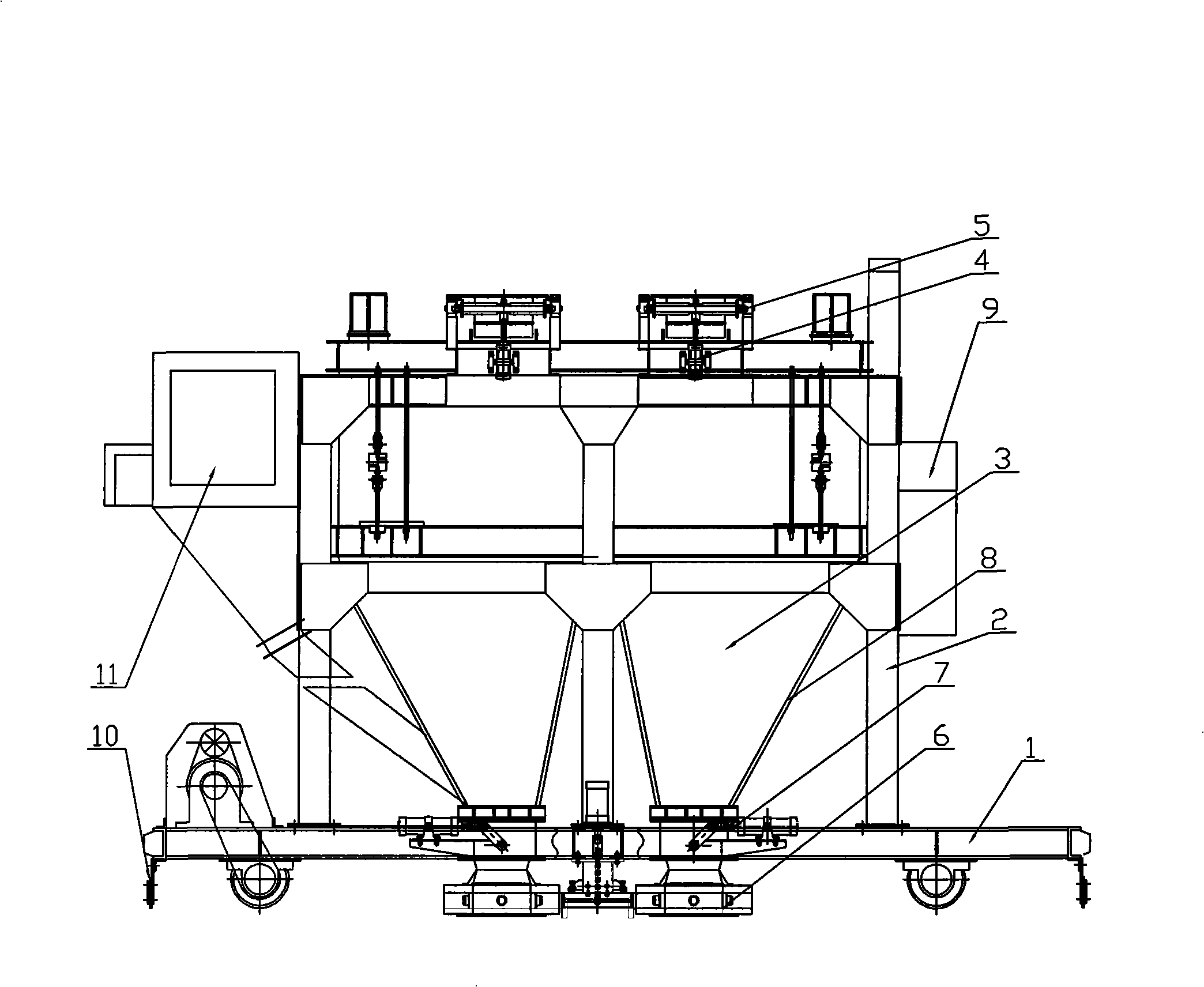

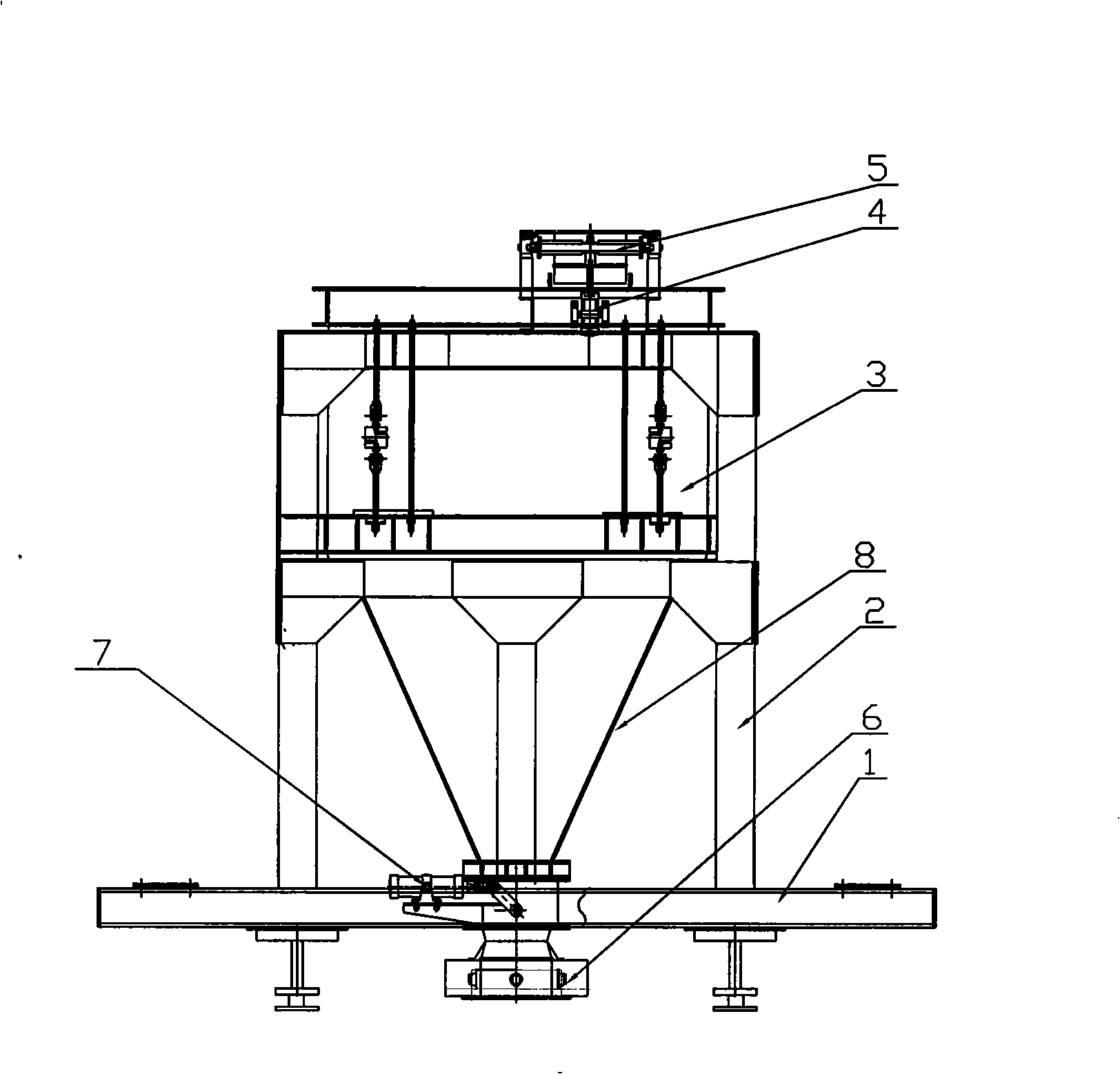

Automatic powder metering system and method

InactiveCN102872749ASmall footprintShorten batching timeMixing methodsMixer accessoriesEngineeringTemporary storage

The invention relates to an automatic powder metering system and method. The system comprises a machine frame, a plurality of storage bins, a plurality of metering bins, a plurality of delivery mechanisms, a temporary storage bin and a powder receiving box, wherein a closed graph enclosed by the storage bins is fixed on the machine frame; the metering bins are positioned below the storage bins and communicated with the storage bins through the delivery mechanisms; each metering bin corresponds to every two adjacent storage bins; the temporary storage bin is positioned at the discharge positions of the metering bins; the powder receiving box is arranged at the discharge position of the temporary storage bin; and the metering bins and the temporary storage bin are respectively fixed on the machine frame. According to the invention, when the powder is filled in the storage bins, the powder in the two adjacent storage bins falls into the same metering bin through the corresponding delivery mechanism; and the powder is metered at the discharge position of the metering bin, then directly falls into the temporary storage bin, and finally into the powder receiving box at the discharge position of the temporary storage bin. According to the invention, the storage bins, which form the closed figure, and the metering bins are adopted so as to reduce the occupied land space and improve the discharging speed.

Owner:SUZHOU JINPIN LINE MATERIAL

Powder feeding device for forming selective laser melting digital material

PendingCN114346265AHigh precisionShorten batching timeAdditive manufacturing apparatusSelective laser meltingDigitization

The invention discloses a powder feeding device for selective laser melting digital material forming. The powder feeding device comprises two independent powder feeding mechanisms. The two independent powder feeding mechanisms have multi-material weighing and distributing and fixed-point conveying functions; powder of various different materials can be quantitatively and accurately supplied according to the required weight ratio, so that the ratio of the powder in each powder spreading layer is controllable; and the specified material can be accurately conveyed to a preset position of a forming surface, so that the material composition in different directions in each powder paving layer is changed in a gradient manner. According to the powder feeding device, the two independent powder feeding mechanisms are organically integrated, powder laying can be considered, powder of different materials can be put in a fixed-point and fixed-area mode, the powder utilization rate and the multi-material applicability are greatly improved, and a brand-new technical scheme about combination of powder laying and multi-material powder leakage is provided for the technical field of 3D printing.

