Hose joint

A technology of connectors and hoses, applied in the field of hose connectors, can solve the problems of unreliable connection, decrease of sealing performance and falling off strength, etc., achieve reliable hose connection work, improve sealing performance and falling strength, and free The effect of increasing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

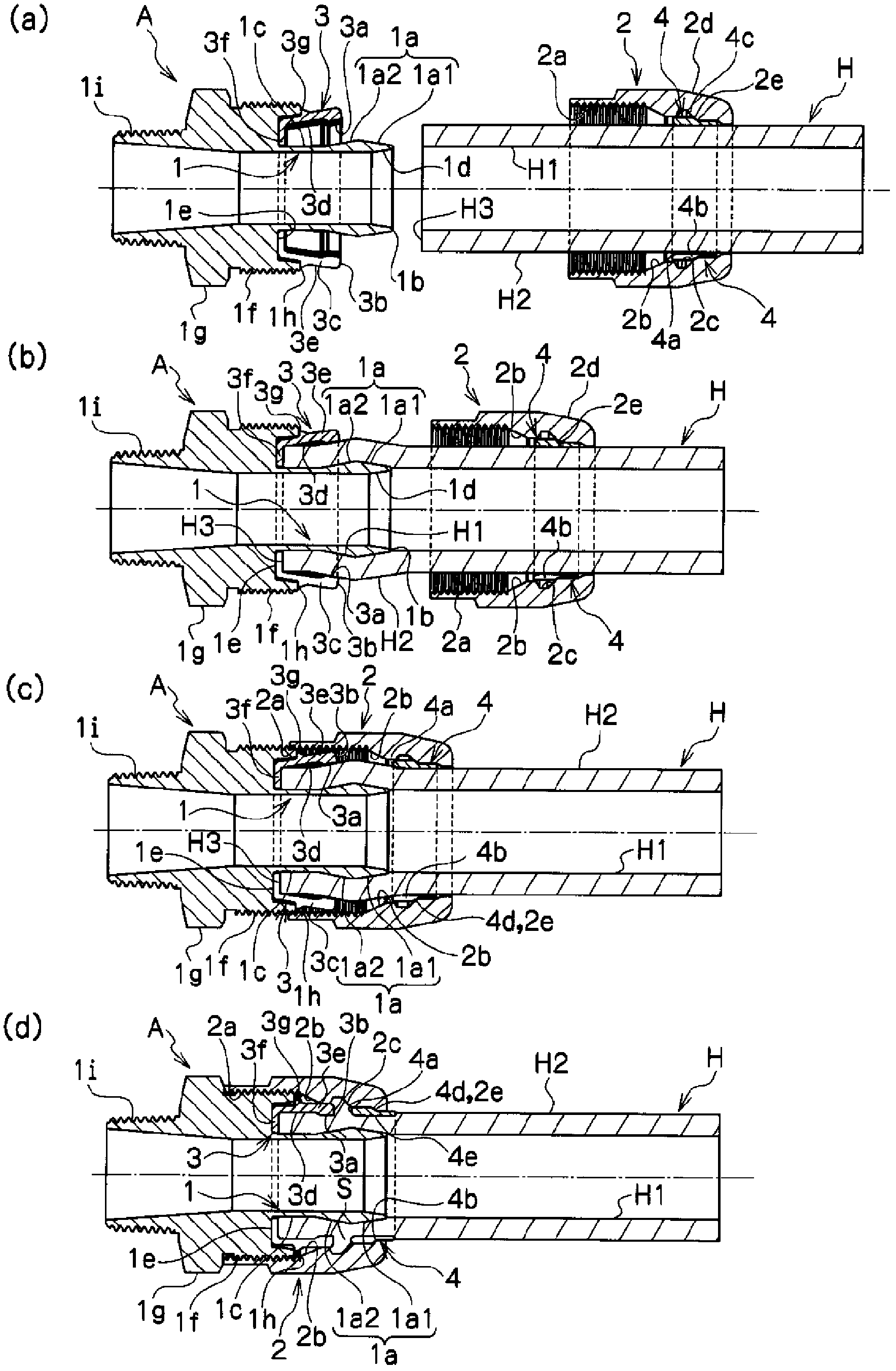

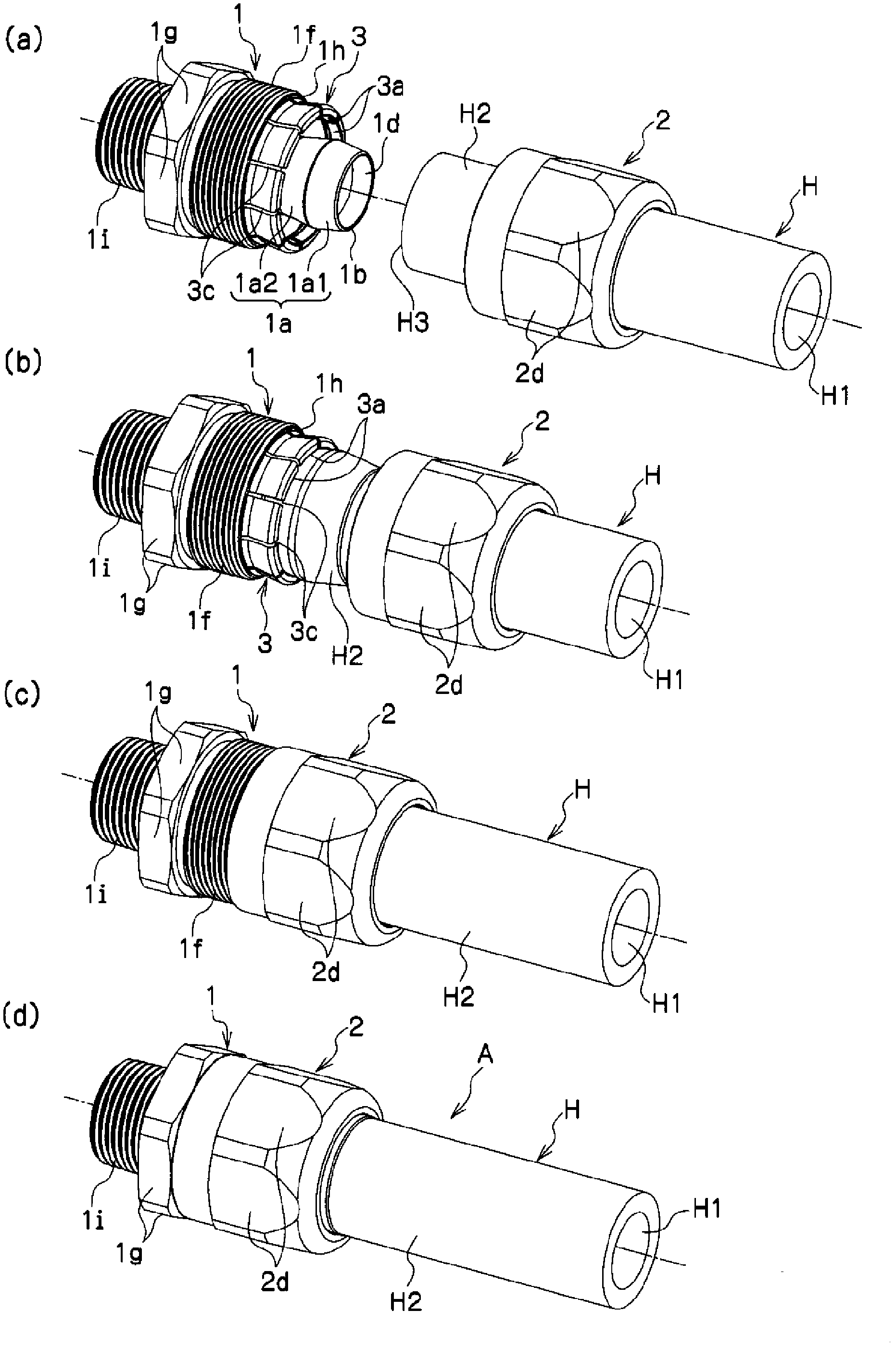

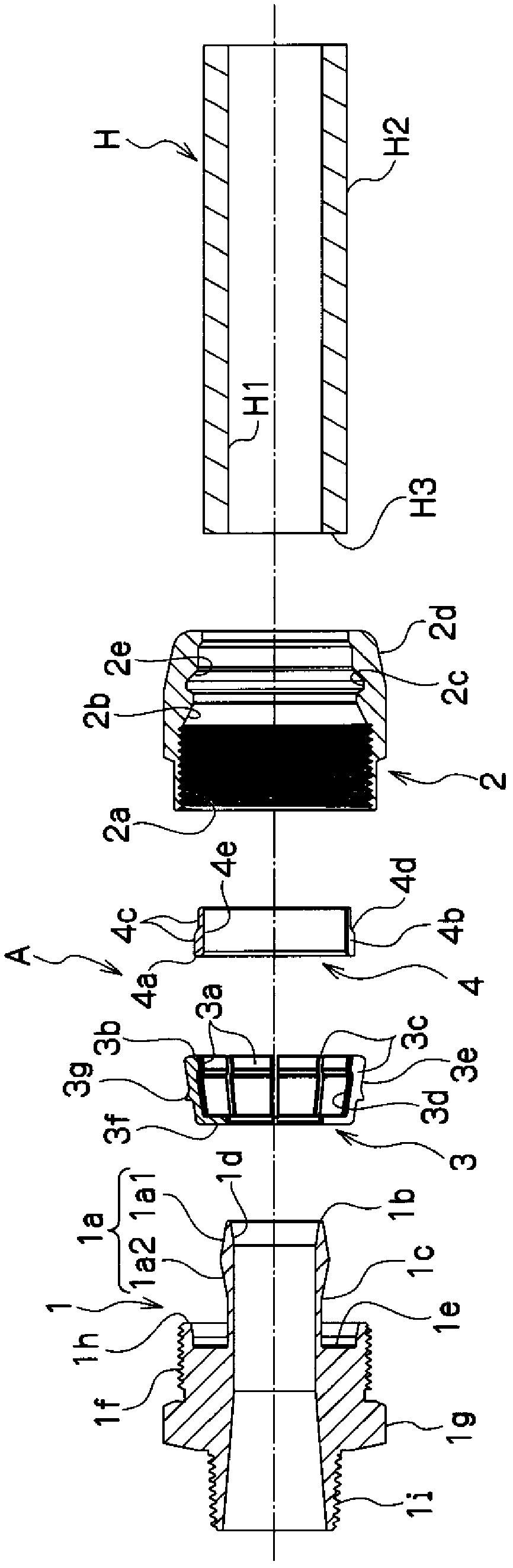

[0053] like figure 1 (a)~(d), figure 2 (a)~(d), image 3 and Figure 4 As shown in (a) and (b), in this embodiment 1, the sliding member 1f as the nipple 1 is engraved with an external thread portion, and the sliding member 2a as the opposite fastener 2 is engraved with an internal thread portion, These external threaded parts 1f and internal threaded parts 2a are screwed together, and the fastener 2 is rotated relative to the nipple 1 to move it in the hose insertion direction, whereby the inner peripheral surface of the fastener 2 integrally formed The pressing surface part 2b presses the inlet part 3a of the telescoping tube 3, and deform|transforms it in diameter reduction.

[0054] like Figure 4 As shown in (a) and (b), the telescoping tube 3 is composed of an annular protrusion serving as the entrance 3a, a cylindrical telescopic tube having an end surface (end surface on the entrance side) 3b on the side opposite to the hose insertion direction, and an inner perip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com