Patents

Literature

44results about How to "Simplify the batching process" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

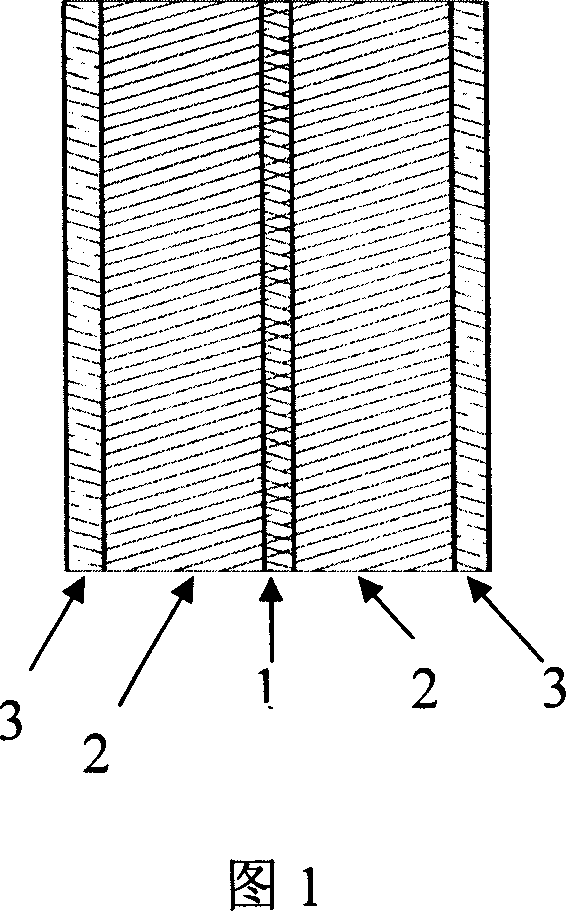

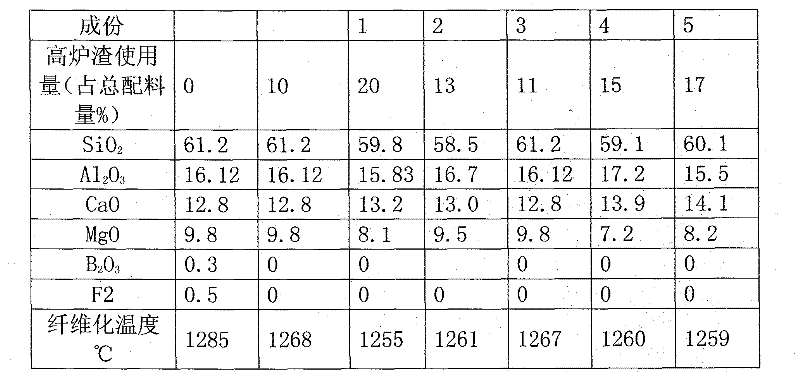

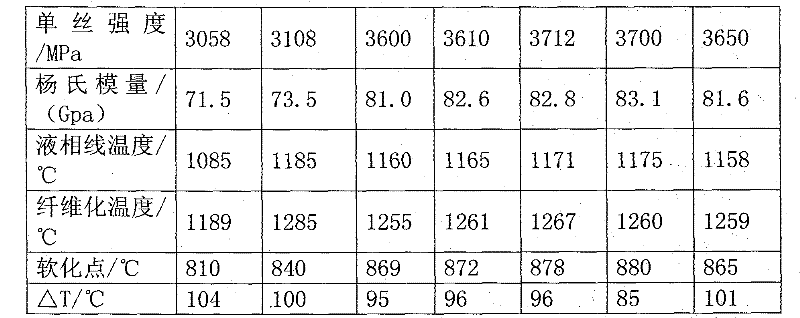

Method for preparing environment-friendly high-modulus glass fiber

The invention relates to an environment-friendly high-modulus glass fiber composition, and discloses a glass component combination used for preparing the high-modulus glass fiber. The glass fiber prepared by glass components is particularly applied to preparing glass fiber reinforced plastic composite material with higher rigidity requirement. The glass composition has no emission of harmful gas, greatly reduces the emission of greenhouse gas, and is an environment-friendly glass fiber formula. The environment-friendly high-modulus glass fiber composition is characterized in that: a blast furnace slag preferably serves as one of major raw materials for reducing the operational difficulty and prepares the high-modulus glass fiber, and the high-modulus glass fiber can be produced and wiredrawn on a tank furnace having an electro-boost structure on a large scale by adopting a direct method. The fiber mainly comprises the following main components: 57 to 62.5 weight percent of SiO2, 14.5 to 19.5 weight percent of Al2O3, 16 to 23.5 weight percent of RO (wherein RO is the sum of CaO, MgO, SrO and BaO), and less than and equal to 1.5 percent of alkali metal oxide. The glass composition and the adopted raw material mode are suitable for the mass production under the production technological condition of the electro-boost tank furnace, and the glass composition has low production cost.

