Patents

Literature

63 results about "Digital material" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Digital Material is an extensible modeling and software infrastructure to support the representation and simulation of material structure and evolution across multiple length and time scales.

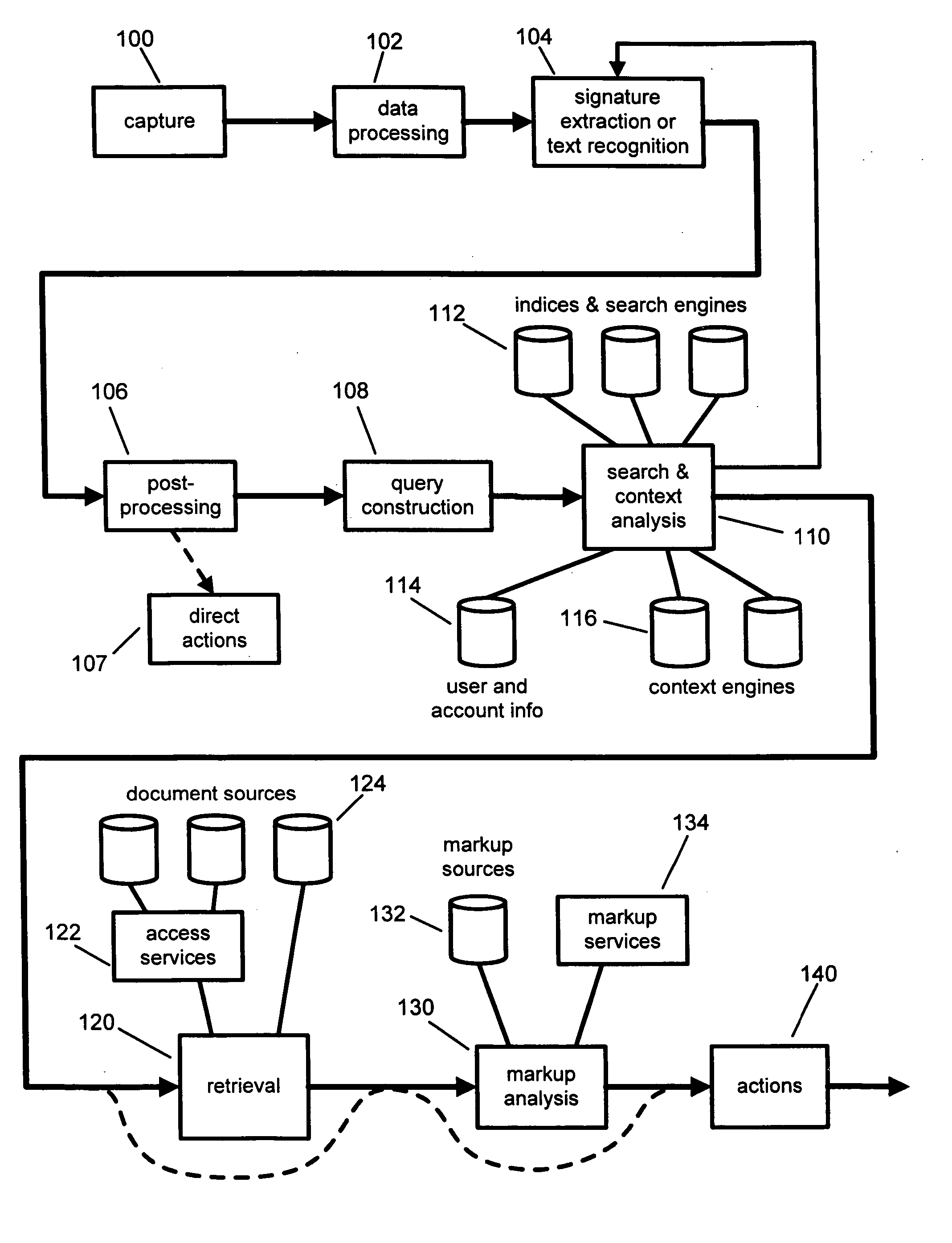

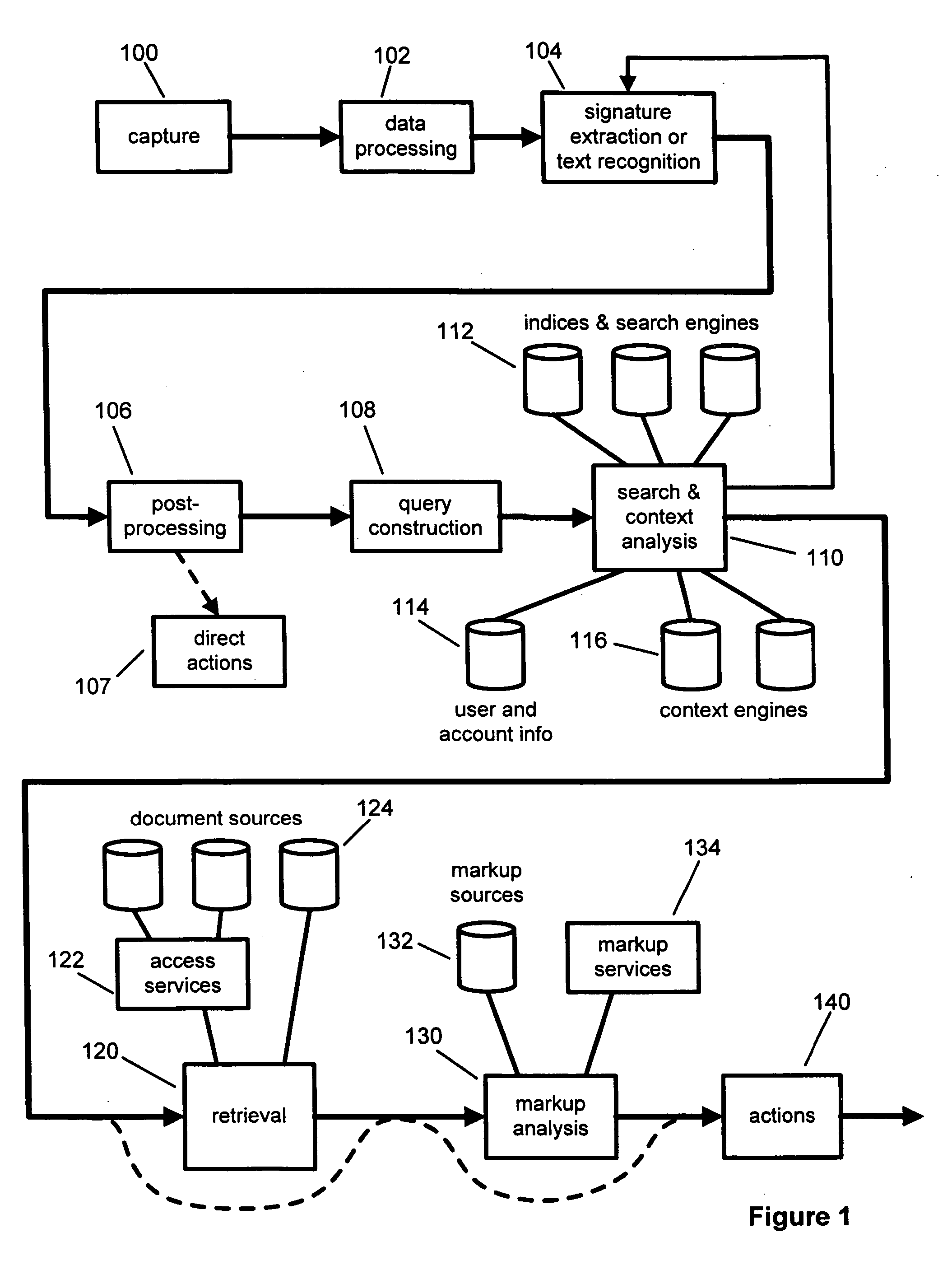

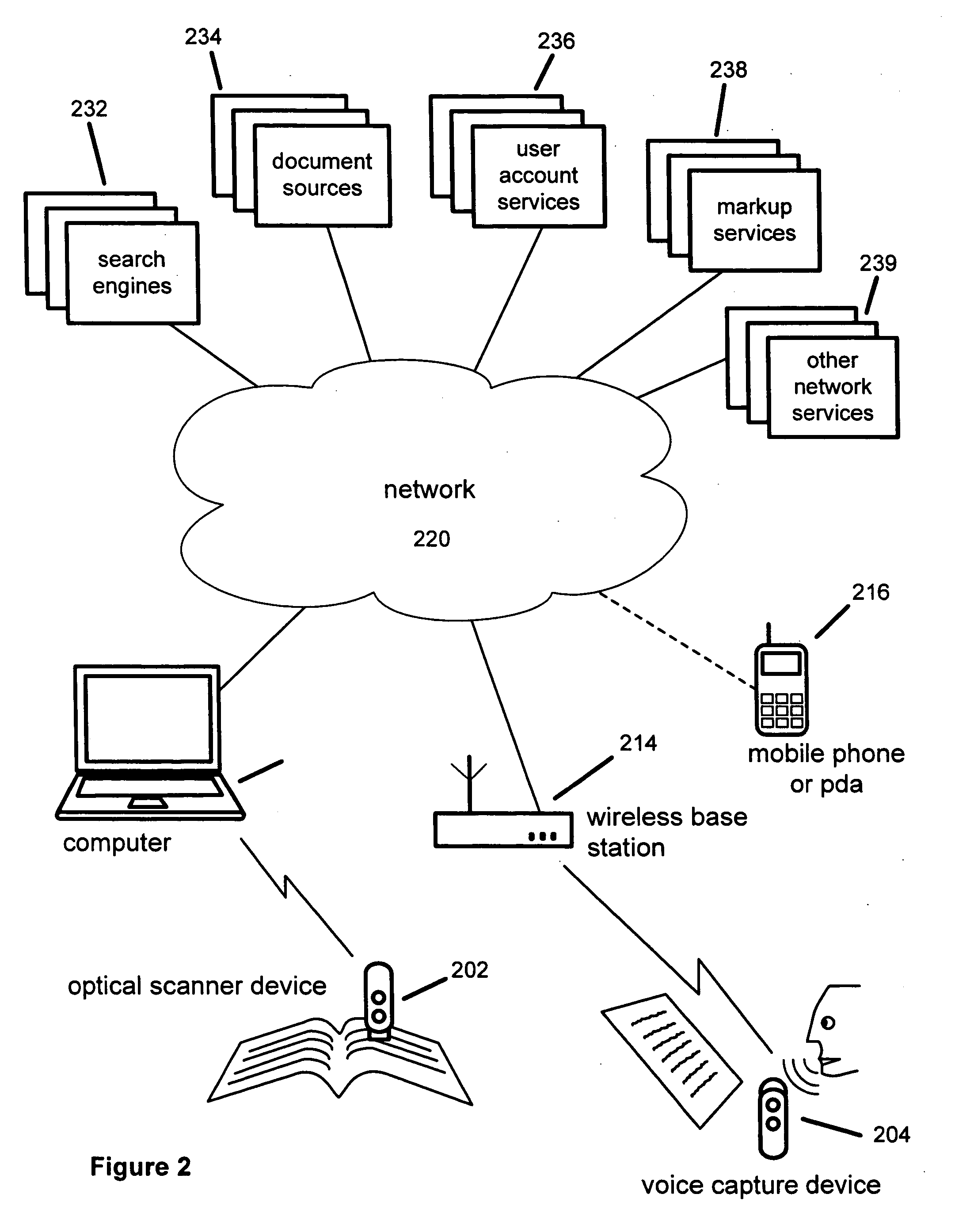

Content access with handheld document data capture devices

ActiveUS20060026140A1Digital data processing detailsCoin-freed apparatusDigital contentDocumentation

Embodiments of the disclosed innovations provide systems and methods for automatically locating and retrieving digital supplemental materials and counterparts of rendered documents. These systems and methods are especially useful when the provider or copyright holder of the digital document charges a fee for access to the digital materials. Some embodiments solve the technical problem of allowing a user to access restricted digital content associated with a rendered document via a search string captured from the rendered document. Some embodiments further provide automatic intermediation to gain access to protected digital materials.

Owner:KYOCERA CORP

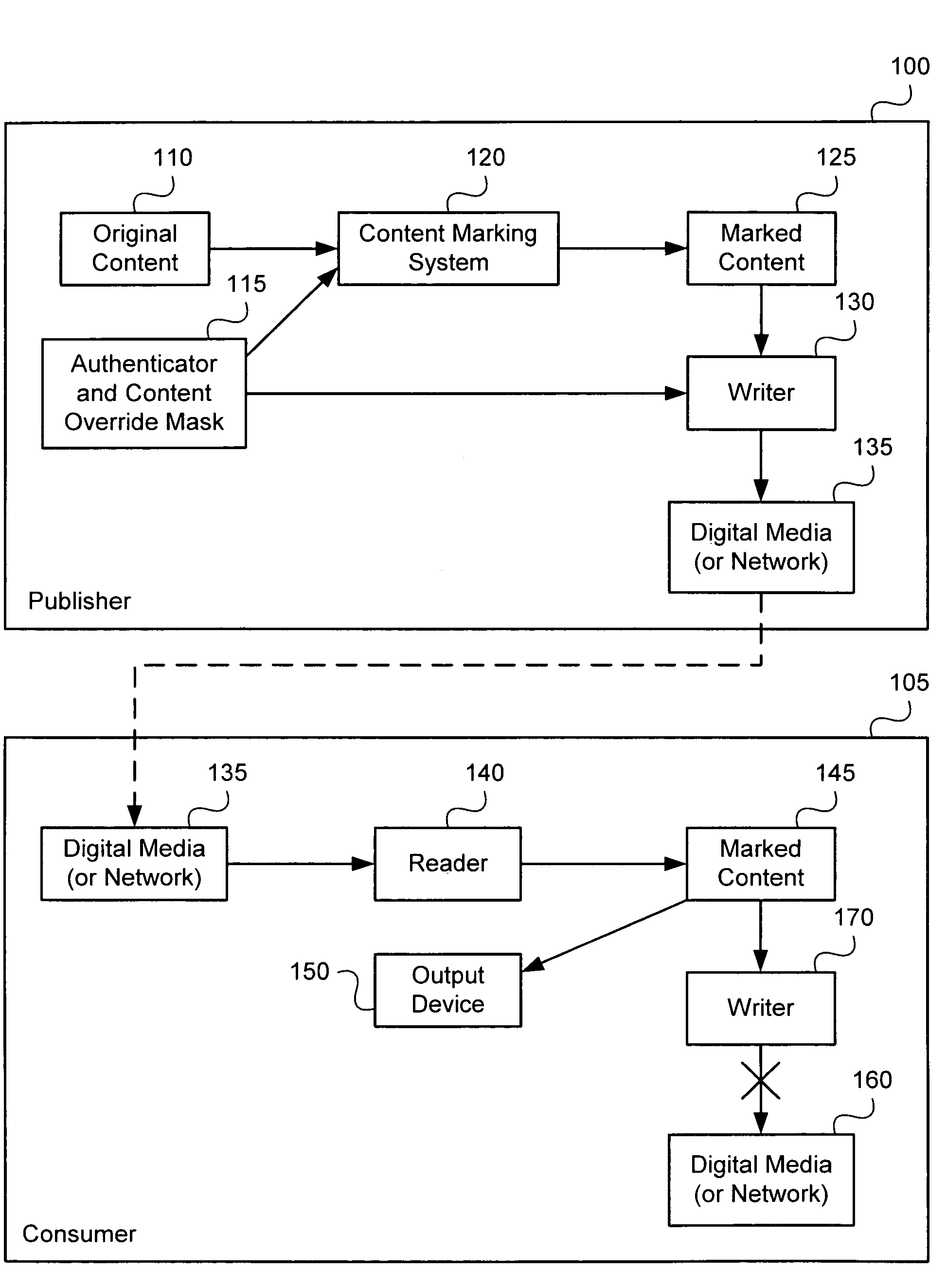

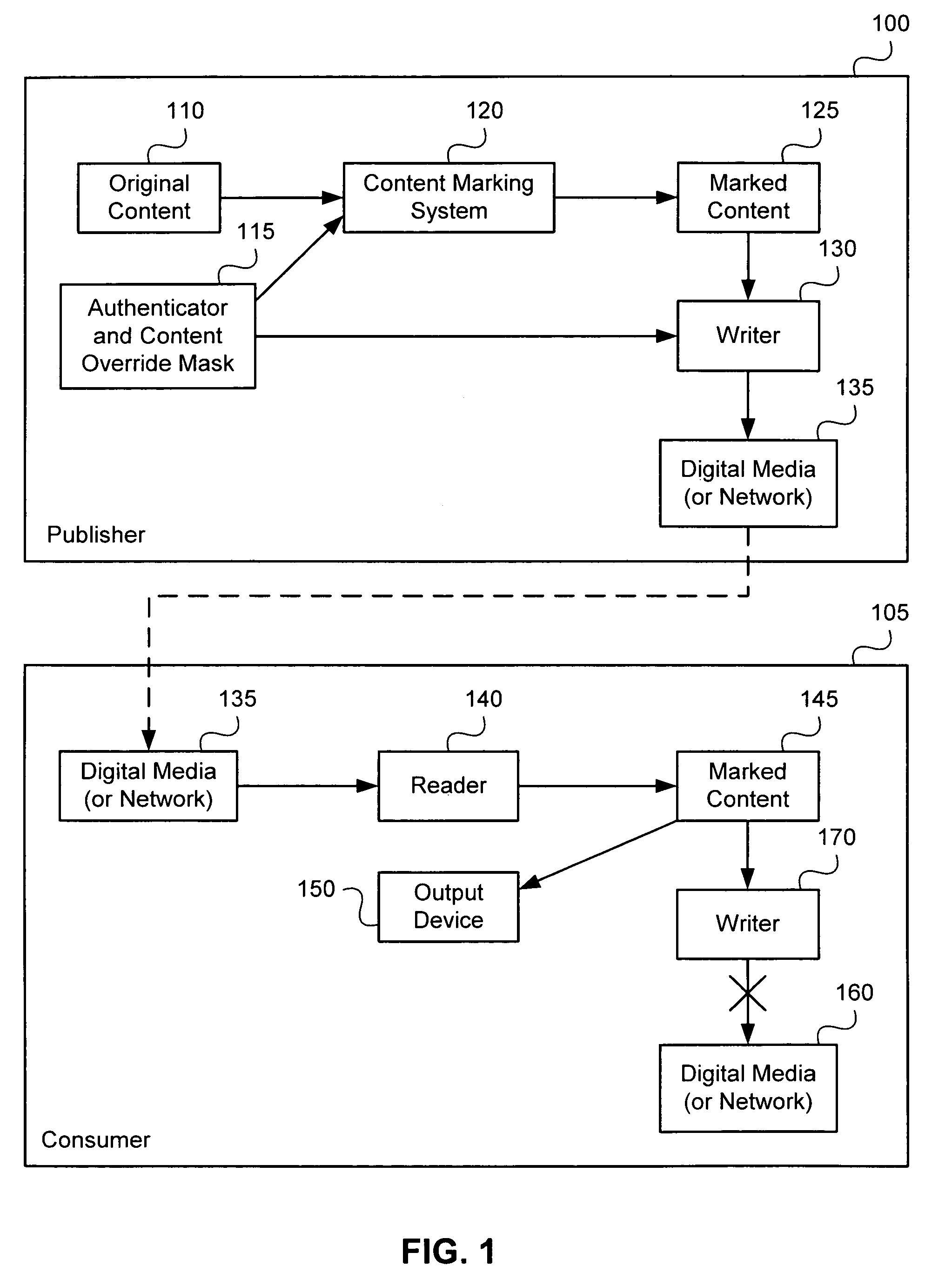

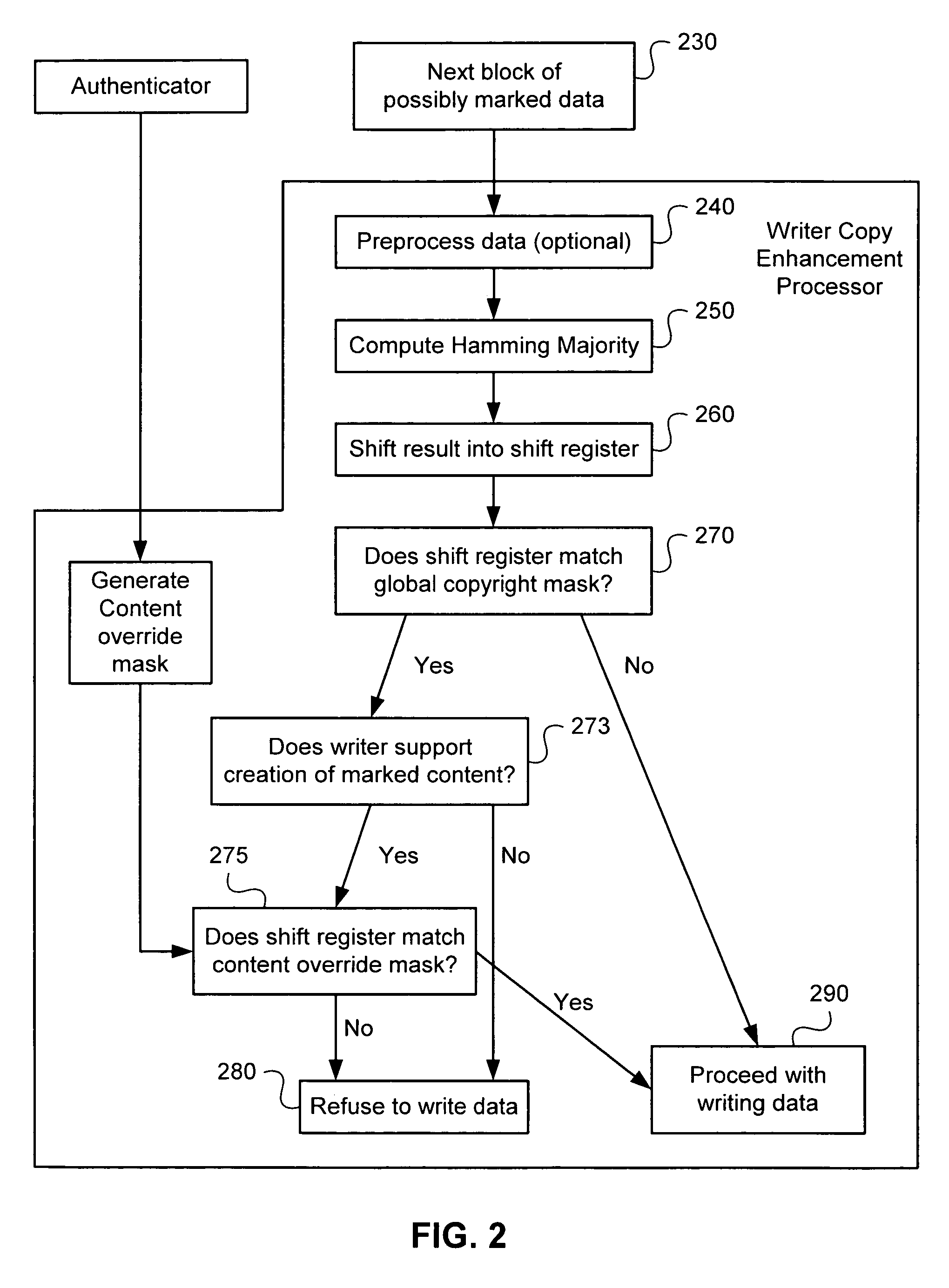

Method and system for copy-prevention of digital copyright works

InactiveUS6978370B1Obstruction is producedHighly effective copy-preventionUser identity/authority verificationTelevision systemsShift registerCoverage function

Methods and apparati for marking digital material and for detecting marks therein. For mark detection, the material is divided into a plurality of blocks, to which a non-collision resistant compression function is applied. Compression outputs are placed in a shift register, whose value is tested for predetermined values or patterns. Mark embedding may be performed by modifying the data (for example by altering low-order bits and other non-critical regions) such that the outputs of the compression operation, when used as an input to the shift register, yield a predetermined value or pattern. A Hamming Majority operation, computed as the most common bit in a block, may be used as the compression operation, enabling marking and mark detection with material of virtually all types and formats. Mark detection technology may be implemented in media writers and other devices to determine whether the digital material is copyrighted or otherwise protected. An override capability is provided to allow authorized parties to bypass the protection.

Owner:IRDETO USA

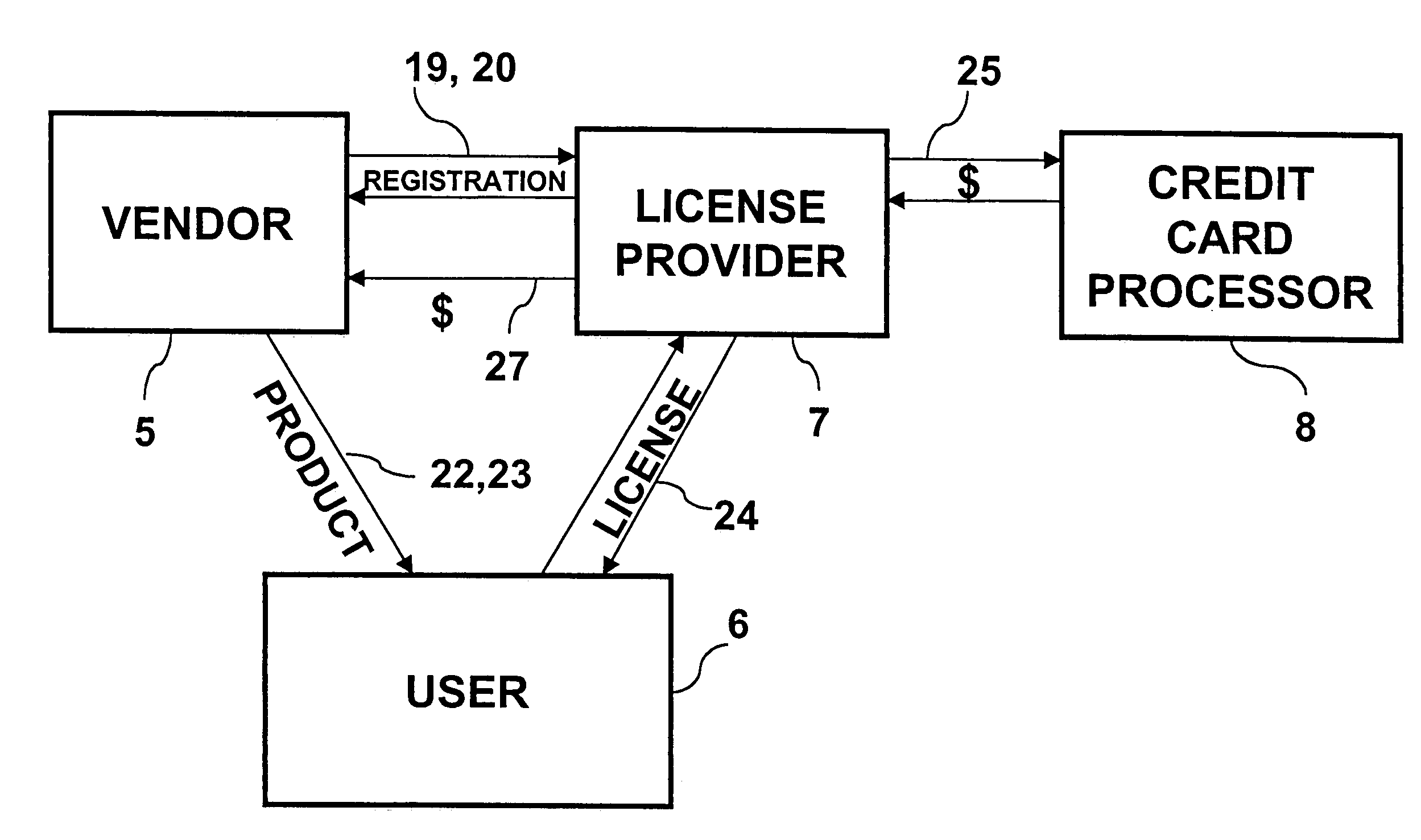

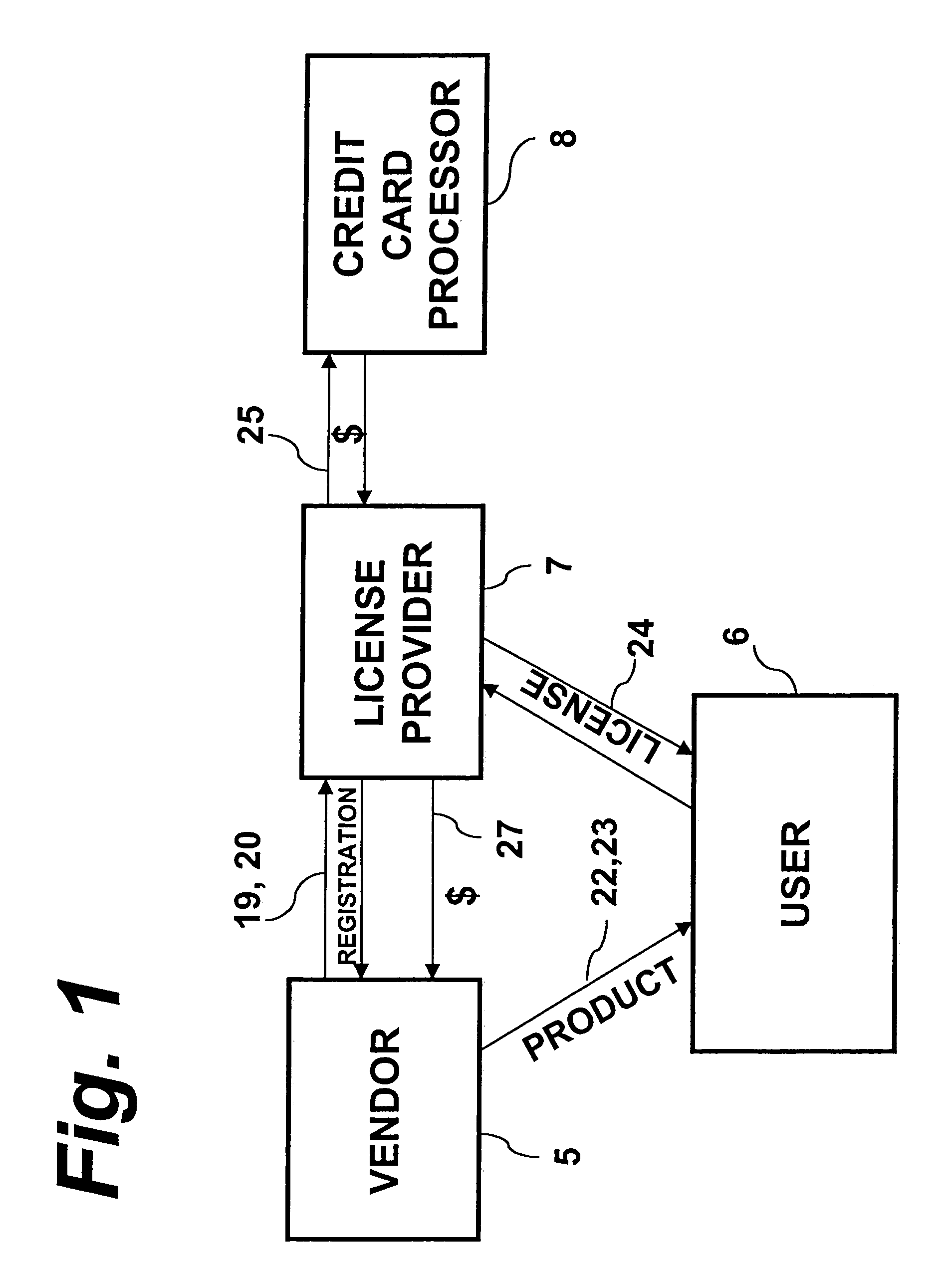

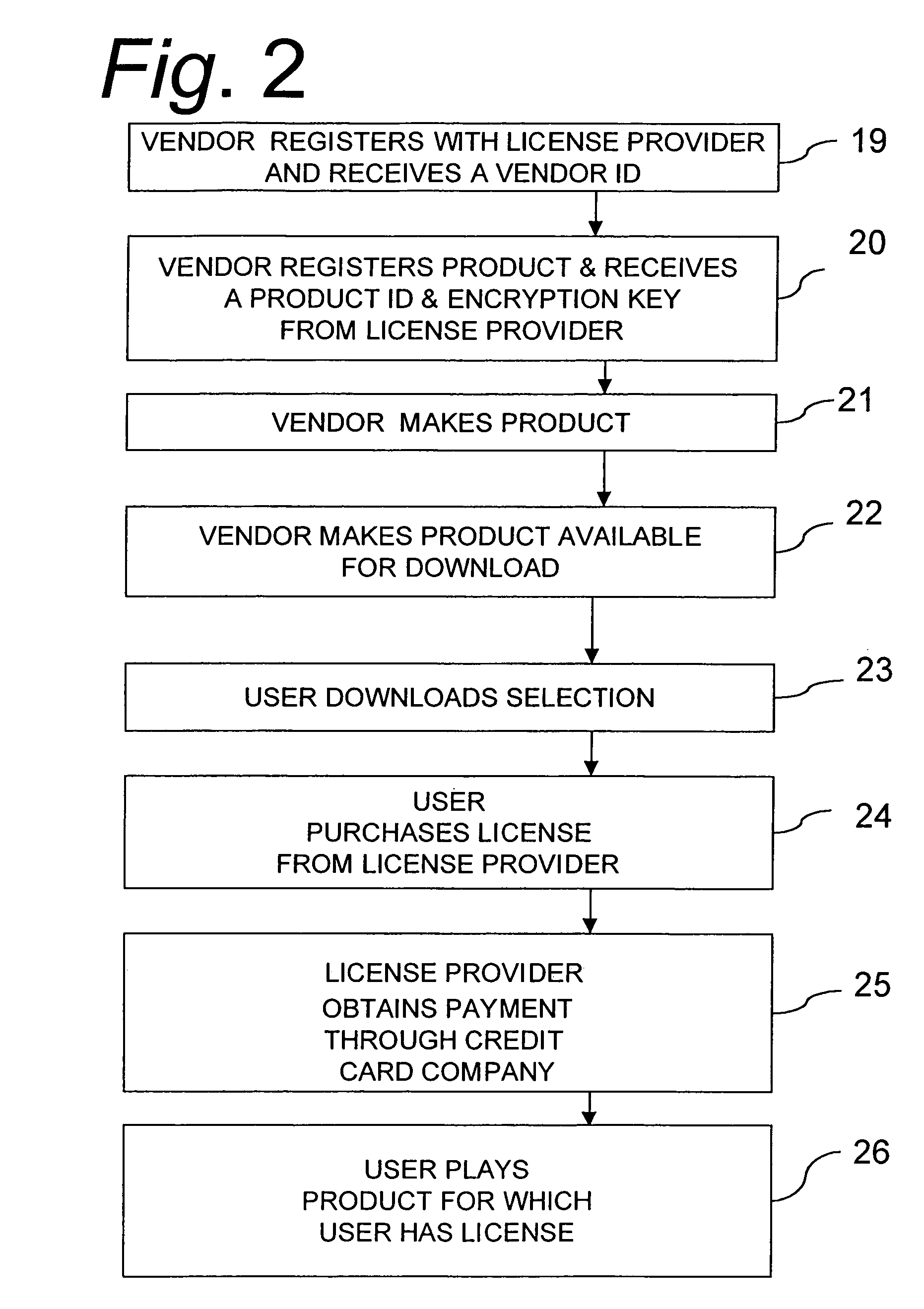

Licensed digital material distribution system and method

InactiveUS7062468B2Provide securityCoupling contact membersPayment architectureDistribution systemSecurity Measure

A system and method distribute licenses for copyrighted material separate from the copyrighted material itself. A producer or “vendor” of copyrighted material registers the material with a License Provider. The License Provider returns an encryption code for the producer to attach to the materials which are in digital form. The vendor distributes that material to one or more users who purchase a license from the License Provider. The license includes an encryption key to decrypt the file containing the materials. The system and method incorporate security measures to prevent unlicensed use and distribution of the materials.

