Patents

Literature

143results about How to "Reliable insertion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

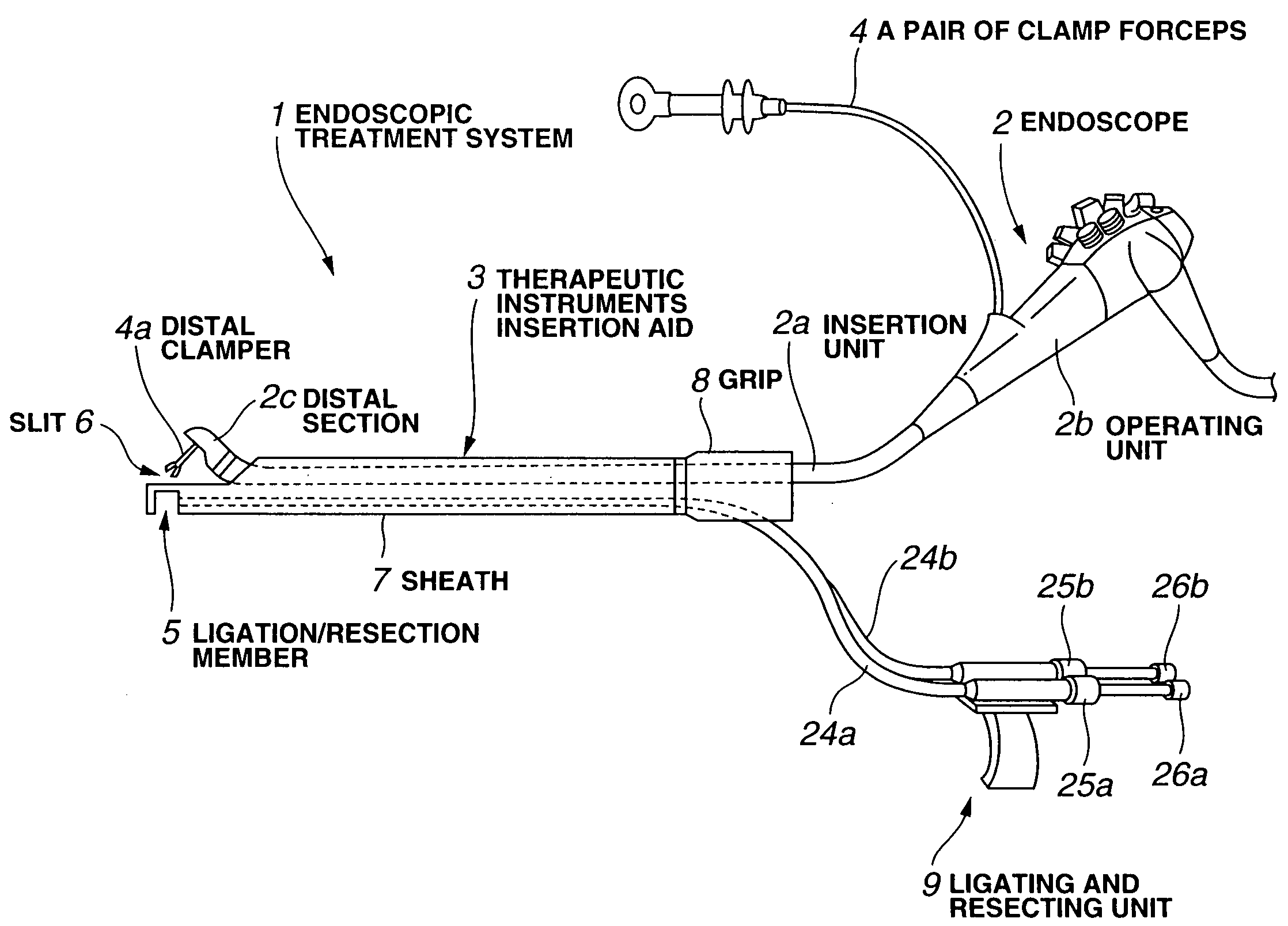

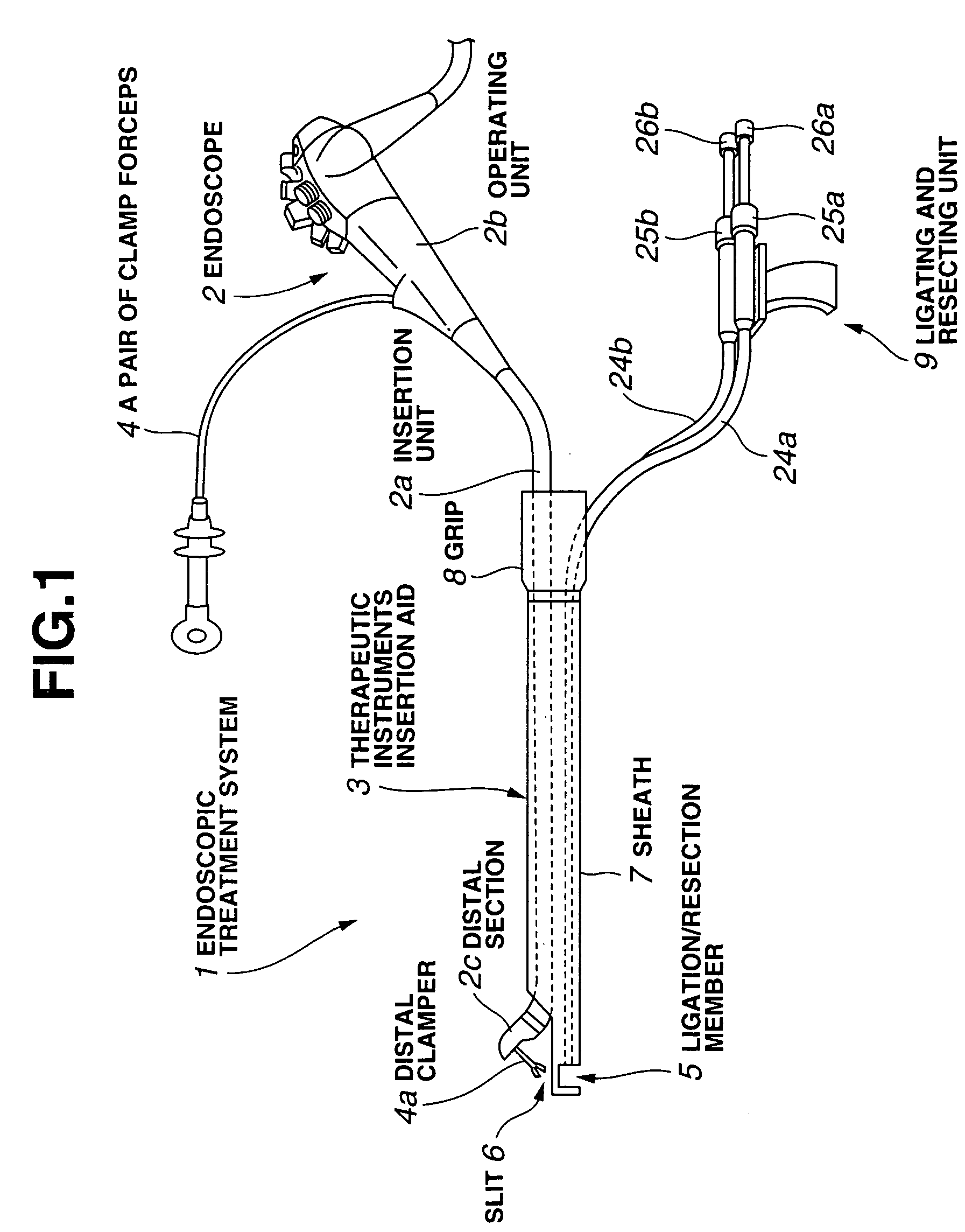

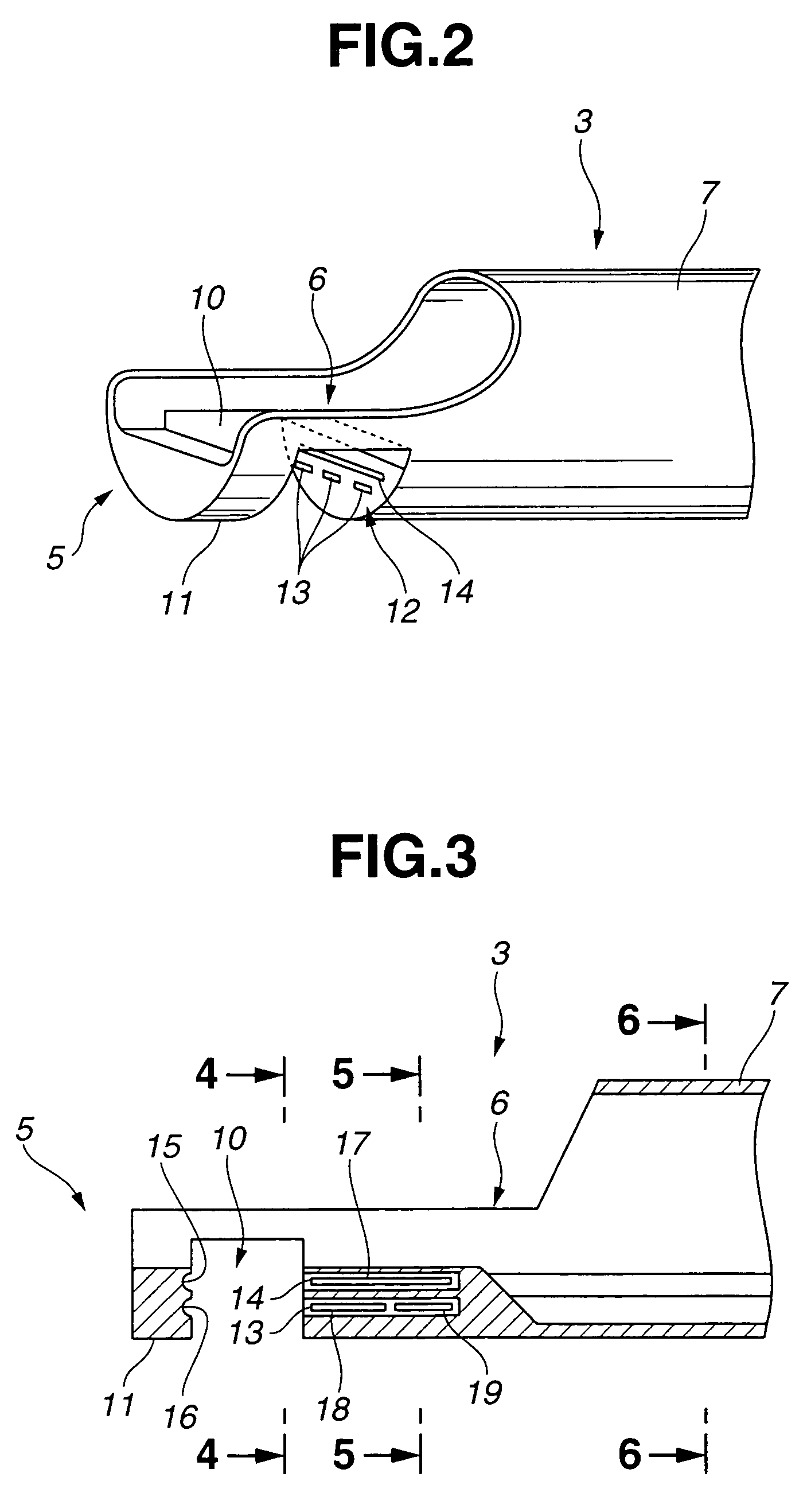

Endoscopic treatment system

InactiveUS7341554B2Reliably suturingReliable resectionSuture equipmentsCannulasBiological bodyEndoscopic treatment

An endoscopic treatment system is designed to suture or resect a lesion while ensuring the ease of insertion into a deep region in the large intestine. The endoscopic treatment system comprises an endoscope and a therapeutic instruments insertion aid into which the endoscope is inserted. The endoscopic treatment system further comprises: a pair of clamp forceps that clamps and lifts a living-body tissue; a lateral hole formed in the therapeutic instruments insertion aid and used to control the position of the living-body tissue clamped and lifted by the pair of clamp forceps or to control the lifting thereof; a ligature used to ligate the living-body tissue whose position or lifting is controlled by the lateral hole; and a cutter used to resect the living-body tissue at a position between a region ligated with the ligature and a region clamped and lifted with the pair of clamp forceps.

Owner:OLYMPUS CORP

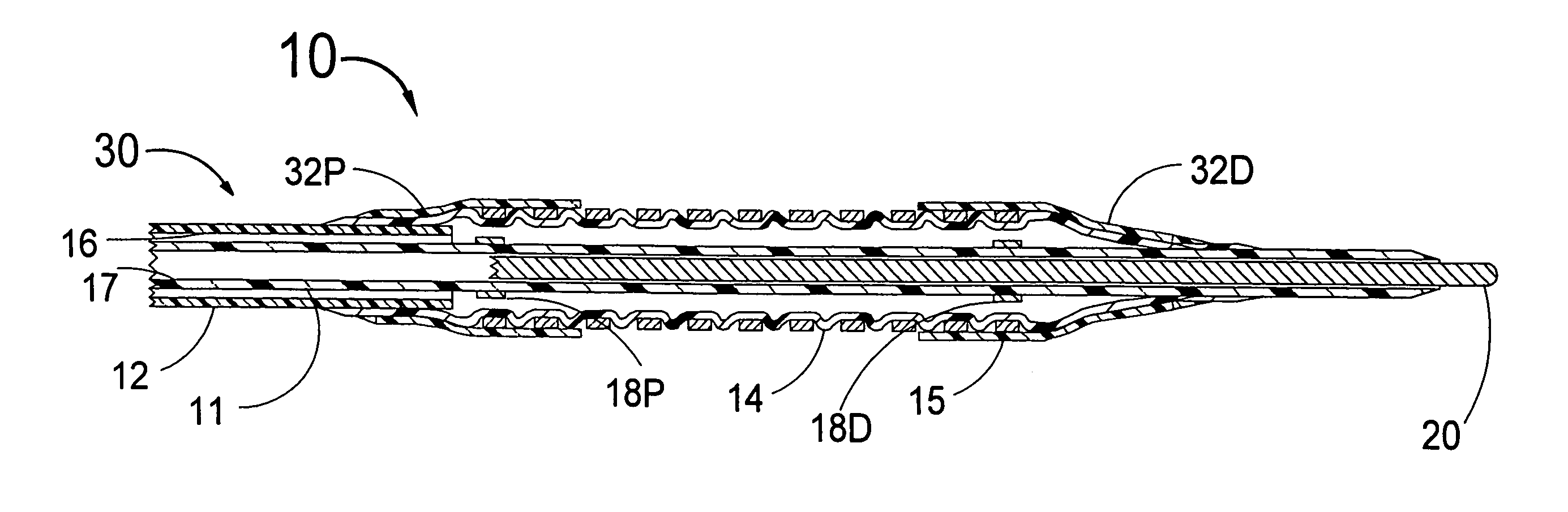

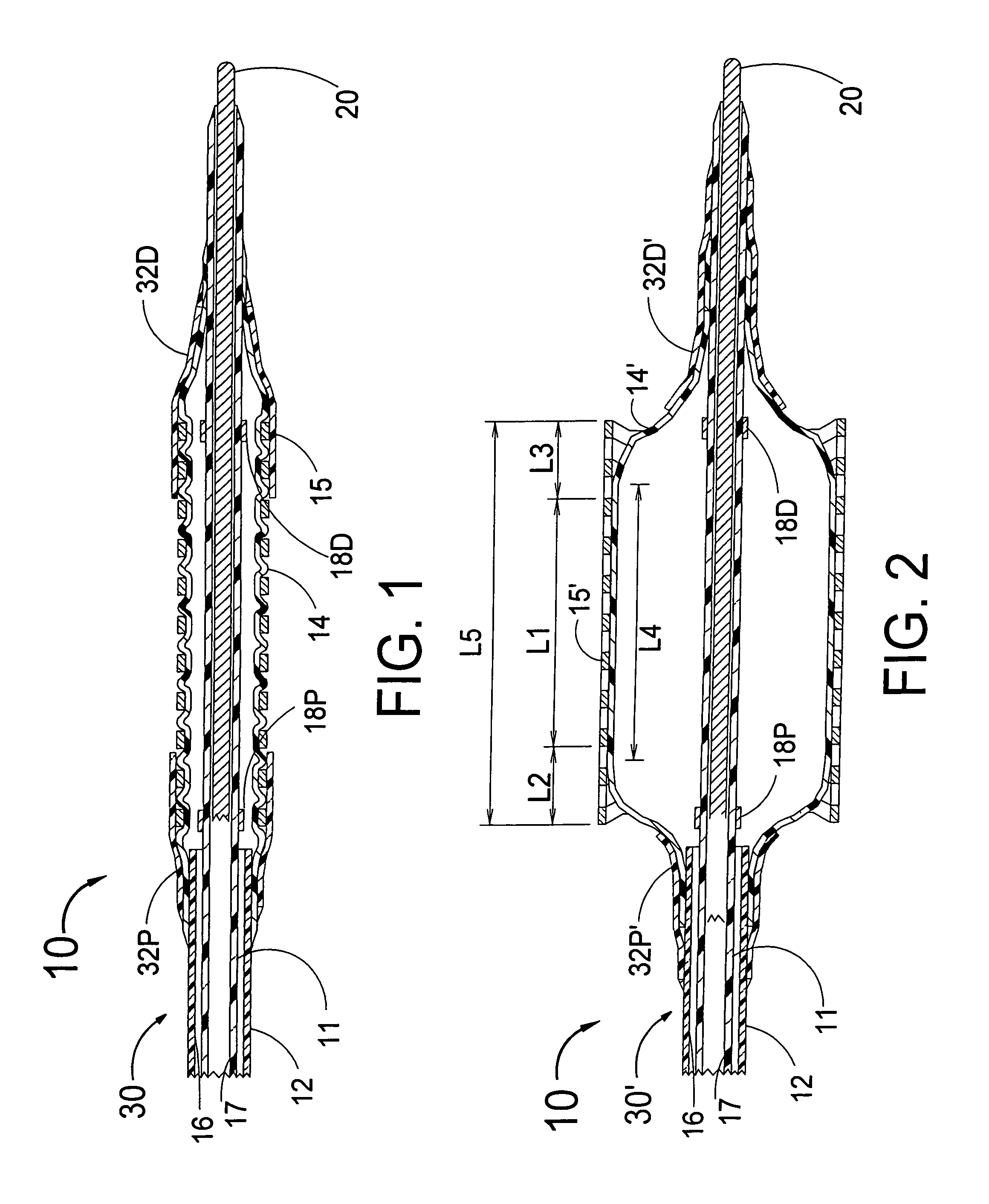

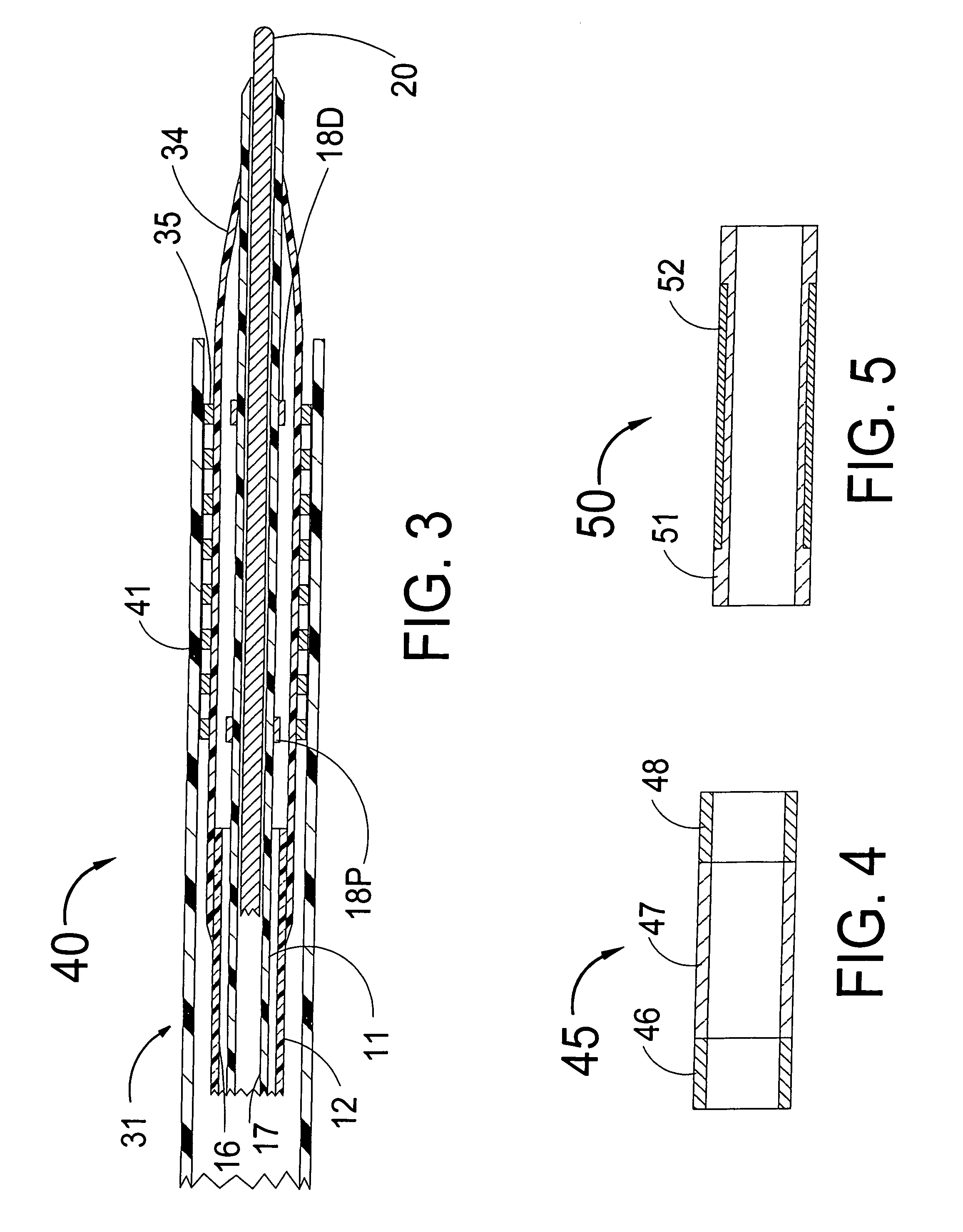

Stent with self-expanding end sections

A hybrid stent that is defined as having a central section that is balloon expandable and end sections that are self-expanding. The entire stent is mounted on a balloon of a balloon angioplasty catheter. One way to retain the self-expanding portion of the stent onto a balloon onto which it has been nested is to place a cylindrical elastomer tube around each of the self-expanding end sections of the stent. Another way to retain the hybrid stent onto a stent delivery system is to use a conventional sheath that is pulled back to initiate stent deployment