Owner:TAISHAN FIBERGLASS INC

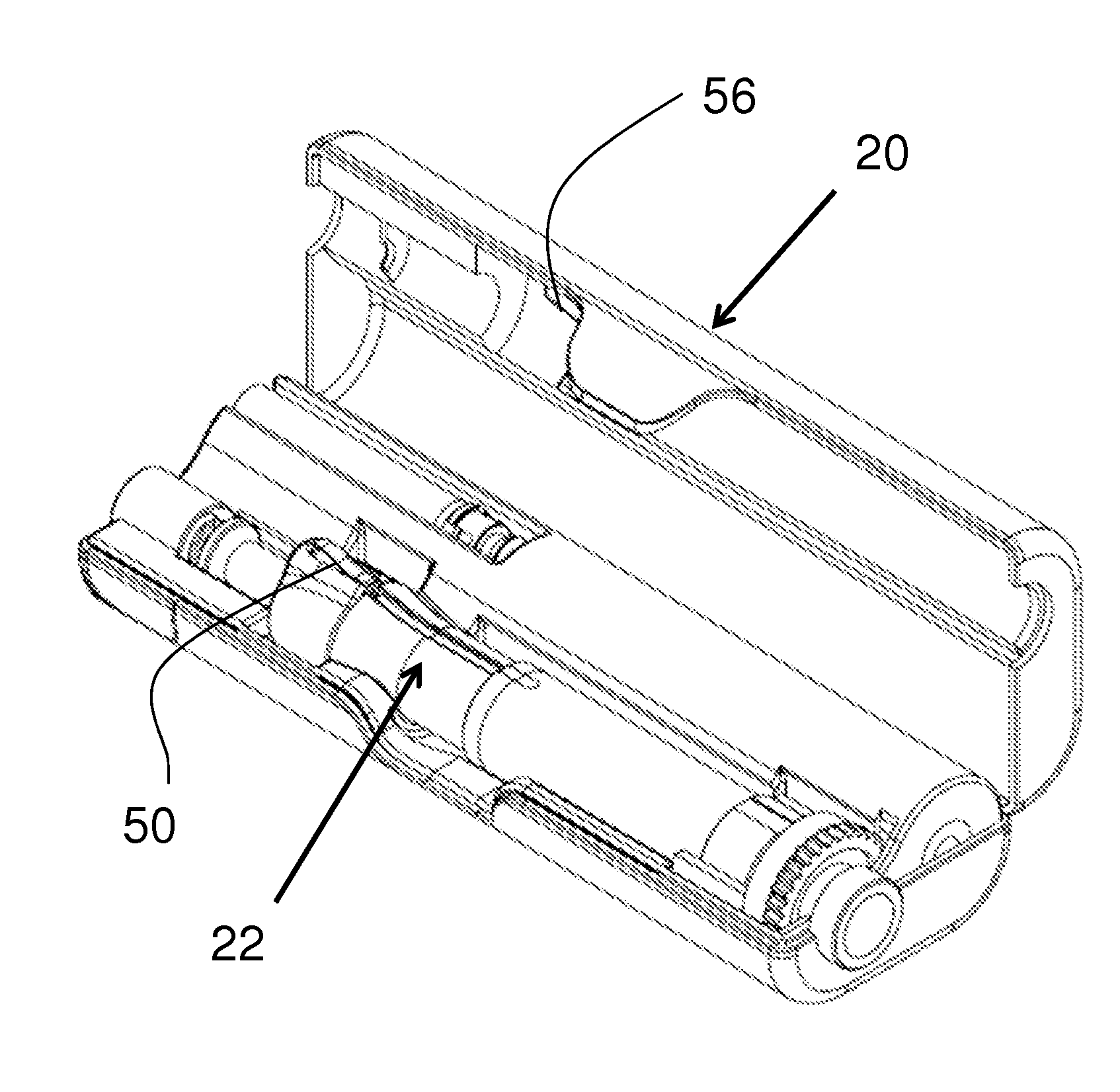

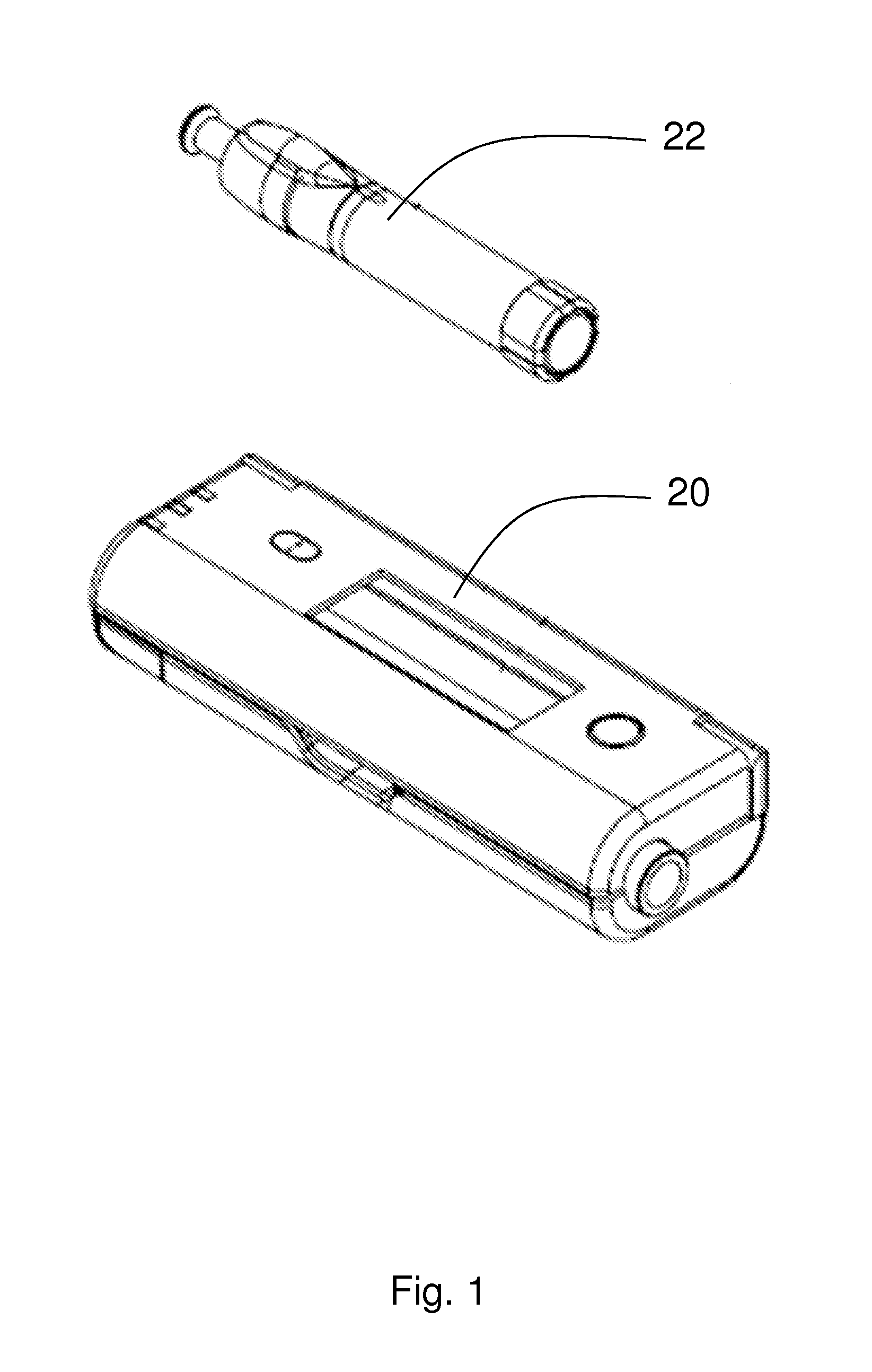

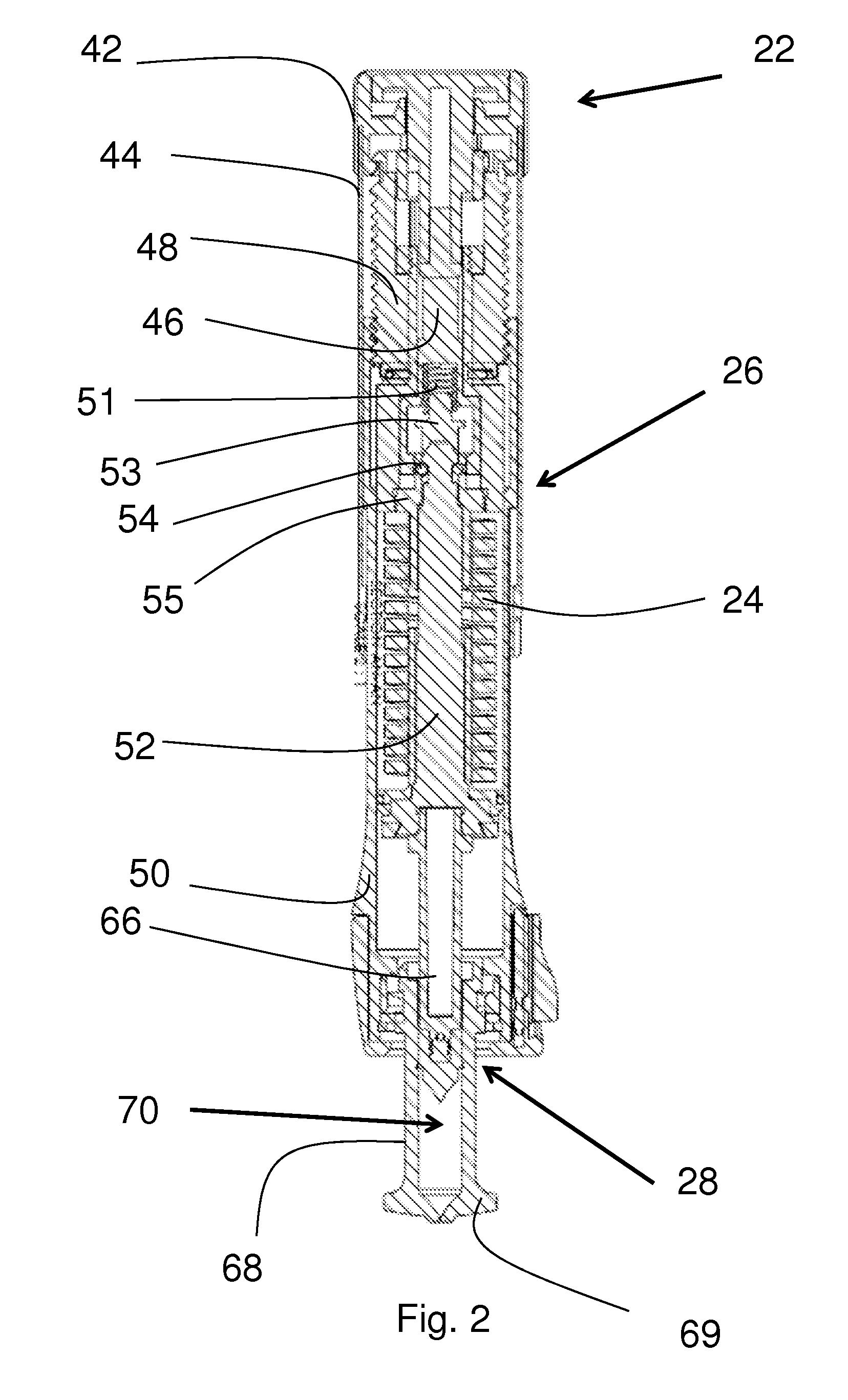

Electrical needle-free injector system

InactiveUS20120302947A1Simplify the batching processReduce the possibilityJet injection syringesAutomatic syringesNeedle Free InjectionNeedle free

In one aspect of the invention, a system comprising a needle-free injector is disclosed. The system comprises a needle-free injector comprising a trigger assembly adapted to exert an injection force, the trigger assembly comprising a spring storing the injection force. The system also comprises a winding mechanism for priming the spring for the storing of the injection force, wherein the winding mechanism is electrically powered. According to another aspect of the present invention, an alternate needle-free injector system is disclosed. The system comprises a needle-free injector comprising a nozzle adapted to be loaded with an injectable. The system also comprises a dosing mechanism for loading the injectable into the nozzle, wherein the dosing mechanism is electrically powered.

Owner:EURO PHARMA GRP

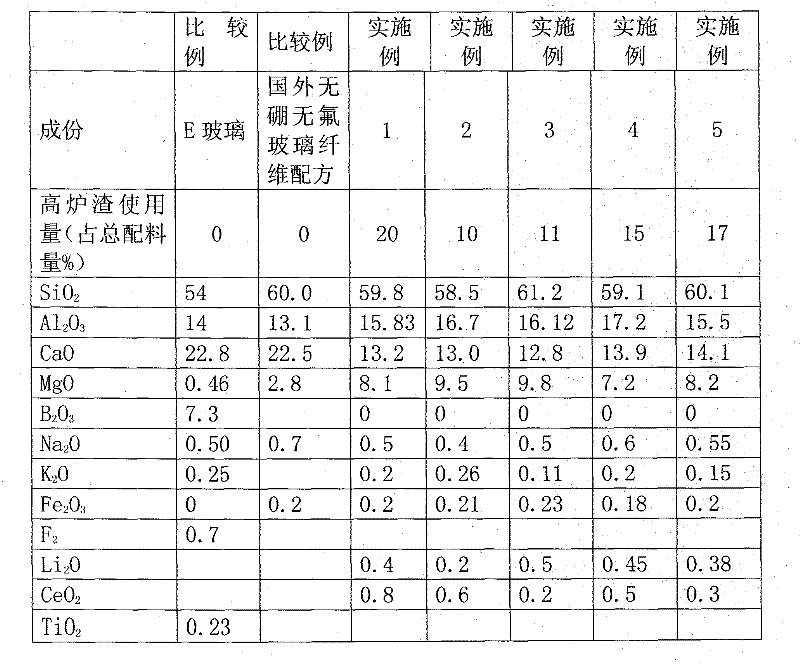

Floride-free low-boron and alkaline-free glass fiber prescription and preparation method

The invention relates to a glass fiber production prescription, in particular to an environment-friendly alkaline-free glass fiber prescription emitting less toxic gas. The prescription is characterized in that the components include SiO2, Al2O3, B2O3, CaO, MgO, K2O and Na2O2. Compared with the E glass fiber widely applied presently, the glass fiber prepared with the prescription of the invention is improved as follows: the raw material containing floride which is most harmful is completely abandoned and the raw material containing volatile boron is largely reduced, but the glass fiber of the invention still remains similar electric performance and mechanical performance. The invention is characterized in that an alkaline-free glass fiber using blast furnace slag as one of the main raw materials, realizing reduction of operation difficulty and great reduction of exhaust emission is preferential and can be produced directly in large scale in a tank furnace including an electric boosting structure. The use of an industrial raw material easy for melting and clearing, namely, the blast furnace slag, ensures the glass fiber to have similar operating performance as the E glass fiber and to adapt to large-scale production under the existing E glass fiber tank furnace production technology.

Owner:TAISHAN FIBERGLASS INC

Combination type full dummy brightness transferring aluminum-plating paper coating and preparing method thereof

ActiveCN101408015AThere will be no phenomenon such as uneven extinctionSimplify the batching processCoatings with pigmentsCoatingsAcrylic resinThermoplastic polyurethane

The invention relates to combination type total matte luster shift aluminum-plated paper paint and a preparation method thereof. The combination type total matte luster shift aluminum-plated paper paint consists of double coating type total matte luster shift aluminum-plated paper paint and separating paint used together with the aluminum-plated paper paint, the double coating type total matte luster shift aluminum-plated paper paint adopts the following components and contents (weight percentage) as raw materials: 6 to 8 percent of solid thermoplastic acrylic resin, 4 to 5 percent of thermoplastic polyurethane resin, 4 to 5 percent of chlorovinyl ether, 0 to 2 percent of nitrocotton, 0.5 to 1 percent of dye, 0.05 to 0.1 percent of auxiliary agent and 80 to 82 percent of solvent. Compared with the prior art, the invention has the following advantages: the batching procedure is simple, the delustering degree is high, the total matte effect of aluminum foil can be reached, and the difficulty that the shift aluminum-plated paper can not be made like matte aluminium-foil paper is solved; the difficulty of the fold foil break of the aluminium-foil card paper is overcome, the cost is lowered; the made products have better printing adaptability and good binding property with paper, aluminum plating luster is soft and simple but elegant, the aluminum plating fastness is good, and the application range is wide.

Owner:SHANGHAI WEIKAI CHEM

Al-Mo-Cr-Sn-Nb-Zr intermediate alloy and preparation method thereof

The invention provides an Al-Mo-Cr-Sn-Nb-Zr intermediate alloy and a preparation method thereof. The Al-Mo-Cr-Sn-Nb-Zr intermediate alloy comprises the following components by mass: 20.0-22.0% of Mo, 11.0-13.0% of Cr, 14.0-16.0% of Sn, 14.0-16.0% of Nb, 15.0-17.0% of Zr and the balance of Al. According to design of the alloy components, the Al-Mo-Cr-Sn-Nb-Zr intermediate alloy has small composition segregation, and is conductive to homogenizing of the alloy components when replacing binary alloy for alloy smelting of TC21 titanium alloy to prevent composition segregation, so that the compounding procedure of TC21 titanium alloy smelting is simplified. Experimental results show that the Al-Mo-Cr-Sn-Nb-Zr intermediate alloy is uniform and stable in component and small in segregation. The preparation method is simple, easy to control and suitable for large-scale industrial production.

Owner:CHENGDE TIANDA VANADIUM IND

Strawberry pudding powder

InactiveCN103652652AAttractive appearanceSmooth tasteFood ingredient as flavour affecting agentFood ingredient as gelling agentSucroseSaccharum

The invention relates to a strawberry pudding powder which is prepared from the following components in percentage by weight: 40-50% of white granulated sugar, 25-35% of milk powder, 10-15% of egg white powder, 8-12% of strawberry powder, 2.3-2.5% of konjac glucomannan, 1.6-1.8% of carrageenin, 0.6-0.8% of sucrose ester and 0.03-0.05% of monascus red. The pudding powder is prepared by the following steps: proportioning, mixing, microwave sterilization and packaging. The strawberry pudding prepared from the strawberry pudding powder has the advantages of seductive appearance, smooth and delicate mouthfeel, thick milk flavor, fresh strawberry flavor and no peculiar smell. The pudding preparation method is simple and convenient, and saves both time and labor; and the proportioning process is completed by adding a certain amount of pure water into the pudding powder, thereby avoiding the inconvenience of weighing, mixing and preparing every component in the proportioning process, and greatly simplifying the proportioning procedure. The product is powdery, and thus, is easier to store and preserve.