Owner:J RIVER INC

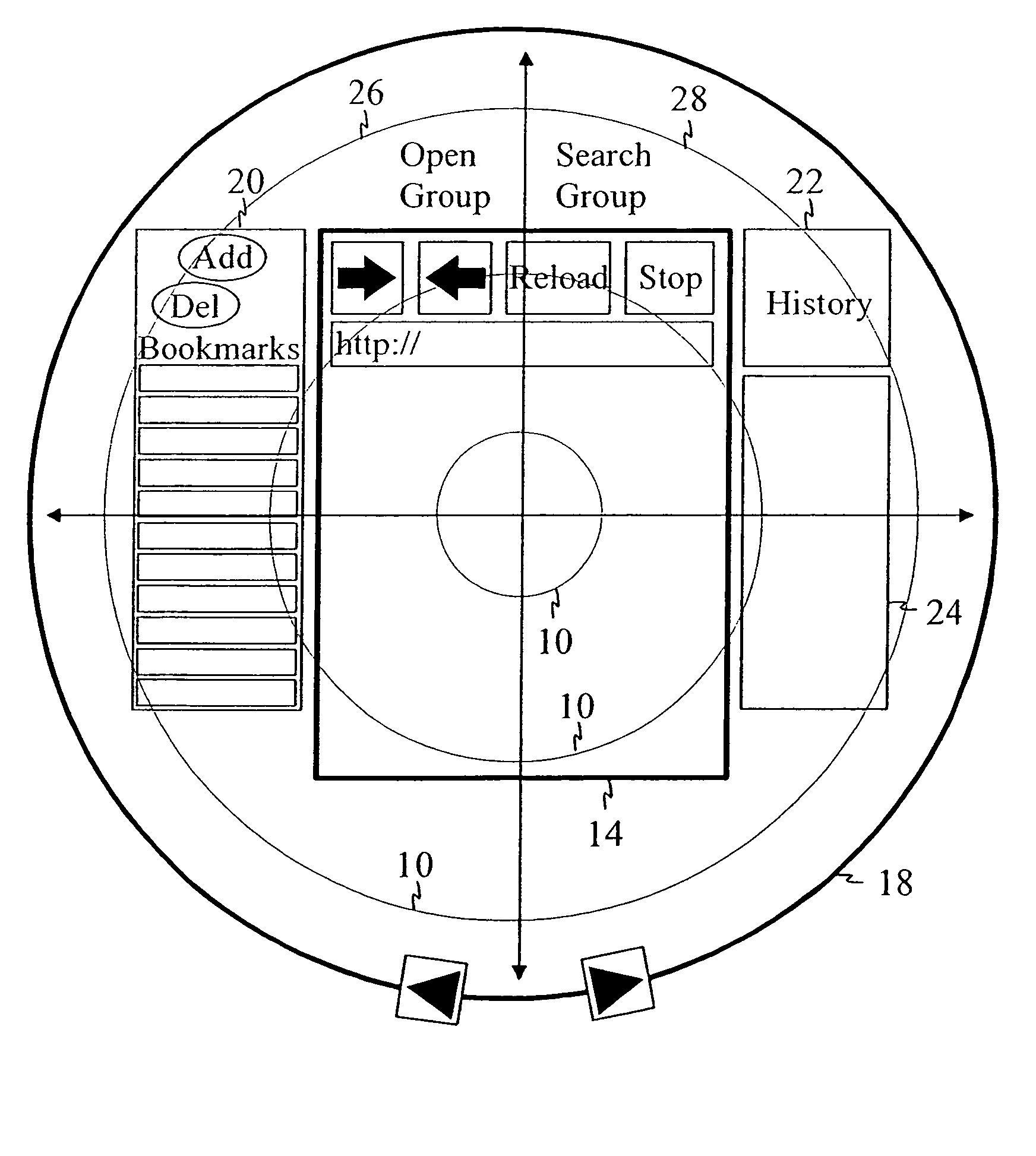

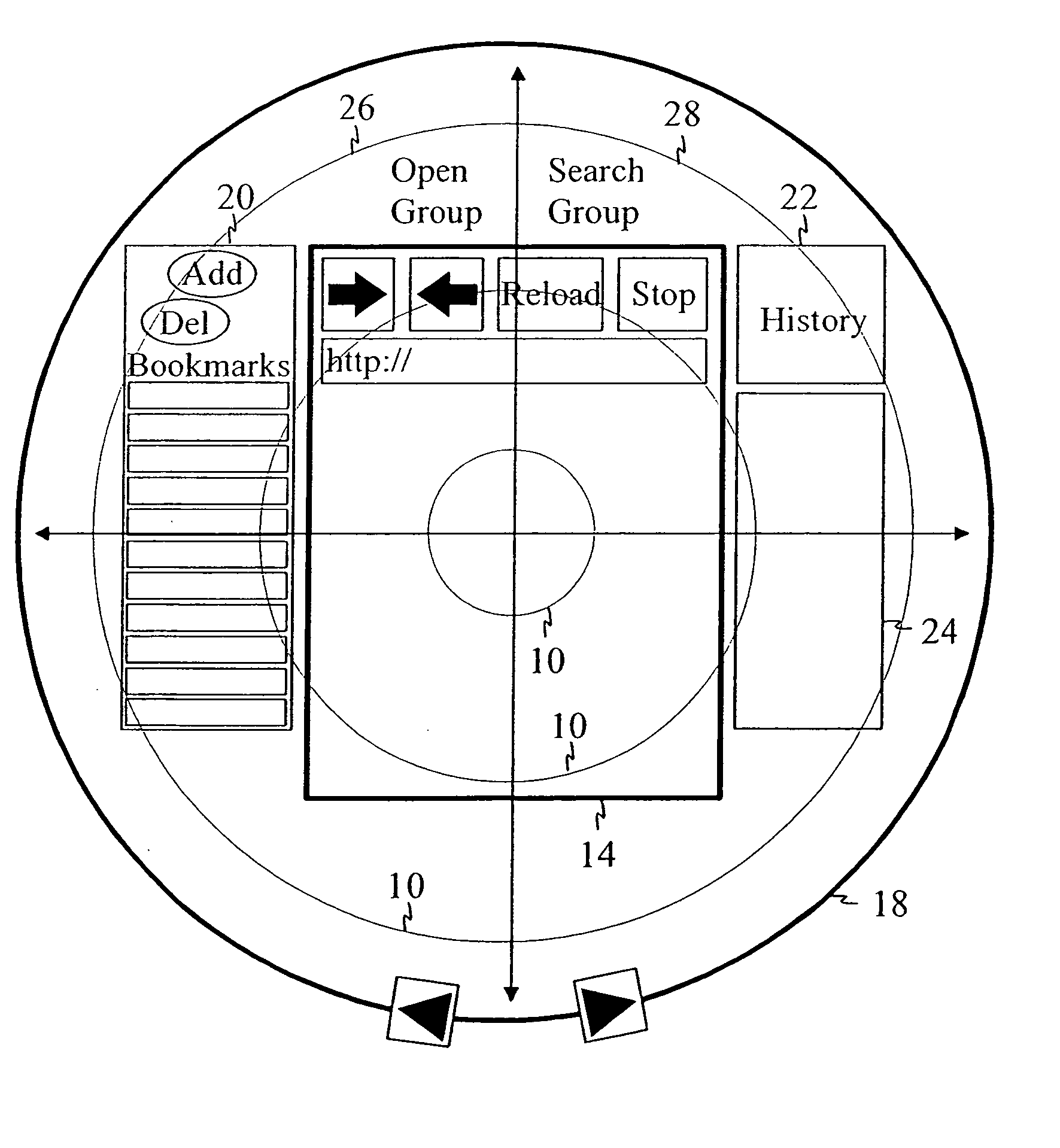

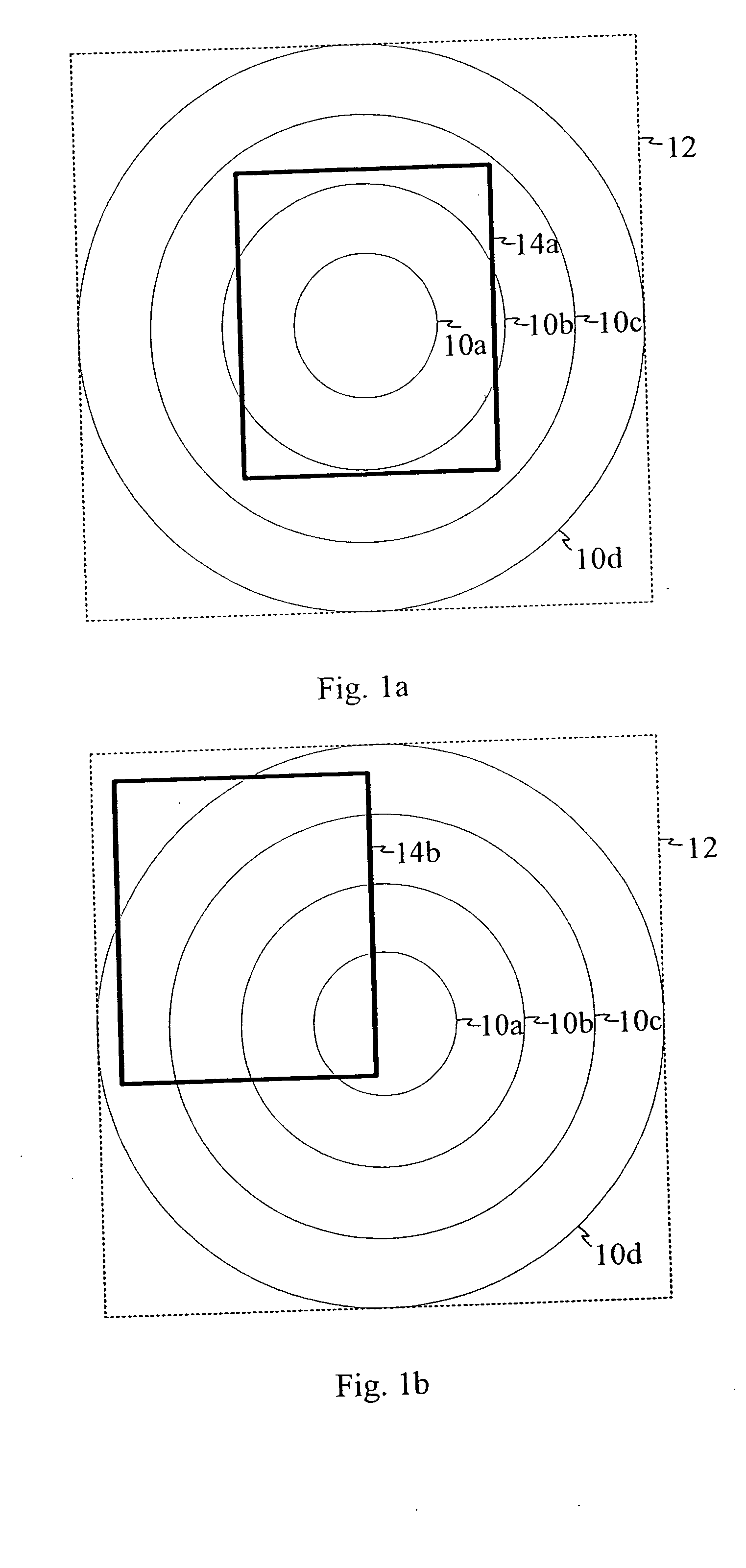

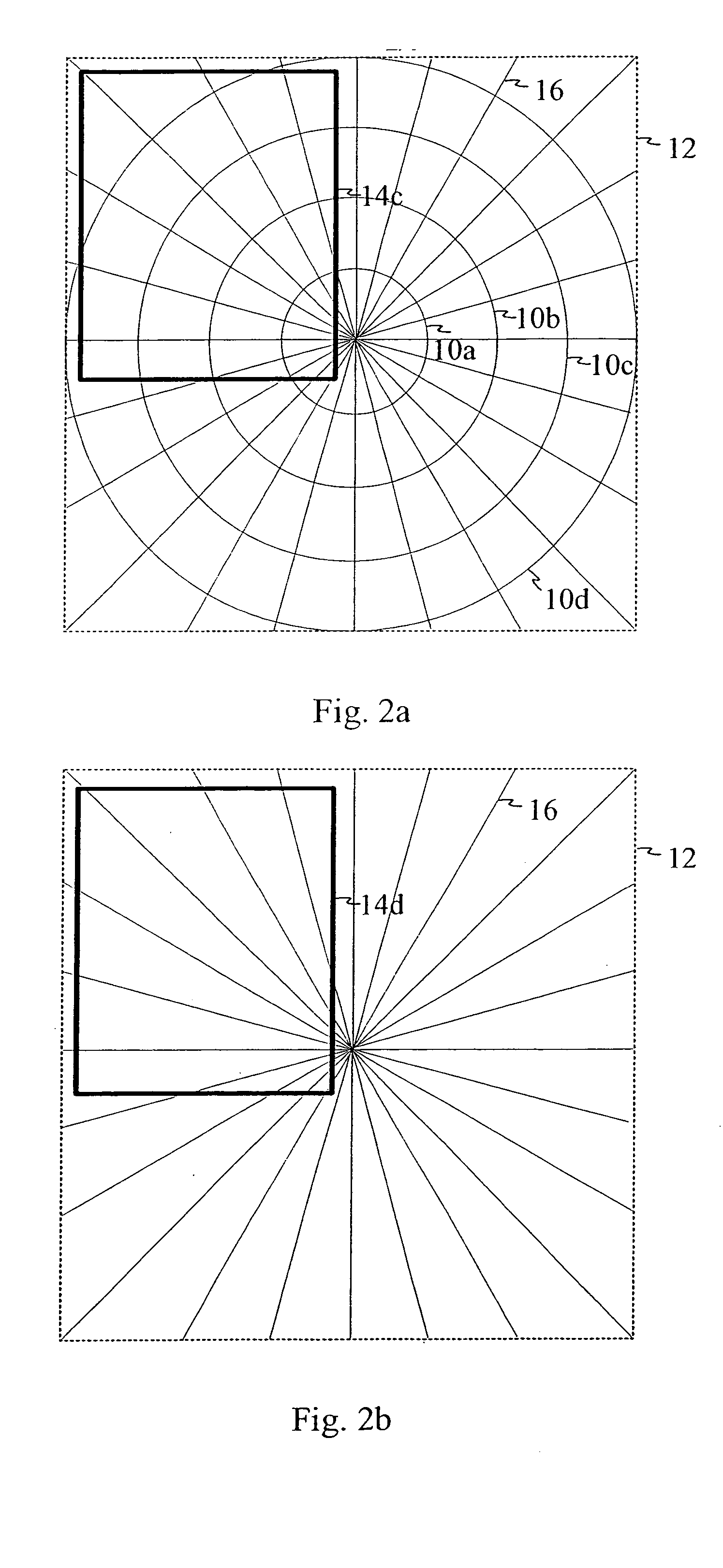

Graphical user interface and method and electronic device for navigating in the graphical user interface

A method, graphical user interface and electronic device for forming guiding lines in a graphical user interface of an electronic device comprising at least a display and a navigating device, wherein a potion of the virtual desktop area of the graphical user interface is seen on the display at a time. In the method, digital material is placed on the virtual desktop area. The method further comprises the steps of determining a point of origin within the digital material and defining at least two points through which a guiding line is drawn, the guiding line indicating the distance and / or direction to the point of origin. The guiding line is then displayed along with the digital material on the display.

Owner:APPLE INC

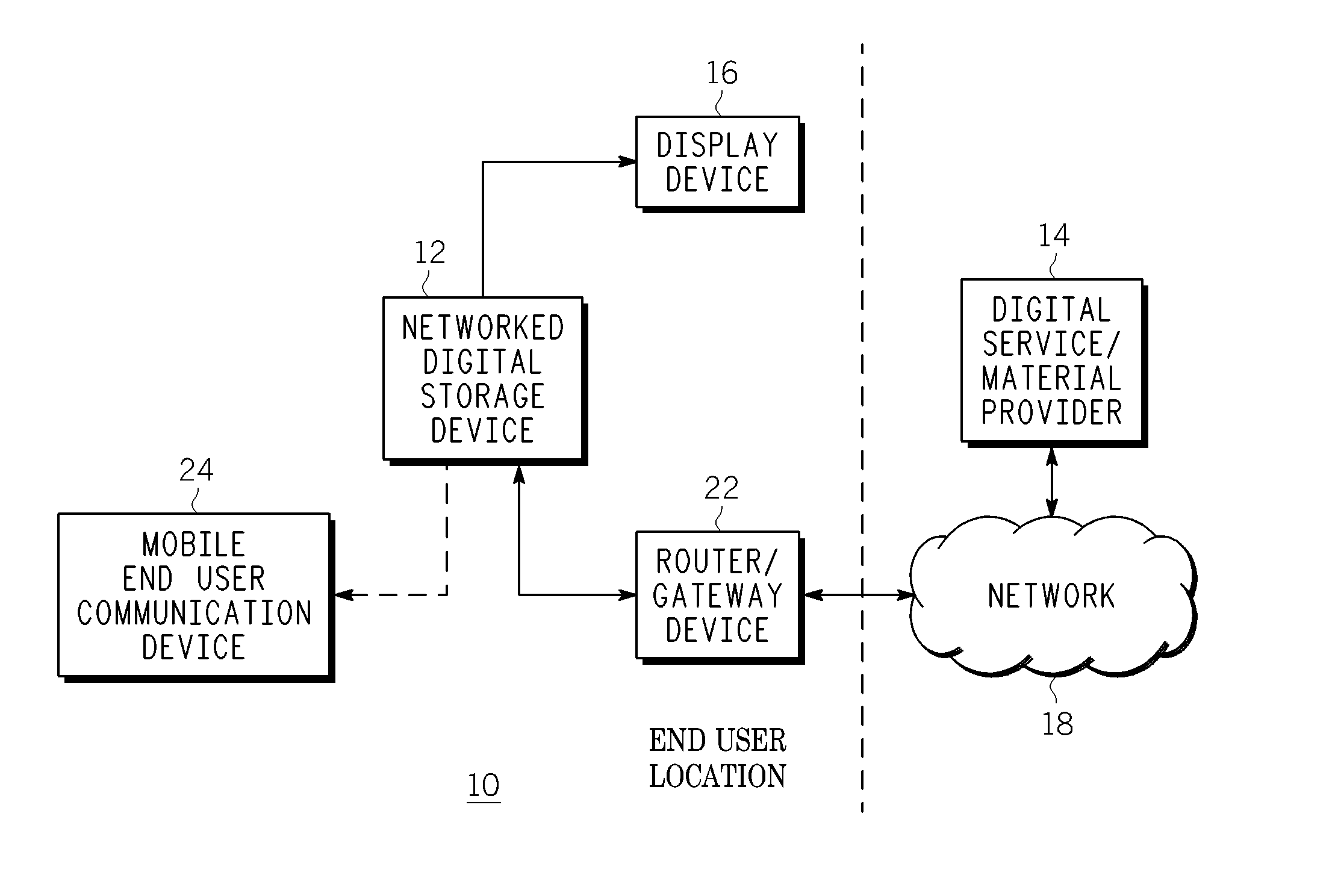

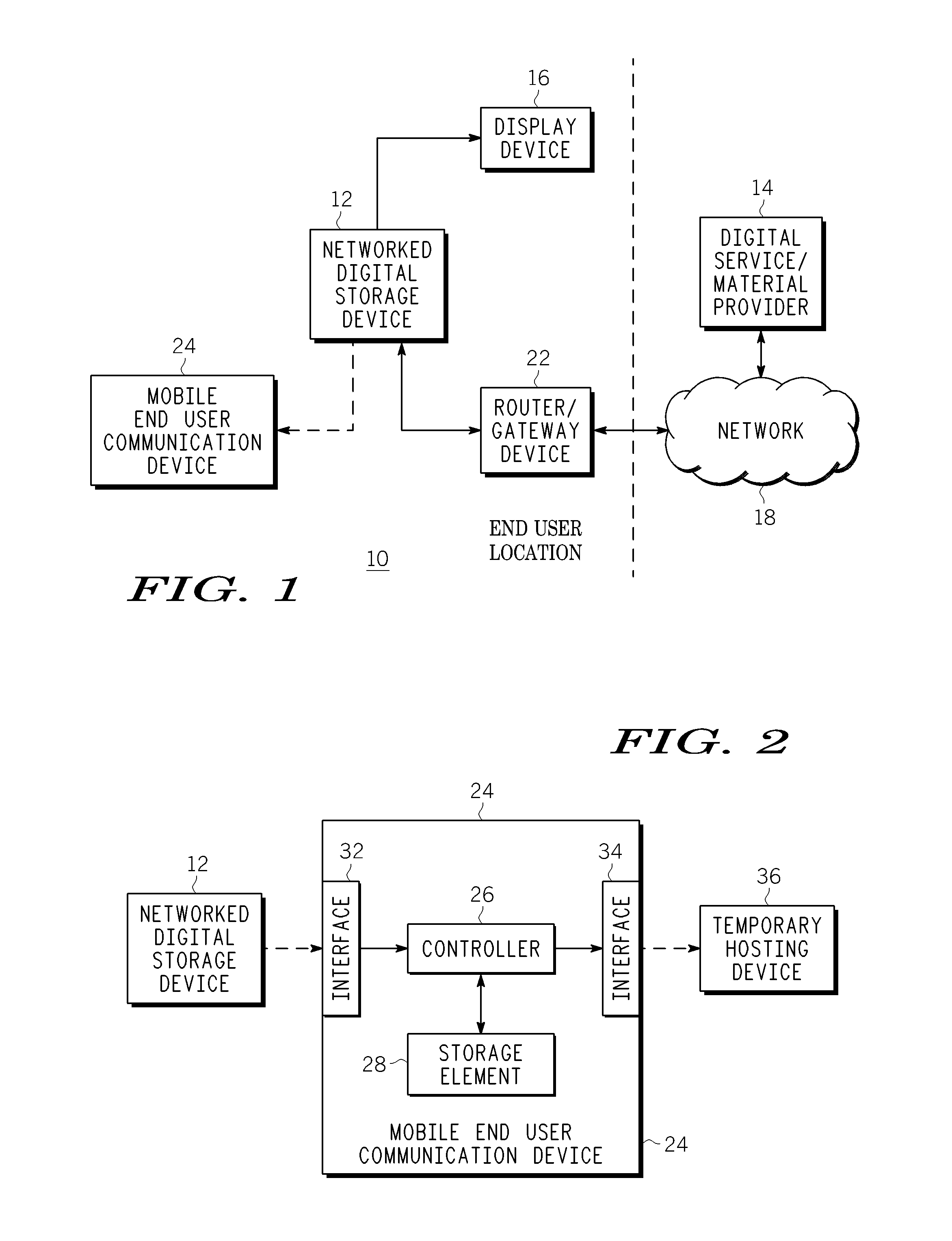

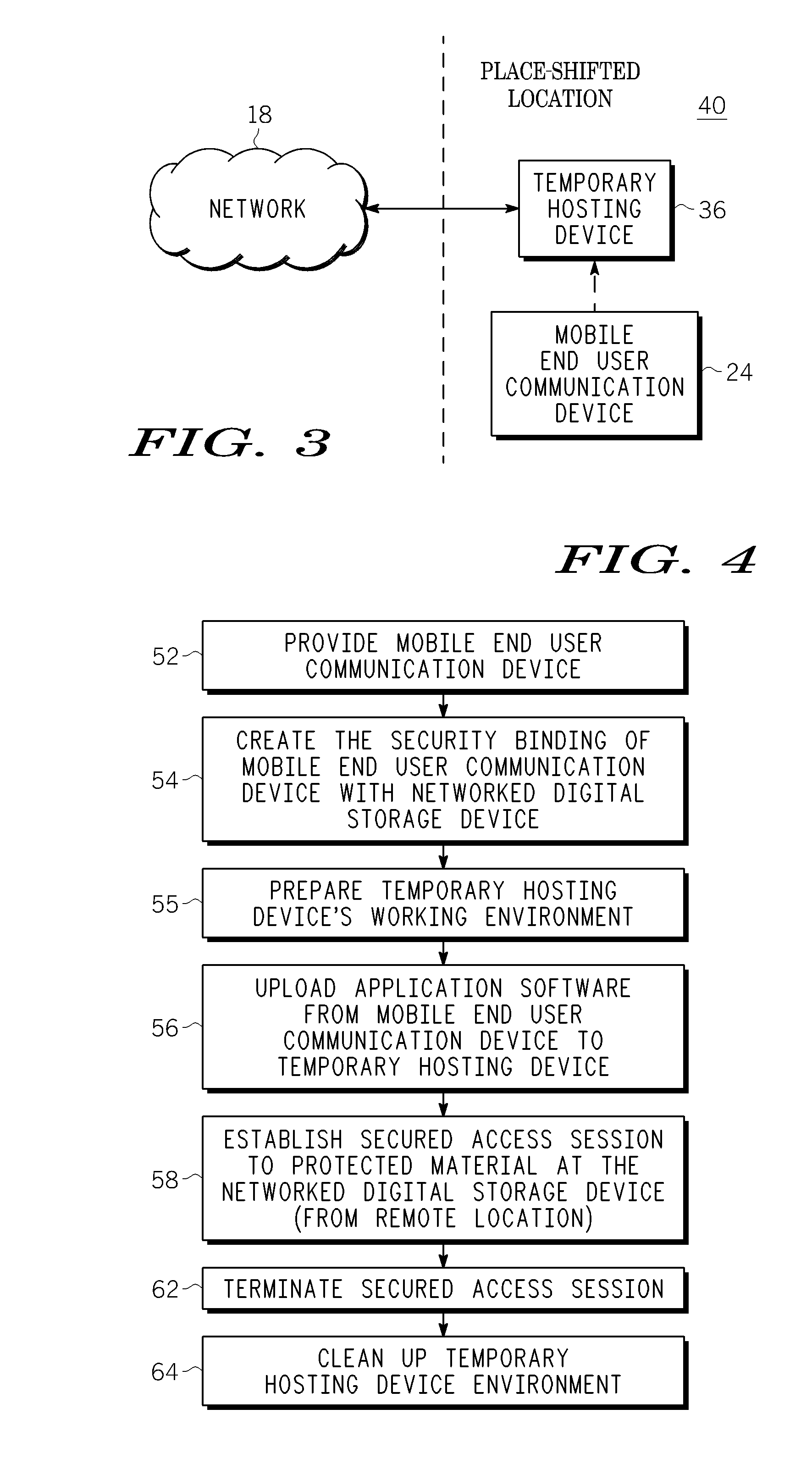

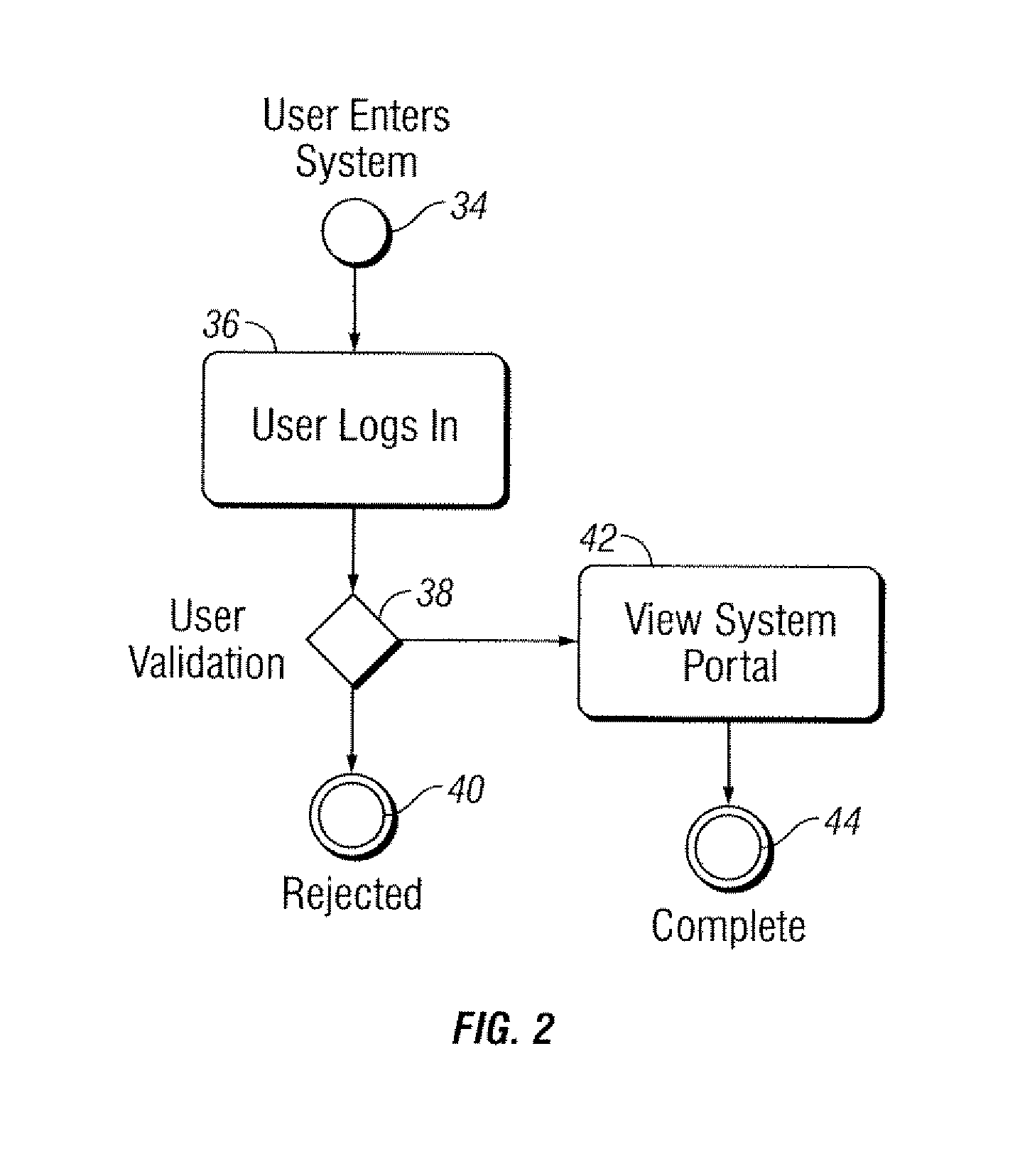

Method, system and device for secured access to protected digital material

ActiveUS20090070884A1Digital data processing detailsAnalogue secracy/subscription systemsDigital storageApplication software

A method, system and device for providing secure access to multimedia content received by a networked digital storage device, such as a set-top box. A mobile device, such as a mobile telephone, obtains appropriate security binding information and application software when coupled to the networked digital storage device at its end user location. The mobile device uploads the security binding information to a randomly located temporary hosting device at its place-shifted location when coupled thereto and, through a logical binding with the temporary hosting device, enables a secure, remote session. The secure binding and transfer of appropriate keys allow the remote hosting device to securely access premium or protected digital material / services available at the networked digital storage device. After completion of the secure, remote access session, termination occurs and the security binding information and the computing activity residue can be removed from the mobile device and the temporary hosting device.

Owner:GOOGLE TECH HLDG LLC

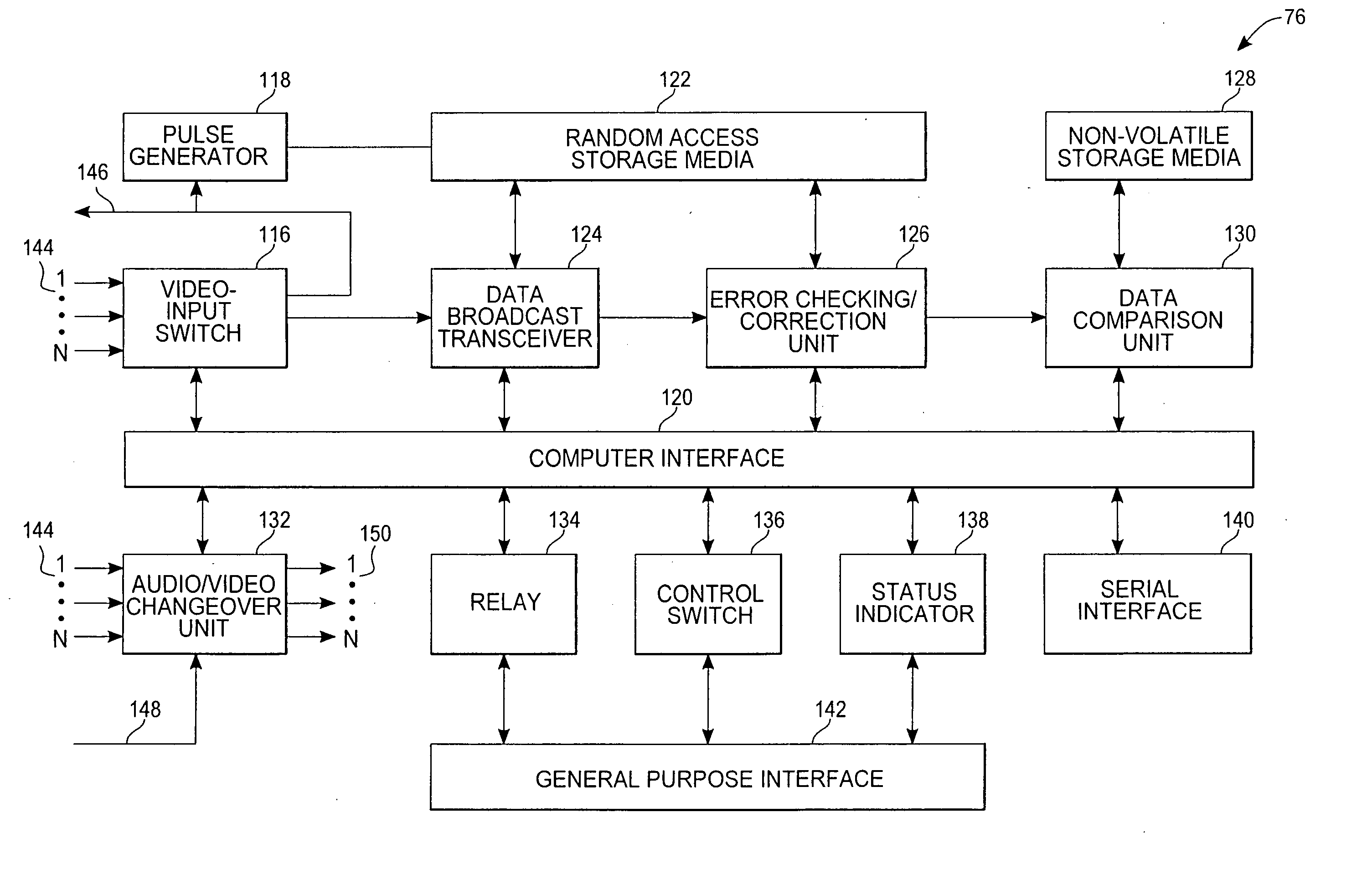

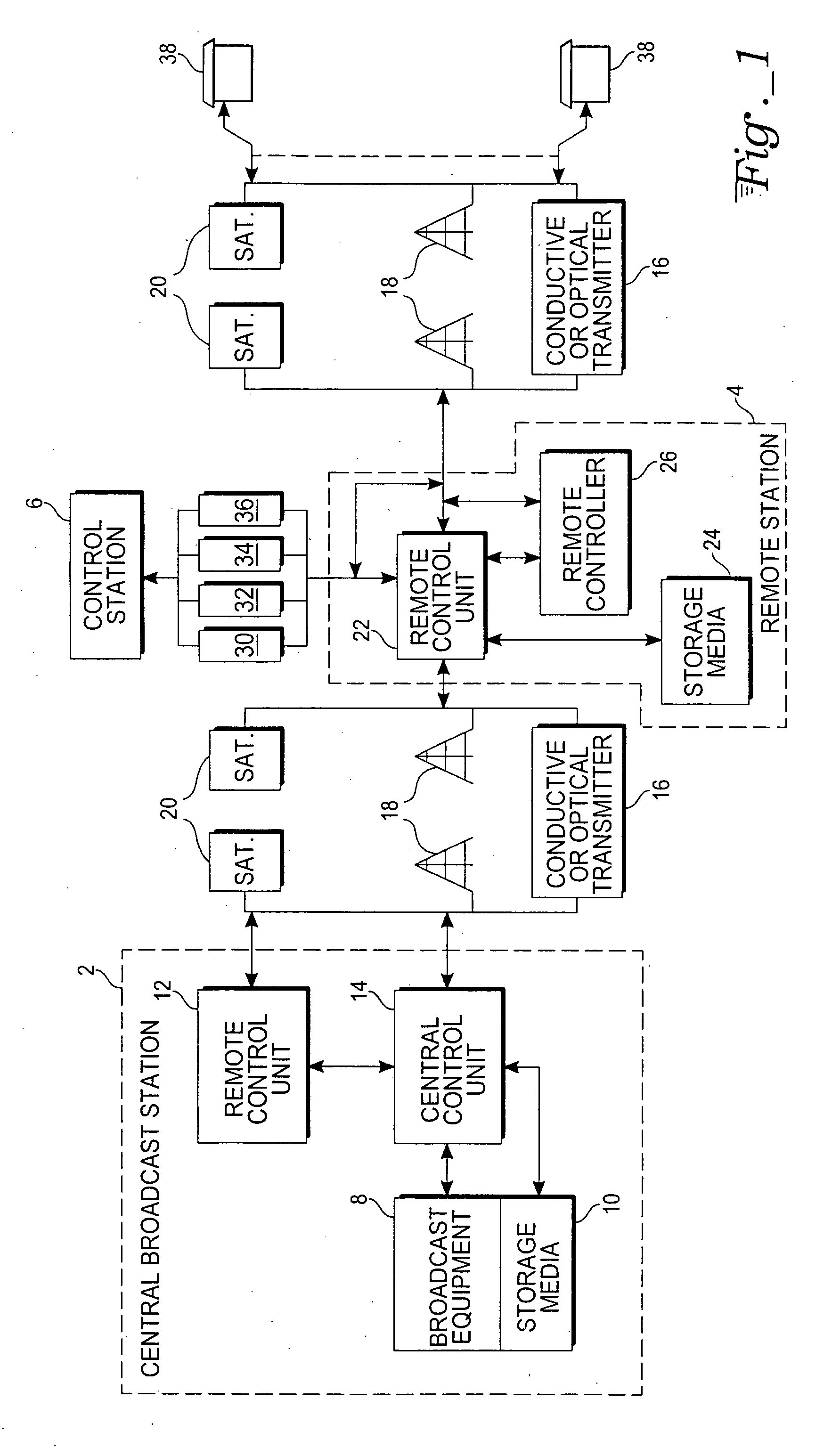

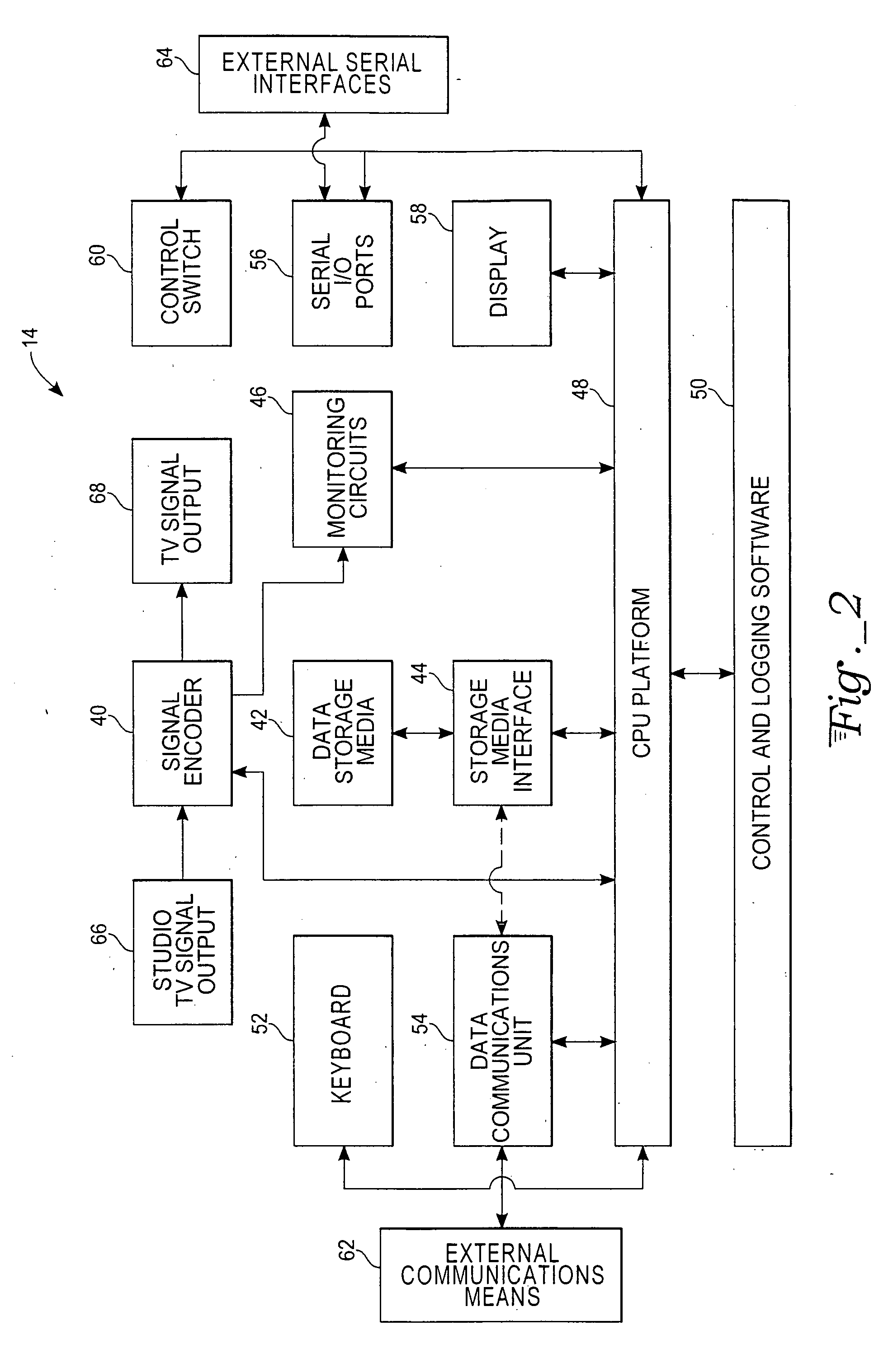

Apparatus and method for insertion of material in broadcasting

InactiveUS20060053442A1Easy to integrateReliable insertionTelevision system detailsSelective content distributionControl signalVertical blanking interval

A system, apparatus, and method for local insertion of analog or digital material into a television broadcast signal. A central insertion control unit controls the insertion of additional material while a remote insertion control unit locally controls the insertion of the additional material. The central insertion control unit contains a processor, storage media, and an encoder for encoding control and information signals into a broadcast signal. The control signal contains a cue signal for information about play lists, and an action signal for triggering insertion of the additional material. The control signal is encoded into a line of the vertical blanking interval. Once the control is detected by the remote insertion control unit the additional material is played and broadcast.