Owner:SALMON SEAN +4

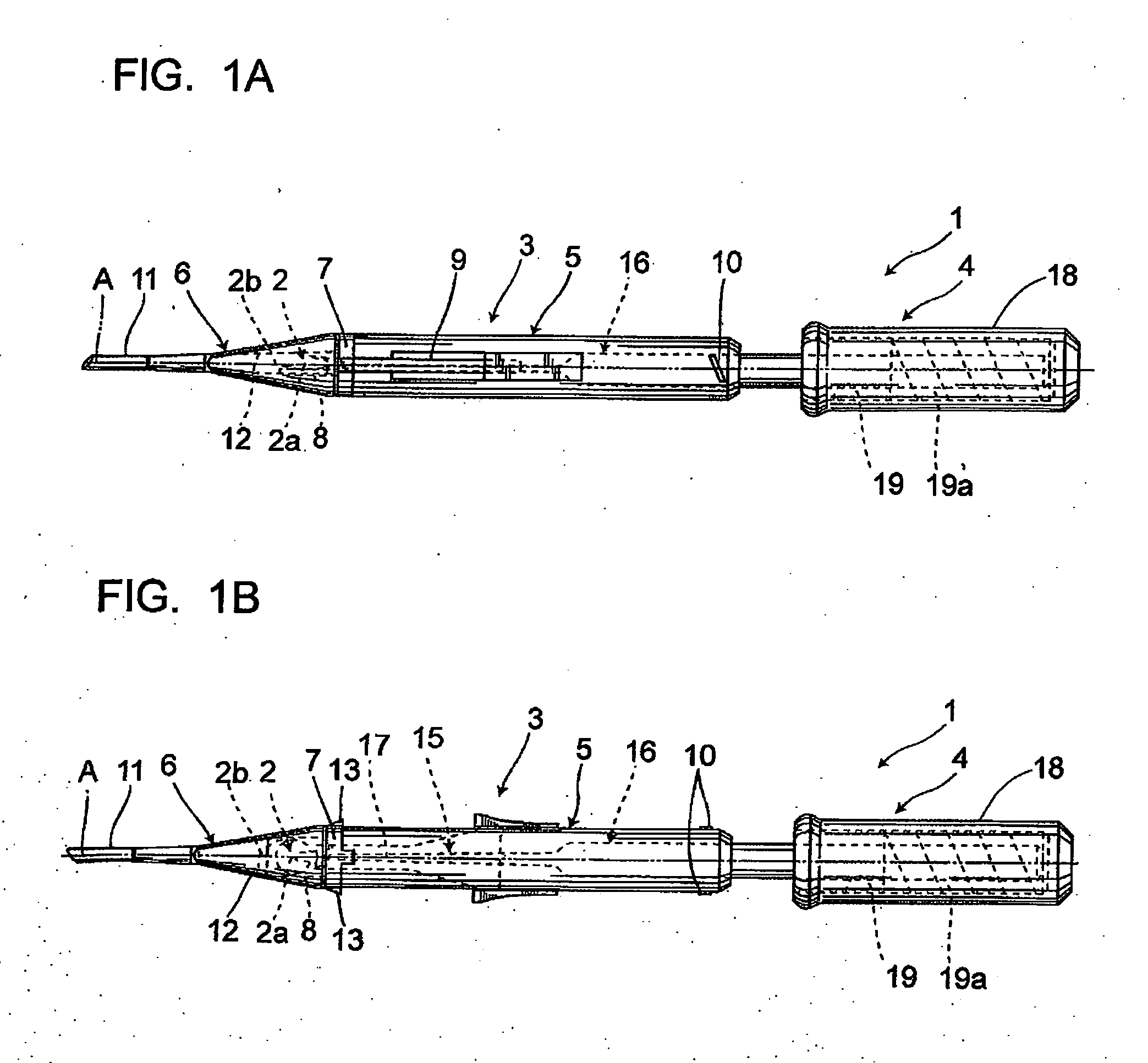

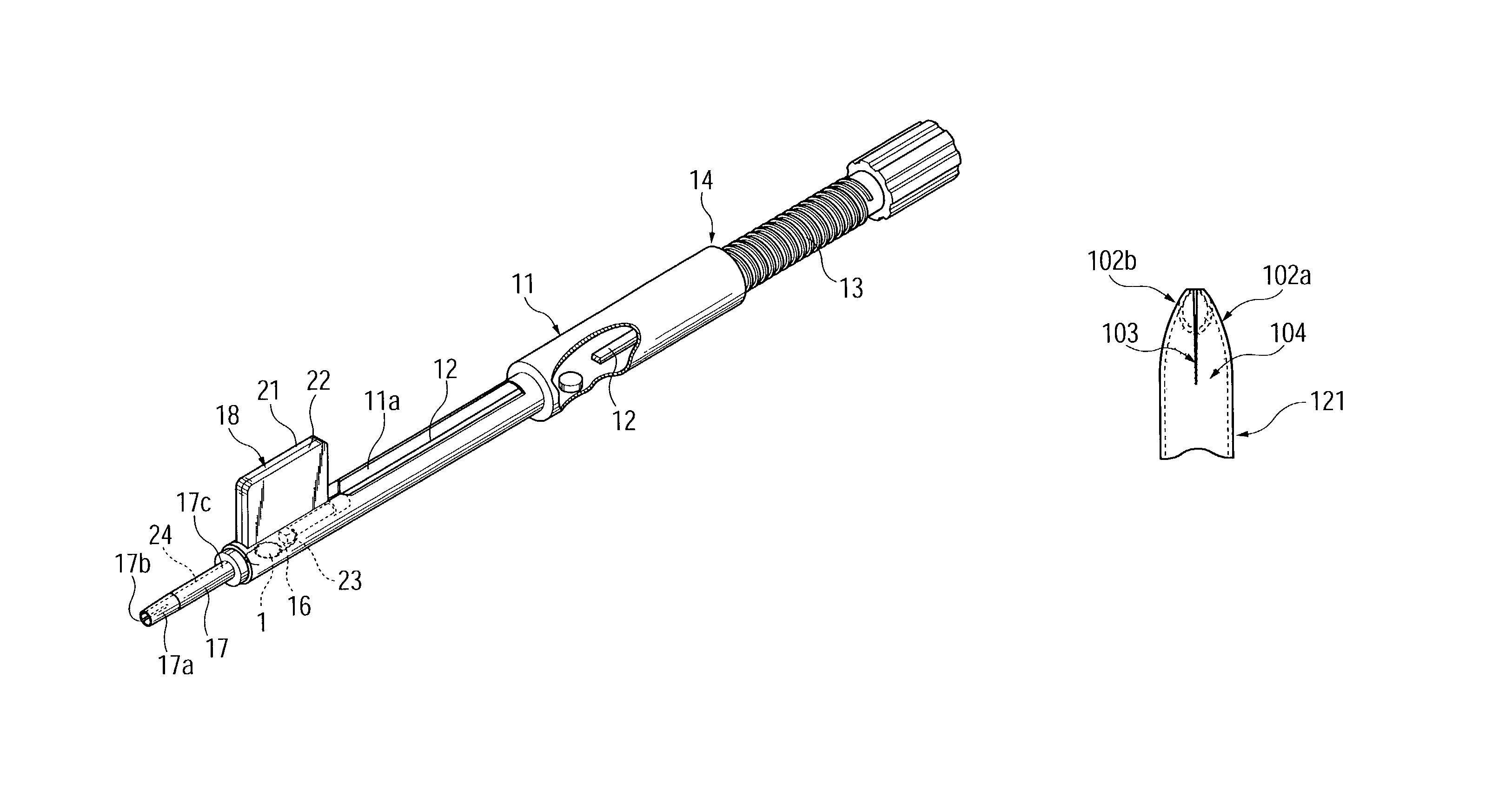

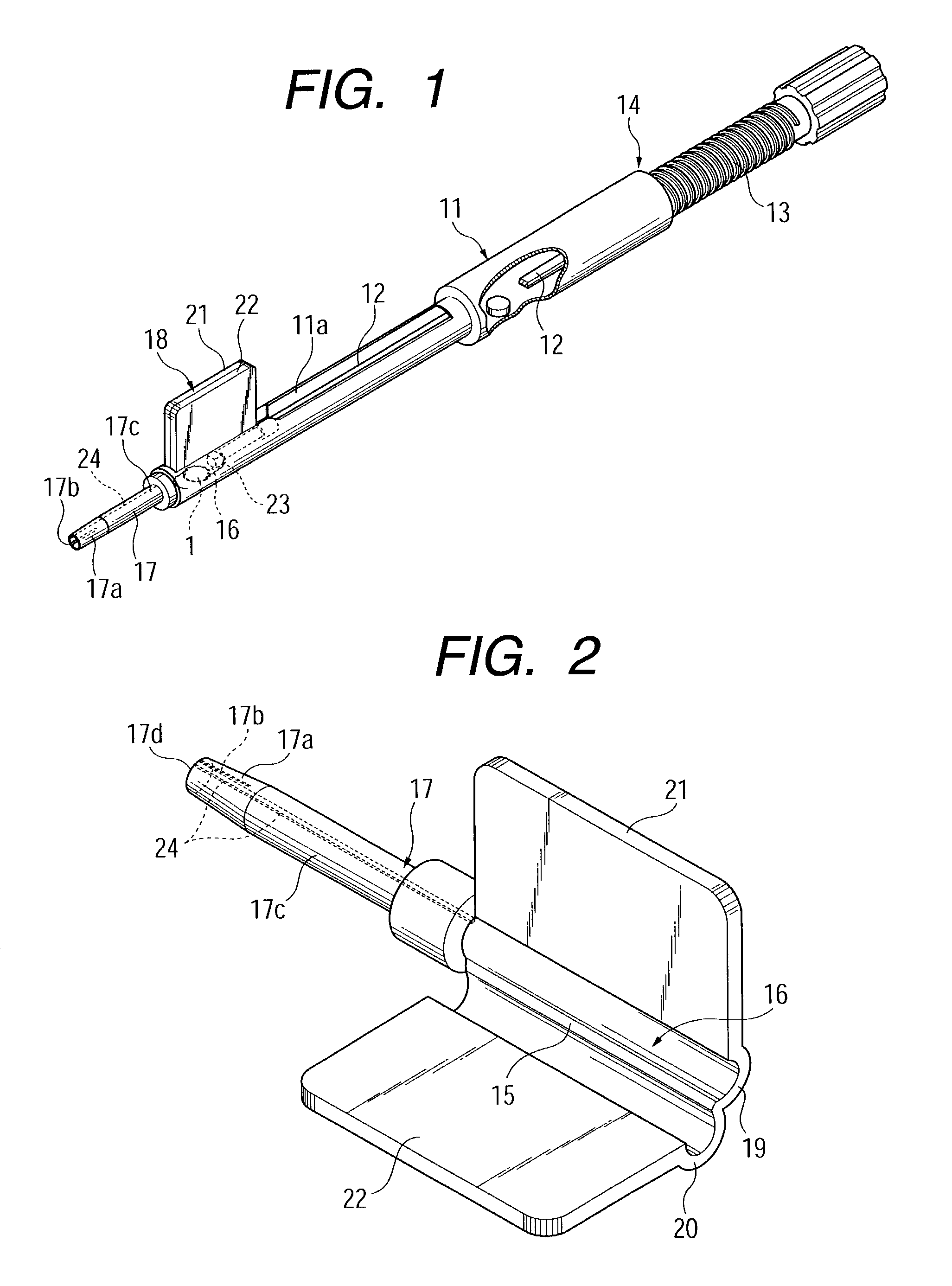

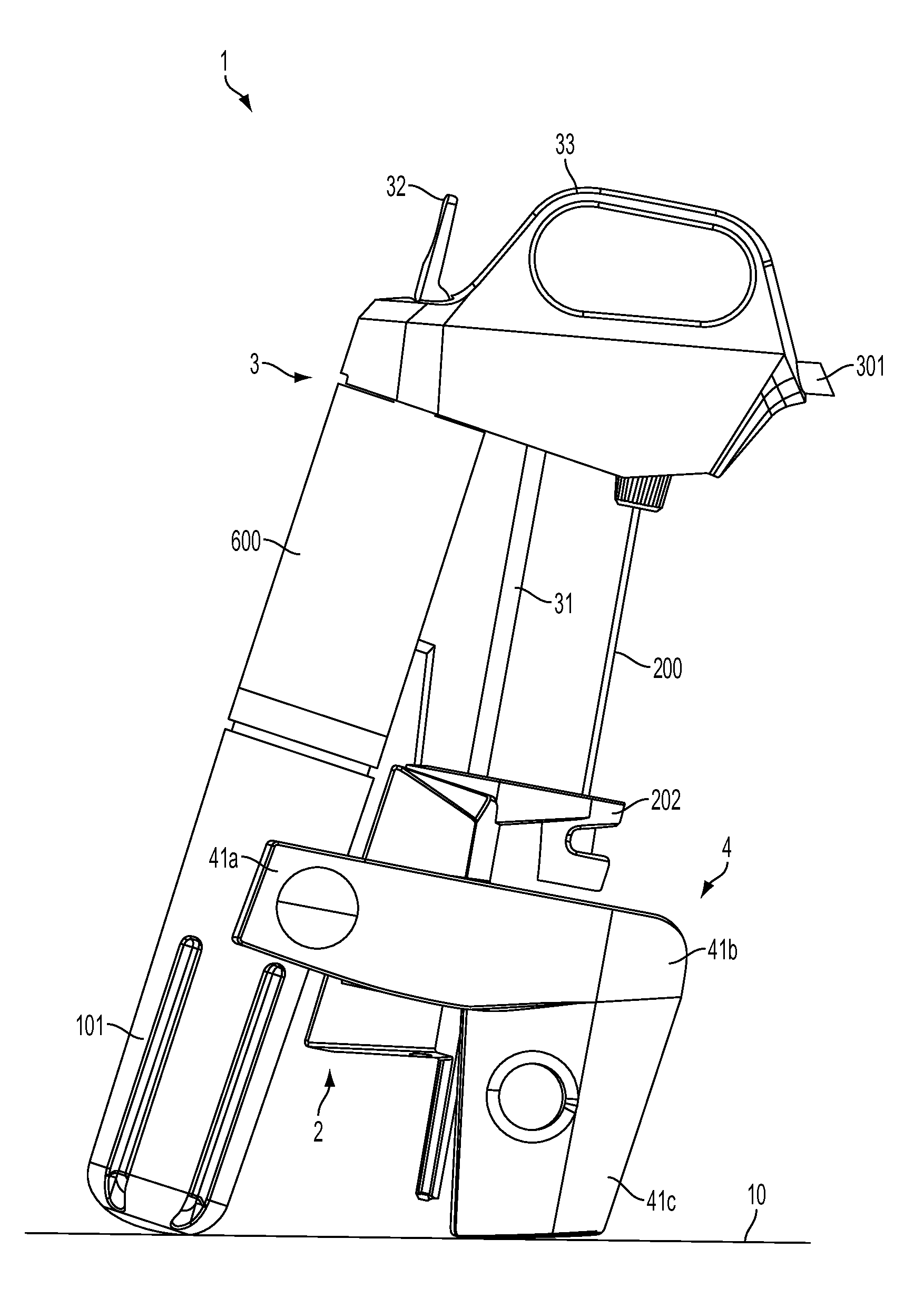

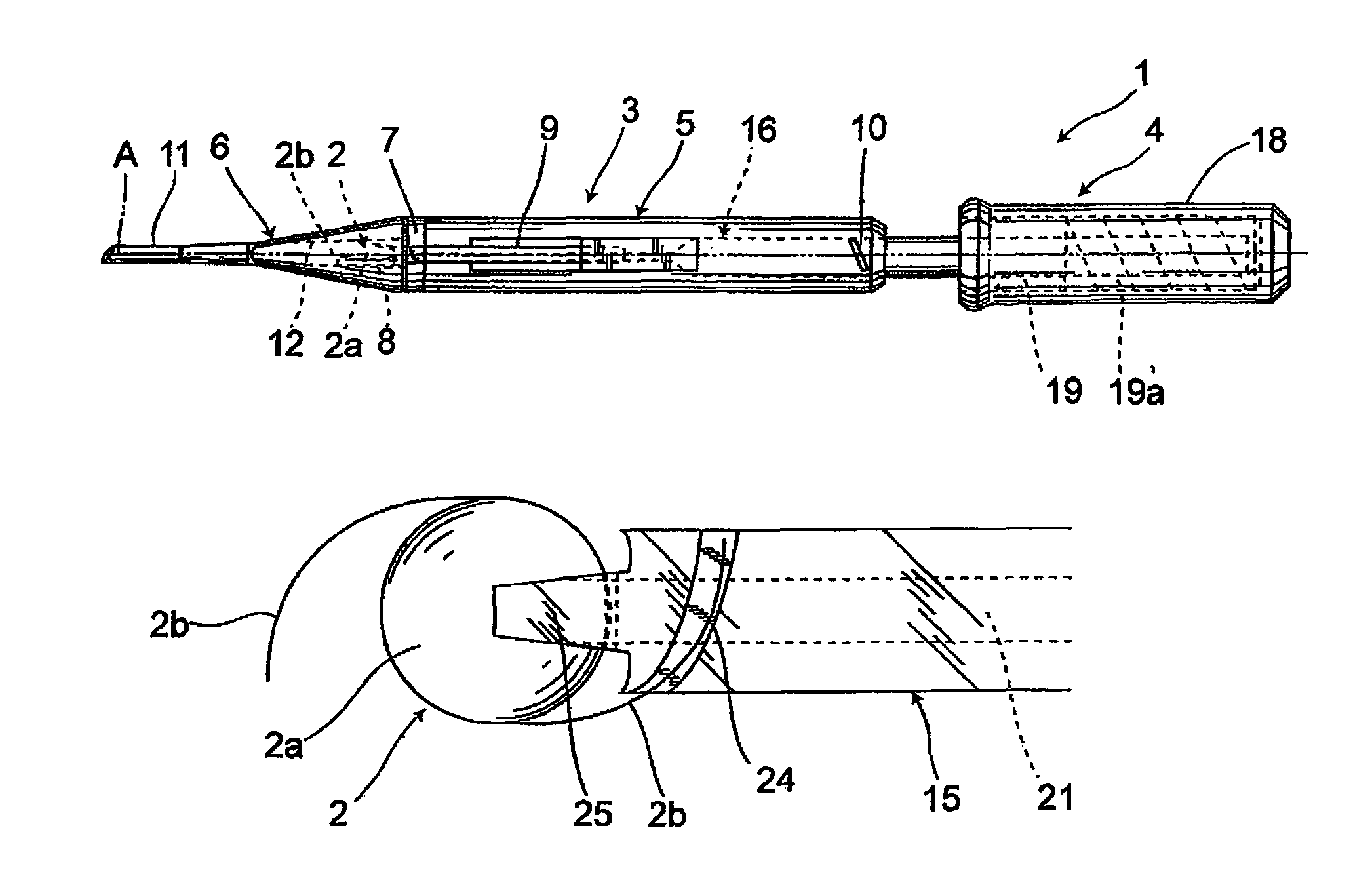

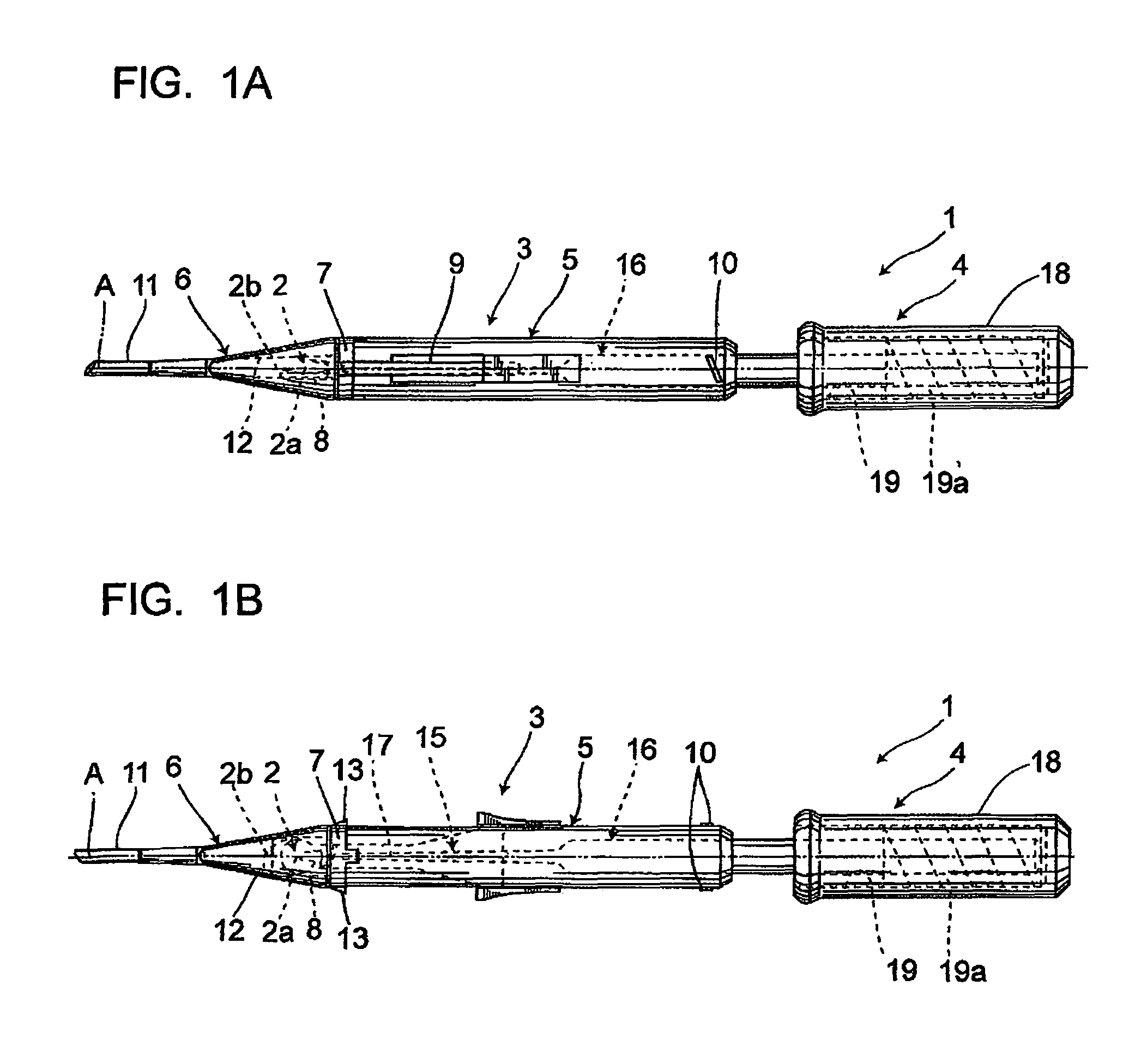

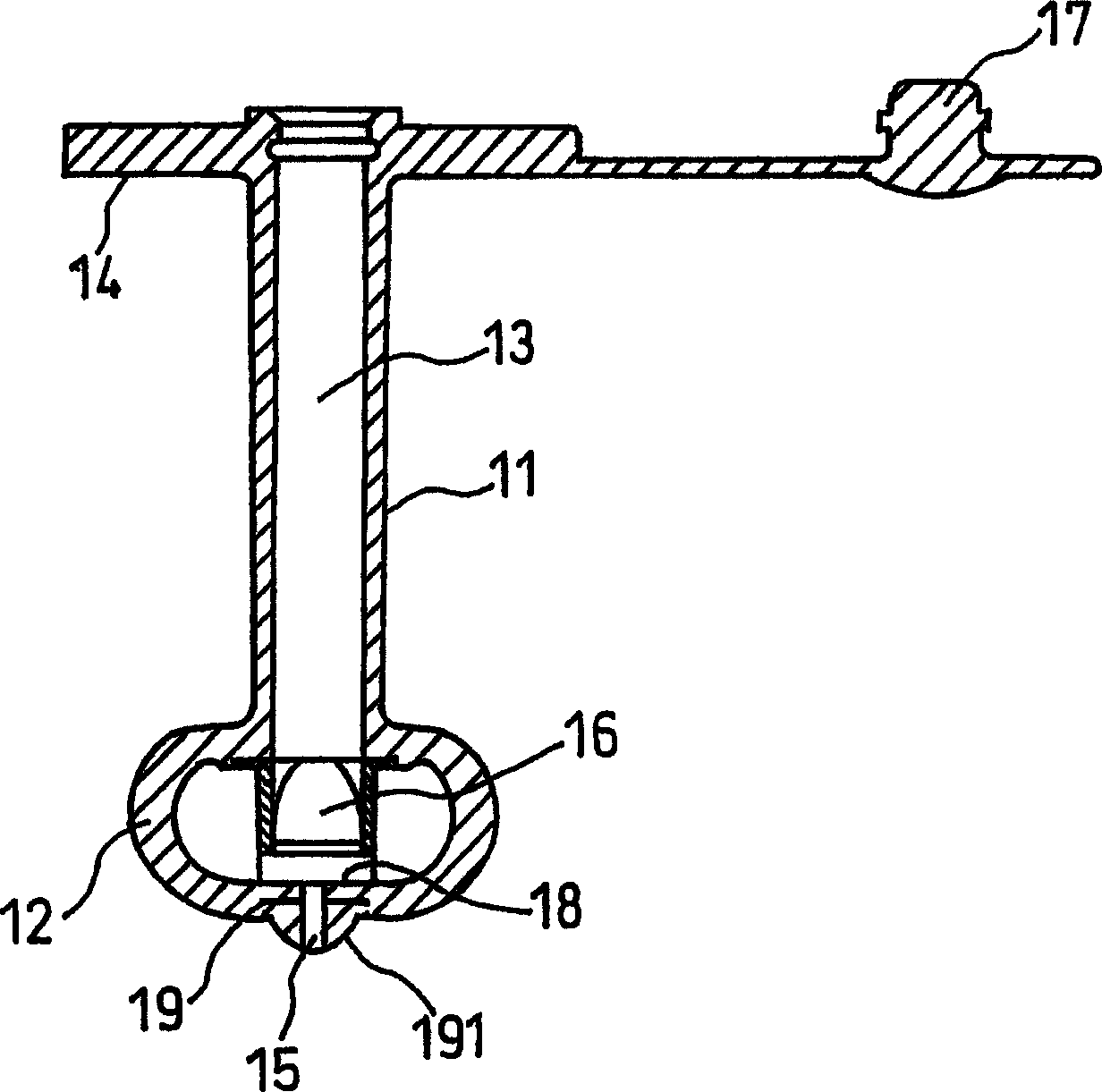

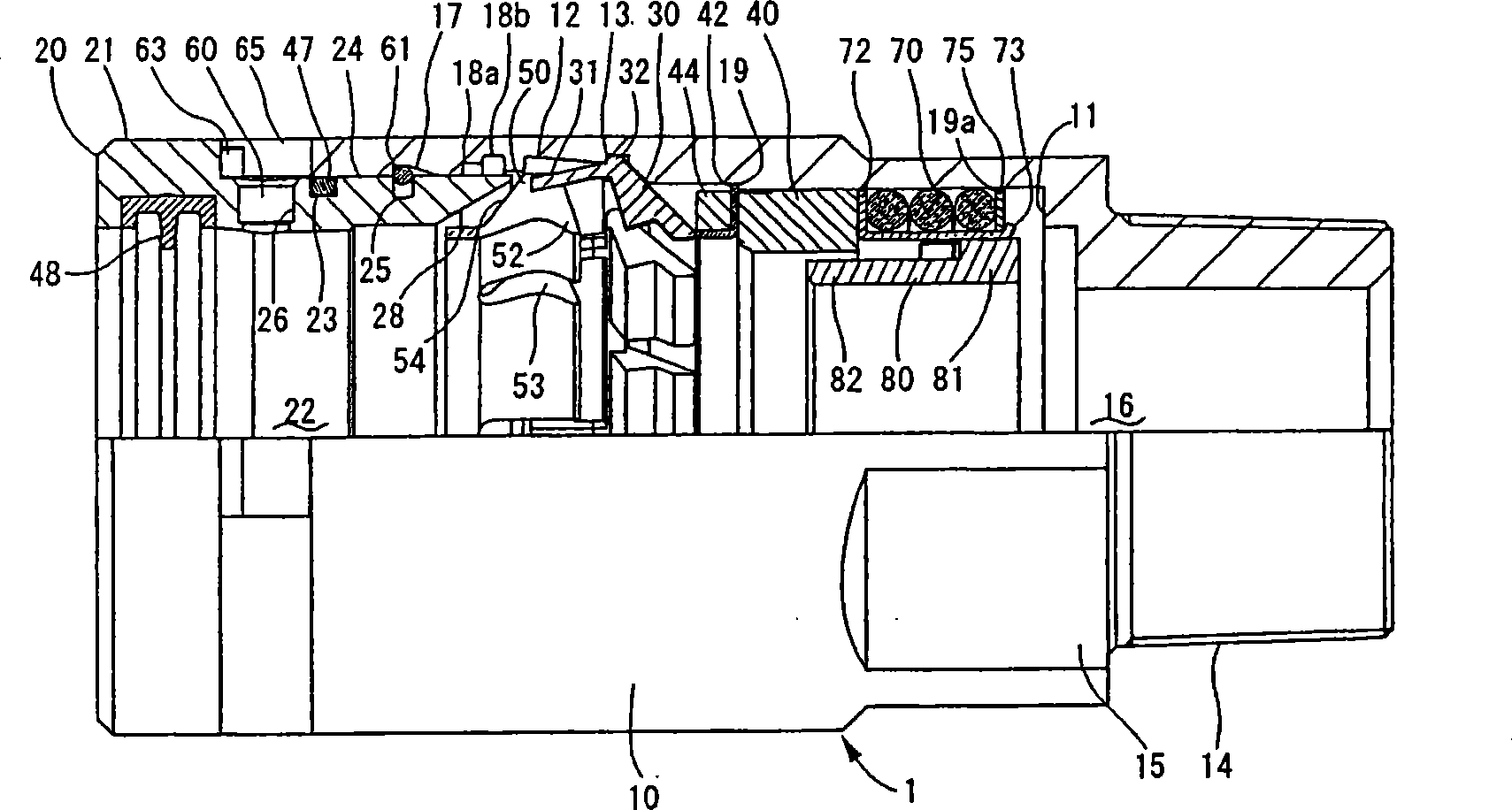

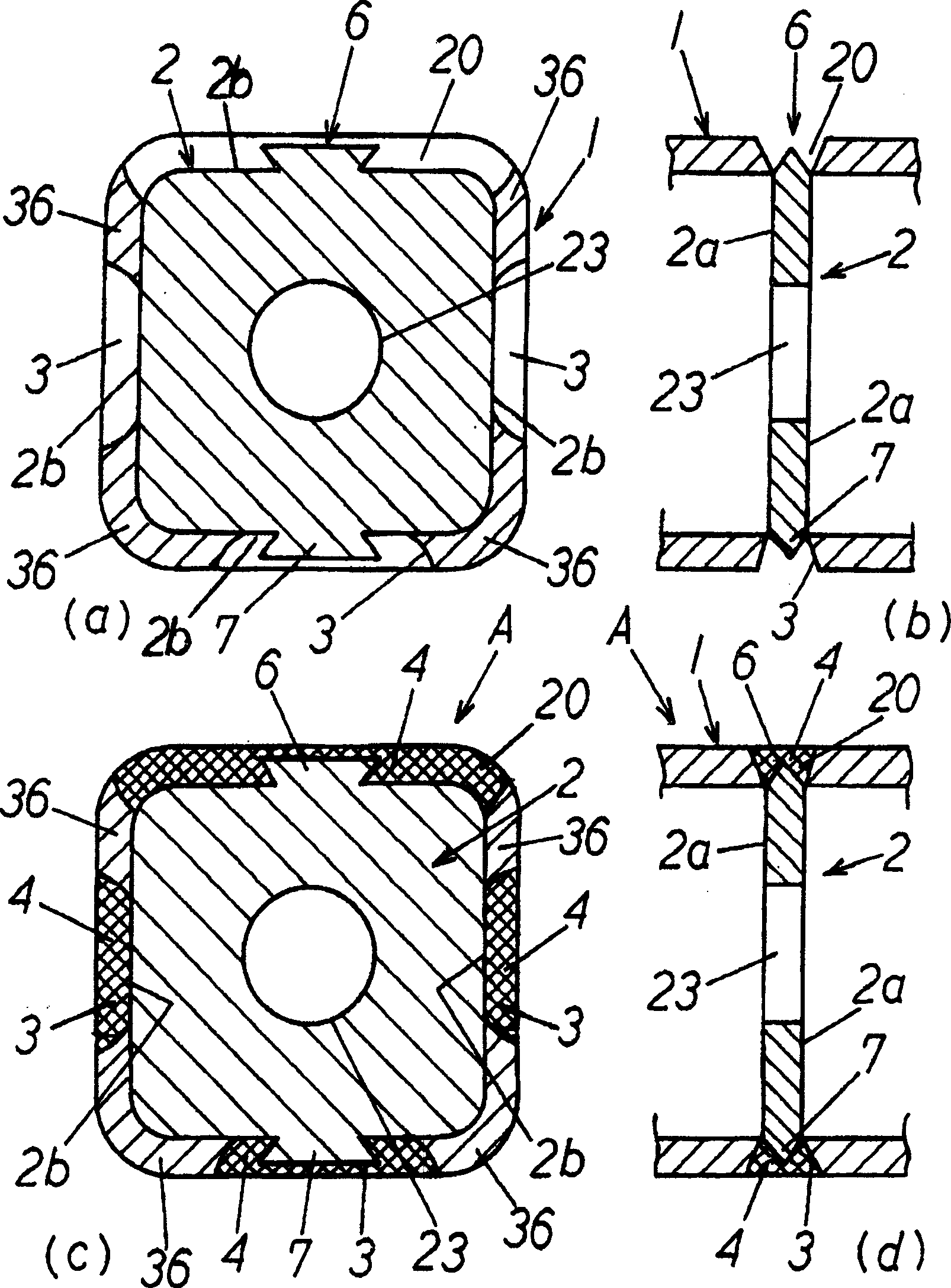

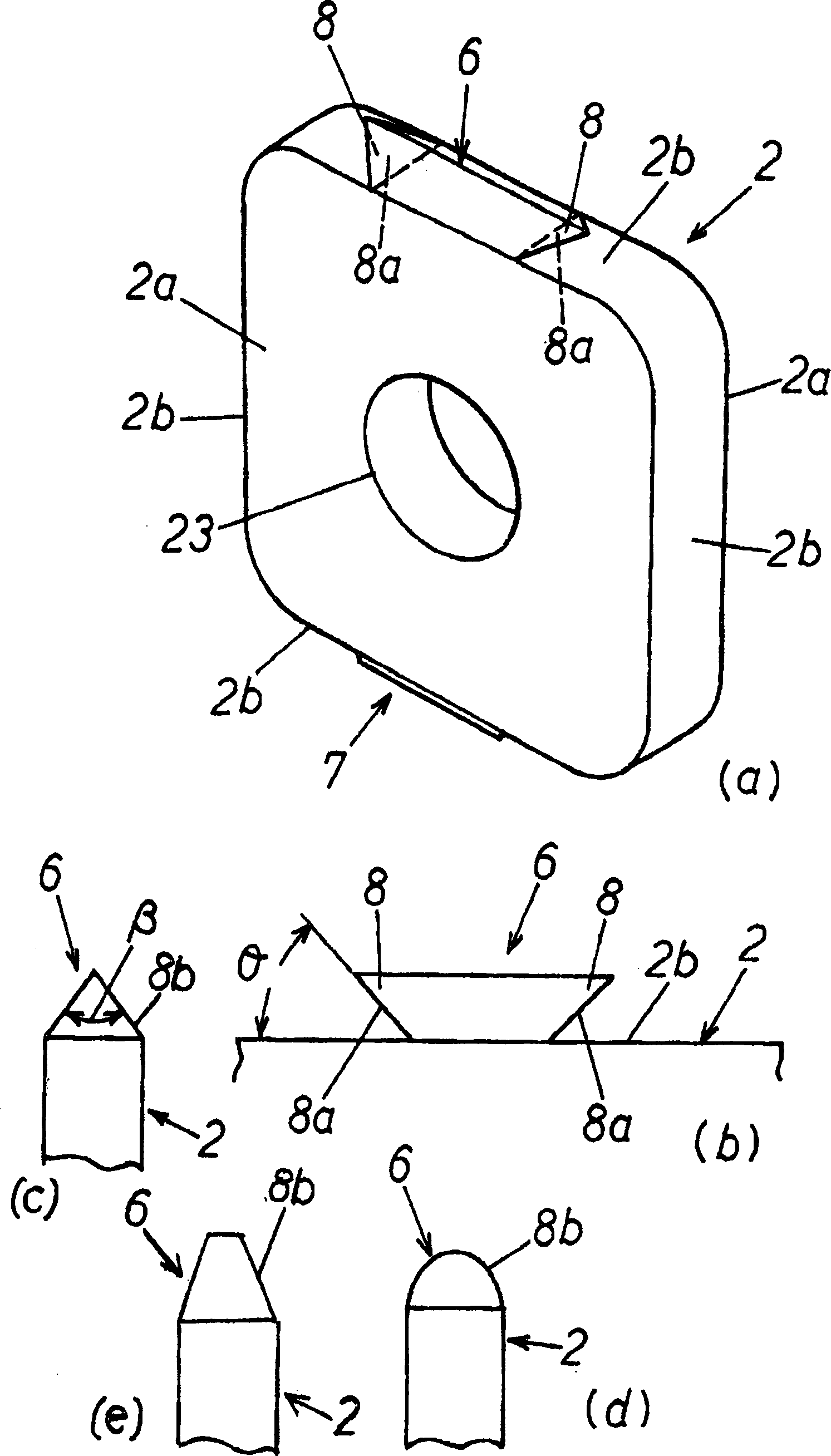

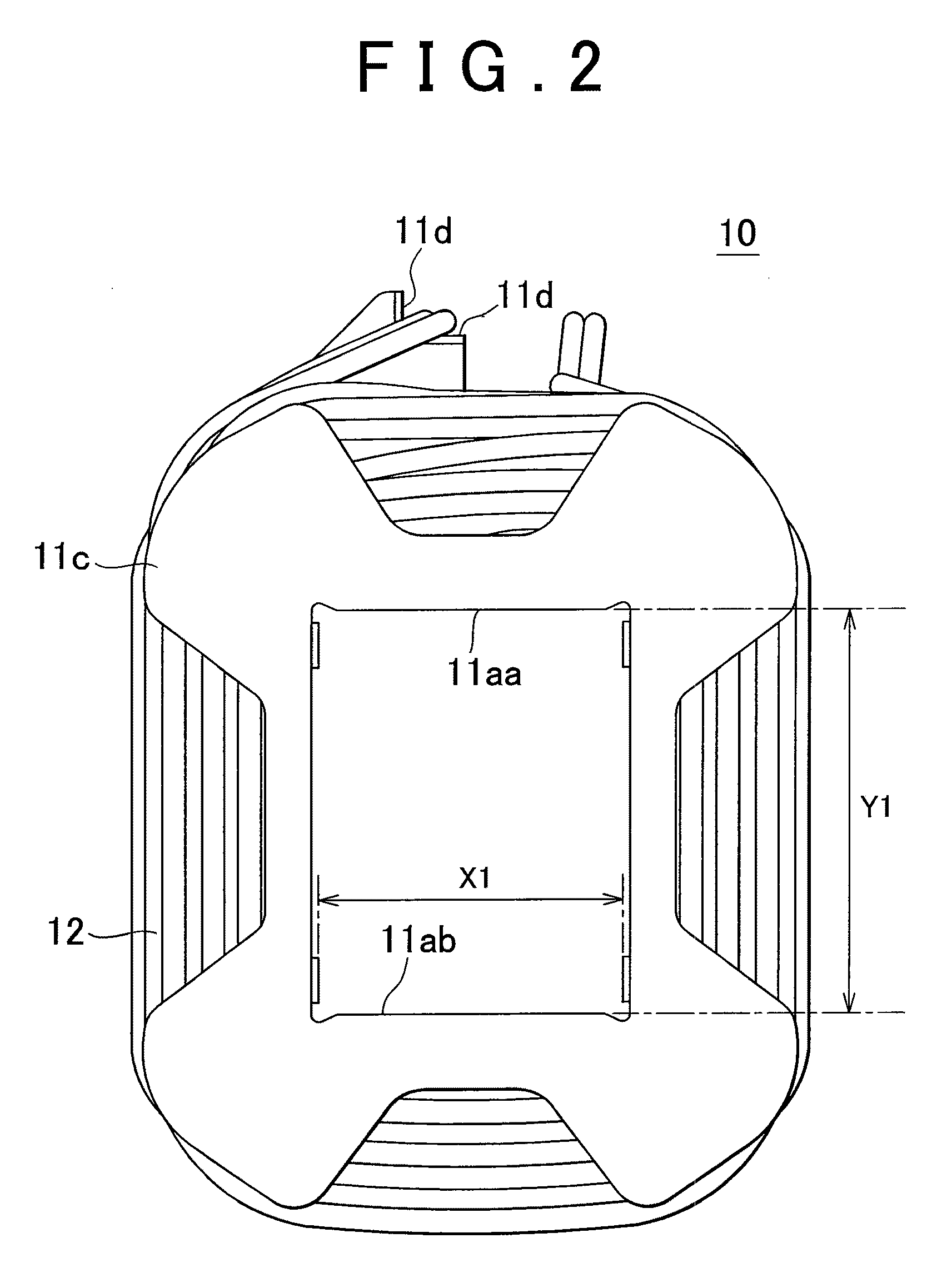

Instrument For Inserting Intraocular Lens

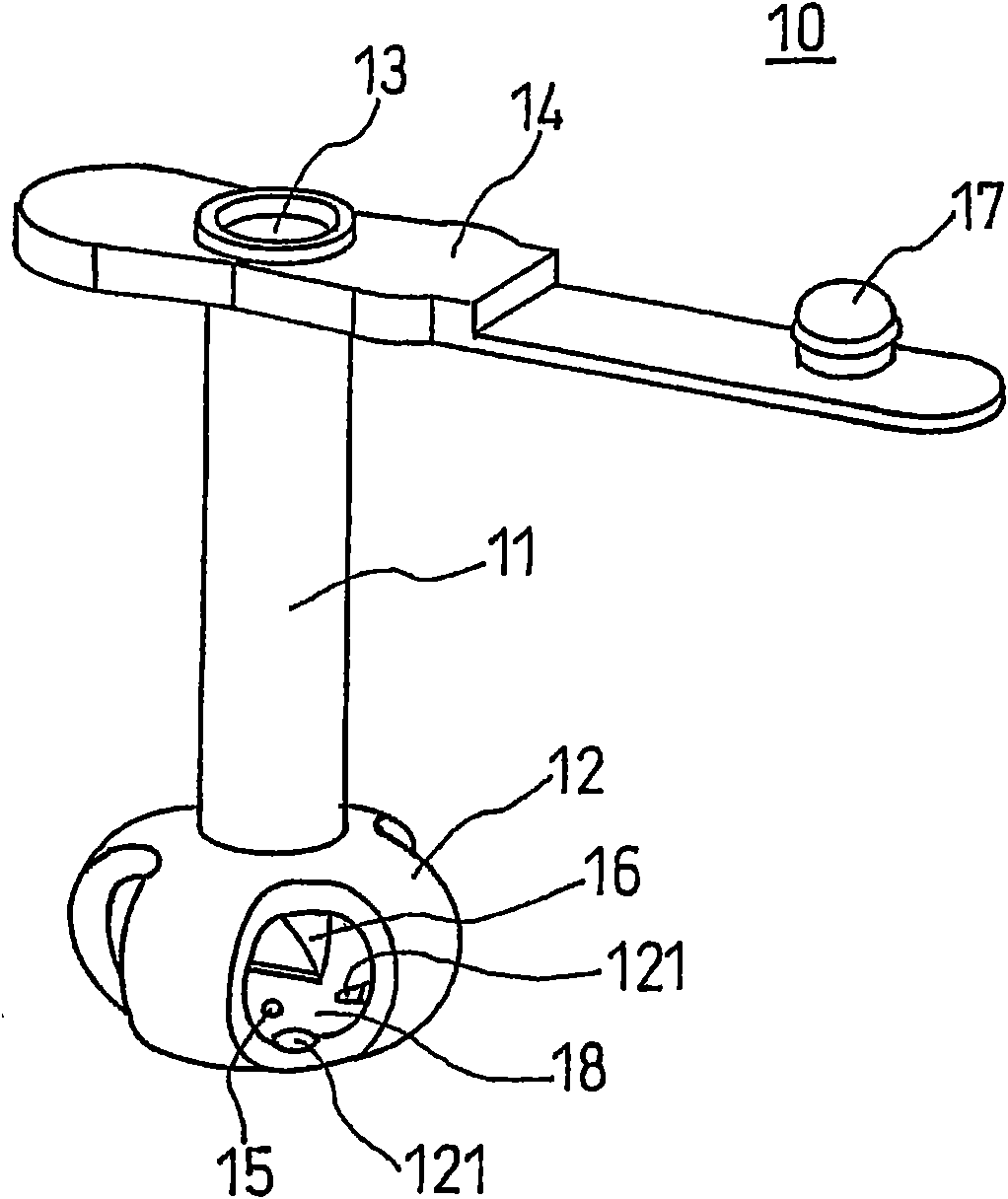

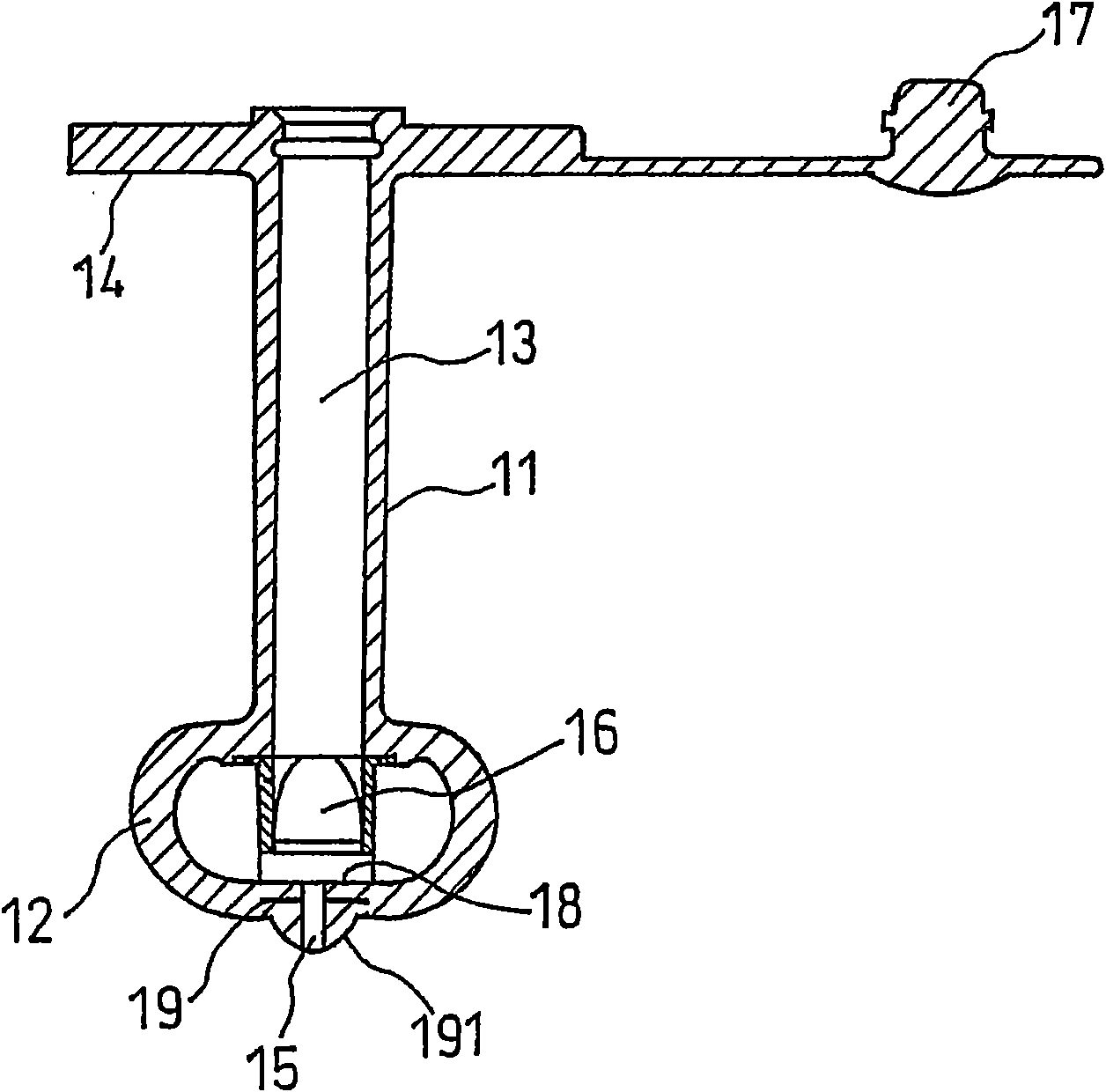

ActiveUS20090036898A1Simple structureGuaranteed uptimeEye surgeryIntraocular lensCamera lensIntraocular lens insertion

An intraocular lens insertion device for inserting an intraocular lens capable of securely and safely pushing out the lens by a simple structure. An intraocular lens insertion device (1) comprises: a main body (3) having a lens placement portion (8) on which the lens (2) with a pair of loop parts (2b) at its optic part (2a) is placed, a transition portion (12) deforming the lens (2), and a nozzle portion (11) discharging the lens (2); and a lens push-out mechanism (4) pushing out the lens (2) placed on the lens placement portion (8). The lens push-out mechanism (4) comprises a plunger (16) pushing out the lens (2) and a slider (15) having a lens contact part (20) larger than the plunger (16). The slider (15) comprises an operating part (23) projected to the outside of the body (3).