Owner:SOUTH CHINA UNIV OF TECH

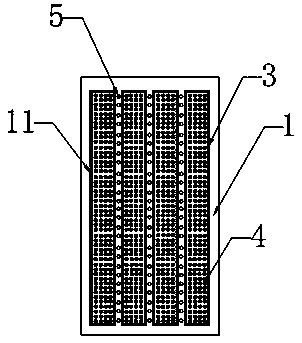

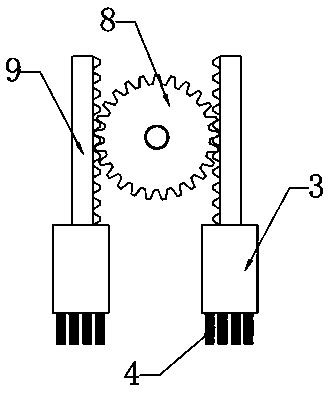

Multifunctional automatic hairbrush

The invention discloses a multifunctional automatic hairbrush. The hairbrush comprises a brush body and a brush handle; the hairbrush is characterized in that at least two slide blocks which oppositely and retractably slide in the length direction of the brush body are arranged in the brush body, and multiple groups of bristles are uniformly distributed on the outer end face of each slide block; at least one nozzle assembly is arranged on the portion, between every two slide blocks, of the brush body or on each slide block, and each nozzle assembly comprises at least two nozzles, and is communicated with a solvent bucket through a paint delivery pipeline. By means of the multifunctional automatic hairbrush, the bristles are arranged on the slide blocks which can oppositely and retractablyslide, the labor intensity of operating personnel is reduced, and the quality of dipping brushing is improved; meanwhile, in the spraying process, the arranged nozzle assemblies directly spray raw coating materials onto objects, dripping and leakage occurring when the hairbrush is transferred while dipped with paint are prevented, the waste of the paint is reduced, and dynamic matching of the multi-component hybrid reaction paint can also be achieved.

Owner:重庆博巨玻璃钢有限公司

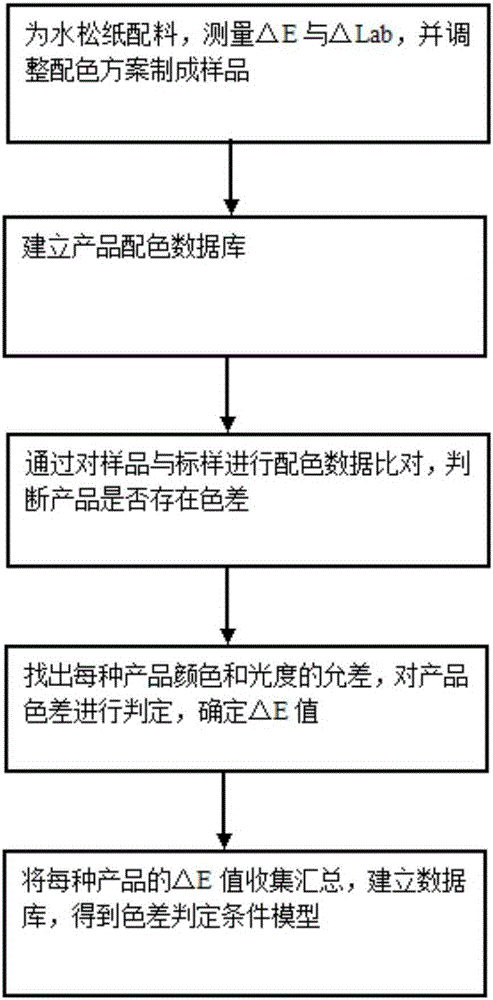

Tipping paper chromatic aberration determination method

InactiveCN105181143AReduce batching time and unit consumptionImprove production efficiency and product qualityColor measuring devicesChromatic contrastChromatic aberration

The present invention provides a tipping paper chromatic aberration determination method. The method comprises the following steps of burdening a tipping paper, measuring the delta E and the delta Lab, and adjusting a color scheme to manufacture samples; establishing a product match color database; determining whether the products exist the chromatic aberration by carrying out the match color data comparison on the samples and a master standard; finding out the permissible deviation of the color and the luminosity of each product, and determining the chromatic aberration of the products to determine the values of delta E; collecting and gathering the values of the delta E of the products, and establishing a database to obtain a chromatic aberration determination condition model. According to the present invention, by establishing the product match color and examination standards, the match color and chromatic aberration examination operation links are standard, the burdening time and the unit consumption are reduced, and the production efficiency and the product quality are improved.