Owner:RIDDERHEIM STEFAN +1

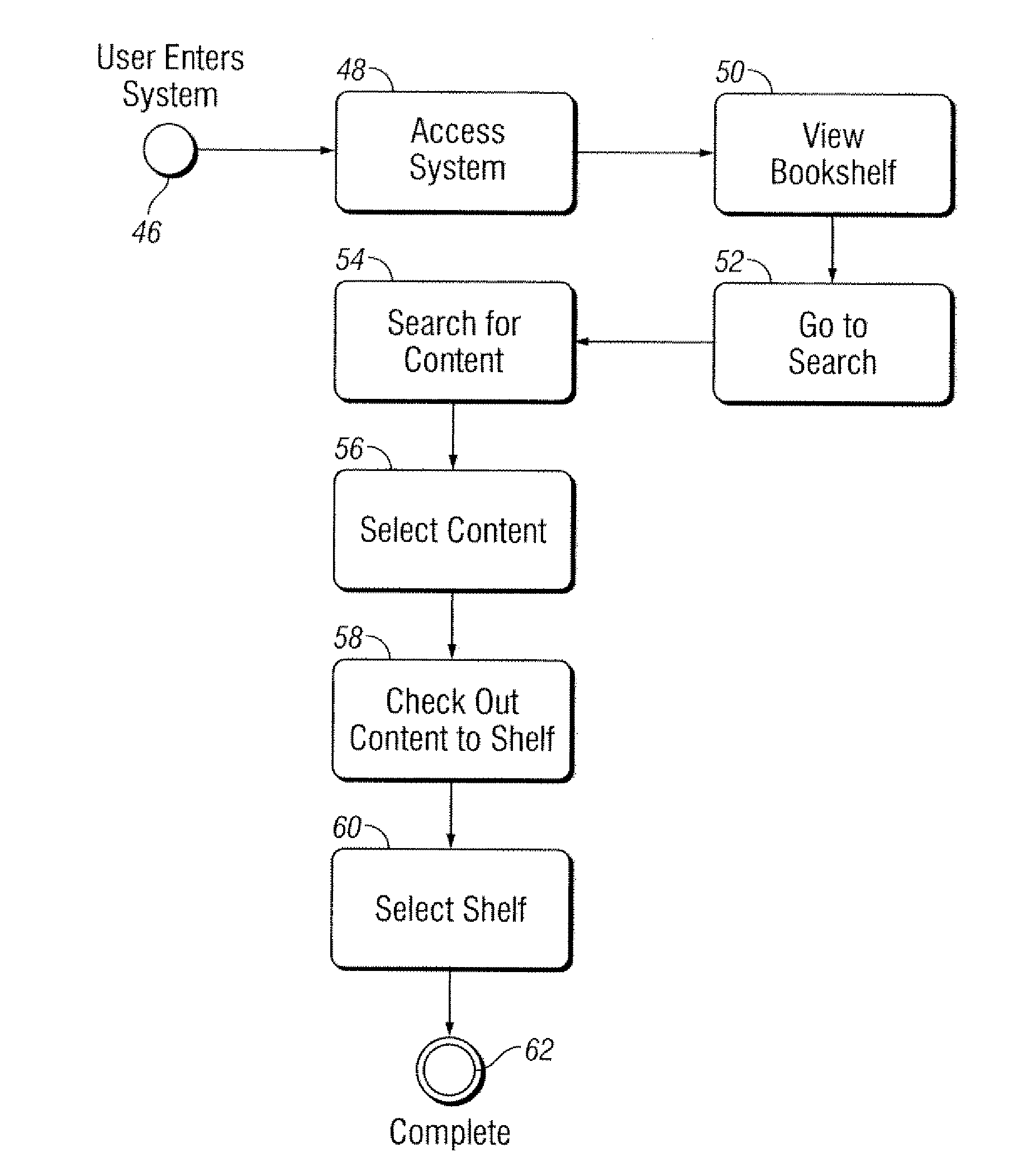

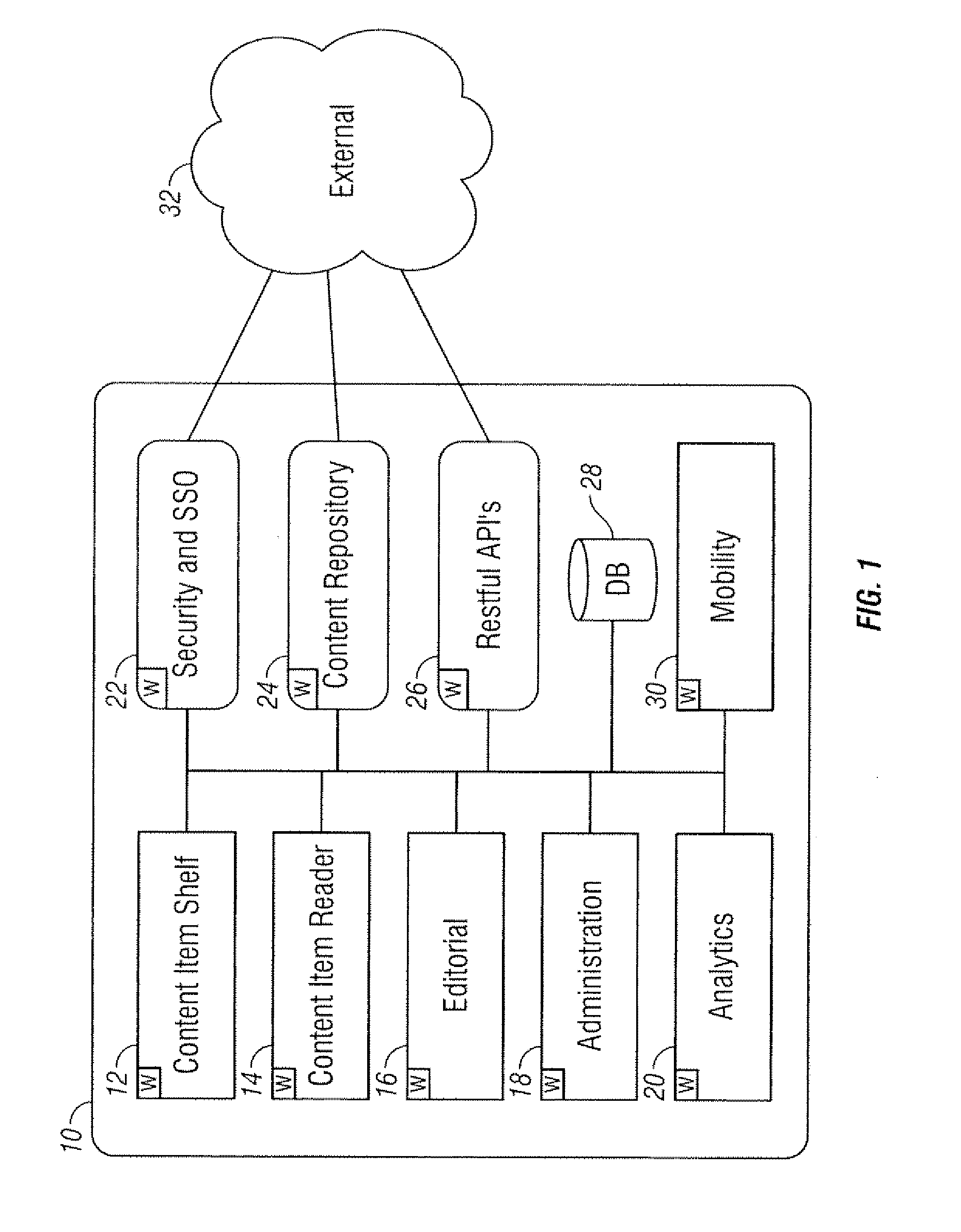

System and method for publishing and displaying digital materials

The present invention provides a system for publishing and displaying digital materials, comprising an ePub publishing module comprising a mechanism for publishers to upload ePub files, a user management module providing a means to add, edit and remove end users from the system, a bookshelf module for organizing the user's content in order to create a logical grouping of content, a reading content module for reading content after the user has been mapped to the content, and an annotating content module for annotating user selected text.

Owner:THE ARIZONA BOARD OF REGENTS ON BEHALF OF THE UNIV OF ARIZONA

Graphical user interface and method and electronic device for navigating in the graphical user interface

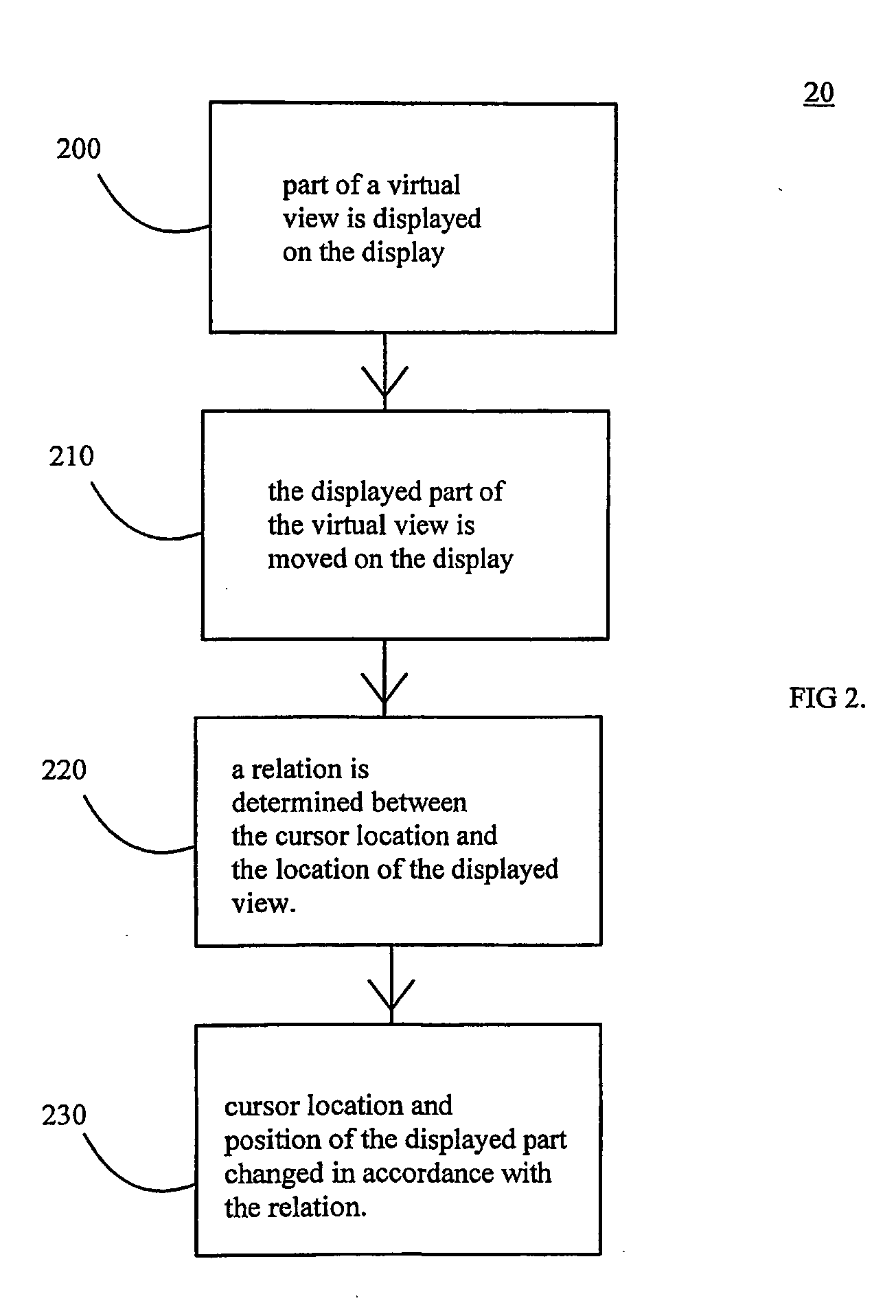

ActiveUS20050076303A1Television system detailsColor television detailsGraphicsGraphical user interface

Owner:APPLE INC

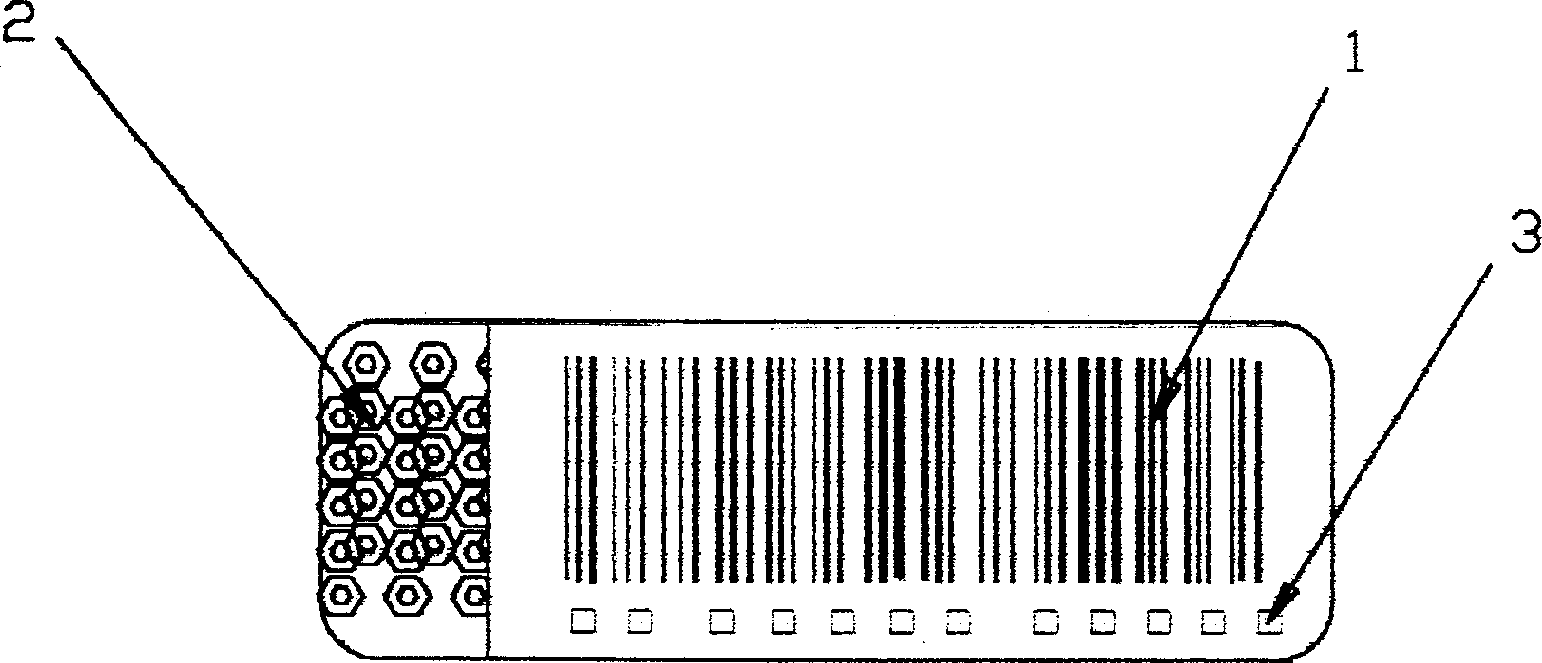

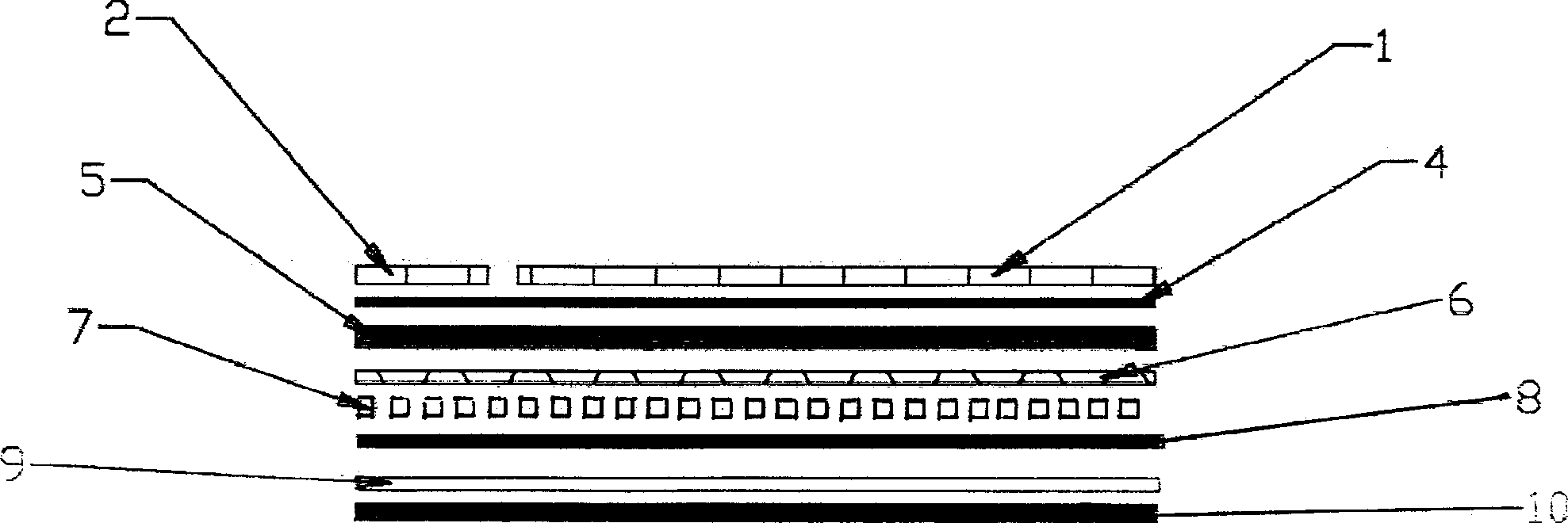

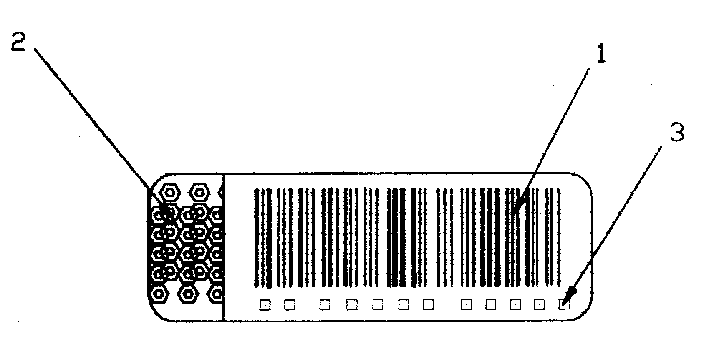

Holographic bar code compound label and making process thereof

A holographic bar code label for material flow management is composed of encrypted bar code about the digital material flow information and the holographic laser ID icon. It is prepared from multiple basic material through special process. Its advantage is high antiforge effect.

Owner:薄振东 +5

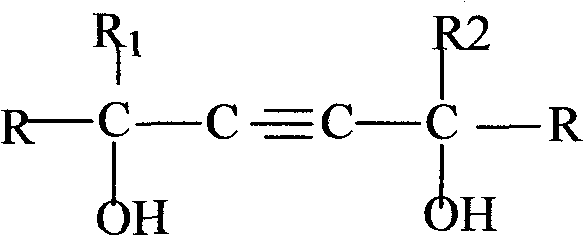

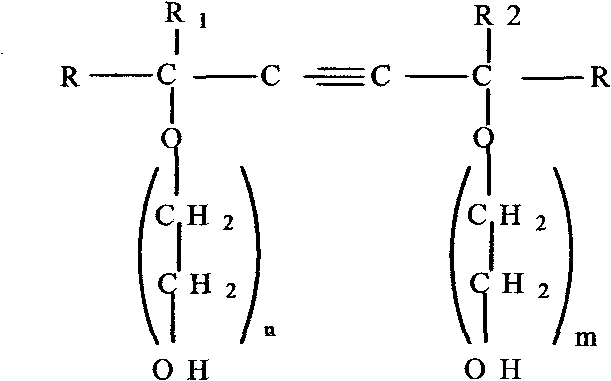

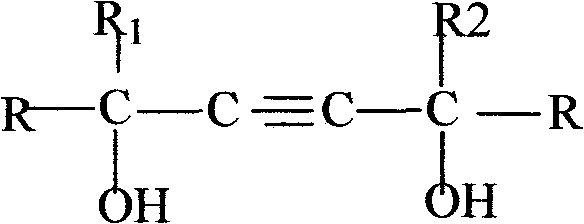

Multifunctional surfactant composition for water-based system and preparation method thereof

InactiveCN102145267ALow dynamic surface tensionNon-macromolecular adhesive additivesTransportation and packagingWater basedAlkane

The invention provides a multifunctional surfactant composition for a water-based system and a preparation method thereof. The surfactant composition used in formulas of a water-based coating, ink, adhesive and a digital material has low foaming effect and has the effect of effectively reducing the dynamic surface tension of the water-based system. The composition is formed by compounding and modifying based on alkynyl diol or alkynyl diol ethoxylate. The key component structure of the composition is an alkane structure in which R, R1 and R2 are straight-chained or branch-chained, and the number of carbons is 1 to 15; R, R1 and R2 can be the same or different groups; the carbon number of the alkane structure in which R, R1 and R2 are straight-chained or branch-chained is 1 to 15; R, R1 and R2 can be the same or different groups; and the sum of m and n is 1 to 30. The invention simultaneously provides the preparation method for the composition.