Owner:HOYA CORP

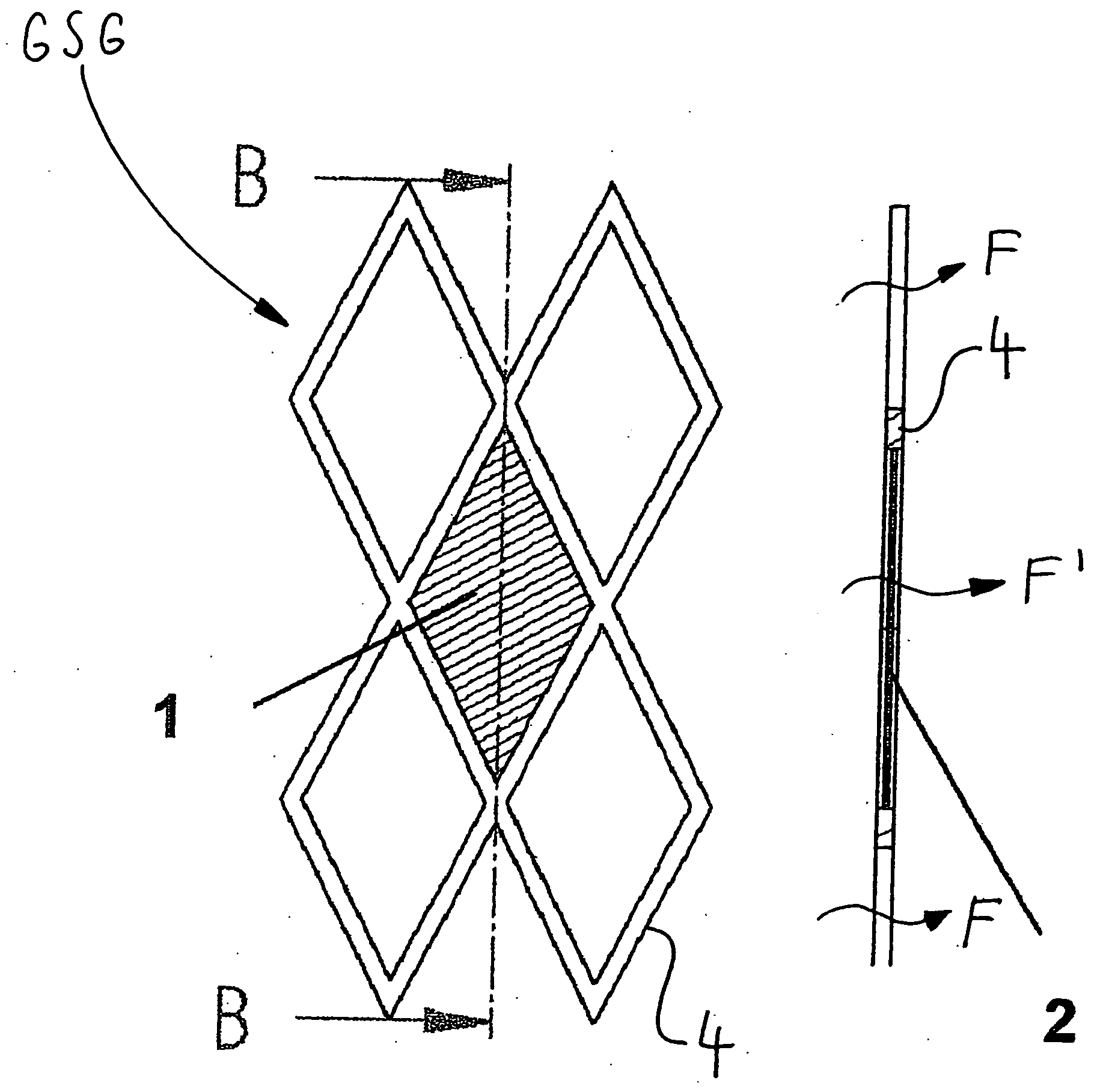

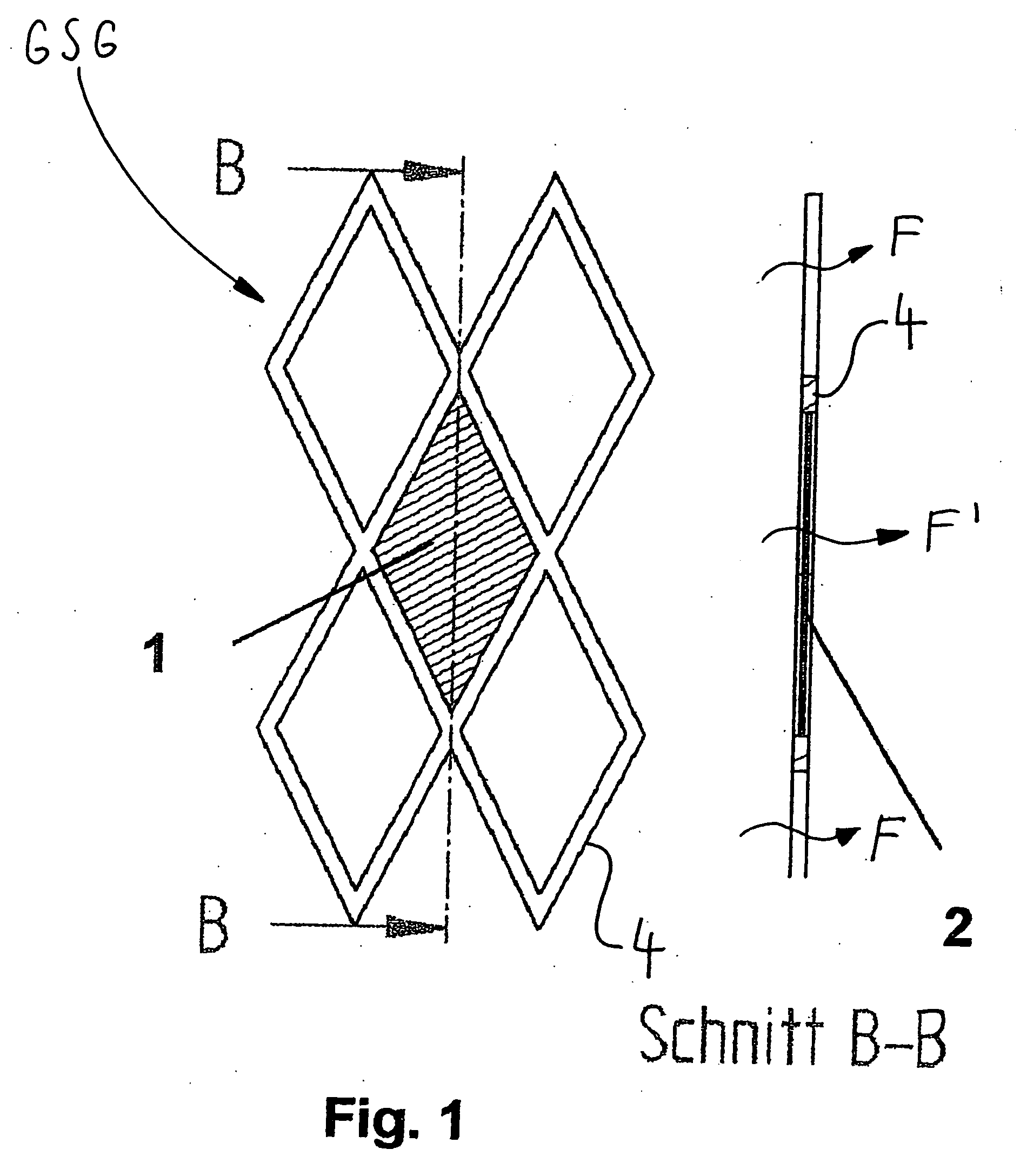

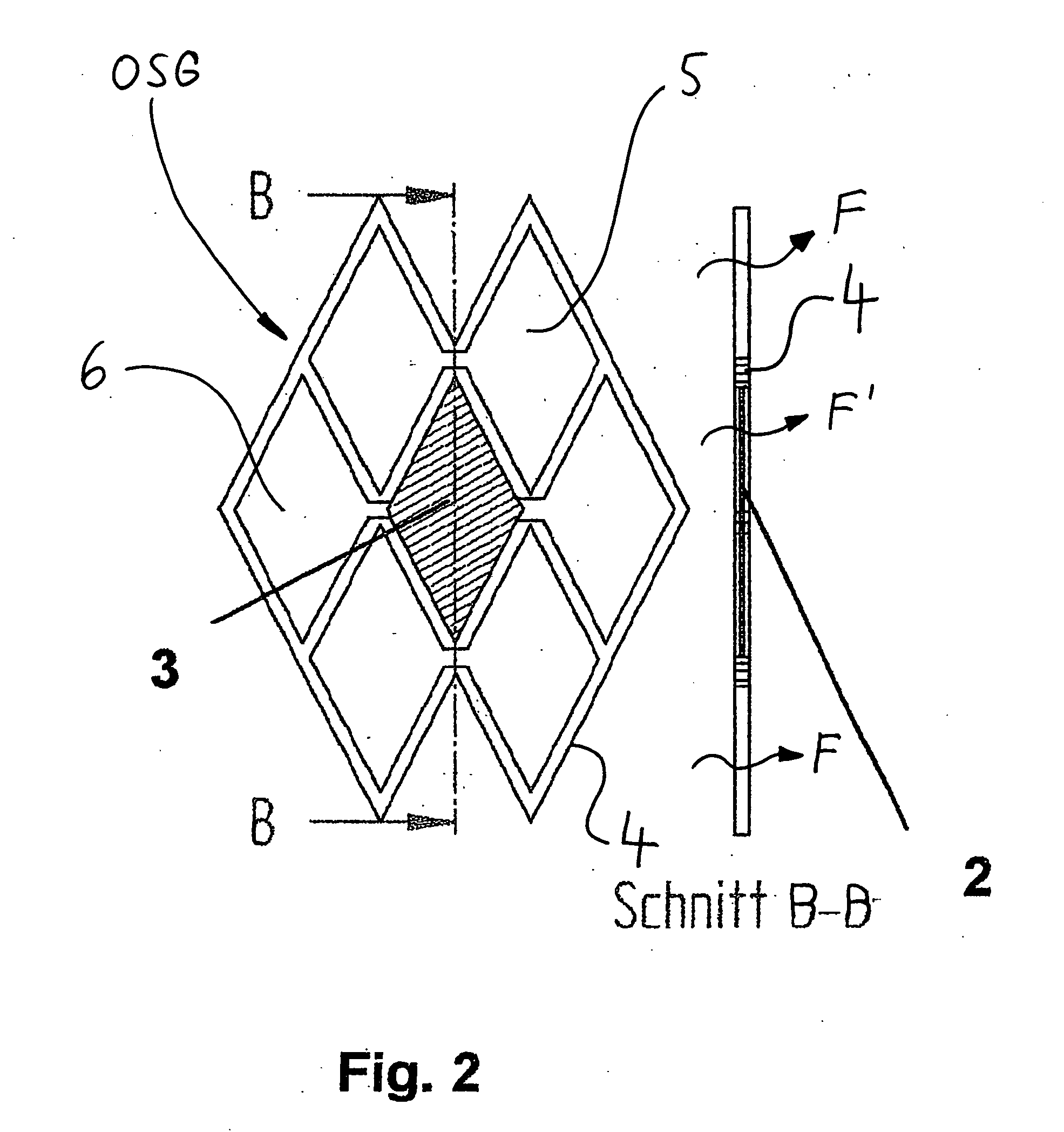

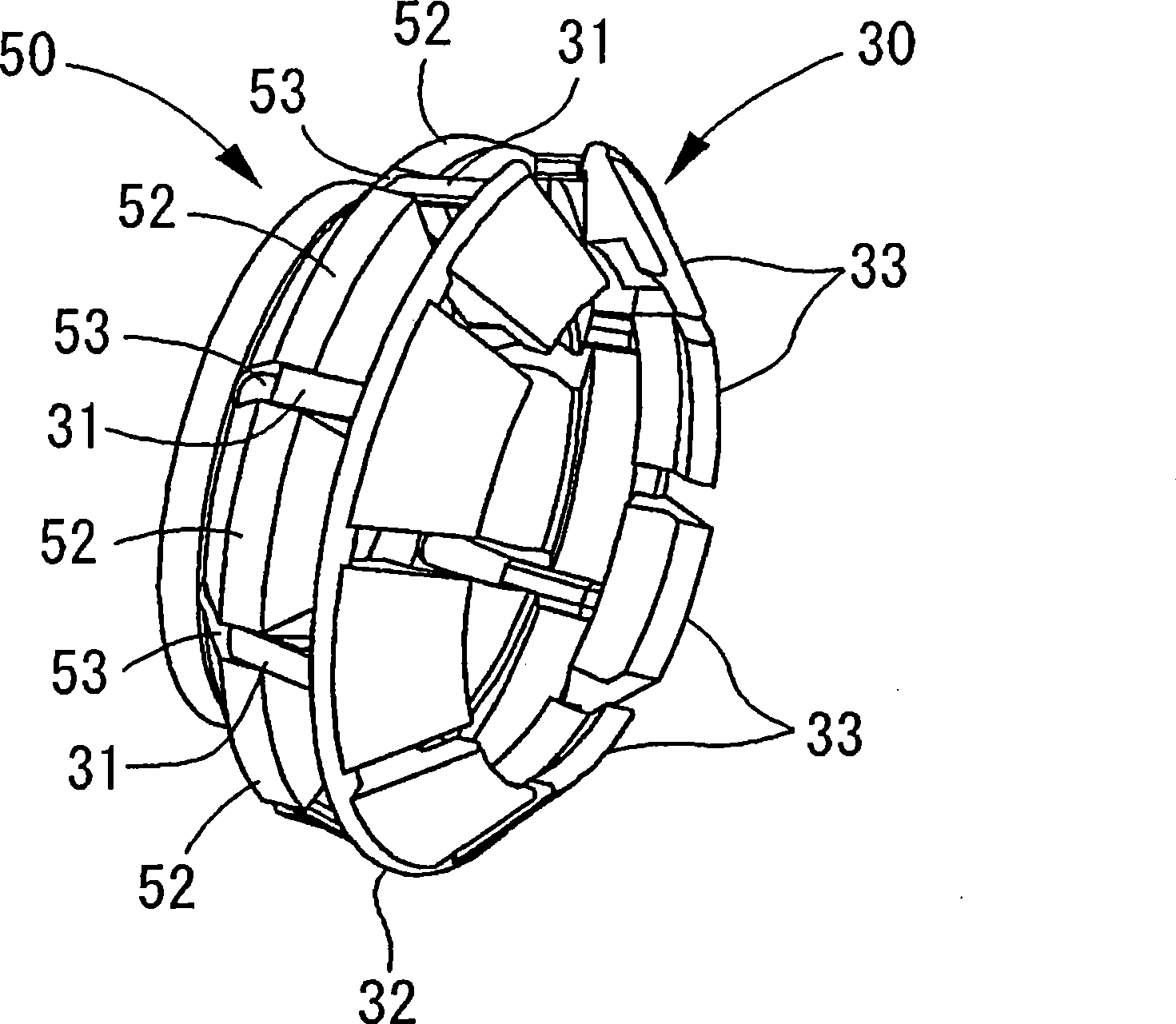

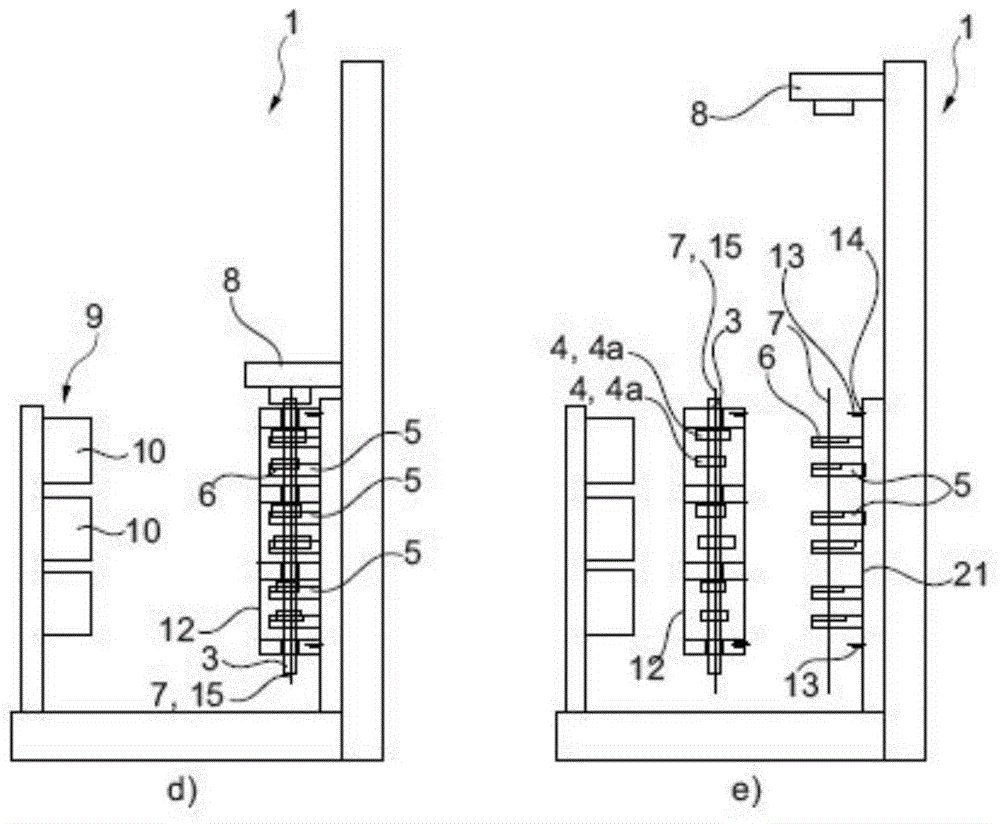

Stent

The present invention relates to an aneurysm stent for implantation into a living body, in particular for treatment of aneurysms, in order to implant the stent in the compressed state in a vessel and expand the stent after positioning it in the vessel, having a grid or mesh structure and at least one membrane (2) or a plurality of membranes (2) for covering at least one or more stent cells (1; 3) in the grid or mesh structure, thereby matching the permeation characteristics of the stent structure to the particular characteristics of the aneurysm.

Owner:ADMEDES SCHUESSLER

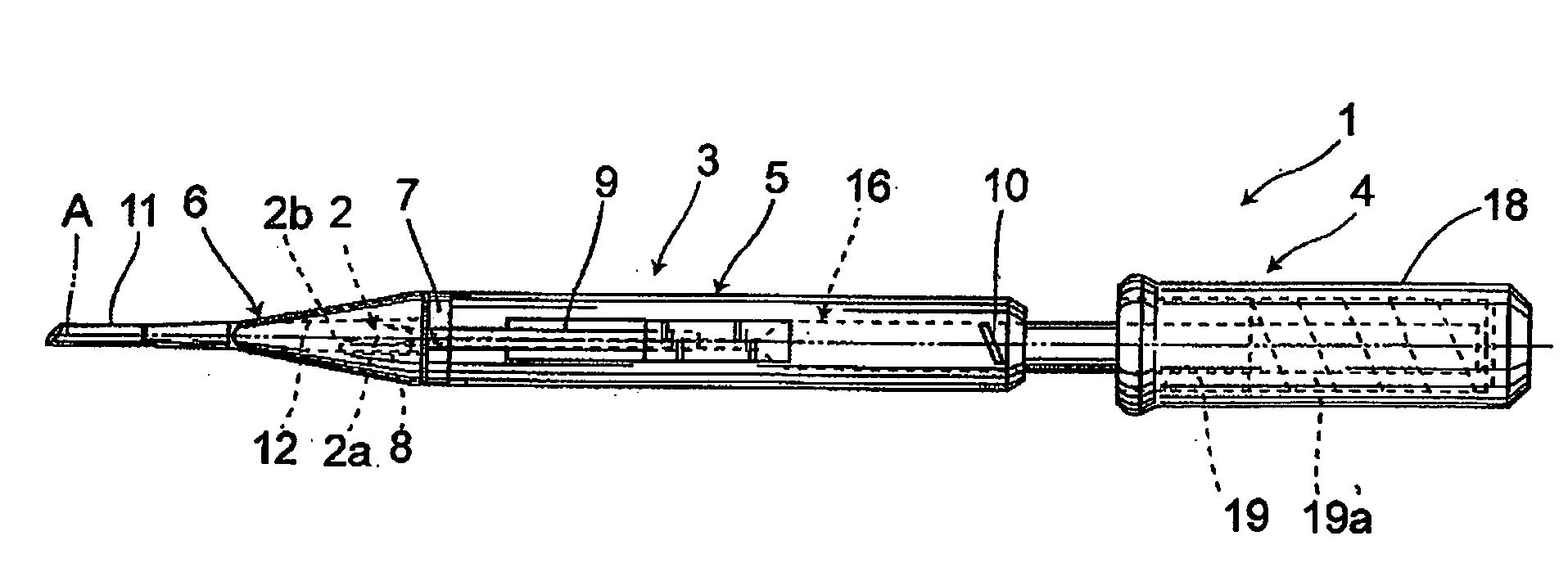

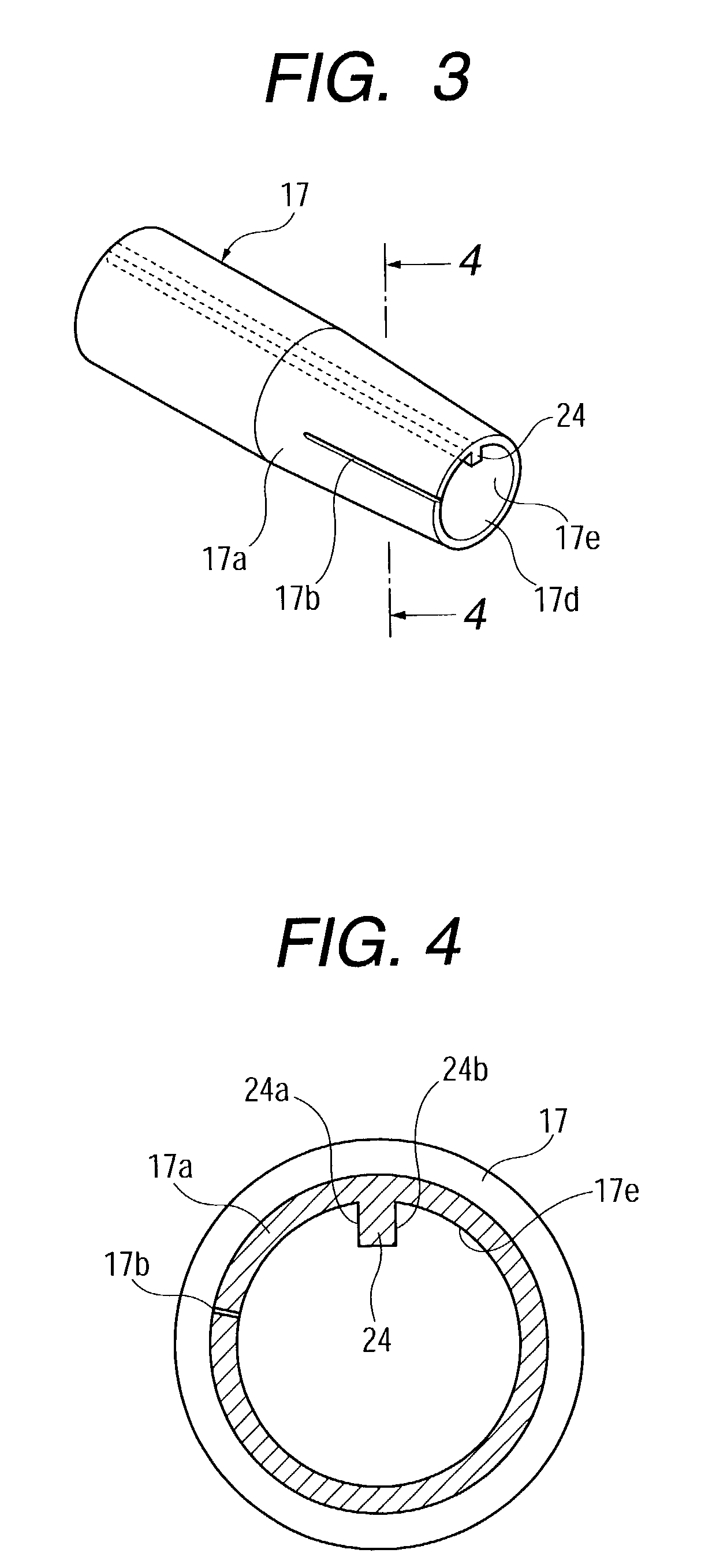

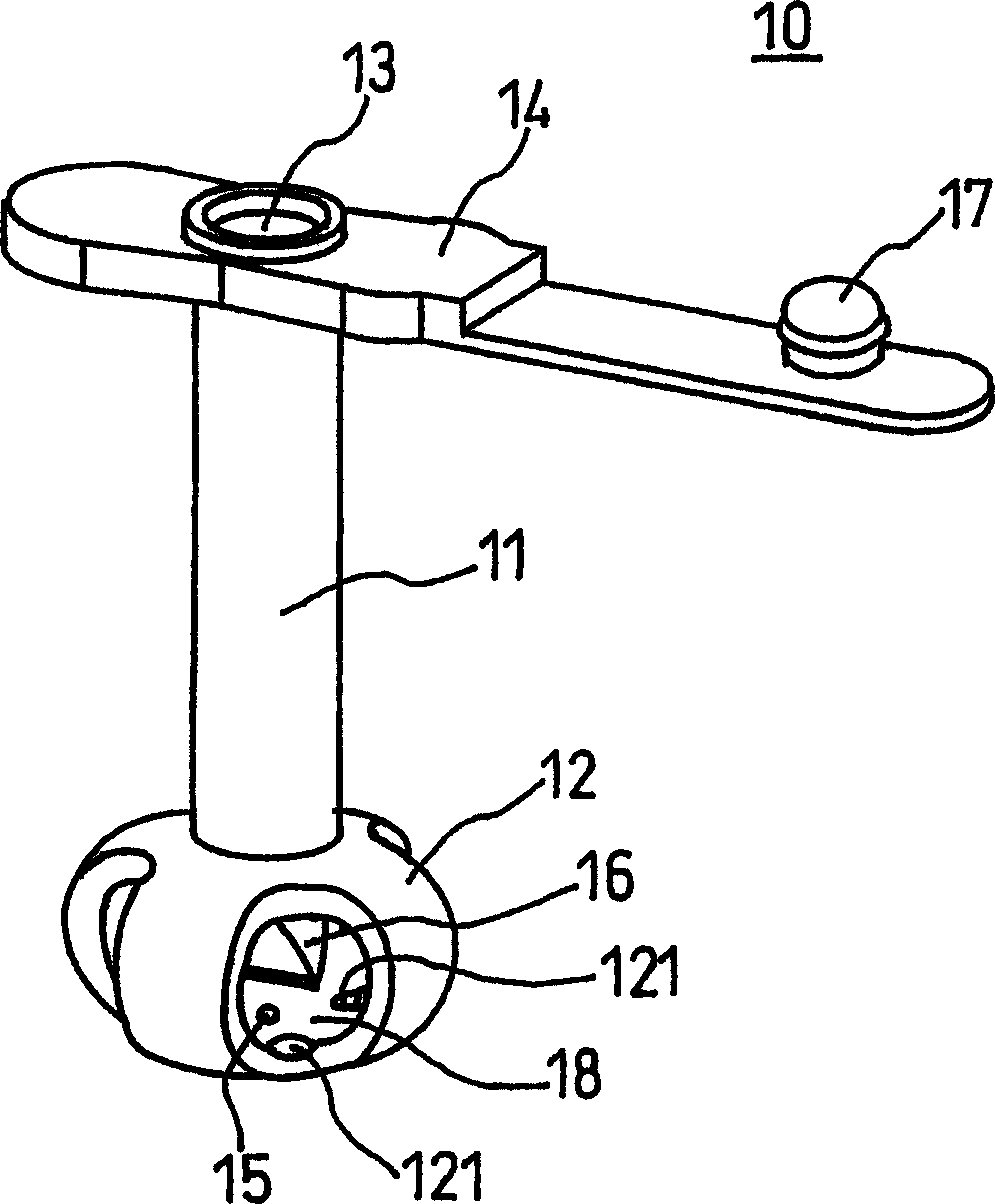

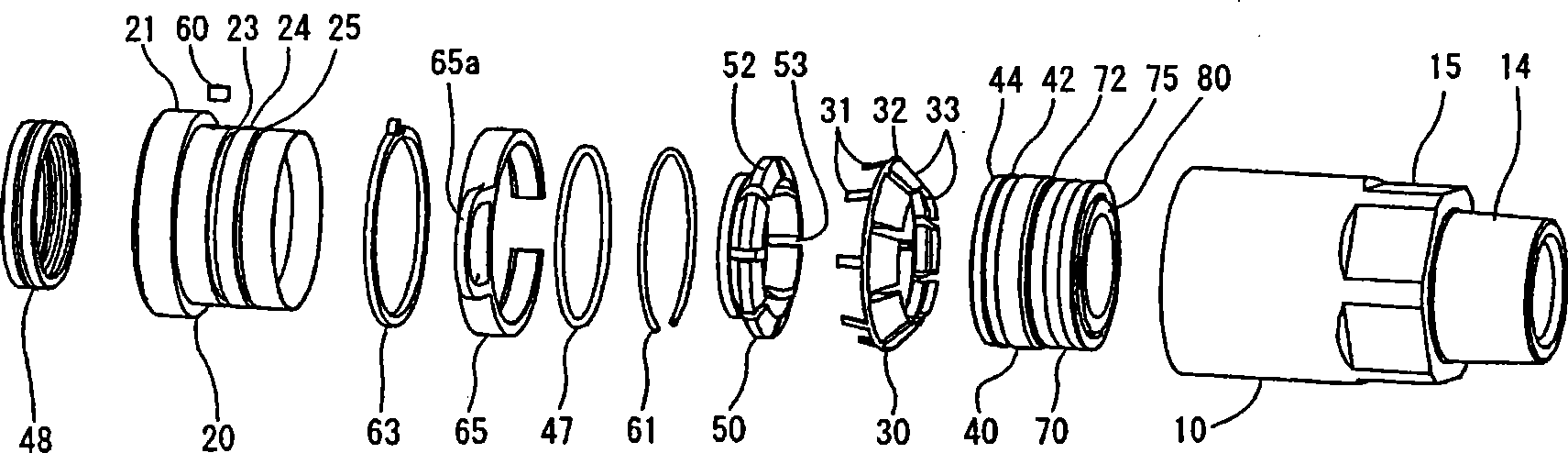

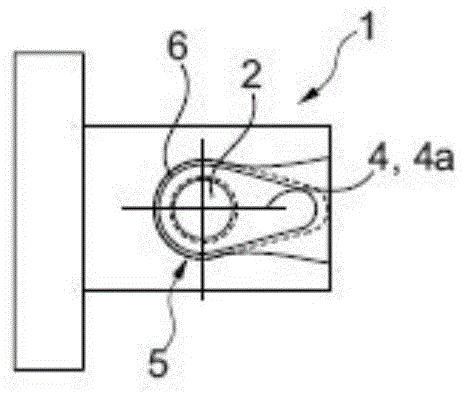

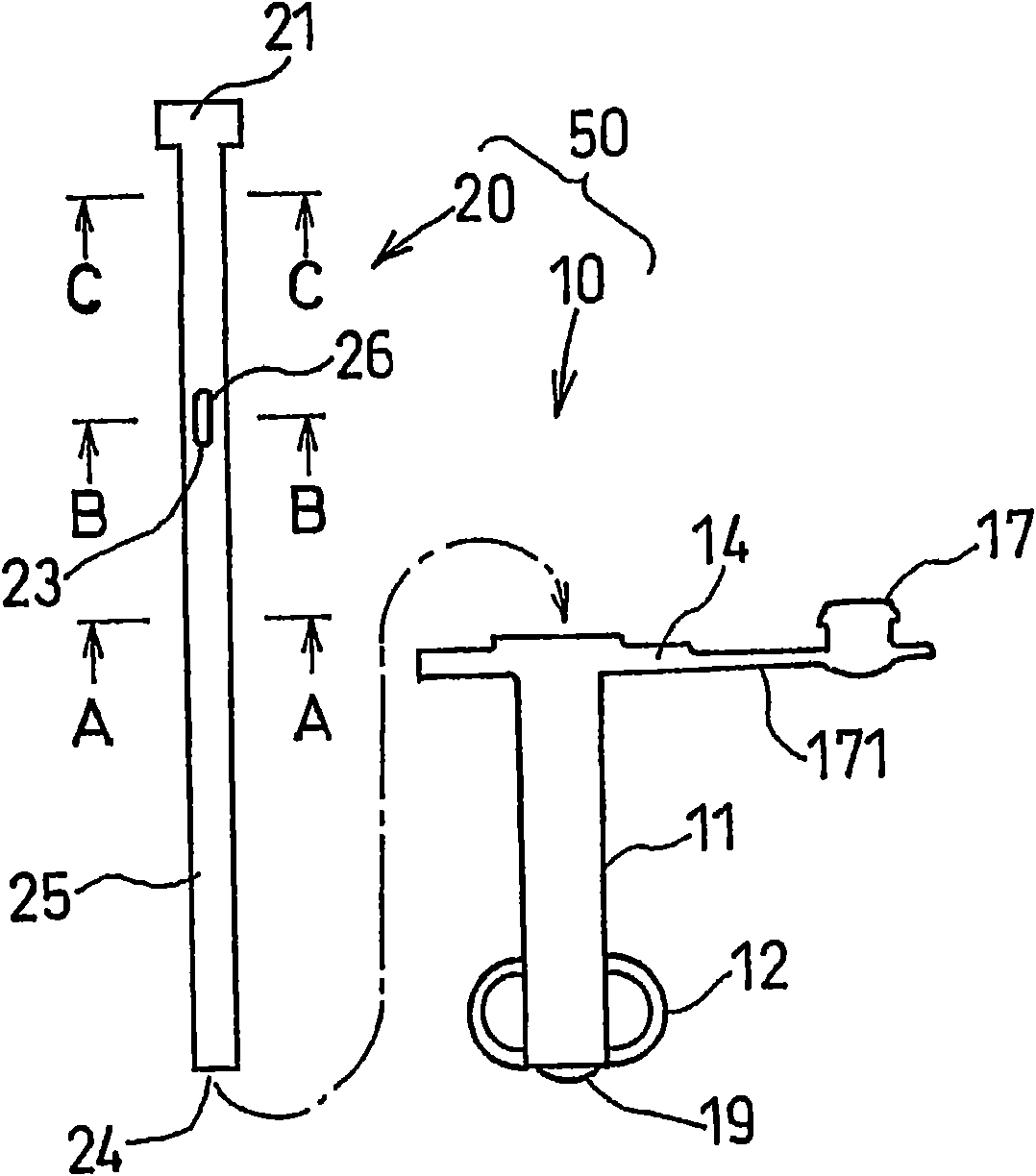

Insertion device for deformable intraocular lens

ActiveUS7037312B2Stably maintain insertion direction and insertion speedPrevent rotationSurgeryEye treatmentPush outIntraocular lens insertion

An intraocular-lens insertion device is adapted to deform a deformable intraocular lens into a smaller size and insert the intraocular lens into an eye via an insertion tube. An intraocular-lens guide is provided on the inner surface of the insertion tube. The guide may be a rail-shaped projection or a groove, which extends parallel to a direction along which the intraocular lens is pushed out. A stress release structure is provided on the insertion tube in order to release stress of the intraocular lens produced due to deformation thereof. Moreover, a frictional-resistance increasing structure is provided on the inner surface of the insertion tube to be located in the vicinity of the stress release structure. The frictional-resistance increasing structure increases frictional resistance between the inner surface of the insertion tube and the intraocular lens. The frictional-resistance increasing structure may be a roughened surface which completely or partially covers the inner surface of the insertion tube.

Owner:STAAR JAPAN

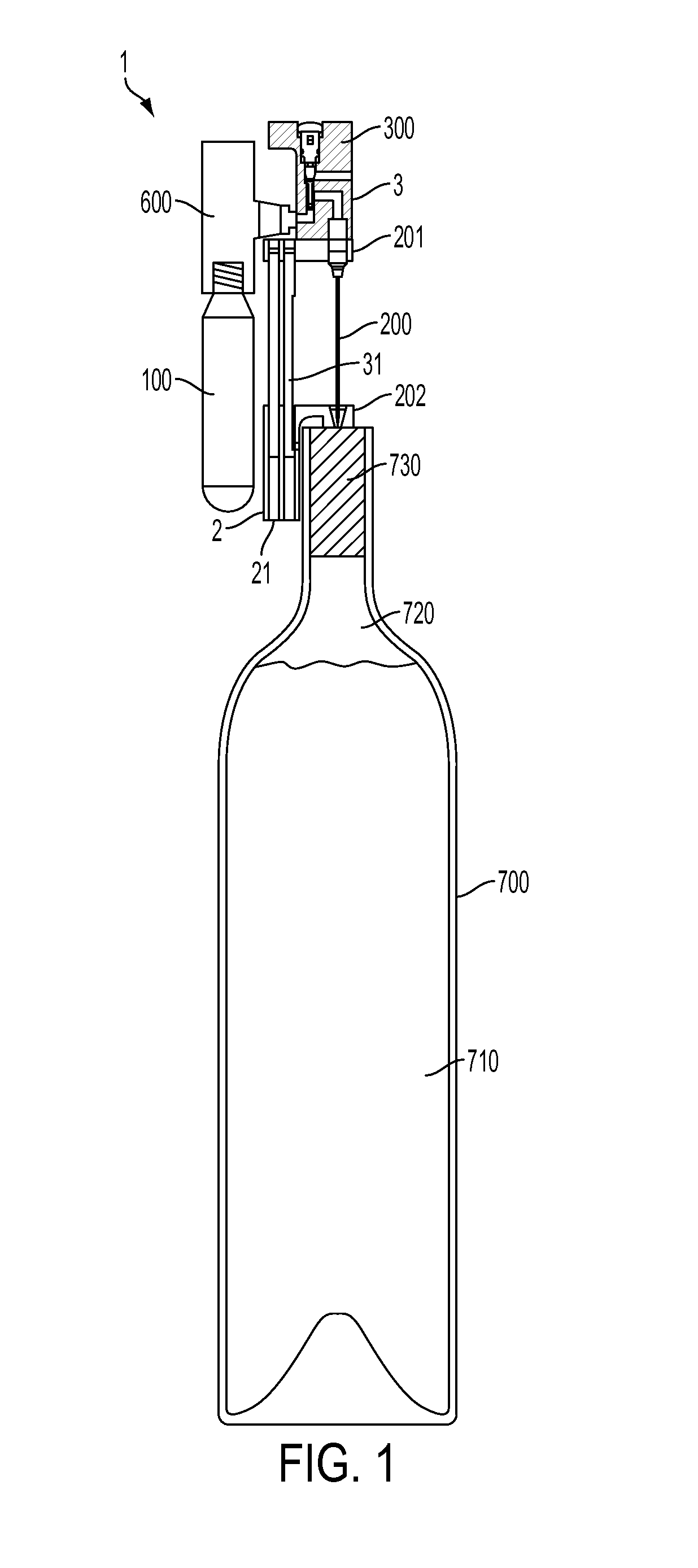

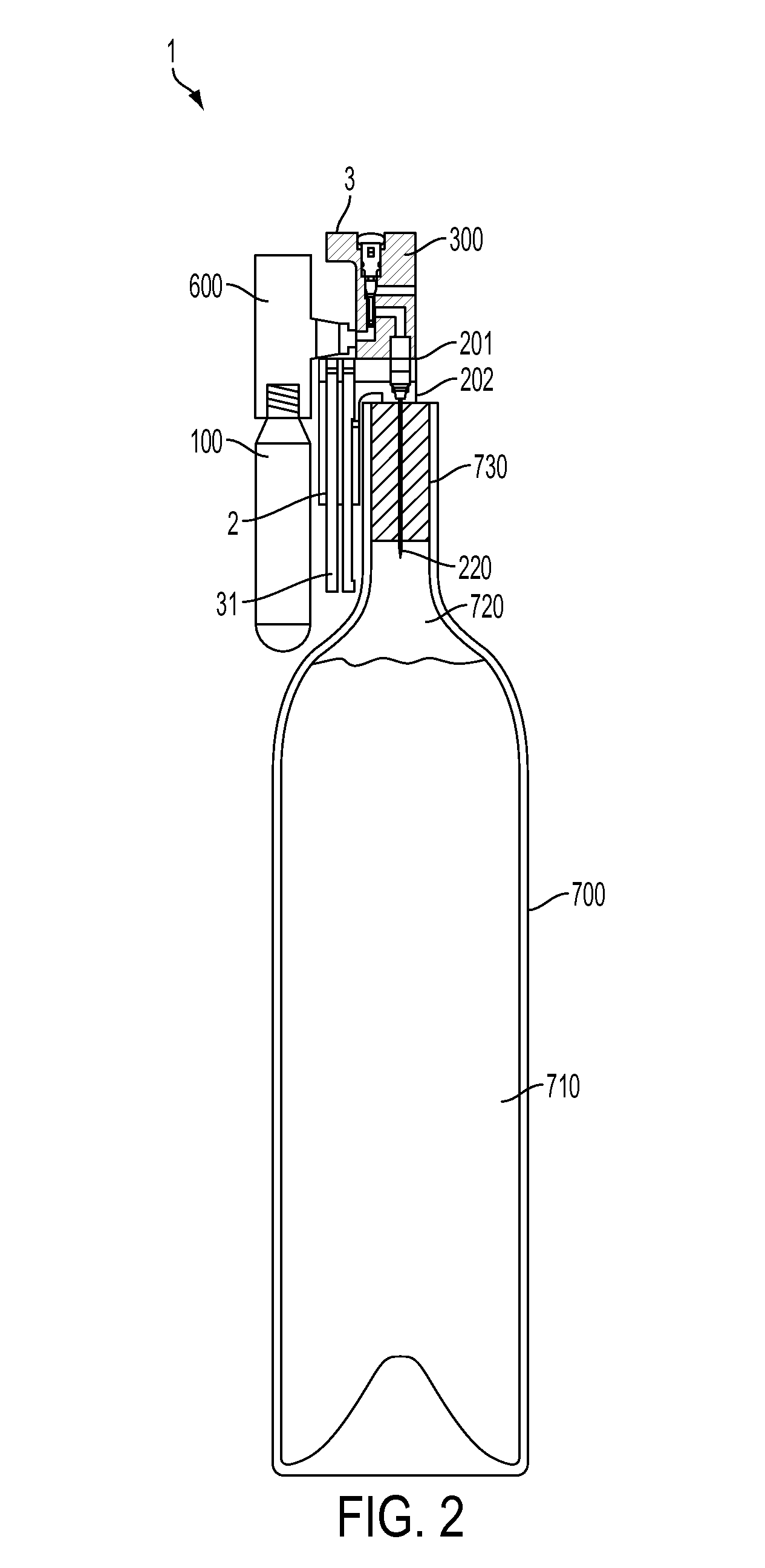

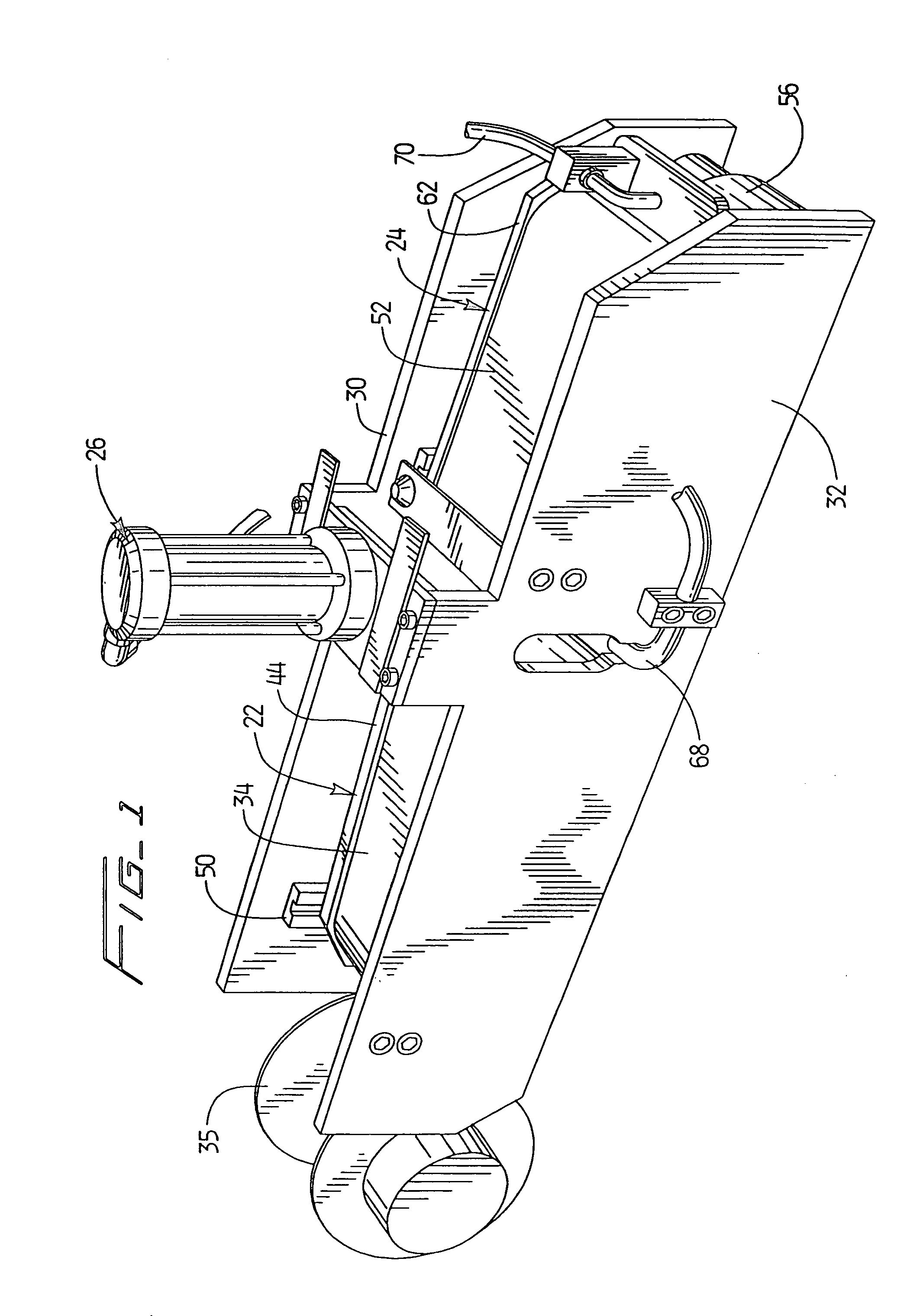

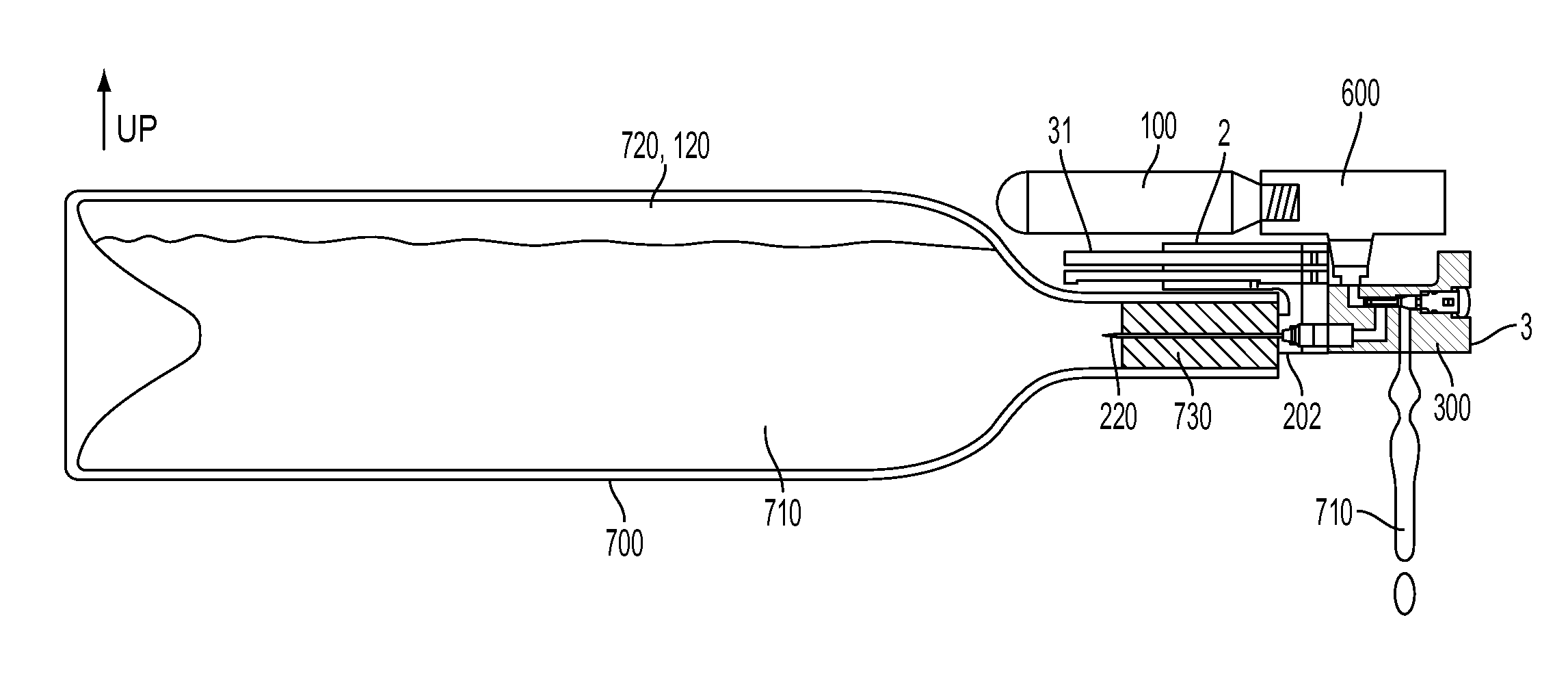

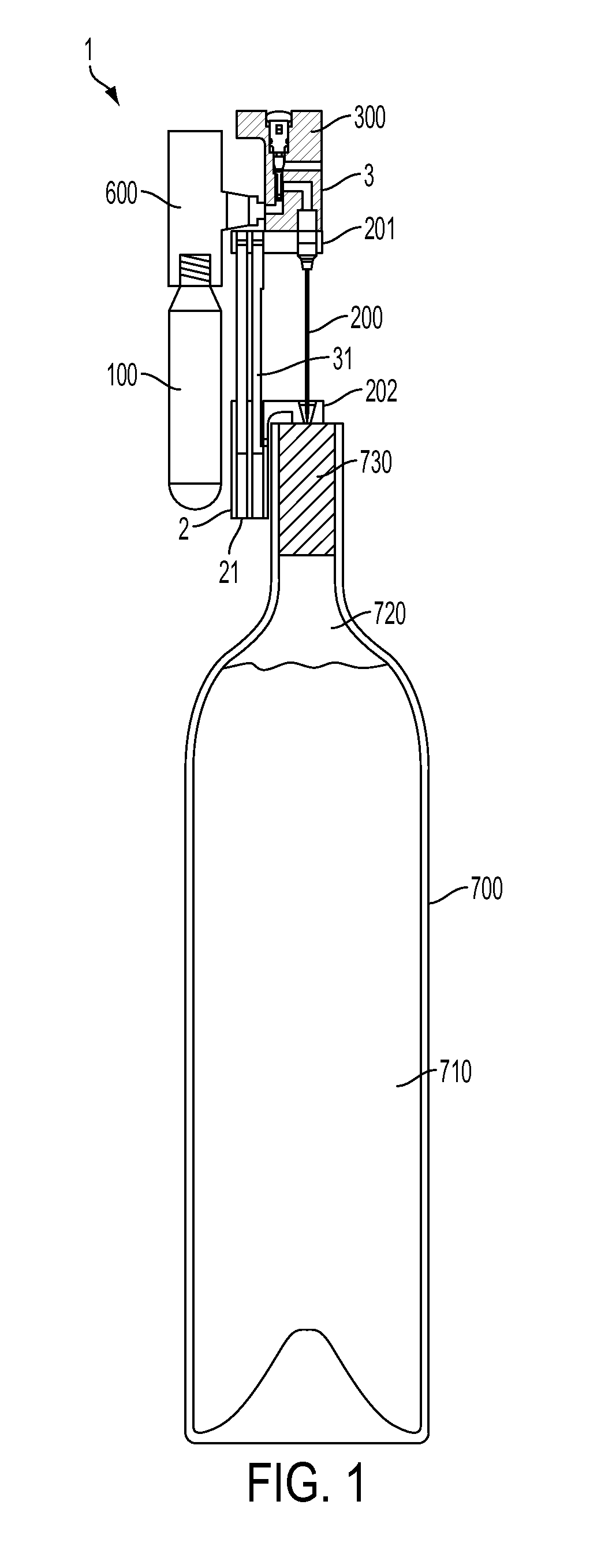

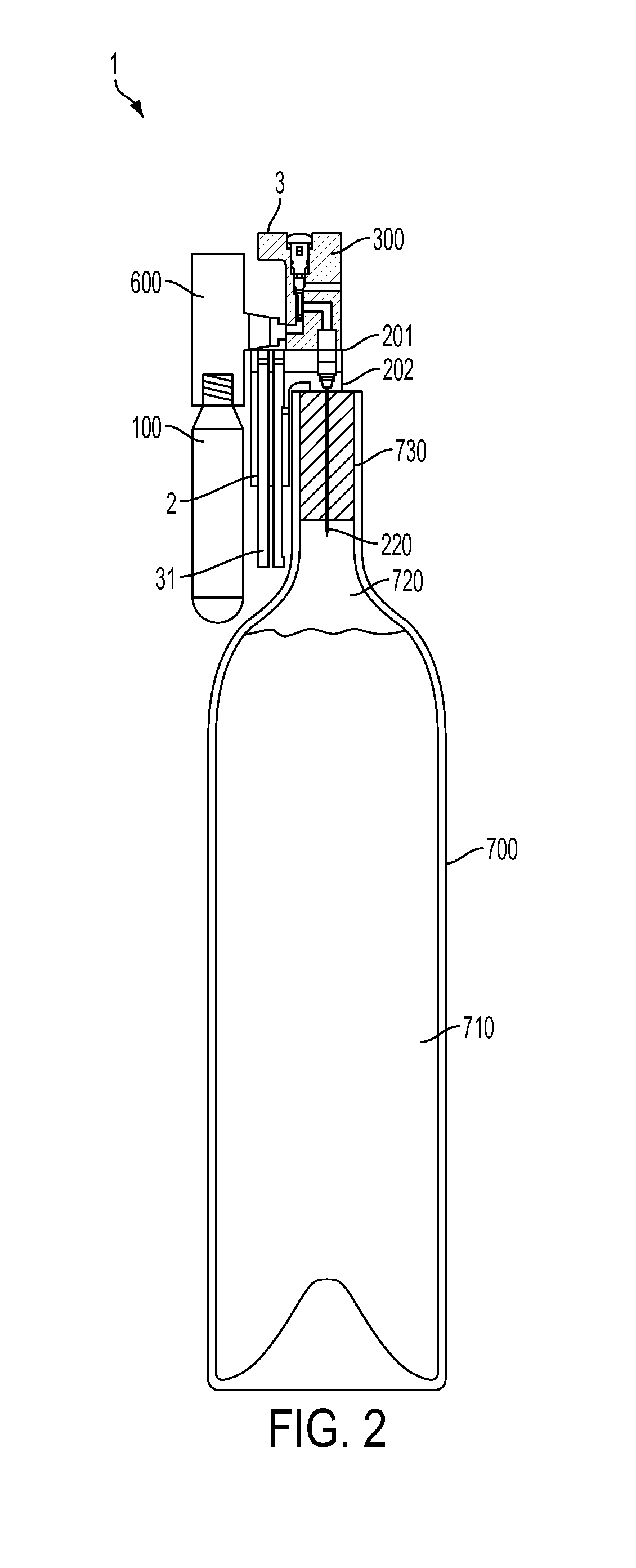

Method and apparatus for engaging a beverage extraction device with a container

ActiveUS9010588B2Little or no effect on beverage qualityImprove sealingSolid materialPackaging under special atmospheric conditionsWine bottleBottle neck

Devices and methods for clamping a beverage extraction device to a beverage container, such as a wine bottle. One or more clamp arms may be arranged to clamp the extraction device to a wine bottle as well as allow the device to be supported upright on a table top. Clamp arms may include tab and ridge features that operate to properly engage and position a wide variety of different bottle neck shapes relative to the device. The one or more clamp arms may move the bottle neck distally, e.g., toward a resilient pad, so that the neck is suitably positioned relative to the device. Proper positioning and engagement of the neck may allow for desired piercing of a cork or other closure of the bottle by the device.

