Method for preparing environment-friendly high-modulus glass fiber

A glass fiber, high-modulus technology, applied in the field of high-modulus glass fiber and its preparation, can solve the problems of difficult operation and high fiberization temperature of high-performance reinforced glass fiber

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

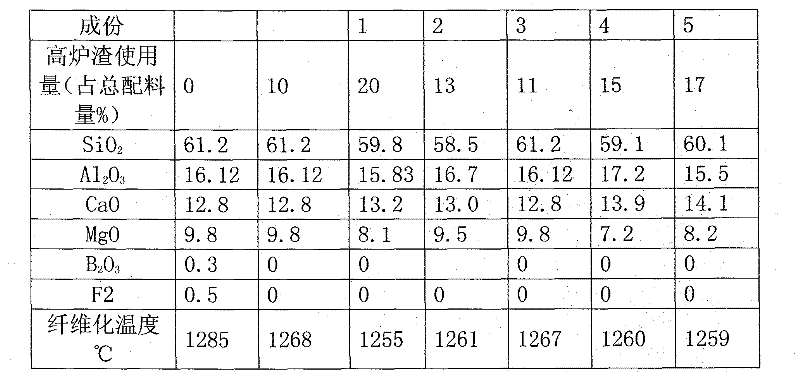

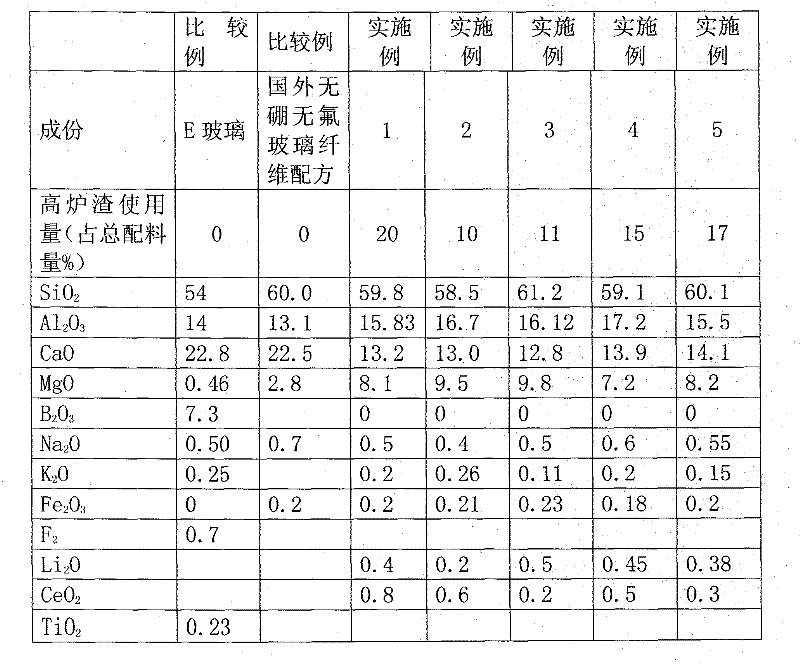

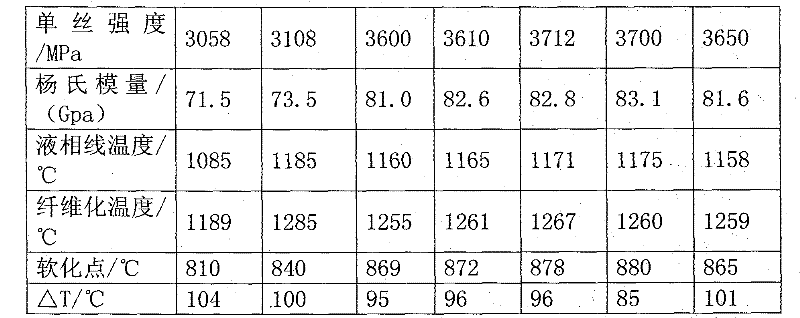

[0038] Example 1, the blast furnace slag that has been quenched at a high temperature above 1300°C from the steelmaking blast furnace is treated with an iron removal system, and the iron content is detected and controlled to be less than or equal to 0.3%. According to the redox property of the detected blast furnace slag, a certain amount of oxidizing compound is added for reconciliation, such as sulfate (about 1 ton of blast furnace slag is added with 1 to 10Kg of oxidizing compound).

[0039] Weigh 200Kg of suitable blast furnace slag for grinding, test its composition, and calculate according to the formula, add corresponding mineral raw materials such as pyrophyllite, quicklime, silica sand, etc. CeO 2 As a clarifying agent, it is melted in a pool kiln with an electric melting structure, and the fully clarified glass is uniformly transported through the channel to the platinum-rhodium alloy bushing plate for drawing to make glass fibers, and the glass fiberization temperat...

Embodiment 2

[0040] Example 2, take 100Kg of processed blast furnace slag as in Example 1, detect its composition, calculate according to the formula, add corresponding mineral raw materials such as pyrophyllite, quicklime, silica sand, and be mixed with 1000Kg of batch materials as shown in the following table, and melt in the pool kiln The glass fiber was melted and drawn, and the glass fiberization temperature was detected to be 1261°C, and the ΔT was 96°C.

Embodiment 3

[0041] Example 3, take 80Kg of processed blast furnace slag as in Example 1, detect its composition, calculate according to the formula, add mineral raw materials such as corresponding pyrophyllite, quicklime, silica sand and be mixed with the batch material 1000Kg of the following table of composition, melt in the pool kiln The glass fiber was melted and drawn, and the glass fiberization temperature was detected to be 1267°C, and the ΔT was 96°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com