Owner:TIANJIN SURFYCHEM T&D

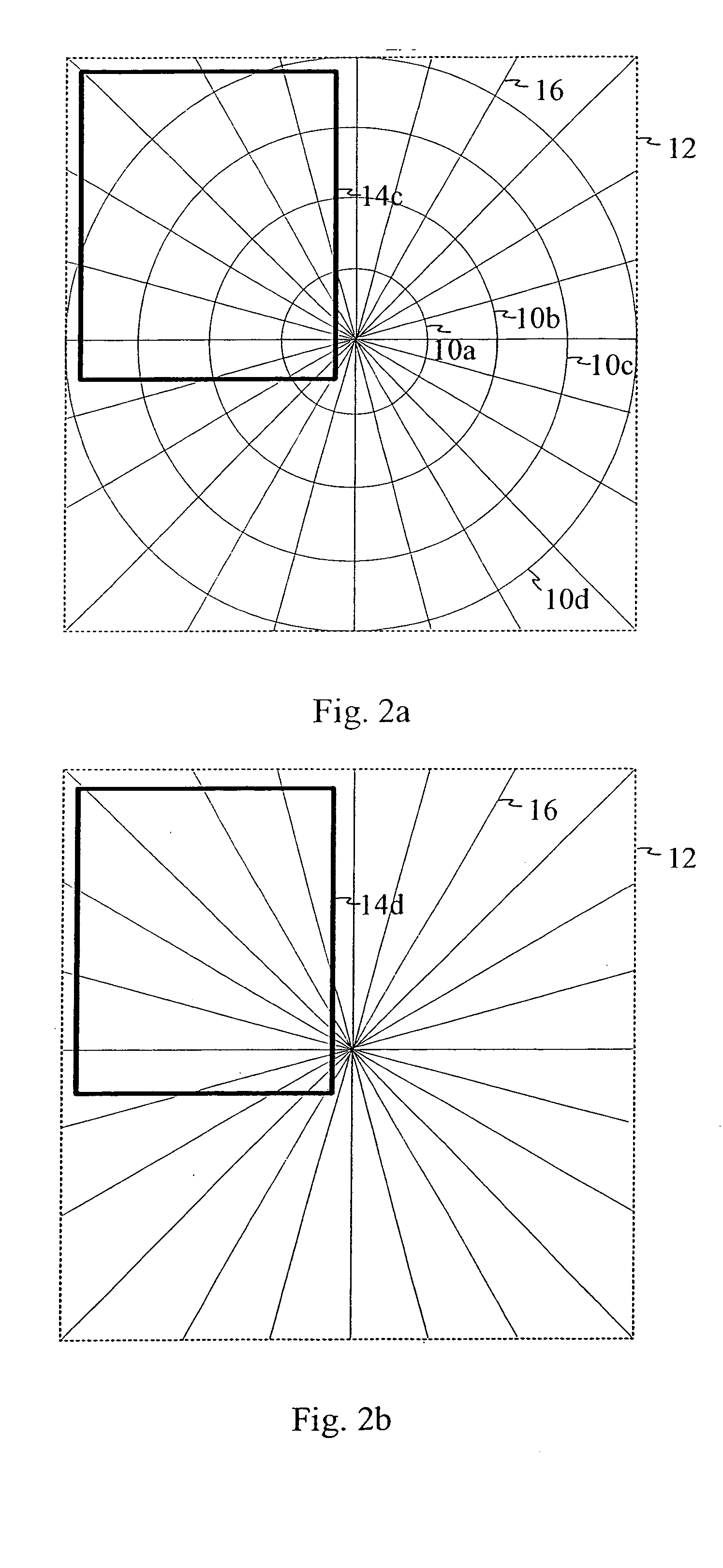

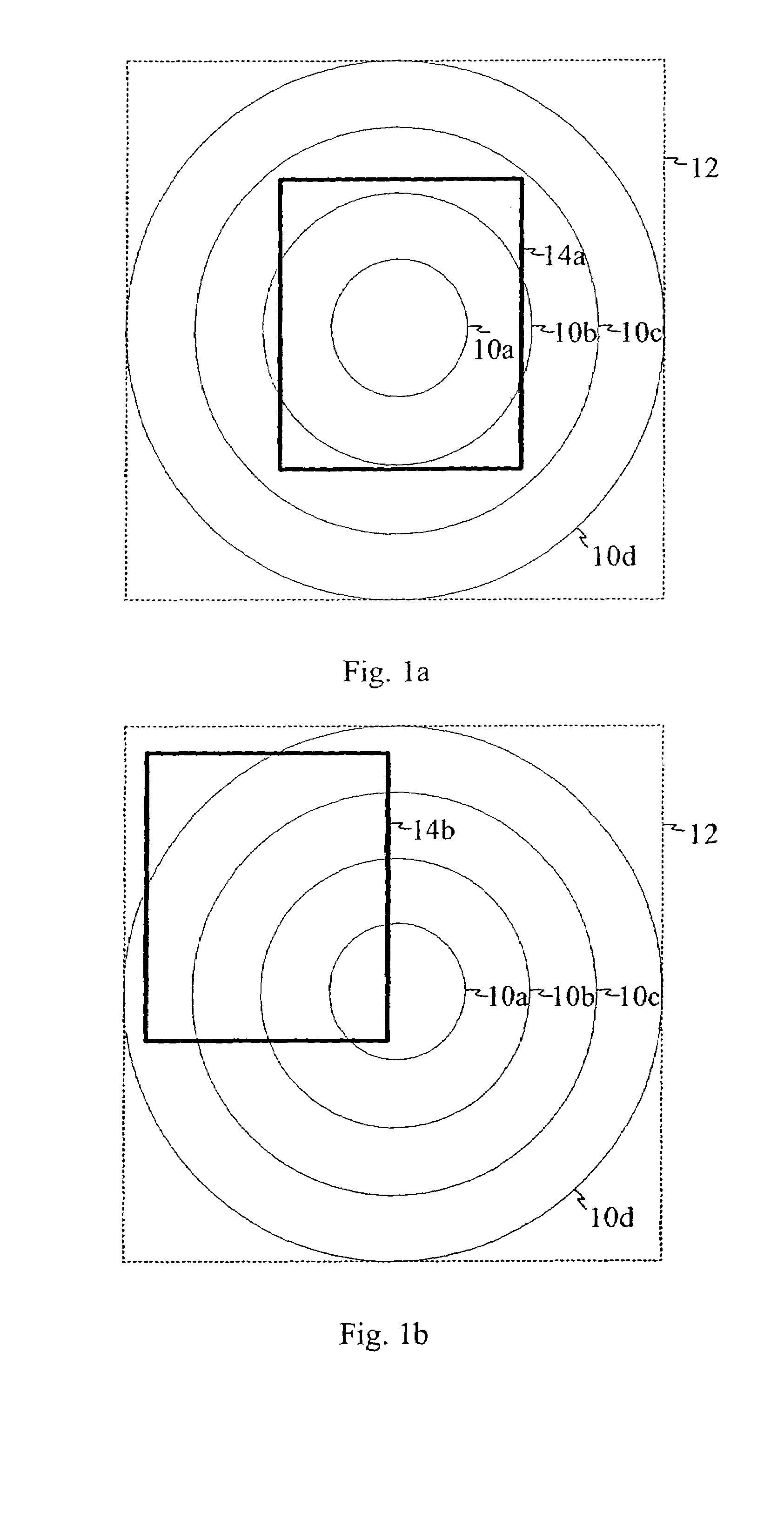

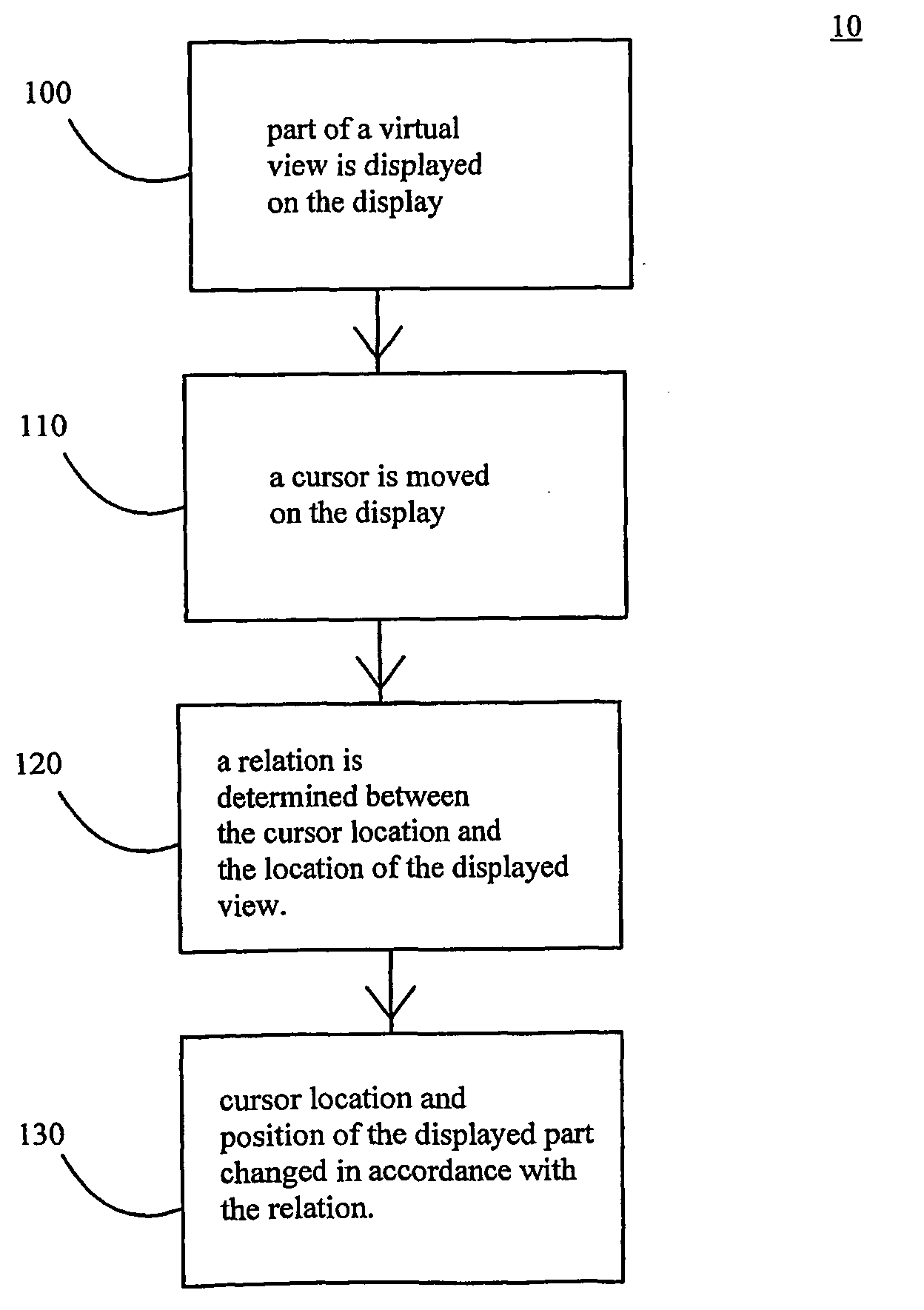

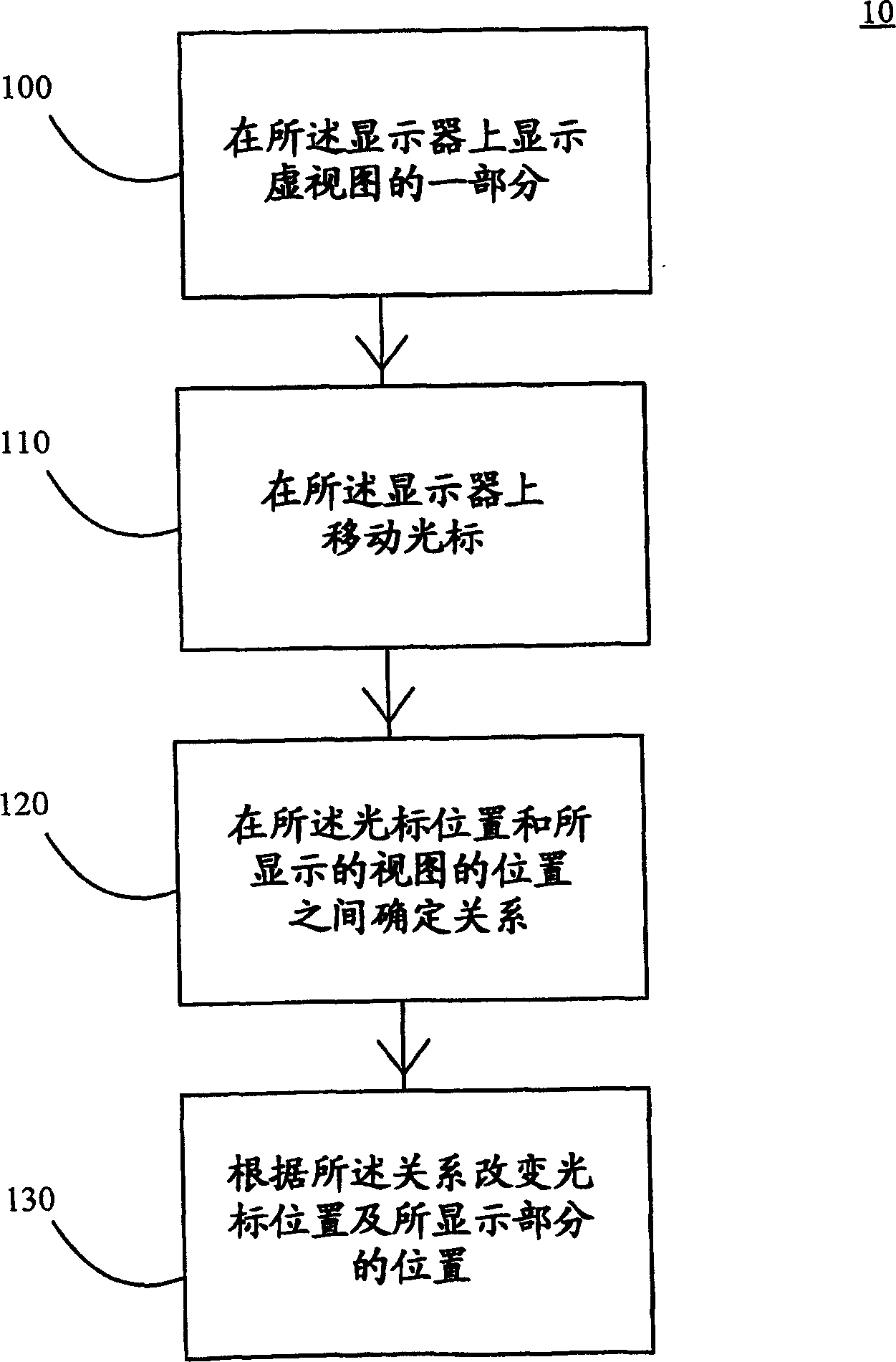

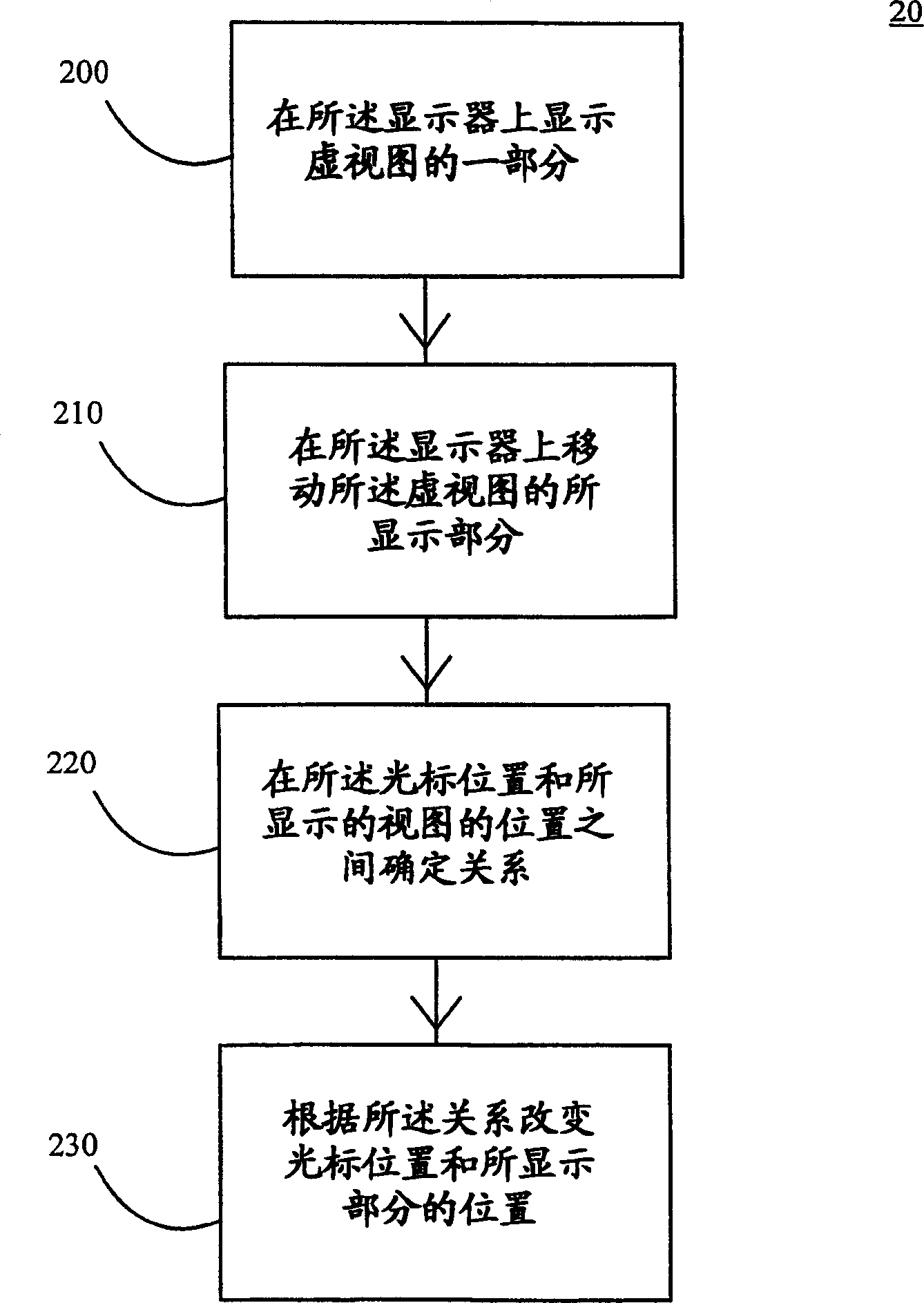

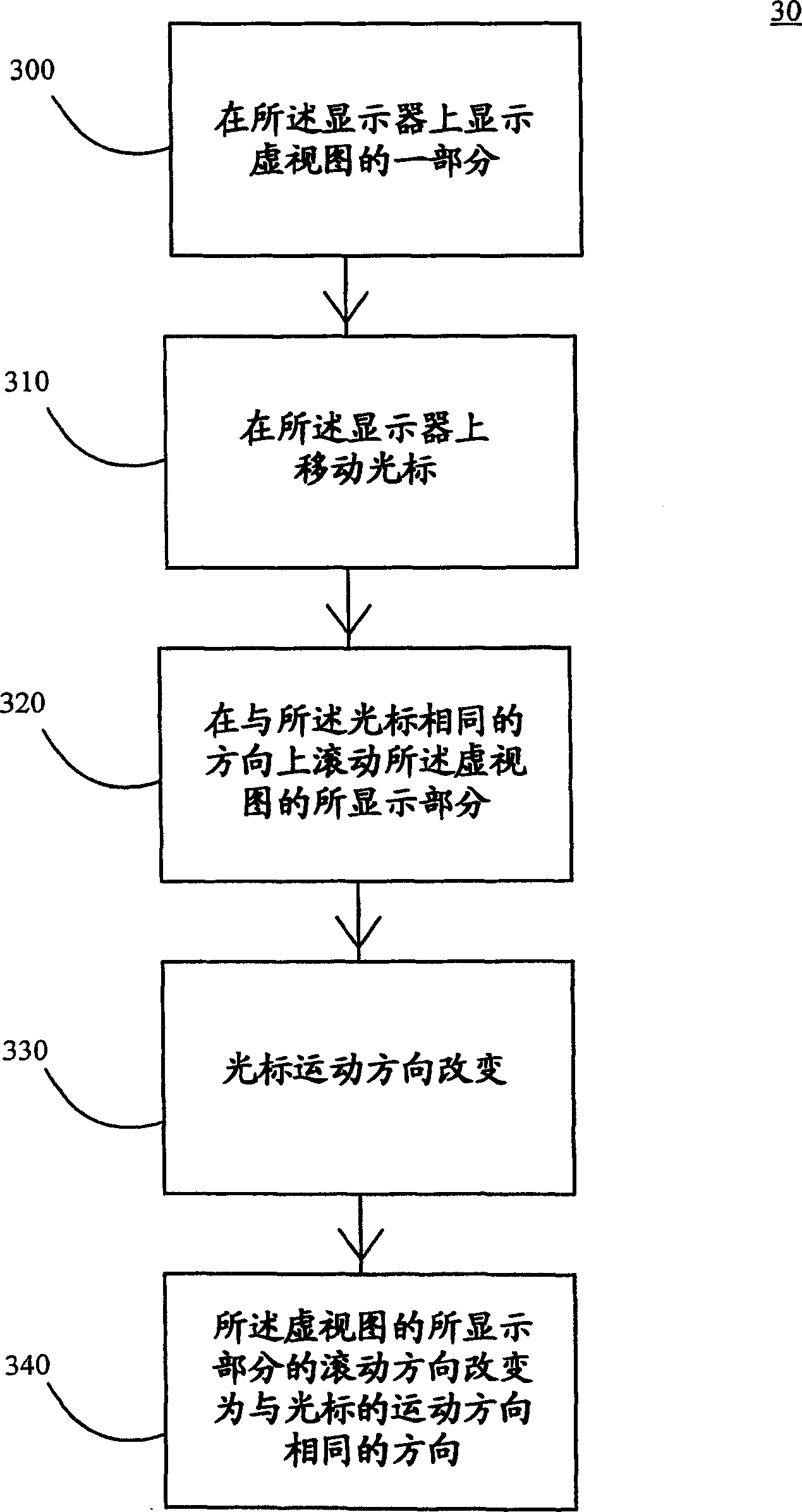

Cursor for electronic devices

InactiveUS20060176294A1Fast perceptionFast wayInput/output processes for data processing3D-image renderingComputer graphics (images)Exact location

The present invention describes a method, electronic device and computer program for displaying a cursor on the display of an electronic device. The size of the display is typically so small that only part of a virtual view is displayed at one time on the display. The user of the electronic device changes the displayed part of the virtual view on the display. In the present invention, a correlation between the cursor location on the display and the location of the displayed part of the virtual view within the whole virtual view is determined so that the cursor location on the display reflects the location of the displayed part of the virtual view in proportion to the whole virtual view. In other words, the user can quickly perceive the exact location e.g. on the virtual desktop or in large digital material displayed on the display of an electronic device.

Owner:APPLE INC

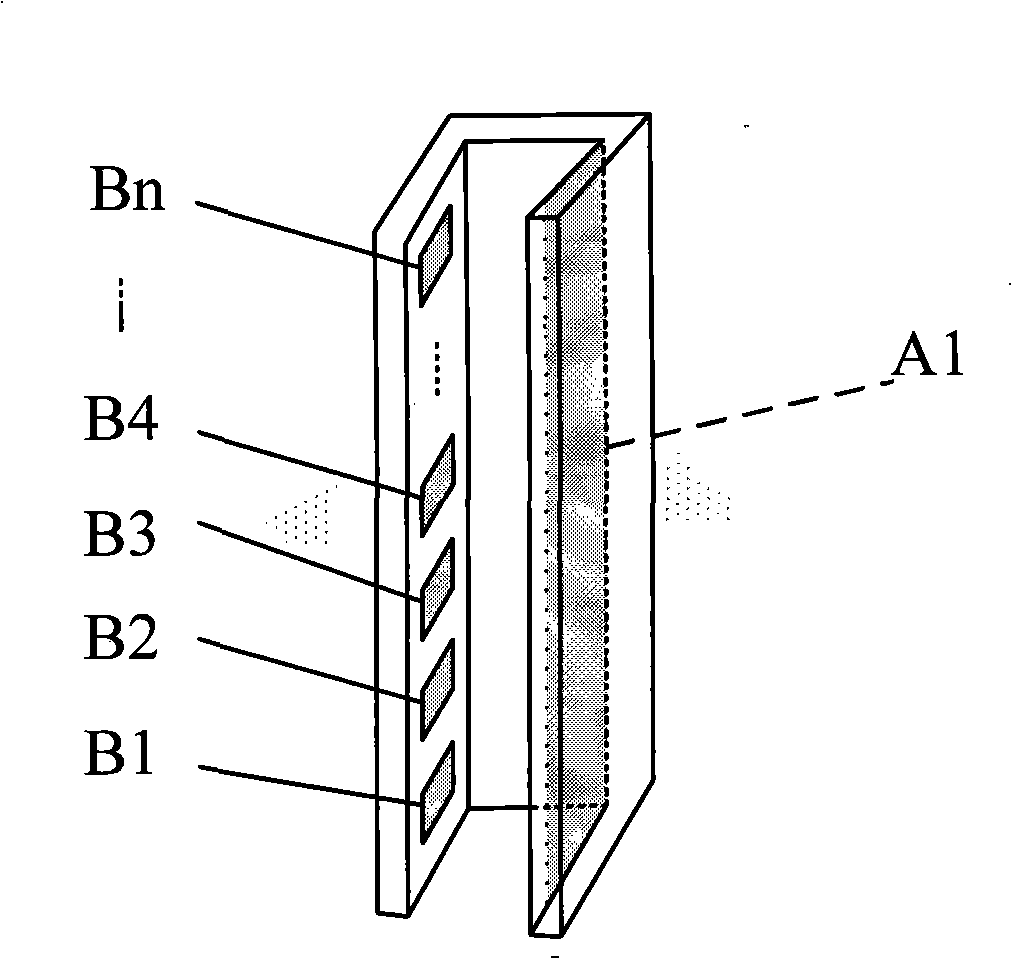

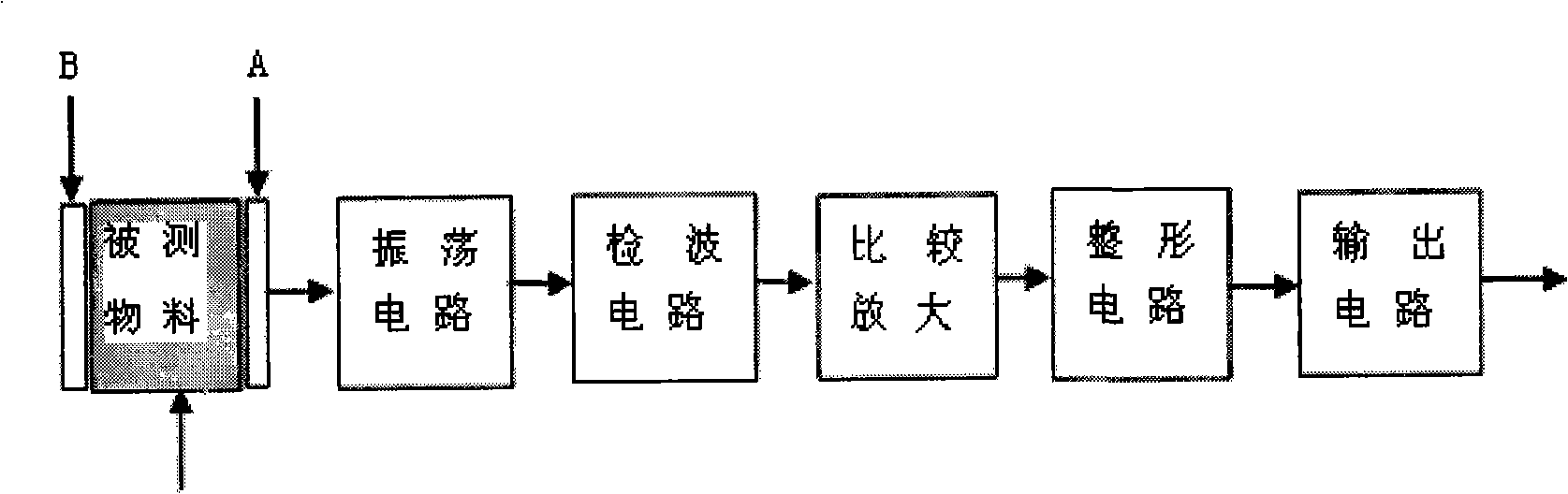

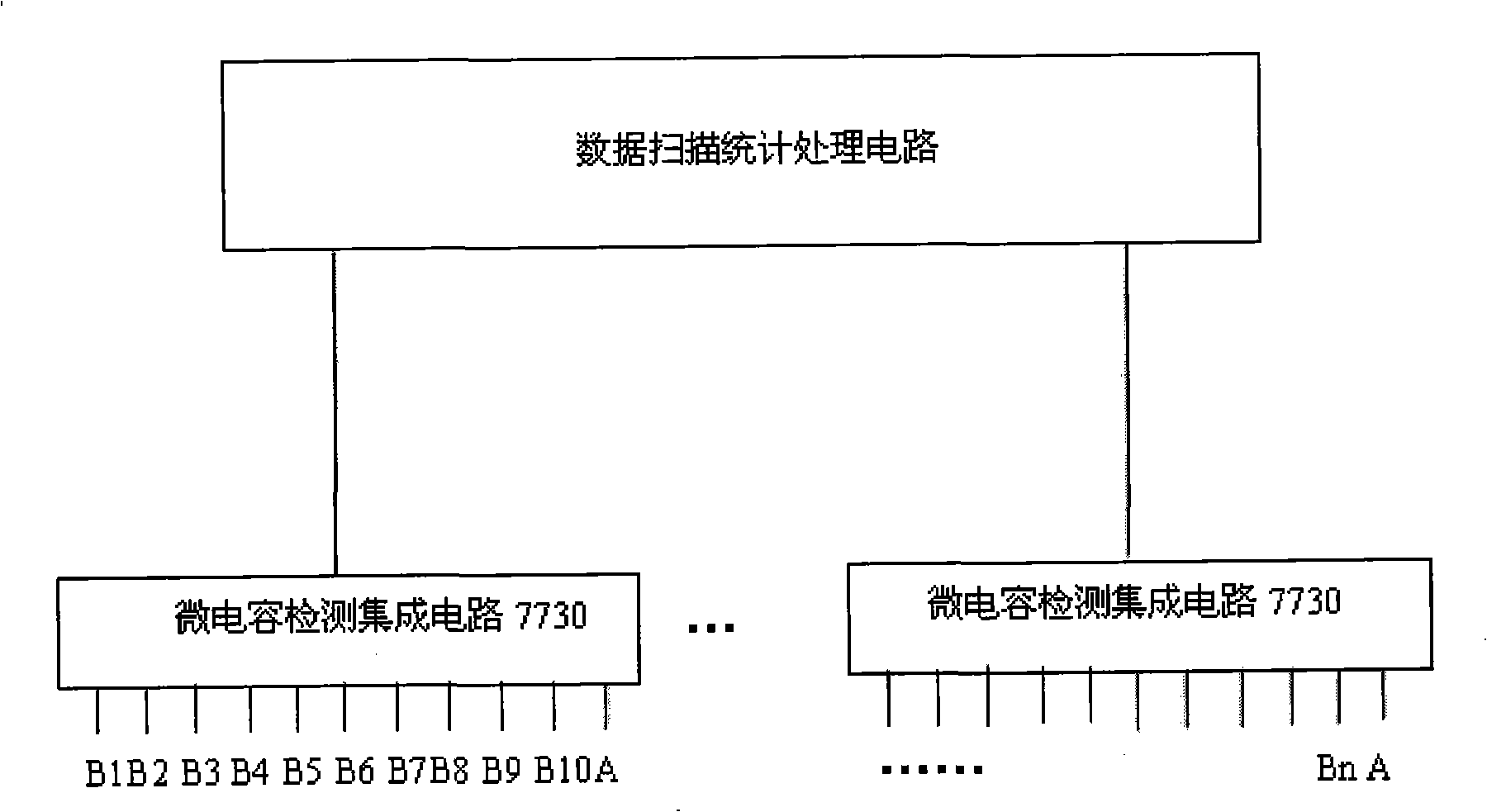

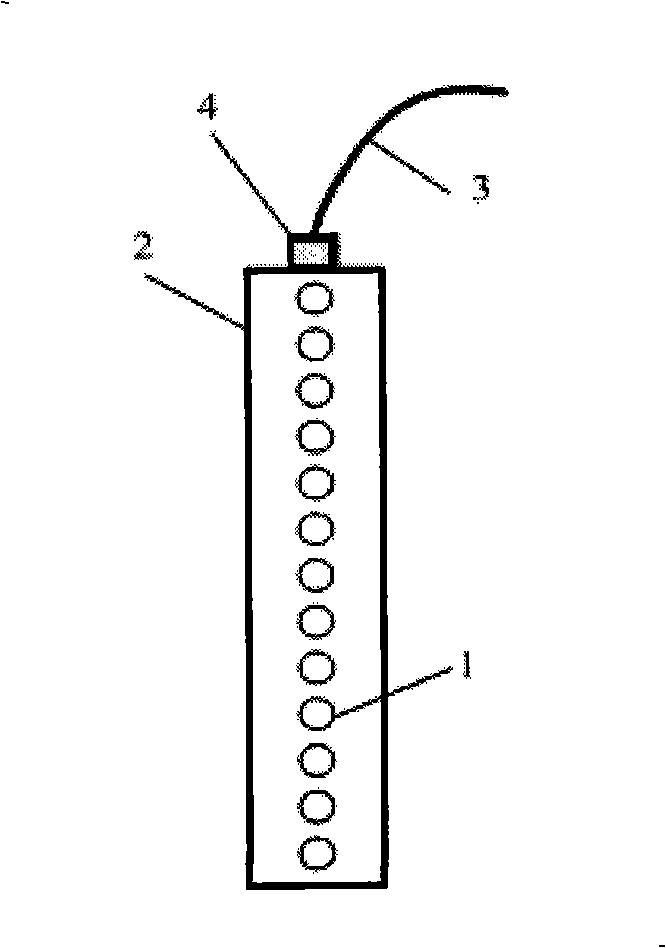

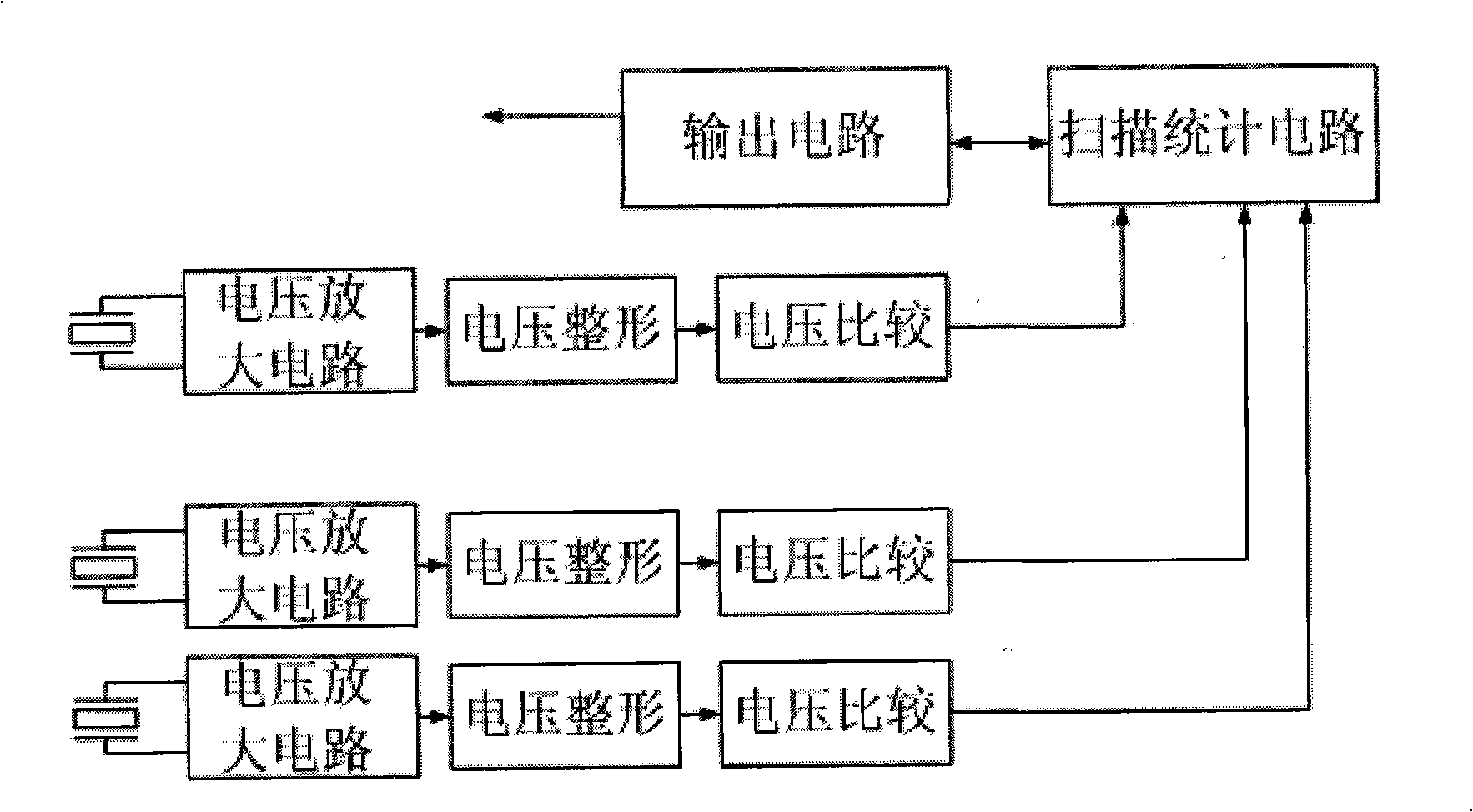

Capacitance type digital material-level sensor and its measurement method

InactiveCN101266167AImprove stabilityImprove reliabilityLevel indicators by physical variable measurementCapacitanceObservational error

The invention discloses a capacitor digital level sensor, characterized in that an electrode plate of a plurality of capacitors is formed by micro-capacitance detection integrated circuit or two or above electrode plates connected by a lead; the measuring method is that fixedly arranging the electrode plates in the detected material, two electrode plates forming a plurality of capacitors, each of which having a corresponding micro-capacitance detection circuit. Output of the electrode plates is zero or one according to alternation of the capacitance, obtaining the digital level by scanning circuit statistics. The invention is compact and reasonable in structure, convenient, rapid and accurate in use, which solves the problem of present level measurement that measuring error is greater caused by effect of factors such as temperature, humidity and capacitance value accumulation error, and enhances anti-inference capacity of the sensor greatly, and improves stability and reliability of the level measurement, in particular applied to directly digital precise measurement of powder or small particle solid, liquid.

Owner:TAIYUAN UNIV OF TECH

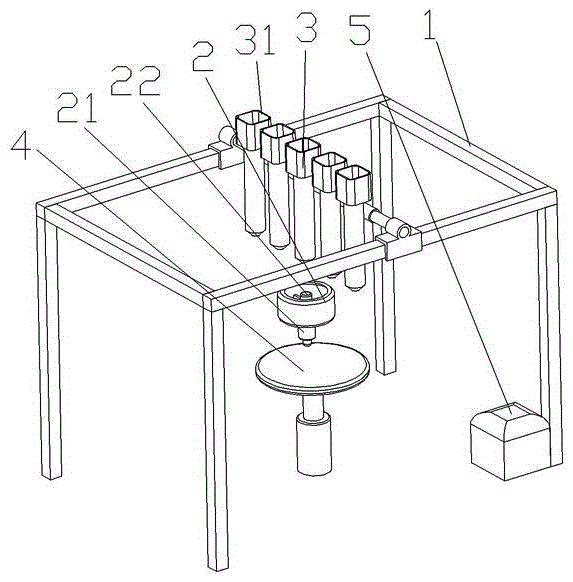

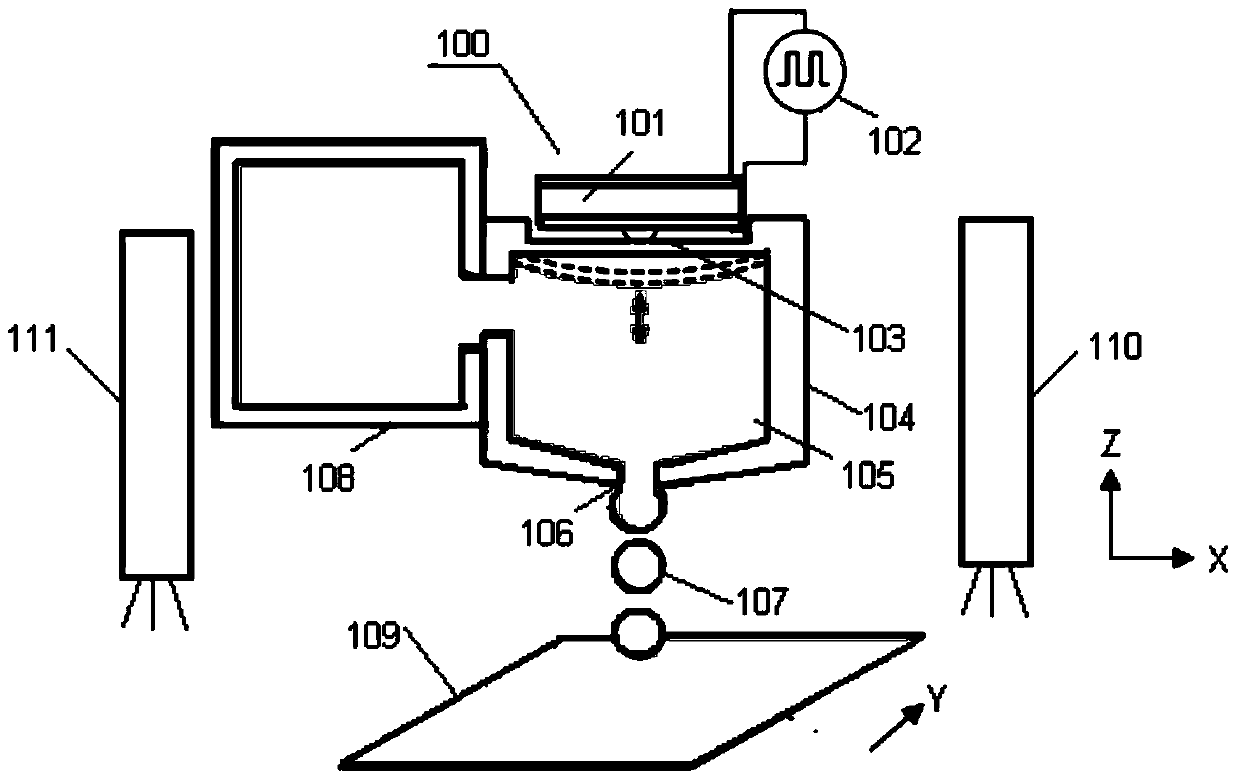

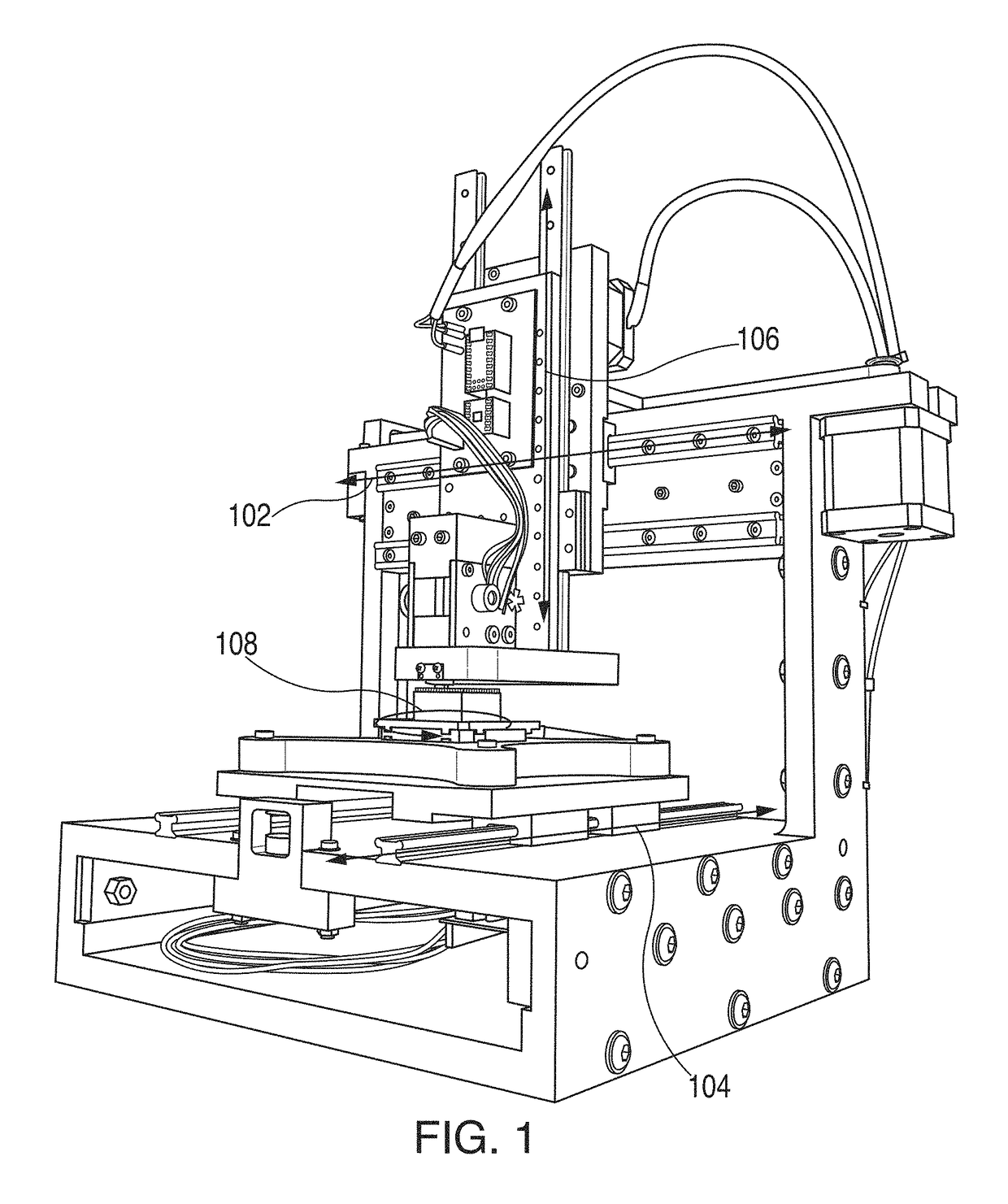

Multi-material part 3D printing device and printing method thereof

The invention discloses a multi-material part 3D printing device and a printing method thereof. The device is composed of a support device, a controllable stirring extrusion head device, a plurality of digital material supply systems, a work platform and a controller. Controllable stirring extrusion heads and the controller are fixedly arranged on the support device. The digital material supply systems are fixedly arranged below the multiple controllable stirring extrusion heads, and the work platform is arranged in the support device. The printing method sequentially comprises the steps of mixed slurry preparing, data modeling treatment, multi-material printing forming, removing of a macromolecule bonding agent in a blank and sintering. The feed amount of various materials is controlled through the digital material supply systems, the proportion of components of the mixed materials is controlled accordingly, the components and proportions of the materials are different according to different space positions, and after degreasing and sintering are finished, parts with the material components constantly changing according to the different positions can be obtained. The technology is simple, the cost is low, and the materials are saved.