Owner:CORAVIN

Intraocular lens insertion device

ActiveUS8574239B2Simple structureGuaranteed uptimeEye treatmentIntraocular lensIntraocular lens insertionPlunger

Owner:HOYA CORP

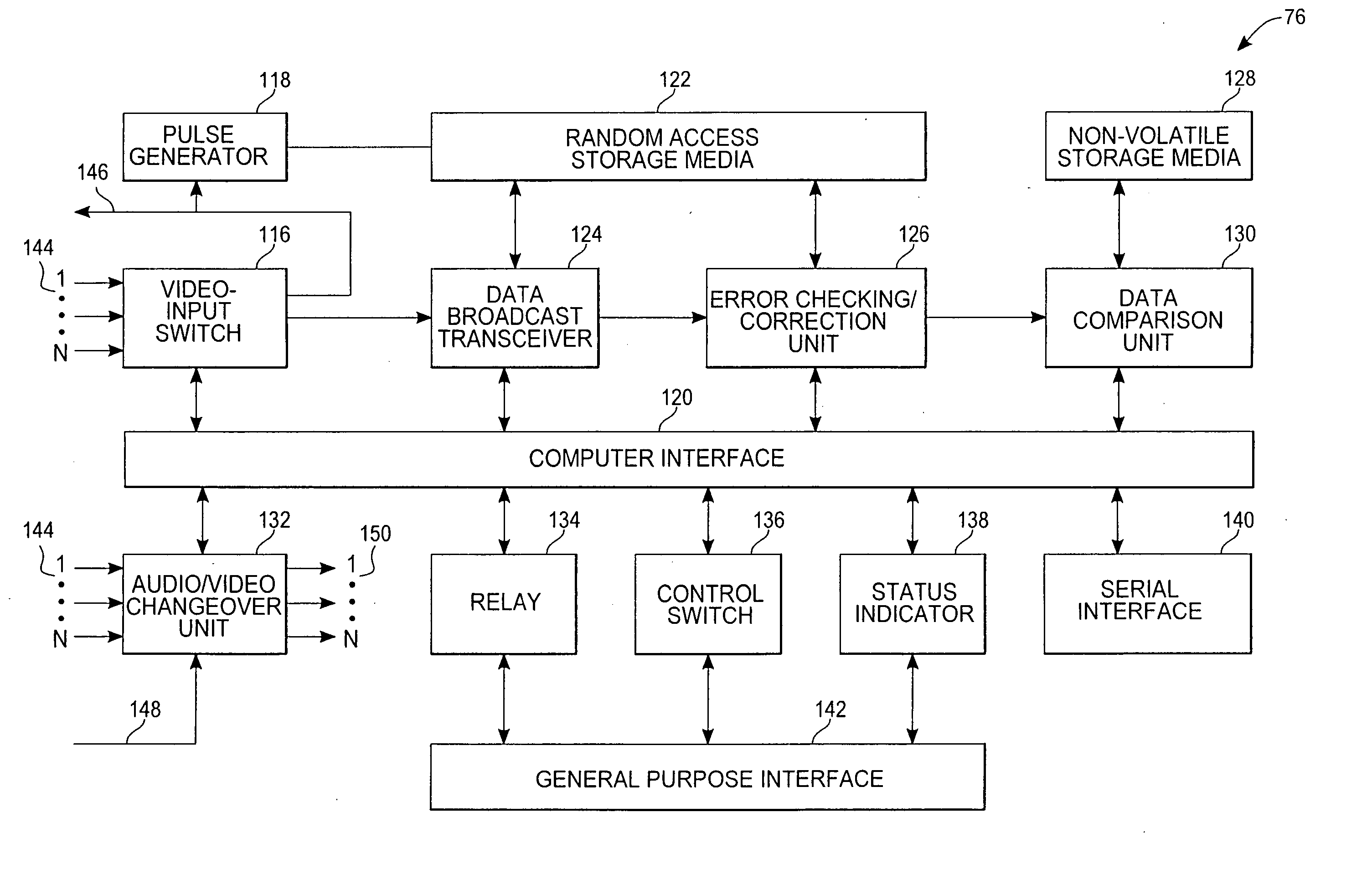

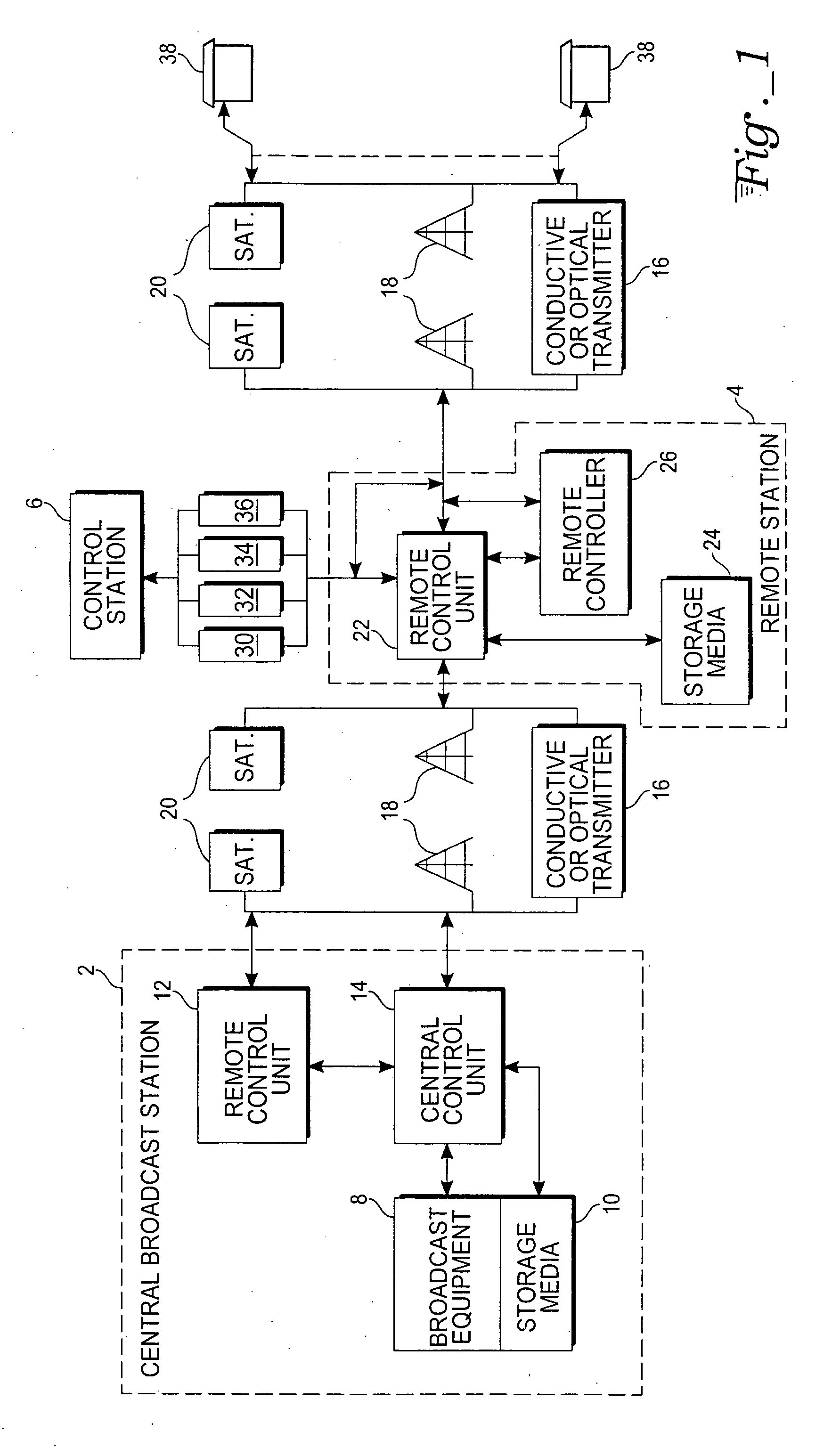

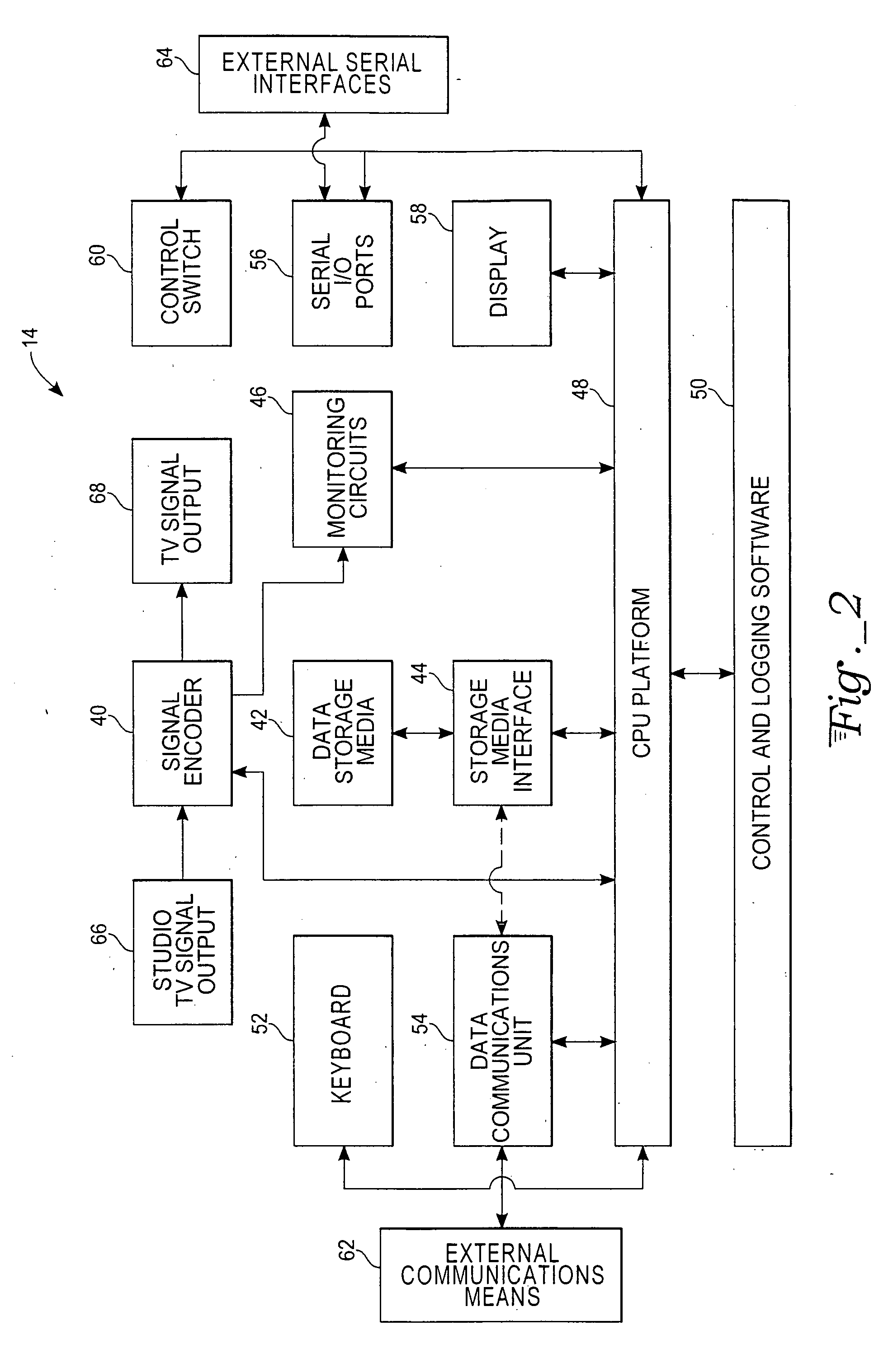

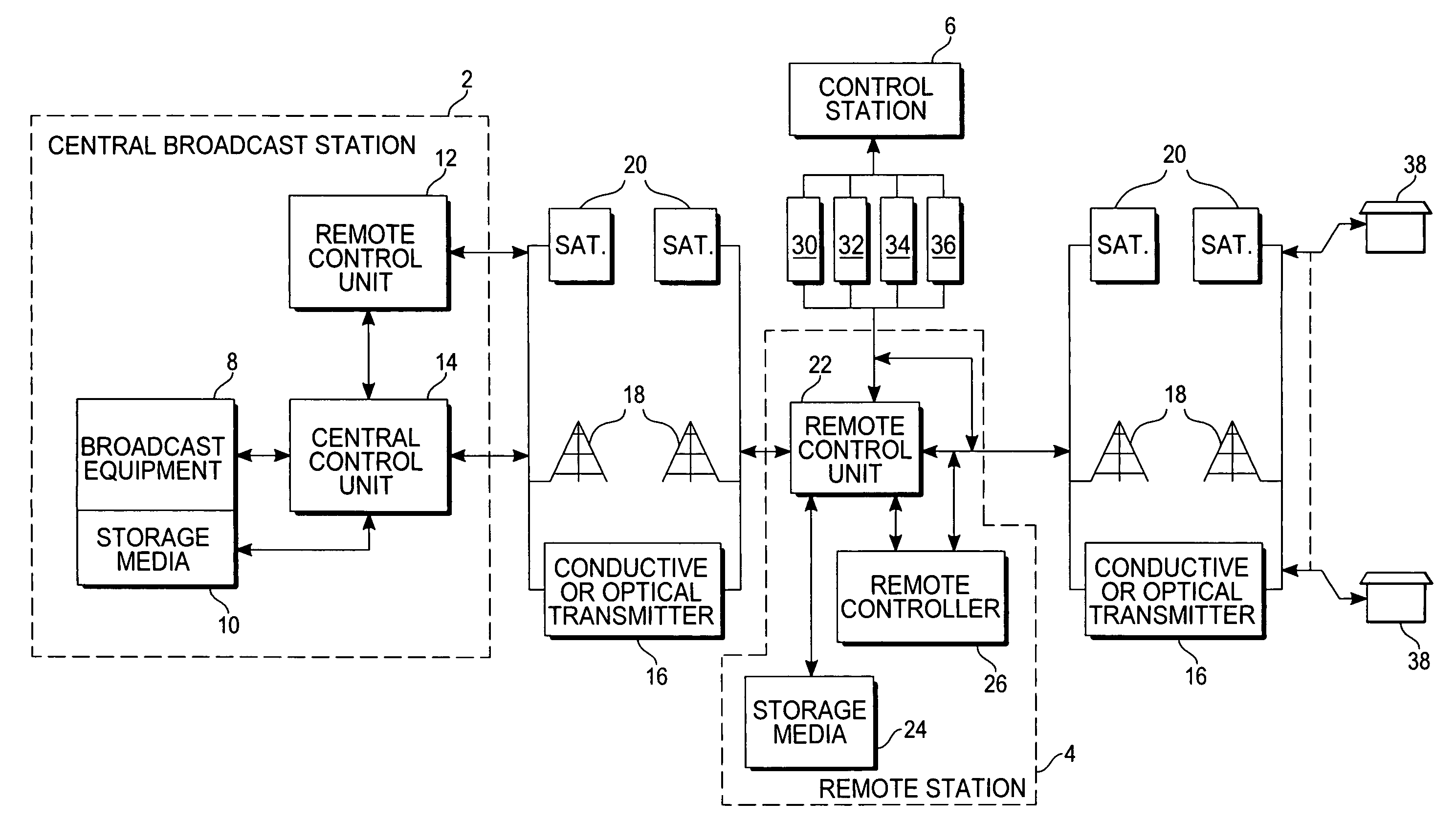

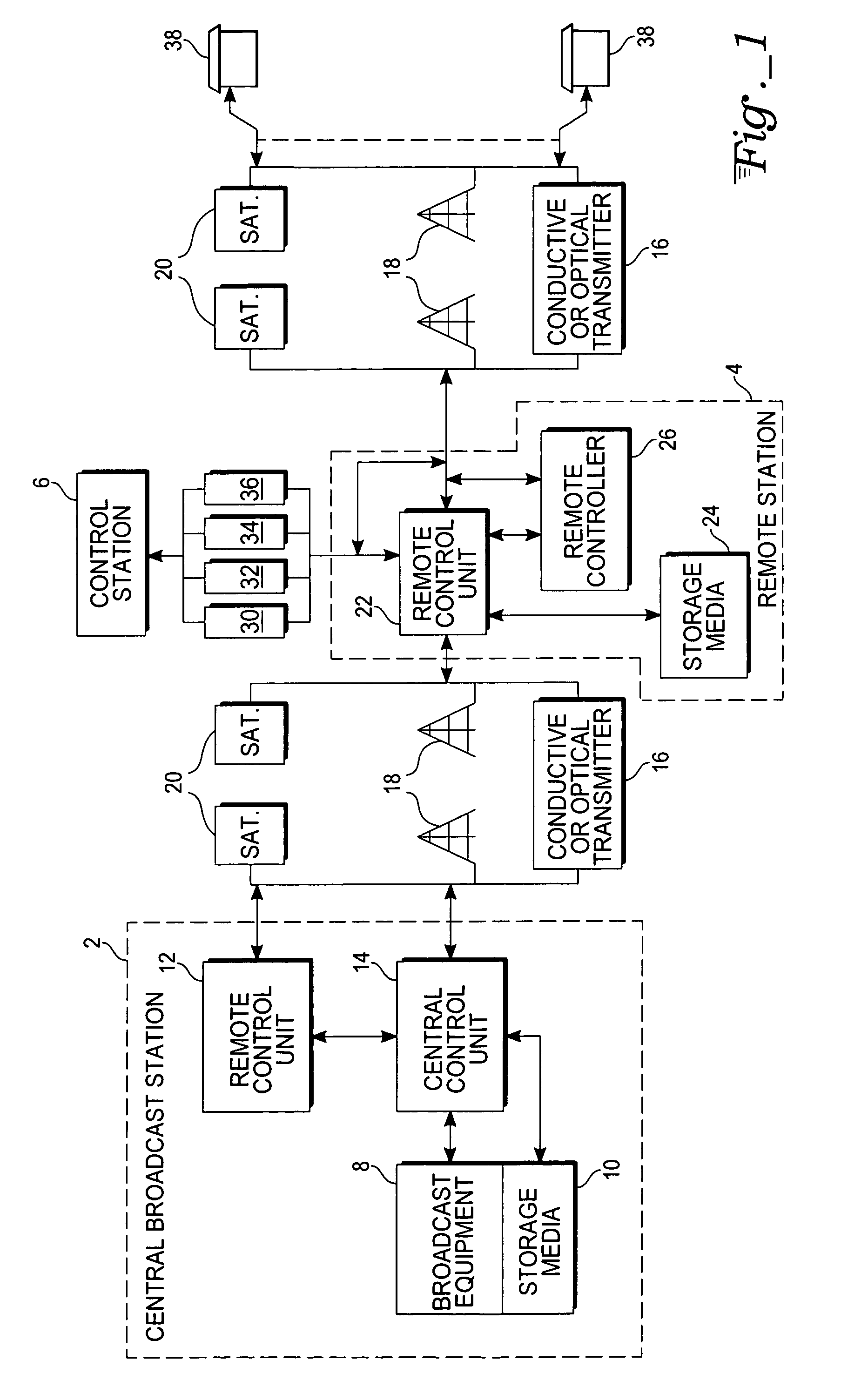

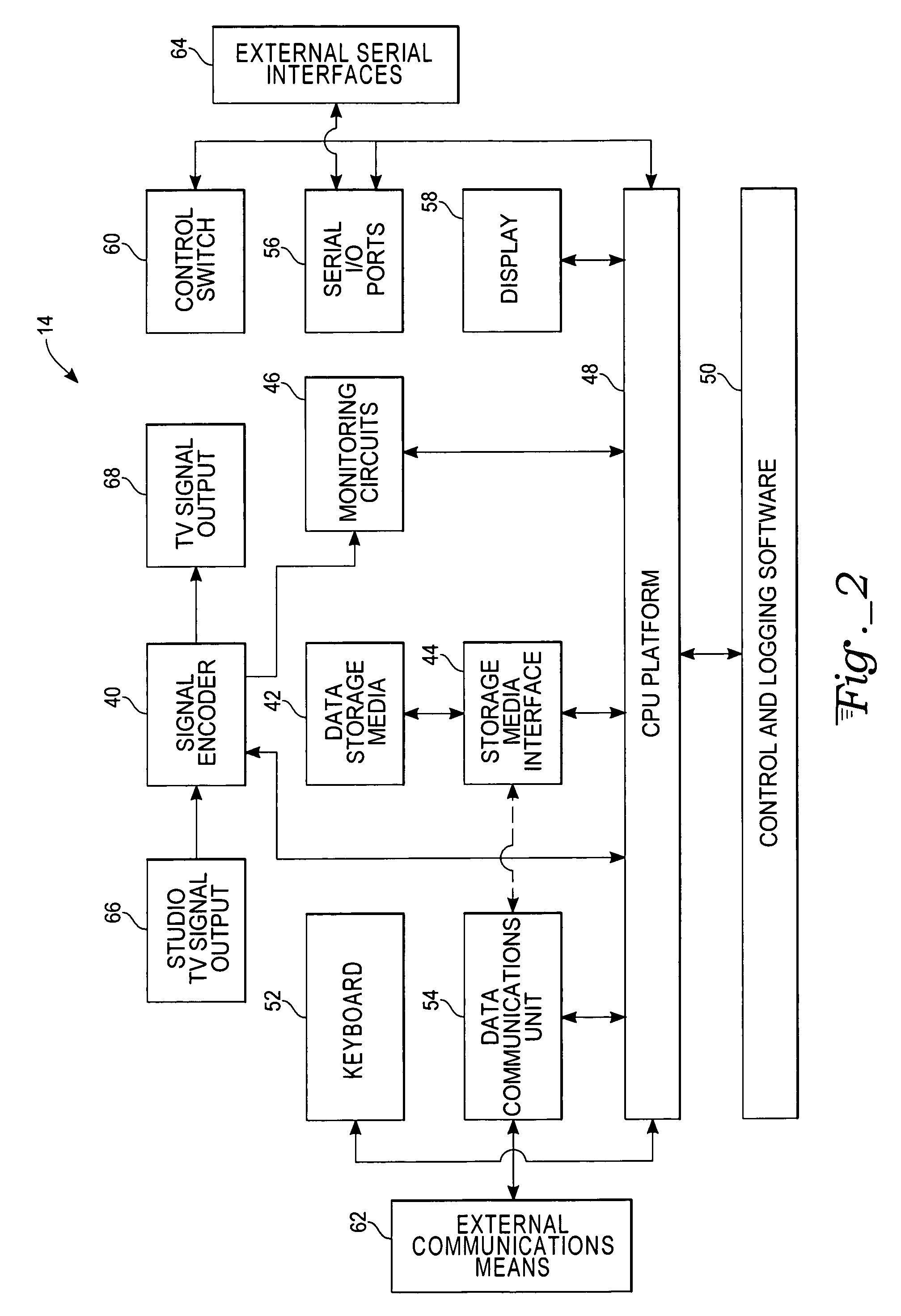

Apparatus and method for insertion of material in broadcasting

InactiveUS20060053442A1Easy to integrateReliable insertionTelevision system detailsSelective content distributionControl signalVertical blanking interval

A system, apparatus, and method for local insertion of analog or digital material into a television broadcast signal. A central insertion control unit controls the insertion of additional material while a remote insertion control unit locally controls the insertion of the additional material. The central insertion control unit contains a processor, storage media, and an encoder for encoding control and information signals into a broadcast signal. The control signal contains a cue signal for information about play lists, and an action signal for triggering insertion of the additional material. The control signal is encoded into a line of the vertical blanking interval. Once the control is detected by the remote insertion control unit the additional material is played and broadcast.

Owner:RIDDERHEIM STEFAN +1

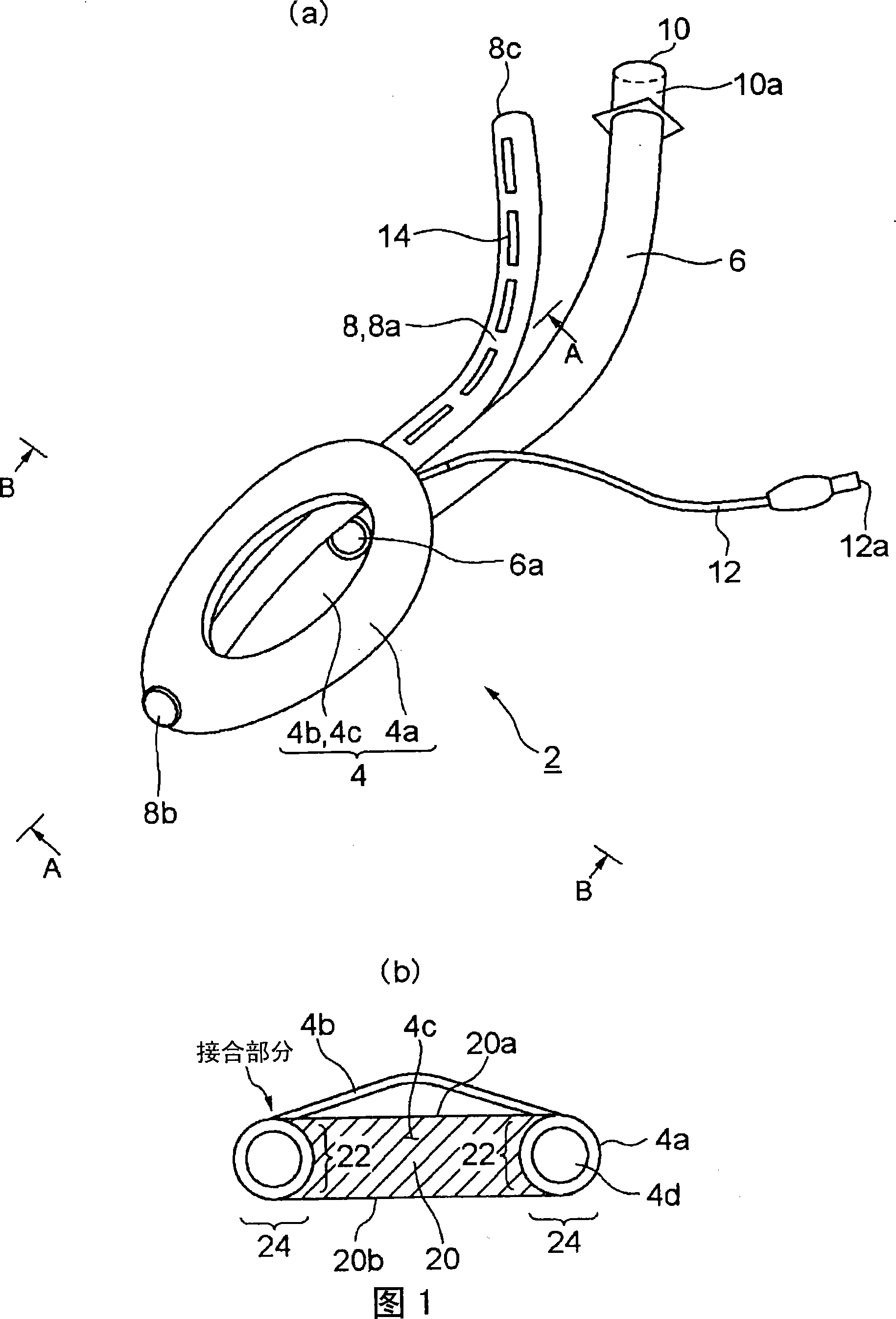

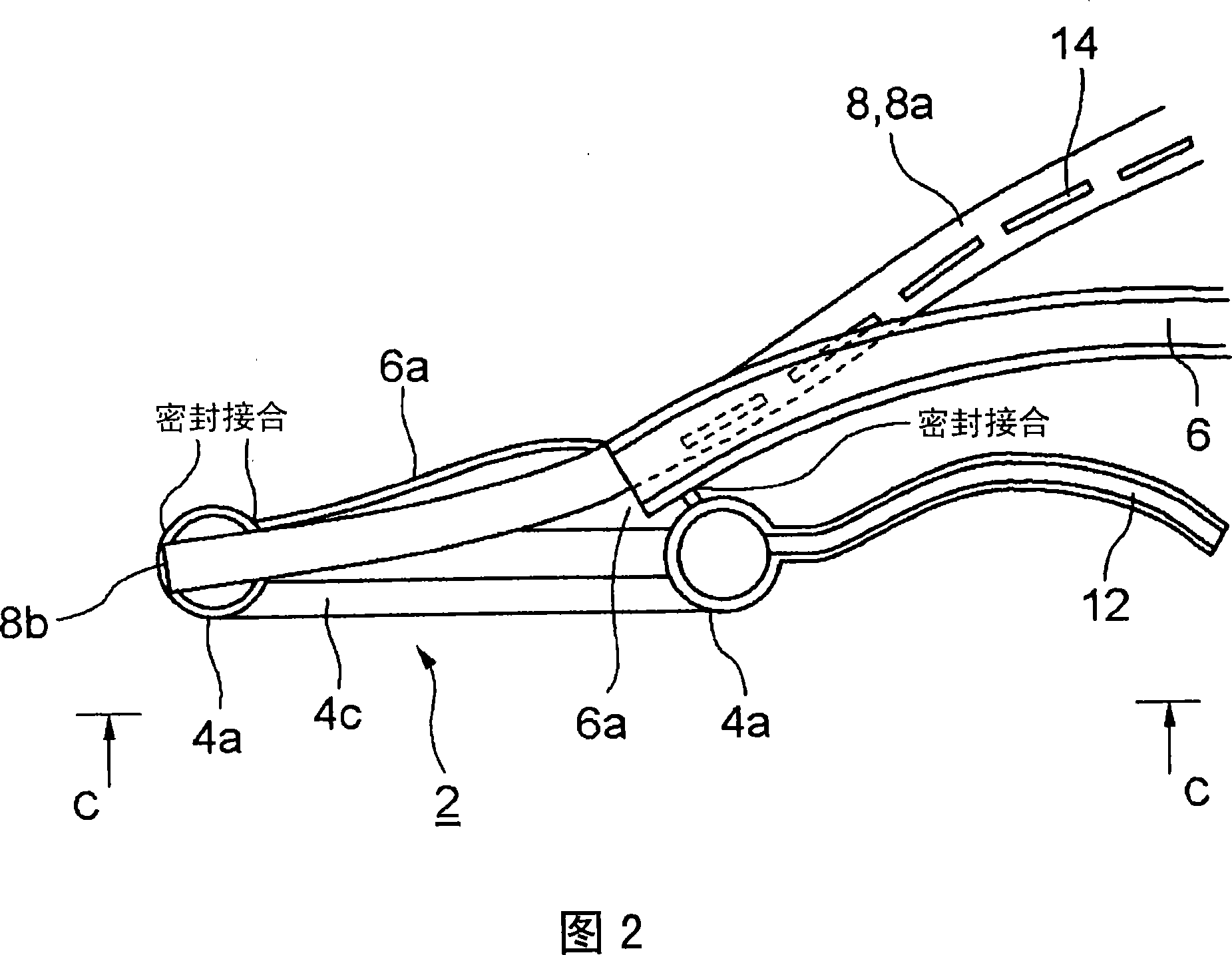

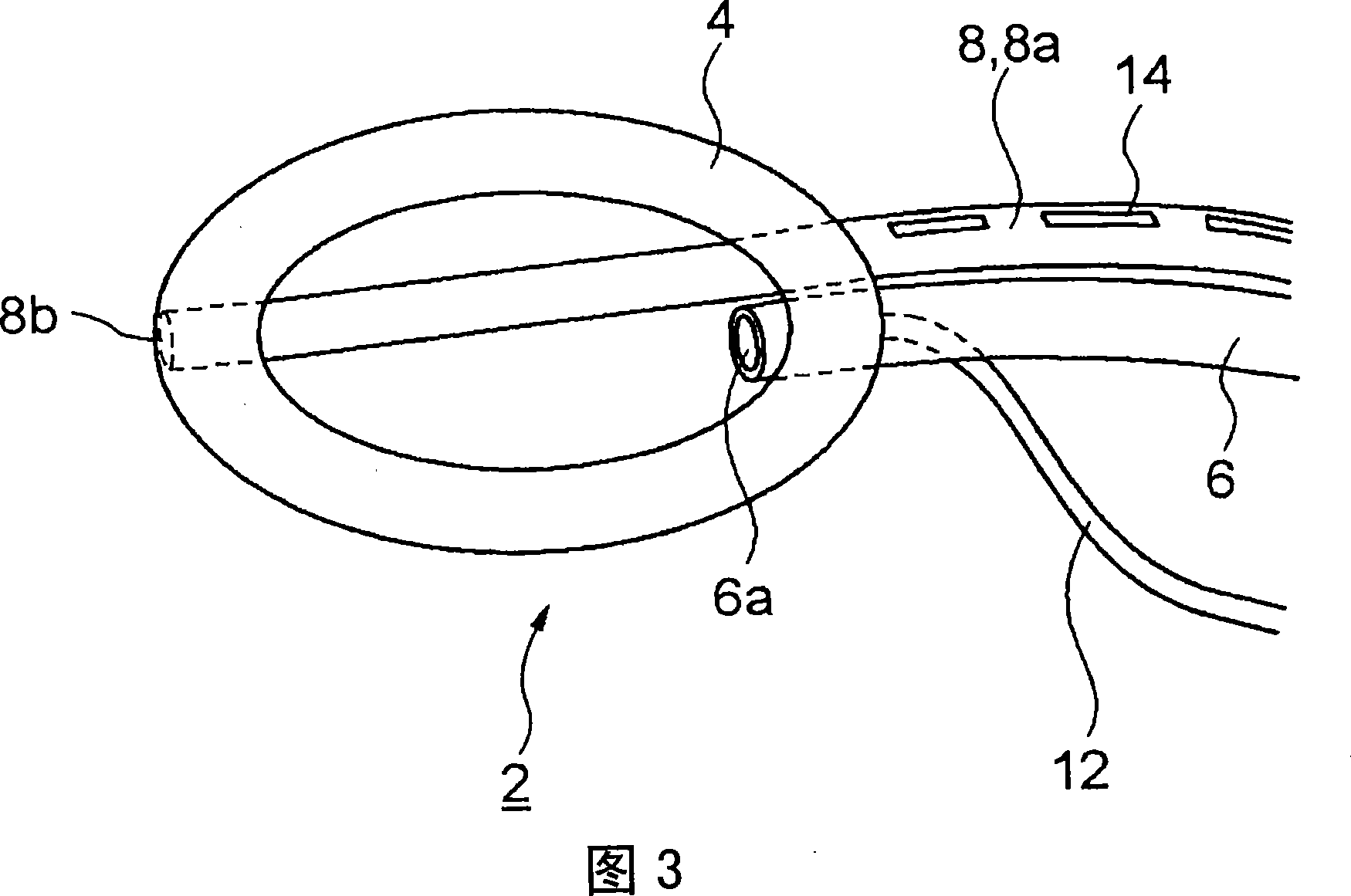

Laryngeal mask with guiding tube used for inserting stomach tube

InactiveCN101057994AEasy and reliable insertionPrevent intrusionTracheal tubesInterior spaceLaryngeal Masks

It is intended to provide a laryngeal mask comprising: an inflation cuff having an inflatable hollow tubular part, a back plate which is air-tightly bonded to the hollow tubular part so as to cover one end of the inside diameter side space, and a cuff inside space which is surrounded by the inside diameter curved face and the inside face of the back plate and has an opening in the side opposite to the back plate; an airway tube which has one end opening toward the cuff inside space and the other end opening toward the space outside the oral cavity; and a gastric tube insertion guide wherein a guide face, which aims at inserting a gastric tube from the mouth until its front edge reaches the stomach or esophagus region in the state of inserting the inflation cuff into the pharyngeal region, is continuously or intermittently provided from the inflation cuff to the outside of the oral cavity.

