Battery negative electrode and lithium secondary battery having same

A lithium secondary battery and negative electrode technology, applied in the field of lithium secondary batteries, can solve the problems such as the negative electrode active material is not easy to loosen, the batching process is complicated, and the negative electrode active material is improved, so as to improve the cycle discharge capacity, improve the first charge and discharge efficiency, and improve the The effect of capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

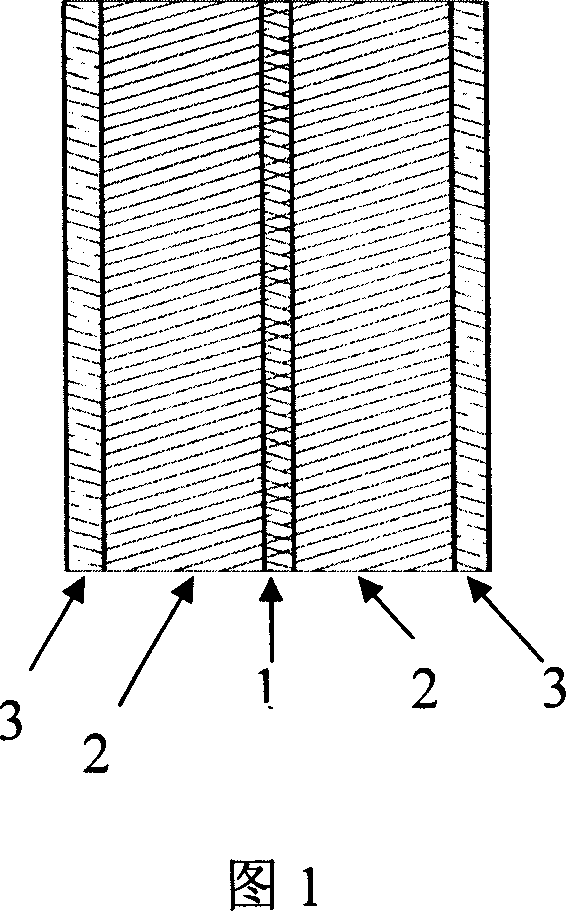

Image

Examples

preparation example Construction

[0020] The preparation method of the negative electrode material and the method of coating the negative electrode material on the current collector to form the negative electrode material layer are known to those skilled in the art. For example, the preparation method of the negative electrode material includes preparing the negative electrode active material, the binder and the optionally contained conductive agent into a negative electrode material slurry with a solvent, and the solvent can be mixed with the negative electrode active material, the binder and the optionally contained conductive agent. The agent can be added at the same time, or it can be added to the binder first to prepare the binder into a binder solution or emulsion, and then the negative electrode active material and the optional conductive agent are added to the binder solution or emulsion to prepare a negative electrode The amount of material slurry and solvent added can be flexibly adjusted according to...

Embodiment 1

[0032] This example is used to illustrate the preparation of the lithium secondary battery of the present invention.

[0033] (1) Preparation of positive electrode

[0034] 100 parts by weight of the positive electrode active material LiCoO 2 , 4 parts by weight of binder polyvinylidene fluoride (PVDF), 4 parts by weight of conductive agent acetylene black are added to 40 parts by weight of N-methylpyrrolidone (NMP), and then stirred in a vacuum mixer to form a stable and uniform dispersion Cathode material slurry. The slurry is evenly coated on a wide aluminum foil with a width of 400 mm and a thickness of 20 microns, then, after drying at 120 ° C and rolling, it is cut into 385 mm × 42 mm × 135 micron on a slitting machine. Positive sheet.

[0035] (2) Preparation of negative electrode

[0036] 100 parts by weight of negative electrode active material natural graphite, 4 parts by weight of binder polytetrafluoroethylene (PTFE), 4 parts by weight of conductive agent carbo...

Embodiment 2-13

[0040] The steps of Example 1 were repeated to prepare LP053048 square lithium secondary battery S2-13, except that the thickness of the lithium alloy layer was shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com