Semi-flexible base material and production method thereof

It is a base material and semi-flexible technology, which is applied to the coagulation pavement, roads, buildings and other directions of on-site paving. The effect of preventing road reflection cracks and low temperature sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

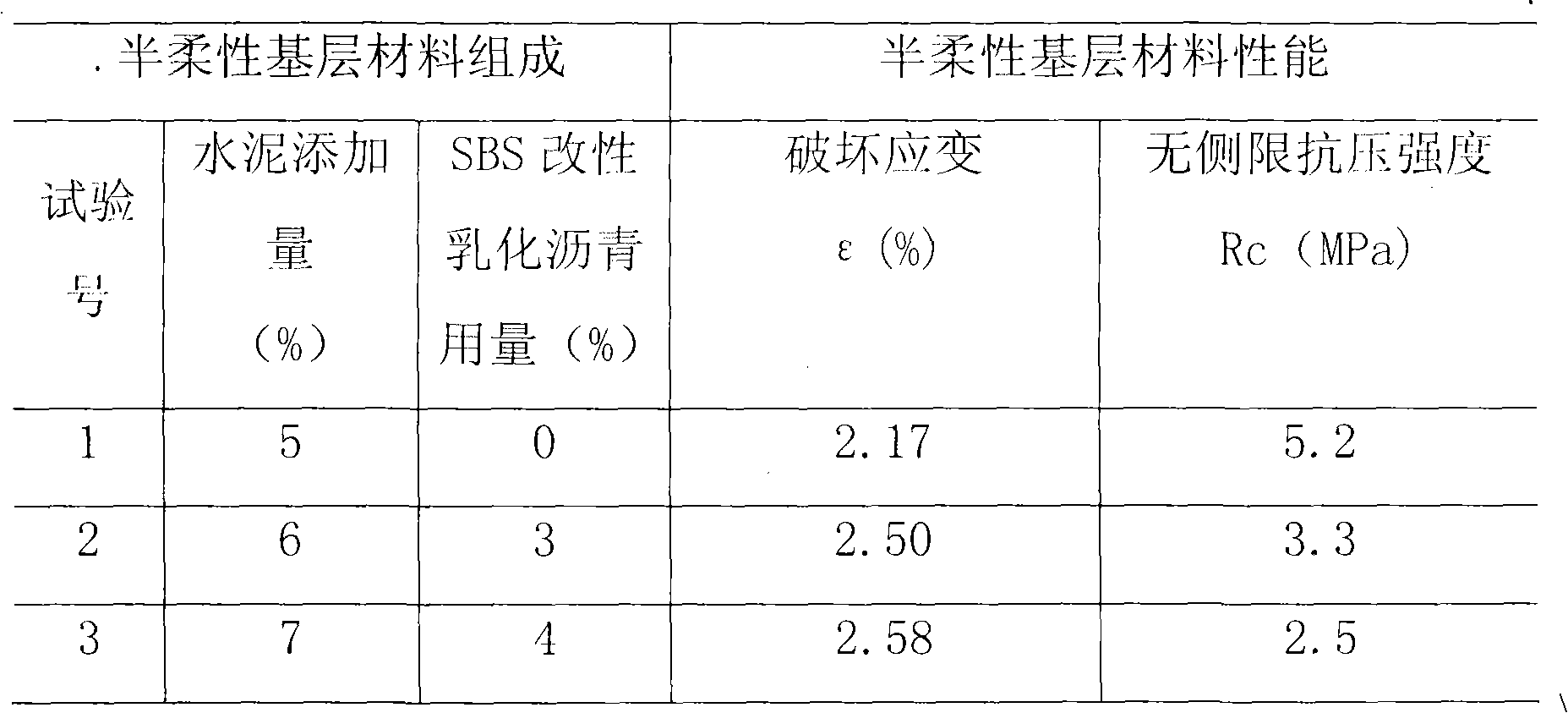

[0029] Composition formula of semi-flexible base material:

[0030] Aggregate 91%

[0031] Cement 5%

[0032] SBS modified emulsified asphalt 4%

[0033] Preparation method of semi-flexible base material:

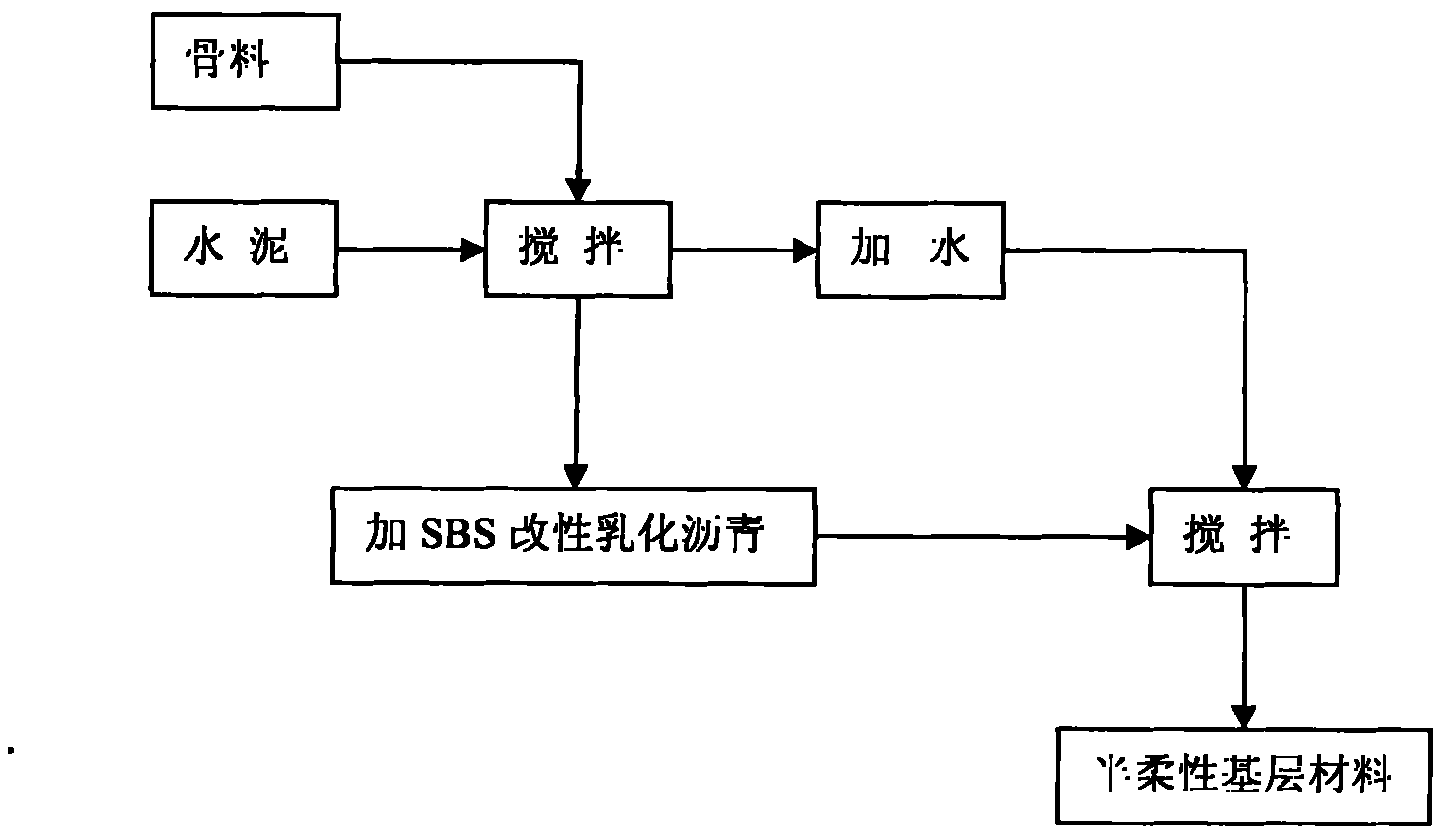

[0034] According to the composition formula, adopt figure 1 Described preparation method flow process

[0035] Firstly dry mix cement and stone evenly, add water and stir, then add SBS modified emulsified asphalt and mix evenly to obtain semi-flexible base material.

[0036] Properties of semi-flexible base material:

[0037] Failure strain ε(%): 2.28

[0038] Unconfined compressive strength Rc (MPa): 2.6

Embodiment 2

[0040] Composition formula of semi-flexible base material:

[0041] Aggregate 88%

[0042] Cement 6%

[0043] SBS modified emulsified asphalt 6%

[0044] Preparation method of semi-flexible base material:

[0045] According to the composition formula, adopt figure 1 Described preparation method:

[0046] a) Dry the aggregate and cement for later use.

[0047] b) Dry mix cement and aggregate evenly, add water and stir, then add SBS modified emulsified asphalt and mix evenly to obtain a semi-flexible base material.

[0048] Properties of semi-flexible base material:

[0049] Failure strain ε(%): 2.27

[0050] Unconfined compressive strength Rc (MPa): 1.6

Embodiment 3

[0052] Composition formula of semi-flexible base material:

[0053] Aggregate 89%

[0054] Cement 7%

[0055] SBS modified emulsified asphalt 4%

[0056] Preparation method of semi-flexible base material:

[0057] According to the composition formula, adopt figure 1 Described preparation method:

[0058] a) Dry the aggregate and cement for later use.

[0059] b) Dry mix cement and aggregate evenly, add water and stir, then add SBS modified emulsified asphalt and mix evenly to obtain a semi-flexible base material.

[0060] Properties of semi-flexible base material:

[0061] Failure strain ε(%): 2.58

[0062] Unconfined compressive strength Rc (MPa): 2.5

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com