Owner:株式会社 佐多商会

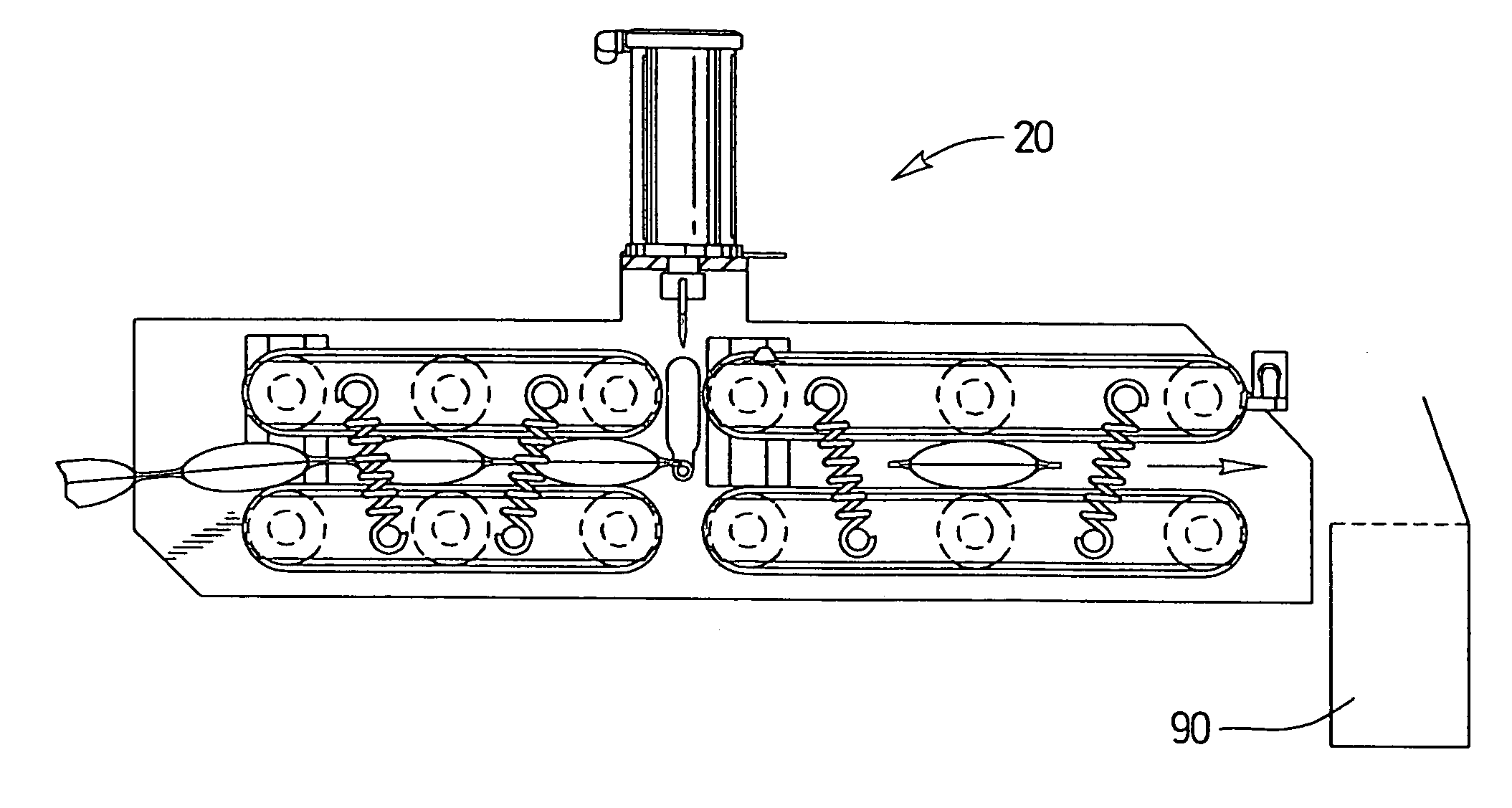

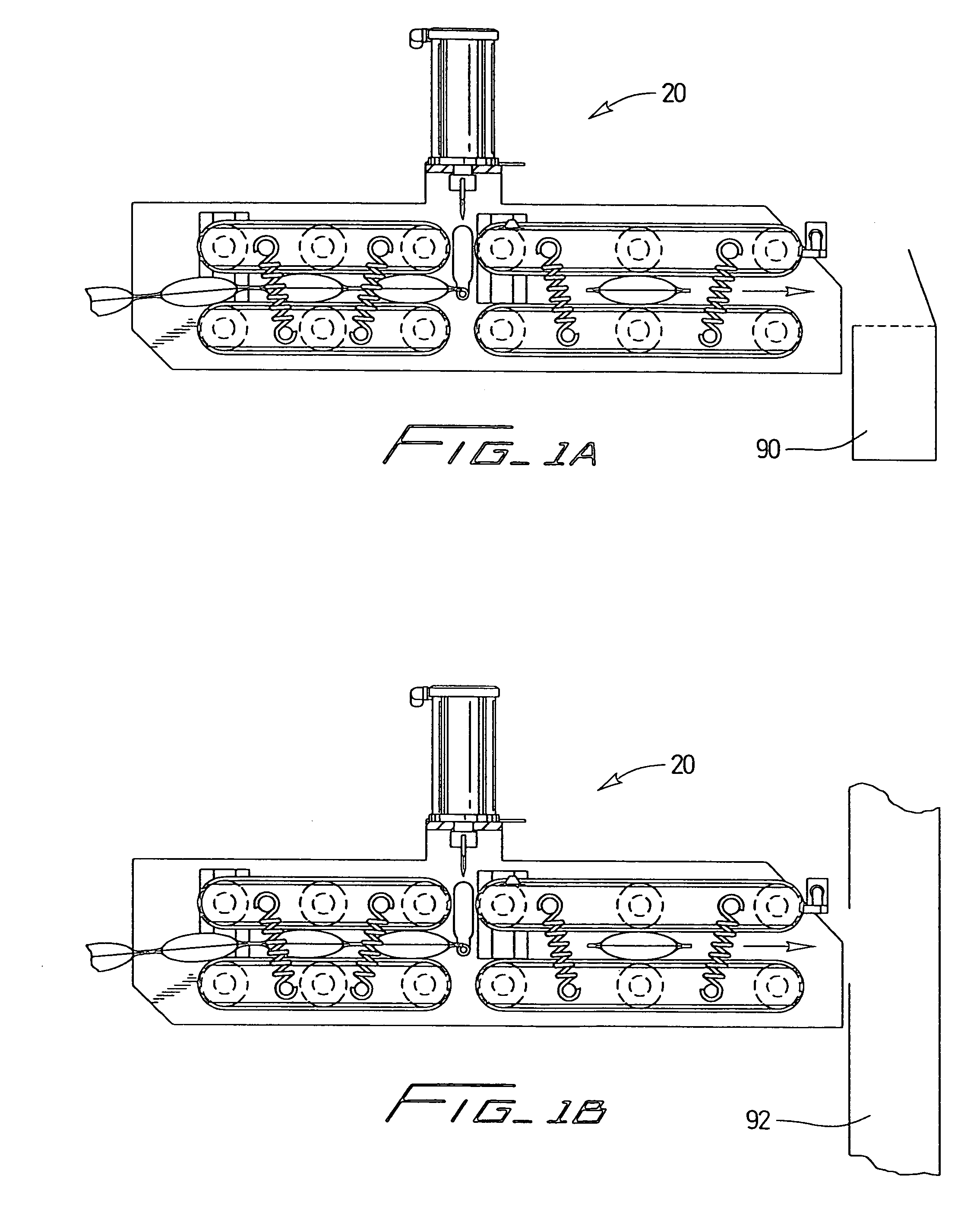

Web burster/inserter

InactiveUS7032774B2Improve reliabilityIncrease speedCoin-freed apparatus detailsSolid materialEngineeringVarying thickness

A web burster / inserter assembly receives a continuous supply of coupons in the form of a web where the forwardmost coupon is attached to the following coupon. The web burster / inserter separates individual coupons from the web and directs the coupons to a desired location. A ram may be used to effectuate the separation. The web burster / inserter is capable of being used with coupons of varying thickness such as plastic prizes and game pieces.