Owner:HARBIN AIKEER FOOD TECH

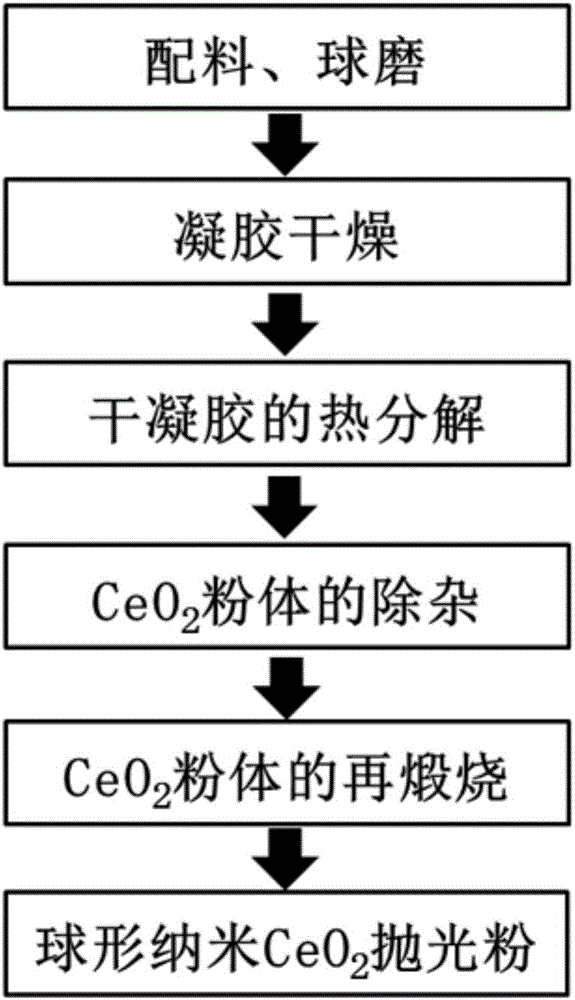

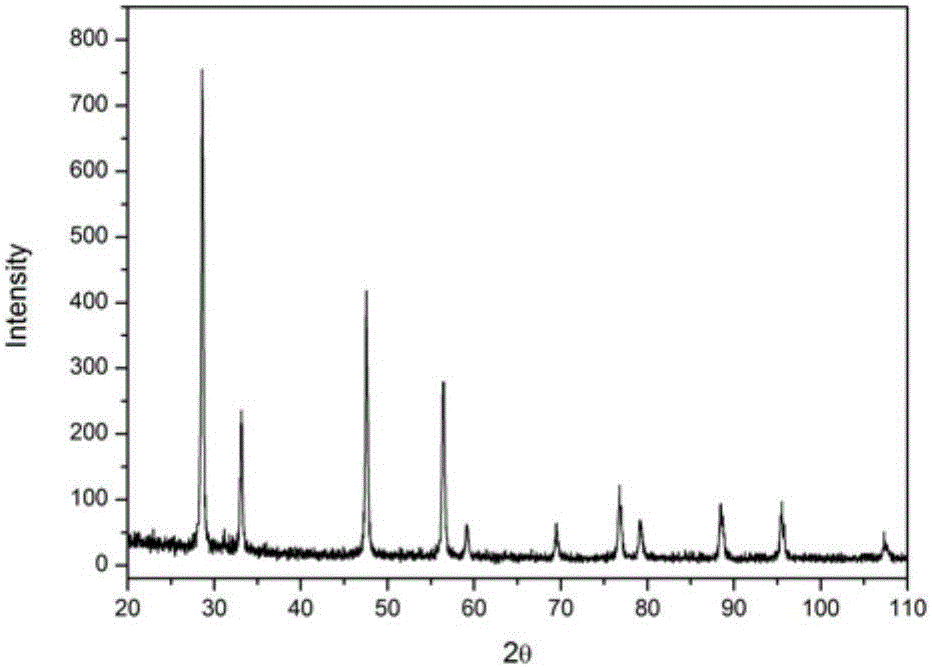

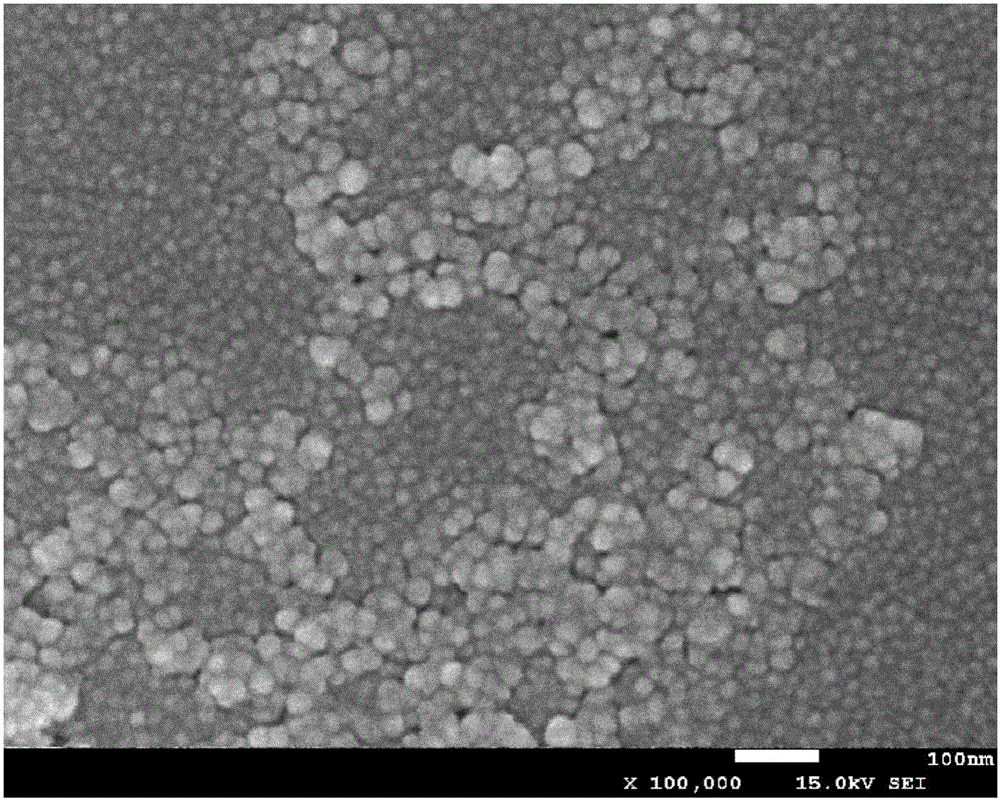

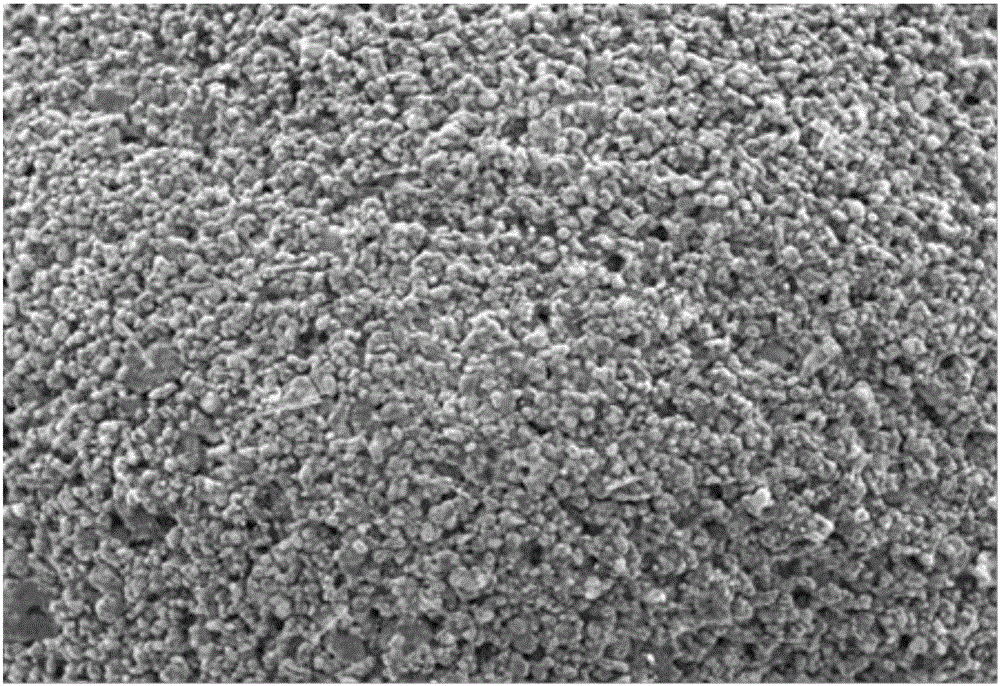

Preparation method of spherical nanometer CeO2 polishing powder

ActiveCN106587131AGranularityUniform particle sizeRare earth metal oxides/hydroxidesPolishing compositions with abrasivesChemical reactionCerium

The invention discloses a preparation method of spherical nanometer CeO2 polishing powder and belongs to the field of nanometer material research. The preparation method utilizes a crystal water-containing cerium salt and citric acid as raw materials, a proper amount of ethanol as a lubricant and the ball milling mechanical force to refine the raw materials so that reaction efficiency is improved. Crystal water released by the raw materials and the lubricant ethanol form a liquid film and precursor gel is directly prepared so that a ball milling solid-phase chemical reaction method and a sol-gel method are combined. The gel can effectively inhibit the agglomeration and growth of cerium oxide particles in later calcination processes so that the pherical nanometer CeO2 polishing powder with uniform particle sizes, good dispersibility and good polishability are prepared. The pherical nanometer CeO2 polishing powder has uniform particle sizes, good dispersibility and good polishability. The preparation method has the advantages of simple processes, high efficiency, no pollution and good reproducibility, and is suitable for industrial mass production.

Owner:SICHUAN UNIV

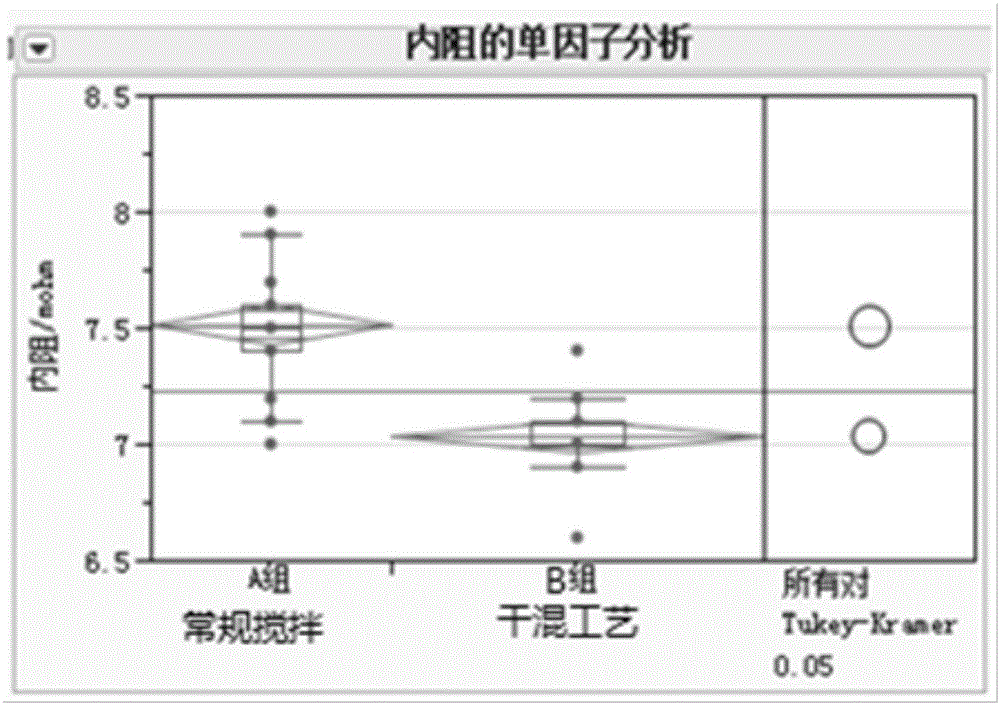

Preparation method of lithium ferric phosphate cathode slurry

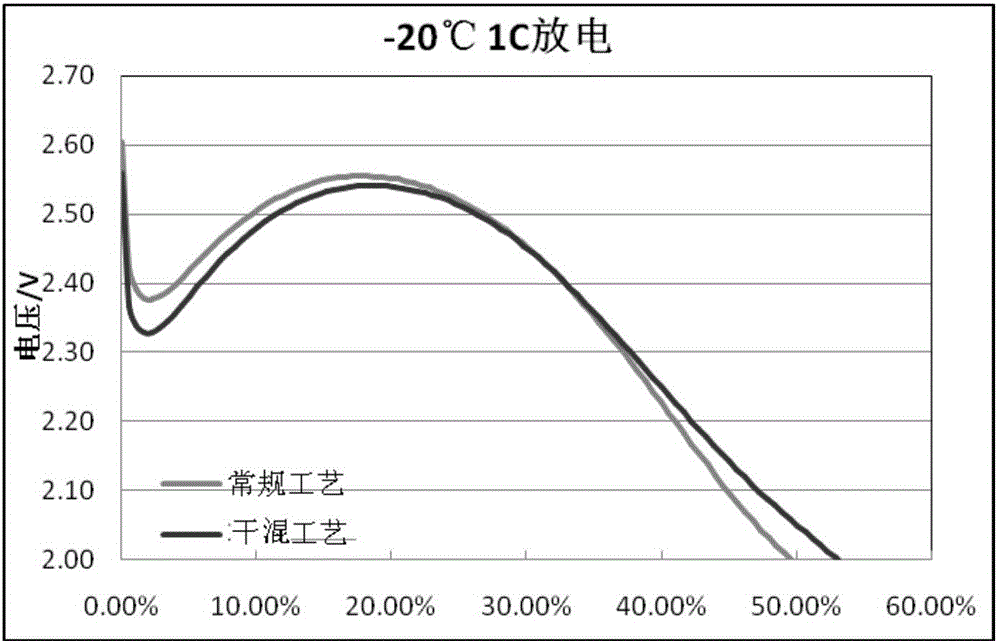

InactiveCN106340649AGood dispersionWell mixedCell electrodesSecondary cellsLithium iron phosphateSlurry