Owner:JILIN UNIV

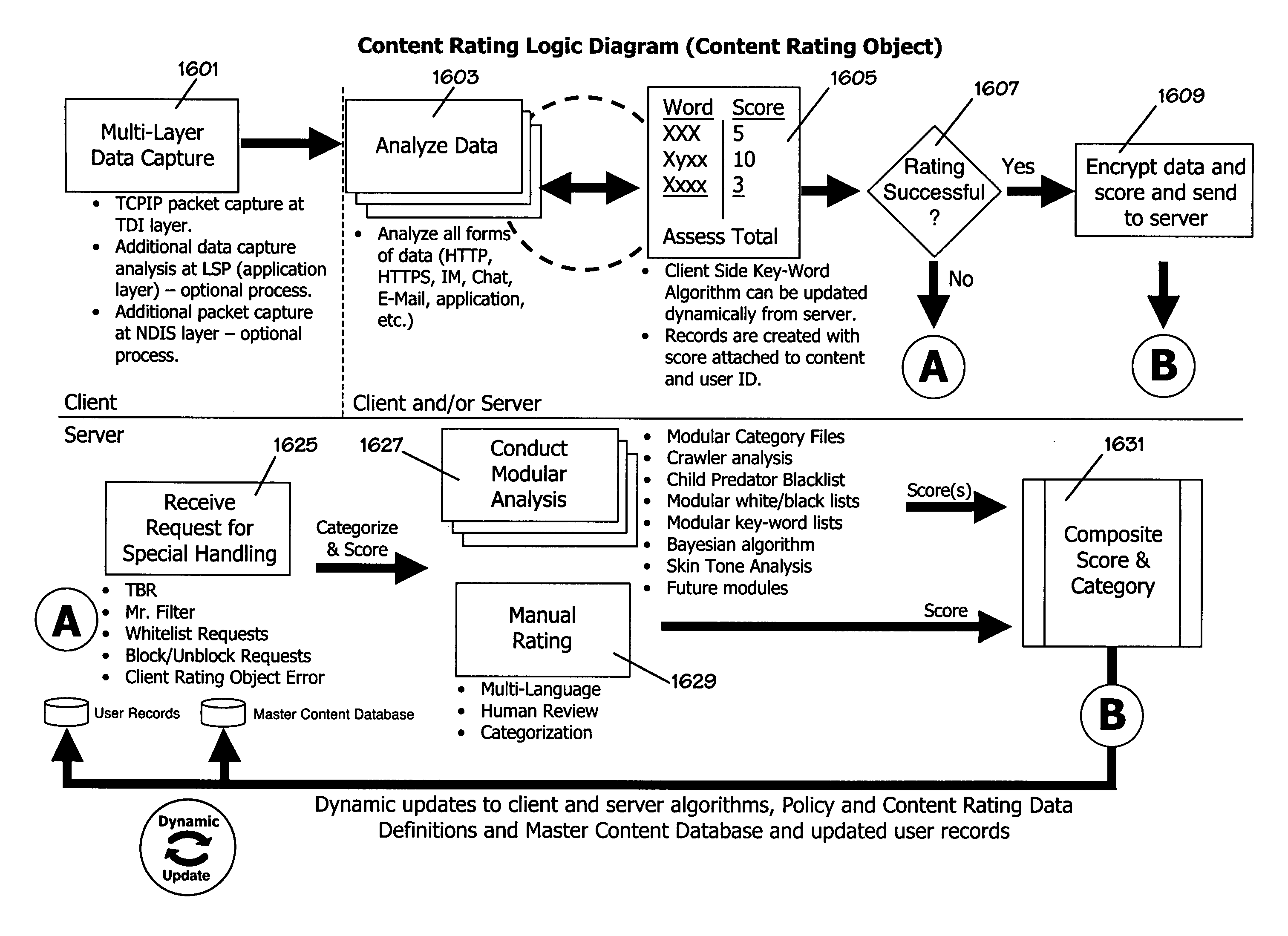

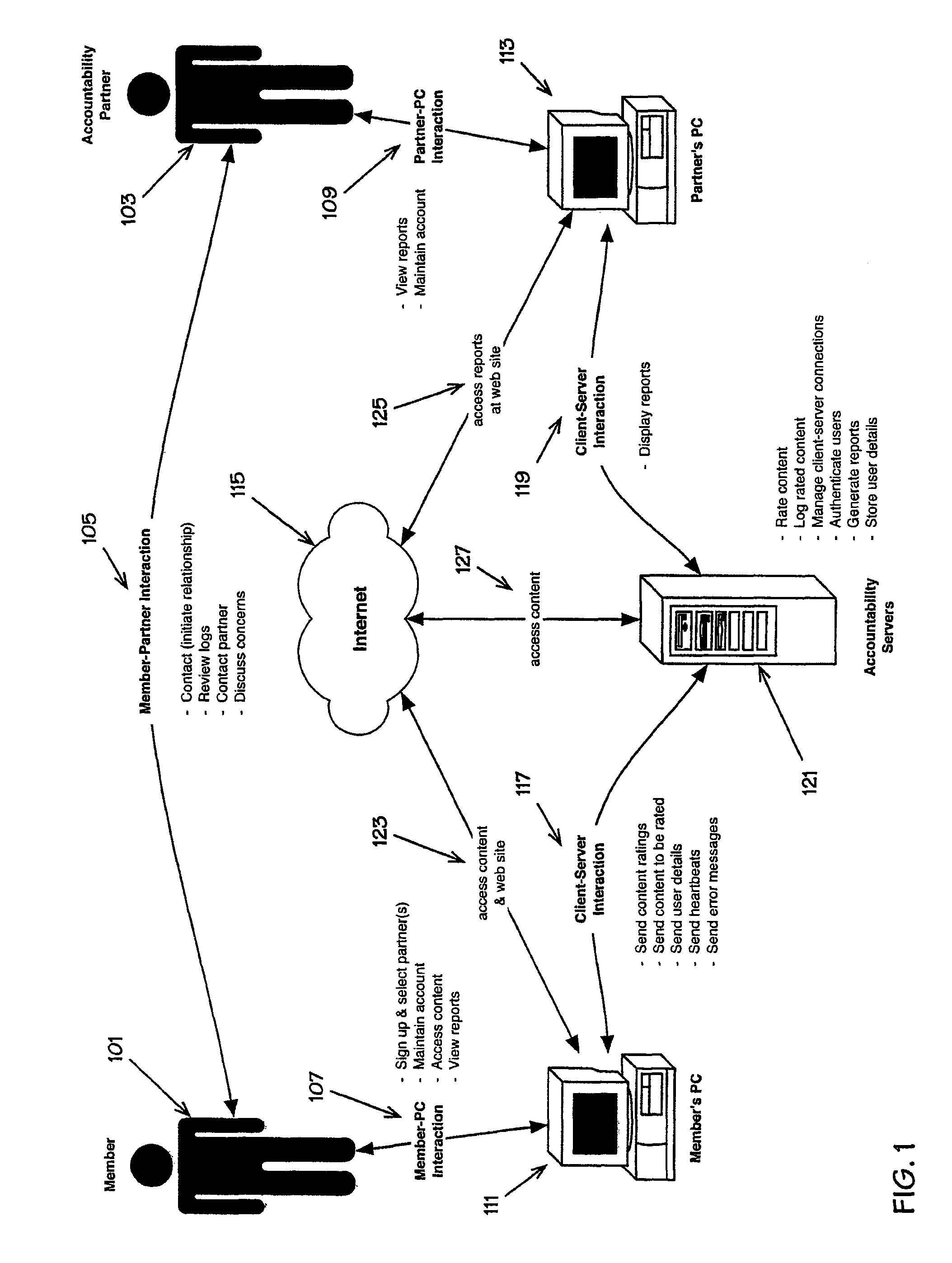

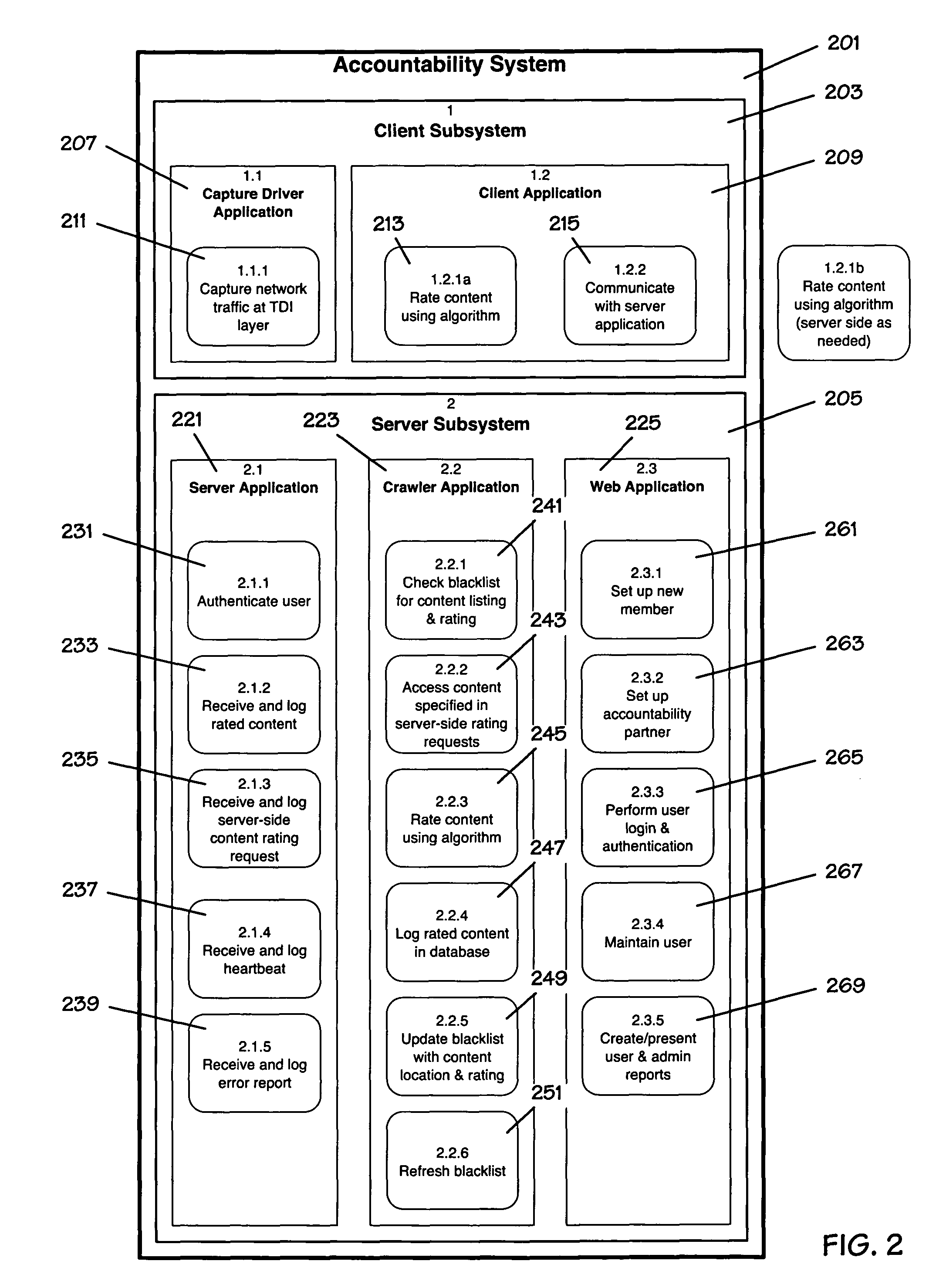

Systems and methods for multi-layered packet filtering and remote management of network devices

ActiveUS7778999B1Digital data information retrievalDigital data processing detailsDigital contentApplication software

Owner:AVAST SOFTWARE

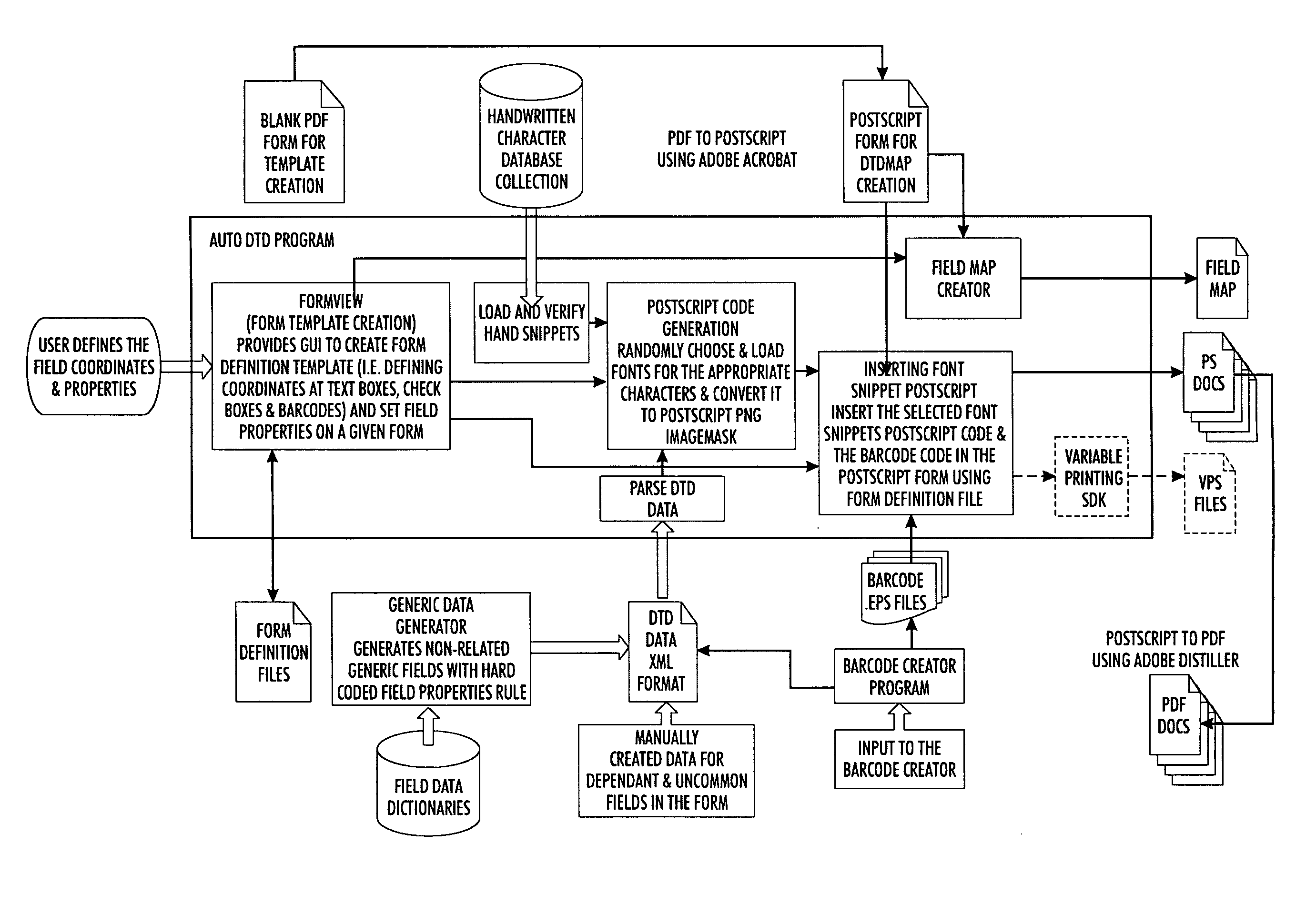

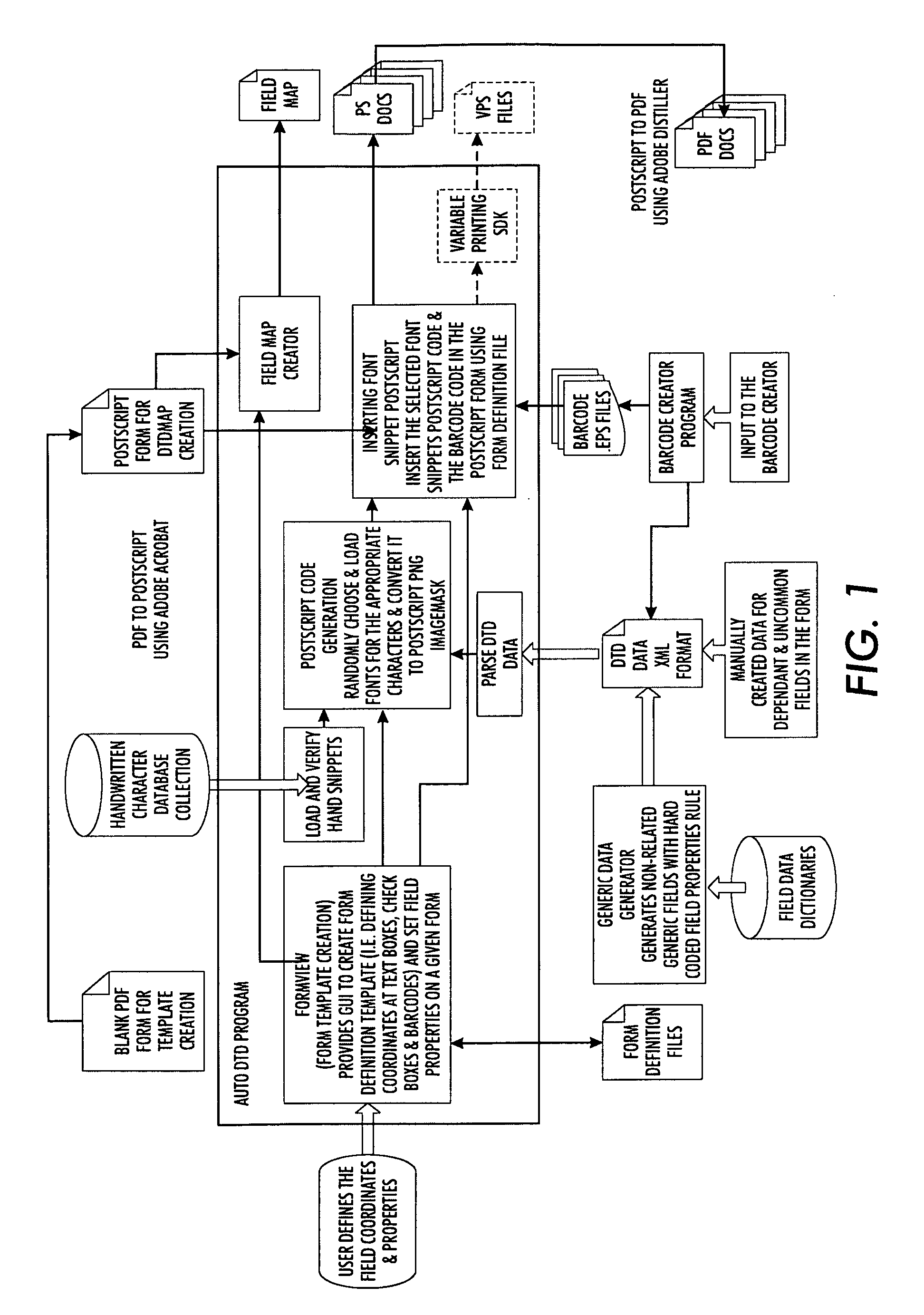

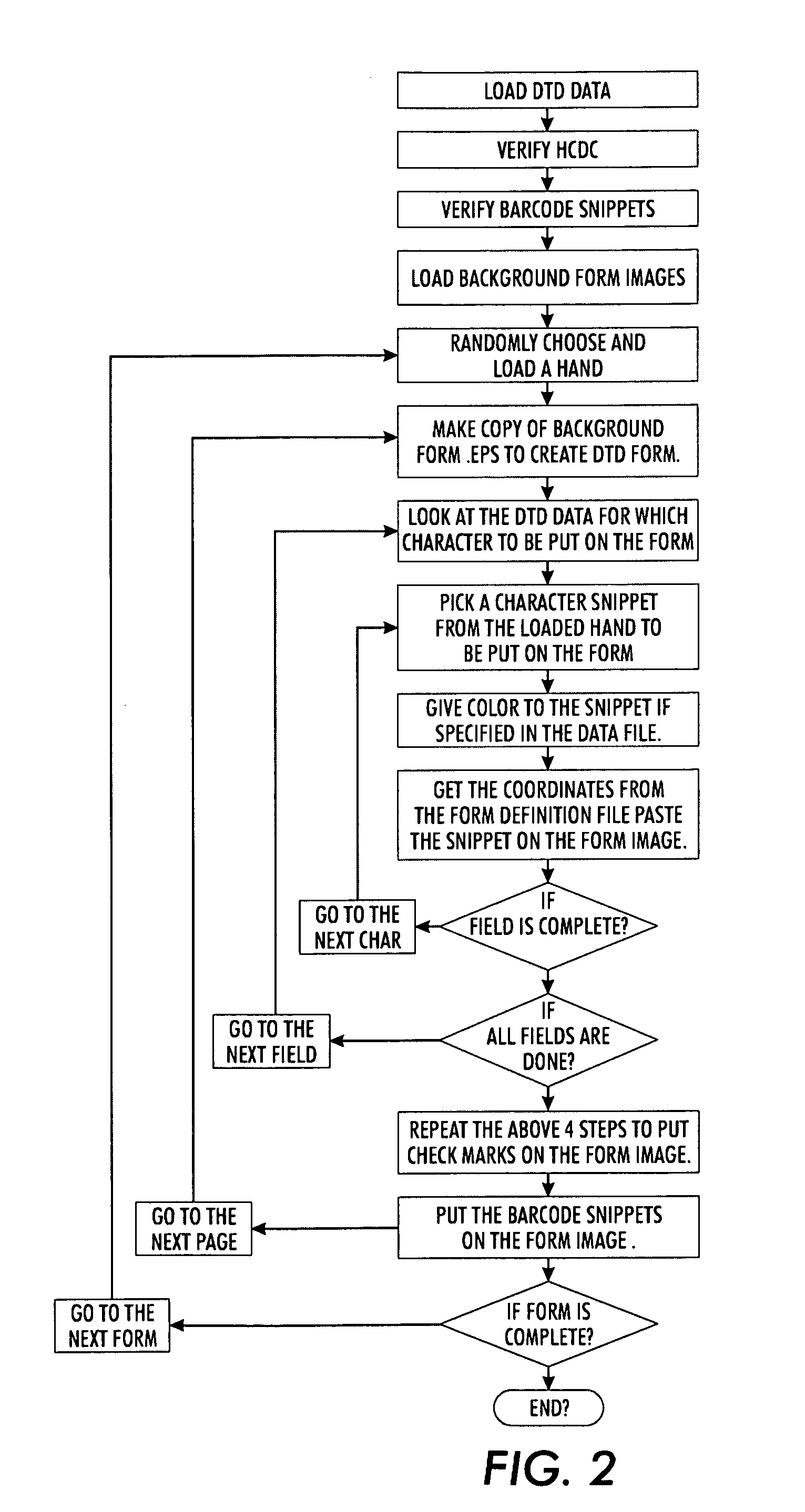

Automating Creation of Digital Test Materials

InactiveUS20080235263A1Quick to useNot easy to make mistakesNatural language data processingSpecial data processing applicationsData contentTest material

A system and method for automatically creating a digital test materials to qualify and test forms processing systems, including preparing a handprint snippet database containing labeled handprint image snippets representing a unique human hand, preparing a form description file and a data content file, selecting handprint snippets from the handprint snippet data base to formulate a form using the data content file, creating a form image using the selected snippets according to the form description file, and, if desired, printing the form image.

Owner:ADI

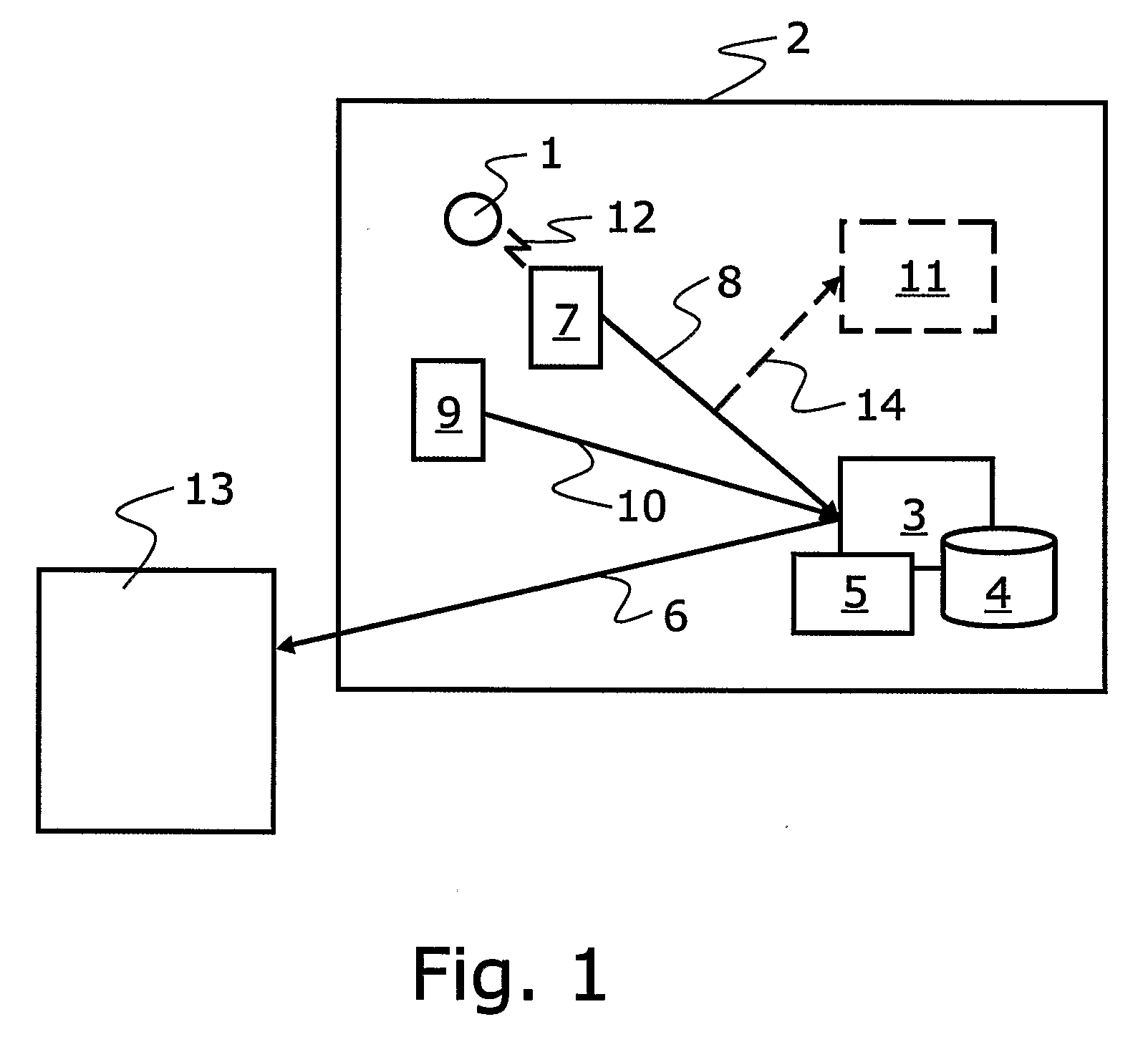

System And Method For Gathering Customer Data

A system and a method for gathering customer data at a physical sales meeting premise. At least one RFID transponder is intended to be placed at the sales meeting premise. A customer data registration system includes storage for storing customer data, and element for compiling a digital material based on stored customer data, and a sender for sending the material to the customer. At least one portable unit includes an RFID reader and a communicator for communicating customer data to the customer data registration system. At least one contact input system includes an input for inputting customer data including an e-mail address and / or mobile phone number of a customer, and a communicator for communicating input customer data to the customer data registration system. Each portable unit is arranged to send customer data, which has been read from at least one RFID transponder, to the customer data registration system. The contact input system is arranged to send the e-mail address and / or mobile phone number of the customer to the customer data registration system. The customer data registration system is arranged to store customer data and compile the digital material based on stored customer data, and send the digital material to the e-mail address or mobile phone number of the customer.

Owner:OMNITUS

Pressure type digital material-level sensor and its measurement method

InactiveCN101261148ASimple structureEasy to useLevel indicators by pressure measurementElectricityFiltration

The invention provides a pressure-typed digital article position sensor, which is characterized in that a rod-shaped body is provided with a plurality of piezoelectric ceramic sheets which are vertically arranged into a line with equal distances and connected with a micro-voltage detection integration circuit and a power supply. During the measurement, each piezoelectric ceramic sheet below the article position generates a weak electric signal which changes into a state of high level '1' with determined amplitude after filtration, amplification, shaping and comparing, and is obviously distinguished from the state of low level '0' output by a plurality of piezoelectric ceramic sheets above the article position; the number of all high levels '1' which is counted by the collecting circuit is the current digital article position value. During the measurement, the pressure-typed digital article position sensor has no relation with the physical performances of the object to be measured such as dielectric constant, magnetic permeability and resistivity, etc., has the advantages of good detection reliability, high precision and simple structure, is especially suitable for the measurement of powder-shaped or small grain-shaped solid article position in coal bins and grain depots, etc.

Owner:TAIYUAN UNIV OF TECH

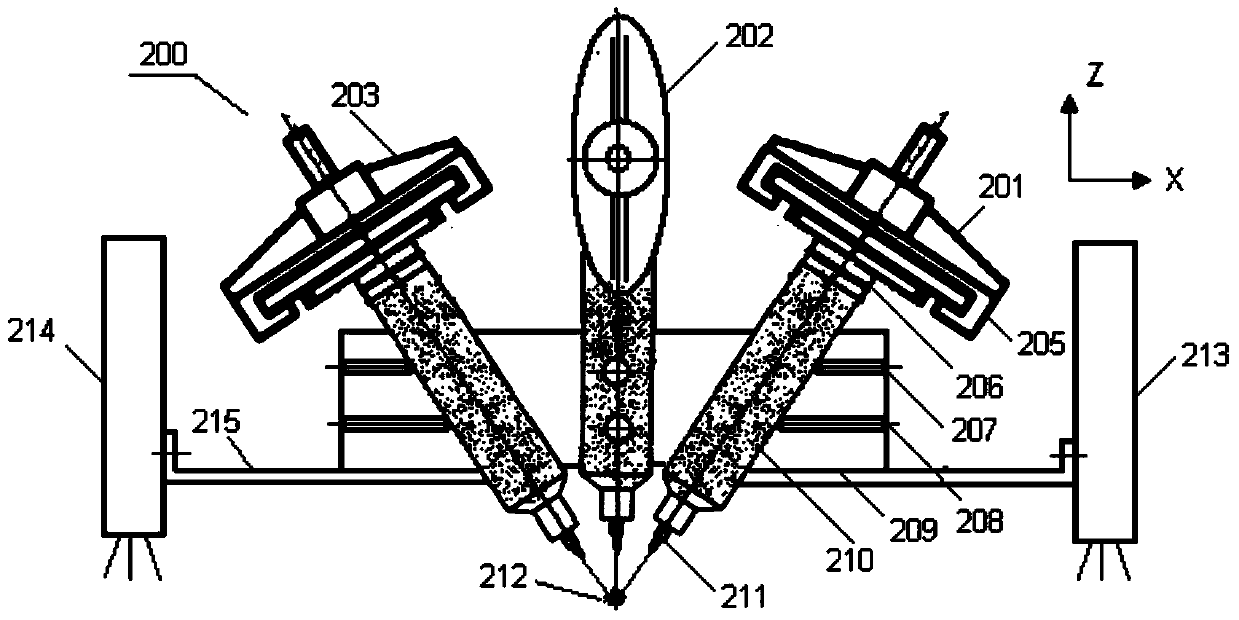

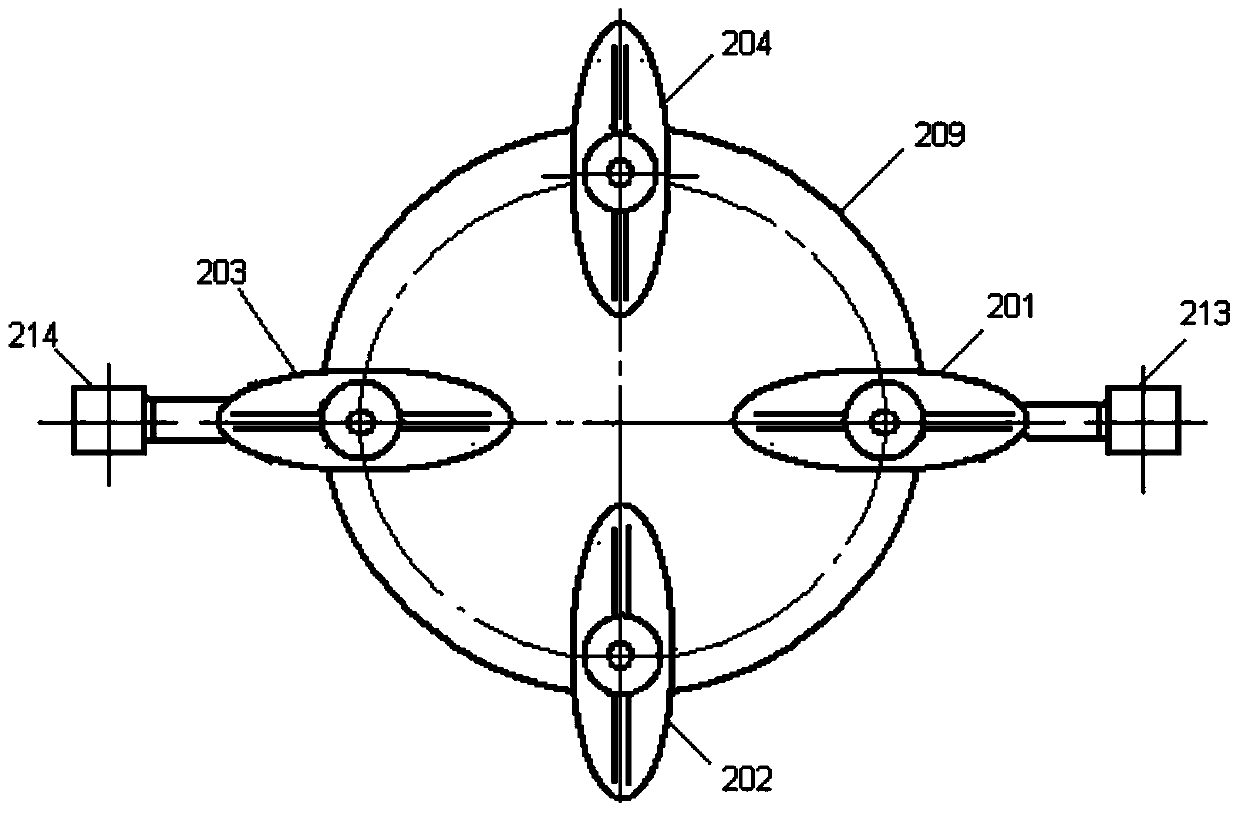

Digital material 3D (Three Dimensional) printing head

The invention discloses a digital material 3D (Three Dimensional) printing head. The digital material 3D printing head comprises a plurality of spaying heads, a plurality of ultraviolet lamps, a material supply system and a pneumatic control system, wherein the spraying heads are used for spraying resin liquid; central lines of the spraying heads are gathered on the same intersection point; the ultraviolet lamps are used for emitting ultraviolet beams and curing the resin liquid sprayed by the spraying heads; the material supply system is connected with the spraying heads and used for supplying the resin liquid for the spraying heads; the pneumatic control system is connected with the spraying heads and used for controlling the spraying action of the spraying heads. The digital material 3D printing head is capable of printing digital resin material; the printing head is a pneumatic gathering type microinjection spraying head which is controlled by a piezoelectric switch valve; the digital material 3D printing head is capable of forming the digital resin material on a forming part in a printing and forming process, so that the performance of the digital resin material is greatly coincident to the requirement of functional plastic members. Consequently, the performance of the similar products from board is achieved; meanwhile, the manufacturing cost is greatly reduced; the digital material 3D printing head is excellent in popularization and application prospects.

Owner:KUNSHAN PORIMY 3D PRINTING TECH CO LTD

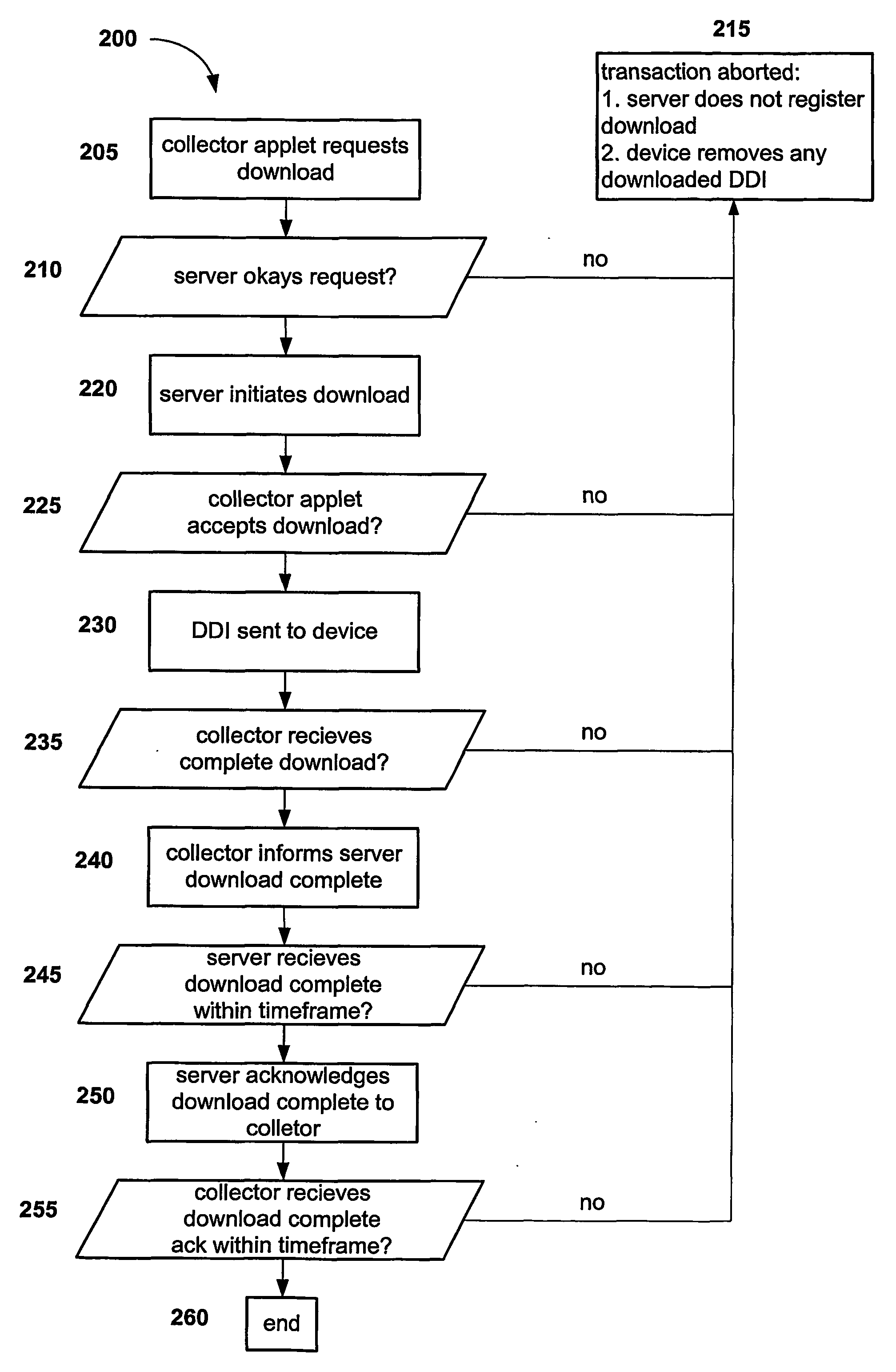

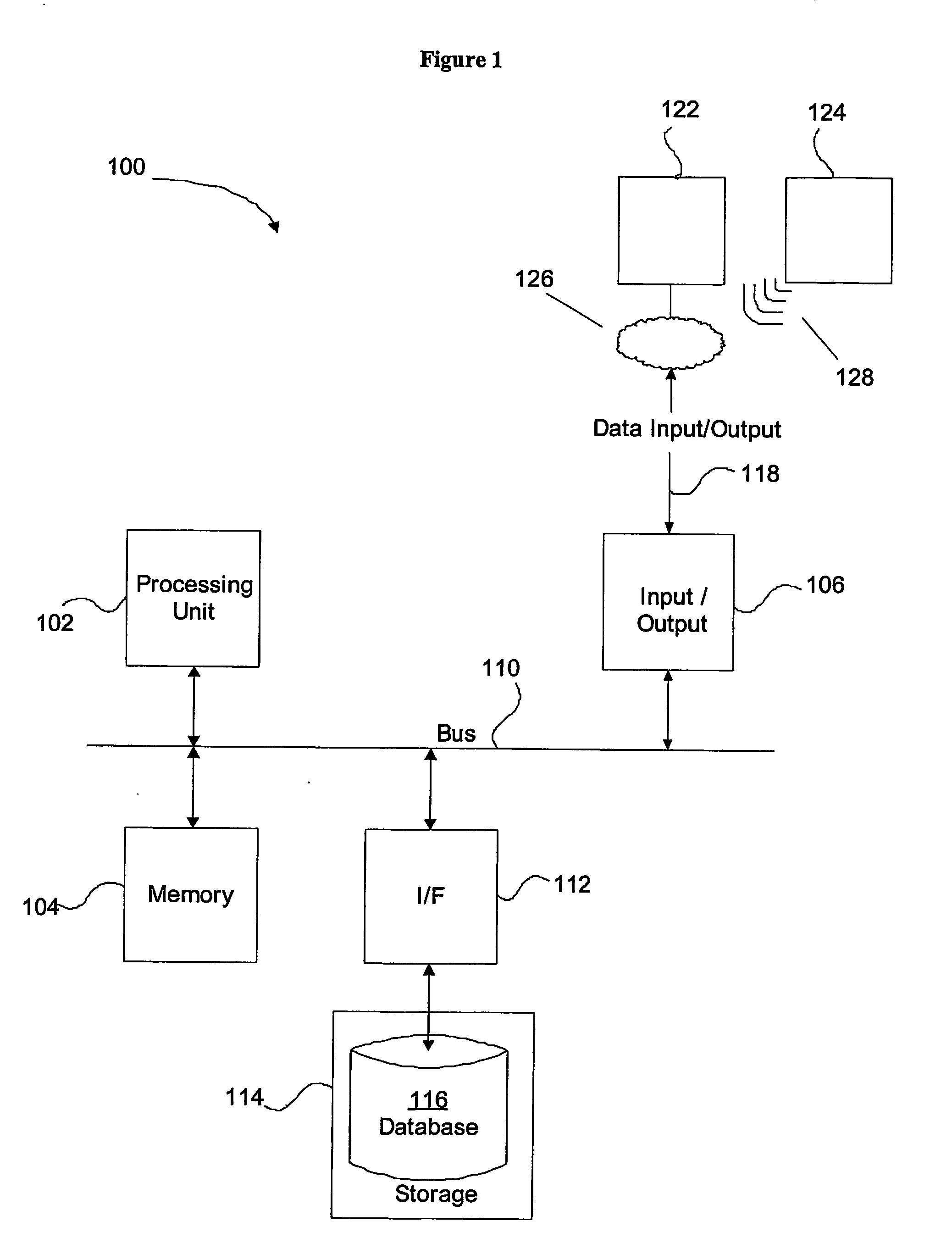

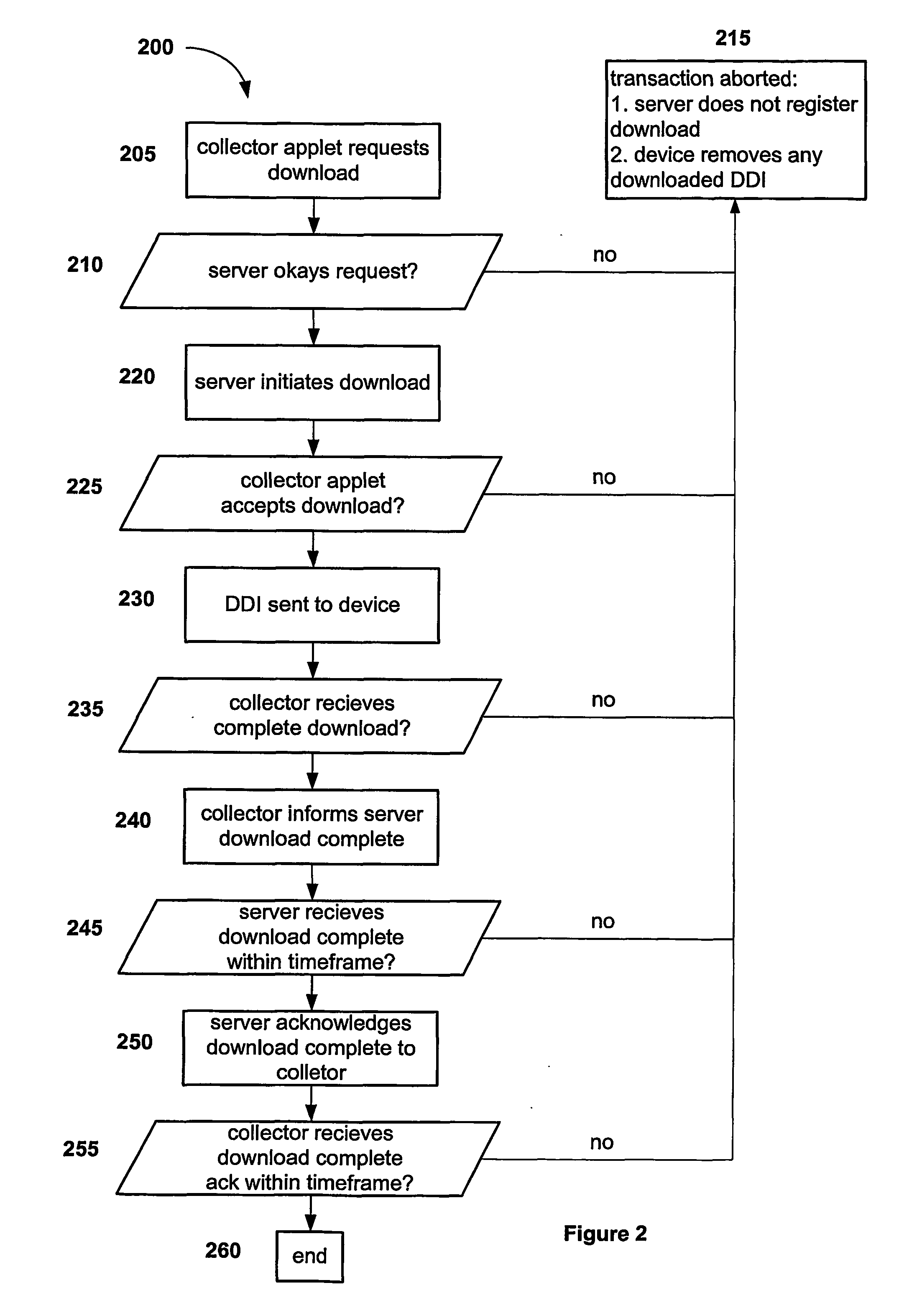

Method and system to download and track digital material

InactiveUS20070150609A1Prevent unauthorised duplicationAvoid prolonged useUnauthorized memory use protectionMultiple digital computer combinationsInformation repositoryDigital data

A method of providing a digital data item to a user, the user having registered on a server so that user information has been stored in a User Information Database, an application also having been associated with a user terminal by encoding a unique identifier of the user terminal in the application, the unique identifier also having been stored in the User Information Database, the method including the steps of: receiving a request for the digital data item from the application on the user terminal; checking the authorisation of the application to obtain the digital data item by querying the User Information Database; and if authorised, transmitting the digital data item to the user terminal.

