Organic montmorillonite modified epoxy asphalt material and preparation method thereof

A technology of epoxy asphalt materials and organic montmorillonite, which is applied in building insulation materials, building components, buildings, etc., can solve problems such as rutting, cracks or looseness, violent sulfur vulcanization reaction, and difficult operation, so as to improve compatibility , low price, and the effect of reducing temperature sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

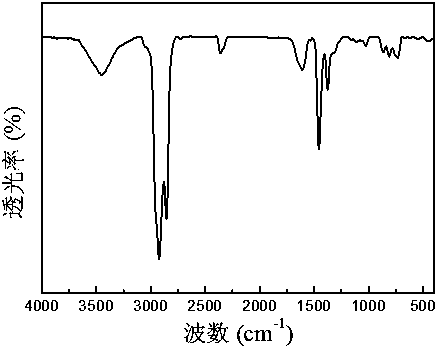

[0042] Add 100 parts (mass parts, 200g, the same below) of molten petroleum asphalt (Maoming Petrochemical Donghai brand 90#) at 150 °C to the reaction vessel, then lower the temperature to 120 °C, add 16 parts of tung oil anhydride and 30 parts of oxalic acid , 10 parts of epoxy asphalt compatibilizer, stirred at 500 r / min for 30 min, and finally added 0.6 parts of tertiary amine accelerator DMP-30, and continued to stir for 15 min to make epoxy asphalt A component.

[0043] Mix component A heated to 140 °C and component B epoxy resin preheated to 70 °C at a mass ratio of 4.0:1 for 15 minutes, and then place it at 140 °C for 4 hours to obtain Epoxy asphalt material, its fluorescence micrograph as image 3 As shown, asphalt does not fluoresce and shows a black phase, and the epoxy resin curing system shows a white phase under blue light irradiation, and the dispersion of epoxy resin in the main phase formed by asphalt is not uniform.

[0044]

Embodiment 2

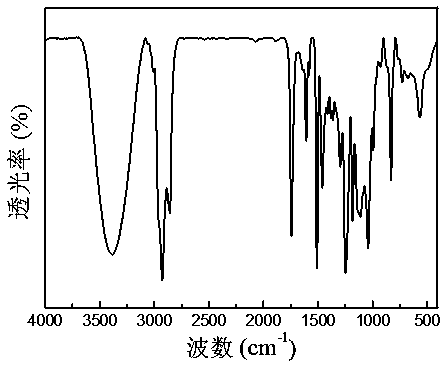

[0046] Add 100 parts of molten petroleum pitch (US Shell 70#) at 170 °C to the reaction vessel, add 1 part of organic montmorillonite (Zhejiang Fenghong DK3 type), and start the shear emulsification mixer at 3000 r / min for 2 h. Then adjust the temperature to 130 ℃, add 16 parts of methyl tetrahydrophthalic anhydride, 36 parts of sebacic acid, 24 parts of epoxy asphalt compatibilizer, stir at 500 r / min for 30 min, and finally add 0.4 parts of tertiary amine accelerator DMP-30, continue to stir for 15 minutes to make epoxy asphalt A component.

[0047] Mix component A heated to 150 °C and component B epoxy resin preheated to 75 °C at a mass ratio of 4.4:1 for 30 min, and then place it at 150 °C for 4 h to obtain Organic montmorillonite modified epoxy asphalt material, its fluorescence micrograph is as follows Figure 4 As shown, the distribution of epoxy resin is relatively uniform and the size becomes larger, indicating that the addition of organic montmorillonite improves the...

Embodiment 3

[0050] Add 100 parts of molten coal tar pitch (Shanxi Hengde Chemical Co., Ltd. 70#) at 140 °C to the reaction vessel, add 2 parts of organic montmorillonite (Zhejiang Fenghong DK1N type), and start the shear emulsification mixer at 3000 r / min. Cut for 2 h. Then adjust the temperature to 120 °C, add 12 parts of methyl hexahydrophthalic anhydride, 25 parts of adipic acid, 20 parts of epoxy asphalt compatibilizer, stir at 500 r / min for 30 min, and finally add 0.3 parts of imidazole accelerator 2 -Ethyl-4-methylimidazole, and continue to stir for 15 min to make epoxy asphalt A component.

[0051] Mix component A heated to 130 °C and component B epoxy resin preheated to 80 °C at a mass ratio of 5.3:1 for 20 min, and then place it at 130 °C for 4 h to obtain Organic montmorillonite modified epoxy asphalt material, its fluorescence micrograph is as follows Figure 5 As shown, the material has obvious phase inversion phenomenon, and the black asphalt is dispersed in the cross-linke...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com