Low-VOC (volatile organic compound)-content low-temperature-resistant solvent type rubber asphalt waterproof paint and preparation method thereof

A technology of rubber asphalt and waterproof coating, applied in asphalt coatings, coatings, etc., to achieve the effect of improving the environmental protection application effect of the product, reducing the VOC content of the product, and improving the low temperature resistance performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

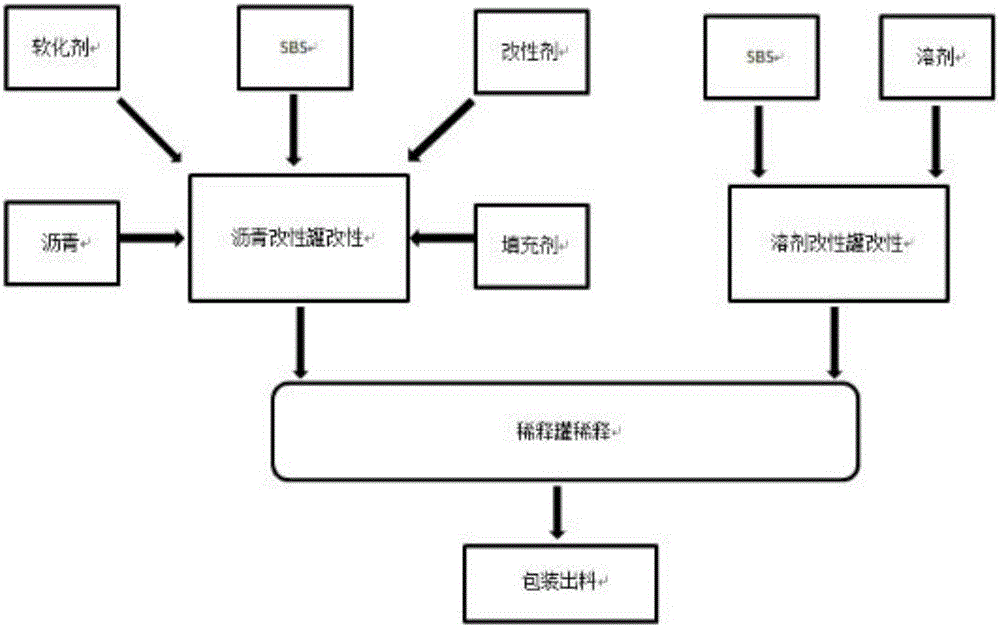

Method used

Image

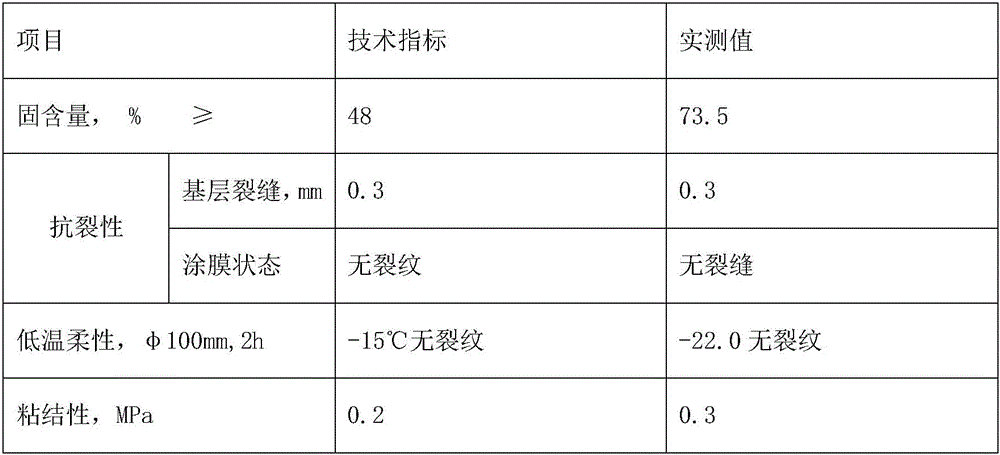

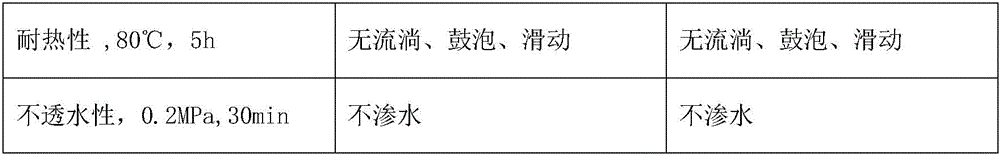

Examples

Embodiment 1

[0023] (1) The first modification of modified asphalt: Add 105 parts by weight of 90# asphalt and 15 parts by weight of second-line oil to the asphalt modification tank, heat up to 140 ° C ~ 160 ° C and mix for 20 minutes; mix 15 parts by weight Add SBS4402 and 1 weight part of polypropylene into the asphalt modification tank, control the temperature to 160-180 °C and stir for 120 minutes to modify and disperse evenly; add 30 weight of light calcium powder, control the temperature to 150-160 °C and stir for 40 minutes to disperse Cool down evenly.

[0024] (2) Solvent dilution and dispersion of SBS: Add 68 parts by weight of xylene and 8 parts by weight of SBS4402 into the solvent modification tank, and control the temperature at 20-30°C to stir and disperse for 30 minutes. The stirring direction needs to be adjusted periodically during this process, and the cycle interval time is 5 minutes. ; This process can be carried out simultaneously with the first modification of asphal...

Embodiment 2

[0031] (1) The first modification of modified asphalt: add 105 parts by weight of 90# asphalt and 15 parts by weight of second-line oil to the asphalt modification tank, heat up to 140 ° C ~ 160 ° C and mix for 20 minutes; mix 20 parts by weight Add SBS4402 and 1 part by weight of polypropylene into the asphalt modification tank, control the temperature to 170-190 °C and stir for 210 minutes to modify and disperse evenly; add 30 parts by weight of light calcium powder, and control the temperature to 150-160 °C and stir for 50 minutes Disperse and cool down evenly.

[0032] (2) Solvent dilution and dispersion of SBS: add 80 parts by weight of xylene and 3 parts by weight of SBS4402 into the solvent modification tank, and control the temperature at 20-30°C to stir and disperse for 15 minutes. During this process, the stirring direction needs to be adjusted periodically, and the period interval is 5 minutes. ; This process can be carried out simultaneously with the first modifica...

Embodiment 3

[0039] (1) The first modification of modified asphalt: add 100 parts by weight of 90# asphalt, 10 parts by weight of 10# asphalt and 15 parts by weight of second-line oil into the asphalt modification tank, and heat up to 140 ° C ~ 160 ° C Stir and mix for 40 minutes to mix evenly; add 18 parts by weight of SBSLG501 and 1.5 parts by weight of shaped olefin copolymer into the asphalt modification tank, control the temperature to 160°C to 180°C and stir for 90 minutes to modify and disperse evenly; add 30 parts by weight of light calcium powder , control the temperature to 150-160°C and stir for 40 minutes to disperse and cool down evenly.

[0040](2) Solvent dilution and dispersion of SBS: Add 70 parts by weight of xylene and 6 parts by weight of SBS4402 into the solvent modification tank, and control the temperature at 20-30°C to stir and disperse for 20 minutes. The stirring direction needs to be adjusted periodically during this process, and the cycle time is 5 minutes. ; Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com