Owner:LEHRER DANIELLE LOUISE +1

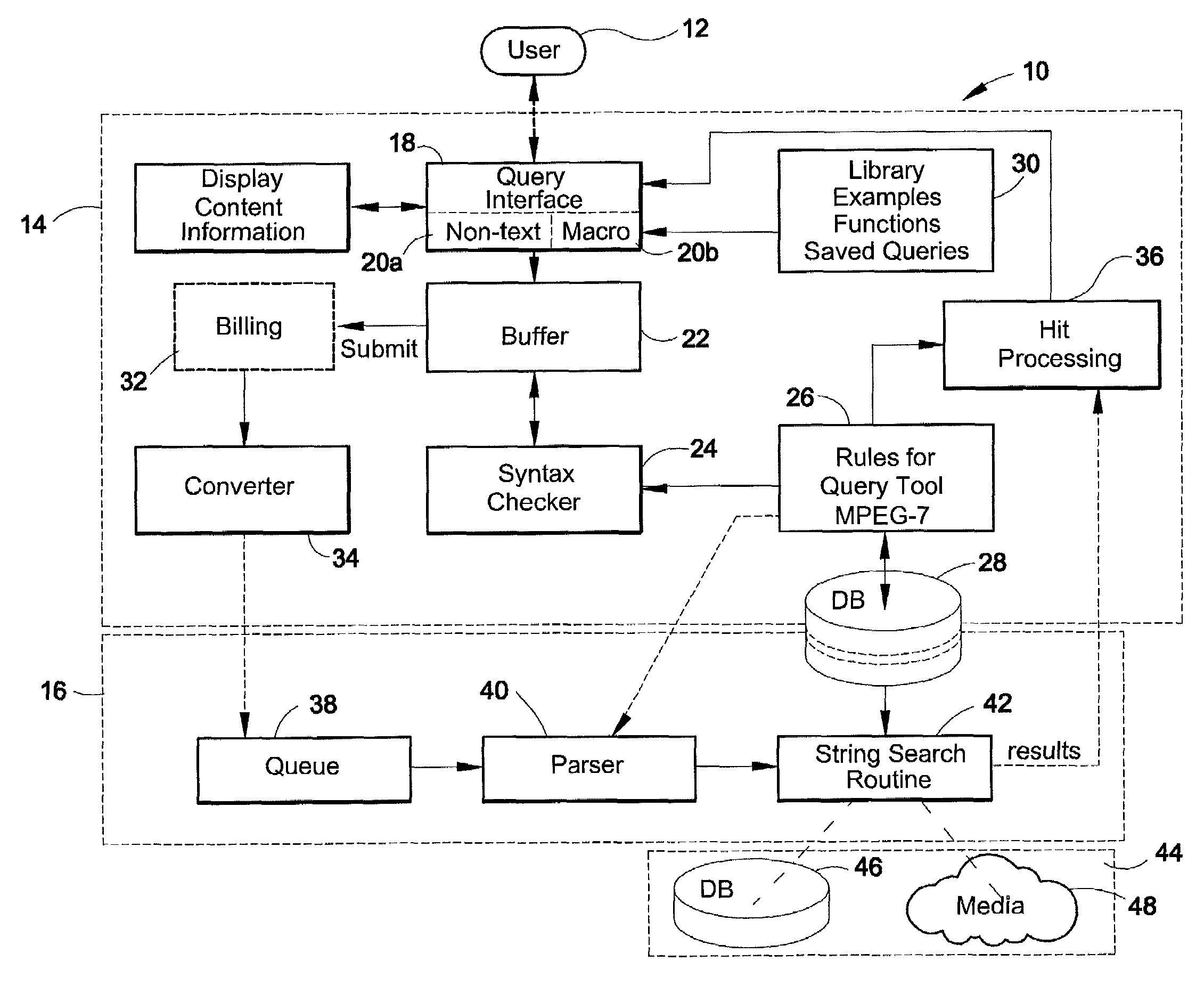

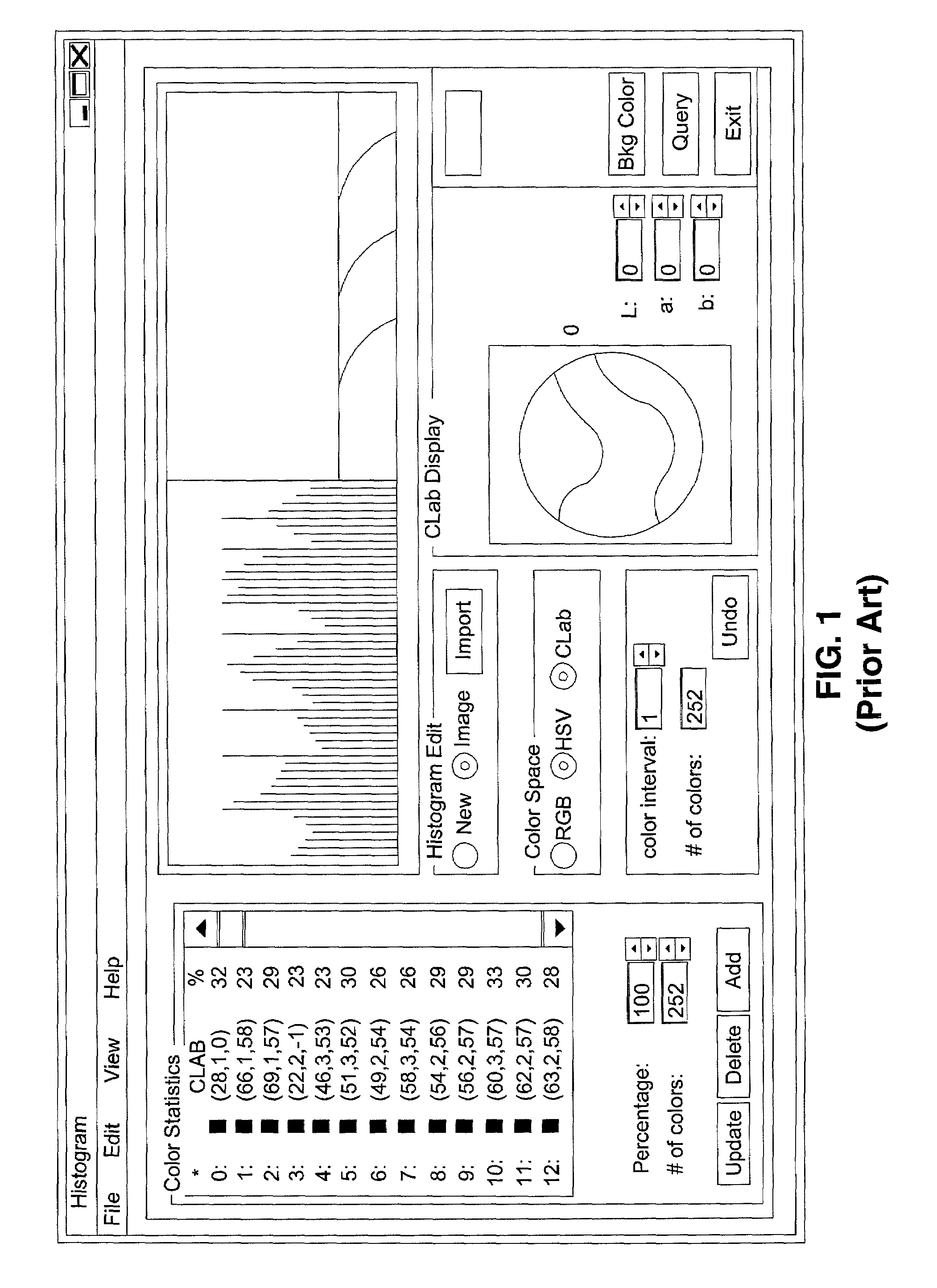

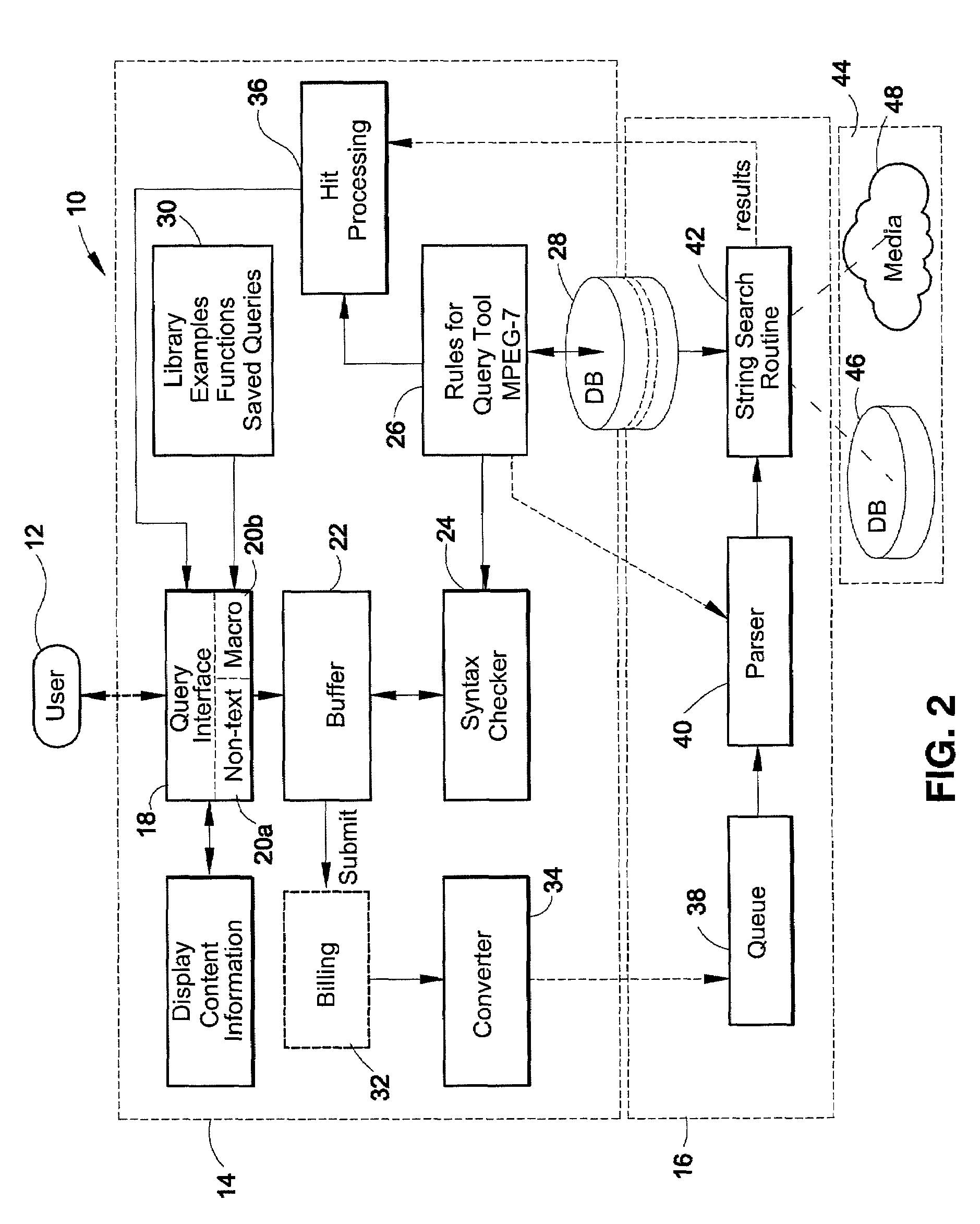

Method and system for utilizing embedded MPEG-7 content descriptions

InactiveUS7664830B2Easy to buildEasy to testDigital data processing detailsMetadata multimedia retrievalWeb siteApplication software

An apparatus for selecting digital material objects containing MPEG-7 content descriptions in response to MPEG-7 content description queries. The apparatus comprises an MPEG-7 content description query generation tool coupled with a search engine configured for searching and comparing embedded MPEG-7 META tag information within file headers, or database information thereof, to the MPEG-7 content description query. The query tool and search engine may be implemented separately or in combination. By way of example, the MPEG-7 query generation tool is implemented within an application program such as a browser, or web site, to allow the user to readily and accurately define the content being sought. The content query being sent to a search engine configured for performing MPEG-7 content searches that return hits based on content related matches.