Owner:CHUZHOU CIGARETTE MATERIALS FACTORY

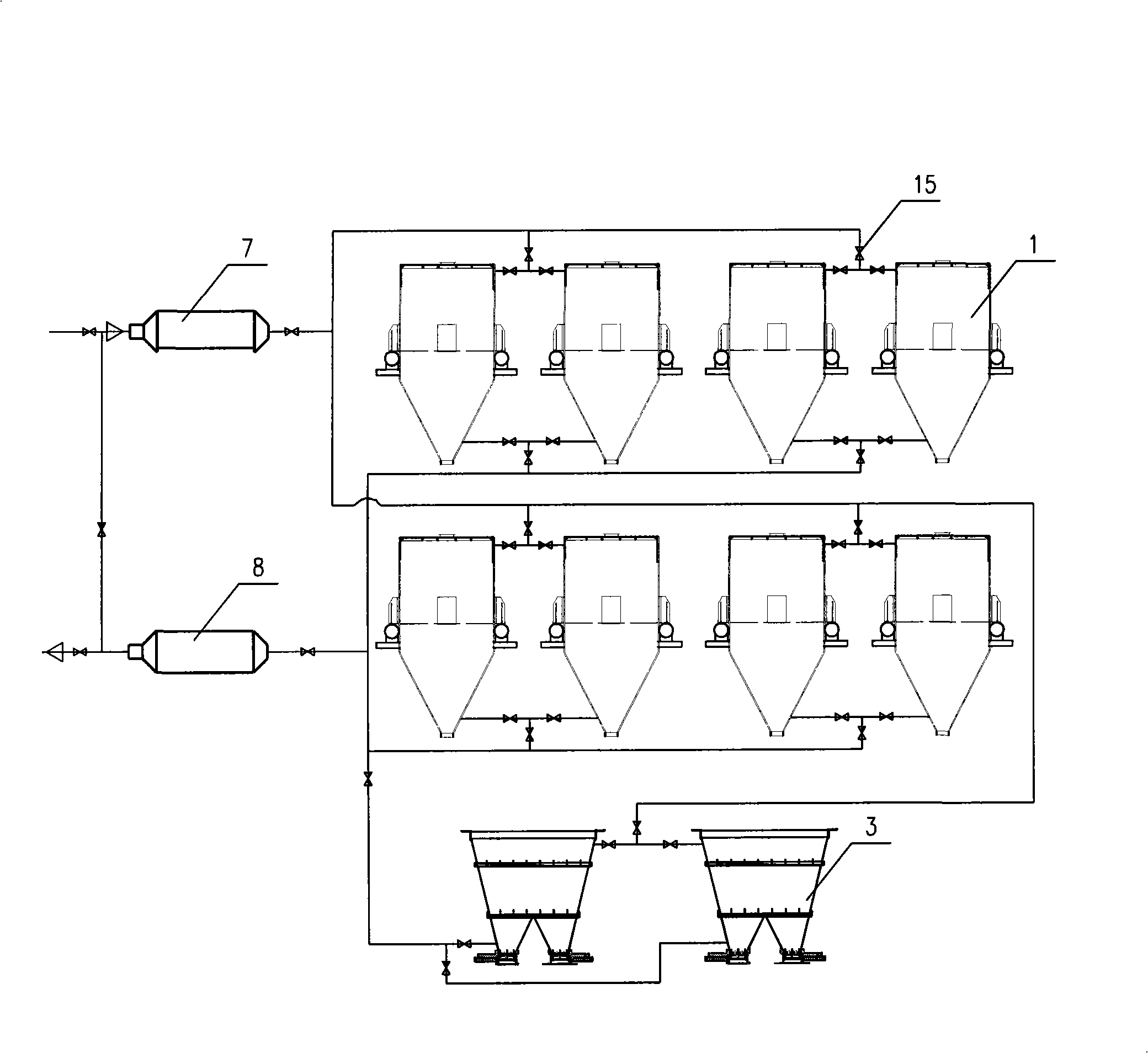

Carbon preheatable feed proportioning system

InactiveCN101348247ARealize fully enclosed productionRaise the preheat temperatureProcess engineeringTruck

The invention discloses a carbon material proportioning system, particularly relating to a carbon preheating and heat preservation material proportioning system. The new system comprises a preheating system, a proportioning bin, a batch scale, a batch truck, a collection hopper and a pugging pot feeding hopper, etc., wherein the preheating system can realize the preheating and heat preservation of materials by pipeline systems arranged in the proportioning bin and the collection hopper, the full closing production can be realized by a precise para position system arranged on the truck, so that the material proportioning time is greatly saved, and the material proportioning efficiency is improved; the materials are preheated, so that the dry mixing time of the materials is greatly saved, and the production capacity of a workshop is improved.

