Joint for corrugated tube

A technology for corrugated pipes and pipes, applied in the direction of pipes/pipe joints/fittings, hose connection devices, mechanical equipment, etc., can solve problems such as leakage, damage to the reliability of flexible pipe connections, and difficulty in handling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach 〕

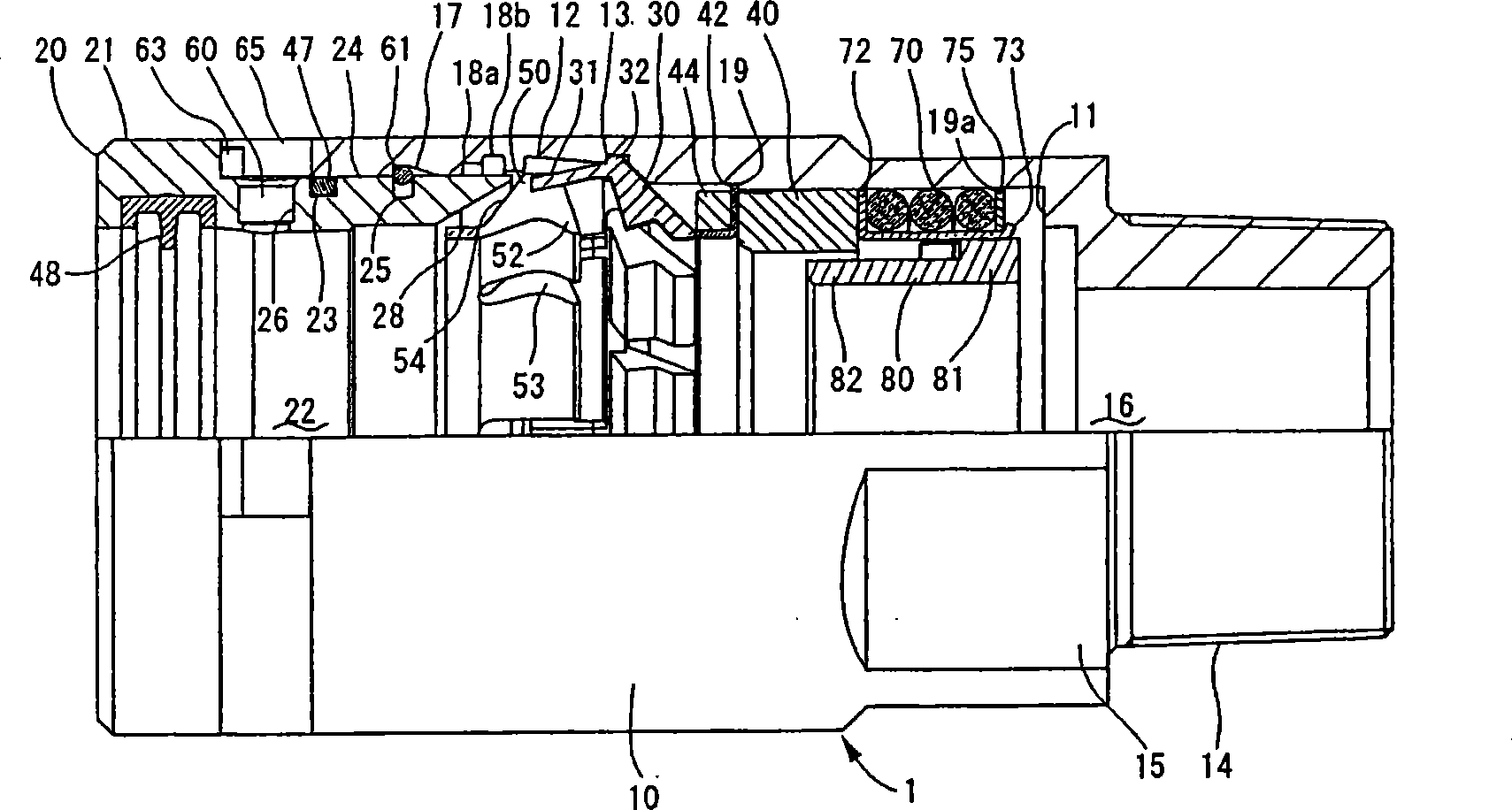

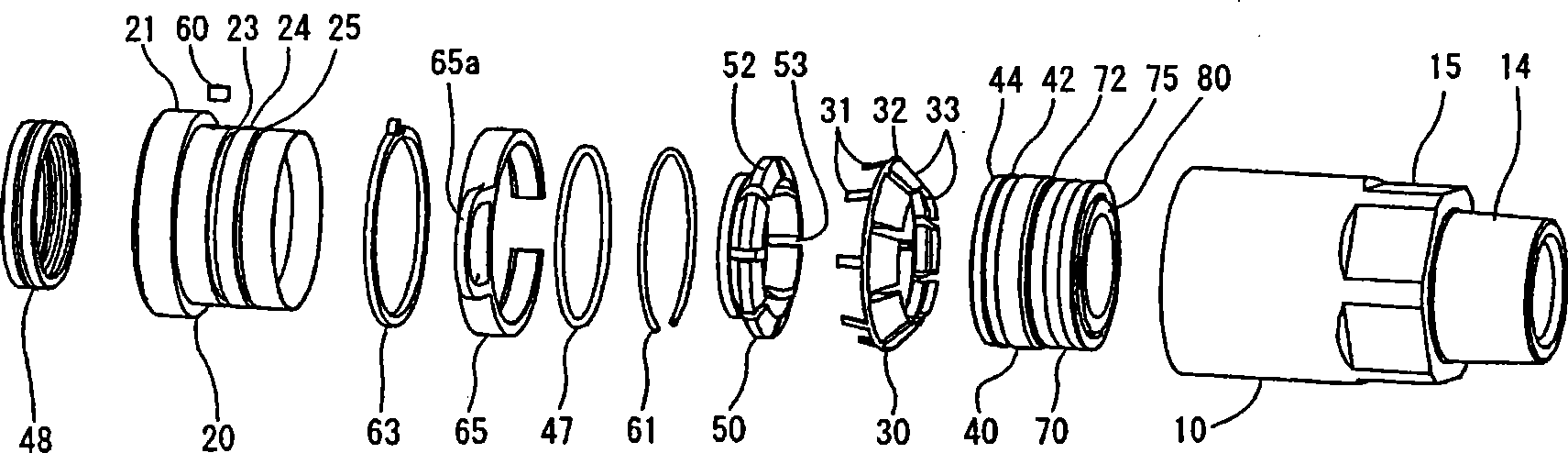

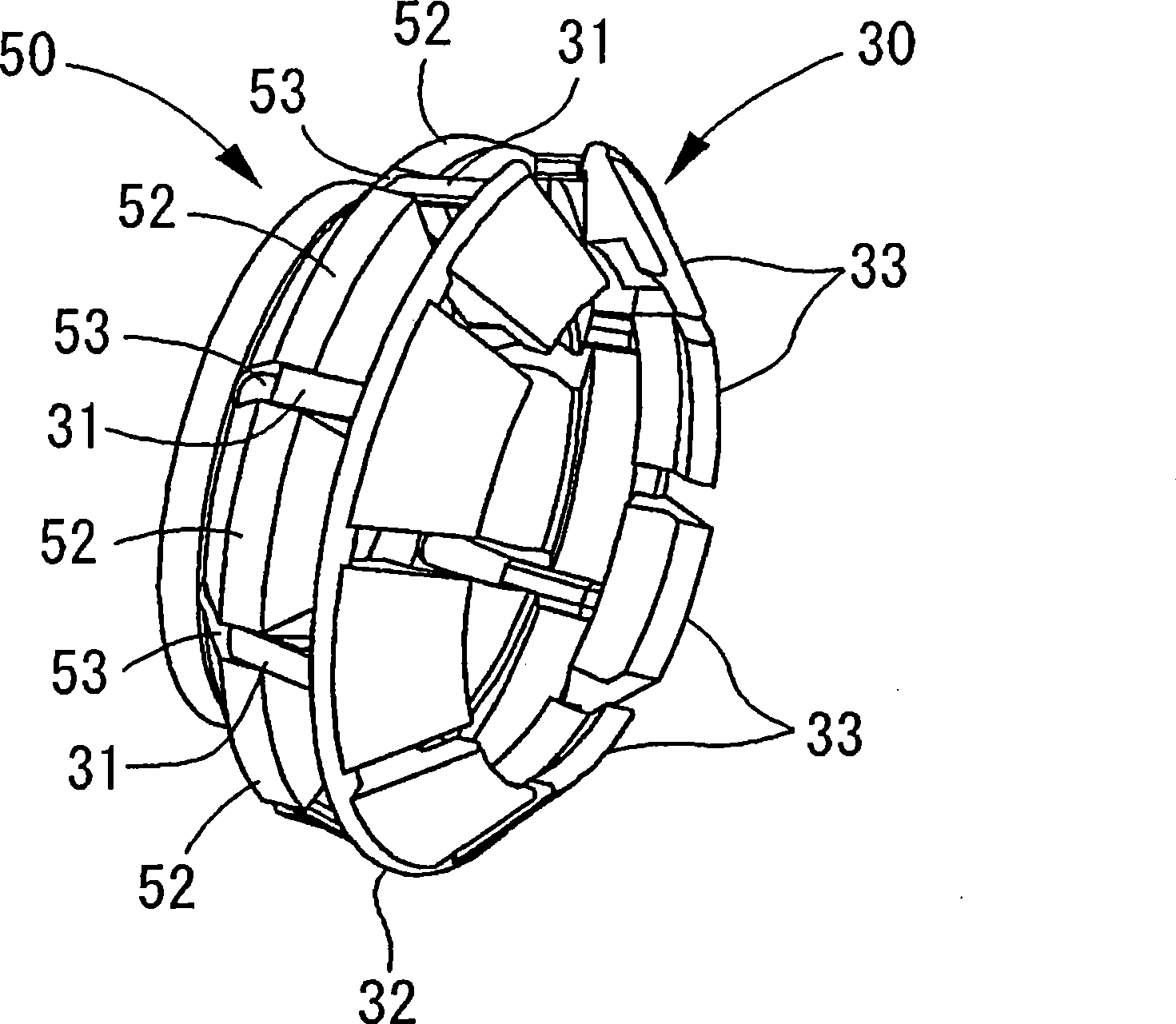

[0143] The first embodiment of the present invention uses Figure 1 to Figure 6 Be explained. figure 1 A half sectional view showing an embodiment of the corrugated pipe joint of the present invention, figure 2 Parts development perspective view showing an embodiment of the corrugated pipe joint of the present invention, image 3 A perspective view showing a state in which a retainer and a restraint member are fitted according to the present invention, Figure 4 A perspective view showing an embodiment of the elastic member of the present invention, Figure 5 A half-sectional view showing a state in which the bellows of the present invention is inserted into a joint for bellows, Image 6 A half sectional view showing a completed state of construction for connecting a bellows to the joint for bellows of the present invention.

