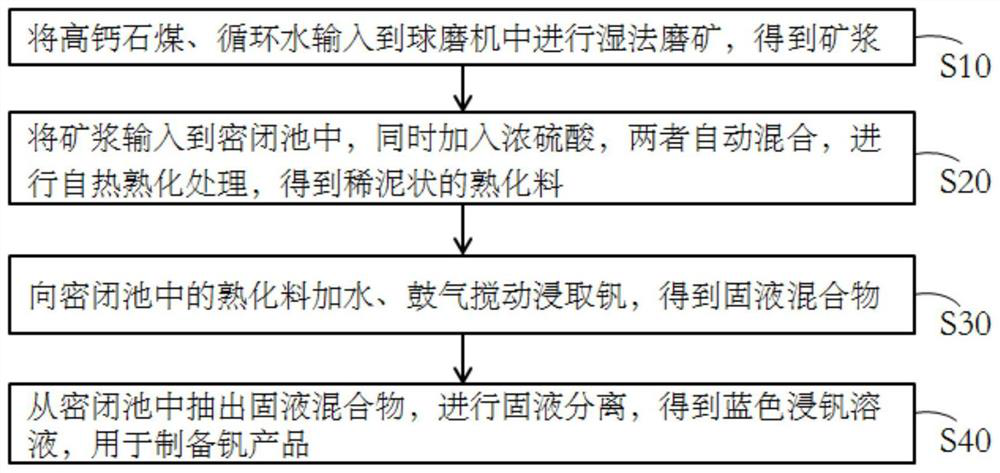

A method for extracting vanadium from high-calcium stone coal

A technology of stone coal and high calcium, applied in the field of hydrometallurgy, can solve the problems of easy damage of mixer, low grinding output, environmental pollution, etc., and achieve the effects of simplifying production process, environmental protection and saving, and low pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

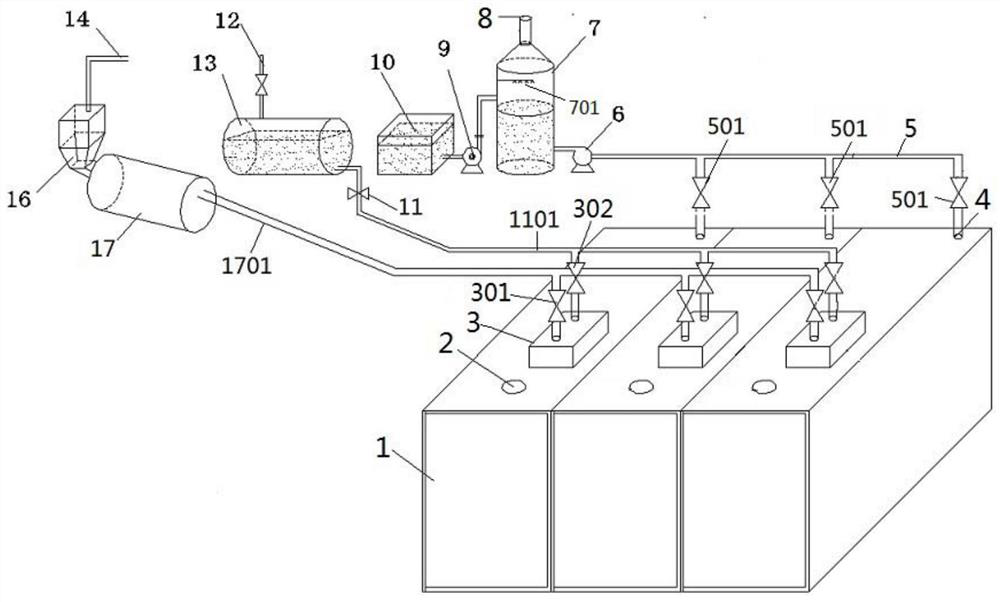

[0056] (1) get the massive high-calcium stone coal (V 2 o 5 The mass content of CaO is 1.28%, the mass content of CaO is 8.14%) 105 tons, adds 29.4 tons of circulating water in ball mill 17 and carries out wet grinding 10min, the grinding output of high-calcium stone coal is 25 tons / hour, obtains particle size It is 80 mesh pulp.

[0057] (2) Open the pulp control valve 301, continuously flow the pulp into the closed pool 1 through the PVC mixture delivery pipeline 1701, and open the sulfuric acid control valve 302 at the same time to add 42 tons of concentrated sulfuric acid to the closed pool 1 (approved by the sulfuric acid metering pump 11) , the two are mixed by themselves to obtain a thin muddy mixture; when importing ore pulp and concentrated sulfuric acid, close the suction port 2 of the airtight pool 1, open the exhaust control valve 501 and the exhaust fan 16, and the waste gas in the airtight pool 1 is transported to The washing tower 7 performs absorption treatme...

Embodiment 2

[0064] (1) get the massive high-calcium stone coal (V 2 o 5 The mass content of CaO is 1.57%, the mass content of CaO is 10.46%) 110 tons, in ball mill 17, add 41.8 tons of circulating water and carry out wet grinding 10min, the grinding output of high-calcium stone coal is 25 tons / hour, obtain particle size It is 100 mesh pulp.

[0065] (2) Open the pulp control valve 301, continuously flow the pulp into the closed pool 1 through the PVC mixture delivery pipeline 1701, and open the sulfuric acid control valve 302 at the same time to add 49.5 tons of concentrated sulfuric acid to the closed pool 1 (approved by the sulfuric acid metering pump 11) , the two are mixed by themselves to obtain a thin muddy mixture; when importing ore pulp and concentrated sulfuric acid, close the suction port 2 of the airtight pool 1, open the exhaust control valve 501 and the exhaust fan 16, and the waste gas in the airtight pool 1 is transported to The washing tower 7 performs absorption treatm...

Embodiment 3

[0072] (1) get the massive high-calcium stone coal (V 2 o 5 The mass content of CaO is 1.18%, the mass content of CaO is 9.47%) 115 tons, adds 38.5 tons of circulating water in ball mill 17 and carries out wet grinding 10min, the grinding output of high-calcium stone coal is 25 tons / hour, obtains particle size It is 120 mesh pulp.

[0073] (2) Open the pulp control valve 301, continuously flow the pulp into the closed pool 1 through the PVC mixture delivery pipeline 1701, and open the sulfuric acid control valve 302 at the same time to add 48.3 tons of concentrated sulfuric acid to the closed pool 1 (approved by the sulfuric acid metering pump 11) , the two are mixed by themselves to obtain a thin muddy mixture; when importing ore pulp and concentrated sulfuric acid, close the suction port 2 of the airtight pool 1, open the exhaust control valve 501 and the exhaust fan 16, and the waste gas in the airtight pool 1 is transported to The washing tower 7 performs absorption trea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com