Fly ash synthesized cement and production method thereof

A technology for synthesizing cement and fly ash, applied in cement production and other directions, can solve the problems of long process, high cost, consumption of external fuel, etc., to achieve the effect of enhancing processing capacity, improving cement strength, and simplifying batching process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] A fly ash synthetic cement is composed of the following components: 50% of fly ash with a carbon content of more than 5%, 40% of lime or carbide slag with calcium oxide as the main component, and 3% of cement or cement clinker as an activator The accelerator is 3% of natural gypsum or desulfurized gypsum, and the corrector is 4% of loess, fine sand, shale, sulfuric acid slag, iron ore powder, slag or coal gangue.

Embodiment 2

[0021] A fly ash synthetic cement is composed of the following components: 60% of fly ash with a carbon content of more than 5%, 20% of lime or carbide slag mainly composed of calcium oxide, and 6% of cement or cement clinker as an activator The accelerator is 6% of natural gypsum or desulfurized gypsum, and the corrector is 8% of loess, fine sand, shale, sulfuric acid slag, iron ore powder, slag or coal gangue.

Embodiment 3

[0023] A fly ash synthetic cement is composed of the following components: 90% of fly ash with a carbon content of more than 5%, 5% of lime or carbide slag with calcium oxide as the main component, and 1.5% of cement or cement clinker as an activator The accelerator is 1.5% of natural gypsum or desulfurized gypsum, and the corrector is 2% of loess, fine sand, shale, sulfuric acid slag, iron ore powder, slag or coal gangue.

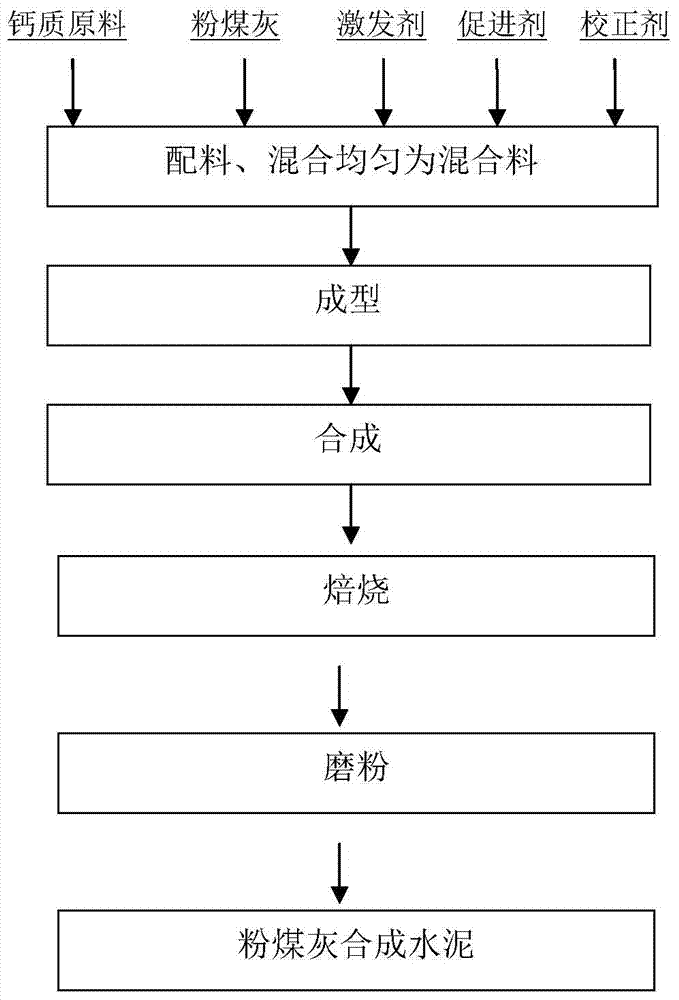

[0024] A kind of production method of fly ash synthetic cement: as figure 1 shown.

[0025] (1) above-mentioned raw material is mixed homogeneously to be compound;

[0026] (2) Process the mixture into agglomerates with forming equipment; the shape of the agglomerate is one of spherical, strip or block, and the diameter or length of the agglomerate is greater than 5 mm; the forming equipment is rod making machine, brick making machine, One of a briquetting machine, a briquetting machine or a ball forming machine;

[0027] (3) Reacting the formed agglome...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com