Preparation method of lithium ferric phosphate cathode slurry

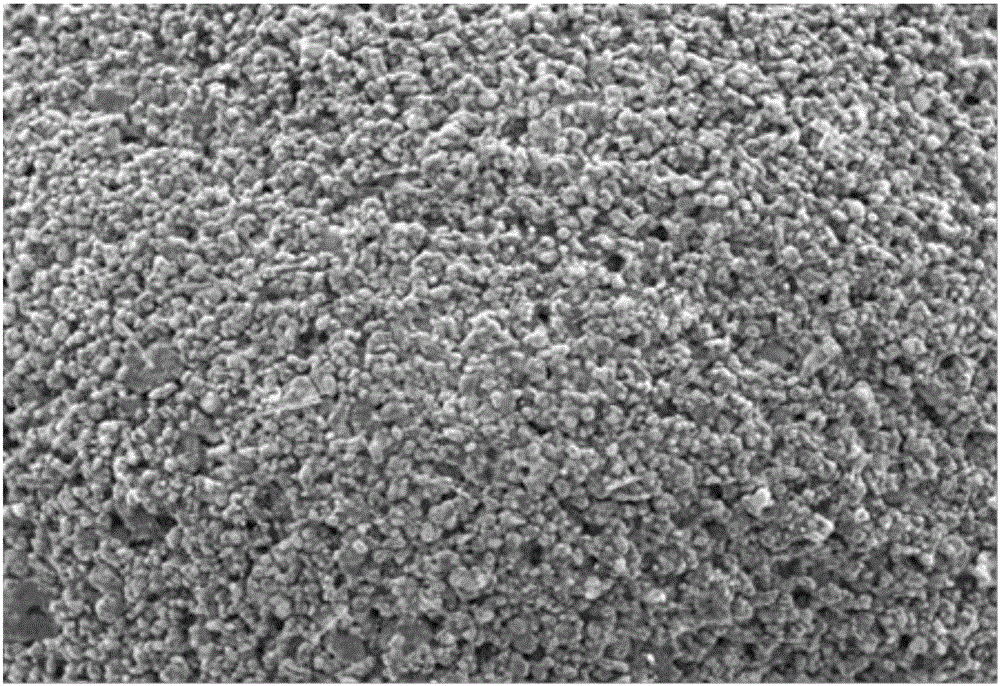

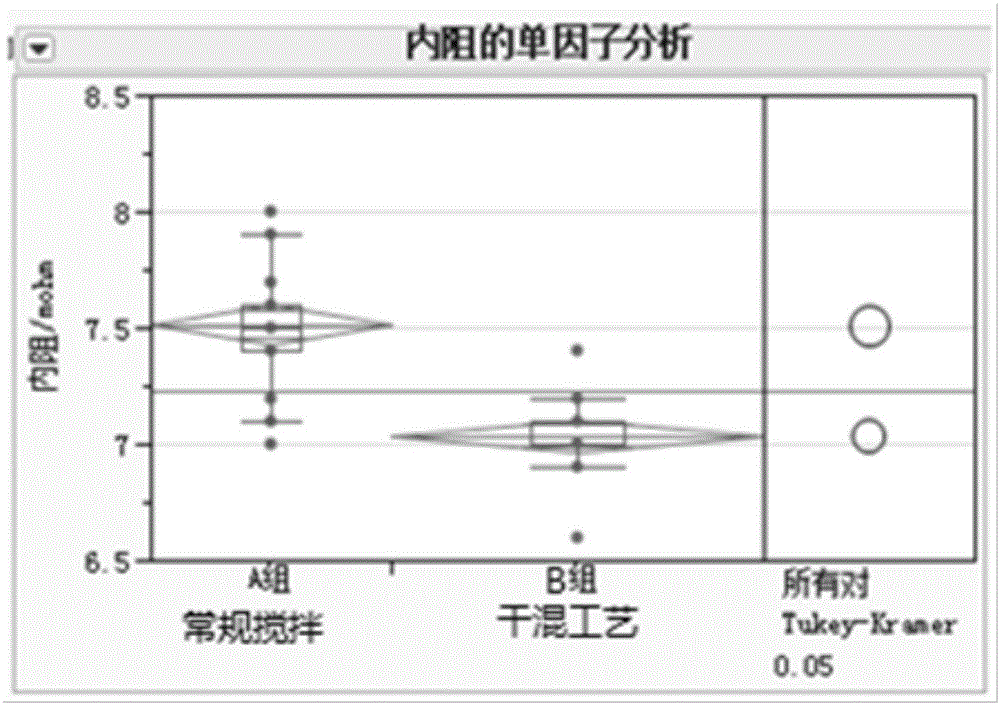

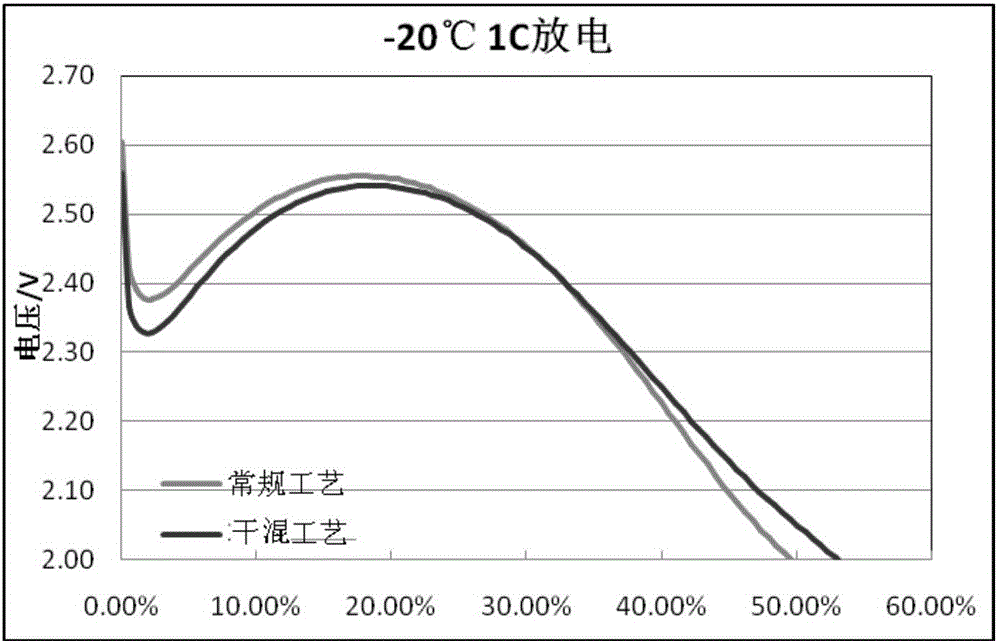

A technology of lithium iron phosphate and positive electrode slurry, applied in chemical instruments and methods, phosphorus compounds, battery electrodes, etc., can solve the problems of long dispersion time of positive electrode slurry, large specific surface area of conductive agent, high comprehensive cost, and save labor. Cost and energy consumption, good low temperature and cycle performance, the effect of streamlining the batching process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0024] The invention provides a preparation method of lithium iron phosphate positive electrode slurry, comprising the following steps:

[0025] Step 1: Add lithium iron phosphate powder and adhesive powder into the mixing tank respectively, and perform the first stirring;

[0026] Step 2: Add all the solvent, turn on the cooling water, carry out the second stirring, and scrape the material after the second stirring;

[0027] Step 3: Adjust the rotating speed of the mixing tank to disperse the slurry obtained in Step 2 at a high speed;

[0028] Step 4: Add the conductive agent for the third stirring, and scrape the material after the third stirring;