[0144] like figure 1 and 2 As shown, the joint 1 for bellows has: a joint main body 10 having a through hole 16 into which the bellows T is inser...

no. 2 approach 〕

[0174] Next, use Figure 7 ~ Figure 11 A second embodiment will be described. Figure 7 A half sectional view showing a second embodiment of the corrugated pipe joint of the present invention, Figure 8 A perspective view showing an example of the constraining member of the second embodiment of the present invention, Figure 9 A half-sectional view showing a state where a bellows is inserted into a second embodiment of the joint for bellows of the present invention, Figure 10 A half-sectional view showing the construction completion state of the second embodiment of the bellows joint of the present invention for connecting the bellows, Figure 11 A half cross-sectional view showing a state in which the push nut is slid when the bellows is insufficiently inserted in the second embodiment of the joint for bellows of the present invention.

[0175] Additionally, with Figure 1 to Figure 6 The same structures of the shown bellows joints are denoted by the same reference numer...

no. 3 approach 〕

[0186] Next, refer to Figure 12 to Figure 15 A third embodiment will be described. Figure 12 It is a half-sectional view of a third embodiment of a joint for bellows of the present invention, Figure 13 A half-sectional view showing a state in which a bellows is inserted into a third embodiment of the joint for bellows of the present invention, Figure 14 A half sectional view showing the construction completion state of the connection bellows of the third embodiment of the joint for bellows of the present invention, Figure 15 A half cross-sectional view showing a state in which the push nut is slid when the bellows is insufficiently inserted in the third embodiment of the joint for bellows of the present invention.

[0187] Additionally, with Figure 1 to Figure 6 The same structures of the shown bellows joints are denoted by the same reference numerals, and description thereof will be omitted.

[0188] like Figure 12 As shown, the bellows joint 1B has: a joint main ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com