Owner:NORTHFIELD CORP

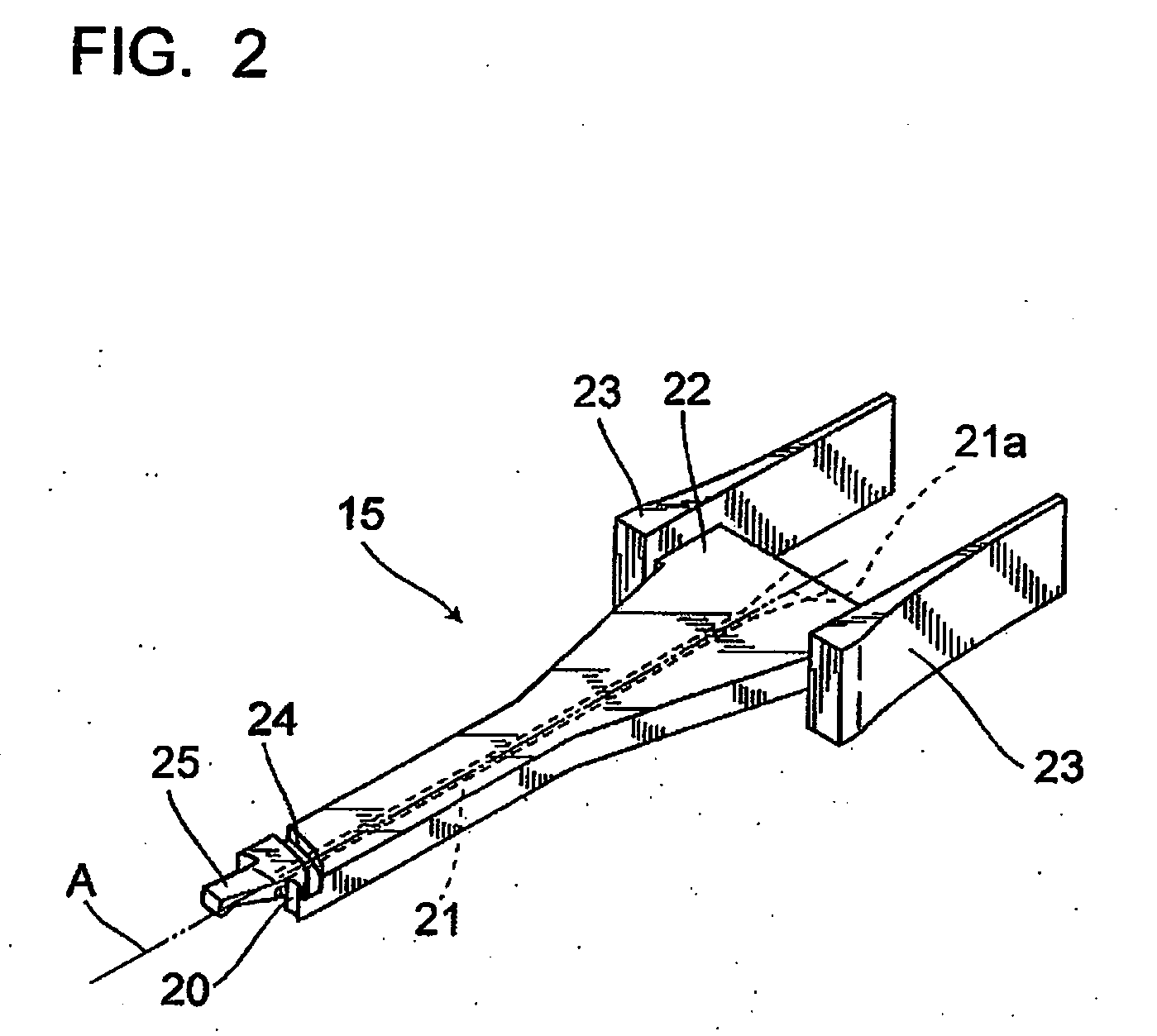

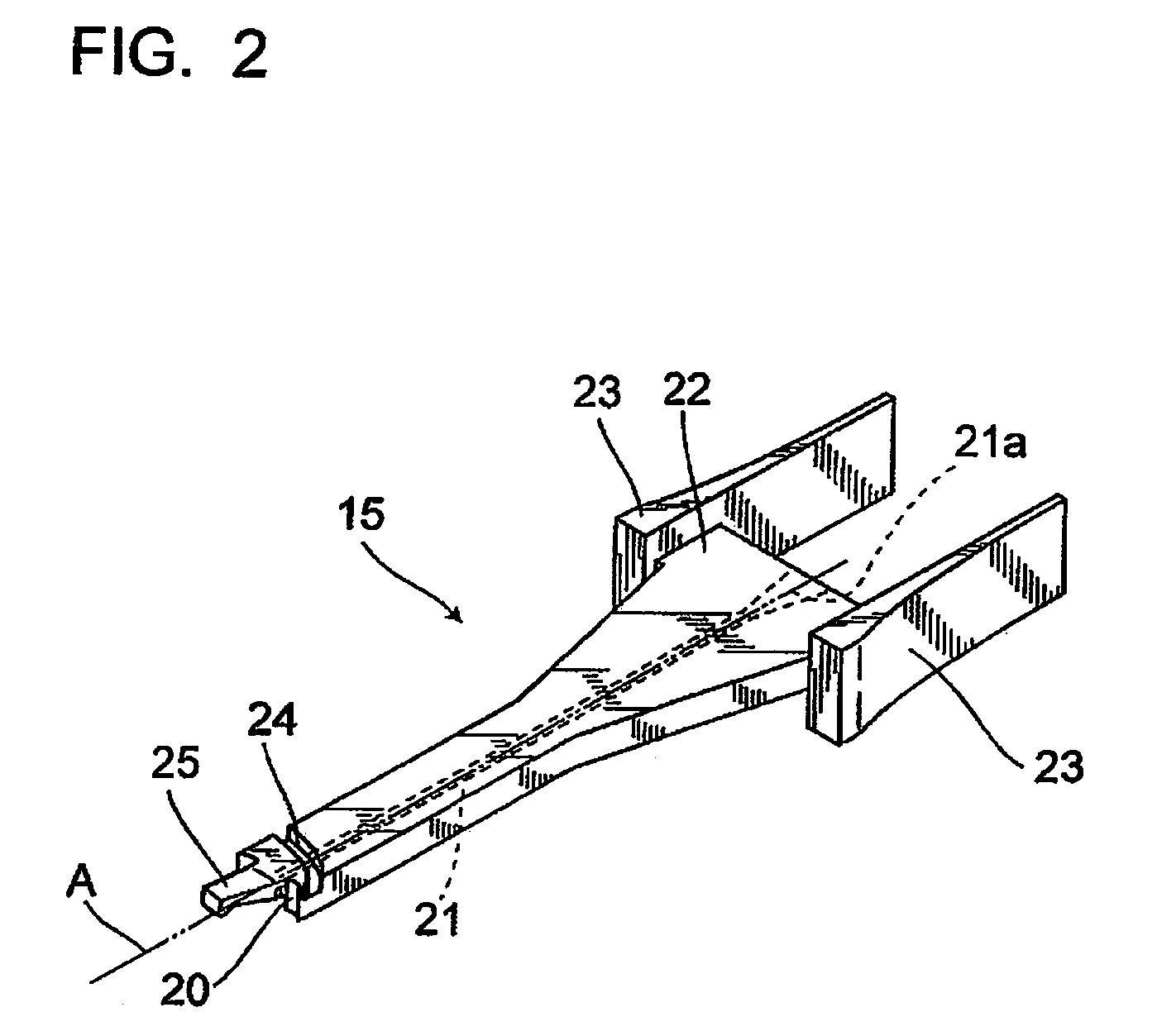

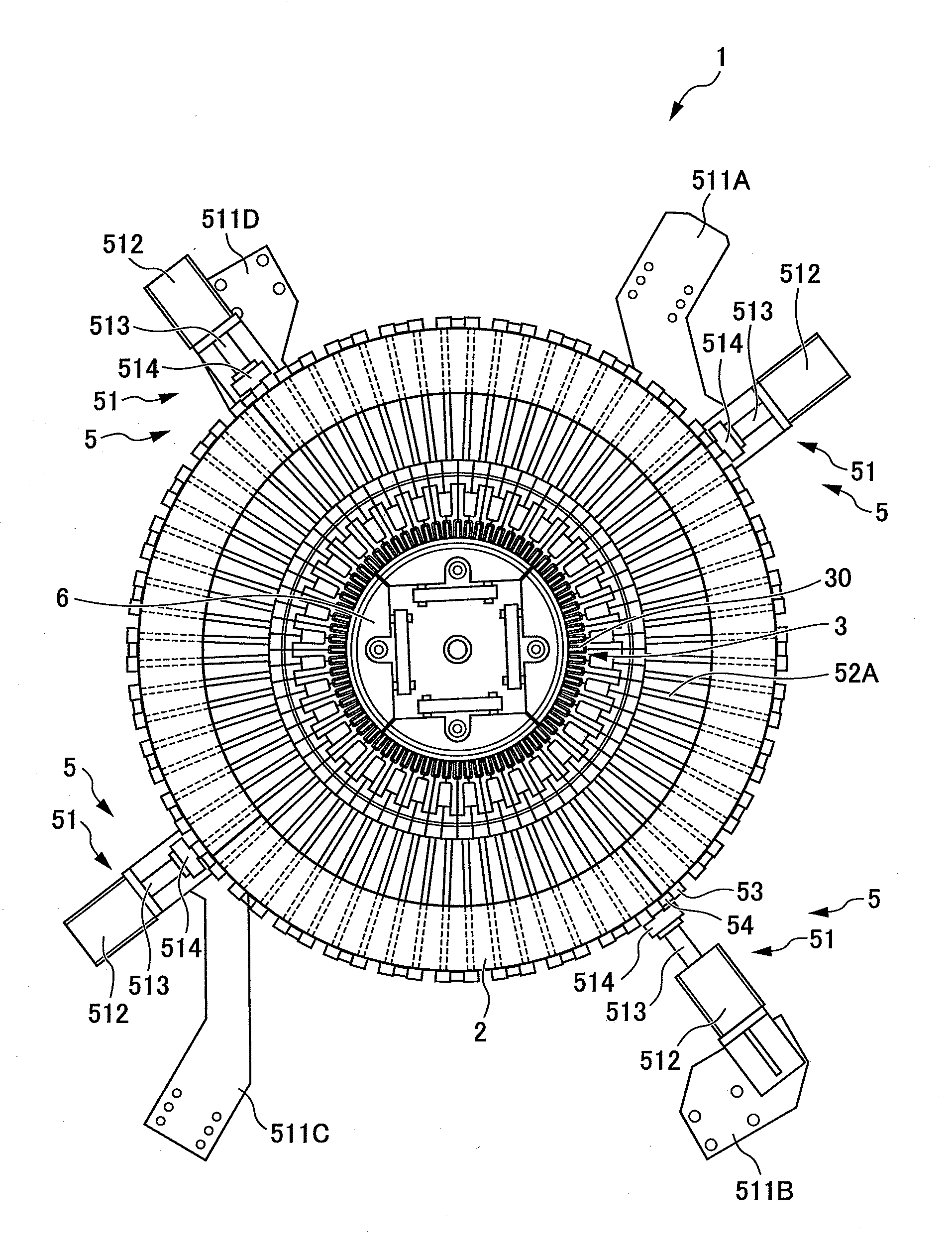

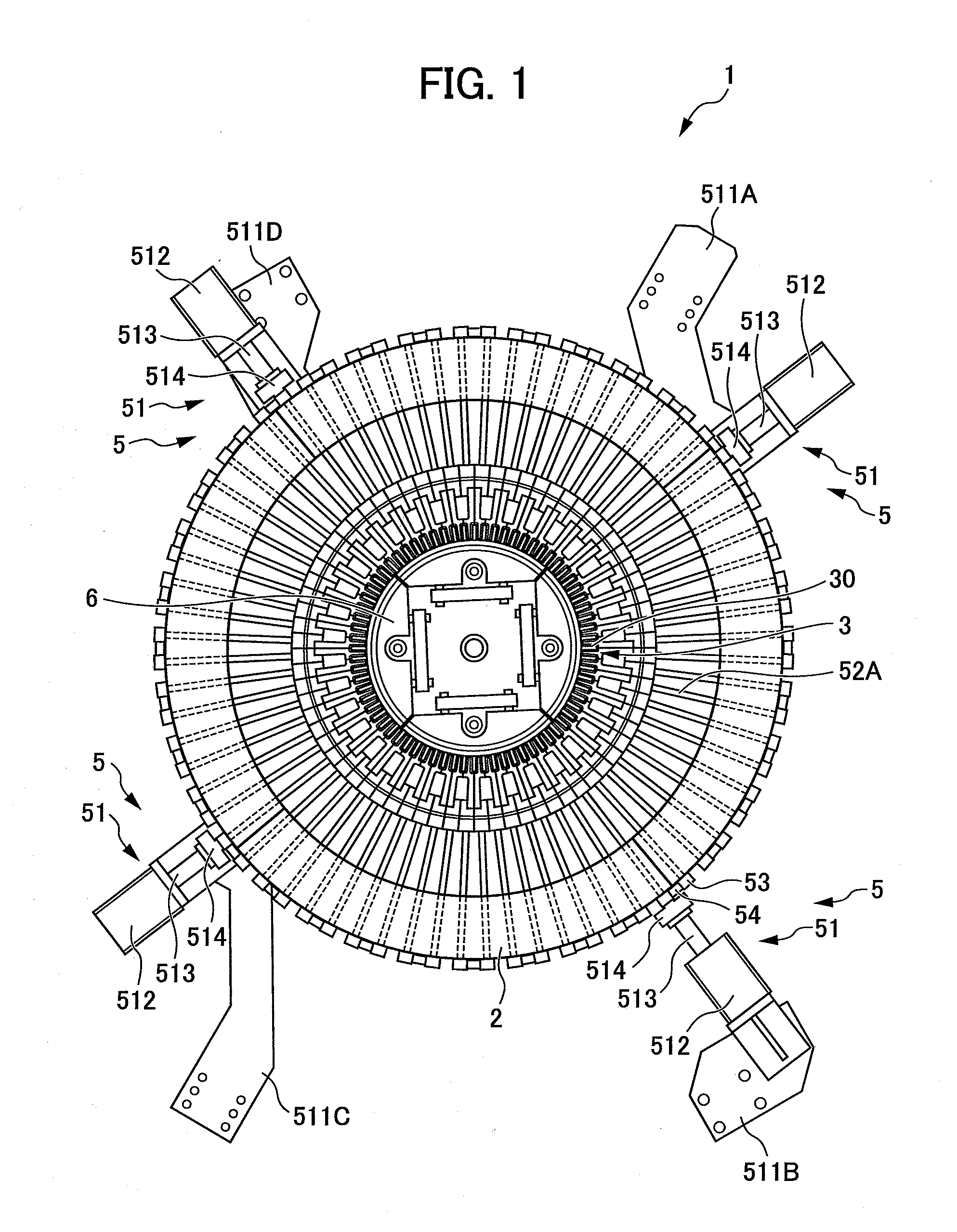

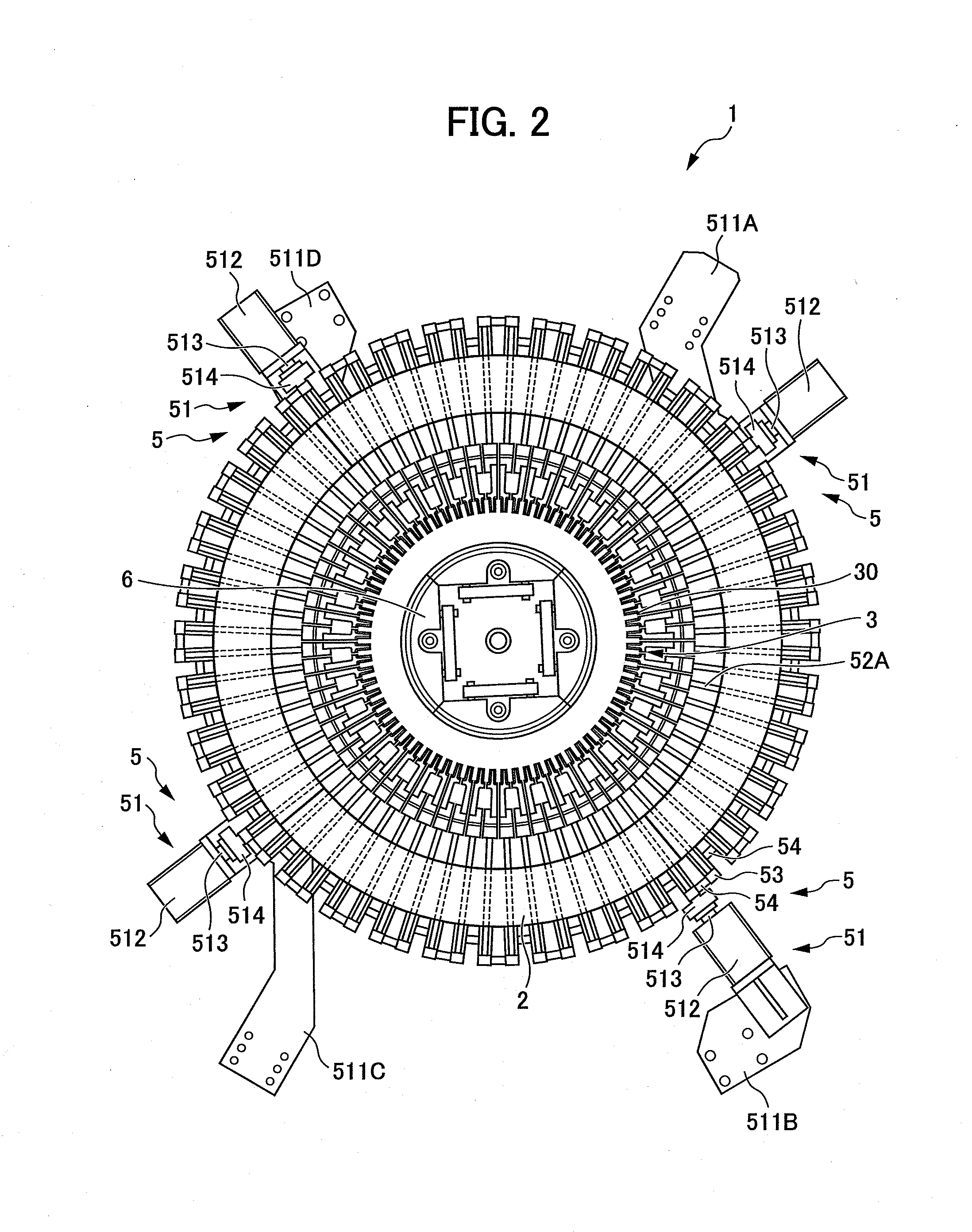

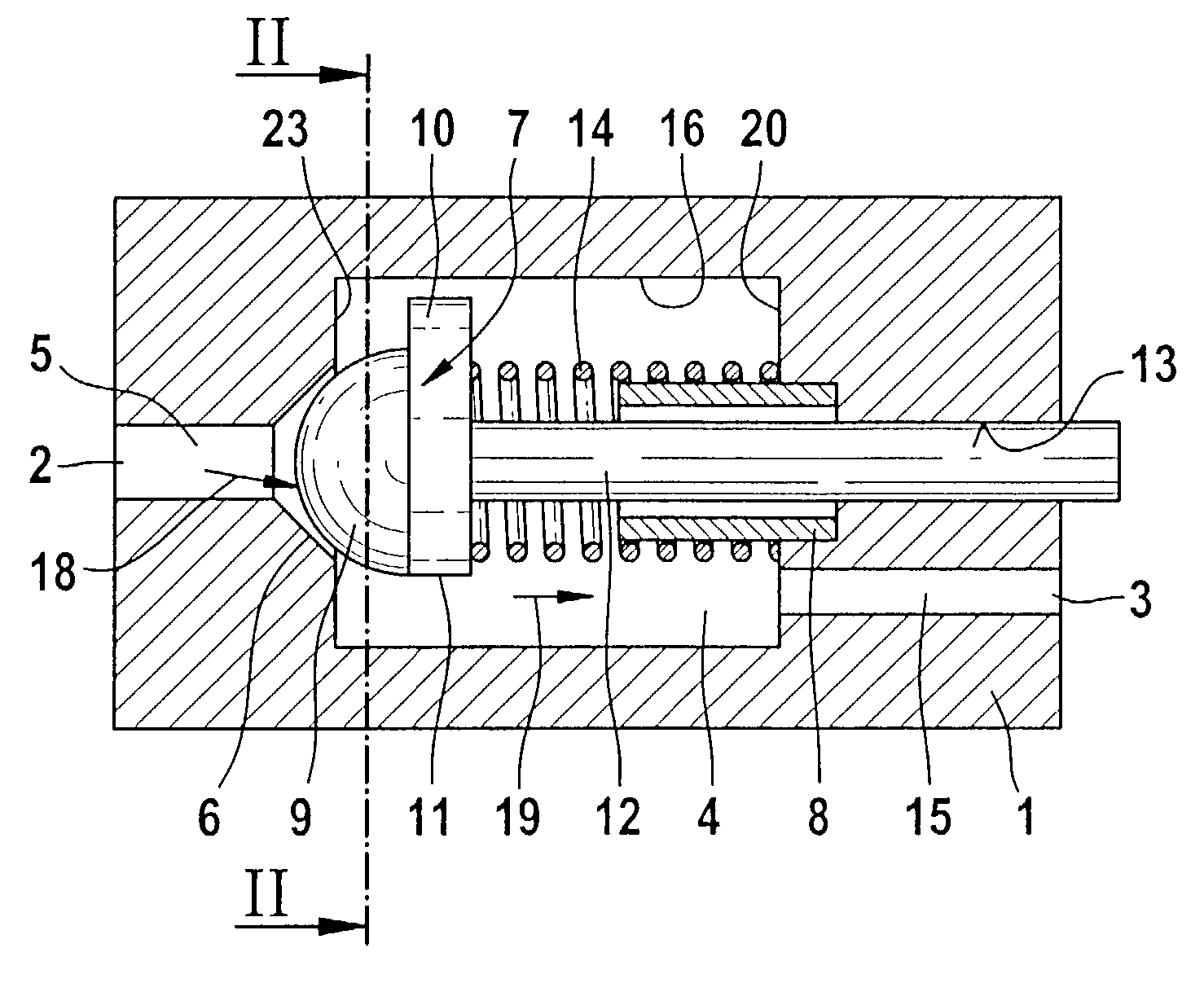

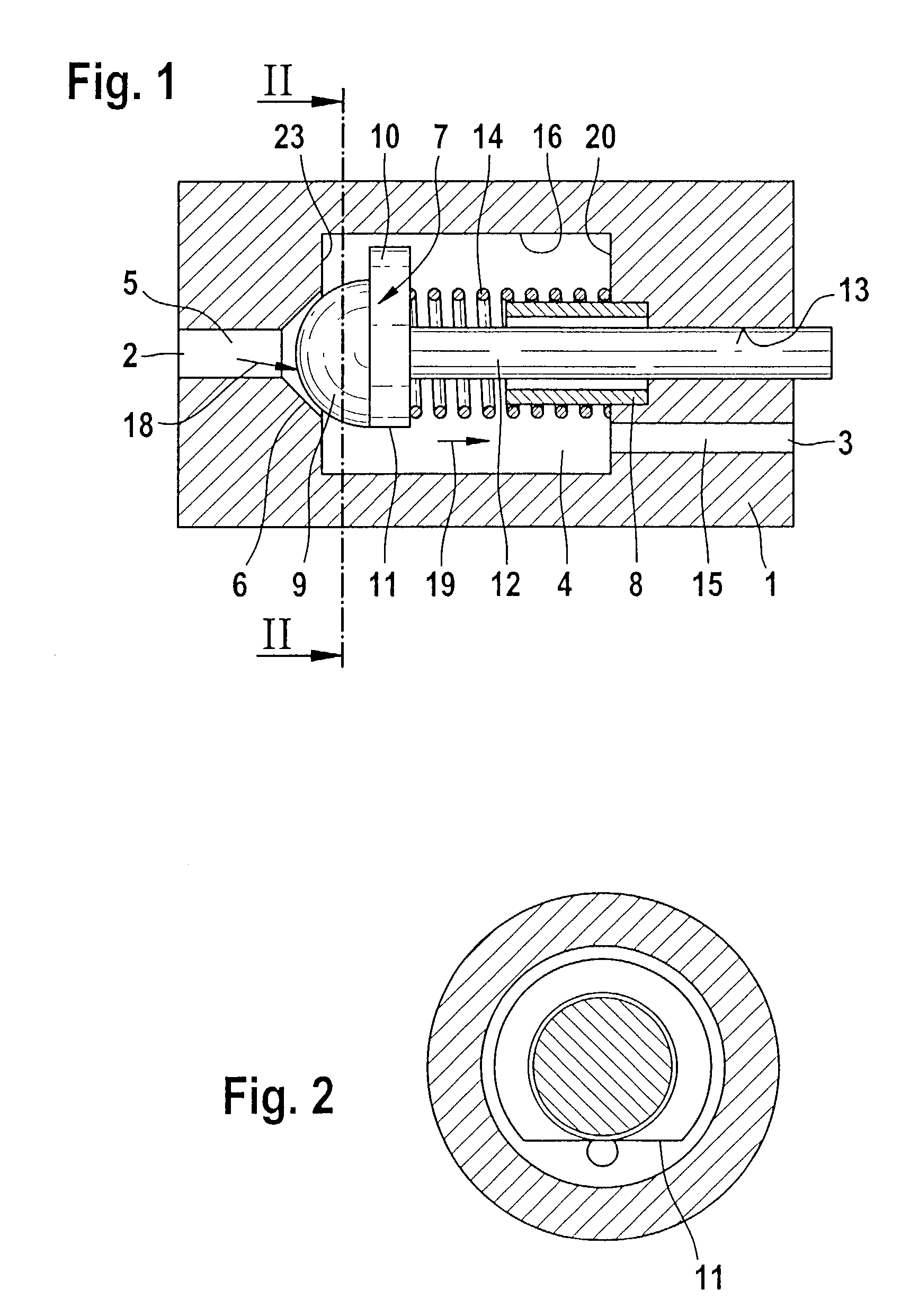

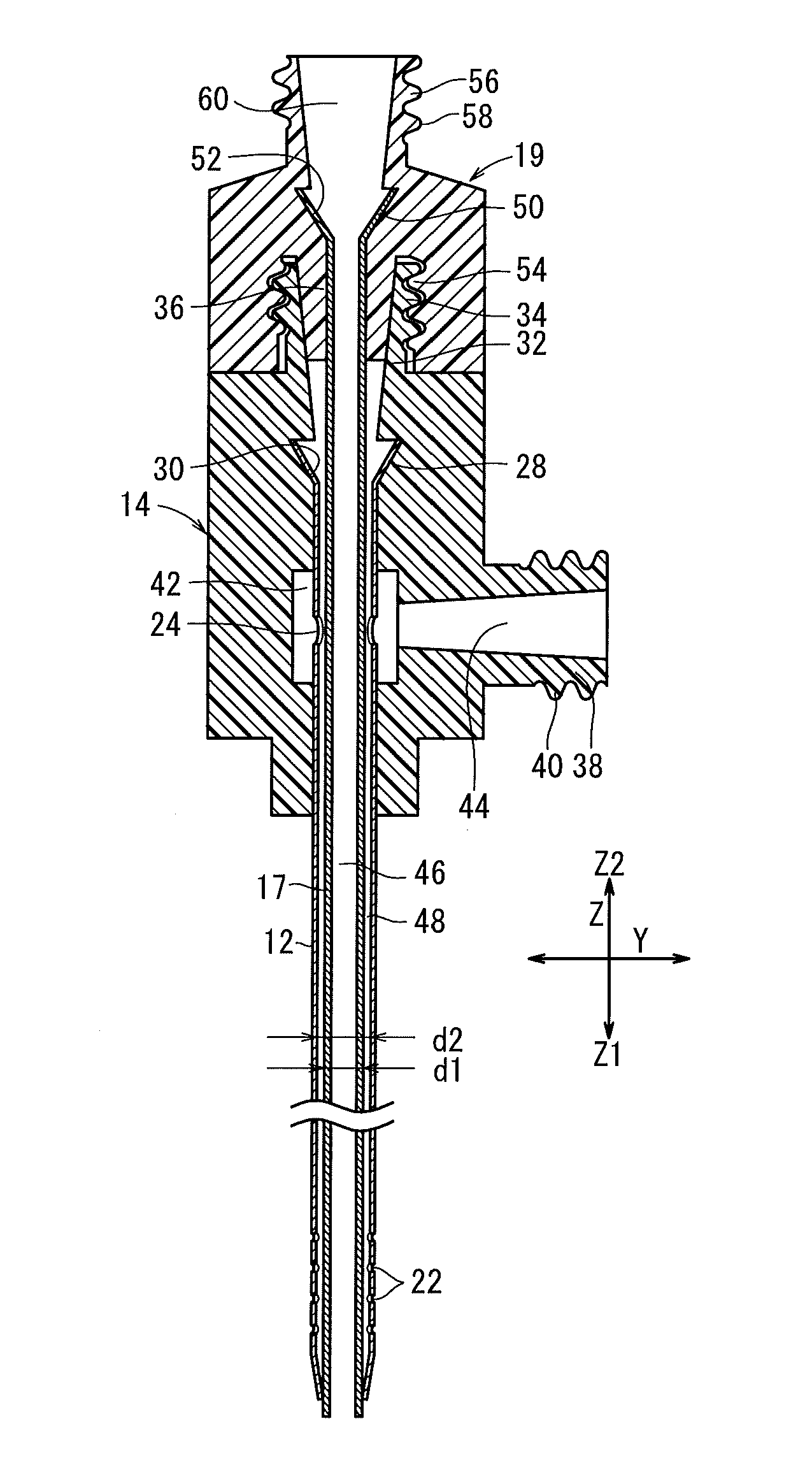

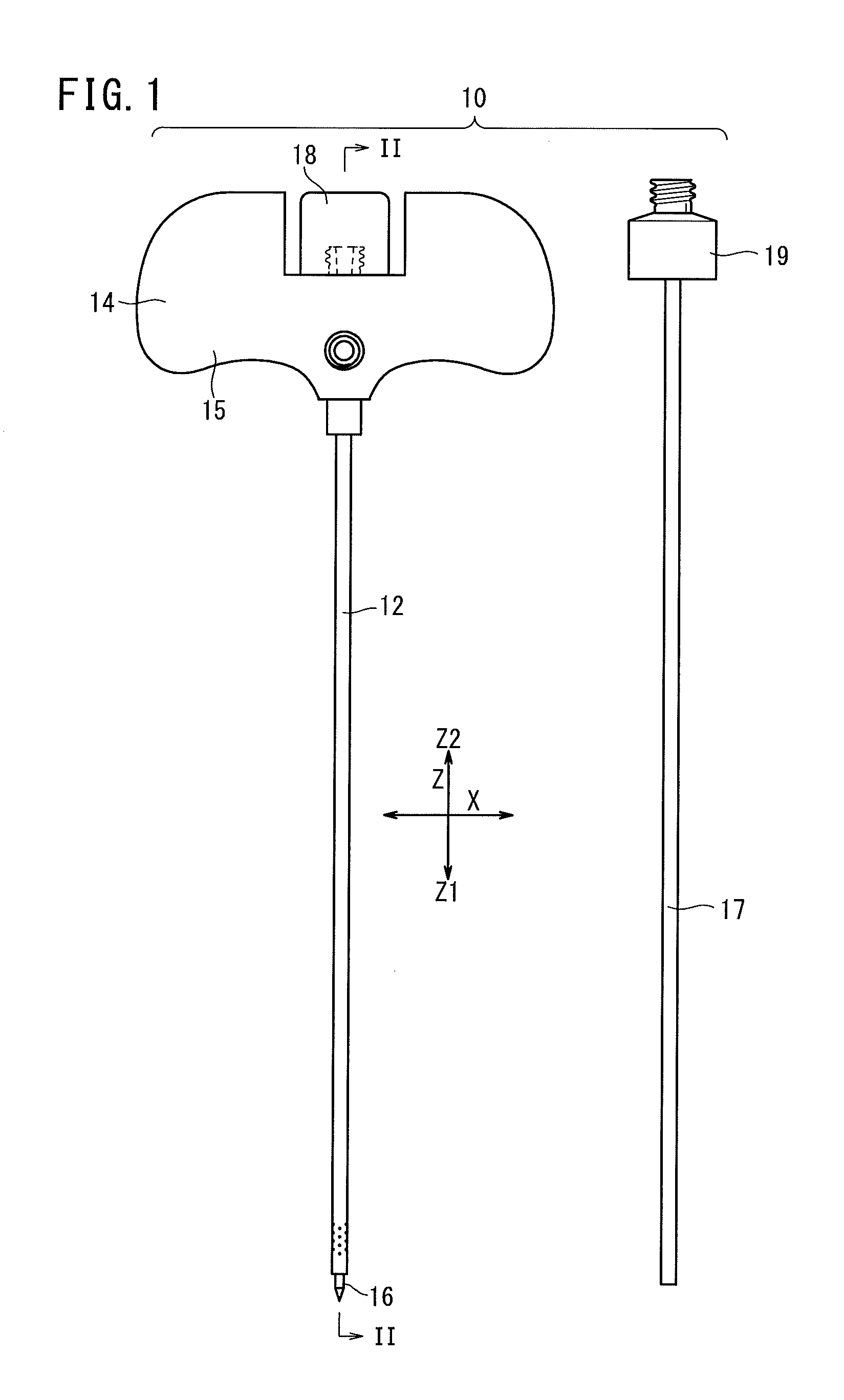

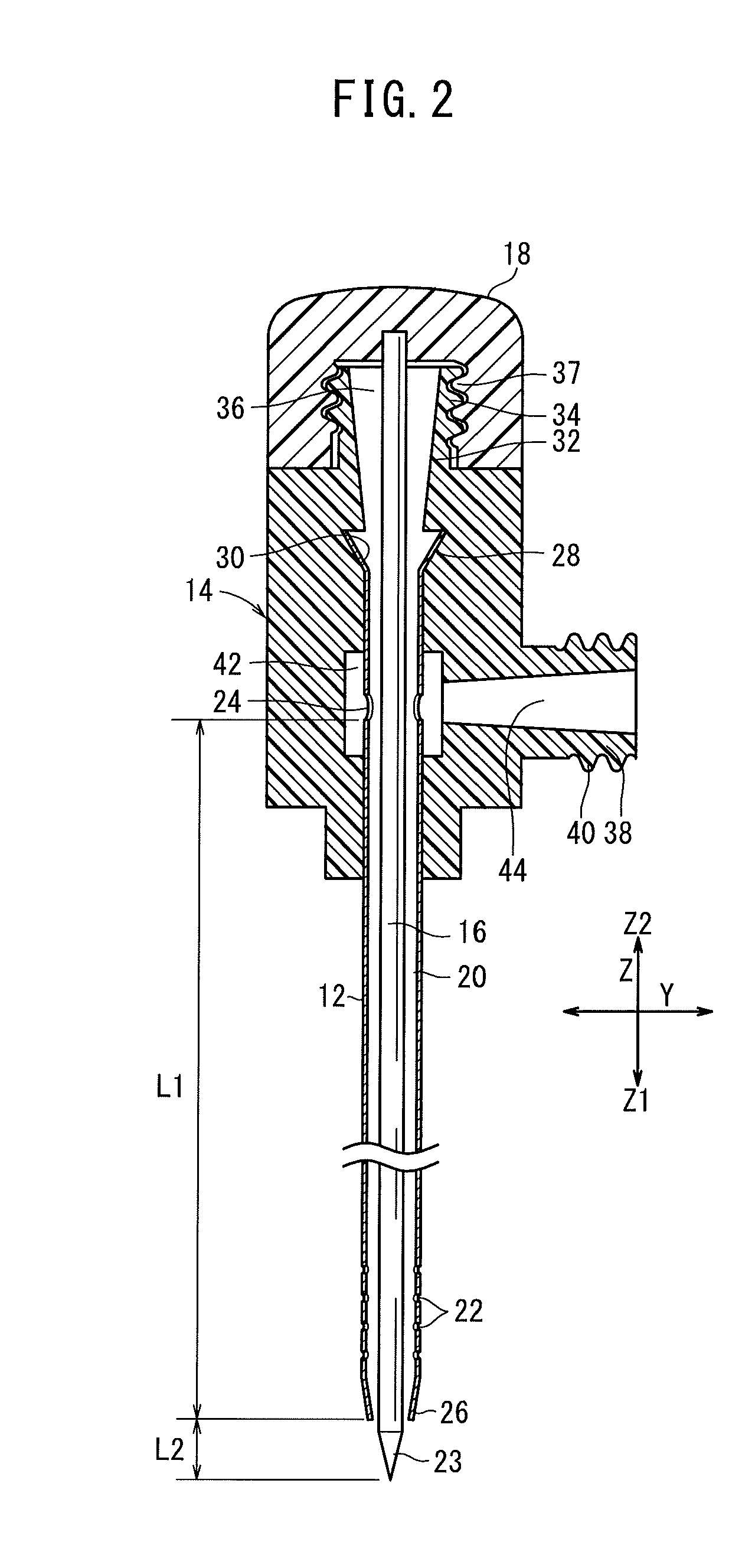

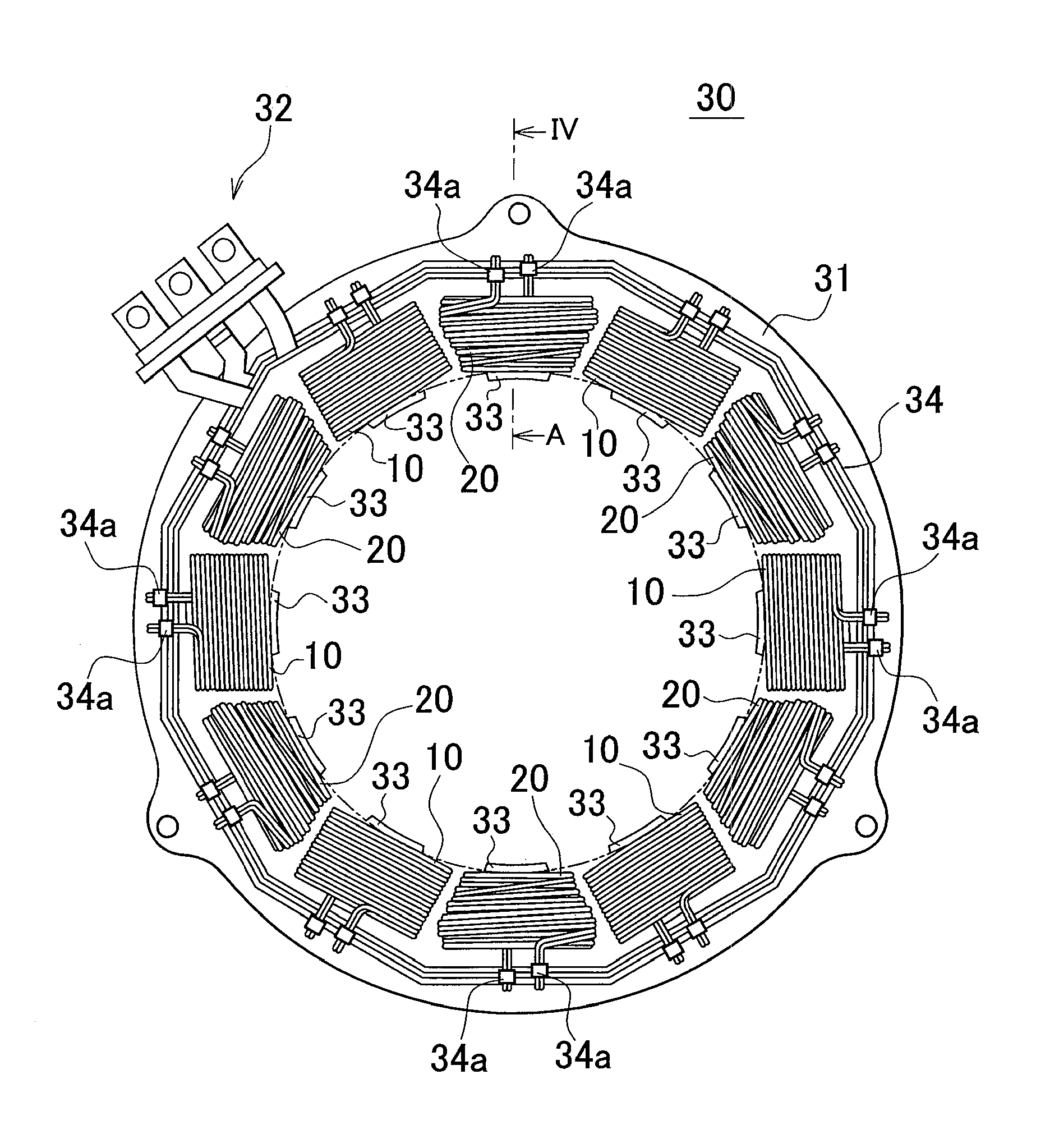

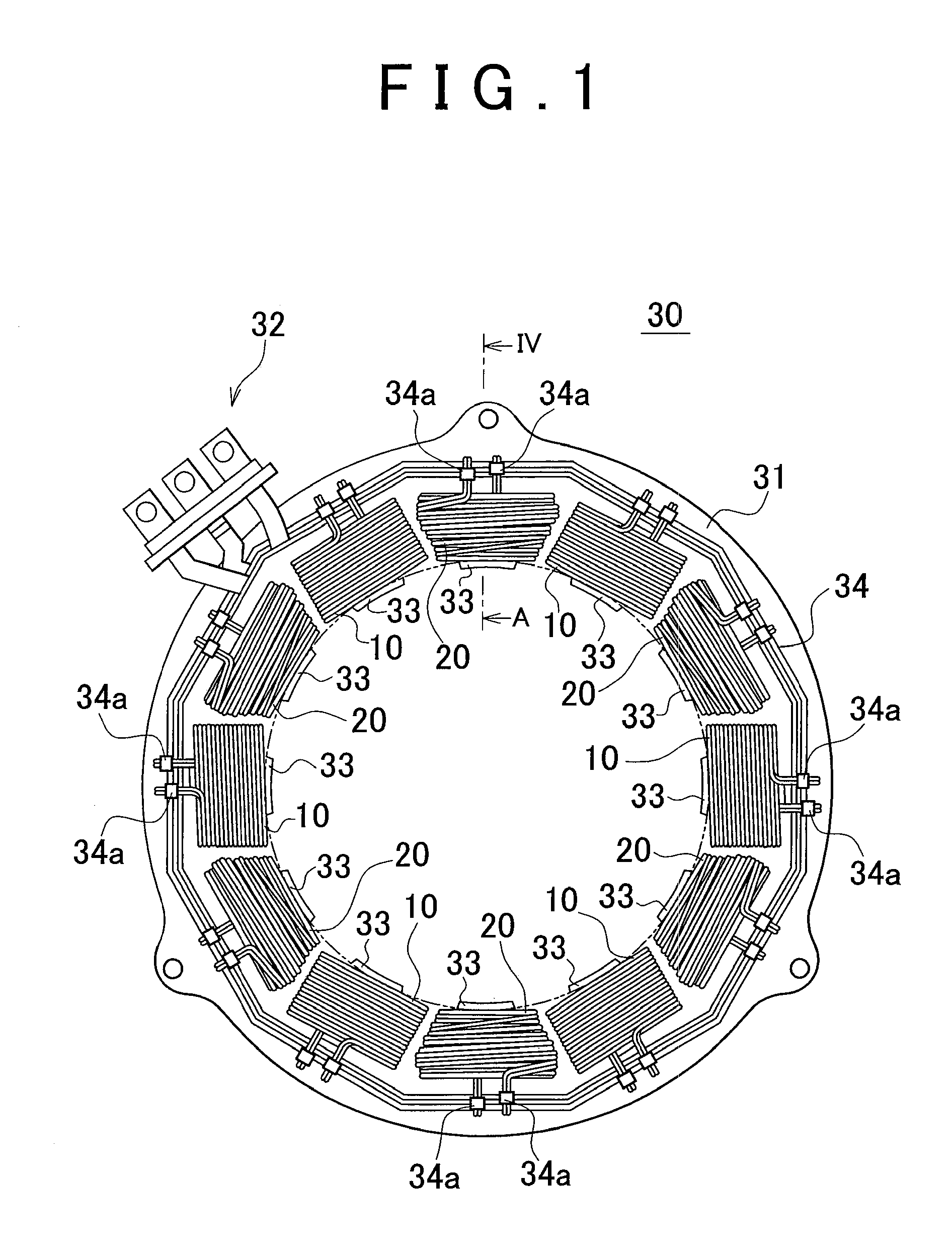

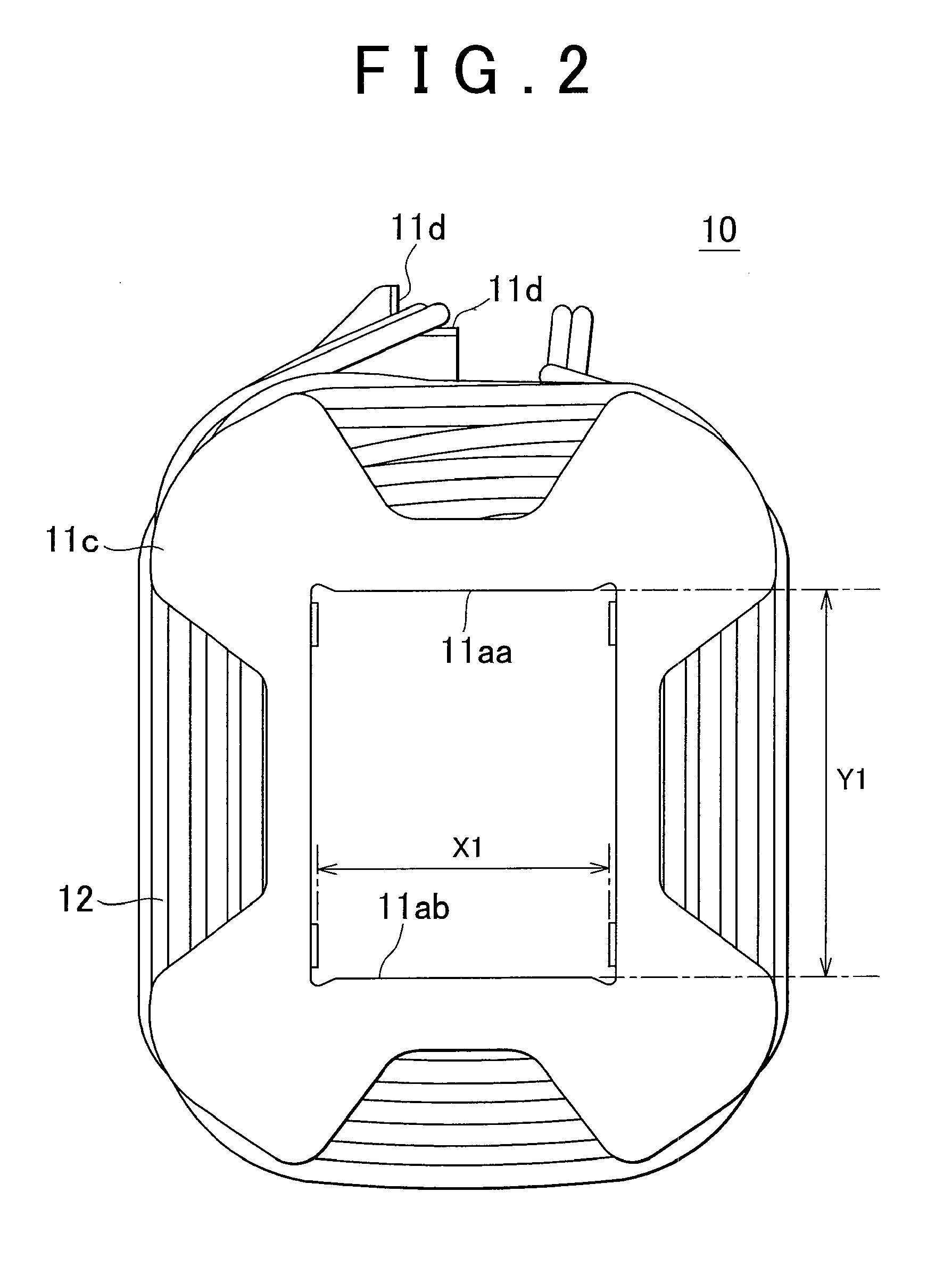

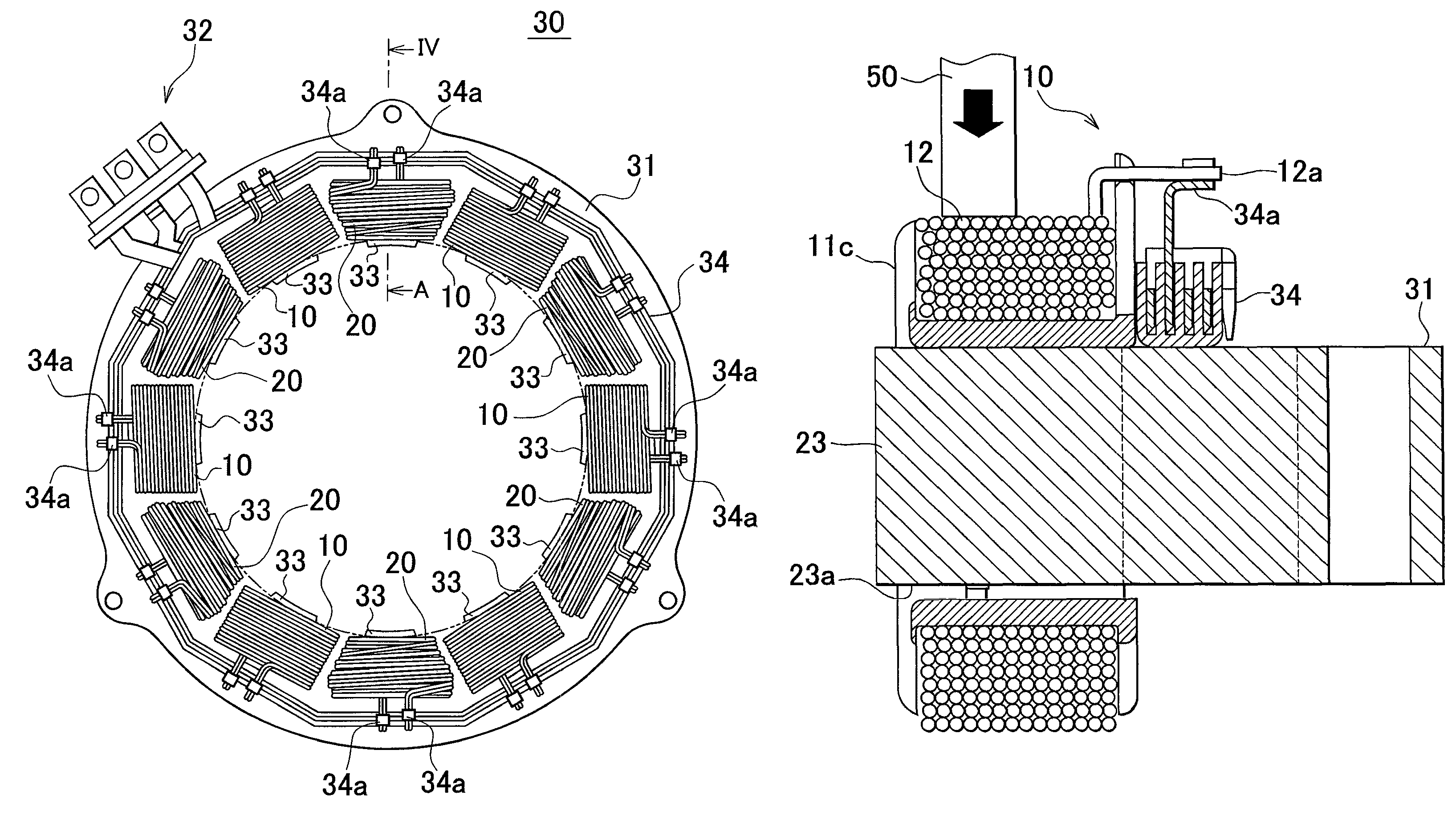

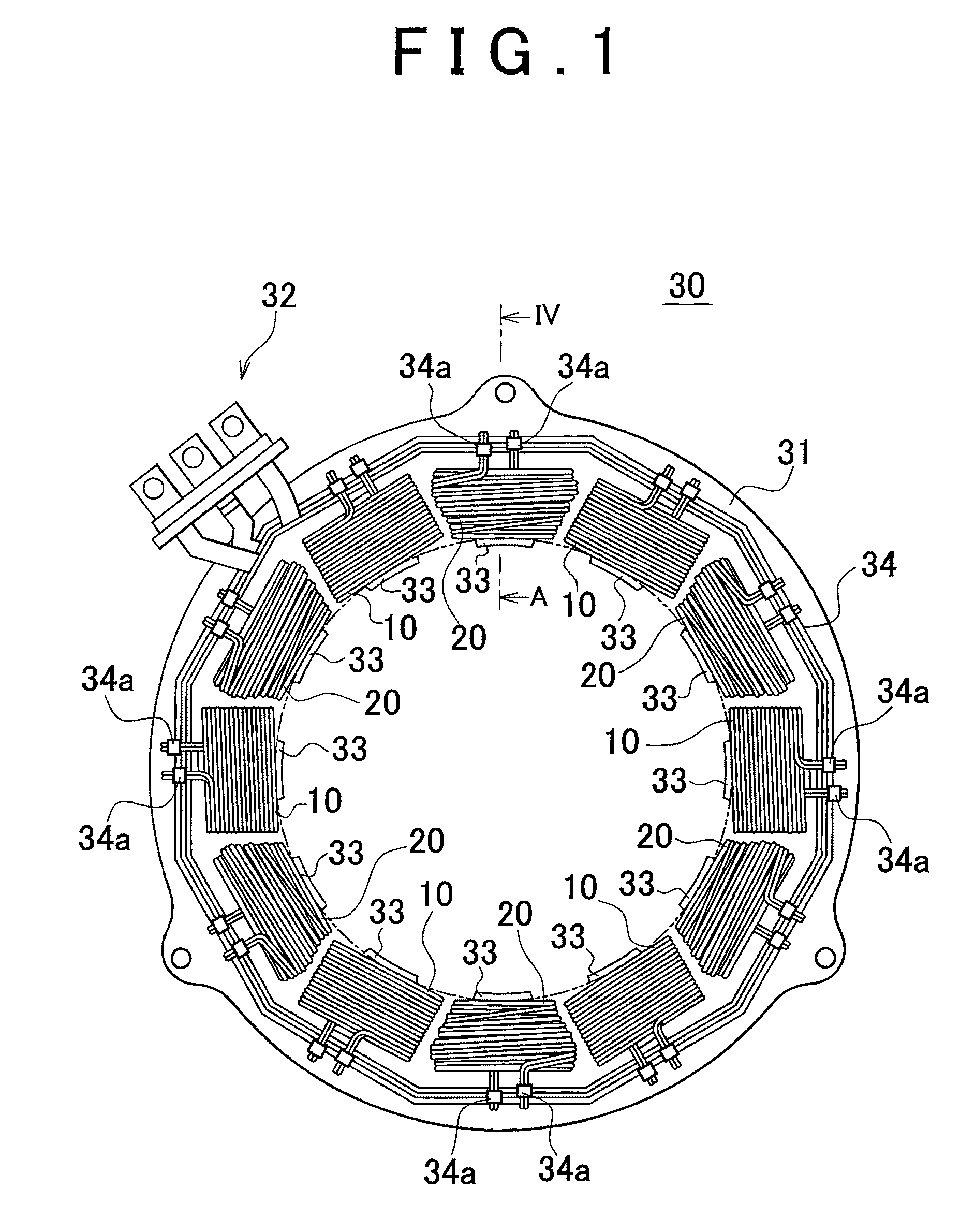

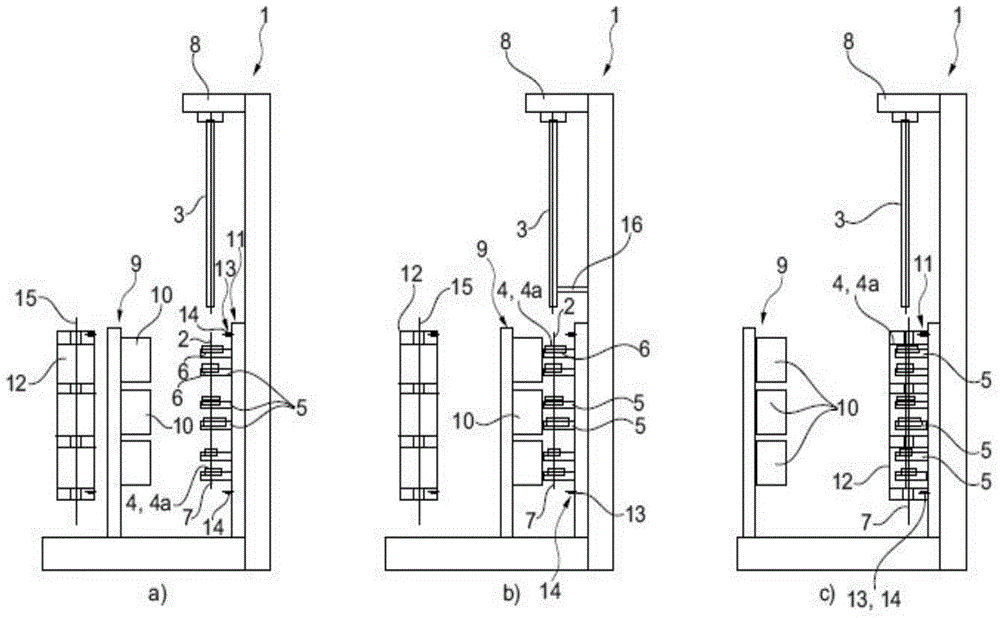

Insertion system for electrical conductor

ActiveUS20140013592A1Avoid obstructionIncrease the gapManufacturing stator/rotor bodiesMetal working apparatusElectrical conductorMoving parts

An insertion system for electrical conductors is provided that can widen the gap between insulating paper. An insertion system (1) includes: a first moving part (4) that causes a leg of the coil element (10) to move in an insertion direction of a slot (16); a guide part (3) that guides the leg into the slot (16); and a pair of first spreader plates (7A) and a pair of second spreader plates (7B) that can spread at a leading end side thereof, in which these pairs of spreader plates are formed so as to extend inclined relative to the insertion direction so as to approach each other towards a leading end side, and a gap therebetween is narrower than a width of insulating paper (17) at the leading end side, and is wider than a width of the leg of the coil element (10) at a base end side.

Owner:HONDA MOTOR CO LTD

Method and apparatus for engaging a beverage extraction device with a container

ActiveUS20130292423A1Little and no effect on beverage qualityImprove sealingLiquid dispensingWine bottleBottle neck

Devices and methods for clamping a beverage extraction device to a beverage container, such as a wine bottle. One or more clamp arms may be arranged to clamp the extraction device to a wine bottle as well as allow the device to be supported upright on a table top. Clamp arms may include tab and ridge features that operate to properly engage and position a wide variety of different bottle neck shapes relative to the device. The one or more clamp arms may move the bottle neck distally, e.g., toward a resilient pad, so that the neck is suitably positioned relative to the device. Proper positioning and engagement of the neck may allow for desired piercing of a cork or other closure of the bottle by the device.

Owner:CORAVIN

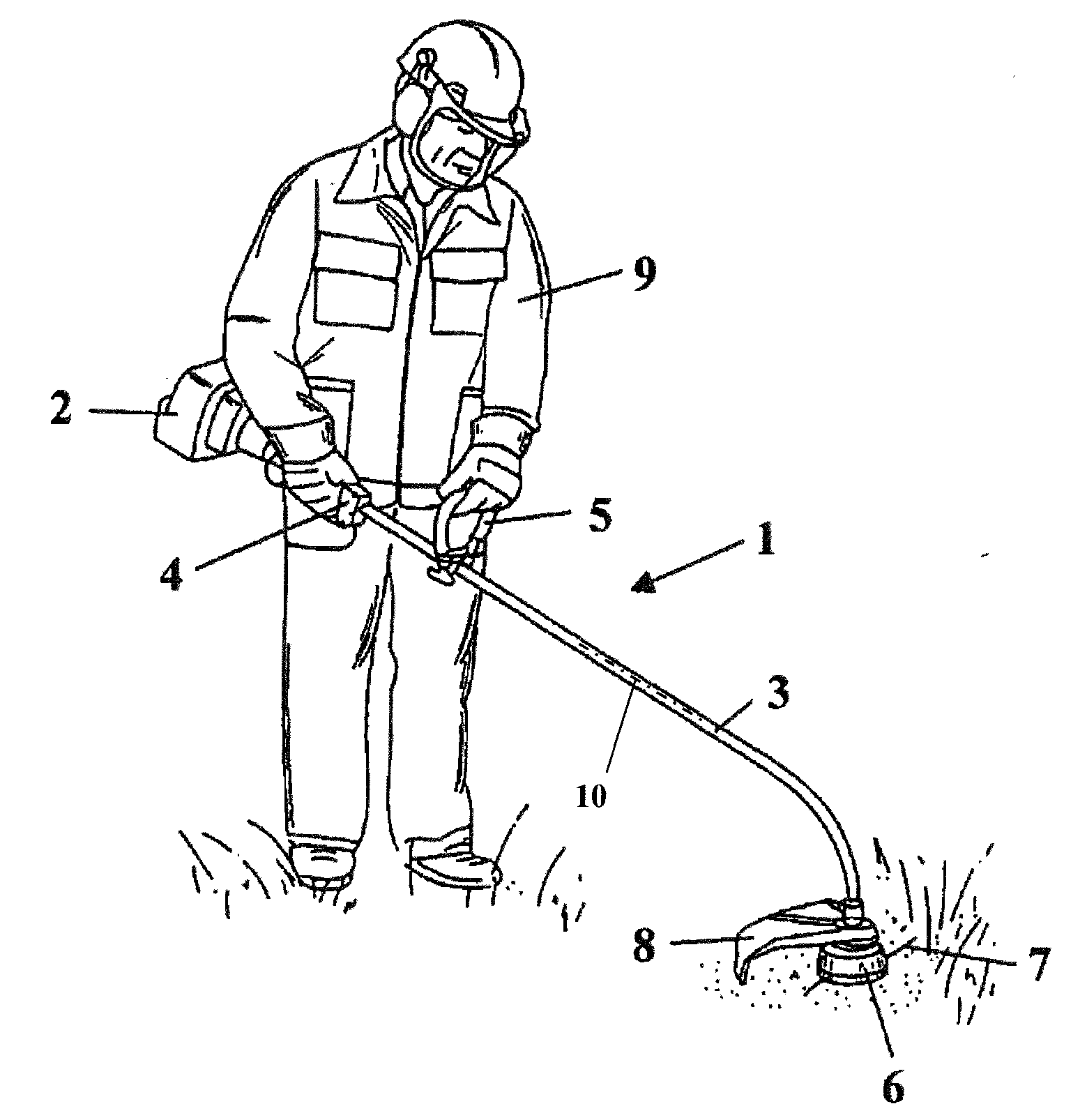

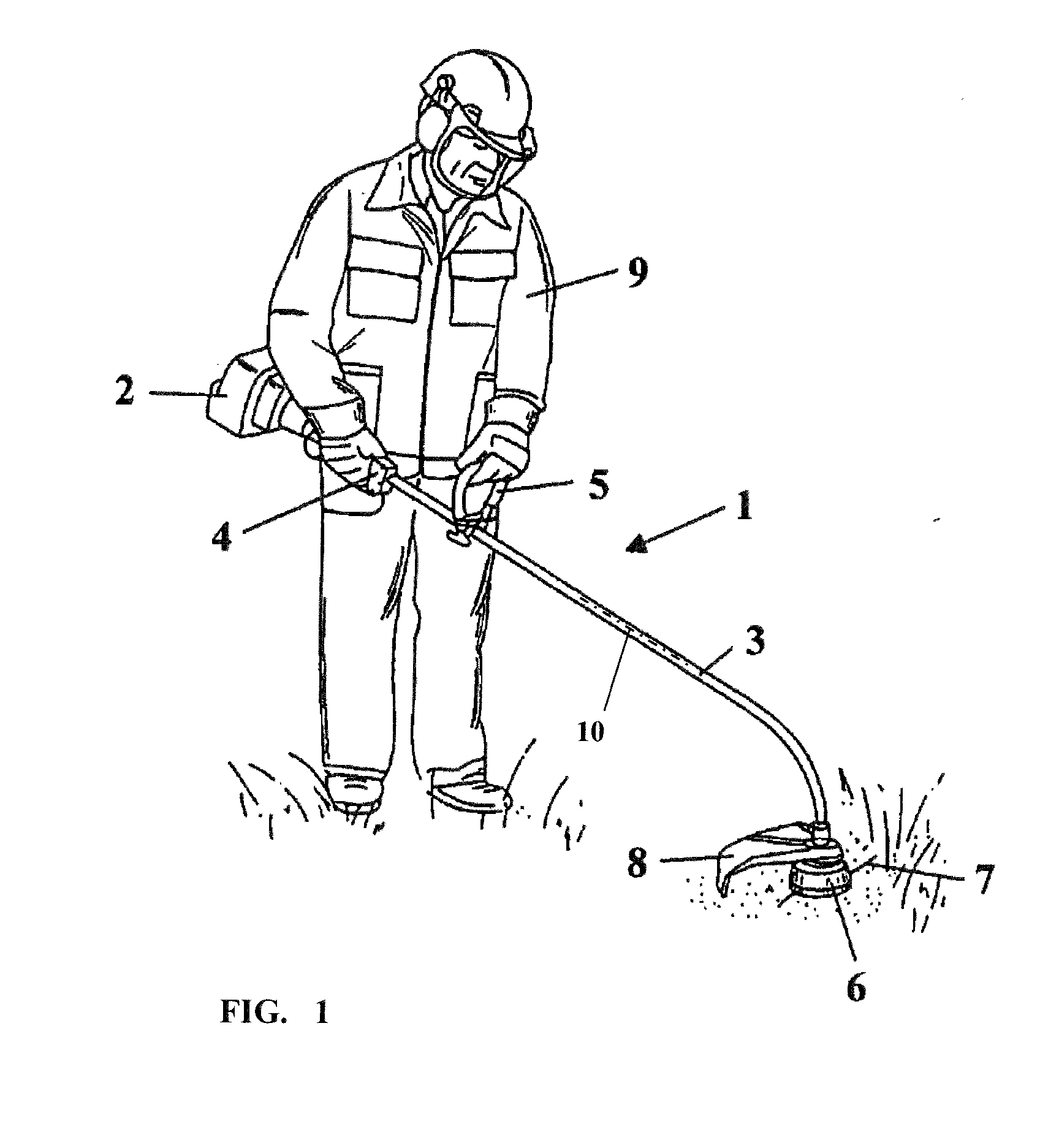

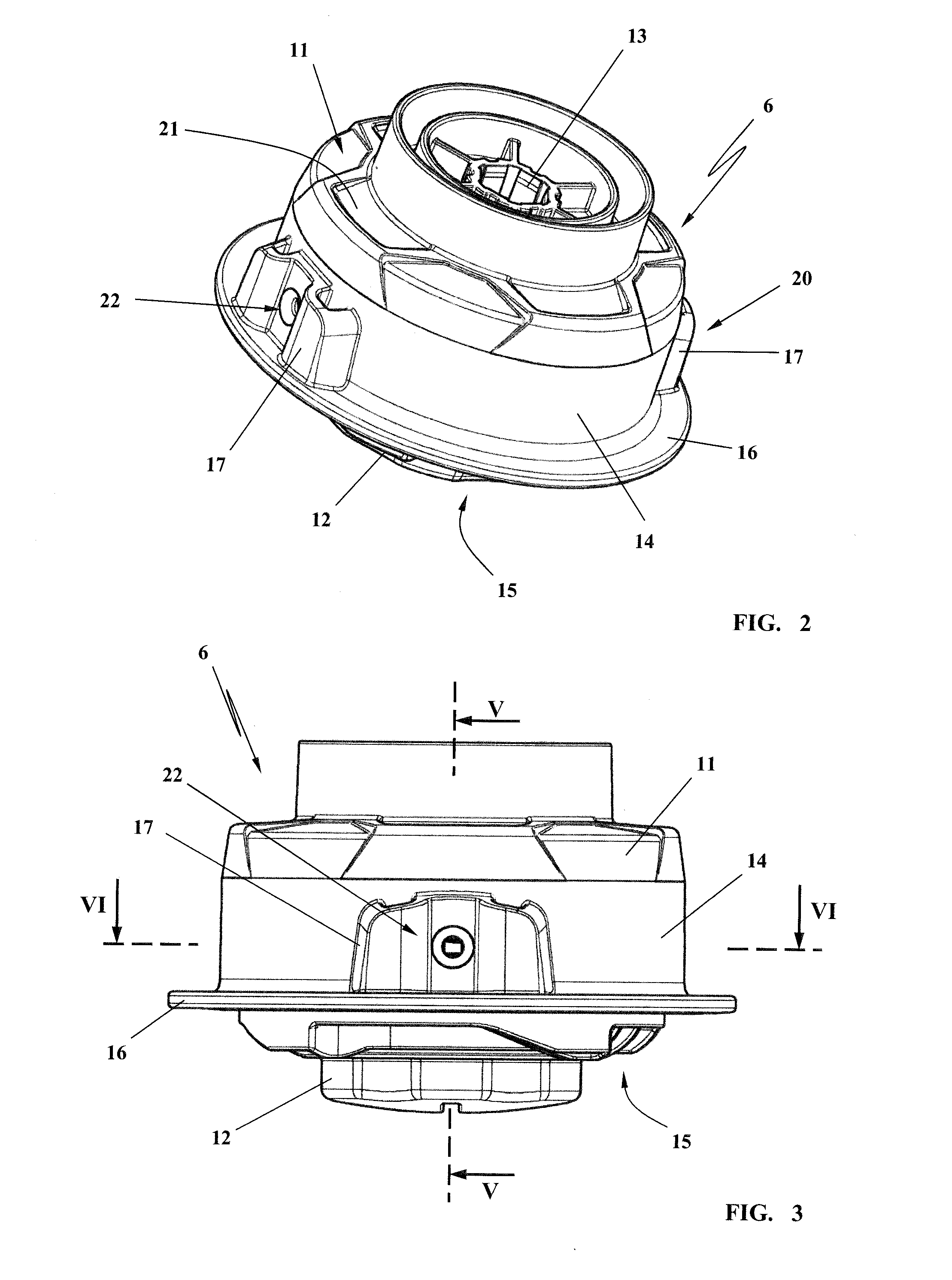

Filament cutterhead for a brushcutter

A filament cutterhead is provided for mounting on the drive shaft of a brushcutter. The filament cutterhead includes a housing with a circumferential wall wherein a first wall opening for a cutting filament is formed. A filament spool arranged in the housing is rotatable relative to the housing. A filament channel with a filament inlet segment is provided in a partition wall of the filament spool. The filament channel extends from the filament inlet segment past the hub to a filament outlet segment which is assigned a second wall opening in the circumferential wall. The filament outlet segment is at an offset (v) with respect to the filament inlet segment in the circumferential direction of the hub. The mouth of the filament inlet segment and the mouth of the filament outlet segment lie within an outside diameter (A) of the partition wall and open into a pass-through space.

Owner:ANDREAS STIHL AG & CO KG

Apparatus and method for insertion of material in broadcasting

InactiveUS6986153B1High degree of integrationLow costElectrical cable transmission adaptationDigital non-picture data transmissionCable televisionControl unit

A system, apparatus, and method for local insertion of analog or digital material into a television broadcast signal. A central insertion control unit controls the insertion of additional material while a remote insertion control unit locally controls the insertion of the additional material. The central insertion control unit contains a processor, storage media, and an encoder for encoding control and information signals into a broadcast signal. The control signal contains a cue signal for information about play lists, and an action signal for triggering insertion of the additional material. The control signal is encoded into a line of the vertical blanking interval. Once the control is detected by the remote insertion control unit the additional material is played and broadcast.

Owner:PINNACLE SYST INC A CORP CALIFORNIA +1

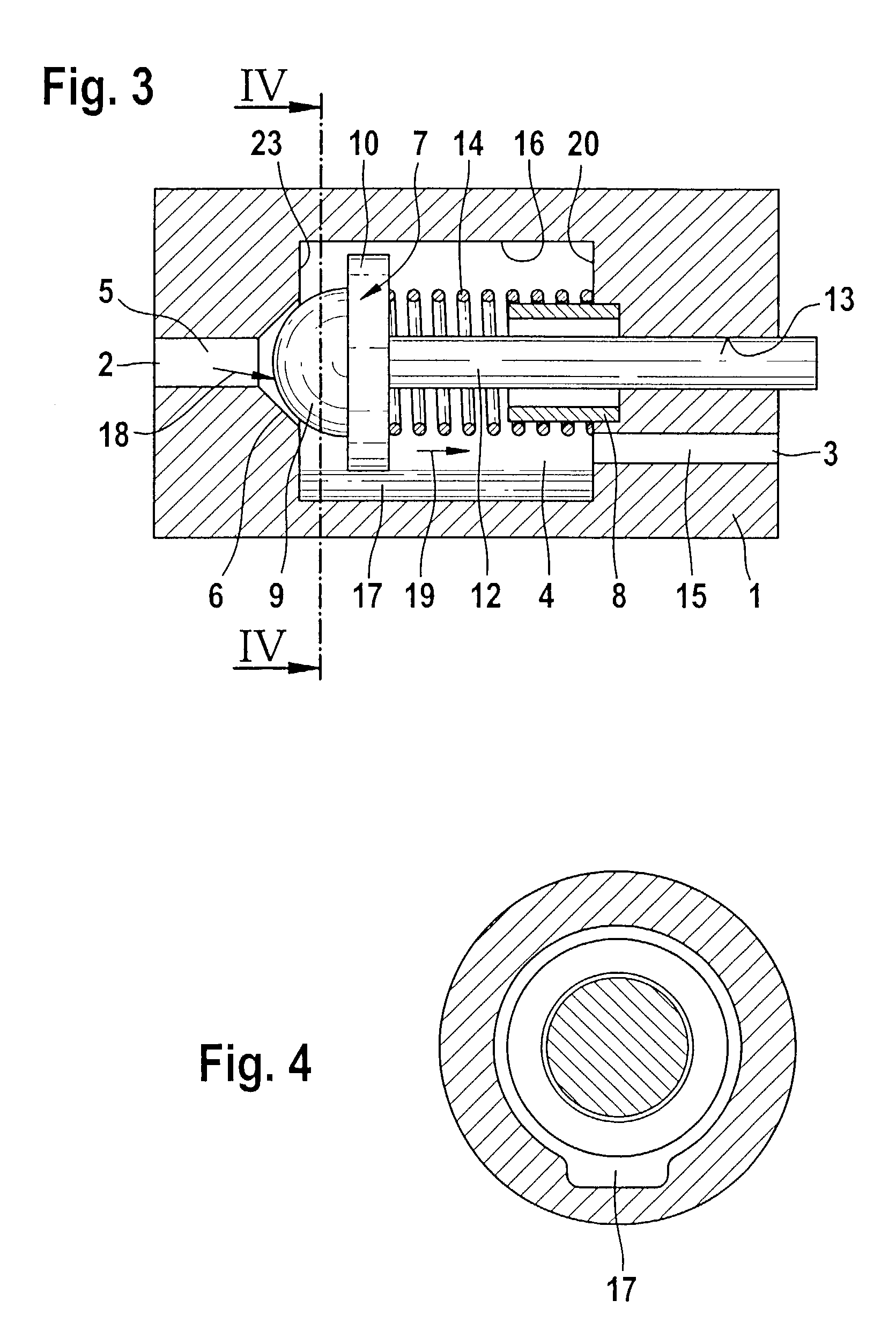

Check valve

InactiveUS6968858B2Improve sealingLow production costCheck valvesEqualizing valvesEngineeringCheck valve

The check valve according to the invention significantly reduces the generation of noise by producing an asymmetrical circulation around the closing body causing a force resulting from the flow and acting on the closing body to have a transverse component in relation to the opening direction, as a result of which increased friction and damping are generated in the closing body guide. The closing body may be asymmetrically embodied, or the housing wall encompassing the closing body may be provided with a conduit extending in the opening direction over at least a part of the travel path of the closing body.

Owner:ROBERT BOSCH GMBH

Catheter kit for burrow

Disclosed is a catheter tool for fistula with excellent operability including a catheter and a sealing device. The catheter has a flexible tube and an indwelling part in the body. The flexible tube extends along the wall of the fistula hole. A nutrition passage is provided inside the fistula hole to introduce nutrition or medicinal liquid into the stomach. The indwelling part in the body is attached to the soft tube. The protruding shape of the front end of the tube is a non-balloon indwelling part in the stomach in the body buried state while shrinking from the protruding state due to the external force caused by the sealing device. The sealing device is pulled out A sealing device that may be matched to the aforementioned catheter, which has a guide wire passage and an operation part, the guide wire passage is used to insert the guide wire attached from the front end to the middle of the guide wire, and the operation part is used to insert the guide wire attached to the rear end of the guide wire passage. The indwelling part in the body transmits the external force, and the rear end part of the guide wire channel and the operation part are arranged in a separated state.