Owner:SHENYANG ALUMINIUM MAGNESIUM INSTITUTE

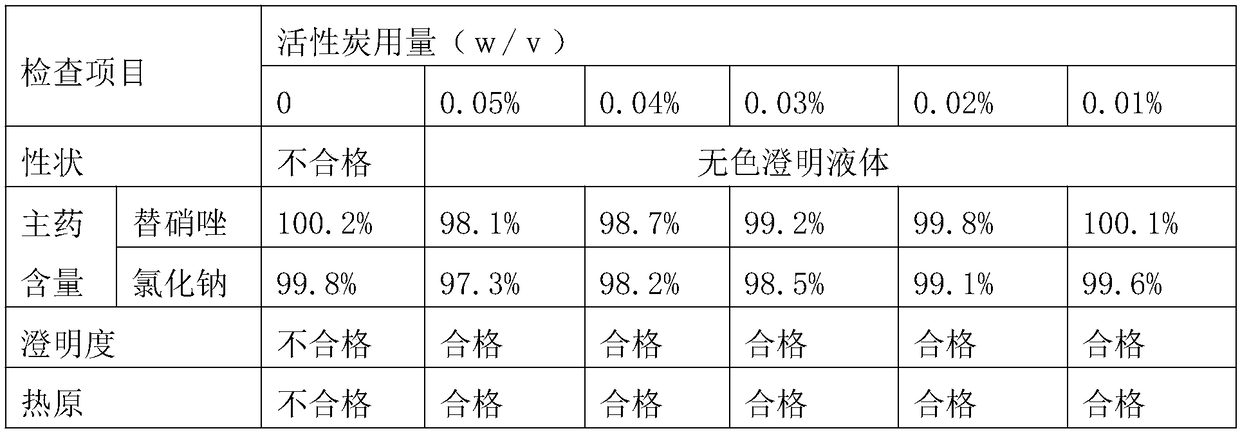

Production process of tinidazole injection

InactiveCN109464387AWell mixedChange natureAntibacterial agentsOrganic active ingredientsActivated carbonTinidazole

The invention provides a production process of a tinidazole injection. The production process comprises liquid preparation, filling and sterilizing. The production process specifically comprises the following steps: firstly, adding water for injection in a concentrating tank; fully dissolving tinidazole and adding the tinidazole into the concentrating tank to be uniformly mixed; then adding activated carbon to stir and adsorb; then adding sodium chloride to prepare a concentrated solution; decarbonizing the concentrated solution and importing the same into a diluted concentrating tank and adding the water for injection to total amount and uniformly mixing the solution to obtain the injection; and finally, filling and sterilizing the injection to obtain a finished product. The tinidazole isdissolved better. The production process can prevent heat source matters from entering the finished product more effectively.

Owner:SICHUAN TAIPINGYANG PHARMA

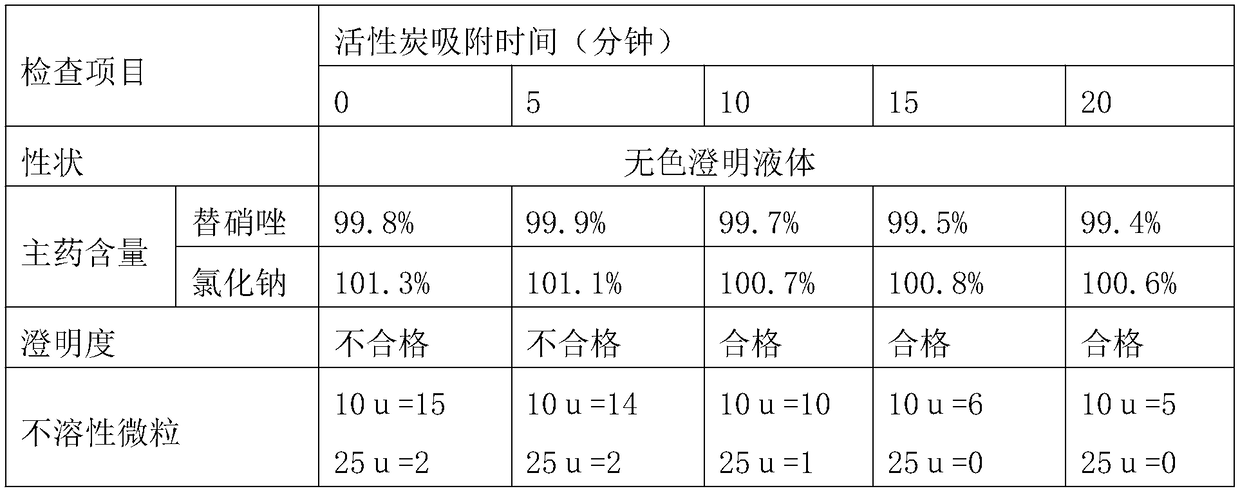

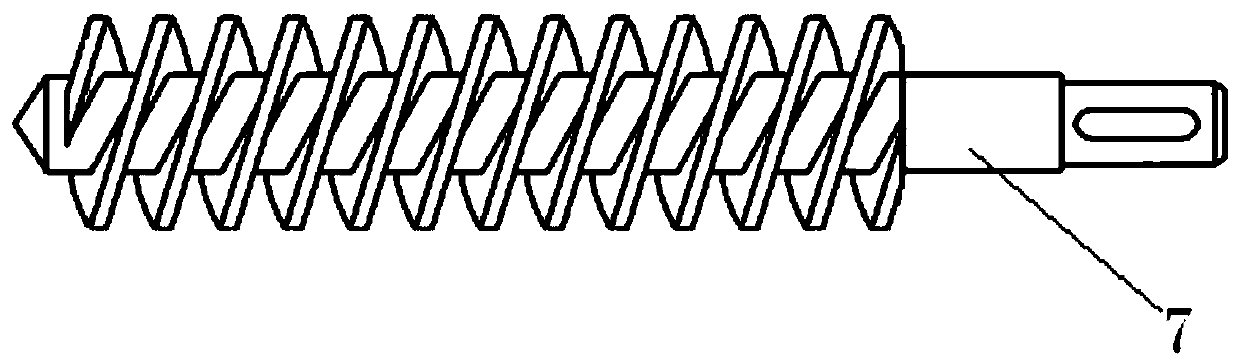

System and method for adjusting raw material flowing speeds in high-flux preparation of multi-element gradient materials