The invention provides a preparation method of lithium ferric phosphate cathode slurry. The preparation method comprises the following steps that 1, lithium ferric phosphate powder and adhesive powder are added to a stirring tank, and first-time stirring is performed; 2, all solvents are added, cooling water is added, second-time stirring is performed, and material scraping is performed after the second-time stirring is completed; 3, the rotating speed of the stirring tank is adjusted, and high-speed dispersion is conducted on the obtained slurry in the step 2; 4, a conductive agent is added to perform third-time stirring, and material scraping is performed after the third-time stirring is completed; 5, the rotating speed of the stirring tank is adjusted, and vacuum defoamation is conducted on the slurry obtained in the step 4. The lithium ferric phosphate cathode slurry prepared by adopting the preparation method is good in dispersion effect and uniform in mixing, a burdening process is simplified, and the labor costs and energy consumption are reduced. The inner resistance, multiplying power, low temperature and cycling performance of a lithium ion battery using the prepared lithium ferric phosphate cathode slurry as an anodic active material are good.

Owner:OPTIMUM BATTERY CO LTD

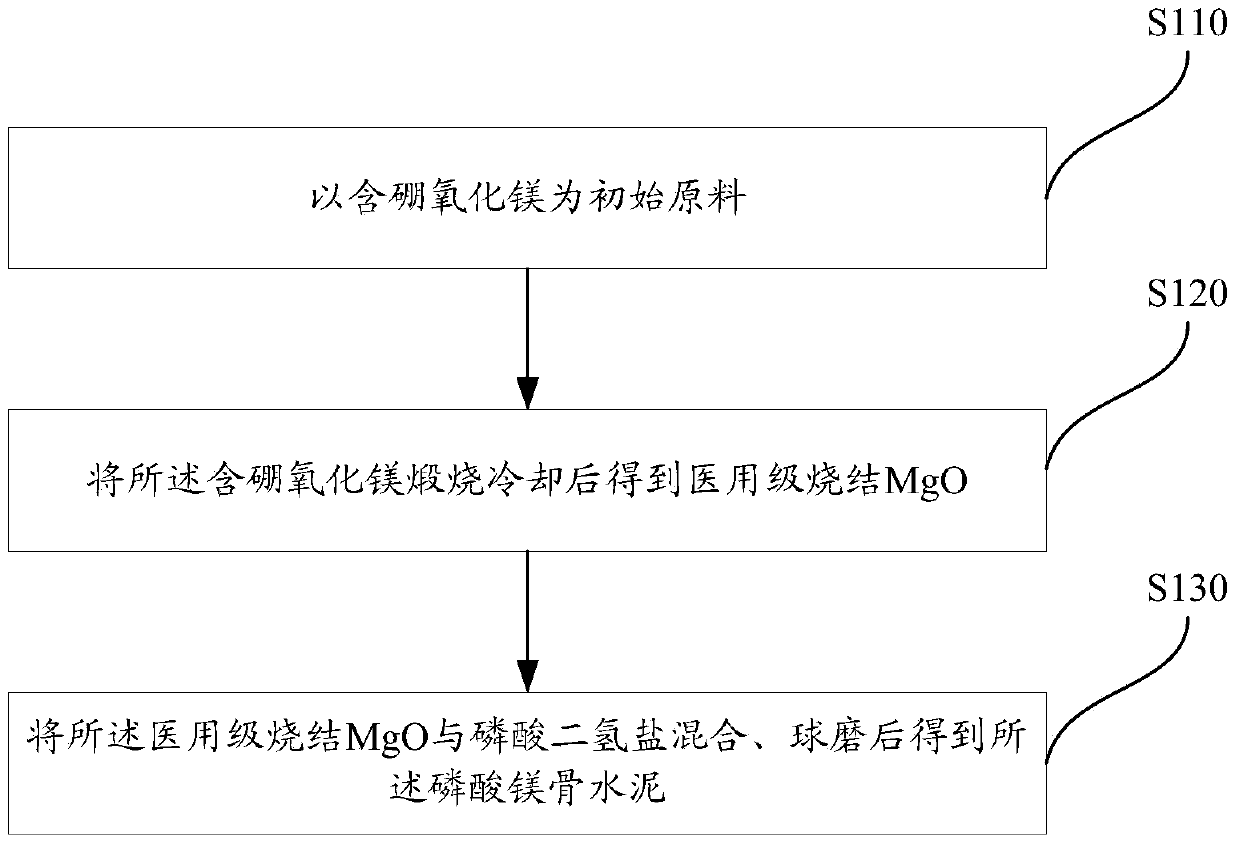

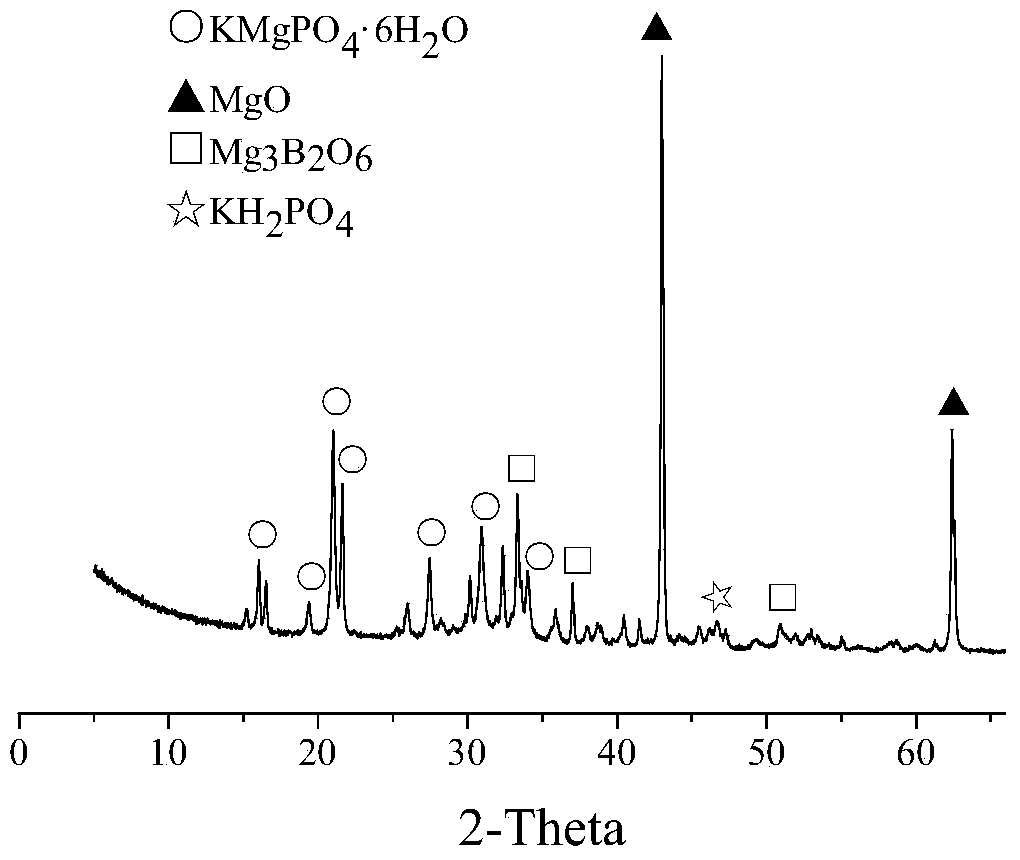

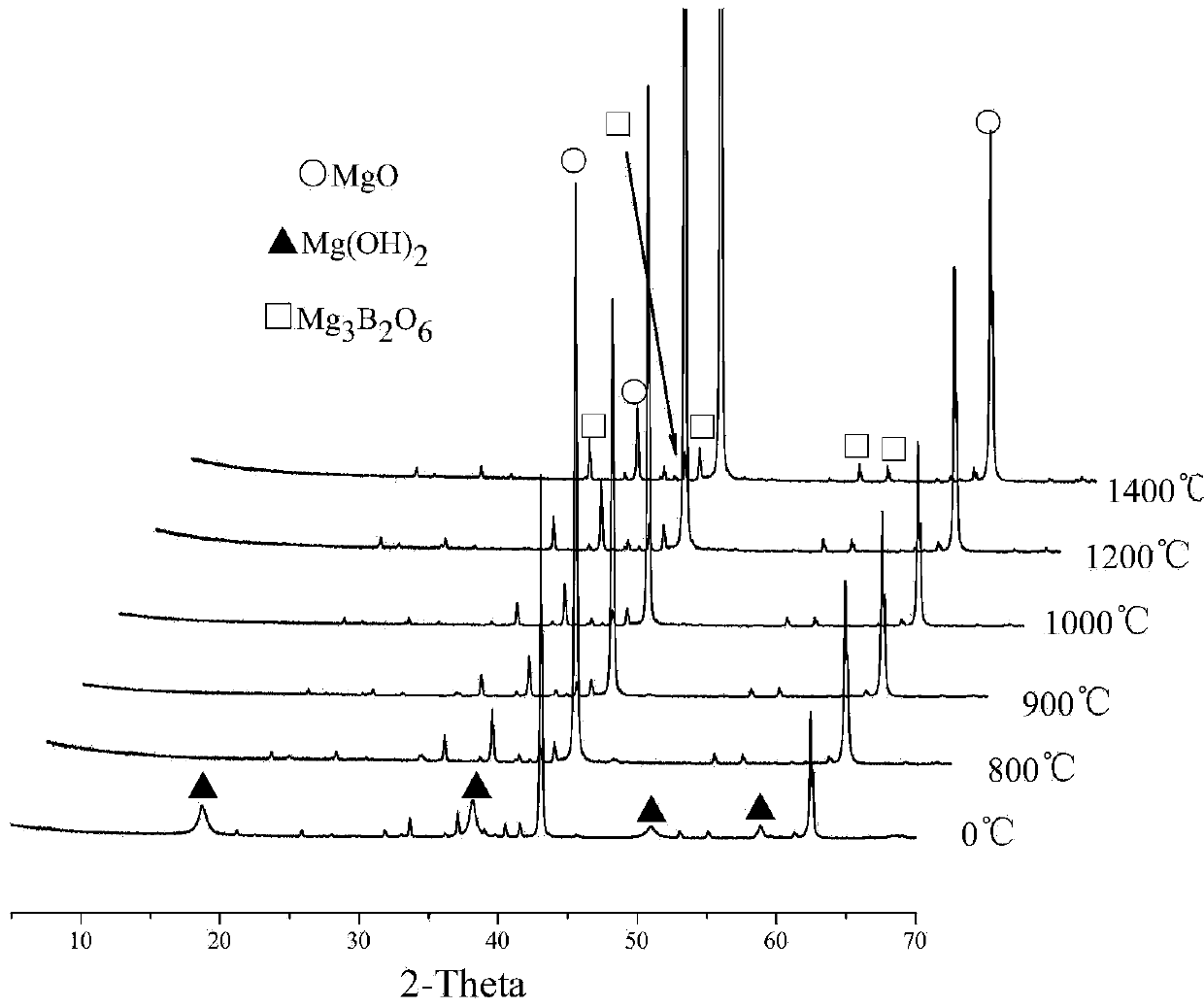

Preparation method and application of magnesium phosphate cement

The invention provides a preparation method of magnesium phosphate cement. The method comprises the following steps: using boron-containing magnesium oxide as an initial raw material, performing calcination on boron-containing magnesium oxide, cooling to obtain sintered MgO, mixing sintered MgO with dihydric phosphate, and performing ball-milling to obtain the magnesium phosphate cement. According to the method for preparing the magnesium phosphate cement, boron-containing magnesium oxide is used as the initial raw material, calcination and cooling are performed on the initial raw material to obtain sintered MgO, then mixing and ball-milling are performed on the sintered MgO and dihydric phosphate to obtain the magnesium phosphate cement. By regulating the calcination temperature of the initial raw material, the setting time and hydration exothermic temperature of MPC slurry can be regulated and controlled without adding extra setting retarders such as boric acid and borax, so that the blending process is simplified, the cost is reduced, and the interferences of other ions in the setting retarders to the inner environment of a human body are avoided.

