Intelligent fluid batching method

A fluid and raw material technology, applied in the field of fluid intelligent batching, can solve problems such as seasonal temperature differences, inconsistent test results, and different experimental conditions, and achieve the effects of reducing participation, saving operating costs, and stabilizing product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

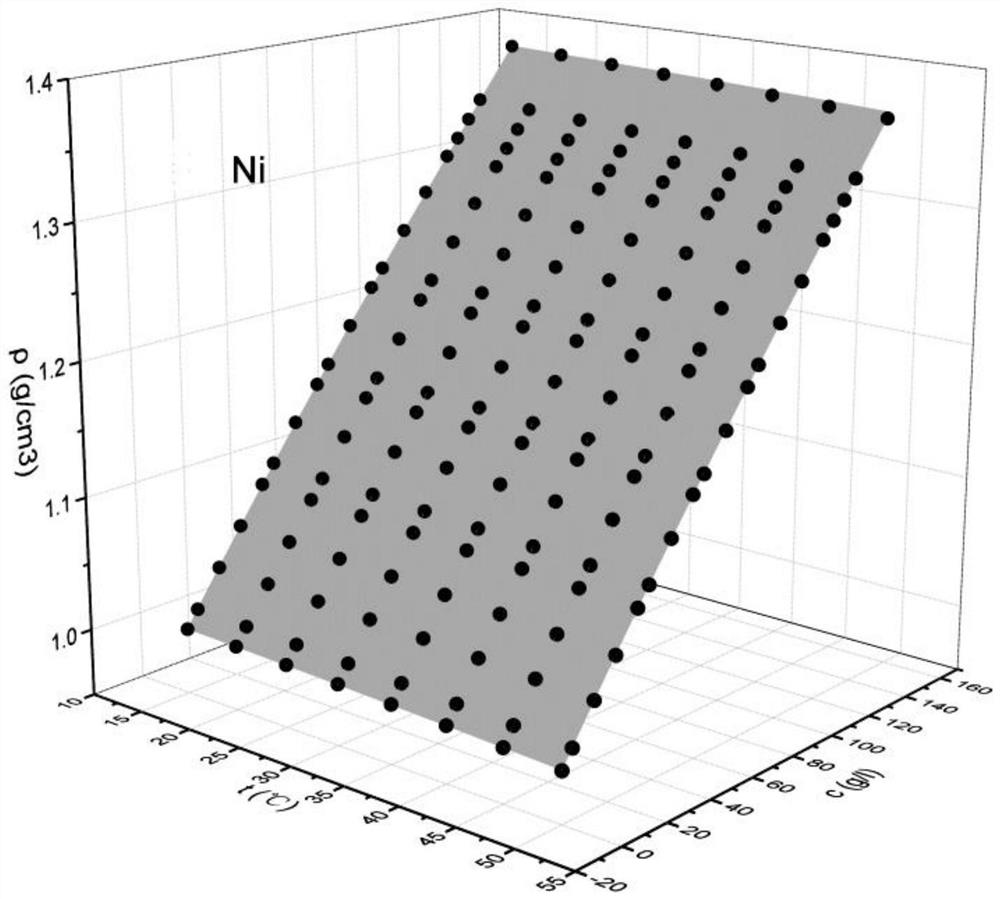

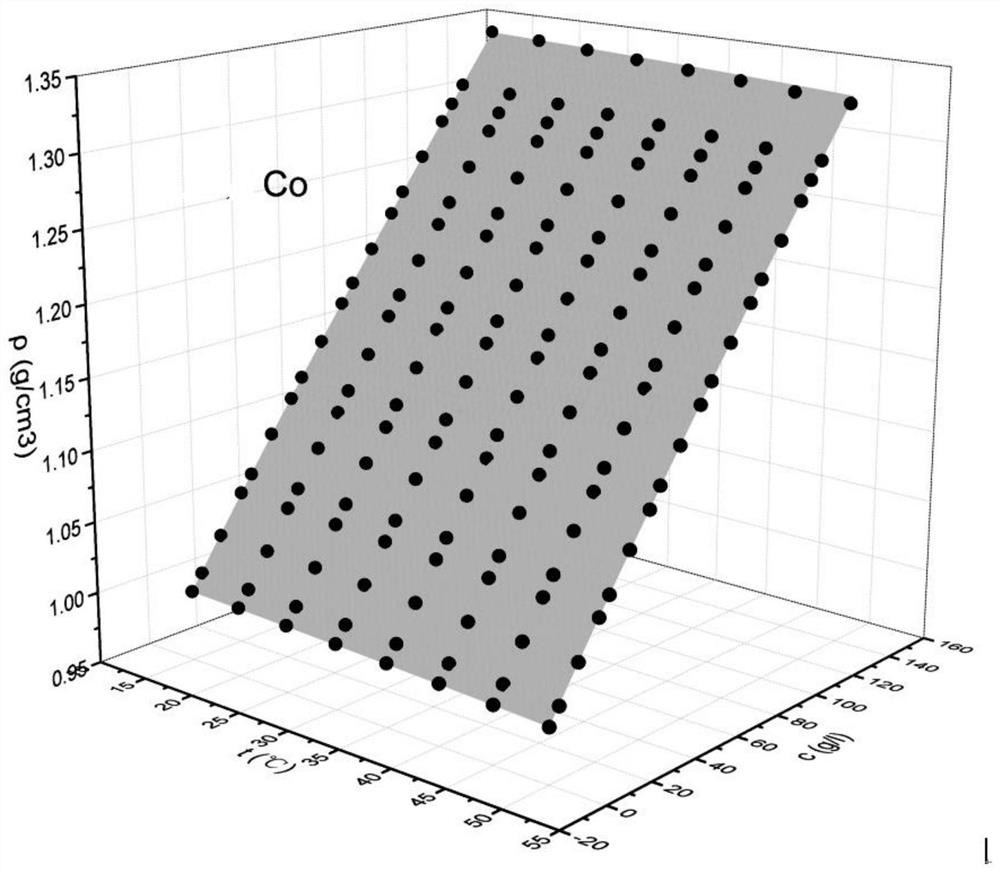

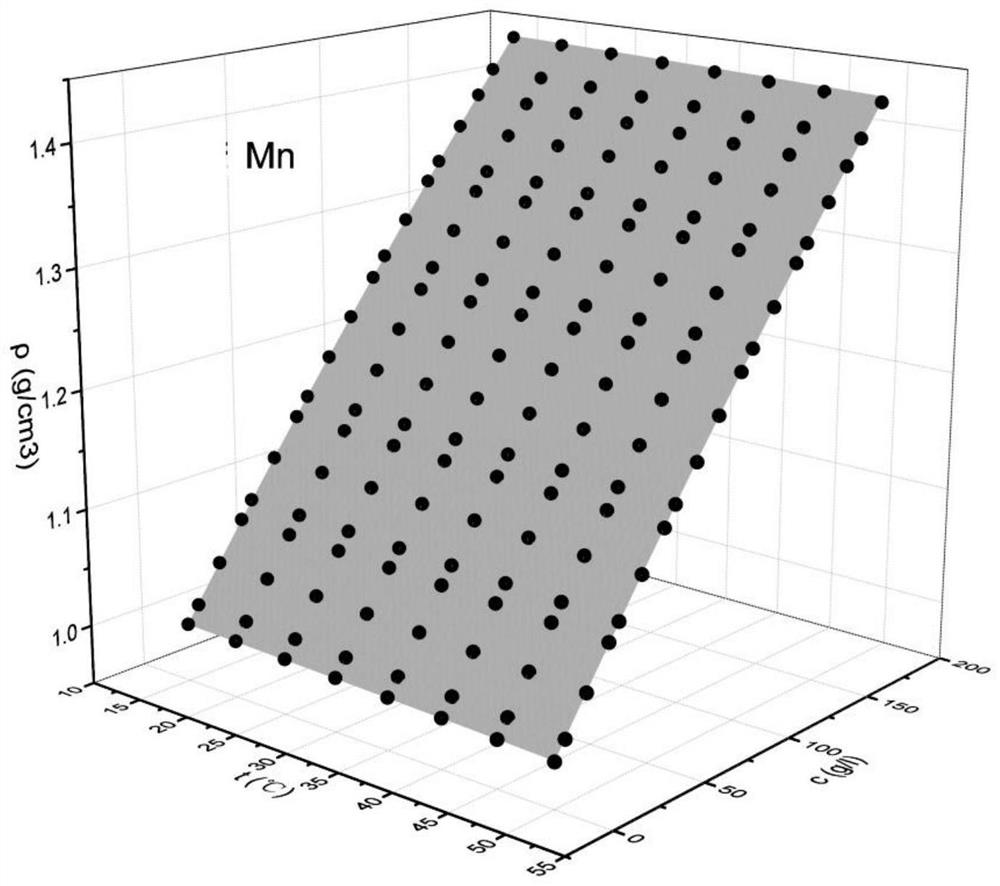

[0061] In the lithium-ion battery industry, in the production process of the precursor of the ternary positive electrode material, it is required to use NiSO4·6H2O, CoSO4·7H2O, MnSO4·H2O to prepare a mixed solution of 50±2m3 at 45°C, so that the Ni, Co, and Mn in the mixed solution The molar ratio is (5±0.05):(2±0.02):(3±0.03), the total concentration of Ni, Co, Mn elements is 120±0.5g / l, the method is as follows:

[0062] 1. The dissolution of NiSO4·6H2O and CoSO4·7H2O is an endothermic process, and the saturation increases with the increase of temperature. In the saturated solution of NiSO4·6H2O in winter, the concentration of Ni can reach 145g / l, whichever is 90% That is 130g / l; in the saturated solution of CoSO4·7H2O, the concentration of Co can reach 143g / l, whichever is 90% is 128g / l. The dissolution of MnSO4·H2O is an exothermic process, and the saturation decreases with the increase of temperature. In the saturated solution of MnSO4·H2O in Xiajie, the concentration of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com