Constituted body for building and its mfg. method

一种建筑物、加强体的技术,应用在建筑物构造、建筑构件、建筑等方向,能够解决不能简单地修正隔板姿势、作业困难、作业性差等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

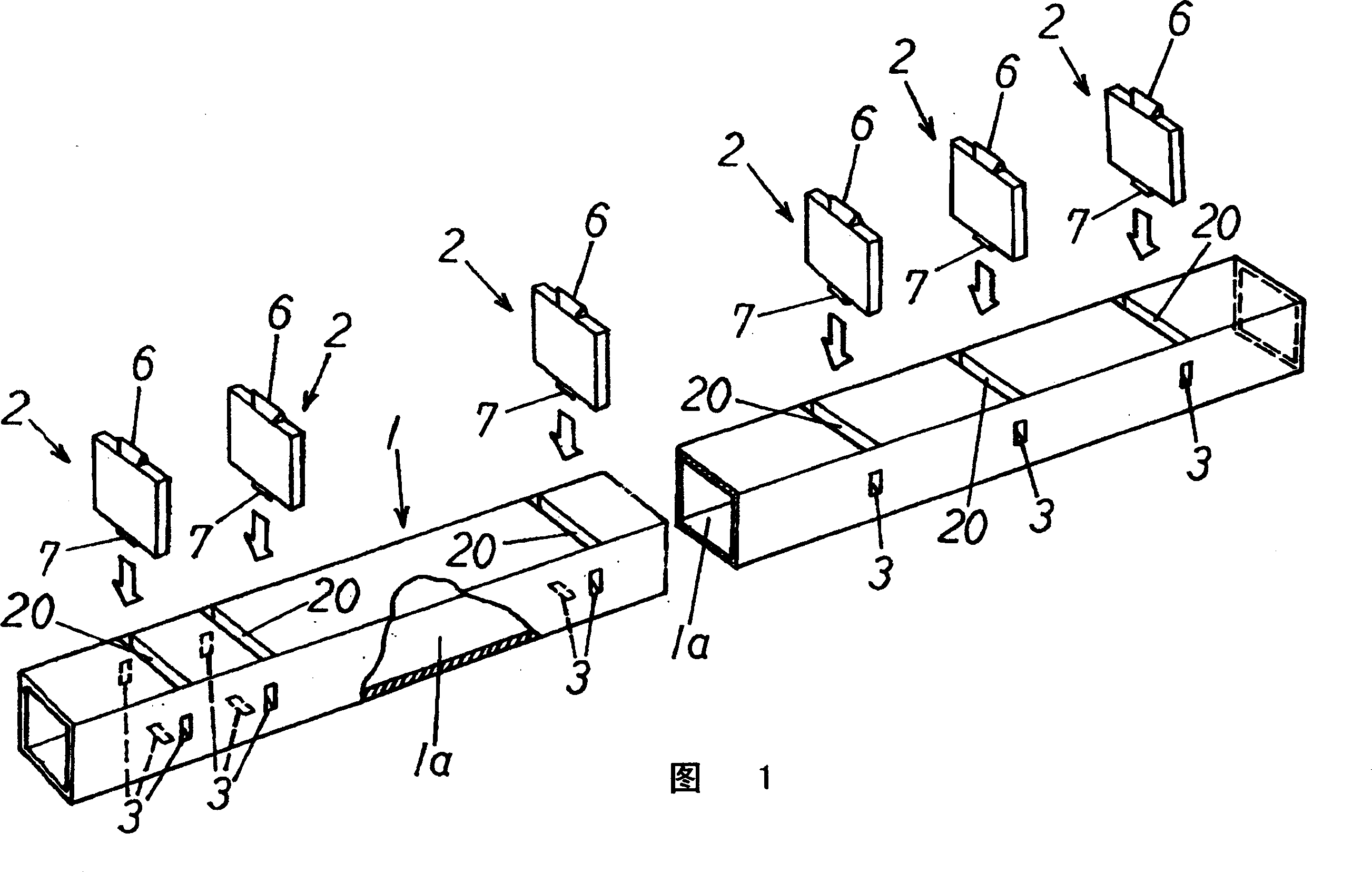

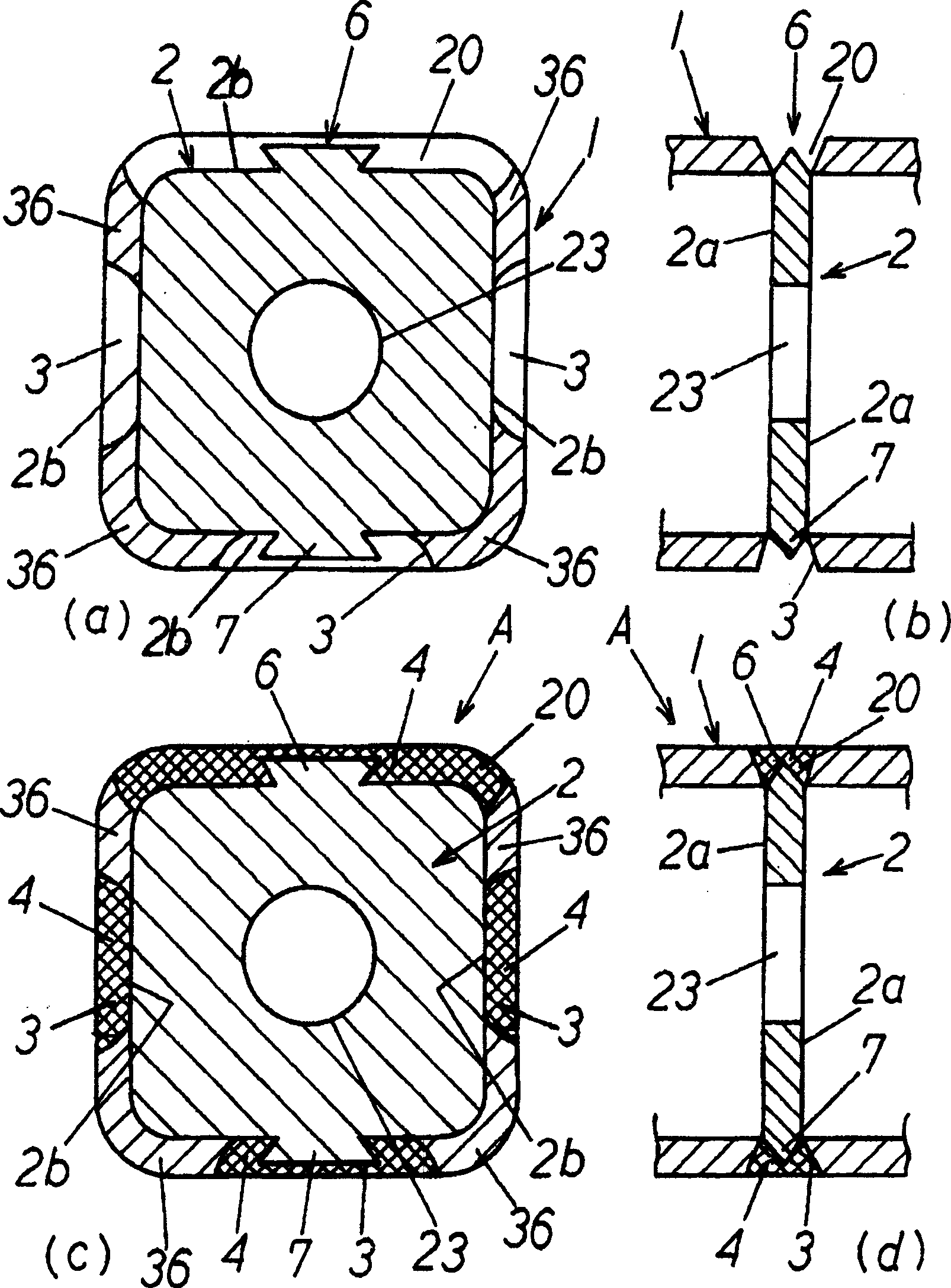

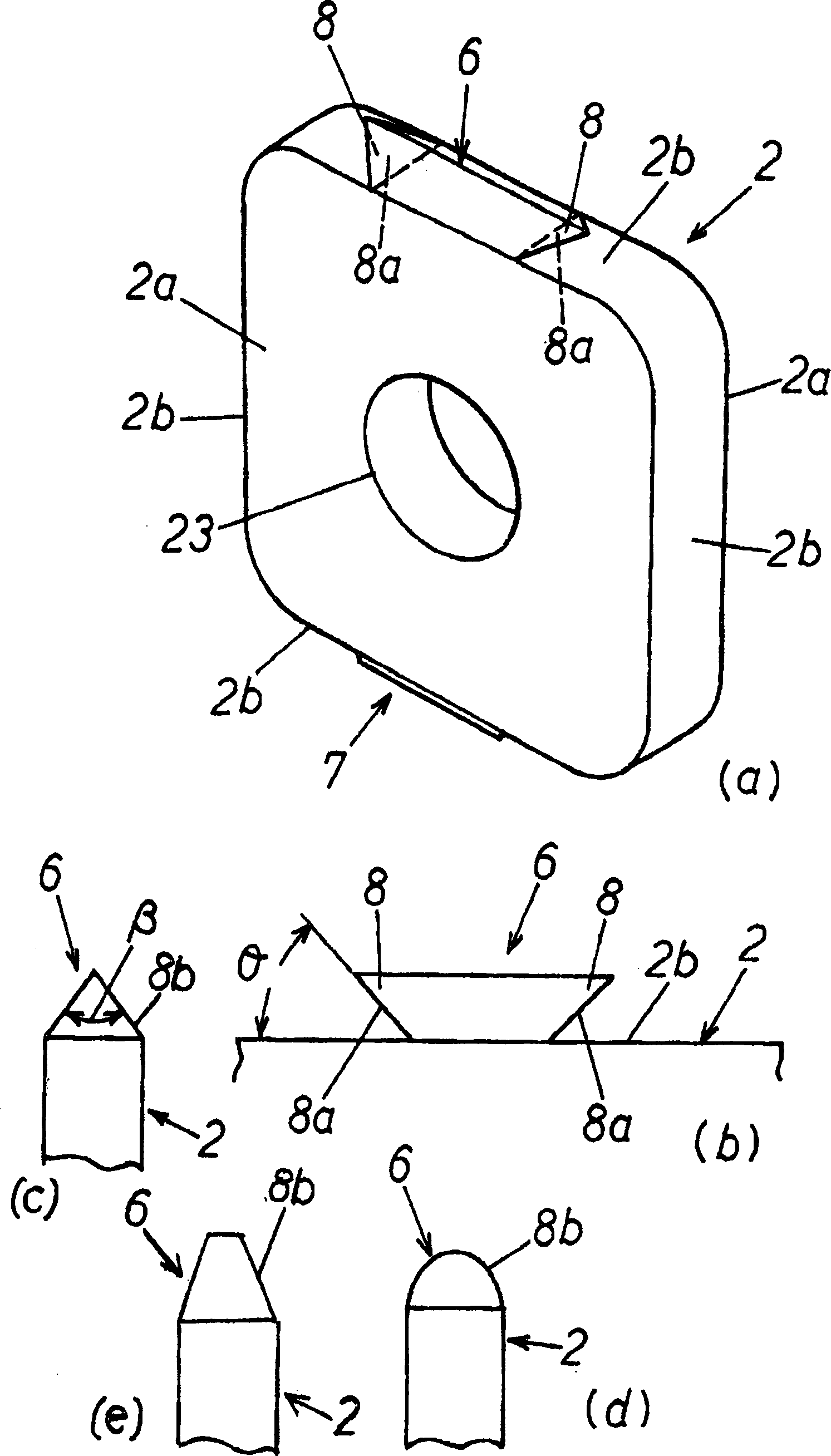

[0075] Hereinafter, embodiments of the building structure of the present invention and its manufacturing method will be described based on the drawings.

[0076] figure 2 with Figure 6 ~ Figure 10 , Picture 12 , Figure 14 Middle A is a structural body for buildings, which is used as a column body that becomes a vertical member for constructing steel frame structures and other structures, and a beam body that becomes a horizontal member or an inclined member. As shown in FIG. 1, it has a hollow interior. The continuous elongated steel pipe component 1 and the reinforcement 2 provided in the hollow portion 1a inside the steel pipe component 1 so as to cross the inside of the steel pipe component 1 in the longitudinal direction are provided on the outer peripheral portion of the steel pipe component 1 In the plurality of joint holes 3, the steel pipe member 1 and the reinforcement body 2 are fastened together by welding joint 4.

[0077] The aforementioned steel pipe member 1 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com