Owner:QINGHAI INST OF SALT LAKES OF CHINESE ACAD OF SCI +1

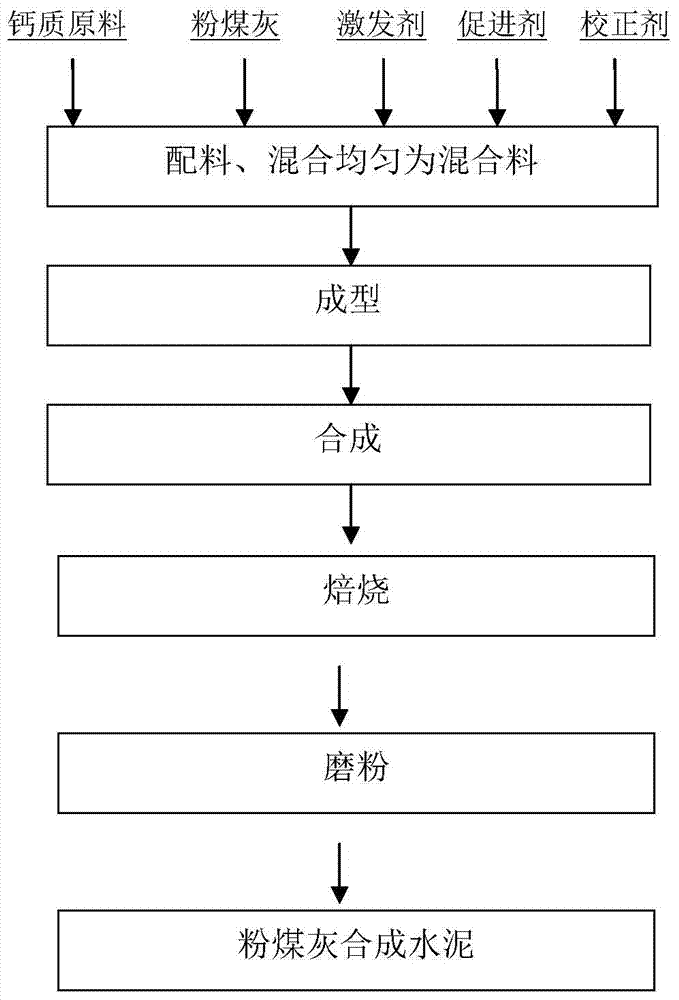

Fly ash synthesized cement and production method thereof

InactiveCN104261705AHas zero emissionsAchieving zero emissionsCement productionCalcium in biologyResidual carbon

The invention discloses a fly ash synthesized cement and a production method thereof. The cement is composed of the following components in percentage by weight: 50% to 90% of fly ash with a carbon content more than 5%, 5 to 40% of calcareous raw material, 1.5 to 10% of initiator, 1.5 to 10% of promoter, and 2 to 10% of corrector. The fly ash synthesized cement has the following advantages: (1) the discharge of sulfur dioxide is zero during the whole production process; (2) the production cost is reduced; (3) the cement strength is improved; (4) the residual carbon and combustible components in the raw materials can be burned; (5) the fuel cost can be saved, and the technology process is enhanced; (6) the residual carbon is taken as the fuel, thus the energy is saved, the cost is reduced, the environmental pollution is reduced, and the environment is protected; (7) the goals of decarbonization and dehydration can be achieved by burning, and moreover the adaptability of the production equipment on raw materials is improved; (8) in the milling procedure, the technology and equipment are identical with the present conventional cement clinker miller, and thus the modification and application of the technology and equipment are easy for the cement entrepreneurs; and (9) the sources of the raw materials and auxiliary materials are wide, the supply is sufficient in the market, and the selected equipment is matured and reliable and has strong universality.

Owner:成浩 +1

Method for preparing high-level refractory material through ferronickel smelting slag

A method for preparing a high-level refractory material through ferronickel smelting slag comprises the following steps: mixing ferronickel smelting slag, magnesite and chromic oxide; performing ballmilling to obtain fine-sized uniform mixture; synchronously adjusting and controlling to realize w(MgO) / w(SiO2)=1.37-1.40 and w(MgO) / w(Cr2O3)=6.02-12.20 in the uniform mixture; additionally adding a binding agent; controlling the sintering temperature of 1200-1500 DEG C; inducing phase and structure transformation of ferronickel smelting slag; and optimizing the refractory phase (Mg2SiO4, [Fe, Mg][Cr, Fe]2O4) crystal transformation to realize directional phase and structure transformation, thus obtaining the refractory material with high crystalizing performance and dense structure. The refractory material is high in refractoriness and compressive strength; the refractoriness is up to 1800-1860 degrees; in addition, the refractory material has the advantages of being high in compressive strength, high in volume density, and low in apparent porosity; the industrial demands on the refractory material can be completely met. The method has the advantages of being high in resource utilization rate, high in production efficiency, high in added value of product, environmentally friendly, easy to control processes, and low in production cost.

Owner:CENT SOUTH UNIV

Yogurt pudding powder

The invention relates to a yogurt pudding powder which is prepared from the following components in percentage by weight: 35-45% of white granulated sugar, 20-30% of yogurt powder, 15-20% of non-dairy creamer, 10-15% of egg white powder, 2.3-2.5% of konjac glucomannan, 1.6-1.8% of carrageenin and 0.6-0.8% of sucrose ester. The pudding powder is prepared by the following steps: proportioning, mixing, microwave sterilization and packaging. The yogurt pudding prepared from the yogurt pudding powder has the advantages of seductive appearance, smooth and delicate mouthfeel, thick milk flavor, typical yogurt flavor and no peculiar smell. The pudding preparation method is simple and convenient, and saves both time and labor; and the proportioning process is completed by adding a certain amount of pure water into the yogurt pudding powder, thereby avoiding the inconvenience of weighing, mixing and preparing every component in the proportioning process, and greatly simplifying the proportioning procedure. The product is powdery, and thus, is easier to store and preserve.

Owner:HARBIN AIKEER FOOD TECH

Red bean pudding powder

InactiveCN103652651AStrong gelGelationFood ingredient as flavour affecting agentFood ingredient as gelling agentFlavorSaccharum

The invention relates to a red bean pudding powder which is prepared from the following components in percentage by weight: 35-45% of white granulated sugar, 20-30% of milk powder, 15-20% of red bean powder, 10-15% of egg white powder, 2.3-2.5% of konjac glucomannan, 1.6-1.8% of carrageenin and 0.6-0.8% of sucrose ester. The pudding powder is prepared by the following steps: proportioning, mixing, microwave sterilization and packaging. The red bean pudding prepared from the red bean pudding powder has the advantages of seductive appearance, smooth and delicate mouthfeel, thick milk flavor, fresh red bean flavor and no peculiar smell. The pudding preparation method is simple and convenient, and saves both time and labor; and the proportioning process is completed by adding a certain amount of pure water into the pudding powder, thereby avoiding the inconvenience of weighing, mixing and preparing every component in the proportioning process, and greatly simplifying the proportioning procedure. The product is powdery, and thus, is easier to store and preserve.

Owner:HARBIN AIKEER FOOD TECH

Battery negative electrode and lithium secondary battery having same

InactiveCN1929165AIncrease capacityImprove the first charge and discharge efficiencyElectrode carriers/collectorsActive material electrodesAlloyEngineering

This invention relates to lithium secondary battery cathode, which comprises integration and cathode materials layer on the integration part, wherein, the battery cathode comprises lithium alloy layer outside cathode layer; the battery has high initial discharging efficiency and first recycle discharging capacity and second one.

Owner:BYD CO LTD

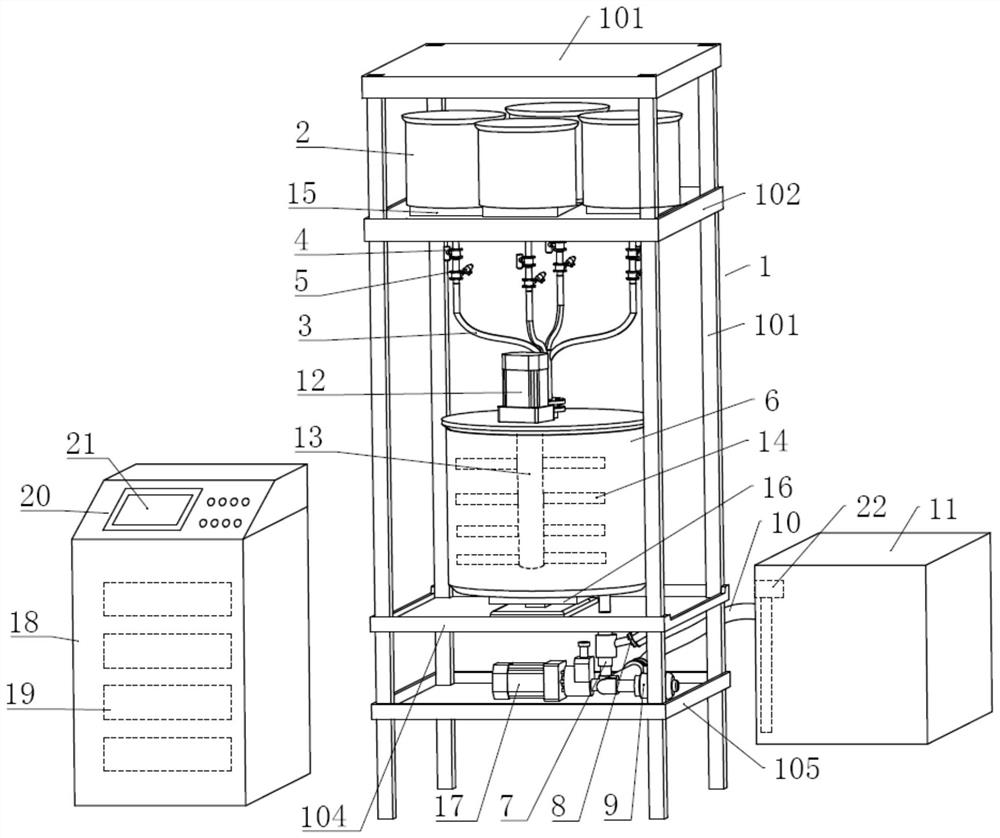

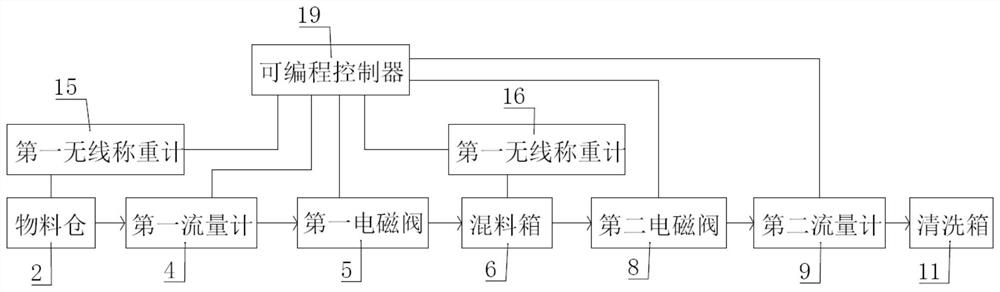

Multi-material full-automatic mixing device for SV type cleaning equipment and control system thereof

InactiveCN111701480AControl inputPrecise ratioRotary stirring mixersTransportation and packagingControl systemWireless traffic

The invention relates to the technical field of material mixing devices for cleaning equipment. The invention provides a multi-material full-automatic mixing device for SV type cleaning equipment anda control system thereof. The multi-material full-automatic mixing device for the SV-type cleaning equipment comprises: a machine frame, wherein a plurality of material bins are arranged at the top ofthe rack; the bottoms of the multiple material bins communicate with conveying pipes; a first wireless flow meter and a first electromagnetic valve are installed on each conveying pipe; the ends, away from the material bin, of the multiple conveying pipes communicate with the material mixing barrel; the bottom of the material mixing barrel communicates with a discharging pipe, and a second electromagnetic valve and a second wireless flow meter are installed on the discharging pipe; the end, away from the material mixing barrel, of the discharging pipe communicates with a connecting pipe whichcommunicates with the cleaning box. According to the invention, automatic and accurate control of material conveying, proportioning and stirring is realized, the operation is simple, and the materialproportioning is accurate and uniform.

