Preparation method and application of magnesium phosphate cement

A technology of magnesium phosphate bone cement and dihydrogen phosphate, which is applied in the field of medical biomaterial preparation, can solve the problems of high cost, long time consumption, high calcination temperature, etc., achieve good biocompatibility, facilitate growth, and simplify the batching process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

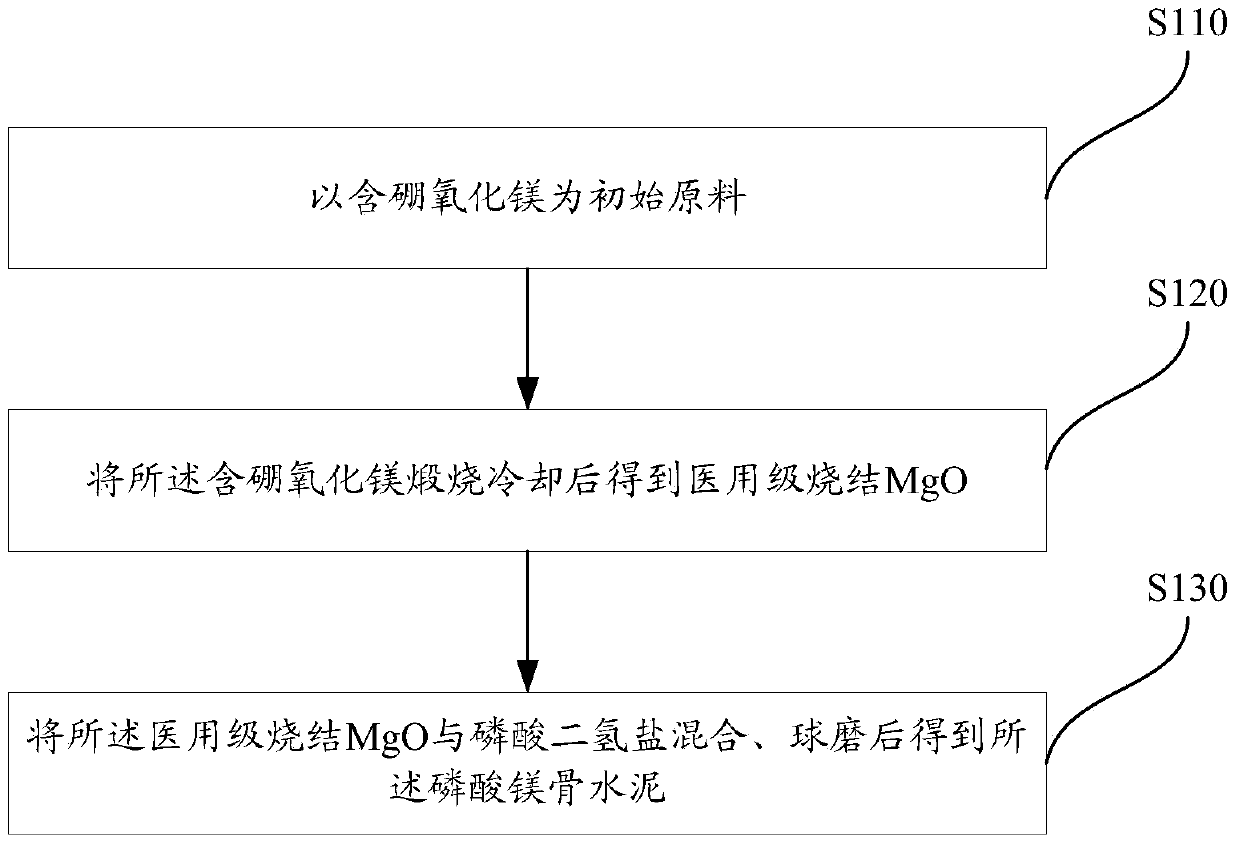

Method used

Image

Examples

Embodiment 1

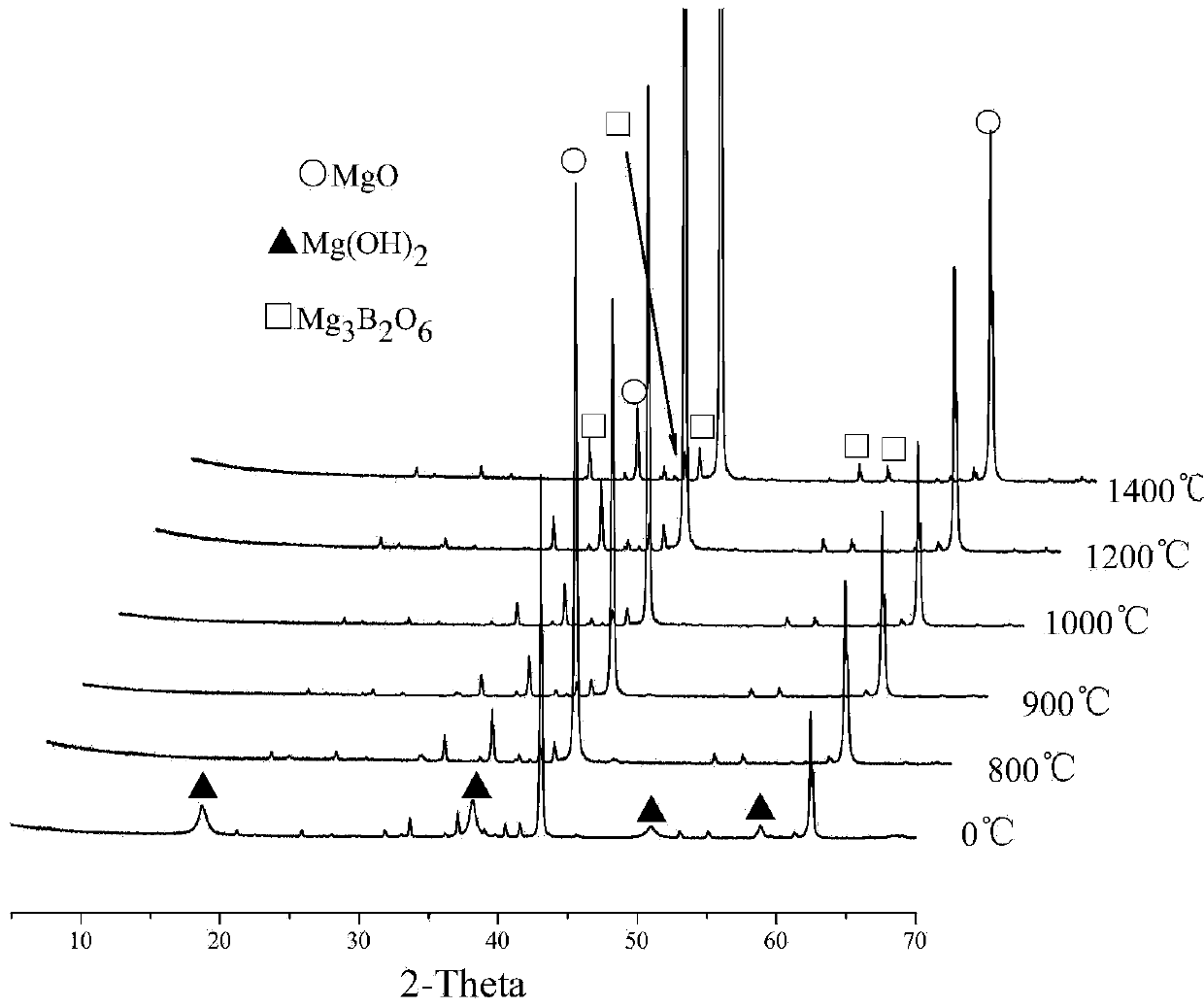

[0050] Firstly, the boron-containing magnesium oxide, a by-product of lithium extraction from salt lake, was calcined at 800°C for 3 hours, and then sintered MgO was produced after cooling, and then the sintered MgO was mixed with NaH 2 PO 4 According to the mass ratio of 1:1, the materials were mixed in a ball mill and ball milled for 60 minutes to make magnesium phosphate bone cement with a particle size ranging from 5 to 100 μm. When in use, add twice-distilled water as a solidification solution to the magnesium phosphate bone cement, the liquid-solid ratio is 0.5mL / g, and stir to obtain a uniform bone cement slurry, which can be used in bone repair operations.