InactiveCN110538586AImprove production efficiencySimple structureFlow mixersMixing methodsMaterials preparationProgrammable logic controller

The invention belongs to the field of material preparation and mainly discloses a system and a method for adjusting raw material flowing speeds in high-flux preparation of multi-element gradient materials such as round tube rods made of materials such as multi-element alloys, resins and glass of which chemical components are in continuous gradient variation along a length direction. The system mainly comprises a PLC (programmable logic controller) control system, raw material granule or powder storage devices, a screw rod conveying pipeline, a raw material mixer, and the like. The device has the advantages of being simple in structure, convenient in operation, easy to control, and the like. According to the device, different raw material storage devices are controlled by the system to continuously convey raw materials into the mixer at continuous and variable speeds, the raw materials from different raw material storage devices are uniformly mixed in the raw material mixer and are continuously fed into a smelting device, and sequential smelting is completed. By adopting the method, continuous gradient material blending of components of materials such as alloys, resin and glass of different components can be achieved, the blending time can be shortened, preparation procedures are simplified, the cost is lowered, and the preparation efficiency of the material is improved.

Owner:UNIV OF SCI & TECH BEIJING

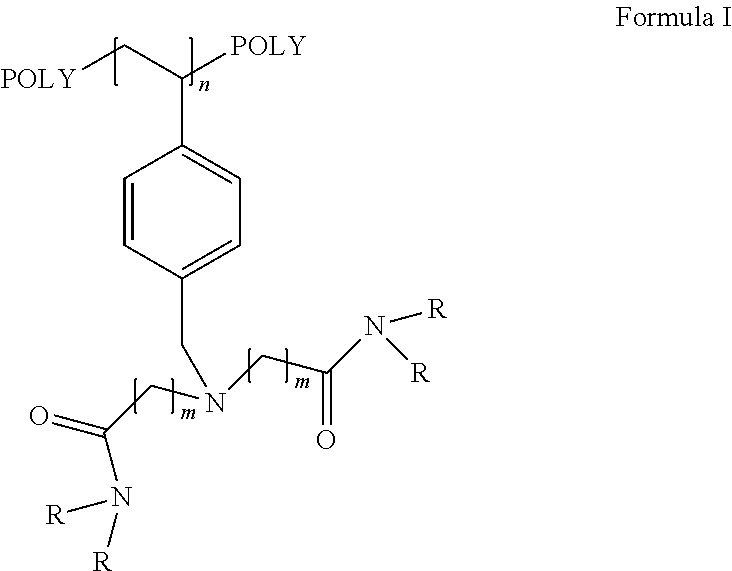

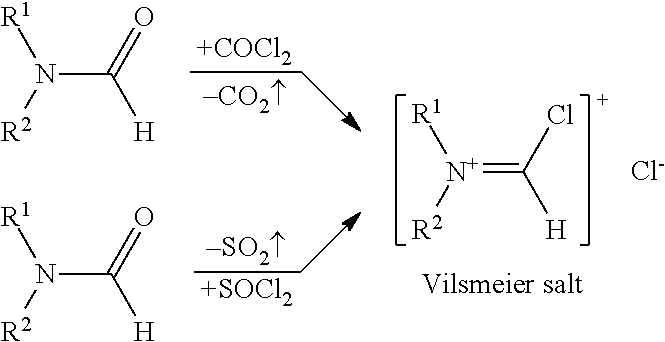

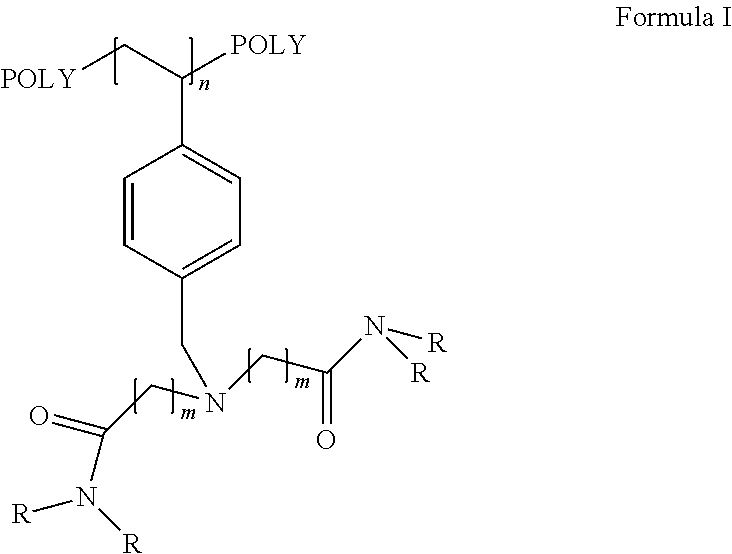

Recyclable catalysts for chlorination of organic acids and alcohols

ActiveUS20170274362A1Easy to separateWithout losing efficiencyOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsRecyclable catalystOrganic acid

The present invention discloses recyclable polymeric catalyst of Formula I, for chlorination of organic acids and alcohols using chlorinating agents such as carbonyl chloride, oxalyl chloride or thionyl chloride,wherein, ‘m’ on the pendent groups on polystyrene backbone can have values from 1 to 5 and R is the alkyl group ranging from C1 to C5.