Owner:WEIFANG VOCATIONAL COLLEGE

B05-grade autoclaved aerated concrete block and preparation method thereof

The invention discloses a B05-grade autoclaved aerated concrete block and a preparation method thereof. The B05-grade autoclaved aerated concrete block comprises the following raw materials in percentby weight: 77-78% of fly ash, 13.5-14.5% of lime, 6-7% of cement, 2-2.5% of gypsum and 0.061-0.065% of silicon dioxide-coated aluminum powder. A gas-forming agent, namely aluminum powder, is pretreated by a coating method so as to cover a part of the surface thereof with a film layer, so that the contact surface area between the aluminum powder and a slurry is reduced, and thus the stirring timeof the aluminum powder in the slurry is prolonged; after a longer stirring time, the aluminum powder is dispersed in the slurry as uniformly as possible, so that the finally formed aerated concrete block is guaranteed to have relatively high porosity and a uniform porous structure and thus light weight and high strength are achieved.

Owner:SICHUAN UNIV +1

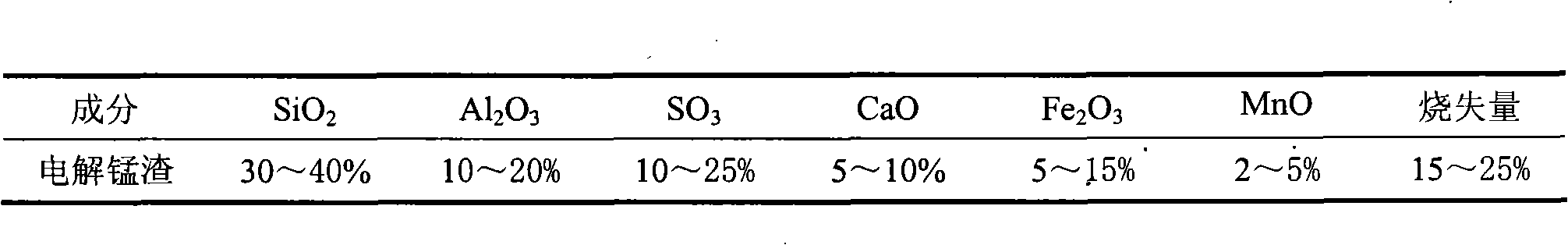

An electrolytic manganese slag black glass decoration material and method of producing the same

An electrolytic manganese slag black glass decoration material and method of producing the same pertains to the field of the black glass decoration material technology. The raw materials of the invention is manganese slag and sodium carbonate, and charcoal powder; the inventive method takes the manganese slag and sodium carbonate, and charcoal powder as raw materials, mixes and melts into a glass flux, and then naturally cools to obtain the completed product after molding and annealing process. The invention has fewer raw materials, only three kinds, and has large electrolytic manganese slag consumption amount, which is an effective method of industrial waste resource use and resolving the environment pollution. The invention method has less process, good energy-saving effect, low fabricating cost, good popularization and application; and the temperature for melting glass flux is 300 DEG C lower than the prior process. The color and luster of the black glass decoration material prepared by the invention is just as ink, and its bright as a mirror. Therefore, the products prepared by the present invention can be widely used as building, furniture and office supplies, art and daily utensils, and the like black glass decoration material products.

Owner:CHONGQING UNIV

Cherry milkshake powder

InactiveCN103651793ASolve the problem of unstable emulsification systemSmooth tasteMilk preparationFlavorSucrose

The invention relates to cherry milkshake powder which comprises the following components in percentage by weight: 35-45 percent of white granulated sugar, 25-30 percent of yoghurt powder, 15-25 percent of vegetable fat powder, 10-12 percent of cherry powder, 0.8-1.2 percent of sucrose ester, 0.6-0.8 percent of sodium carboxymethylcellulose and 0.04-0.06 percent of monascus red. The cherry milkshake powder is prepared through blending, mixing, microwave sterilizing and packaging. When the cherry milkshake powder prepared by using the invention is made into cherry milkshake, the cherry milkshake powder has the advantages of convenience in making, time and labor saving, and the like; and the blending process is completed by adding a defined amount of pure water in the cherry milkshake powder, thus troubles of weighing, re-mixing and preparing of each component during blending are avoided, and the blending procedure is greatly simplified. The cherry milkshake prepared by using the cherry milkshake powder is smooth and tender in mouth feel, and strong in milk flavor, and has a sour and sweet taste and the fragrance of cherry.

Owner:HARBIN AIKEER FOOD TECH

Coconut pudding powder

The invention relates to a coconut pudding powder which is prepared from the following components in percentage by weight: 35-45% of white granulated sugar, 20-30% of milk powder, 15-20% of coconut powder, 10-15% of egg white powder, 2.3-2.5% of konjac glucomannan, 1.6-1.8% of carrageenin and 0.6-0.8% of sucrose ester. The pudding powder is prepared by the following steps: proportioning, mixing, microwave sterilization and packaging. The coconut pudding prepared from the coconut pudding powder has the advantages of seductive appearance, smooth and delicate mouthfeel, thick milk flavor, fresh coconut flavor and no peculiar smell. The pudding preparation method is simple and convenient, and saves both time and labor; and the proportioning process is completed by adding a certain amount of pure water into the coconut pudding powder, thereby avoiding the inconvenience of weighing, mixing and preparing every component in the proportioning process, and greatly simplifying the proportioning procedure. The product is powdery, and thus, is easier to store and preserve.

Owner:HARBIN AIKEER FOOD TECH

Mango milk shake powder

InactiveCN103651790ASolve the problem of unstable emulsification systemSmooth tasteMilk preparationSucroseAdditive ingredient

The invention discloses mango milk shake powder which consists of the following components in percentage by weight: 35-45 percent of white granulated sugar, 25-30 percent of yoghourt powder, 15-25 percent of non-dairy creamer, 10-15 percent of mango powder, 0.8-1.2 percent of sucrose ester, 0.6-0.8 percent of sodium carboxymethylcellulose and 0.04-0.06 percent of gardenia yellow. The mango milk shake powder is prepared by blending the materials, mixing the materials, performing microwave sterilization and packaging finished products. When the mango milk shake powder disclosed by the invention is used for making mango milk shake, the advantages of convenience in making, time and labor conservation and the like are realized. The material blending process can be finished by adding a fixed amount of pure water into the mango milk shake powder, so that the troubles that every component is required to be weighed, mixed and prepared during blending are avoided, and the blending working procedure is greatly simplified. The mango milk shake prepared by the mango milk shake powder tastes smooth and fine, has mellow milk smell and fruity fragrance of a mango and can even be a delicacy in beverage.

Owner:HARBIN AIKEER FOOD TECH

Method for preparing environment-friendly high-modulus glass fiber

The invention relates to an environment-friendly high-modulus glass fiber composition, and discloses a glass component combination used for preparing the high-modulus glass fiber. The glass fiber prepared by glass components is particularly applied to preparing glass fiber reinforced plastic composite material with higher rigidity requirement. The glass composition has no emission of harmful gas,greatly reduces the emission of greenhouse gas, and is an environment-friendly glass fiber formula. The environment-friendly high-modulus glass fiber composition is characterized in that: a blast furnace slag preferably serves as one of major raw materials for reducing the operational difficulty and prepares the high-modulus glass fiber, and the high-modulus glass fiber can be produced and wiredrawn on a tank furnace having an electro-boost structure on a large scale by adopting a direct method. The fiber mainly comprises the following main components: 57 to 62.5 weight percent of SiO2, 14.5 to 19.5 weight percent of Al2O3, 16 to 23.5 weight percent of RO (wherein RO is the sum of CaO, MgO, SrO and BaO), and less than and equal to 1.5 percent of alkali metal oxide. The glass composition and the adopted raw material mode are suitable for the mass production under the production technological condition of the electro-boost tank furnace, and the glass composition has low production cost.

Owner:TAISHAN FIBERGLASS INC

Apple milk shake powder

The invention discloses apple milk shake powder which consists of the following components in percentage by weight: 35-45 percent of white granulated sugar, 25-30 percent of yoghourt powder, 15-25 percent of non-dairy creamer, 10-12 percent of apple powder, 0.8-1.2 percent of sucrose ester, 0.6-0.8 percent of sodium carboxymethylcellulose and 0.03-0.05 percent of sodium copper chlorophyllin. The apple milk shake powder is prepared by blending the materials, mixing the materials, performing microwave sterilization and packaging finished products. When the apple milk shake powder disclosed by the invention is used for making apple milk shake, the advantages of convenience in making, time and labor conservation and the like are realized. The material blending process can be finished by adding a fixed amount of pure water into the apple milk shake powder, so that the troubles that every component is required to be weighed, mixed and prepared during blending are avoided, and the blending working procedure is greatly simplified. The apple milk shake prepared by the apple milk shake powder tastes smooth and fine, has mellow milk smell and fruity fragrance of an apple and can even be a delicacy in beverage.

Owner:HARBIN AIKEER FOOD TECH

A kind of frozen dough and its preparation method and application

The invention belongs to the technical field of food processing, and in particular relates to a frozen dough and its preparation method and application. The frozen dough of the present invention is made of the following raw materials in parts by weight: 1 to 5 parts of yeast, 180 to 230 parts of high-gluten flour, 10 to 30 parts of sugar, 1 to 5 parts of edible salt, 10 to 30 parts of inulin, 20 to 30 parts of 40 parts of eggs, 0.5-1 part of edible glycerin, 50-70 parts of water, 10-20 parts of butter. The dough made from the above raw materials is relaxed, proofed, divided and shaped, and then frozen to obtain the frozen dough of the present invention. Inulin and edible glycerin are added to the frozen dough of the invention, and the formula is simple and the cost is low. Moreover, the inulin and edible glycerin in the frozen dough of the present invention have a coordination effect after being mixed, can obviously improve the texture properties of the food, and improve its processing performance and nutritional value.

Owner:HENAN UNIV OF SCI & TECH

Yellow peach pudding powder

The invention relates to a yellow peach pudding powder which is prepared from the following components in percentage by weight: 40-50% of white granulated sugar, 25-30% of milk powder, 10-15% of egg white powder, 8-12% of yellow peach powder, 2.3-2.5% of konjac glucomannan, 1.6-1.8% of carrageenin, 0.6-0.8% of sucrose ester, 0.4-0.6% of peach essence and 0.04-0.06% of monascus yellow pigment. The pudding powder is prepared by the following steps: proportioning, mixing, microwave sterilization and packaging. The yellow peach pudding prepared from the yellow peach pudding powder has the advantages of seductive appearance, smooth and delicate mouthfeel, thick milk flavor, fresh yellow peach flavor and no peculiar smell. The pudding preparation method is simple and convenient, and saves both time and labor; and the proportioning process is completed by adding a certain amount of pure water into the yellow peach pudding powder, thereby avoiding the inconvenience of weighing, mixing and preparing every component in the proportioning process, and greatly simplifying the proportioning procedure. The product is powdery, and thus, is easier to store and preserve.