Owner:SONY CORP +1

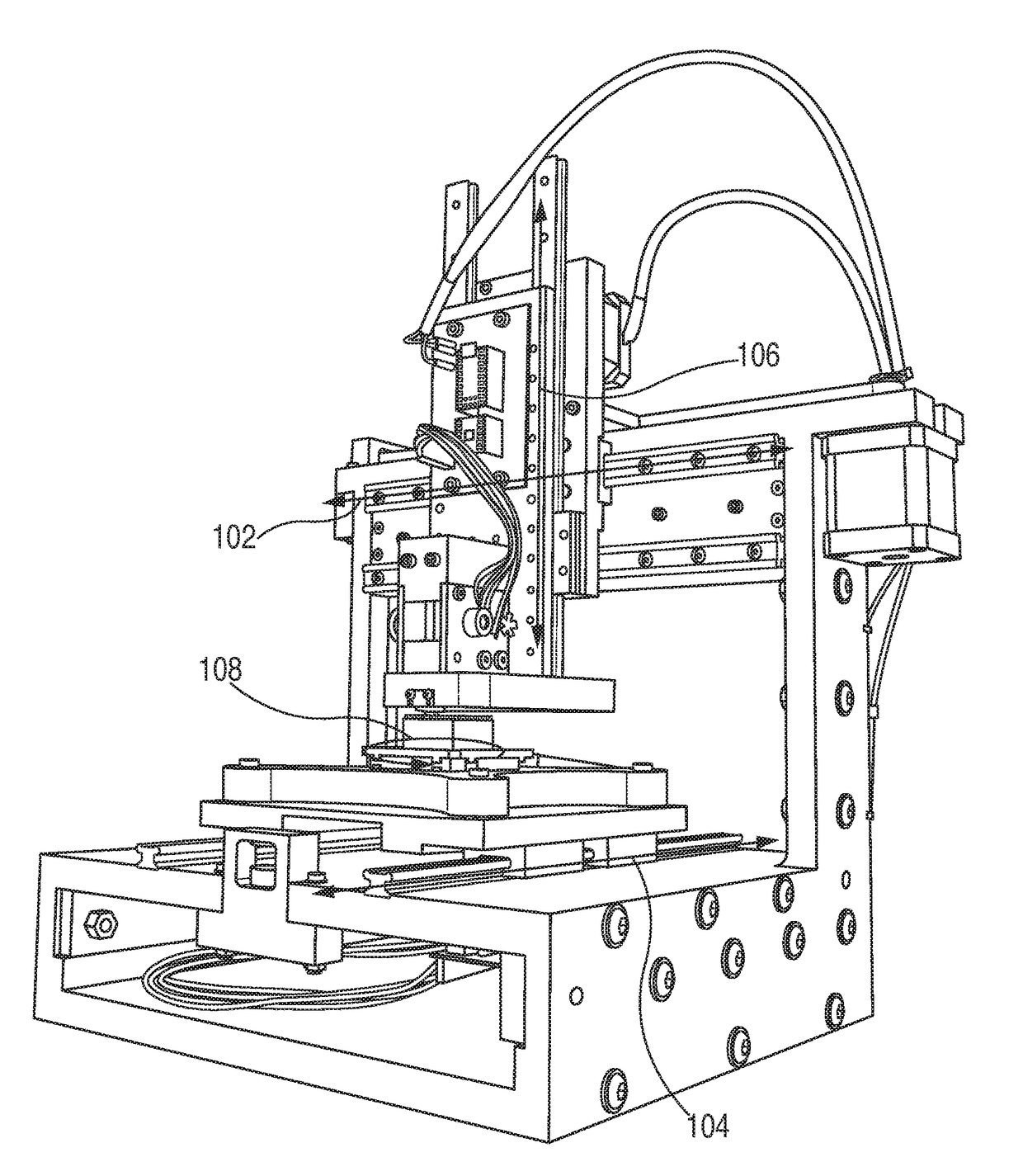

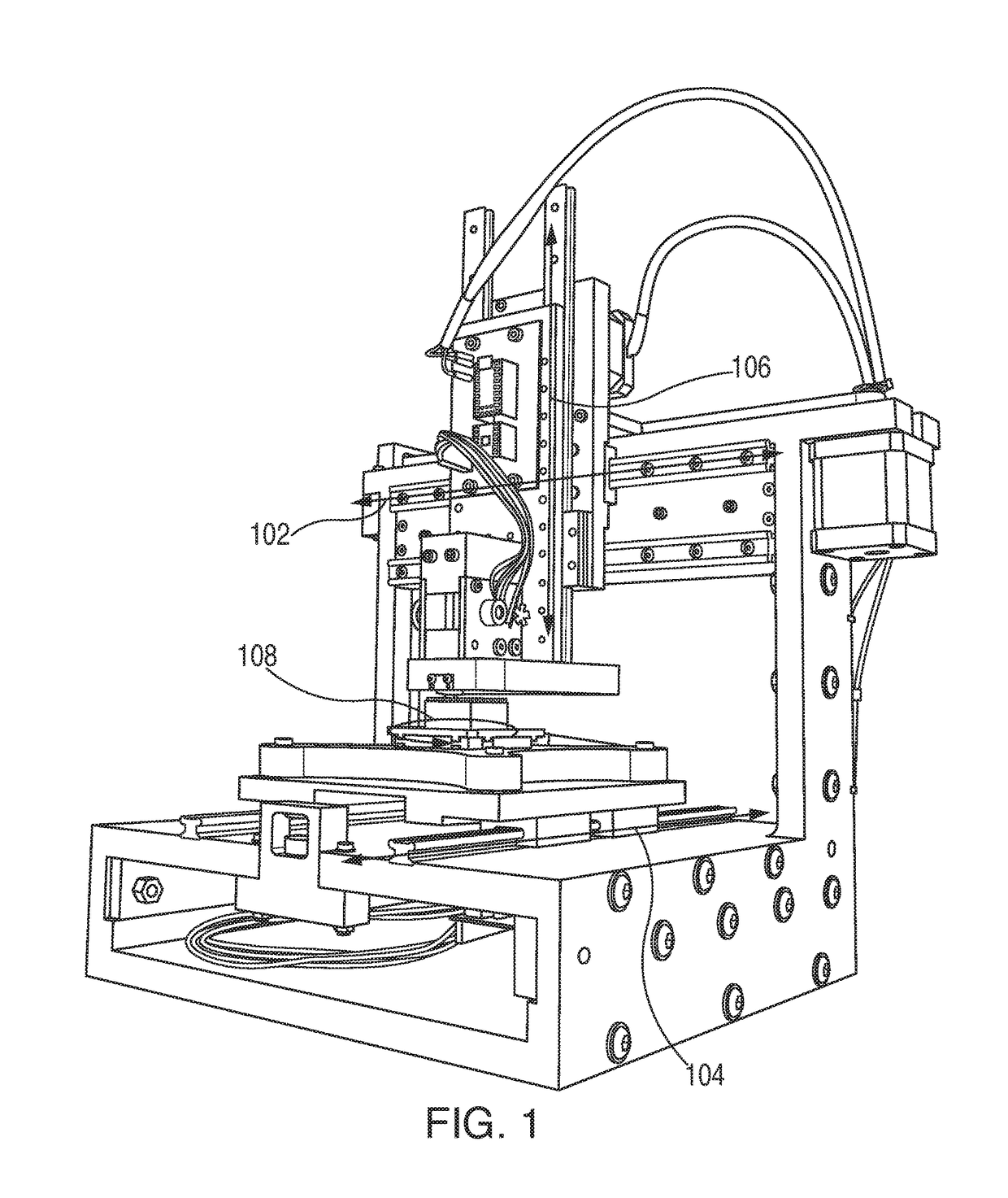

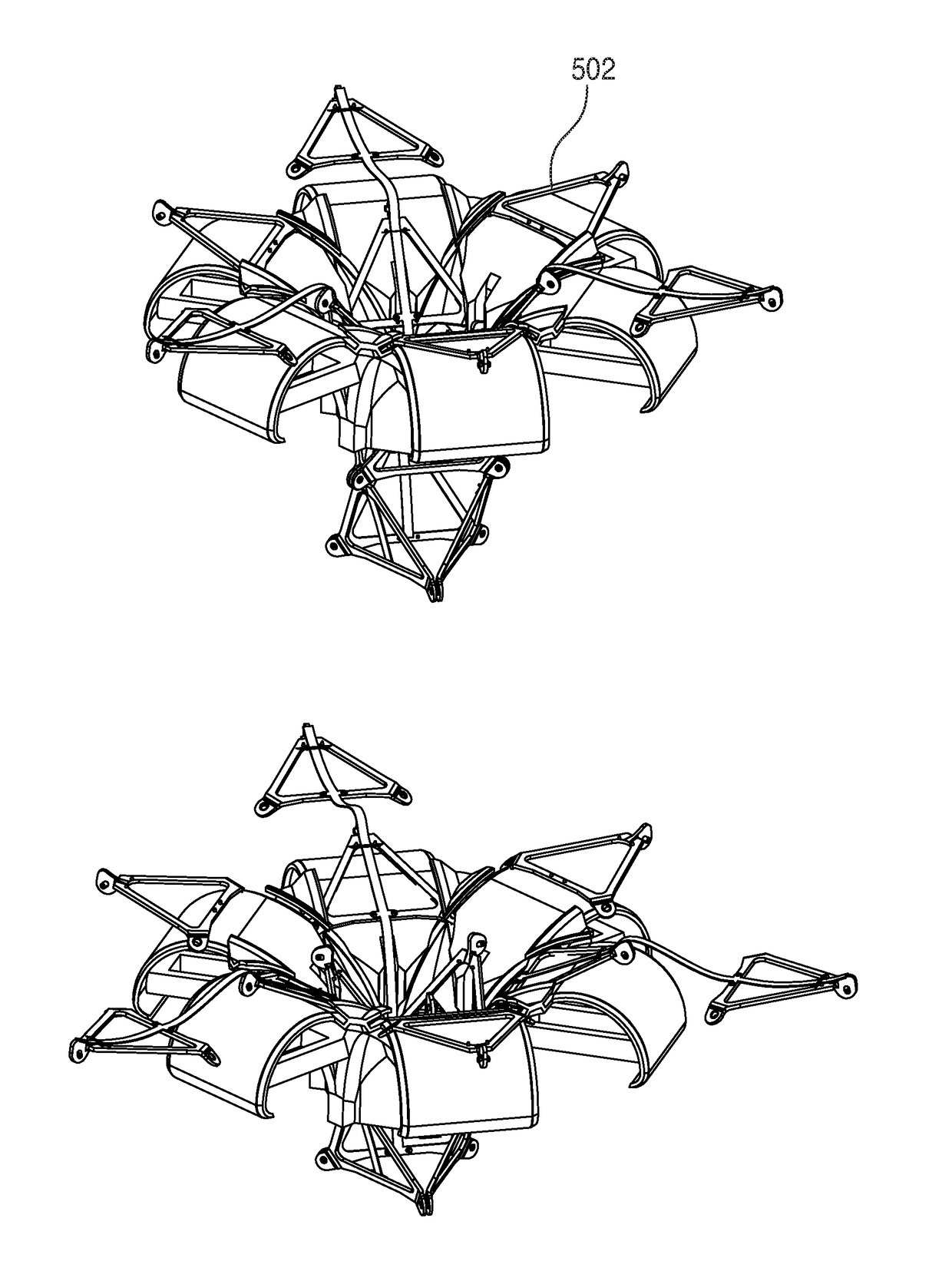

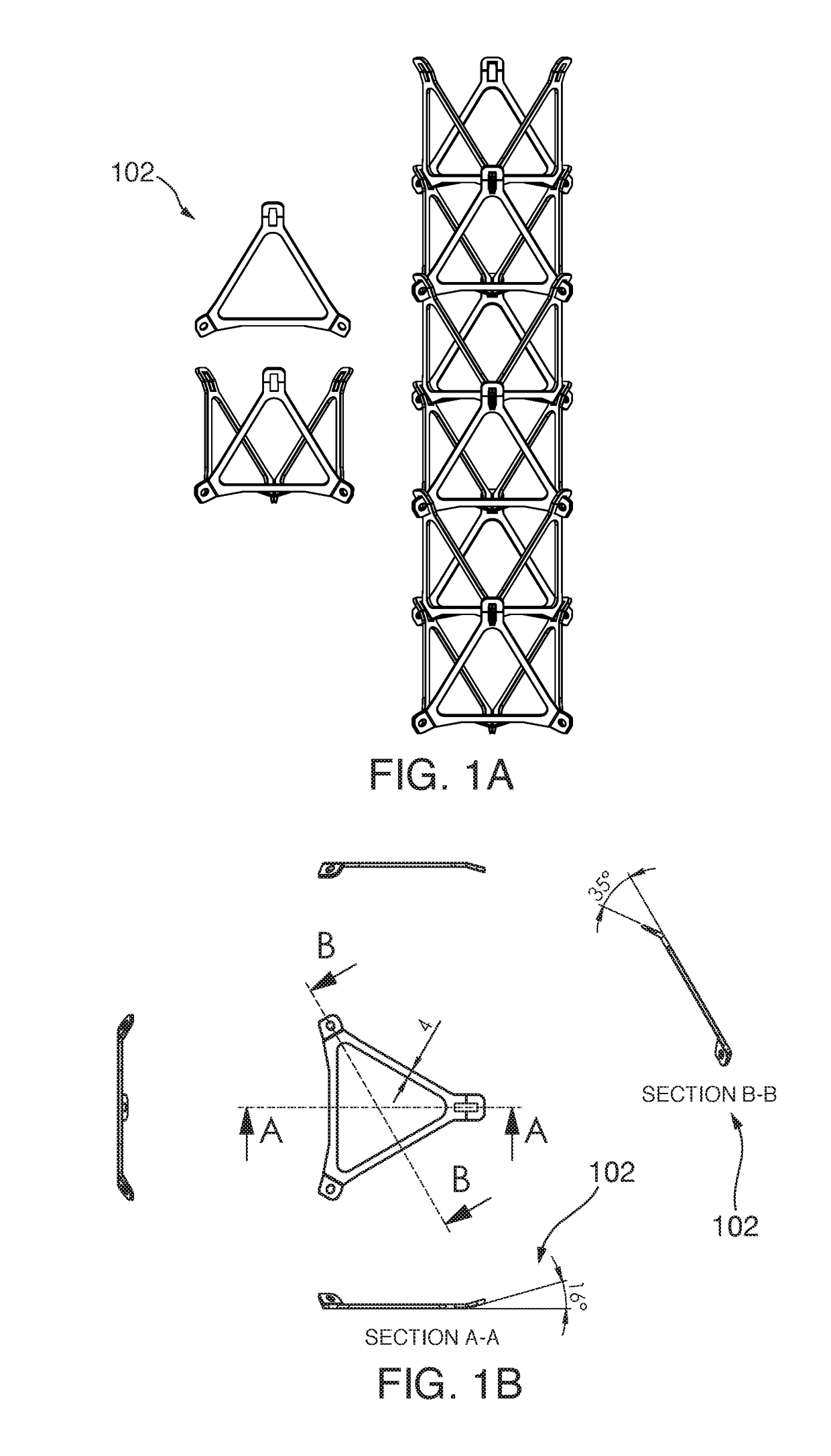

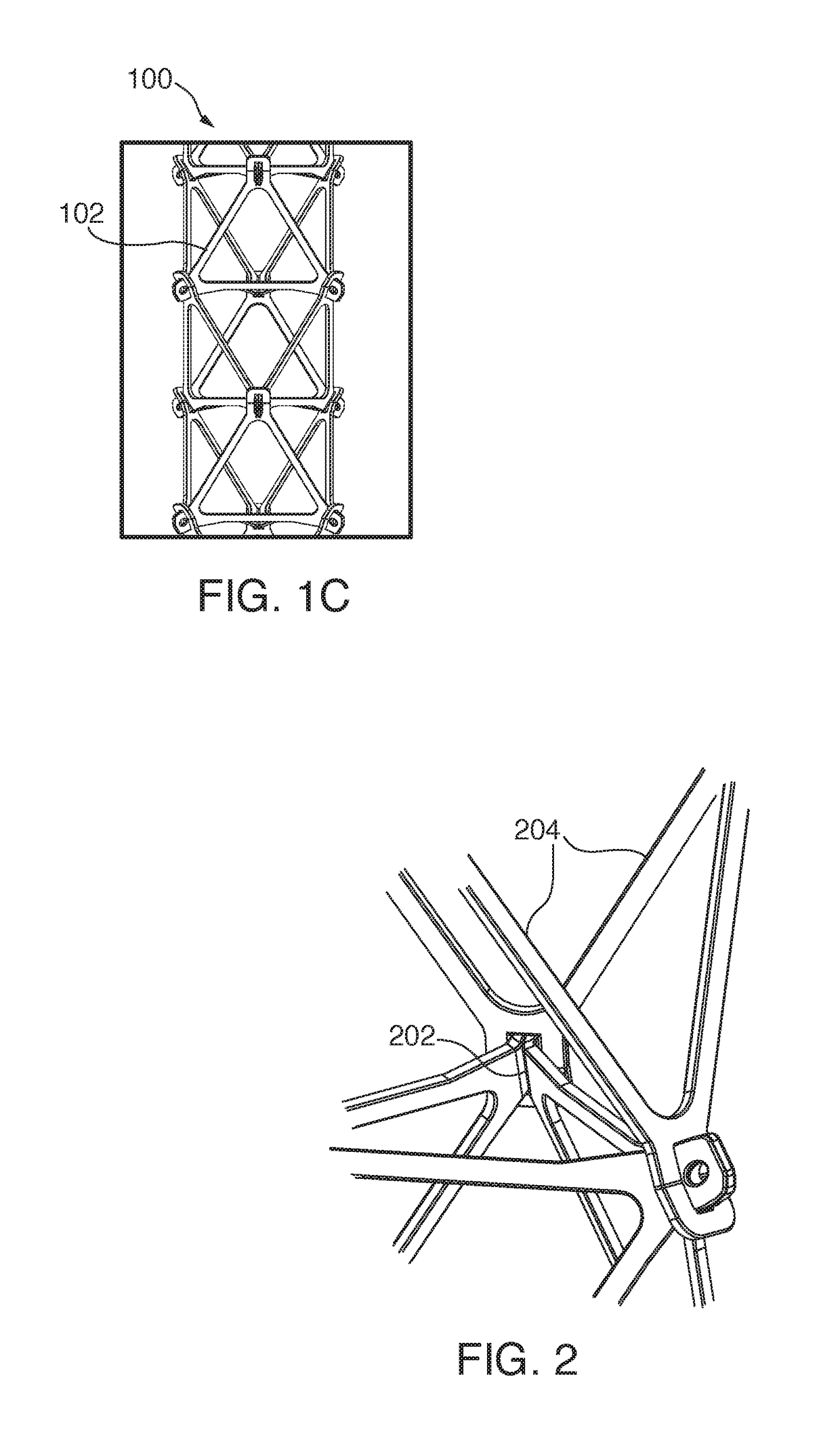

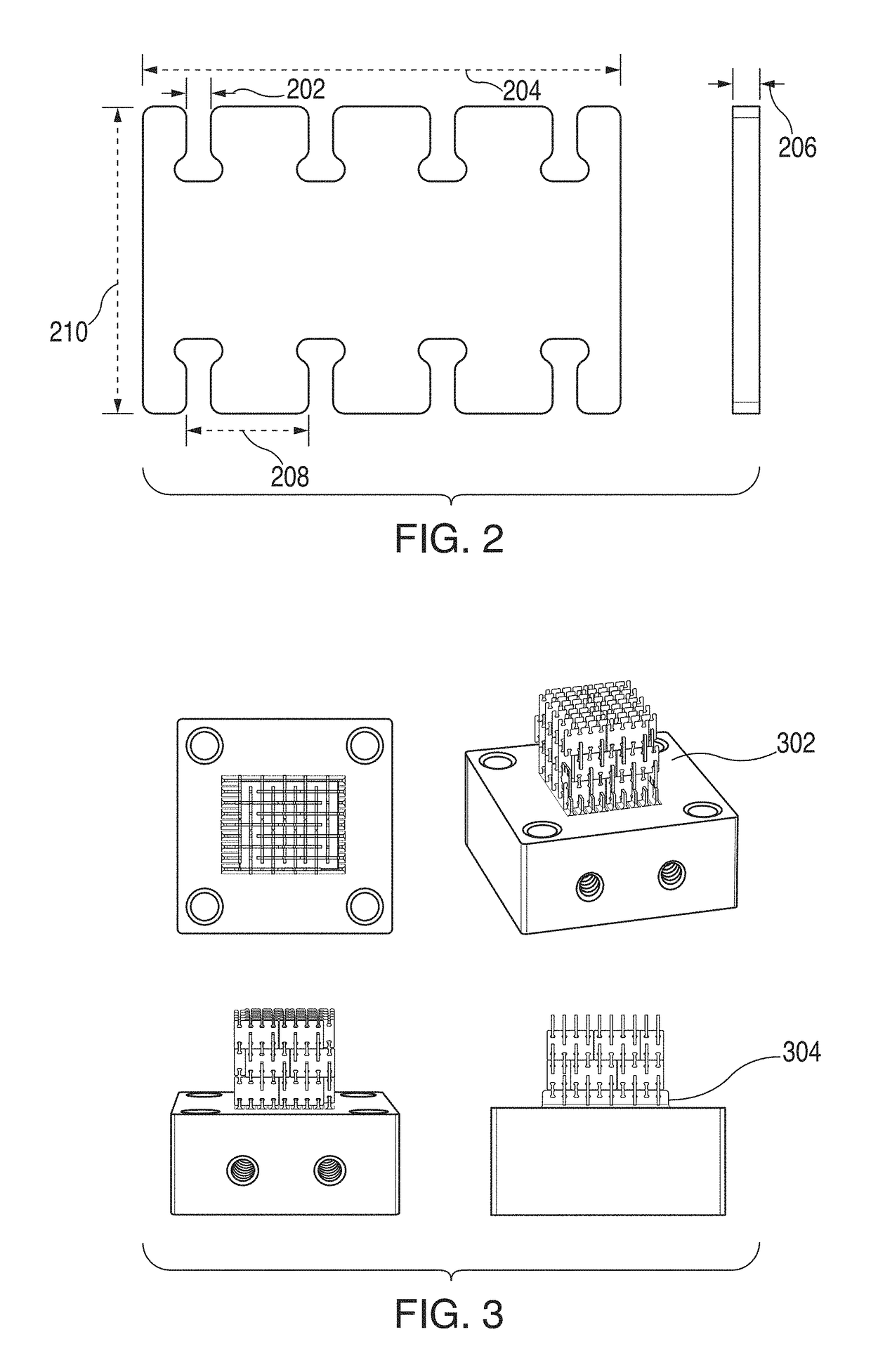

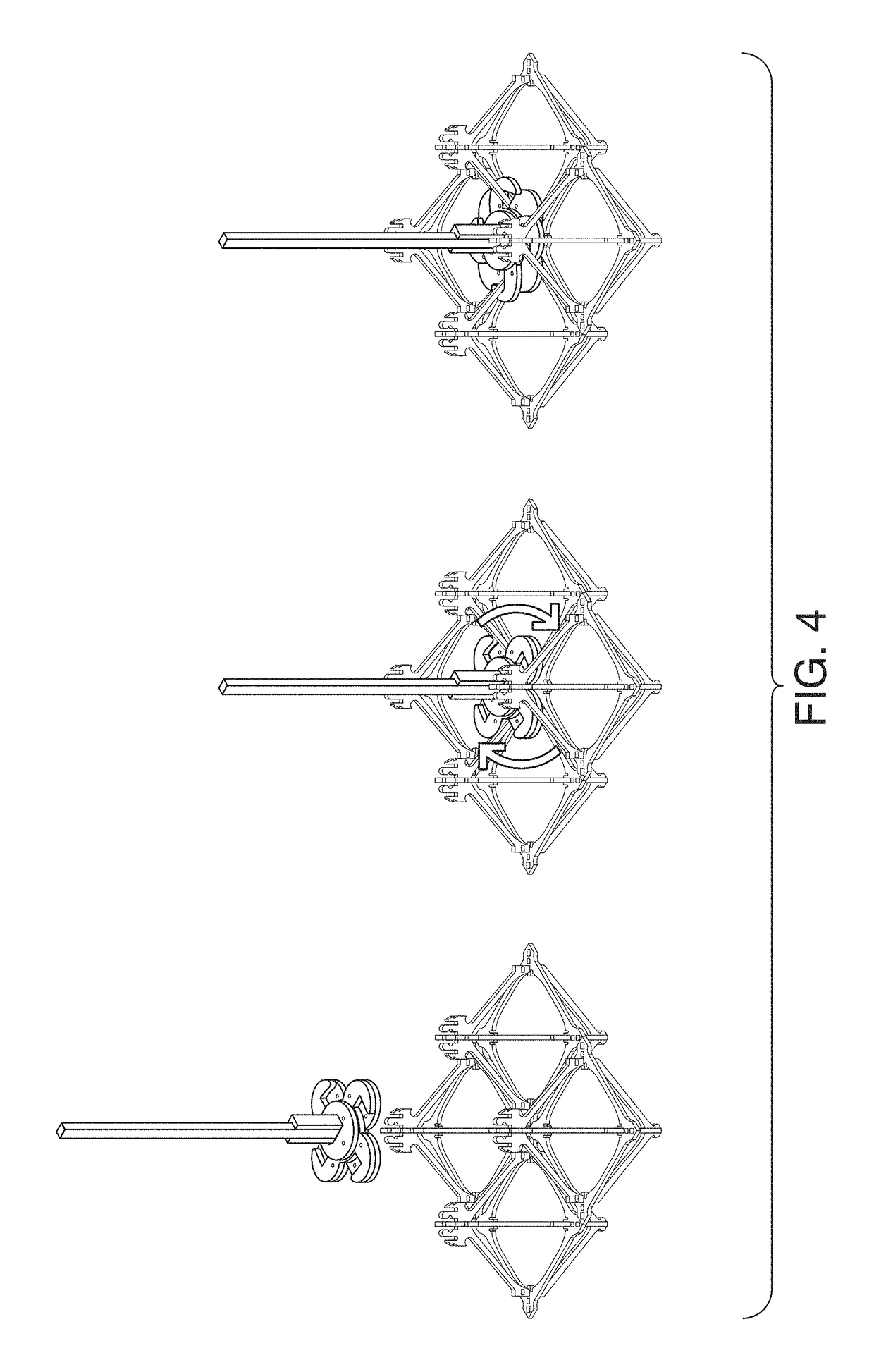

Discrete Assemblers Utilizing Conventional Motion Systems

InactiveUS20180009110A1Assembly precisionEasy to joinProgramme controlProgramme-controlled manipulatorCamMotion system

An alternative to additive manufacturing is disclosed, introducing an end-to-end workflow in which discrete building blocks are reversibly joined to produce assemblies called digital materials. Described is the design of the bulk-material building blocks and the devices that are assembled from them. Detailed is the design and implementation of an automated assembler, which takes advantage of the digital material structure to avoid positioning errors within a large tolerance. To generate assembly sequences, a novel CAD / CAM workflow is described for designing, simulating, and assembling digital materials. The structures assembled using this process have been evaluated, showing that the joints perform well under varying conditions and that the assembled structures are functionally precise.

Owner:MASSACHUSETTS INST OF TECH

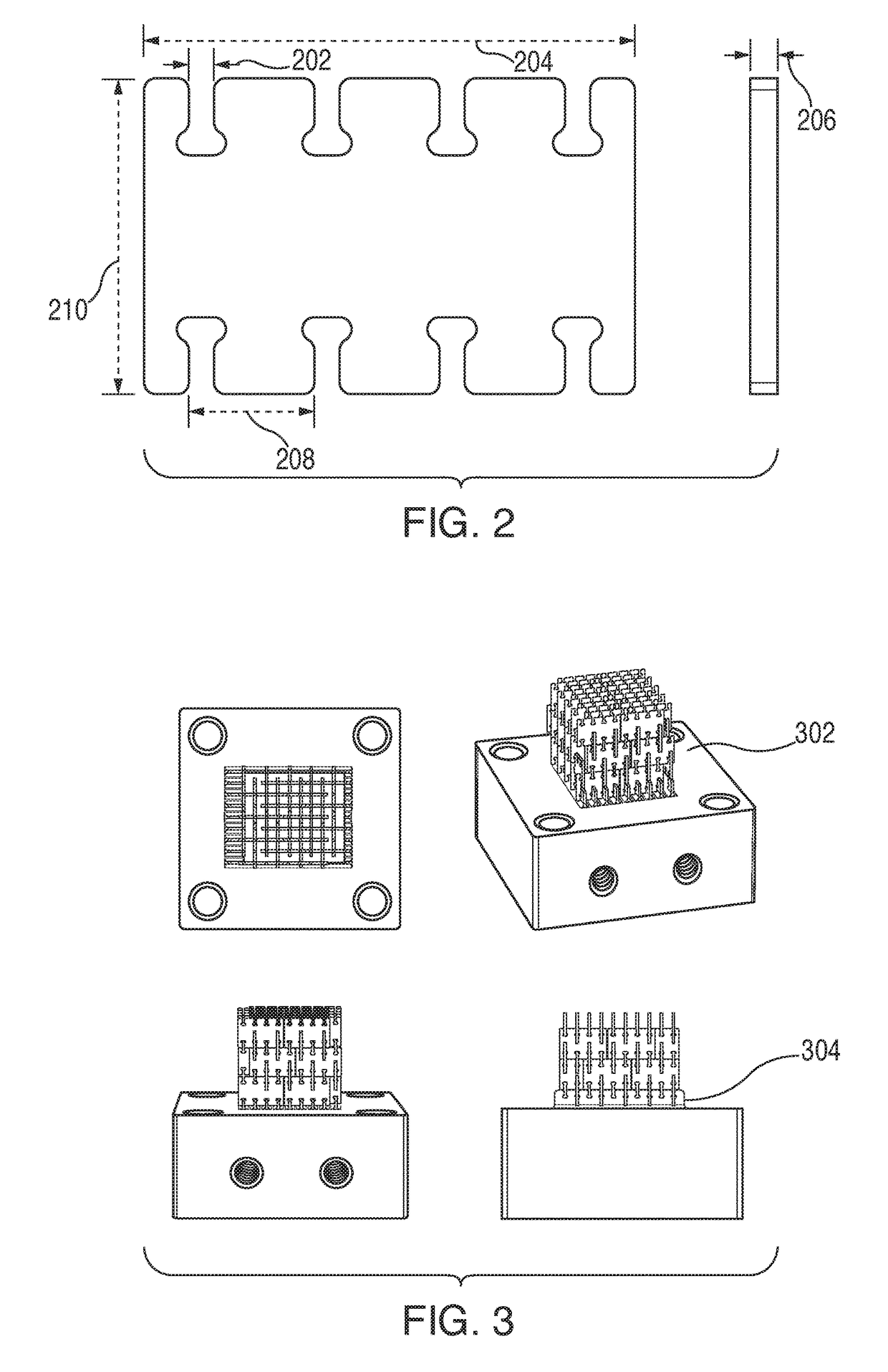

Digital Material Assembly By Passive Means And Modular Isotropic Lattice Extruder System (MILES)

A set of machines and related systems build structures by the additive assembly of discrete parts. These digital material assemblies constrain the constituent parts to a discrete set of possible positions and orientations. In doing so, the structures exhibit many of the properties inherent in digital communication such as error correction, fault tolerance and allow the assembly of precise structures with comparatively imprecise tools. Assembly of discrete cellular lattices by a Modular Isotropic Lattice Extruder System (MILES) is implemented by pulling strings of lattice elements through a forming die that enforces geometry constraints that lock the elements into a rigid structure that can then be pushed against and extruded out of the die as an assembled, loadbearing structure.

Owner:MASSACHUSETTS INST OF TECH

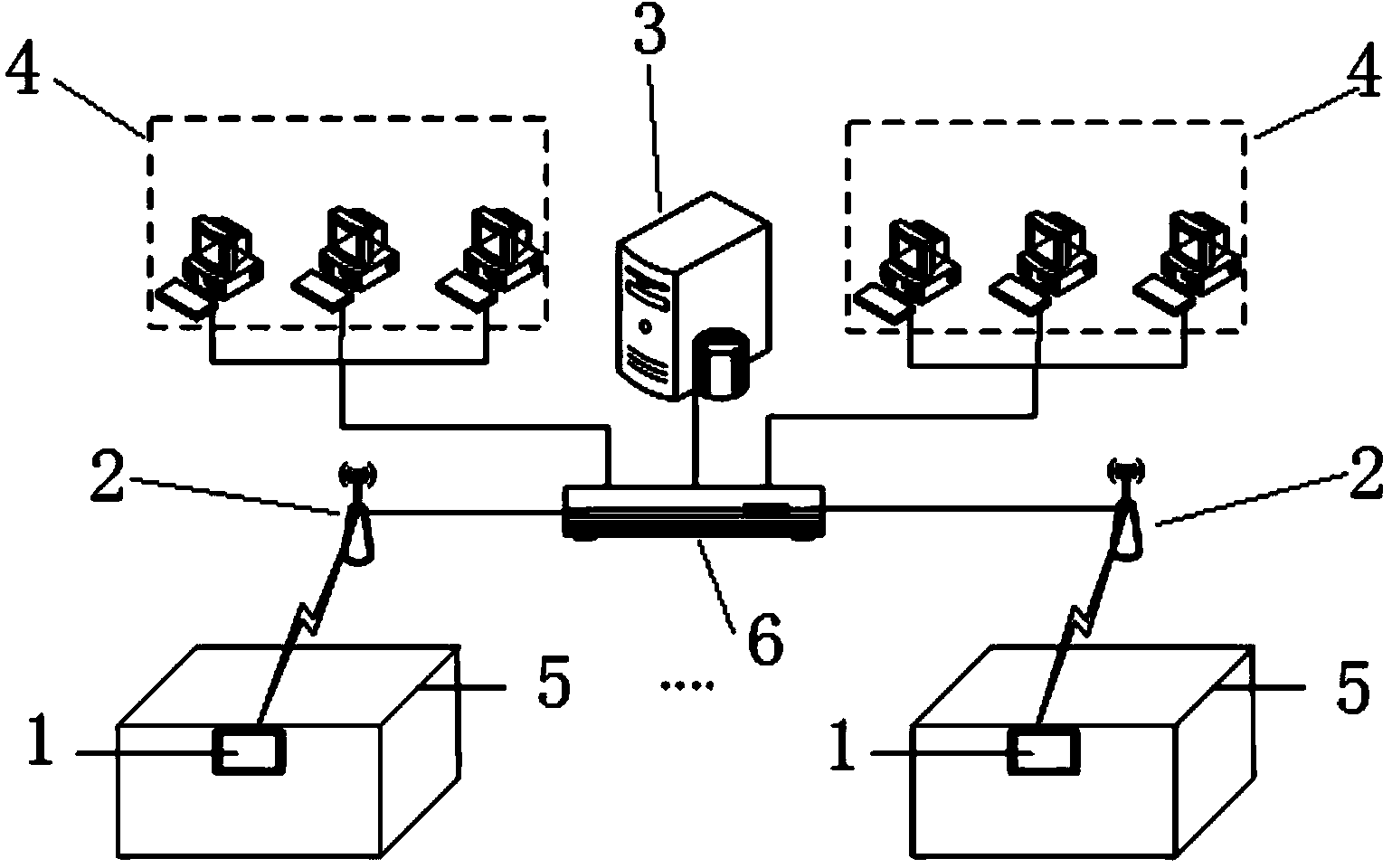

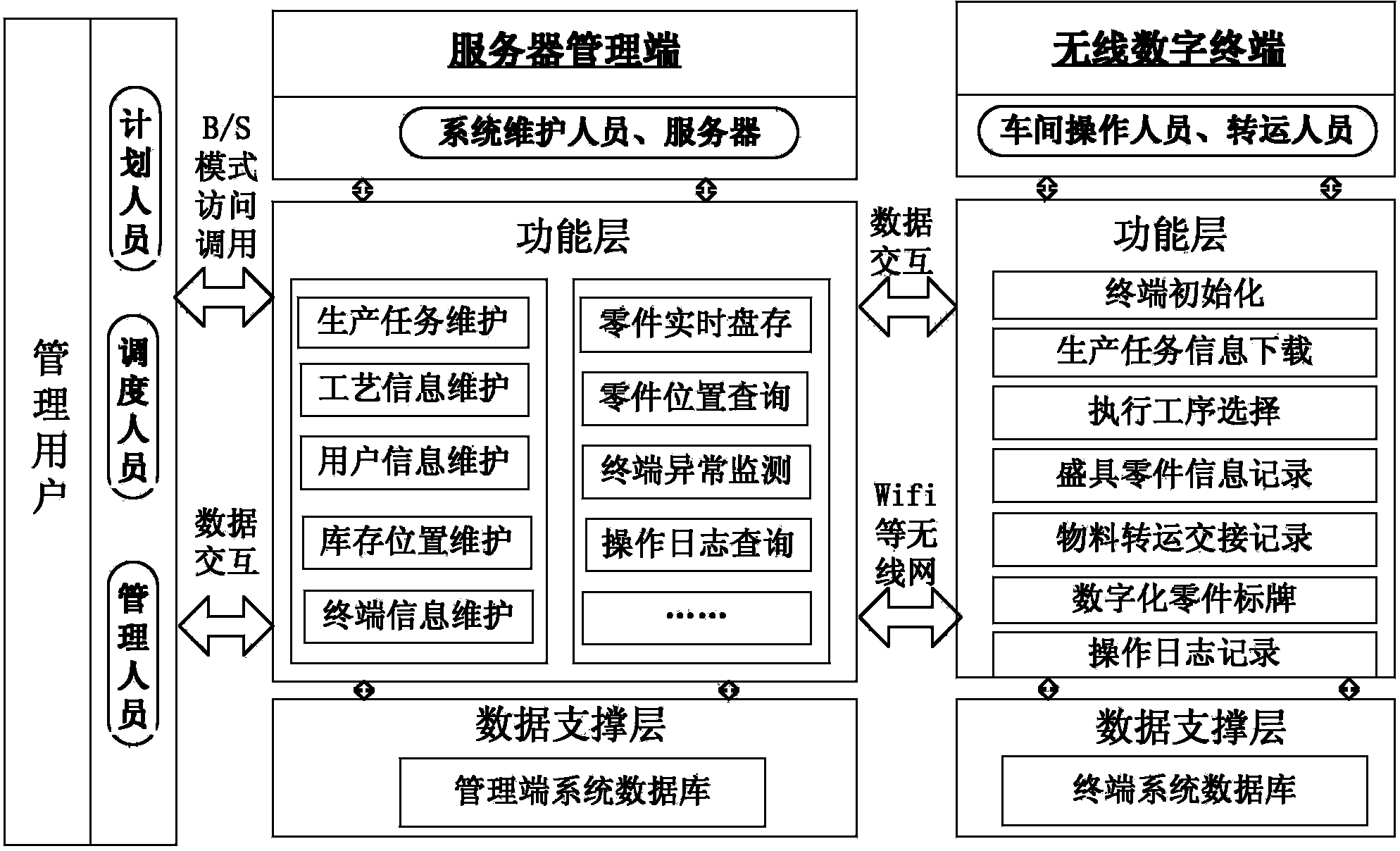

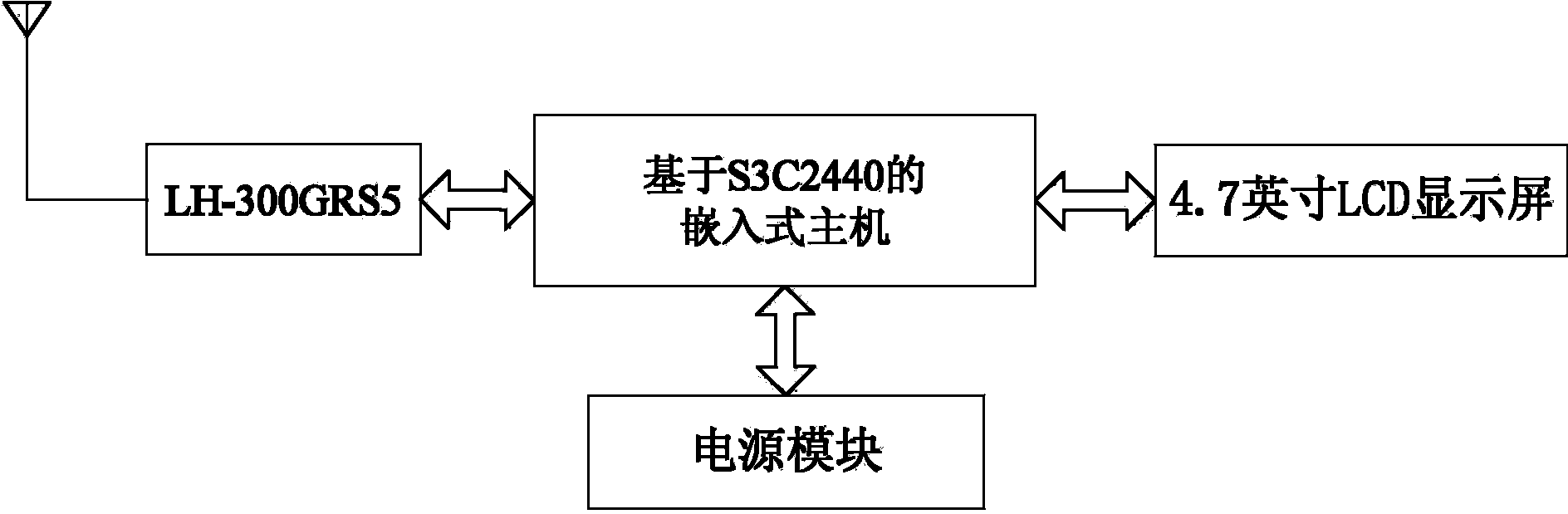

Wireless digital terminal based real-time monitoring system and method for machined work-in-process parts

InactiveCN103530809AReduce backlogImprove circulation efficiencyData processing applicationsTransmissionNetwork connectionMonitoring system

The invention discloses a wireless digital terminal based real-time monitoring system and method for machined work-in-process parts. The system comprises wireless digital terminals, wireless APs (access points), a server management end and management user ends, wherein the wireless digital terminals are connected through the wireless APs and access a workshop wireless local area network; the wireless APs are connected with a workshop switchboard through twisted pairs, so that the wireless digital terminals access an enterprise wired local area network and are in network connection with the management user ends and the server management end; the wireless digital terminals are installed on containers storing the parts, access the enterprise local area network through the wireless APs and are connected with the server management end; and management users access the server management end in a B / S (browser / server) mode, monitoring and management of the work-in-process parts, such as dynamic digital display of part labels, real-time enterprise workshop digital stocktaking, digital material handover recording, work-in-process part positioning and the like, can be realized conveniently, overstocking of workshop work-in-process is reduce effectively, and the circulation efficiency of the work-in-process parts is improved.

Owner:CHONGQING UNIV OF POSTS & TELECOMM +1

Cursor for electronic devices

InactiveCN1748196AMove quicklyDetails for portable computersInput/output processes for data processingComputer graphics (images)Display device

The present invention describes a method, electronic device and computer program for displaying a cursor on the display of an electronic device. The size of the display is typically so small that only part of a virtual view is displayed at one time on the display. The user of the electronic device changes the displayed part of the virtual view on the display. In the present invention, a correlation between the cursor location on the display and the location of the displayed part of the virtual view within the whole virtual view is determined so that the cursor location on the display reflects the location of the displayed part of the virtual view in proportion to the whole virtual view. In other words, the user can quickly perceive the exact location e.g. on the virtual desktop or in large digital material displayed on the display of an electronic device.

Owner:MOTIONIP

Discrete assemblers utilizing conventional motion systems

InactiveUS10155313B2Assembly precisionEasy to joinProgramme-controlled manipulatorAdditive manufacturing apparatusCamMotion system

An alternative to additive manufacturing is disclosed, introducing an end-to-end workflow in which discrete building blocks are reversibly joined to produce assemblies called digital materials. Described is the design of the bulk-material building blocks and the devices that are assembled from them. Detailed is the design and implementation of an automated assembler, which takes advantage of the digital material structure to avoid positioning errors within a large tolerance. To generate assembly sequences, a novel CAD / CAM workflow is described for designing, simulating, and assembling digital materials. The structures assembled using this process have been evaluated, showing that the joints perform well under varying conditions and that the assembled structures are functionally precise.

Owner:MASSACHUSETTS INST OF TECH

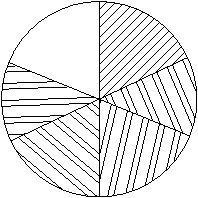

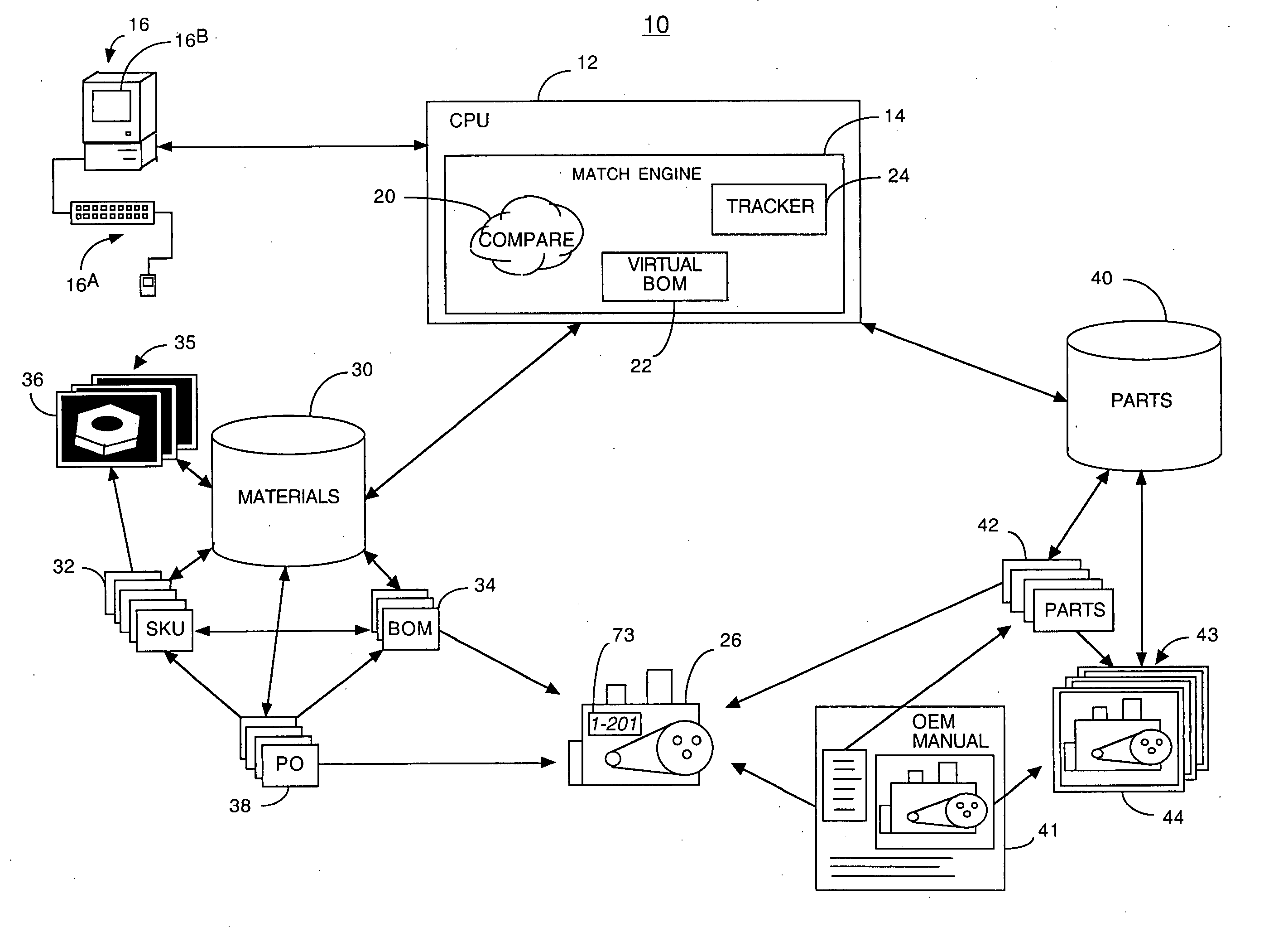

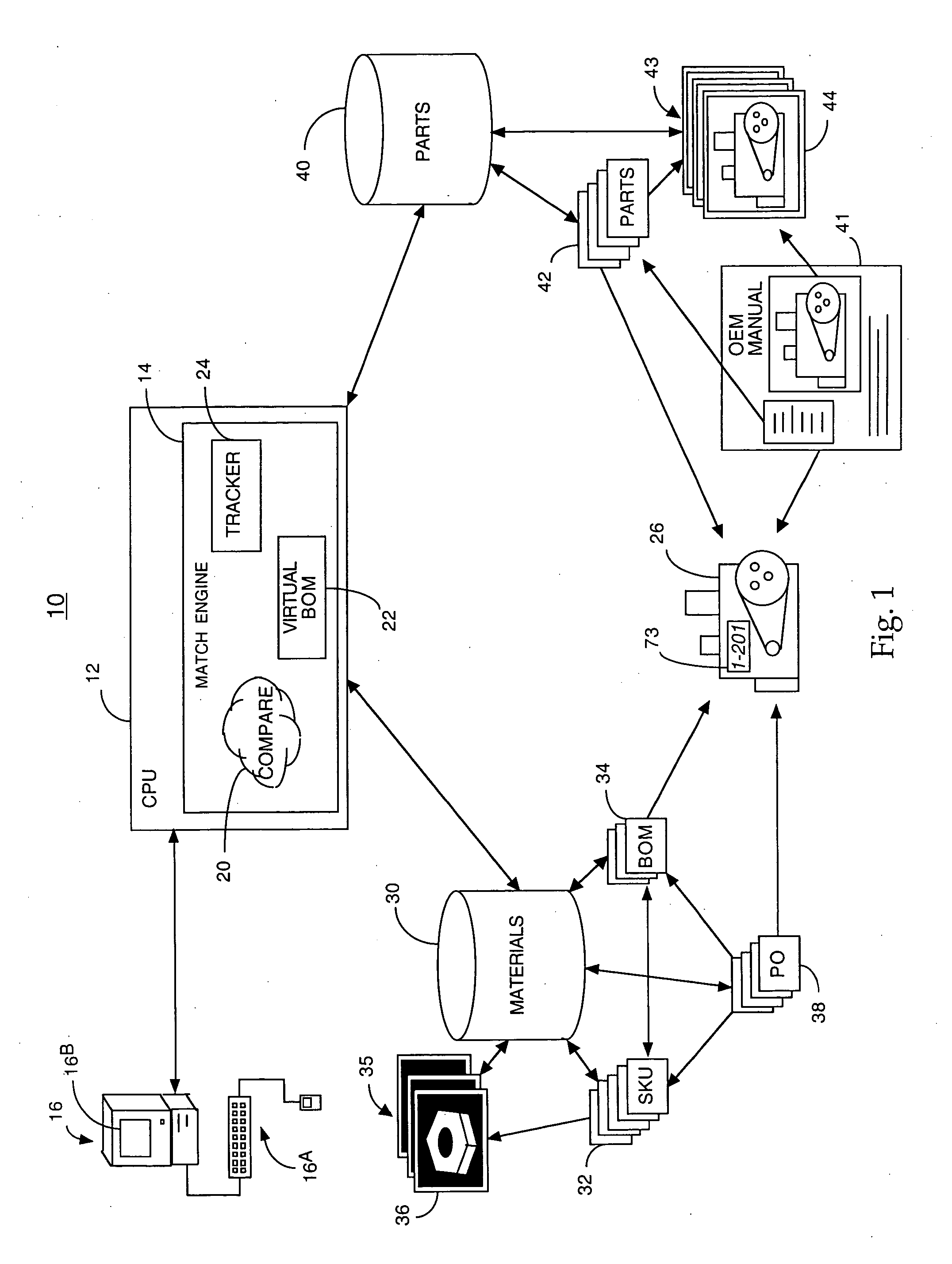

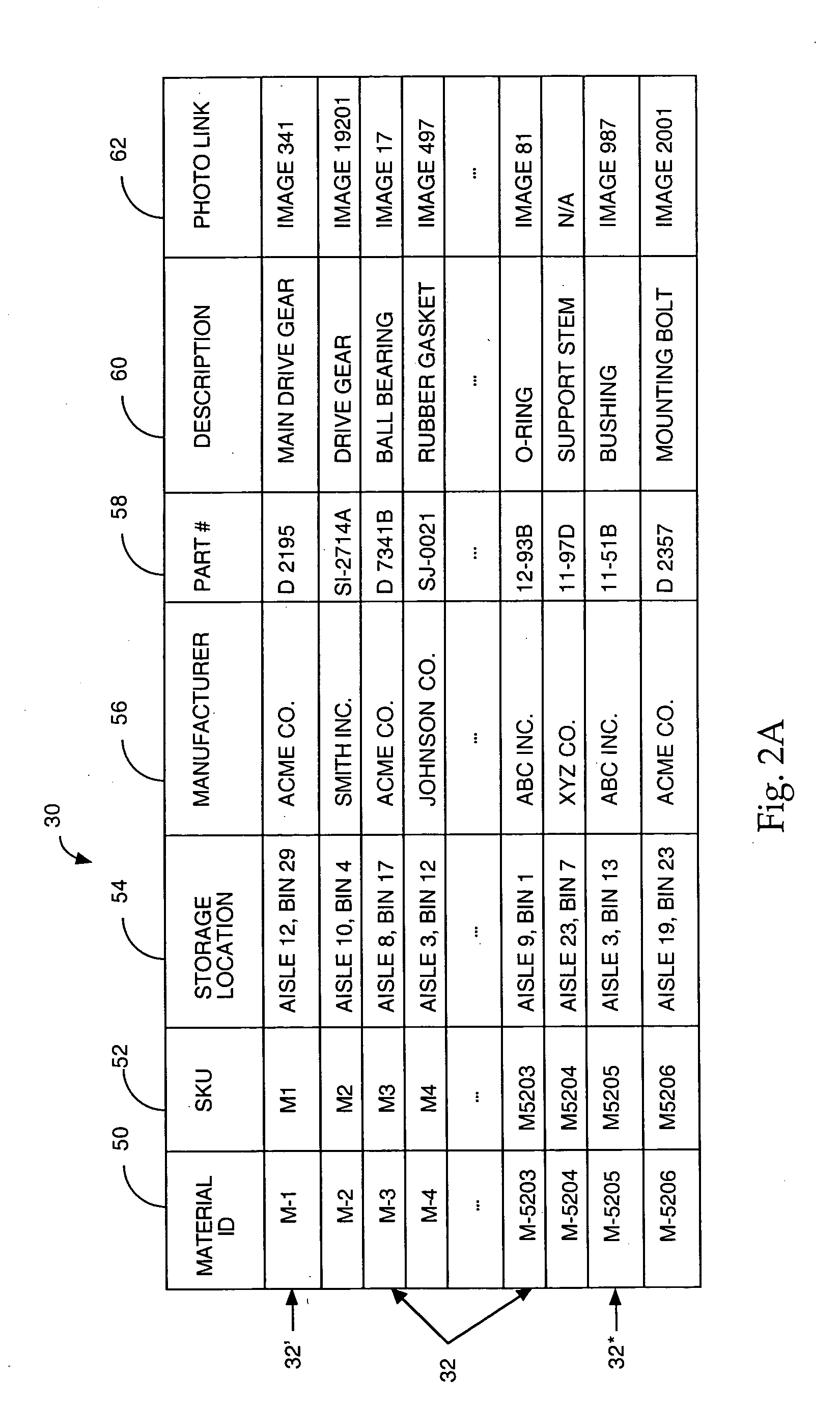

Systems and methods for the matching of materials data to parts data

Systems and methods for correlating materials records to part records. At least one materials record is provided with a corresponding digital materials images and a plurality of parts records are provided with at least one corresponding digital parts image. The materials records are automatically compared to the part records, and potential matches are identified. Any digital materials images and parts images for the potential matches are displayed to the user for confirmation of a match.

