Ecological sand plastic composite composition, method for preparing the ecological sand plastic composite, and prepared material

A composite material and composition technology, applied in the field of ecological sand plastic composite material composition and preparation of ecological sand plastic composite material, can solve the problems of limited environmental bearing capacity of profiles, unfavorable sustainable development, unstable physical and chemical properties, etc. The effect of stable speed ratio, saving production cost and stable chemical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

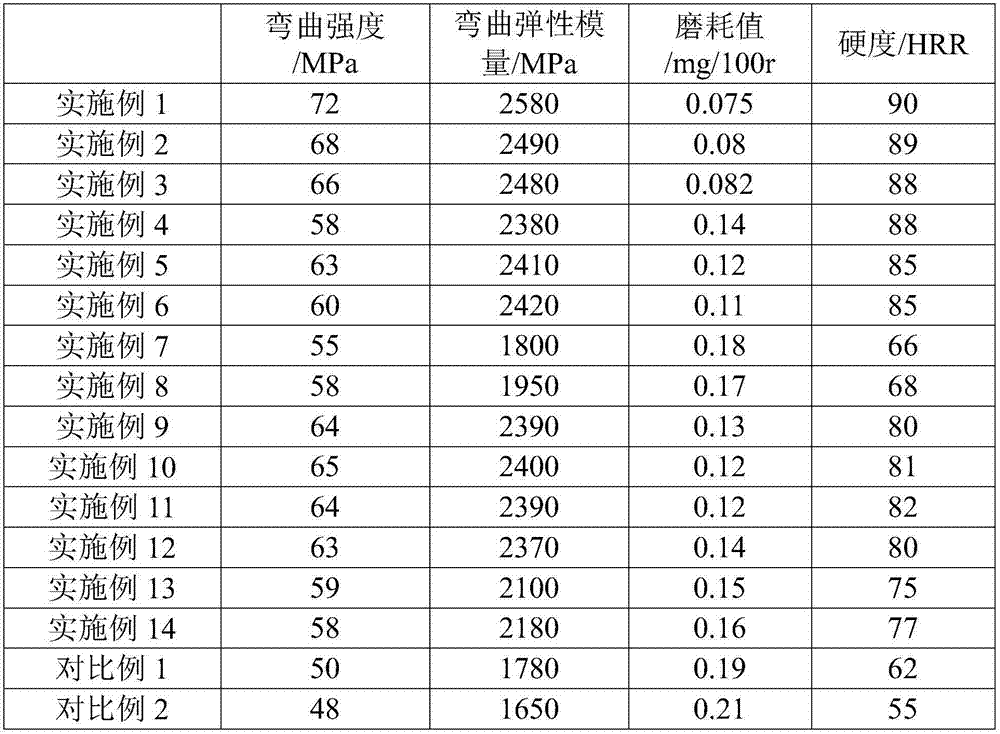

Examples

preparation example Construction

[0047] In the preparation method provided by the second aspect of the present disclosure, aeolian sand and fly ash are blended and compounded as filler, and then copolymerized with resin to prepare a new environmentally friendly ecological sand-plastic composite material. The key problem in the compounding of aeolian sand and resin matrix is the interfacial bonding. Directly adding aeolian sand to the resin has only simple mechanical bonding, and the strength of the obtained product cannot meet the requirements for use. This disclosure adopts the method of binary composite filler, first compounding the aeolian sand and fly ash, so that the aeolian sand particles are embedded in the porous structure of fly ash to form a composite inorganic filler, and then carry out a copolymerization reaction with the resin to coat Strong chemical bonds can be formed between the aeolian sand particles of fly ash and the resin, and the coexistence of chemical bonds and mechanical bonds can imp...

Embodiment 1

[0065](1) Take 58 kg of aeolian sand, add 40 kg of water to the continuous scrubbing and desilting machine for scrubbing, and scrub for 20 minutes, then dry the scrubbed aeolian sand at 100-200°C for 20 minutes, and dry the dried sand The water content of the aeolian sand is 0.5% by weight, and then sieved to obtain 6 kg of the first aeolian sand with a particle size of 20-40 mesh and 48 kg of the second aeolian sand with a particle size of 100-200 mesh.

[0066] (2) Take 25 kg of fly ash, sieve and dry at 100-200° C. for 20 minutes to obtain 20 kg of pretreated fly ash with a particle size of 600 mesh and a water content of 0.6% by weight.

[0067] (3) Put the first aeolian sand obtained in step (1) and the second aeolian sand and the pretreated fly ash obtained in step (2) into a high mixer, and mix them at 50°C After 30 minutes, the aeolian sand particles coated with fly ash were obtained.

[0068] (4) 1kg of cross-linking modifier aluminate coupling agent, 0.5kg of intern...

Embodiment 2

[0072] (1) Take 110 kg of aeolian sand, add 60 kg of water to the continuous scrubbing and desilting machine for scrubbing, and scrub for 30 minutes, then dry the scrubbed aeolian sand at 150-180°C for 20 minutes, and dry The water content of the aeolian sand is 0.6% by weight, and then sieved to obtain 5 kg of the first aeolian sand with a particle size of 20-40 mesh and 95 kg of the second aeolian sand with a particle size of 100-200 mesh.

[0073] (2) Take 30 kg of fly ash, sieve and dry at 180° C. for 20 minutes to obtain 28 kg of pretreated fly ash with a particle size of 600 mesh and a water content of 0.9% by weight.

[0074] (3) Put the first aeolian sand obtained in step (1) and the second aeolian sand and the pretreated fly ash obtained in step (2) into a high mixer, and mix them at 110°C After 10 minutes, aeolian sand particles coated with fly ash were obtained.

[0075] (4) 0.3kg cross-linking modifier silane coupling agent, 0.4kg internal and external lubricant l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com