Owner:HARBIN AIKEER FOOD TECH

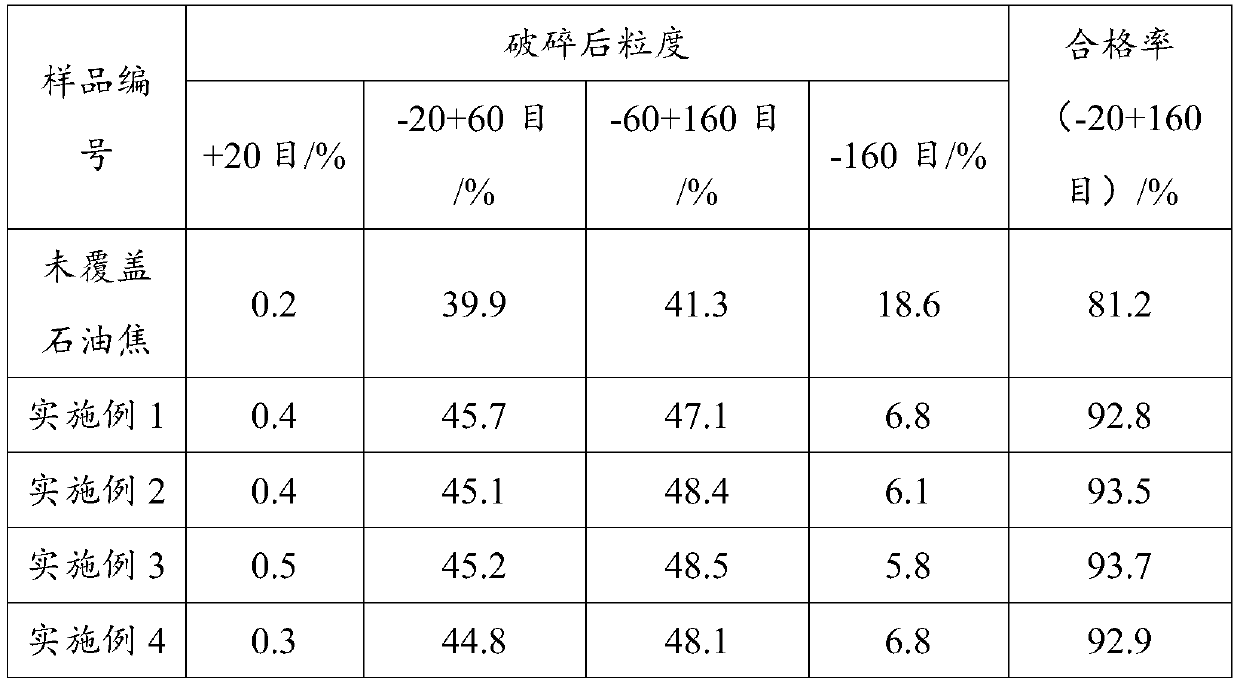

Method for preparing TiO2 raw material for chlorination process from titanium-rich fine powder

The invention provides a method for preparing a TiO2 raw material for a chlorination process from titanium-rich fine powder. The method comprises the following steps: S1, weighing the titanium-rich fine powder, and uniformly mixing the titanium-rich fine powder with a solid organic binder and petroleum coke at room temperature; S2, uniformly covering the surface of a mixed material obtained in thestep S1 with petroleum coke, and then performing low-temperature coking at 380-420 DEG C for 2.5-4 hours; and S3, crushing the material having undergone low-temperature coking in the step S2 into particles for the first time, then carrying out high-temperature coking at 900-1200 DEG C for 20-60 minutes, and crushing a coked material into particles again so as to obtain the TiO2 raw material for the chlorination process. The method can prepare the TiO2 raw material with high yield (higher than 92%) and qualified granularity for the chlorination process and realizes the cyclic utilization of the titanium-rich fine powder; and the batching procedure of a later chlorination reaction is reduced by adding the petroleum coke in advance.

Owner:HENAN BILLIONS NEW MATERIAL CO LTD

Snow pear milkshake powder

InactiveCN103651796ASolve the problem of unstable emulsification systemSmooth tasteMilk preparationFrozen sweetsMaterials preparationPEAR

The invention provides snow pear milkshake powder. The snow pear milkshake powder is composed of white granulated sugar, yoghurt powder, non-dairy creamer, snow pear powder, a sucrose ester, sodium carboxymethylcellulose and edible pear essence. All the components are as follows in percentage by weight: 35%-45% of the white granulated sugar, 25%-30% of the yoghurt powder, 15%-25% of the non-dairy creamer, 10%-12% of the snow pear powder, 0.8%-1.2% of the sucrose ester, 0.6%-0.8% of the sodium carboxymethylcellulose and 0.4%-0.6% of the edible pear essence. The snow pear milkshake powder is prepared by preparing the materials, mixing, sterilizing by microwaves and packaging. When being used for preparing snow pear milkshake, the snow pear milkshake powder has the advantages of convenience for production, time conservation, labor conservation and the like. Quantitative pure water is added into the snow pear milkshake powder to finish the material preparation process and troubles of weighing each component in the material preparation process, remixing and preparing are saved; and a material preparation procedure is greatly simplified. The prepared snow pear milkshake is smooth and fine in mouth feel and is rich in milk flavor; and the prepared snow pear milkshake has a sour and sweet mouth feel and aroma of snow pears and is a good beverage.