Owner:NRX GLOBAL

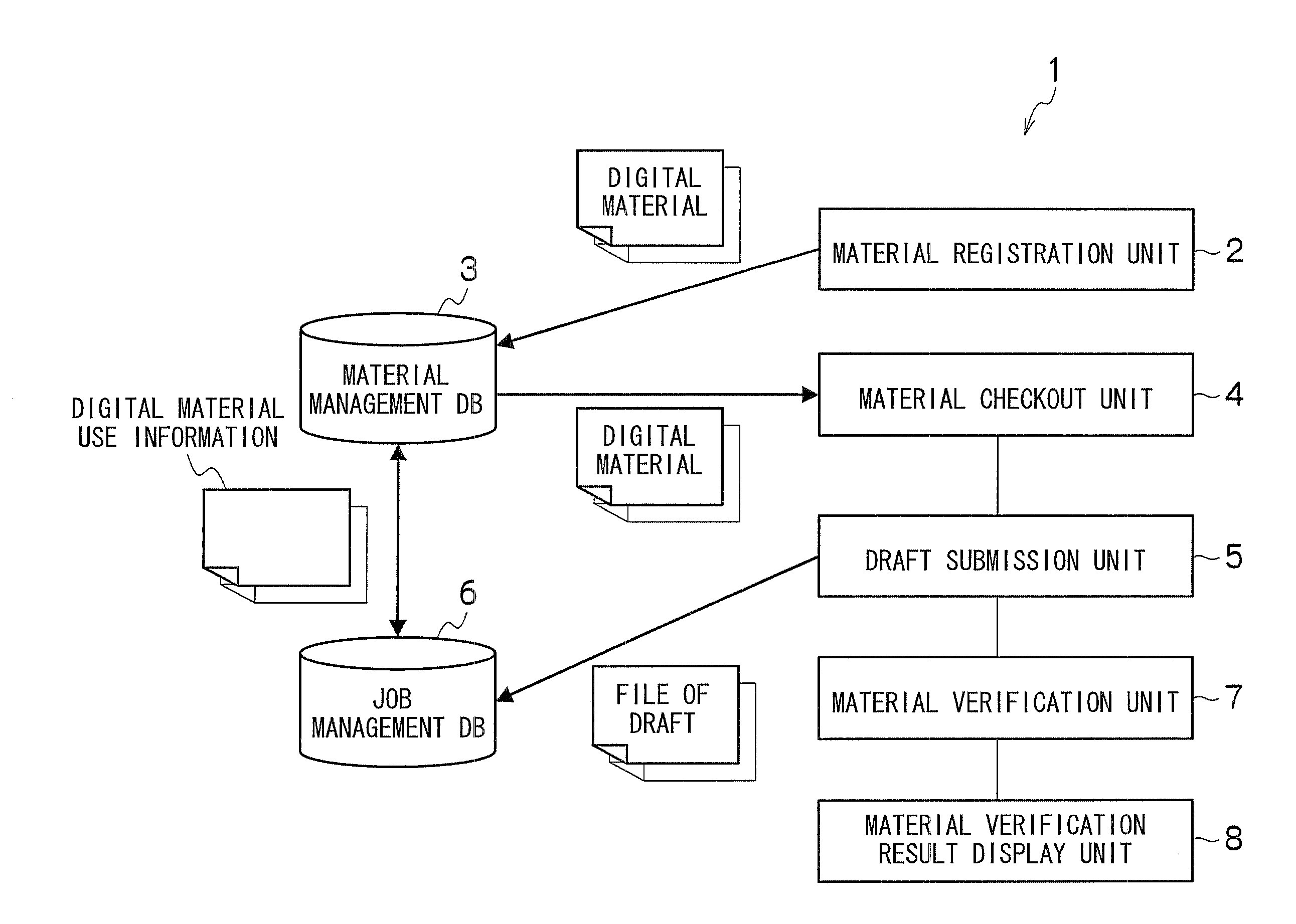

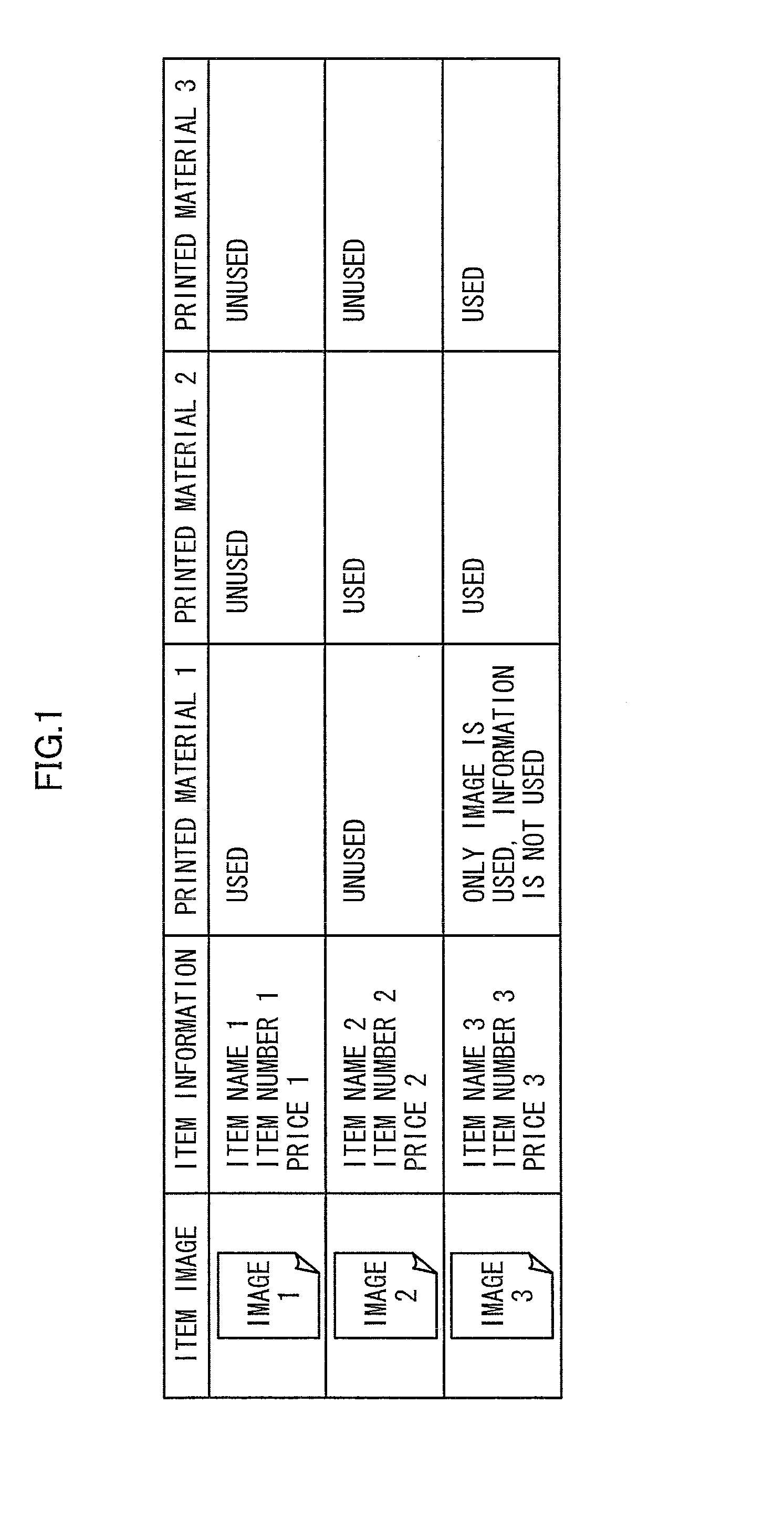

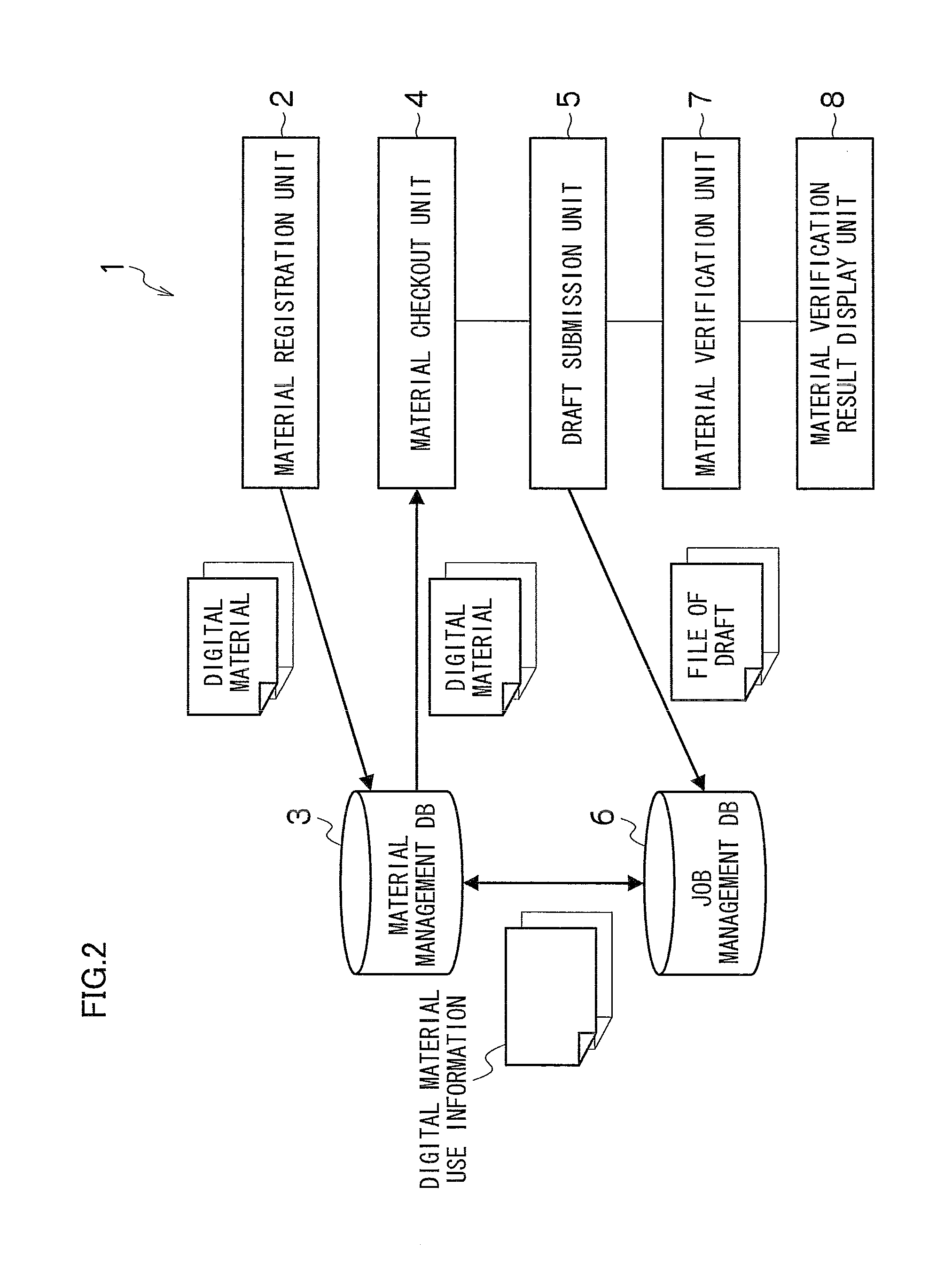

Digital material management method, digital material management system, and workflow management system

ActiveUS20100168888A1Improve efficiencySave powerDigitally marking record carriersDigital computer detailsWorkflow management systemDigital rights management

An aspect of the present invention provides a digital material management method including a verification step of automatically verifying, in manufacturing of a product in which digital materials are used, digital materials that should be used and digital materials that are actually used in the product. According to the digital material management method of the present invention, whether the entire digital materials that should be used in the product manufactured using the digital materials are arranged and used is automatically checked, and the result is displayed. Therefore, the use of the digital materials that should be used in the product can be automatically checked. The efficiency is improved, and the power can be saved.

Owner:FUJIFILM CORP

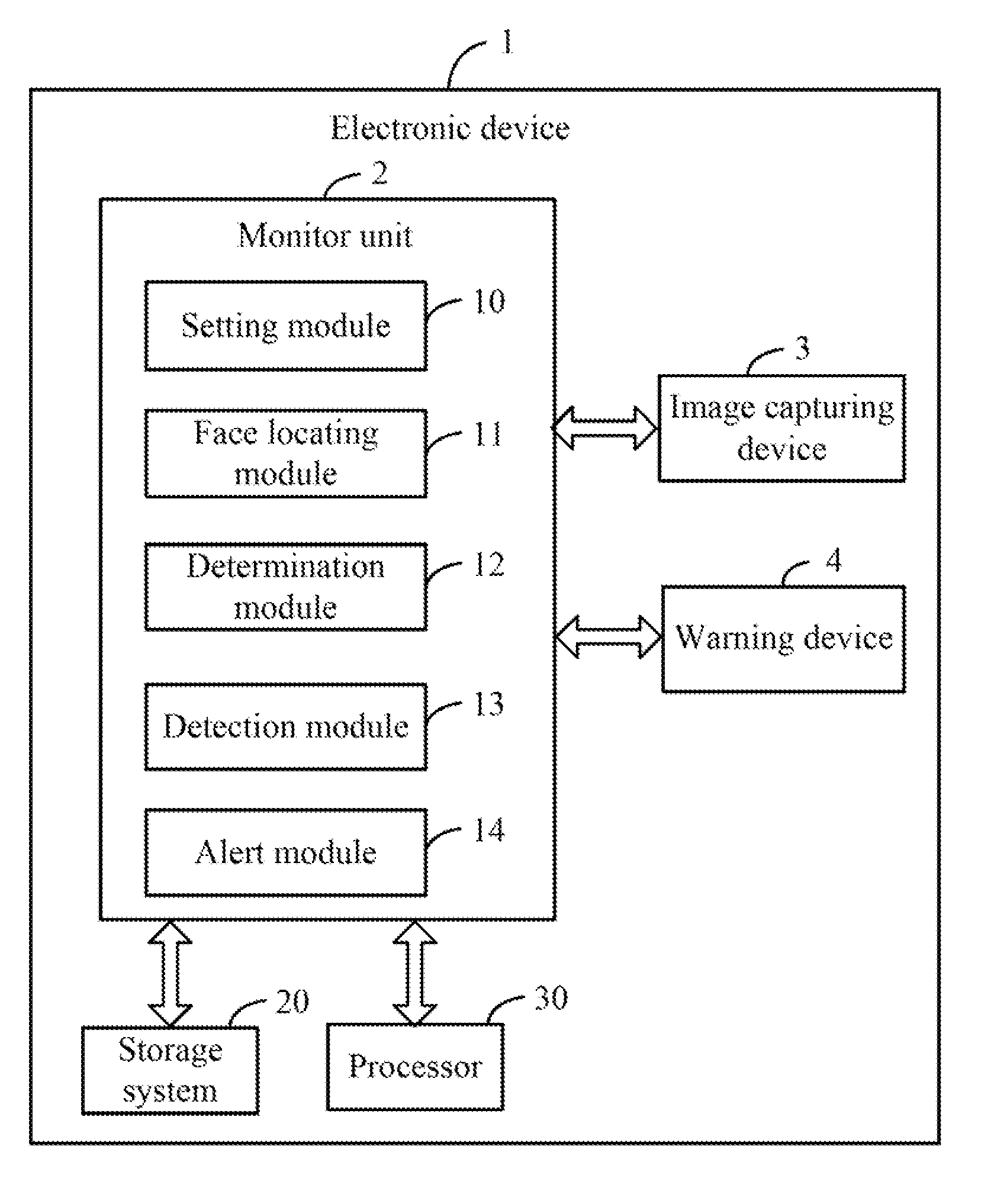

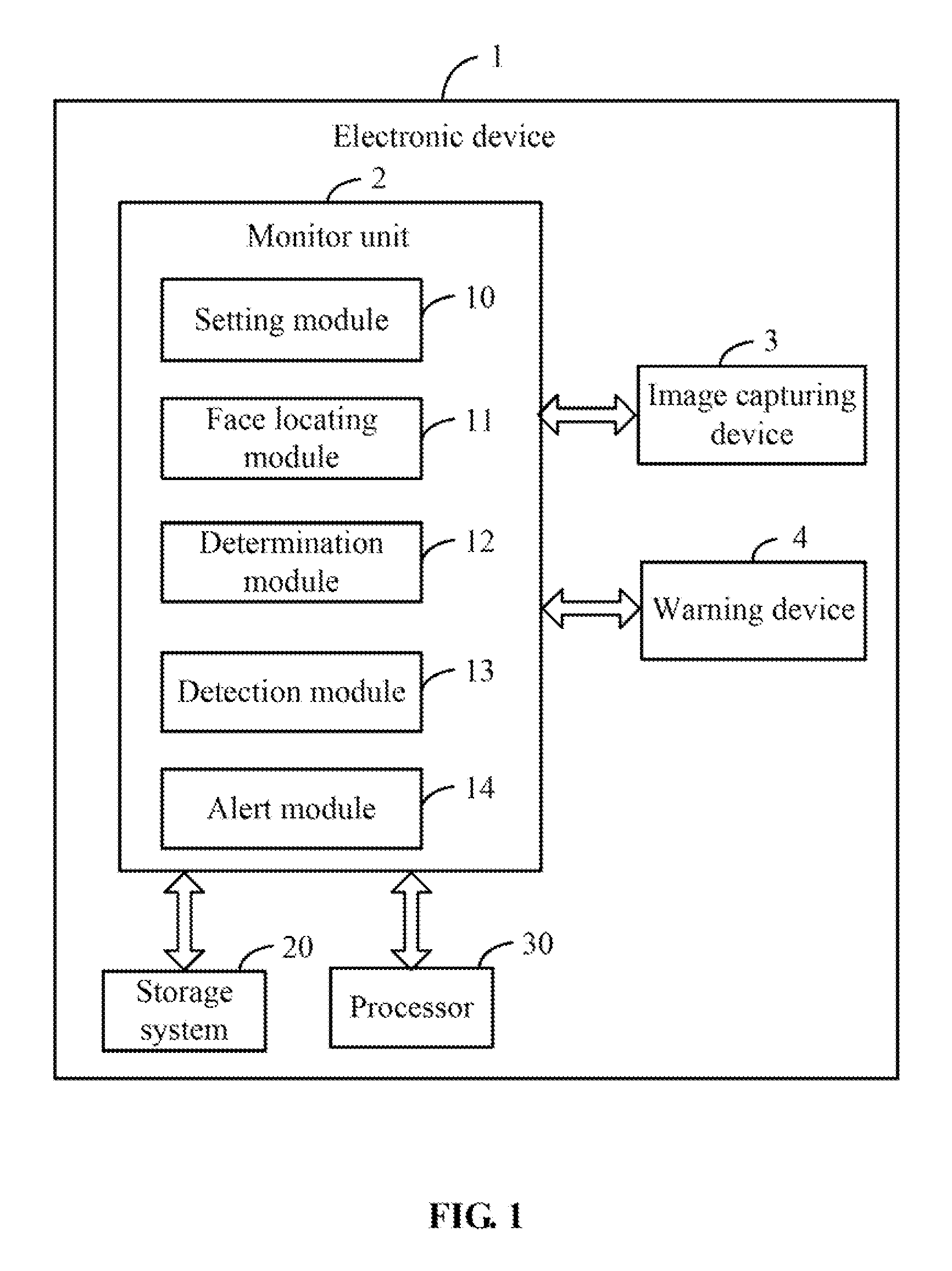

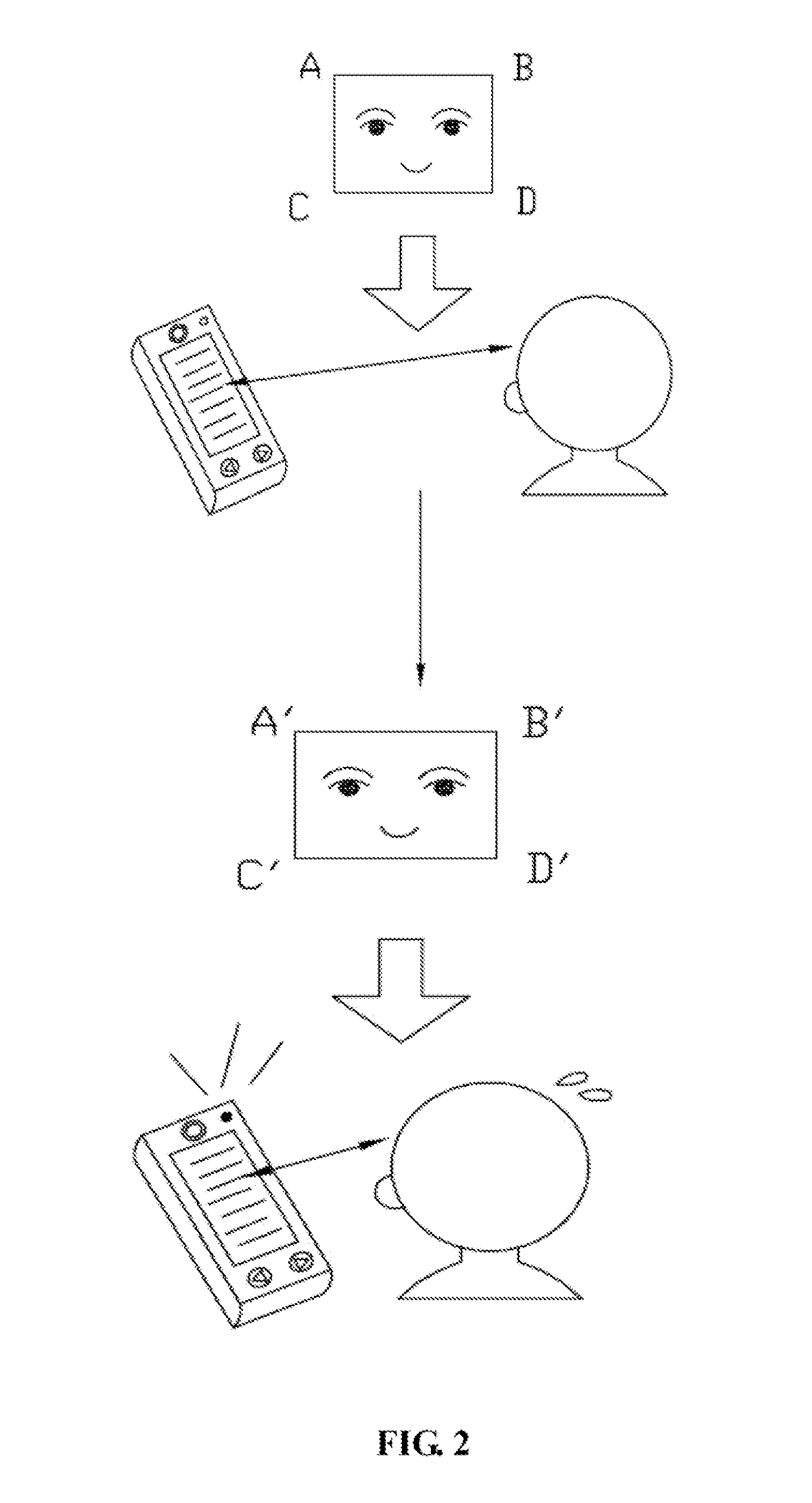

Electronic device and method for monitoring user state

InactiveUS20110221608A1Television system detailsCharacter and pattern recognitionComputer hardwareFace shape

A method that monitors user state using an electronic device locates a face shape from a current image of a user captured by an image capturing device of the electronic device, and calculates a current area of the face shape when the user reads digital material using the electronic device. Additionally, the method determines whether the current area is greater than a standard area stored in a storage system of the electronic device, and triggers a warning device of the electronic device to output an alarm signal to warn the user to keep a proper distance from the electronic device upon the condition that the current area is greater than the standard area.

Owner:HON HAI PRECISION IND CO LTD

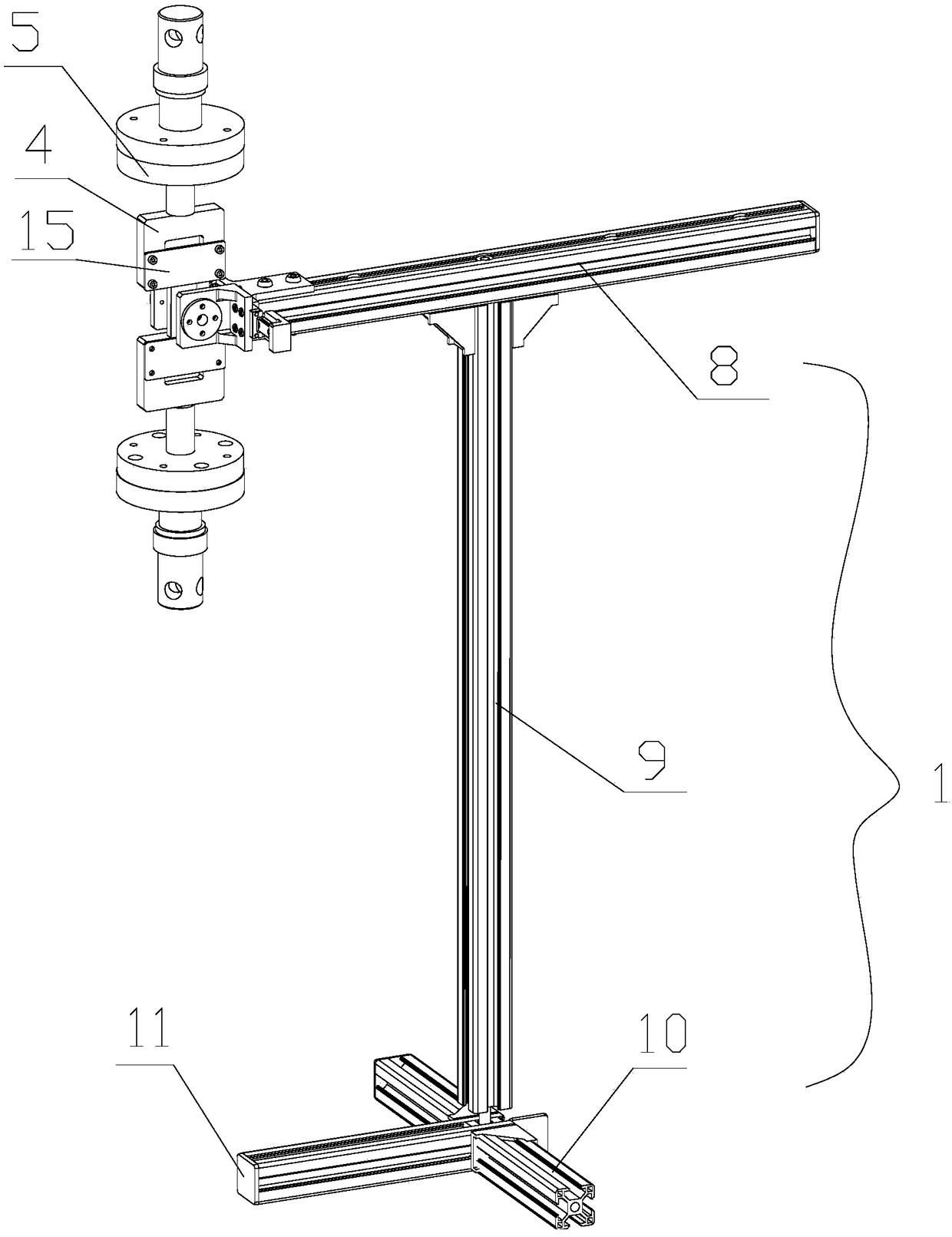

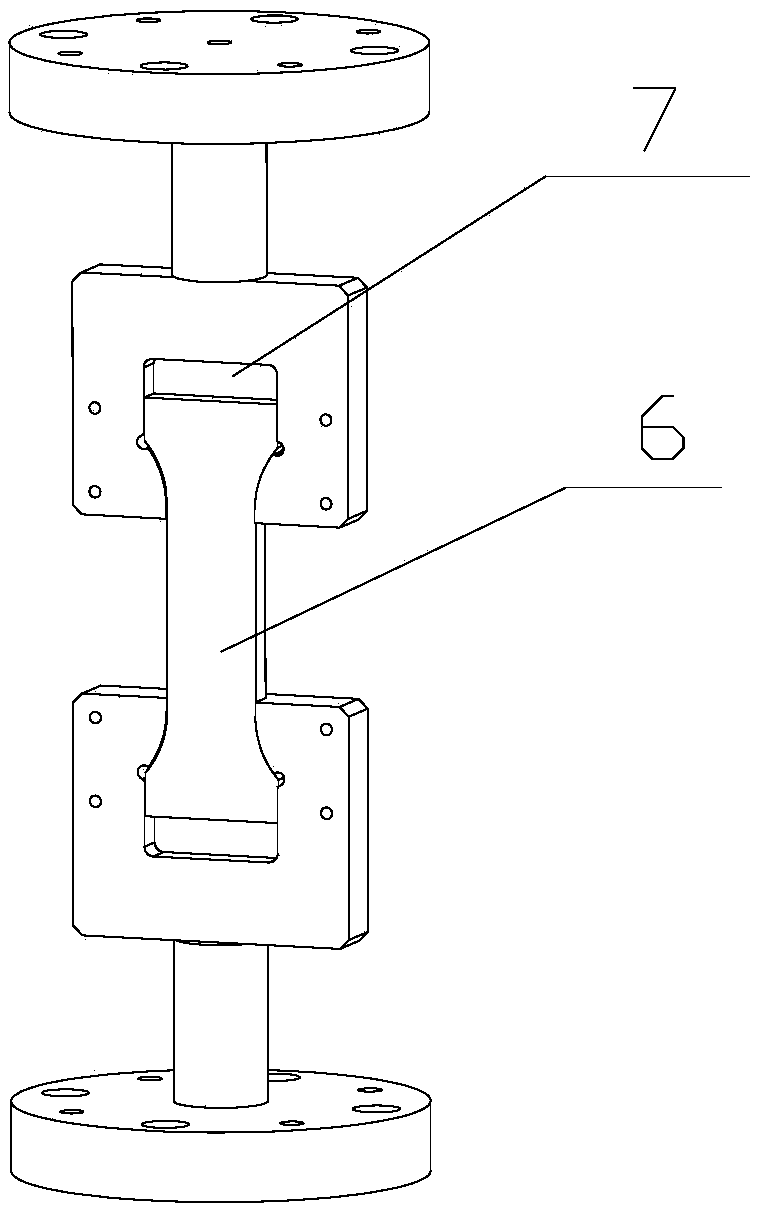

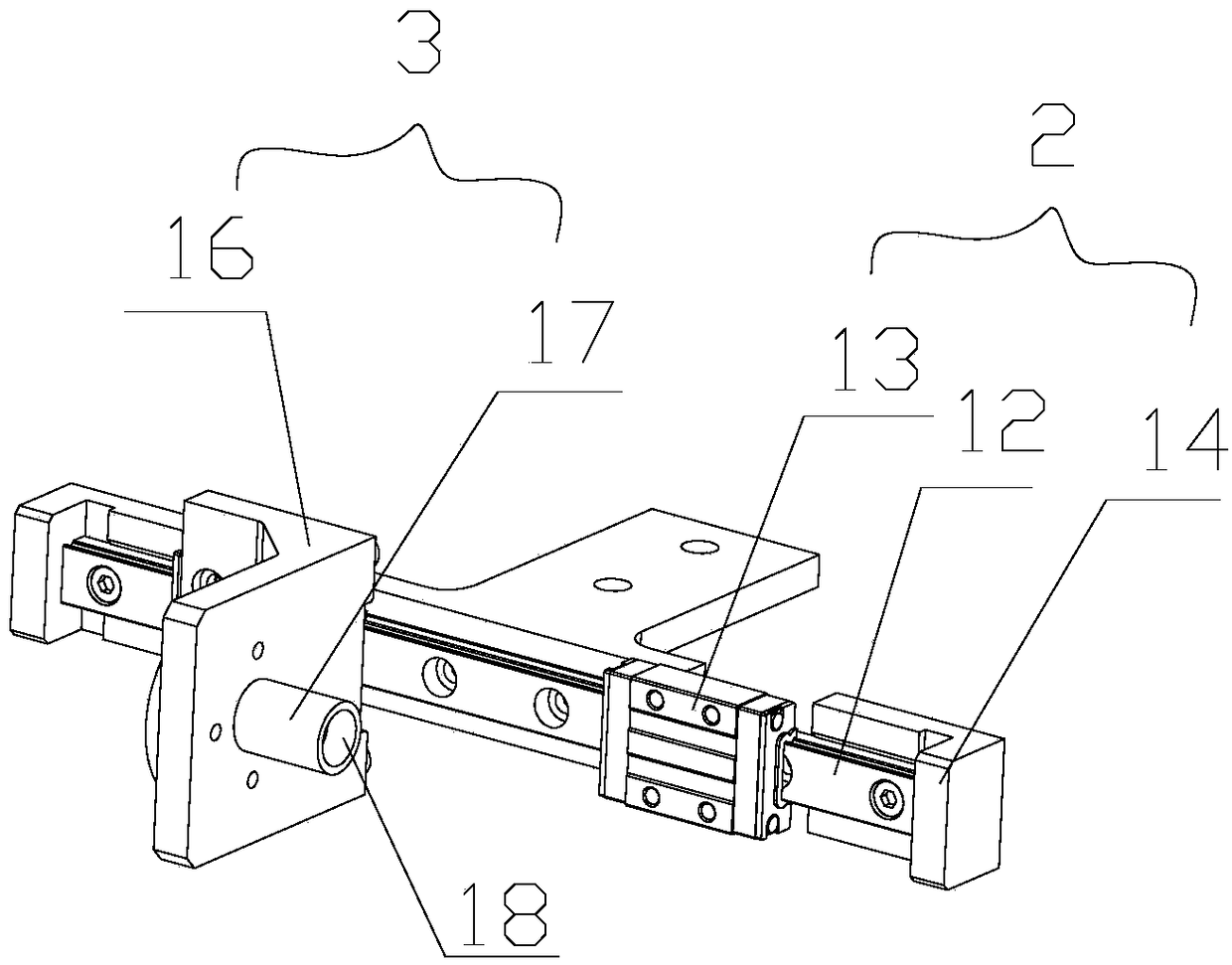

Sonoelastic coefficient calibration device for detecting residual stress of explosive through ultrasonic detection method

PendingCN108827533AControl distanceFar from simpleApparatus for force/torque/work measurementForce/torque/work measurement apparatus calibration/testingEngineeringTime difference

The invention relates to the field of residual stress detection of explosives, and specifically relates to a sonoelastic coefficient calibration device for detecting the residual stress of an explosive through an ultrasonic detection method. The device comprises a digital material testing machine and an ultrasonic stress meter. The digital material testing machine comprises an explosive jaw and atensioning machine clamping tool, wherein the explosive jaw is provided with a fixing groove for clamping an explosive sample, and the shape of the fixing groove is matched with the shape of the explosive sample. A cover plate is arranged on the explosive jaw, and the tensioning machine clamp is connected with a tension machine, and the ultrasonic stress meter comprises a frame. A sliding rail device is mounted on the frame, and an ultrasonic detecting device is fixed on the sliding rail device. The ultrasonic detecting device comprises an ultrasonic probe bracket and an ultrasonic probe, wherein the ultrasonic probe is fixed on the ultrasonic probe bracket, and an elastic member is disposed between the ultrasonic probe brackets. The device can detect the acoustic time difference - load curve of the explosive sample during the loading of a load, and is suitable for the calibration of the sonoelastic coefficient of the explosive sample.

Owner:杭州戬威科技有限公司

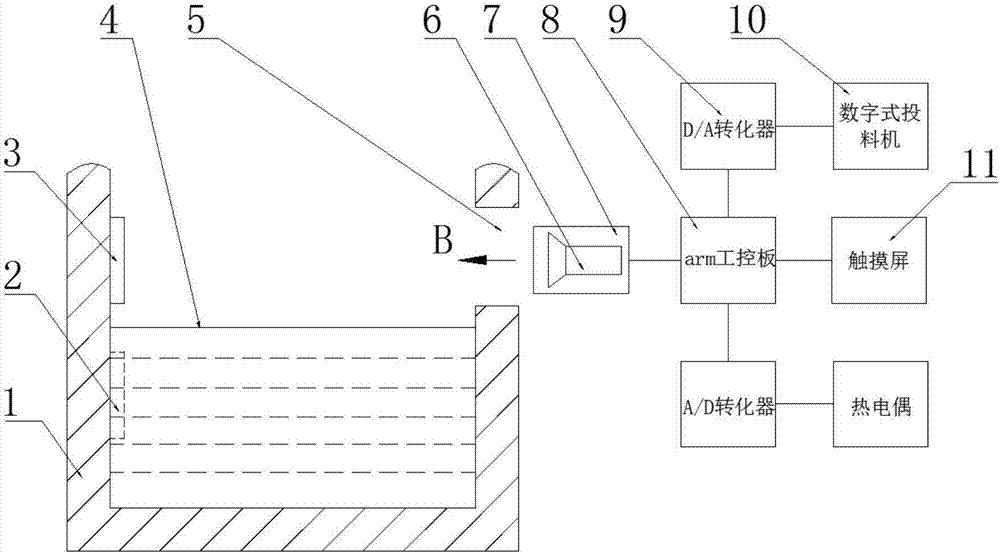

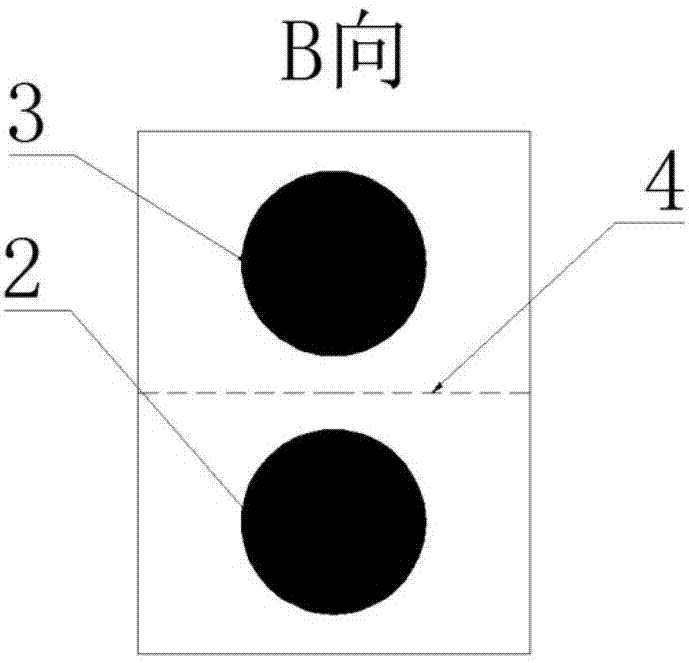

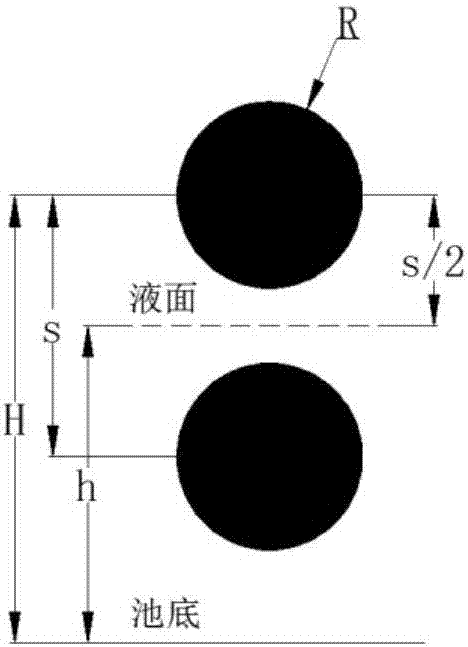

Glass melting furnace liquid level height measuring and controlling method based on machine vision

InactiveCN107367311AAccurate measurementEasy to controlImage enhancementImage analysisMachine visionControl signal

The invention provides a glass melting furnace liquid level height measuring and controlling method based on machine vision. A digital camera (6) collects images in a melting furnace through a peephole (5), the images are transmitted to an arm industrial control board (8) through a USB interface, the images are processed and the liquid level height is obtained in the arm industrial control board (8), the liquid level height and the images are displayed on a touch screen (11), the deviation e and the deviation change ec are calculated according to the designated liquid level height and the real-time liquid level height, a fuzzy PID algorithm is used for obtaining a suitable material feed speed, finally a speed control signal is sent to a digital material feeder (10) by the arm industrial control board (8) through a D / A converter (9), the feed speed is changed, and the control over the glass liquid level height is realized. The liquid level height in the glass melting furnace can be precisely measured and controlled, and high-quality glass liquid is provided for glass forming.

Owner:WUHAN UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com