Owner:SUMITOMO BAKELITE CO LTD +1

Bone cement injection puncture needle

InactiveUS20120330320A1Reduce internal pressurePrevent buildupBone implantSurgical needlesMedicineSurgery

An outer needle of a bone cement injection puncture needle has first side holes near the tip, and second side holes near the base. When an inner needle is removed from the outer needle and an inner tube is inserted into the outer needle in place thereof, a reduced-pressure passage is formed between the outer needle and the inner tube. When bone cement is injected into a bone, gas and liquid in the bone pass through the reduced-pressure passage and are discharged from the body, thereby preventing increased pressure in the bone. As a result, the bone cement can be prevented from leaking to outside of the bone.

Owner:ST MARIANNA UNIV SCHOOL OF MEDICINE +1

Stator mounting method

InactiveUS20090230793A1Reduce in quantityReduce dispersionSynchronous generatorsWindingsEngineeringLower face

In a stator mounting method in which a coil unit is inserted into a stator core and a lead wire protruding from the coil unit is inserted into and mounted on a terminal portion of the stator core, the lead wire is passed through a lead wire pullout portion located at a predetermined position of a coil frame body, a height from an inner peripheral upper face of the coil frame body to the lead wire pullout portion is equalized with a distance from a core upper face of the stator core to a lead wire insertion position inner peripheral lower face of the terminal portion, and the core upper face of the stator core is held in contact with an inner peripheral upper face of the coil frame body after the lead wire is inserted into the terminal portion.

Owner:TOYOTA JIDOSHA KK

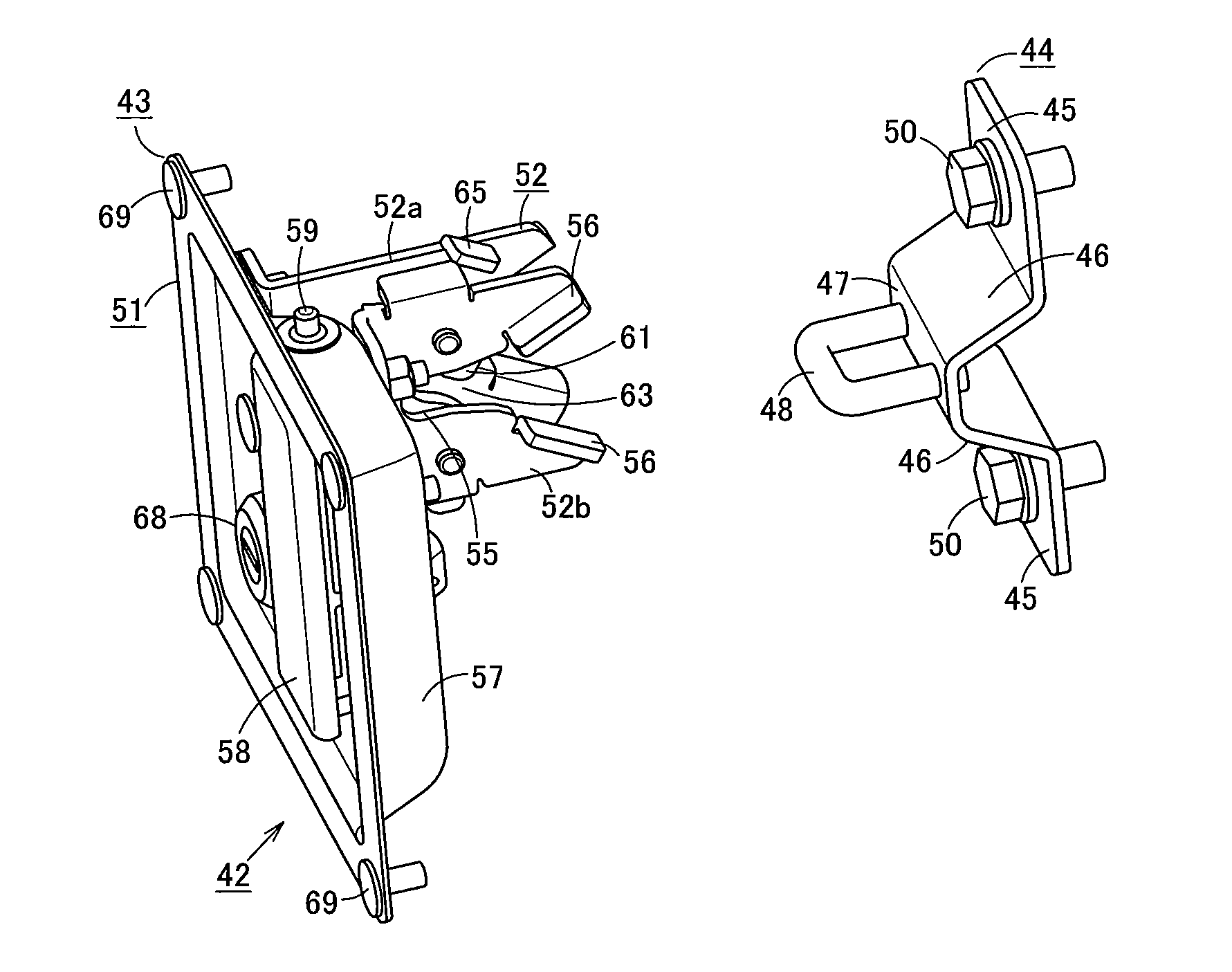

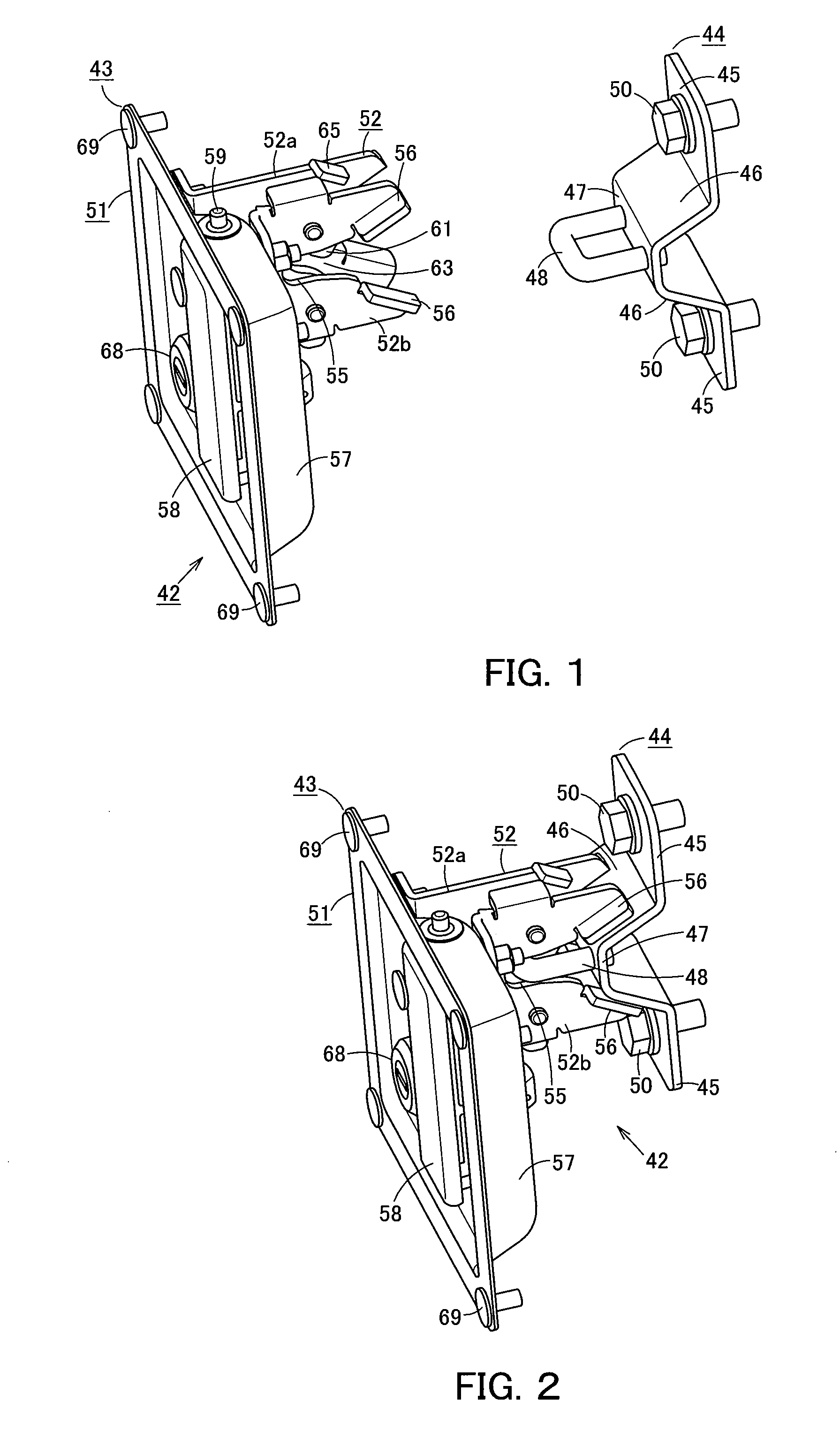

Door unit

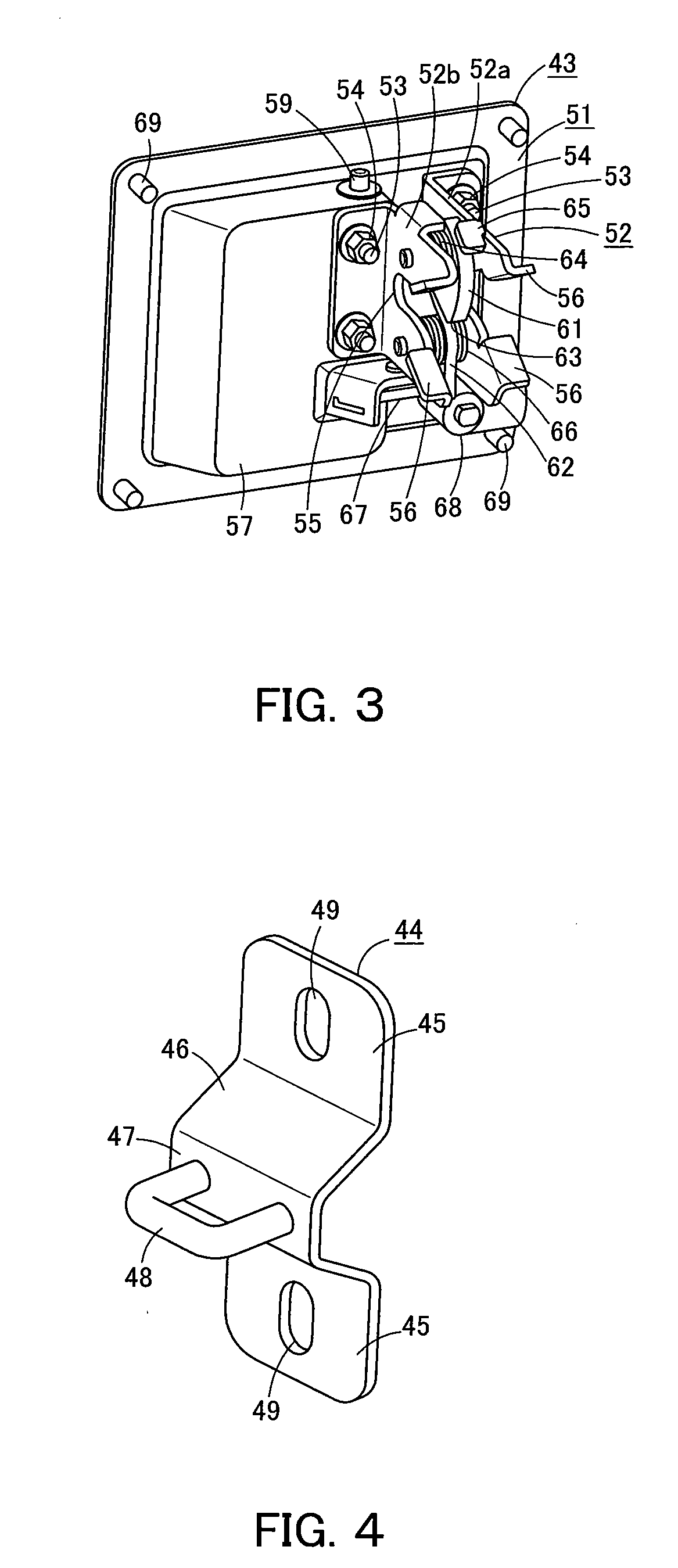

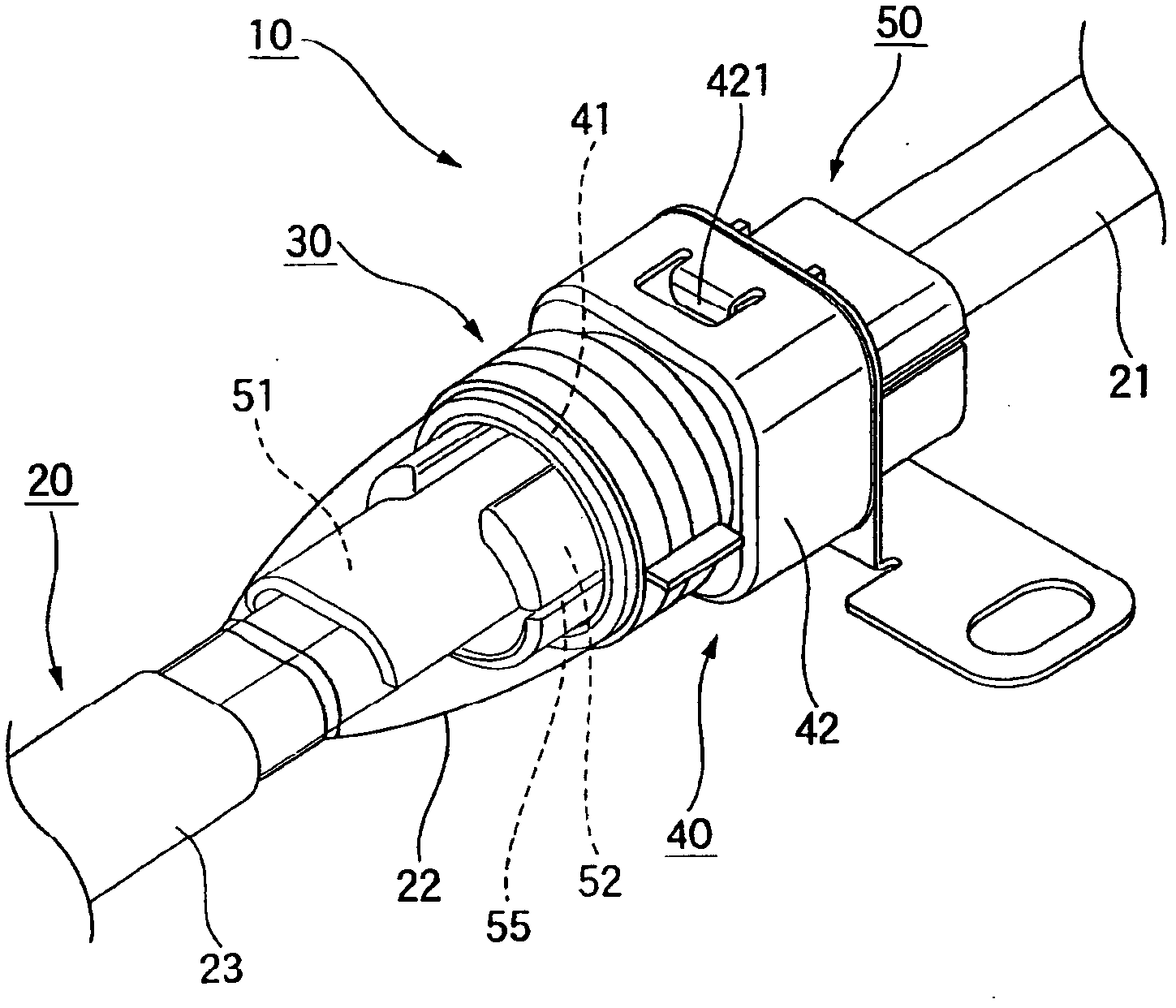

ActiveUS8439409B2Layout can be facilitatedAvoid vibrationNoise-prevention/anti-rattling lockingWing fastenersEngineeringHooking

Owner:CATEPILLAR SARL

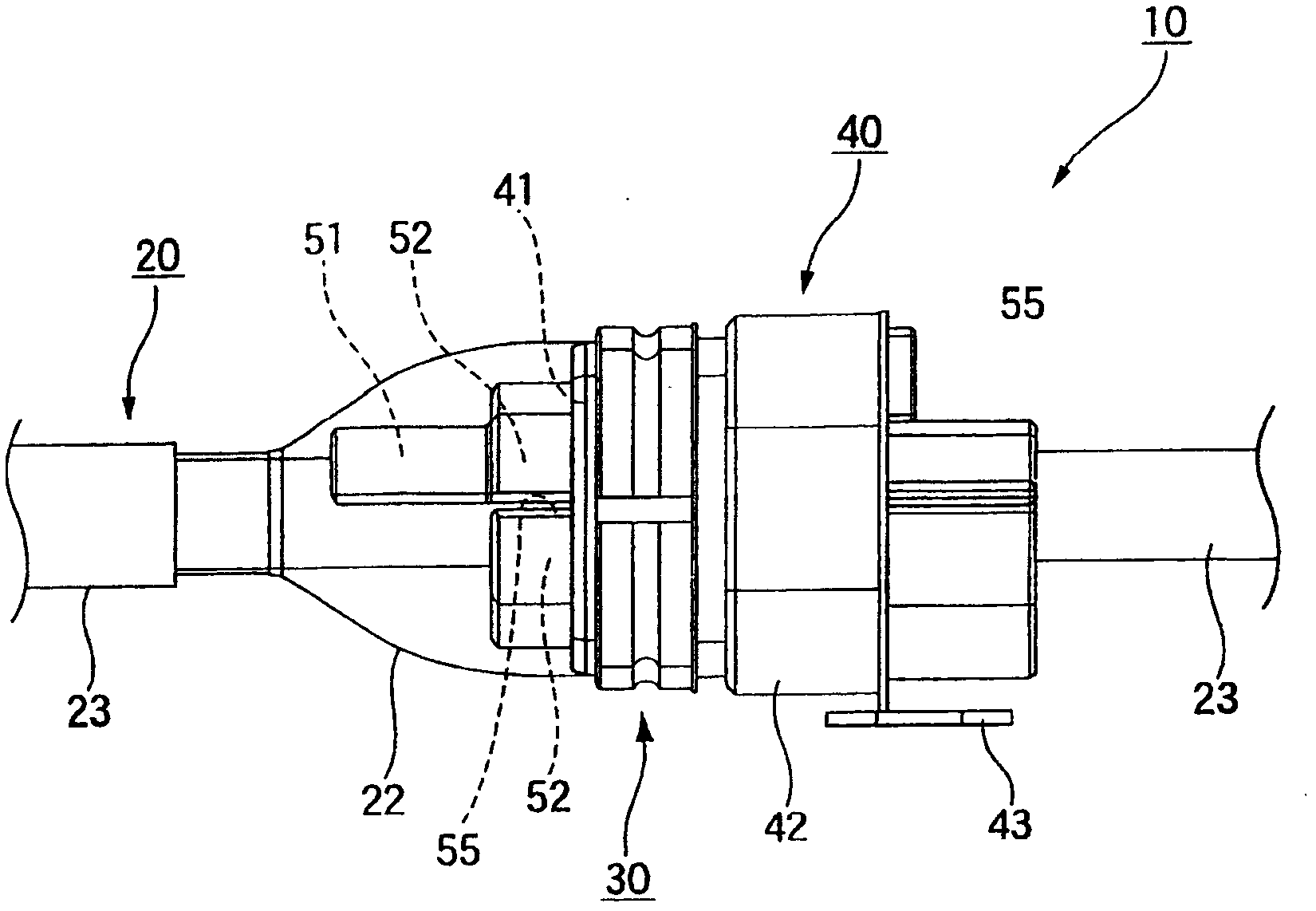

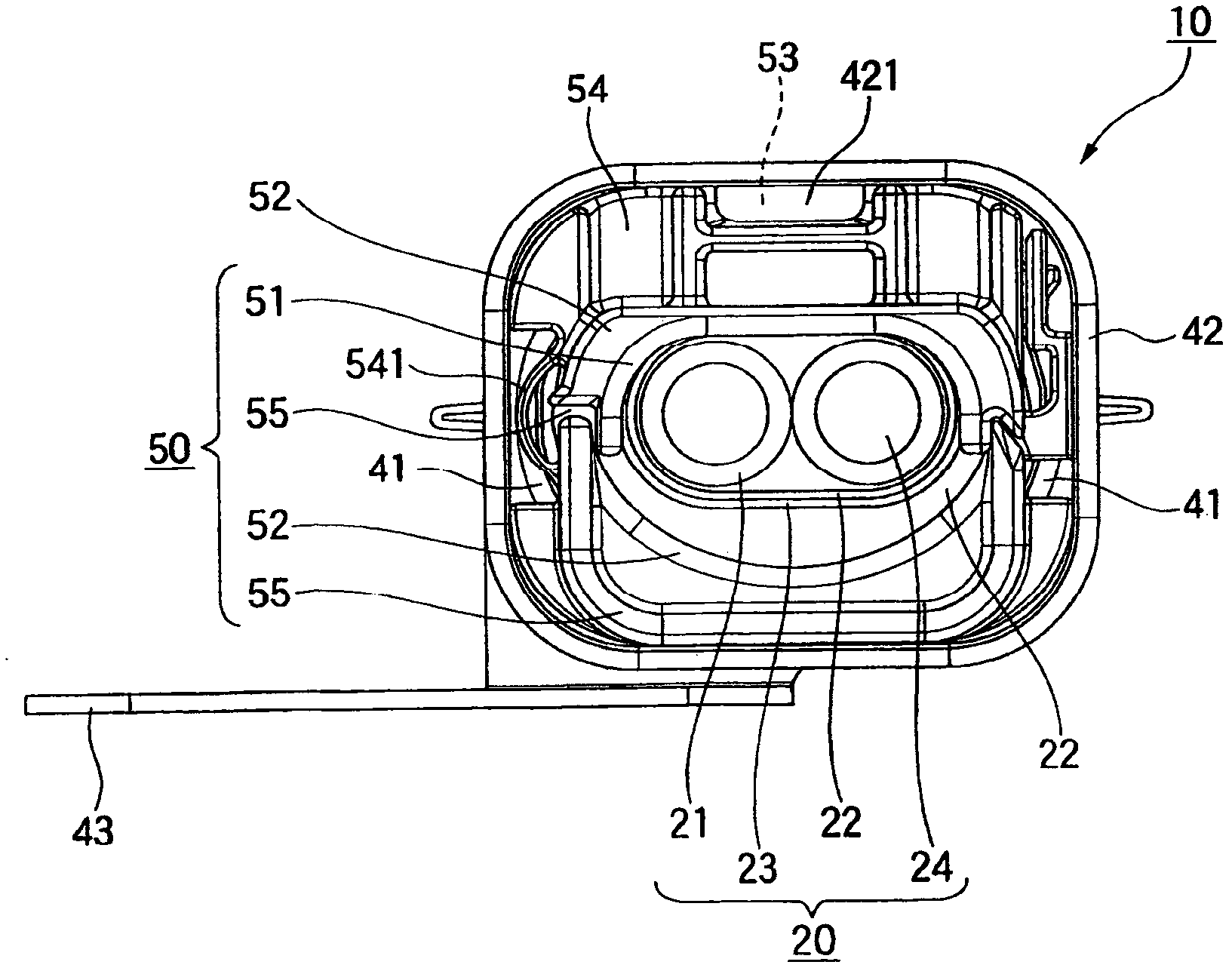

Fixing structure of shield electric wire and fixing method for shield electric wire

ActiveCN102422490AAvoid distortionAvoid deformationElectrically conductive connectionsCoupling protective earth/shielding arrangementsEngineeringElectric wire

A fixing structure includes: a shield electric wire; a shield shell having a small diameter part having a hollow tubular-shape through which the exposed part passes, and an outer periphery being covered with an end of a peeled braided part of the shield electric wire, and a main body part having a hollow shape extended from the small diameter part and through which the shield electric wire passes; a shield ring clamped to the small diameter part under a state that the end of the peeled braided part is located between the shield ring and the small diameter part; and an inner holder that is inserted into and fixed to an inner part of the main body part under a state that the shield electric wire passes through the inner holder.

Owner:YAZAKI CORP

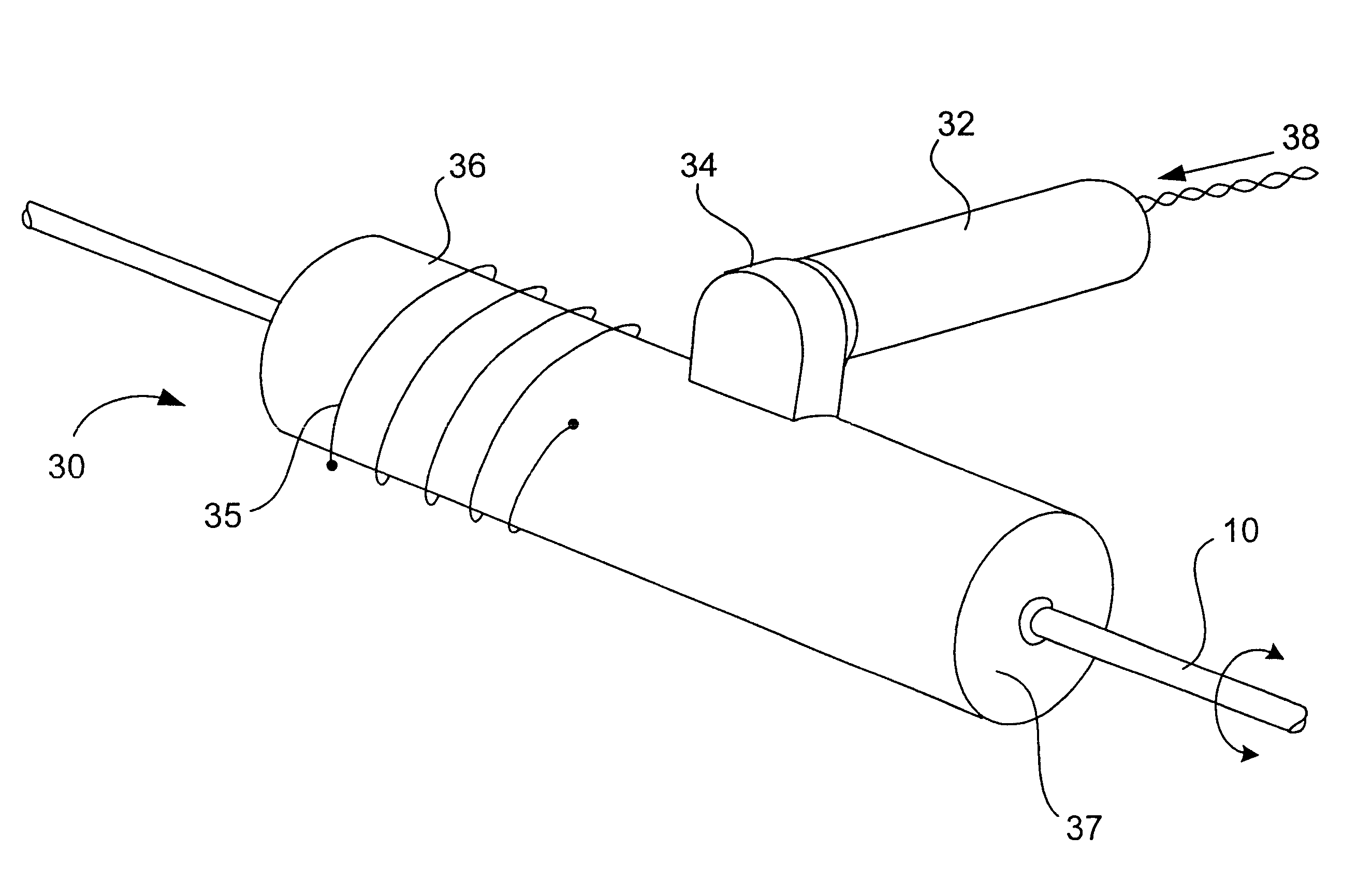

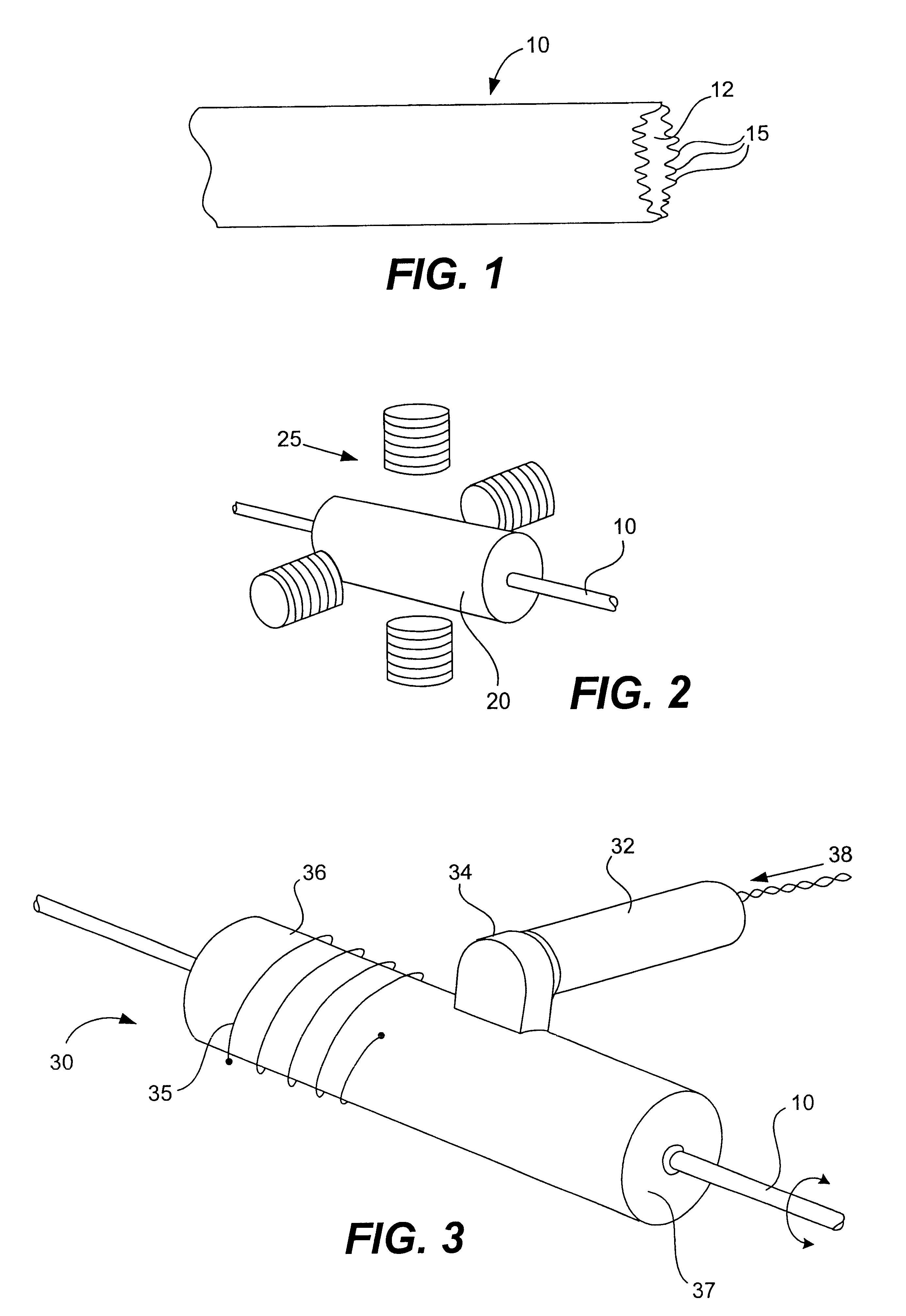

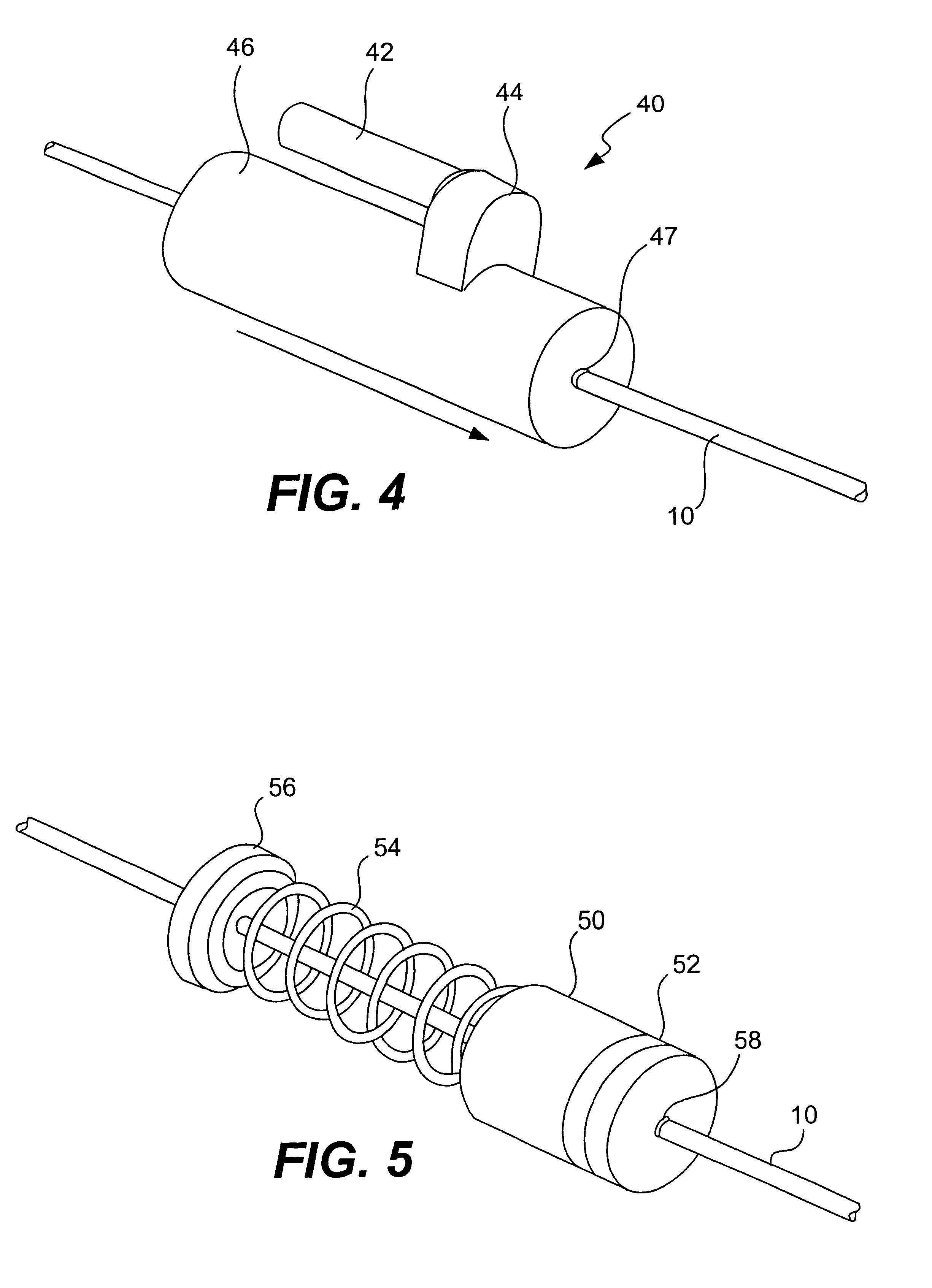

Brachytherapy apparatus and methods

InactiveUS6712782B2Reliable insertionPrecise positioningElectrotherapyDiagnosticsLinear motionBrachytherapy device

A brachytherapy apparatus is composed of a tubular needle with forwardly protruding cutting edges at its tip, a holder supporting the needle and a driver for electromechanically causing the needle to undergo a continuous or oscillatory rotary motion around its axis and / or a reciprocating linear motion in the longitudinal direction such that its front opening at its tip can reliably reach a specified position inside a patient's tissue without being deflected or bowing when it encounters an obstruction such as a calcification or a small bone. Such motions may be provided by a piezoelectric hammer and a piezoelectric tamper. After the needle is thus correctly positioned, a brachytherapy device such as a radioactive seed or a reflector may be pushed through and out of the needle by means of a pusher as the needle is retracted to leave a track inside the tissue. A quickly hardening liquid may be thereafter injected through the needle to immobilize the deposited brachytherapy device. Another brachytherapy device may be deposited similarly after the needle is retracted by a specified distance. A plurality of brachytherapy devices may be preliminarily prepared as a unit having them linearly arranged inside a hardened liquid and mutually separated by specified distances such that they can be pushed together through the needle, or they may be injected together with a quickly hardening liquid.

Owner:VARIAN MEDICAL SYSTEMS

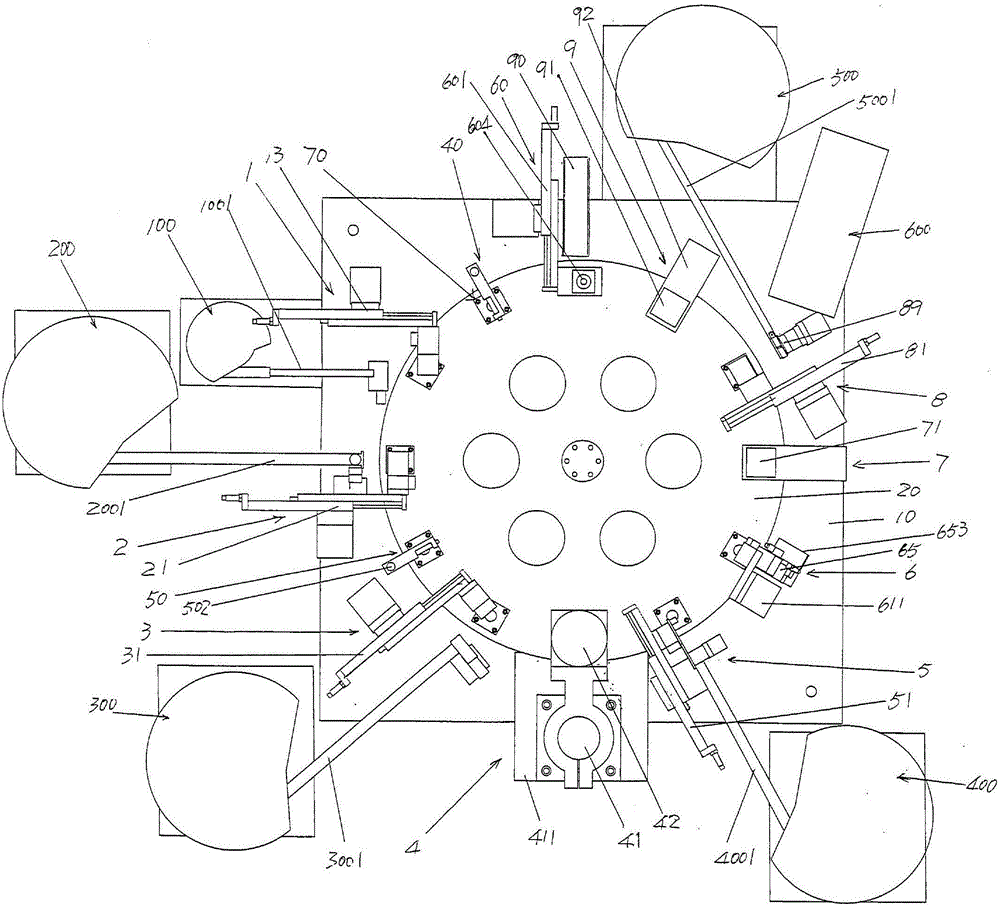

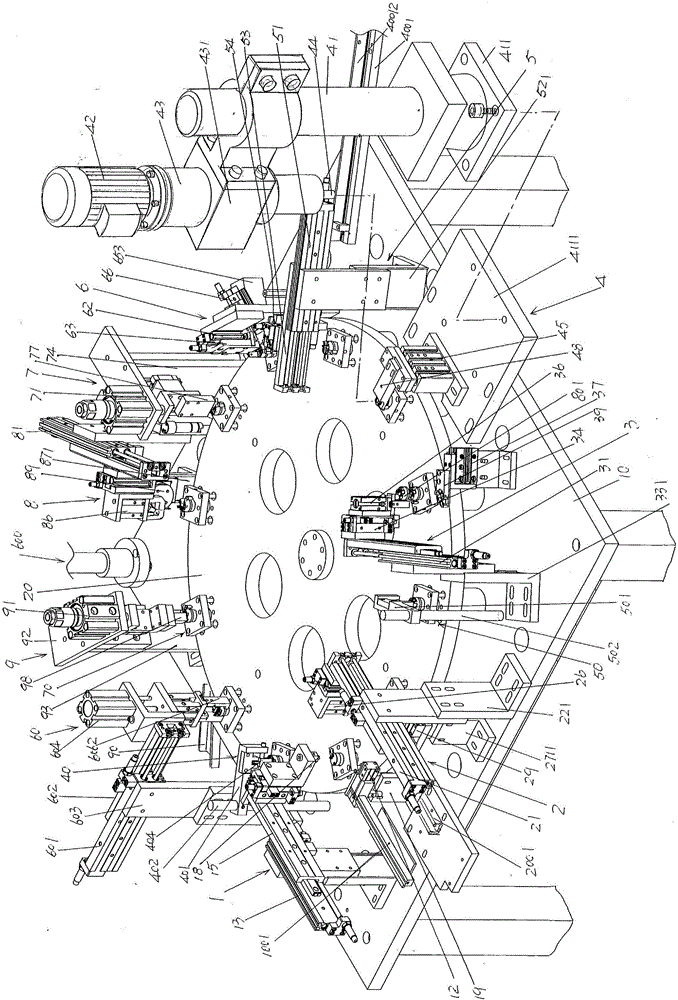

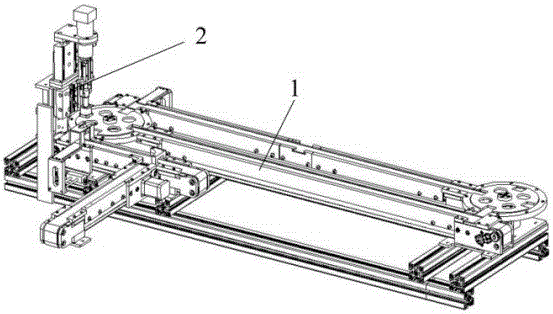

Automatic refrigerating compressor motor protector assembling device with plug-in sheet pressing and fixing function

ActiveCN106624793AReliable insertionAvoid loosening or falling out of the protector baseAssembly machinesRefrigeration compressorEngineering

An automatic refrigerating compressor motor protector assembling device with a plug-in sheet pressing and fixing function comprises a workbench, a rotary disc, a rotary disc driving mechanism, a retained workpiece detecting and sensing mechanism, a rivet installing mechanism, a protector base fetching and releasing mechanism, a workpiece omission detecting and sensing mechanism, a static contact installing mechanism, a rivet spinning and riveting mechanism, a movable contact fetching and releasing mechanism, a movable contact prepressing mechanism, a movable contact hold-down mechanism, a plug-in sheet fetching and releasing mechanism and a protector removing mechanism. The automatic refrigerating compressor motor protector assembling device is characterized by further comprising a plug-in sheet pressing and fixing mechanism which is located between the plug-in sheet fetching and releasing mechanism and the protector removing mechanism, the plug-in sheet pressing and fixing mechanism comprises a plug-in sheet pressure foot air cylinder, a plug-in sheet pressure foot air cylinder seat, plug-in sheet pressure foot air cylinder seat supporting stand columns, a plug-in sheet pressure foot air cylinder seat bearing plate, a plug-in sheet pressure foot air cylinder and column connecting seat, a plug-in sheet pressure foot air cylinder and column connecting seat sliding block, plug-in sheet pressure foot seats and plug-in pressure feet. By the adoption of the automatic refrigerating compressor motor protector assembling device, the situation that plug-in sheets are loose and even are disengaged from a protector base in the using process is avoided.