Owner:GALAXY SURFACTANTS

Carbon environmental protecting type burden charging carriage

InactiveCN101347962AImprove environmental performanceReduce the chance of errorMixing operation control apparatusMixer accessoriesInsulation layerEngineering

The invention relates to a carbon environmentally-friendly burden charging carriage which comprises a platform trolley, a fixed support, a collection storage hopper, a feeding opening and a discharge opening. An insulation layer is arranged on the outer wall of collection storage hopper. The feeding and discharge openings are provided with a feeding pushing device and a discharge pushing device. A positioning sensor is respectively arranged at the two ends of the platform trolley; a dust catcher and a control box are arranged at the outer side of the fixed support. The dust collecting mouth of the dust catcher is communicated with the feeding and discharge openings. The invention realizes the wholly confined production of the feeding and discharge of the trolley,. Therefore, the secondary pollution is reduced, the eco-friendly effects of blending are greatly increased, and the probability of incorrect blending and blending time are reduced, thus improving the blending efficiency; at the same time, the insulation layer arranged on the outer wall of the collection storage hopper can reduce the heat loss of raw materials to the minimum, thus increasing the wet ability of the combination of the raw materials and liquid asphalt.

Owner:SHENYANG ALUMINIUM MAGNESIUM INSTITUTE

Honing liquor dedicated for piston ring

The invention discloses a honing liquid of piston, which comprises the following parts: abradant, mechanic oil and additive, wherein the additive is composed of extreme-pressure resistant additive, cleaning additive and rust-proof additive, which improves using efficiency without odor and harm for skin; the invention can be soaked in the kerosene for 0.5min to use, which adopts common water-based abluent or diesel or kerosene or petrol to clean.

Owner:唐玉冰

Negative electrode of lithium ion battery, and lithium ion battery

InactiveCN102856531AIncrease energy densityImproved magnification performanceCell electrodesSecondary cellsSolid componentAdhesive

The invention relates to the technical field of lithium batteries, and in particular to a negative electrode of lithium ion battery, and a lithium ion battery. The copper foil or the aluminum foil is used as the substrate, the substrate is coated by slurry and prepared into the negative electrode end product of the lithium ion battery, and the slurry is a novel high-performance negative electrode aqueous formula comprising effective solid components and liquid components; the formula comprises the following effective solid components by weight percent: 47.04%-56.26% of negative electrode active substance, 0.98%-1.74% of polyacrylonitrile type aqueous conductive adhesive and 0.24%-0.86% of conductive agent, wherein the negative electrode active substance is graphite; and the liquid components comprise 36.36%-51.01% of deionized water, 0.01%-2.81% of N-methyl pyrrolidinone and 0.01%-2.81% of defoamer. According to the negative electrode of lithium ion battery and the lithium ion battery provided by the invention, the energy density, the rate capability and the cycle performance of the lithium ion battery can be improved obviously, and the time for preparing materials also can be reduced.

Owner:SHENZHEN MEIBAI ELECTRONIC CO LTD

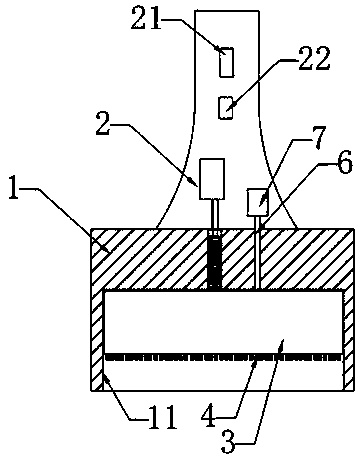

Printing ink powder raw material taking device

InactiveCN108946196AImprove controllabilityShorten batching timeLoading/unloadingPrinting inkEngineering

The invention relates to the technical field of printing ink raw material taking, in particular to a printing ink powder raw material taking device. The device comprises a first cylinder, the first cylinder is connected with a second cylinder in a communicating mode, the feed ends of the first cylinder and the second cylinder are away from each other, the inner side wall of the first cylinder is connected with a hopper, and the right end of the hopper communicates with the second cylinder through the first cylinder. An operator takes the second cylinder by hand and inserts the first cylinder into a storage device for taking materials, and when the raw materials need to be poured out drastically, the first cylinder is toppled; the second cylinder is used when the raw materials need to be poured out gradually and slowly, and the raw materials are gathered through the hopper and poured out through the second cylinder; and the device is provided with two outlet ends, the raw material dumping controllability is enhanced, and the burdening time is shortened.