[0029] Step 5: Adjust the rotation speed of the mixing tank, and vacuum defoam the slurry obtained in Step 4.

[0030] Specifically, in the first step, the rotation speed of the stirring tank for the first stirring is: 0-800 rpm for rotation, 0-40 rpm for revolution, and the stirring time for the first time is 5-60 minutes.

...

Embodiment

[0038] (1) Add lithium iron phosphate and adhesive powder into the mixing tank respectively, the rotation speed of the mixing tank is: rotation 200rpm, revolution 38rpm, and the mixing time is 20min;

[0039] (2) Add all the NMP (N-methylpyrrolidone) solvent, turn on the cooling water, the rotation speed of the stirring tank is: rotation 200rpm, revolution 38rpm, stirring time is 30min, scrape the material after stirring;

[0040] (3) The rotation speed rotation of the mixing tank is adjusted to: autobiography 1350rpm, revolution 38rpm, and continue to stir for 30min;

[0041] (4) Add SP and KS-6 conductive agent and stir for 30 minutes, and scrape the material after stirring;

[0042] (5) Adjust the rotating speed and rotation of the mixing tank as follows: the rotation is 1350rpm, the revolution is 38rpm, the vacuum degree is less than or equal to -0.085MPa, scrape the material after stirring for 60min, and continue stirring for 120min;

[0043] (6) Turn off the rotation of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com