Owner:CHANGSHU TIANYN ELECTROMECHANICAL

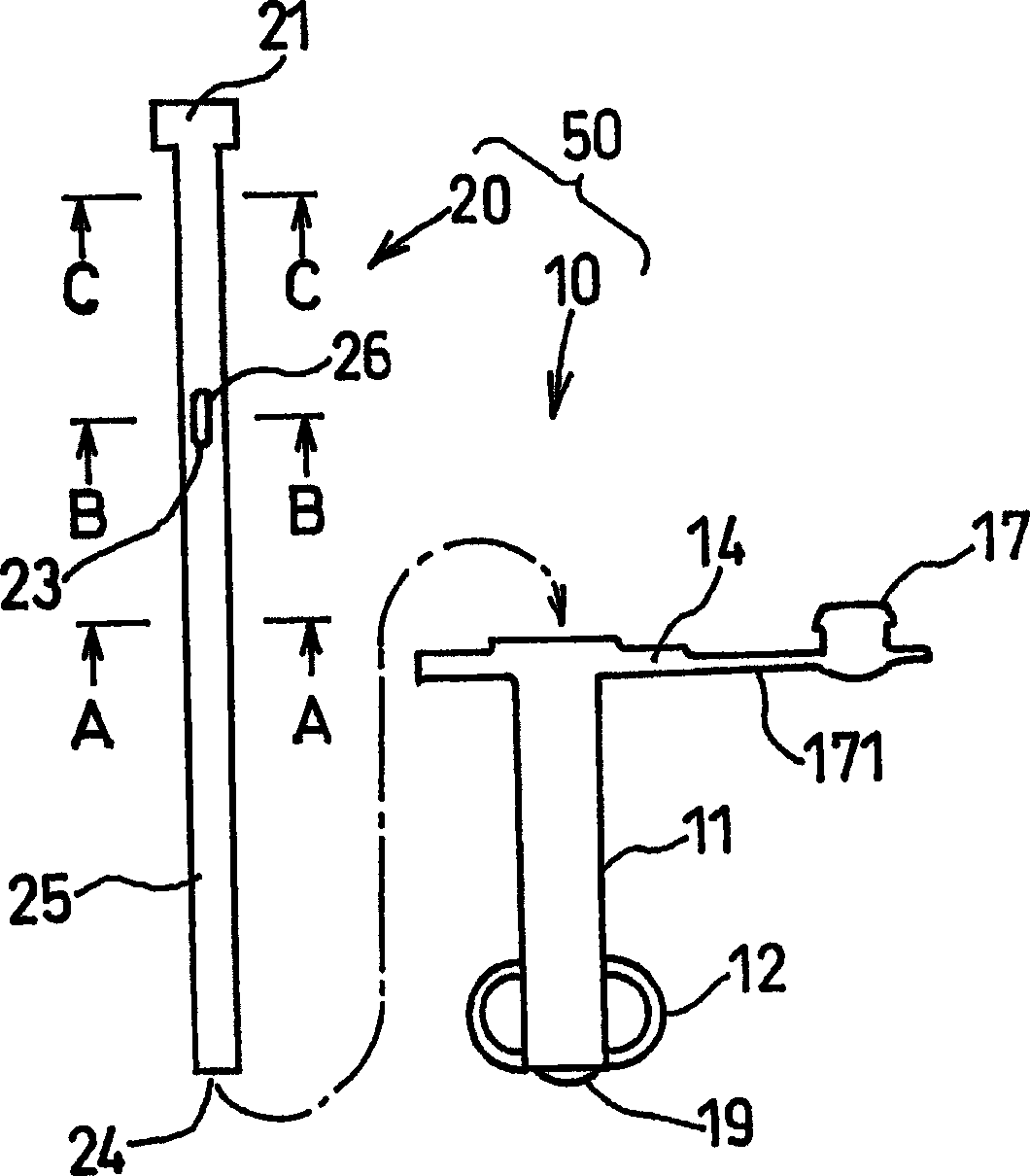

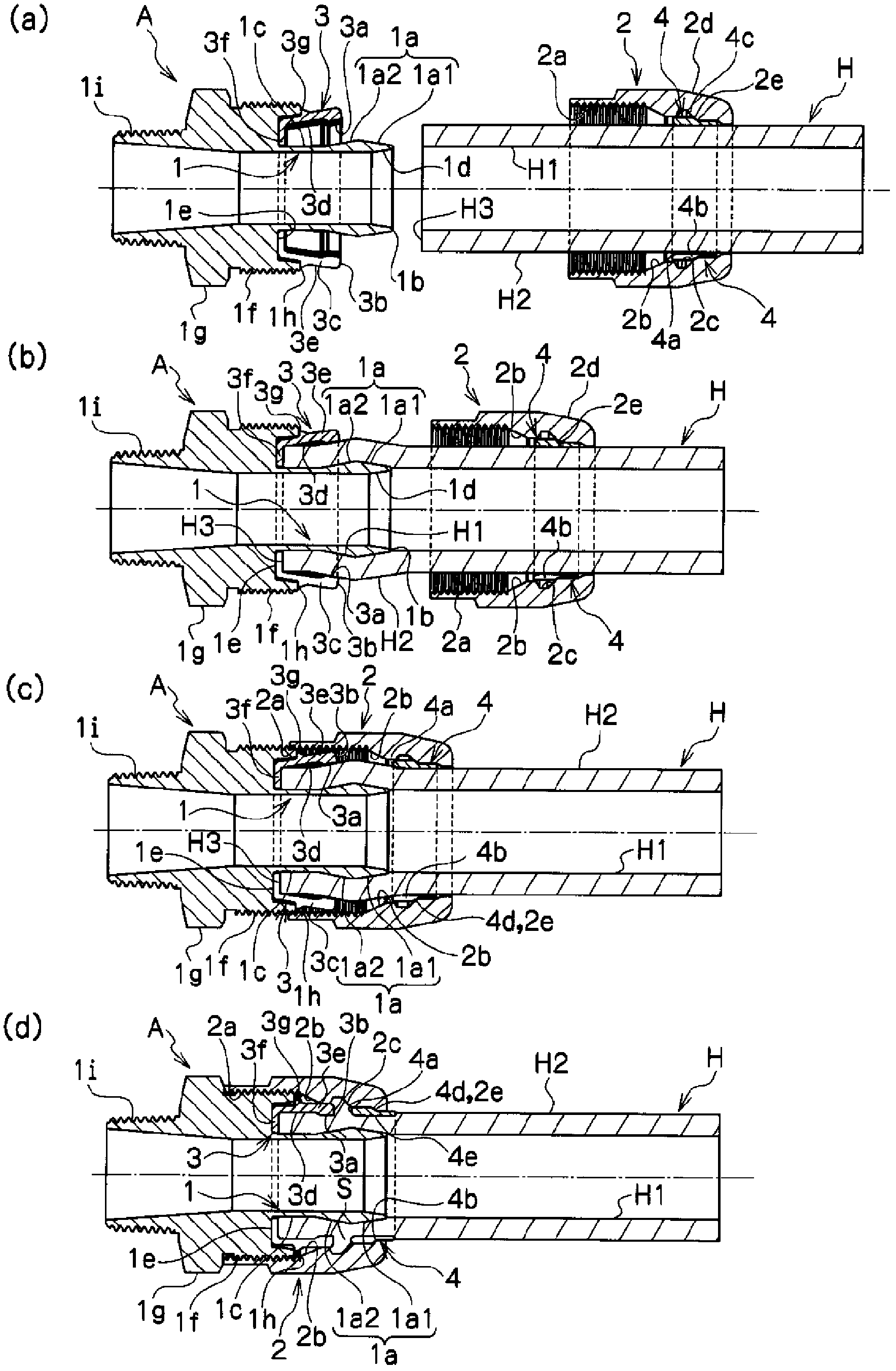

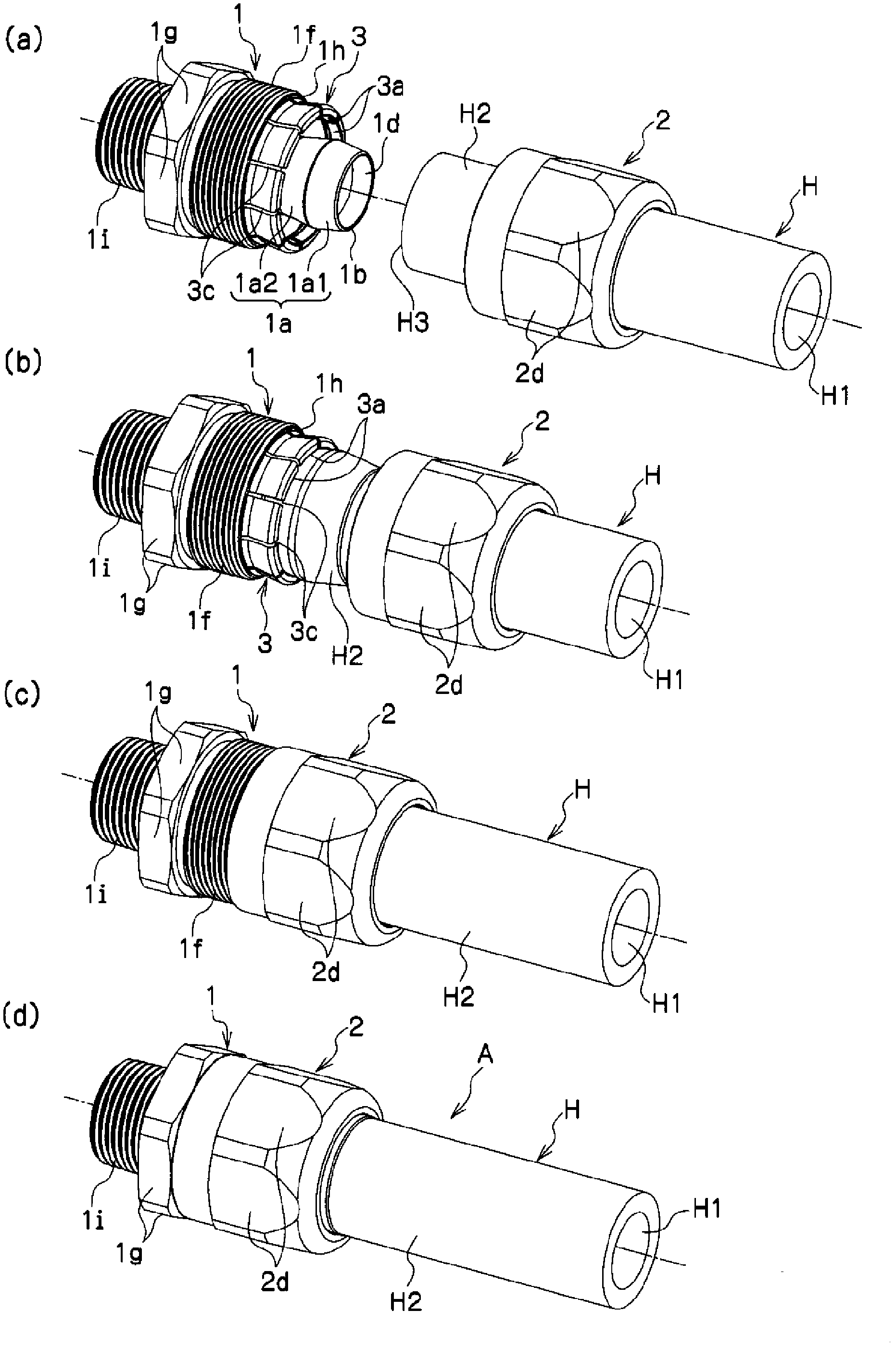

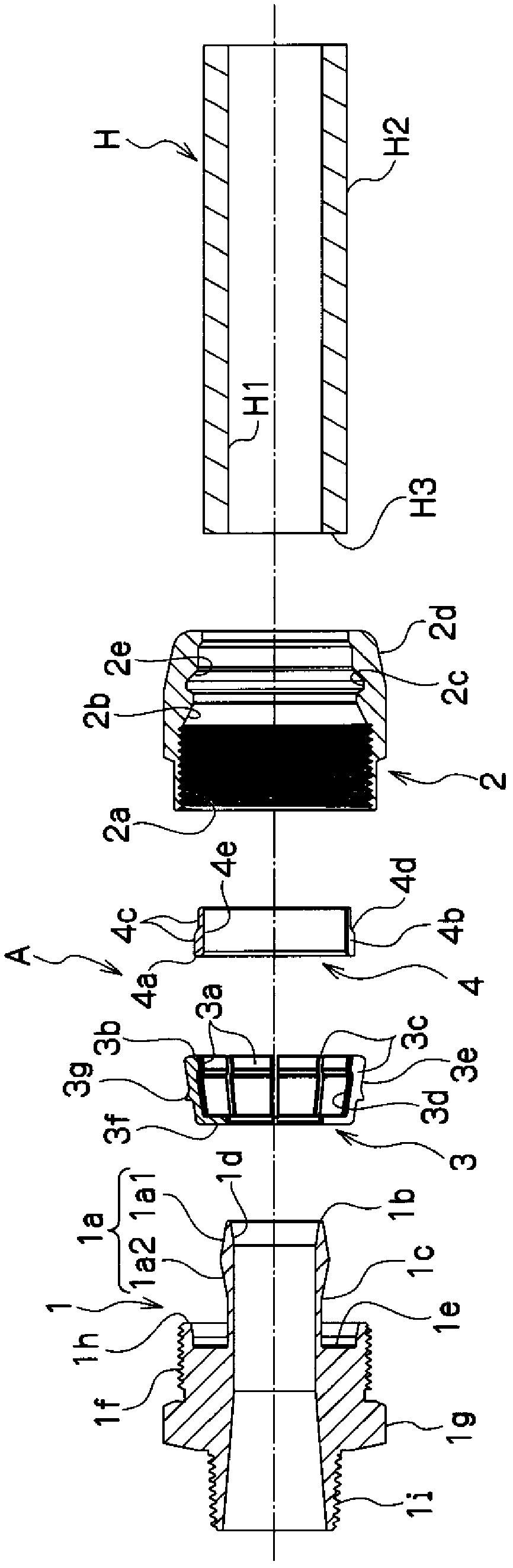

Joint for corrugated tube

ActiveCN101382220AReliable insertionMaintain airtightnessHose connectionsElastic componentEngineering

The invention relates to a joint for a corrugated pipe, which can reliably insert the corrugated pipe into a stated position. The joint (1) for the corrugated pipe comprises: a joint body (10) provided with a through hole (16) for inserting the corrugated pipe (T), a press nut (20) which can slide in the inside direction of the through hole (16) and one end of which is inserted with the through hole (16), an annular stoppage component (50) one end of which forms a plurality of partition parts (53), a restraining component (30) forming a projecting part (31) inserted on the partition parts (53), a sealing component (40) on the outer peripheral face of the sealed corrugated pipe (T), an elastic component (70) kept in a compressed state, and a movable component (80) pressed by the front end of the corrugated pipe (T) and sliding in the inside direction of the through hole (16). When the movable component (80) pressed by the corrugated pipe (T) can slide in the inside direction of the through hole (16), the compressed state of the elastic component (70) is opened, so that the projecting part (31) inserted with the partition parts (53) is released.

Owner:HITACHI METALS LTD

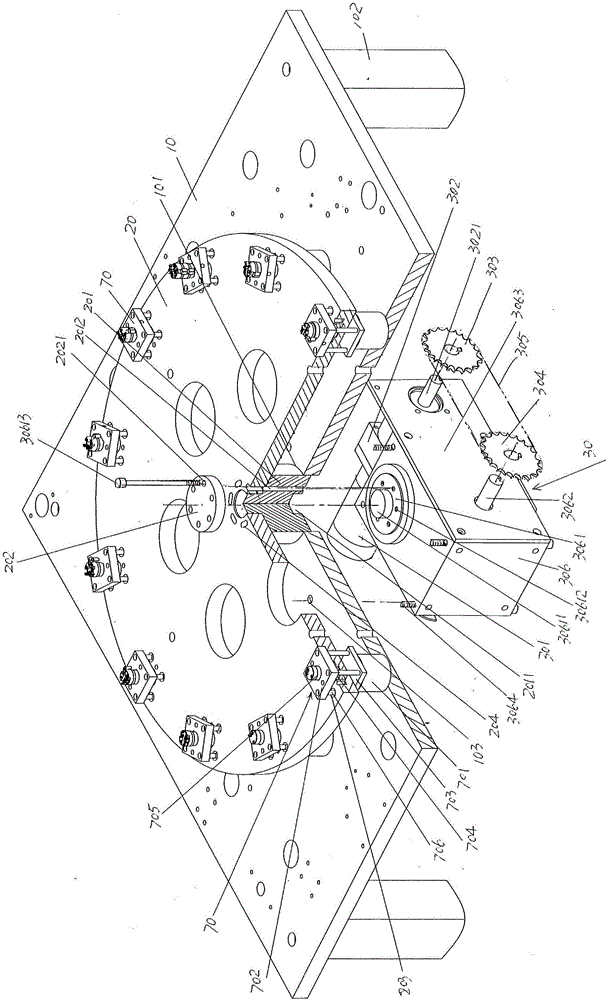

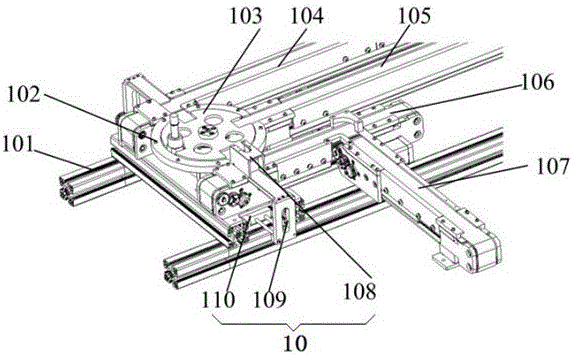

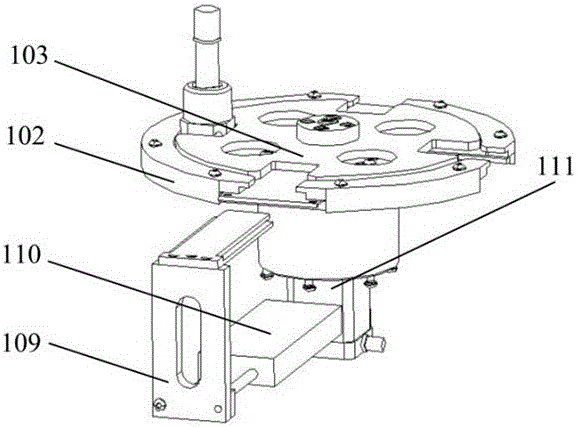

Blood collection tube automatic scanning device and method thereof, and test tube holder

The invention discloses a blood collection tube automatic scanning device and a method thereof, and a test tube holder. The blood collection tube automatic scanning device comprises a blood collection tube transmission mechanism and a blood collection tube code-scanning mechanism. The blood collection tube transmission mechanism is capable of transmitting the test tube holder with inserted blood collection tubes to the blood collection tube code-scanning mechanism. The blood collection tube code-scanning mechanism is capable of scanning the bar codes on the blood collection tubes. After the blood collection tube code-scanning mechanism completes code scanning, the blood collection tube transmission mechanism is capable of transmitting the test tube holder with the inserted blood collection tubes to a next station. The device can realize automatic scanning of the blood collection tubes, the code scanning progress can be effectively controlled by a rotating disc, any adjacent blood collection tubes can be scanned according to the same time interval, interference can be avoided, and the device has the advantages of simple structure and small volume occupation.

Owner:深圳瑞智捷医疗科技有限公司

Hose joint

InactiveCN102575801AImprove sealingHigh strengthHose connectionsUltimate tensile strengthBiomedical engineering

Provided is a hose joint by which an insertion position of a front end of a hose is stabilized to thereby enhance the sealing efficiency and a disconnecting strength between the outer surface of a nipple and the hose. When the hose (H) is inserted, the inner diameter of an inlet portion (3a) of an expandable and contractible sleeve (3) opposed to a decreasing diameter portion (1a2) is set to be larger than the outer diameter of the hose (H) which is inserted along the decreasing diameter portion (1a2) of a bulged portion (1a), whereby the front end of the hose (H) is smoothly introduced between the expandable and contractible sleeve (3) and the decreasing diameter portion (1a2) without causing the front end of the hose to butt against the inlet portion (3a) of the expandable and contractible sleeve (3) and can be inserted to a predetermined position. Thereafter, when pressed by a pressing surface portion (2b) in accordance with the axial movement of a fastening tool (2), the inner diameter of the inlet portion (3a) of the expandable and contractible sleeve (3) is set to be smaller than the outer diameter of the hose (H) inserted along the decreasing diameter portion (1a2) of the bulged portion (1a), whereby the hose (H) is held between the inlet portion (3a) of the expandable and contractible sleeve (3) and the decreasing diameter portion (1a2) of the nipple (1).

Owner:TOYOX CO LTD

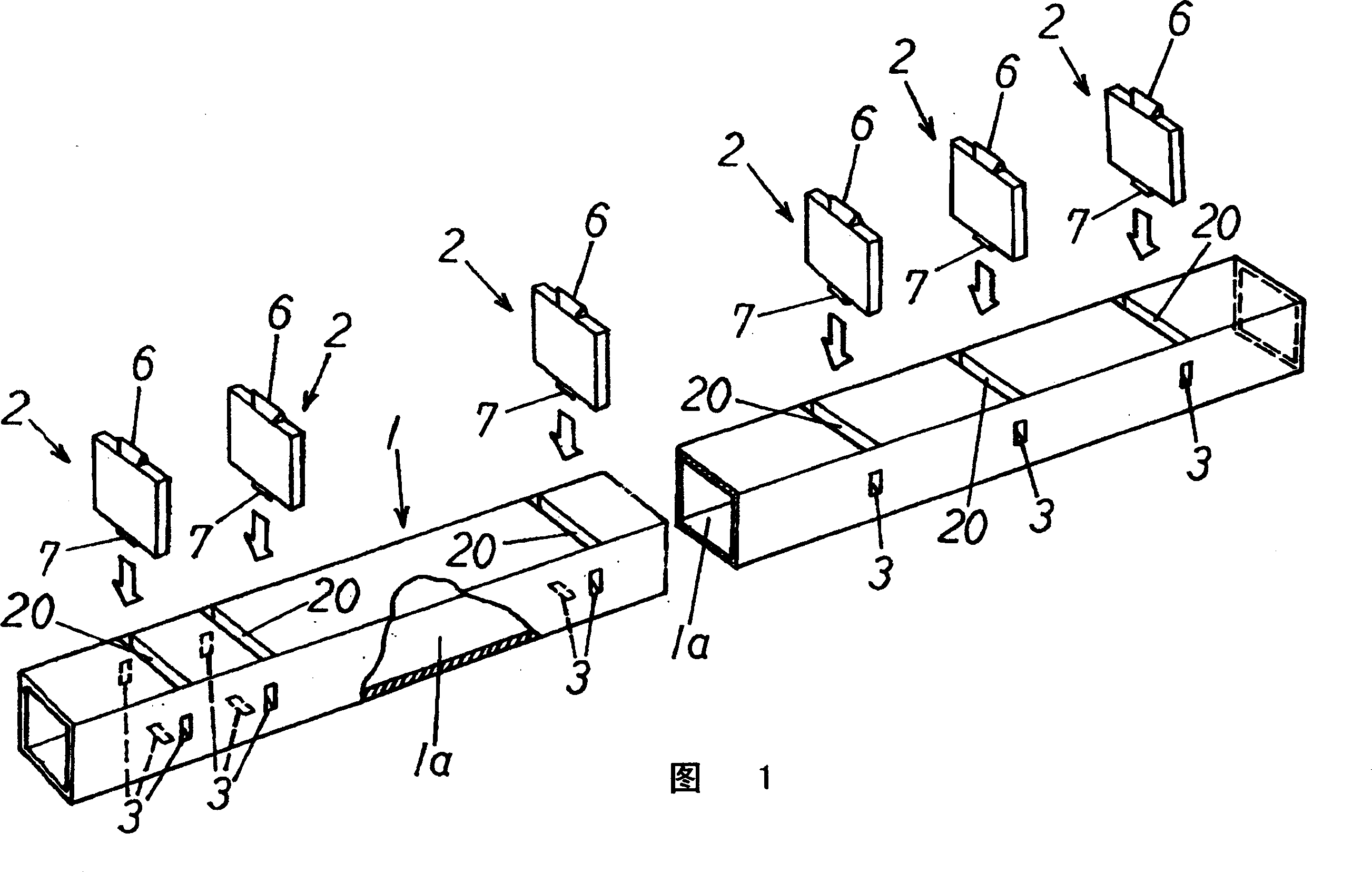

Constituted body for building and its mfg. method

InactiveCN1499023AReliable and properly installedReliable insertionStrutsArc welding apparatusHigh intensityEngineering

It is an object to provide a construct for buildings and a method for manufacturing the same exhibiting favorable workability through a simple structure and capable of achieving high strength and accuracy when used in structural steelworks constructed through constructs for buildings such as pillar elements or beam elements; for achieving this object, the construct A for buildings comprises a steel pipe member 1 and reinforcing elements 2 provided in a hollow portion 1a of the interior of the steel pipe member 1 to cross the interior of the steel pipe member 1 in the longitudinal direction, with the steel pipe member and the reinforcing elements being welded and joined; wherein inserting holes 20 for the reinforcing elements are formed at mounting positions for the reinforcing elements on an outer peripheral portion of the steel pipe member to have a width meeting width dimensions of the reinforcing elements, wherein these inserting holes are successively formed from the outer peripheral surface of the steel pipe member to the interior thereof, and wherein the reinforcing elements are inserted from these inserting holes from the outer peripheral surface of the steel pipe member to the interior in a direction that is substantially orthogonal to the longitudinal direction of the steel pipe member.

Owner:平垣实

Stator mounting method

InactiveUS7930818B2Reduce in quantityReduce dispersionSynchronous generatorsWindingsLower faceElectrical and Electronics engineering

In a stator mounting method in which a coil unit is inserted into a stator core and a lead wire protruding from the coil unit is inserted into and mounted on a terminal portion of the stator core, the lead wire is passed through a lead wire pullout portion located at a predetermined position of a coil frame body, a height from an inner peripheral upper face of the coil frame body to the lead wire pullout portion is equalized with a distance from a core upper face of the stator core to a lead wire insertion position inner peripheral lower face of the terminal portion, and the core upper face of the stator core is held in contact with an inner peripheral upper face of the coil frame body after the lead wire is inserted into the terminal portion.

Owner:TOYOTA JIDOSHA KK

Device for positioning multiple function elements

ActiveCN103934667APrecise alignmentFixed and accurateCamsValve arrangementsEngineeringMechanical engineering

The invention relates to an apparatus (1) for assembling a composite arrangement, consisting of a plurality of functional elements (4) on a shaft (3), said elements having an aperture (2) for the shaft (3), wherein the apparatus (1) has a plurality of retaining devices (5) each intended for accommodating a functional element (4). It is pertinent to the invention here that the retaining devices (5) are arranged vertically one above the other, that a vertically displaceable guide carriage (8) is provided for the shaft (3), in which case the shaft (3) is joined to the functional elements (4) in the vertical direction, that there is a separately arranged heating device (9) provided, it being possible for at least two functional elements (4) to be heated simultaneously thereby, and that a gripping device (10) is provided, it being possible for the latter to remove preferably all the functional elements (4) together from the heating device (9) and introduce them into the retaining devices (5) of the apparatus (1). This makes it possible to dispense with high-outlay guidance of the shaft (3), which has been necessary hitherto, during the joining operation.

Owner:MAHLE INT GMBH

Catheter kit for burrow

Owner:SUMITOMO BAKELITE CO LTD +1

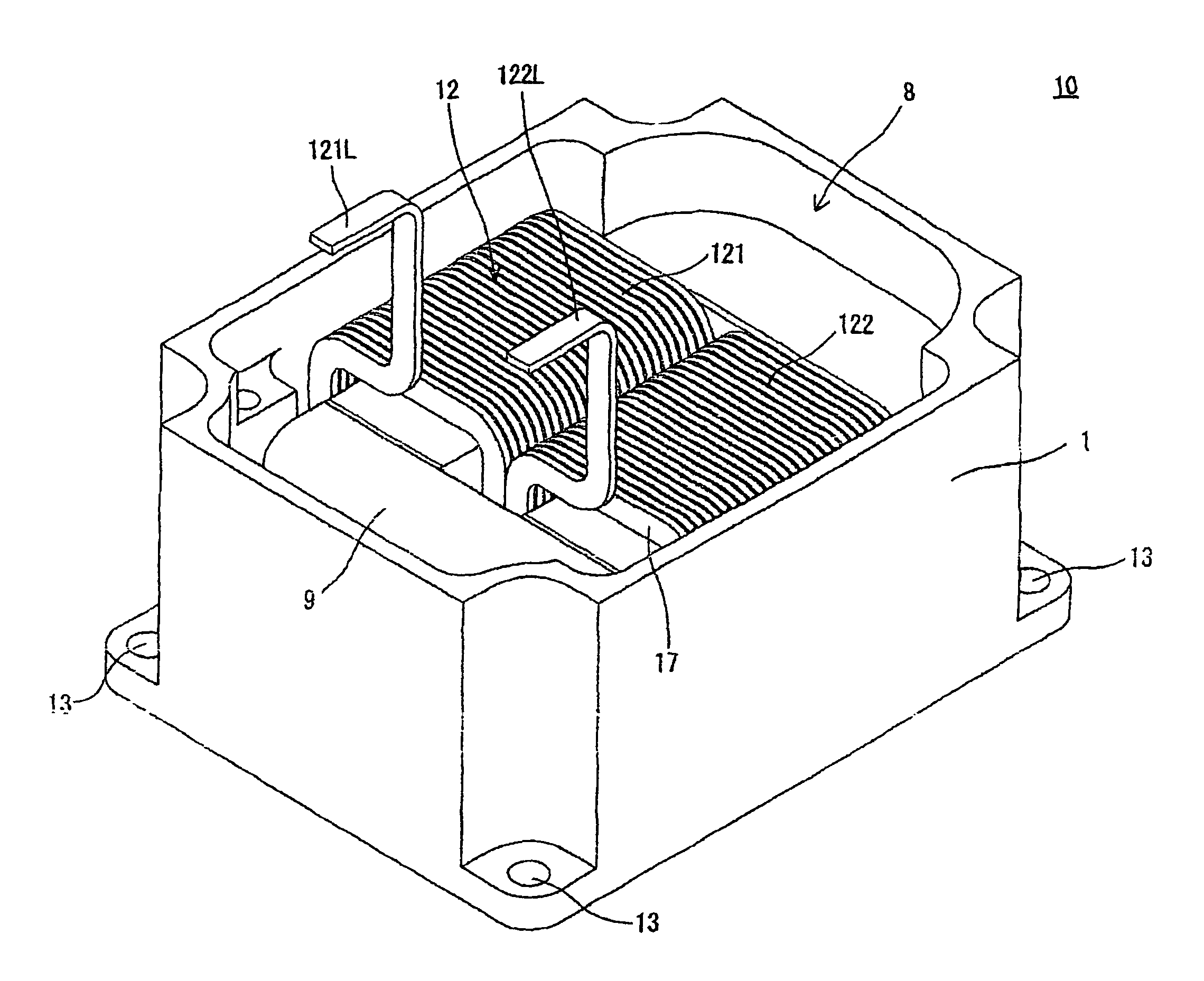

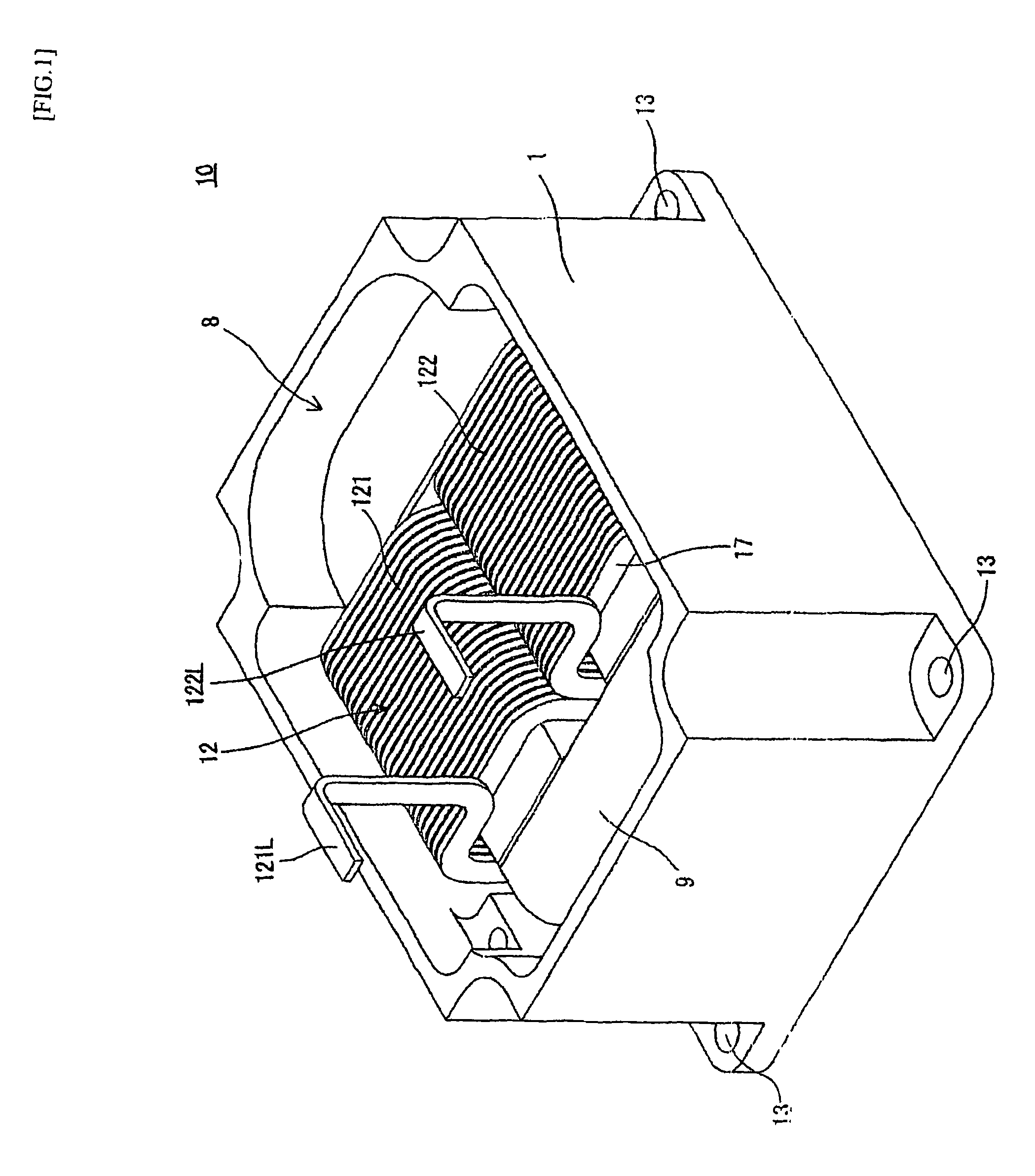

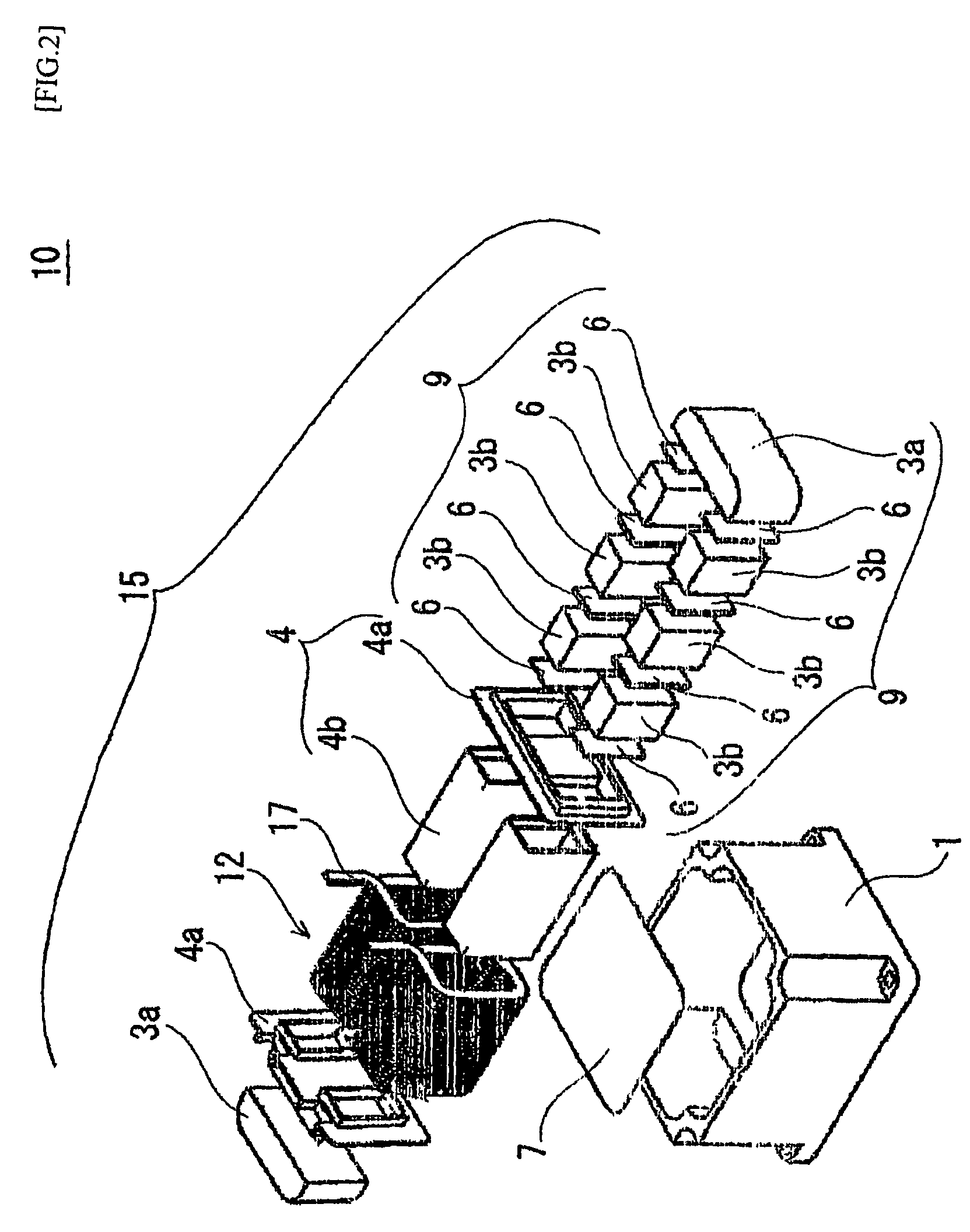

Method for forming coil

ActiveUS8091211B2Simplifying manufacturing workImprove accuracyTransformers/inductances coils/windings/connectionsTransformers/inductances magnetic coresWire rodEngineering

A reactor coil includes first and second coil elements each formed by edgewise and rectangular winding of one piece of rectangular wire rod in a manner in which the wound rectangular wire rod is stacked rectangularly and cylindrically and, at a winding terminating end point of the first coil element, the rectangular wire rod is bent approximately 90 degrees in a direction opposite to the winding direction of the first coil element so that the rectangular wire rod is stacked in a direction opposite to the stacking direction of the first coil element and is wound edgewisely and rectangularly in a direction opposite to the winding direction of the first coil element to form the second coil element and, as a result, the first coil element and second coil element are aligned in parallel to each other in a continuous state.

Owner:TAMURA KK +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com