Owner:安徽雅美油墨有限公司

Automatic batching device

ActiveCN113368743AAvoid crushing problemsShorten batching timeFeeding-stuffRotary stirring mixersSpiral bladeBall screw

The invention belongs to the field of feed mechanical equipment, and particularly relates to an automatic batching device. The device comprises a rack, a raw material mechanism and a motor, the raw material mechanism and the motor are both arranged on the rack, a rotating shaft of the motor is connected with a ball screw, and the ball screw is connected with a sliding block through threads; the raw material mechanism comprises a hopper, a round ball and a connecting rod, a funnel-shaped discharging opening is formed in the bottom end of the hopper, the round ball is used for opening and closing the discharging opening and connected with the sliding block through the connecting rod, a batching box located below the raw material mechanism is further arranged on the rack, and a spiral blade is arranged in the batching box; and the spiral blade is fixedly connected to a rotating shaft. According to the scheme, the motor is arranged to complete the actions of raw material blanking and raw material stirring, so that the batching time is saved, and the automatic batching efficiency is improved.

Owner:重庆众信农牧科技有限公司

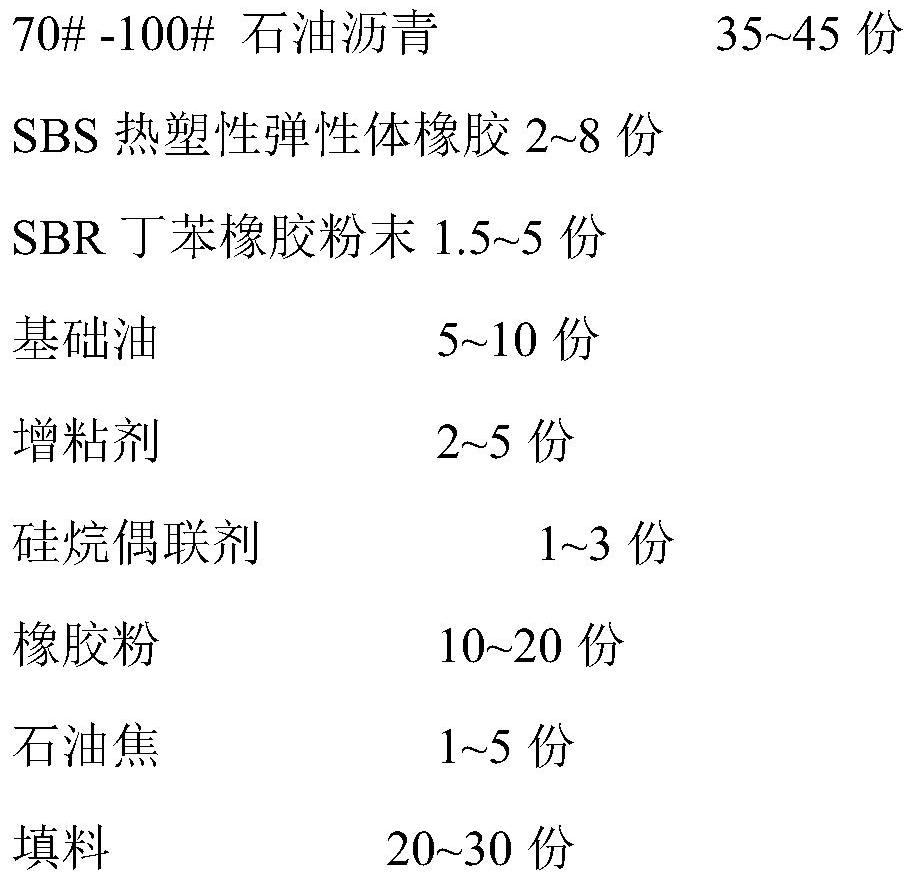

Petroleum coke high polymer modified asphalt waterproof coiled material and preparation method thereof

ActiveCN113136107AHigh tensile strengthGood extensibilityTextiles and paperBuilding insulationsElastomerBituminous waterproofing

The invention discloses an asphalt waterproof coiled material added with petroleum coke as a modifier. The asphalt waterproof coiled material comprises a tire base layer and self-adhesive coating layers arranged on the upper surface and the lower surface of the tire base layer, an upper surface covering layer is arranged above the self-adhesive coating layer on the upper surface of the tire base layer, and a lower surface covering layer is arranged below the self-adhesive coating layer on the lower surface of the tire base layer; wherein the self-adhesive coating layer is prepared from the following components in parts by weight: 35 to 45 parts of 70# to 100# petroleum asphalt; 2-8 parts of SBS thermoplastic elastomer rubber; 1.5-5 parts of SBR butadiene styrene rubber powder; 5-10 parts of base oil; 2-5 parts of a tackifier; 1-3 parts of a silane coupling agent; 10-20 parts of rubber powder; 1-5 parts of petroleum coke; and 20-30 parts of filler. Herein, the petroleum coke is used for partially replacing petroleum asphalt and also serves as an asphalt modifier and filler to improve the stability and weather resistance of the coiled material and improve the plasticity, wear resistance and mechanical strength performance of the coiled material, so that the prepared coiled material is good in tensile strength, high in extensibility and excellent in self-healing performance and waterproof performance. The invention also discloses a preparation method of the asphalt waterproof coiled material.

Owner:鞍山科顺建筑材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com