Owner:HARBIN AIKEER FOOD TECH

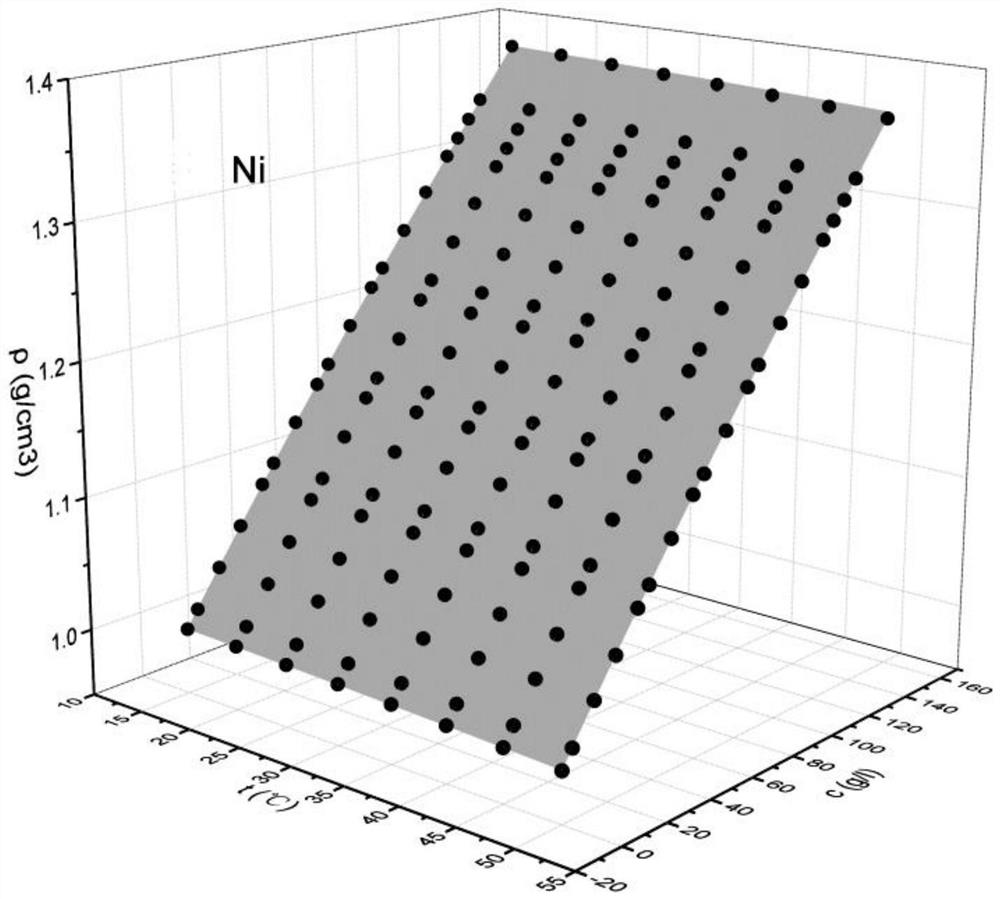

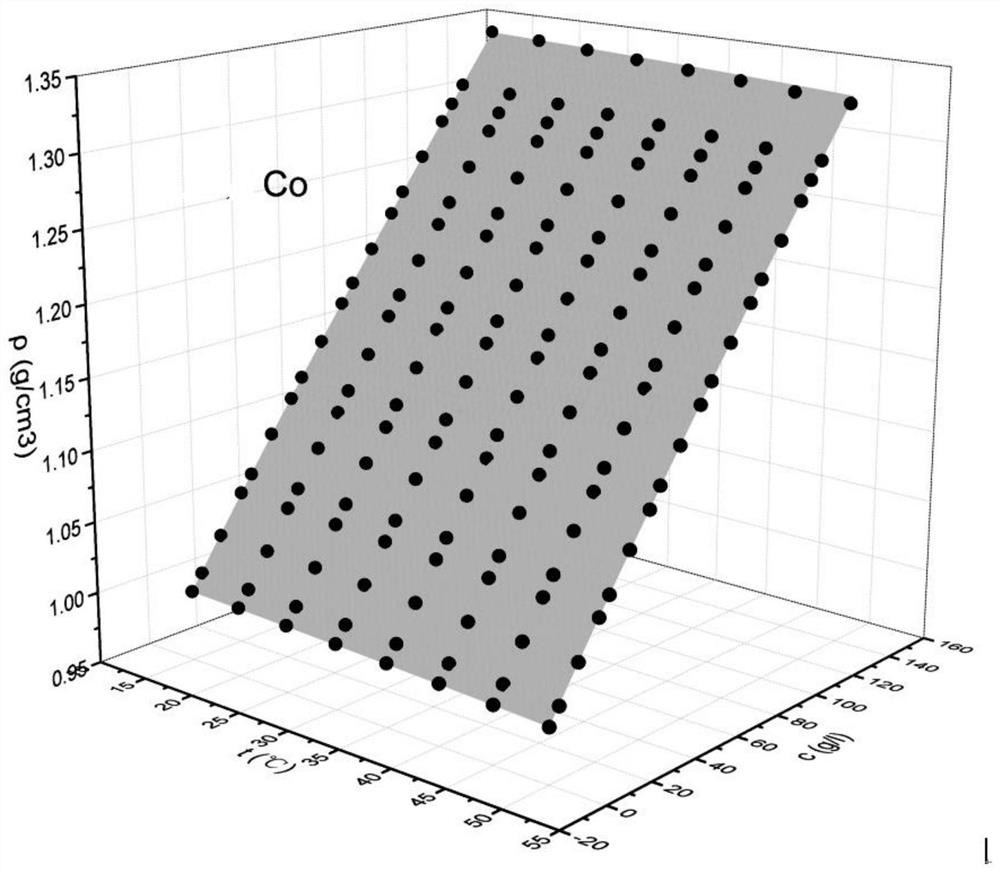

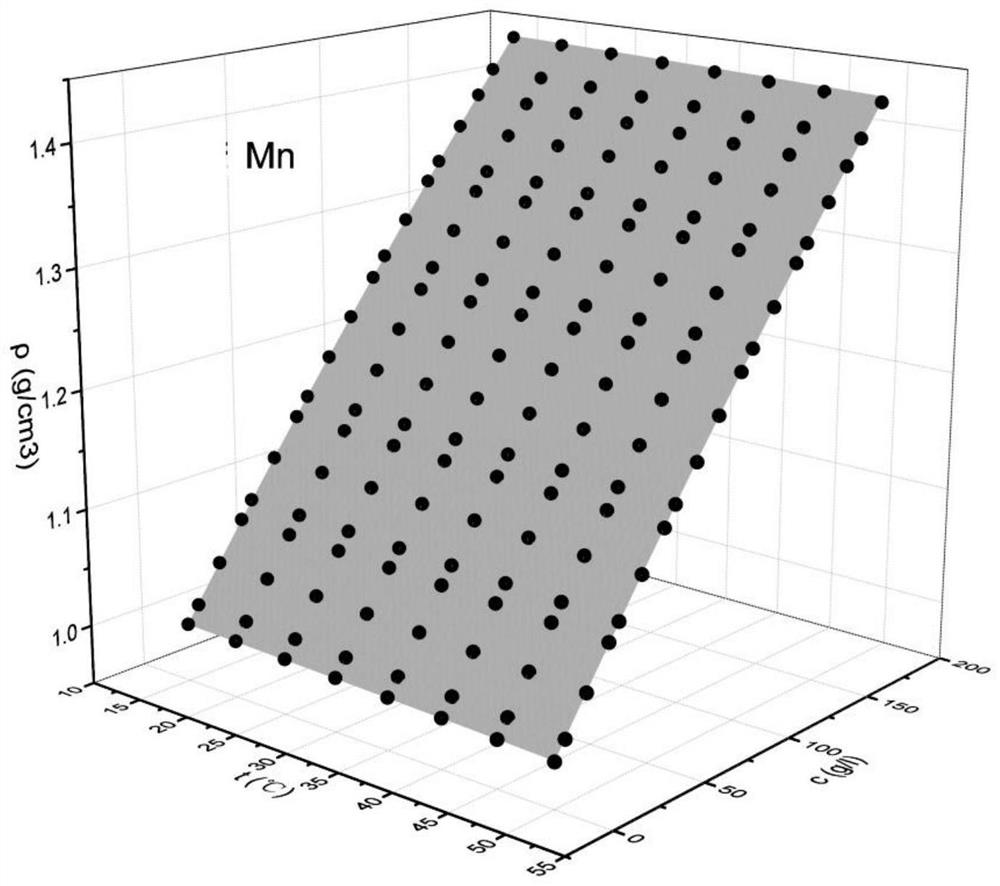

Intelligent fluid batching method

InactiveCN113713702AReduce investmentSave production spaceMixer accessoriesProcess engineeringDissolution

The invention discloses an intelligent fluid batching method. The intelligent fluid batching method comprises the following steps: step 1, conducting early-stage preparation; step 2, determining the allowable maximum concentration value of each raw material solution; step 3, completing dissolution of each raw material; and step 4, completing preparation of a mixed solution. In the first step of early-stage preparation, solutions with different concentrations are prepared for each raw material, the mixed solution is made into solutions with the same raw material proportion but different total concentrations, physical and chemical characteristics of all the solutions at different temperatures are tested, data are recorded, and the corresponding relation between the concentration and the temperature and the corresponding relation between the concentration and the temperature and the physical and chemical characteristics of all the solutions are established. According to the intelligent fluid batching method, while the production space is saved, fixed data investment is saved, online monitoring of the concentration and proportion of raw materials and intelligent batching and supplementing can be achieved, under the condition that the product types are increased, the aim of not increasing the number of dissolving tanks is achieved, the batching process is simplified, and the intelligent production requirement is met.

Owner:陆越自动化科技(上海)有限公司

Coffee pudding powder

InactiveCN103652657ASmooth tasteDelicate tasteFood ingredient as flavour affecting agentFood ingredient as gelling agentSucroseAdditive ingredient

The invention relates to a coffee pudding powder which is prepared from the following components in percentage by weight: 40-50% of white granulated sugar, 25-35% of milk powder, 10-15% of egg white powder, 5-10% of coffee powder, 2.3-2.5% of konjac glucomannan, 1.6-1.8% of carrageenin and 0.6-0.8% of sucrose ester. The pudding powder is prepared by the following steps: proportioning, mixing, microwave sterilization and packaging. The coffee pudding prepared from the coffee pudding powder has the advantages of seductive appearance, smooth and delicate mouthfeel, thick milk flavor, fresh coffee flavor and no peculiar smell. The pudding preparation method is simple and convenient, and saves both time and labor; and the proportioning process is completed by adding a certain amount of pure water into the pudding powder, thereby avoiding the inconvenience of weighing, mixing and preparing every component in the proportioning process, and greatly simplifying the proportioning procedure. The product is powdery, and thus, is easier to store and preserve.

Owner:HARBIN AIKEER FOOD TECH

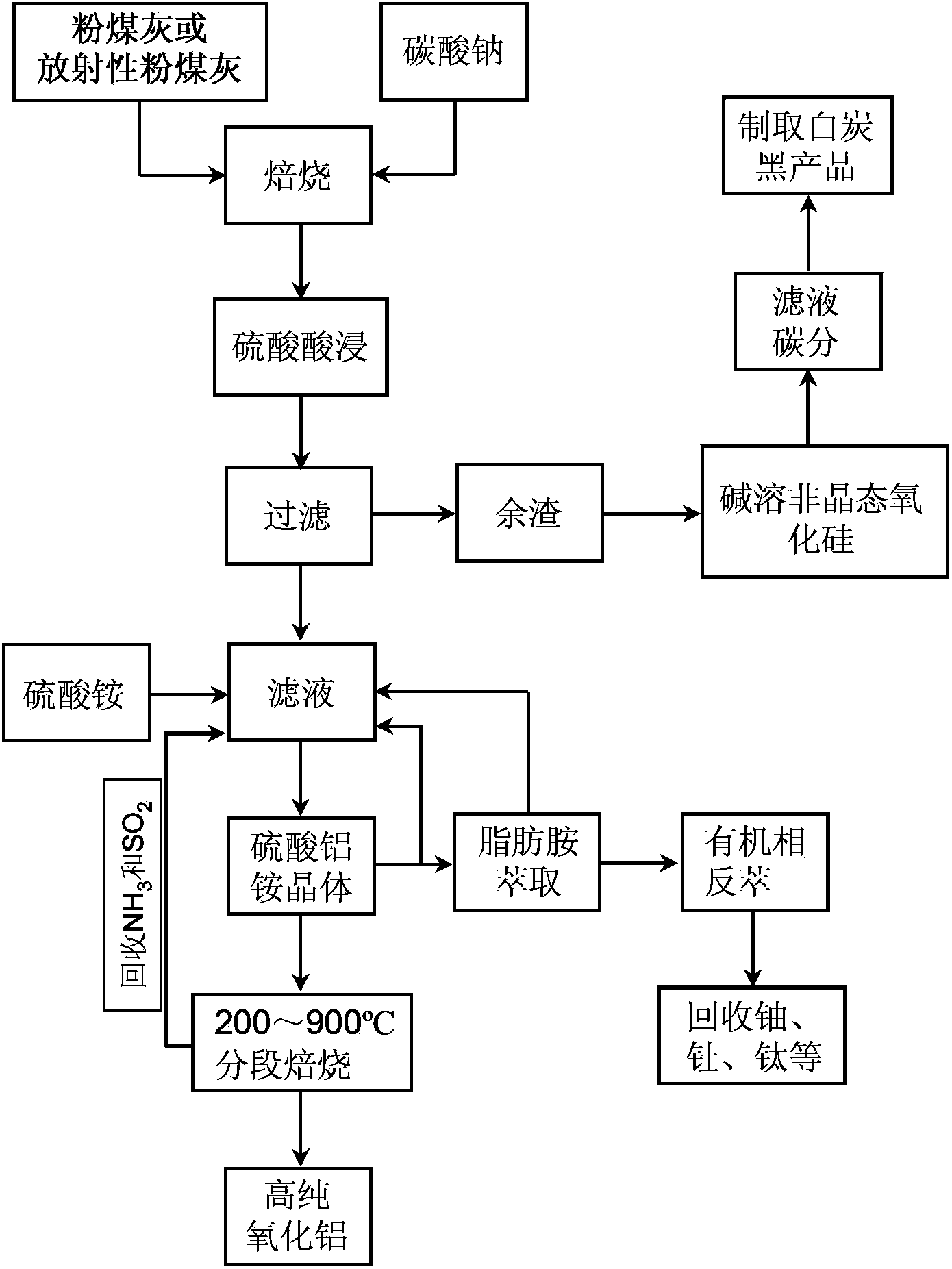

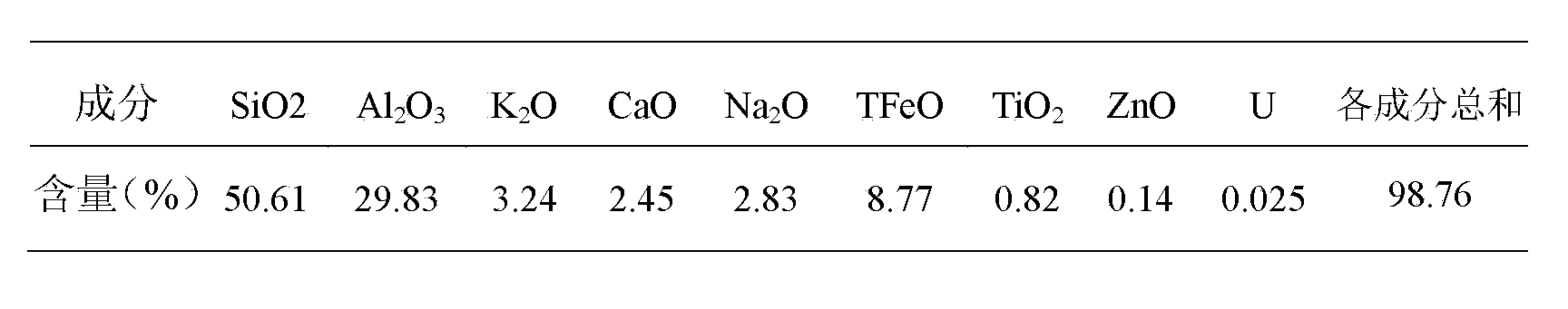

Process method for producing high-purity aluminum oxide and silicate by using pulverized fuel ash

ActiveCN102701242BHigh silicon content indexHigh puritySilicaSolid waste disposalPartial oxidationResource utilization

The invention discloses a process method for producing high-purity aluminum oxide and silicate by using pulverized fuel ash and belongs to the technical field of pulverized fuel ash resource utilization. Aluminum oxide and parts of silicon oxide in the pulverized fuel ash and uranium, thorium and other elements in radioactive pulverized fuel ash are recycled by means of the process method, accordingly the pulverized fuel ash resource utilization and remarkable reduction of solid wastes are achieved, quantity of tailings does not reach quarter of weight of original pulverized fuel ash, and the purity of the aluminum oxide and the silicate produced by means of the process method is high. The industrialization of the process flow of the process method is easily achieved.

Owner:TSINGHUA UNIV

Green tea pudding powder

InactiveCN103652653AAttractive appearanceSmooth tasteFood ingredient as flavour affecting agentFood ingredient as gelling agentSucroseAdditive ingredient

The invention relates to a green tea pudding powder which is prepared from the following components in percentage by weight: 40-50% of white granulated sugar, 25-35% of milk powder, 10-15% of green tea powder, 5-8% of green tea powder, 2.3-2.5% of konjac glucomannan, 1.6-1.8% of carrageenin, 0.6-0.8% of sucrose ester and 0.02-0.04% of sodium copper chlorophyllin. The pudding powder is prepared by the following steps: proportioning, mixing, microwave sterilization and packaging. The green tea pudding prepared from the green tea pudding powder has the advantages of seductive appearance, smooth and delicate mouthfeel, thick milk flavor, fresh green tea flavor and no peculiar smell. The pudding preparation method is simple and convenient, and saves both time and labor; and the proportioning process is completed by adding a certain amount of pure water into the pudding powder, thereby avoiding the inconvenience of weighing, mixing and preparing every component in the proportioning process, and greatly simplifying the proportioning procedure. The product is powdery, and thus, is easier to store and preserve.

Owner:HARBIN AIKEER FOOD TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com