Embodiment 2

[0052] Firstly, the boron-containing magnesium oxide, a by-product of lithium extraction from salt lake, was calcined at 900°C for 3 hours, and then sintered MgO was produced after cooling, and then the sintered MgO was mixed with NaH 2 PO 4 +NH 4 h 2 PO 4 According to the mass ratio of 2:1, the materials were mixed in a ball mill and ball milled for 50 minutes to make magnesium phosphate bone cement with a particle size ranging from 5 to 100 μm. When in use, add solidified liquid physiological saline to the magnesium phosphate bone cement, the liquid-solid ratio is 0.4mL / g, and stir to obtain a uniform bone cement slurry, which can be used in bone repair operations.

Embodiment 3

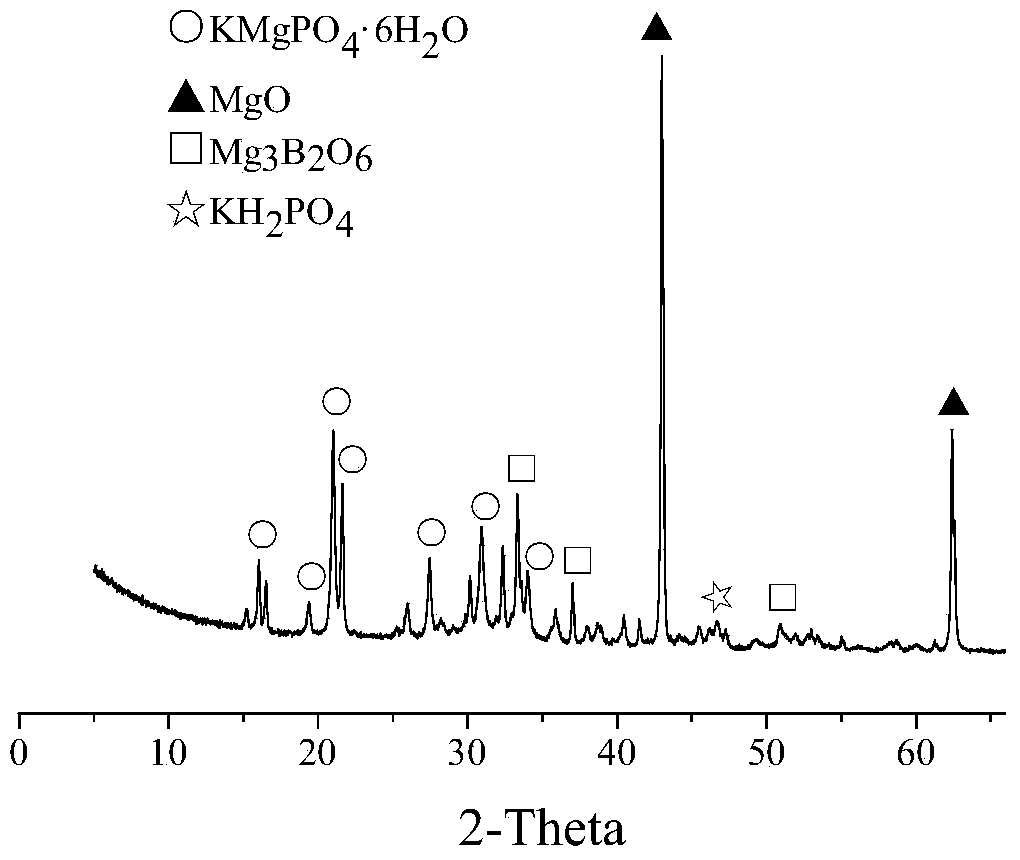

[0054] Firstly, the boron-containing magnesium oxide, a by-product of lithium extraction from salt lake, was calcined at 1000°C for 3 hours, and then sintered MgO was produced after cooling, and then the sintered MgO was mixed with KH 2 PO 4 According to the mass ratio of 3:1, the materials were mixed in a ball mill and ball milled for 40 minutes to make magnesium phosphate bone cement with a particle size ranging from 5 to 100 μm. When in use, add a glucose solution with a mass concentration of 0.9% solidified liquid into the magnesium phosphate bone cement, and the liquid-solid ratio is 0.1mL / g, and stir to obtain a uniform bone cement slurry, which can be used for bone repair operations.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com