Patents

Literature

53results about How to "Simplify connection work" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

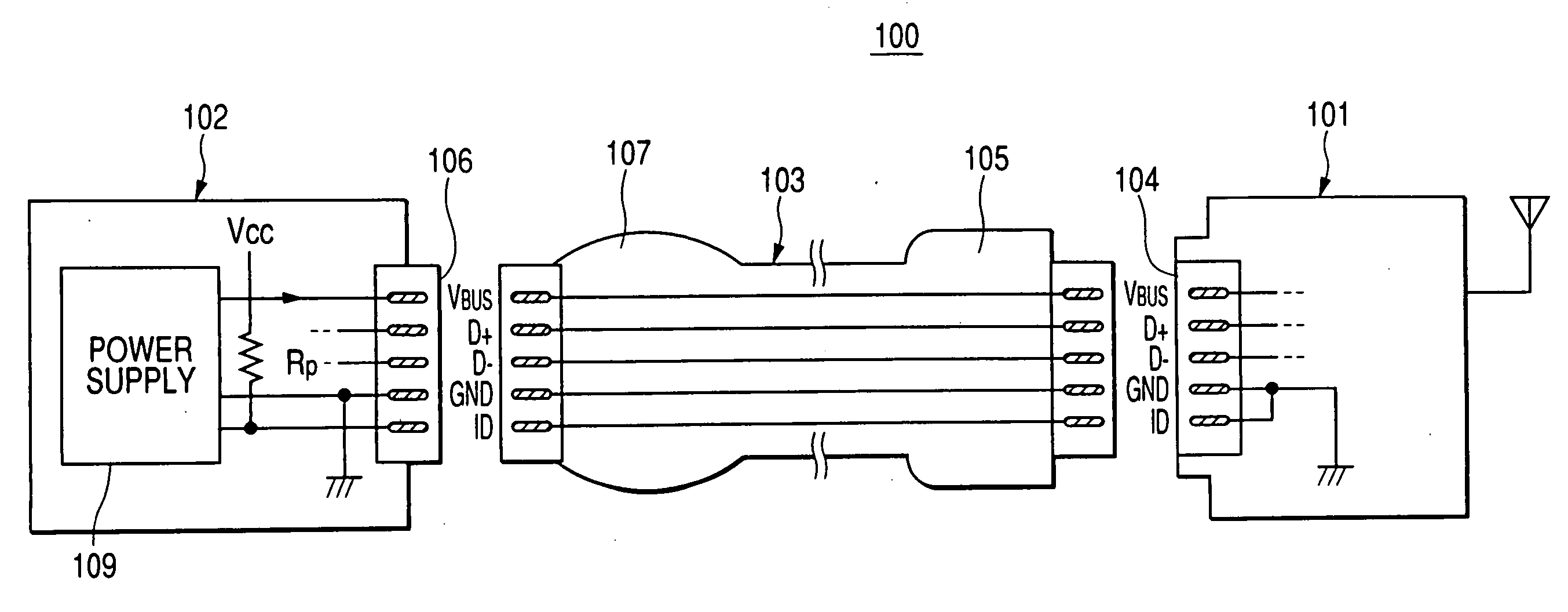

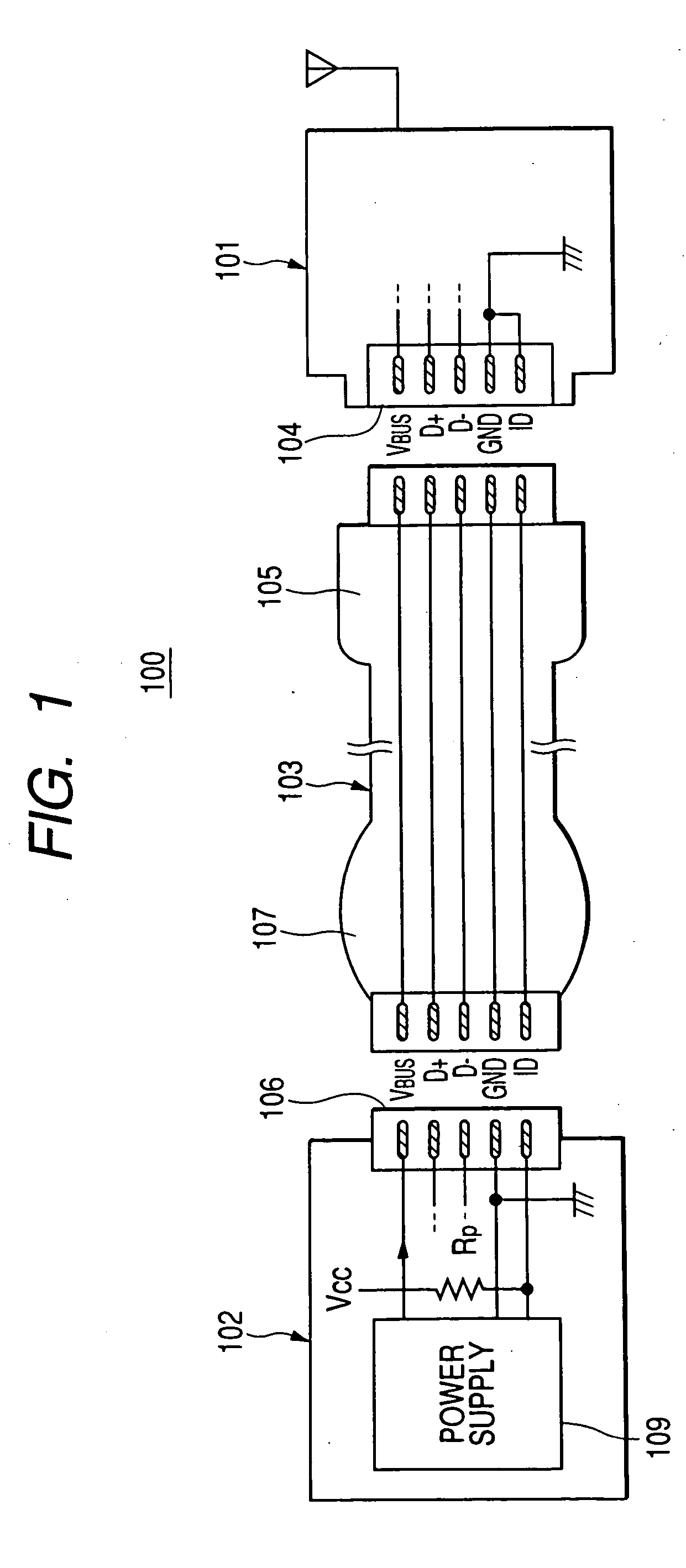

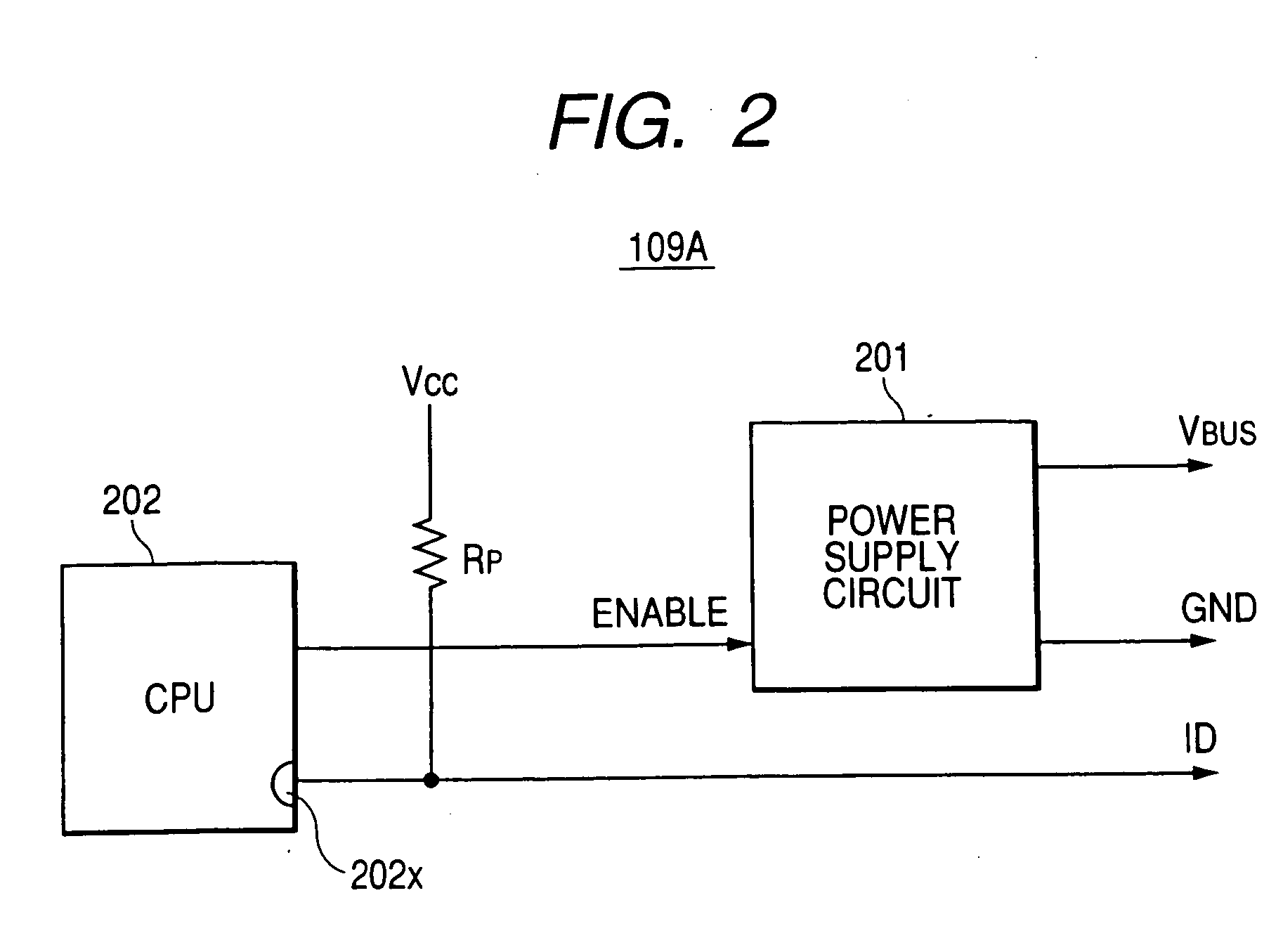

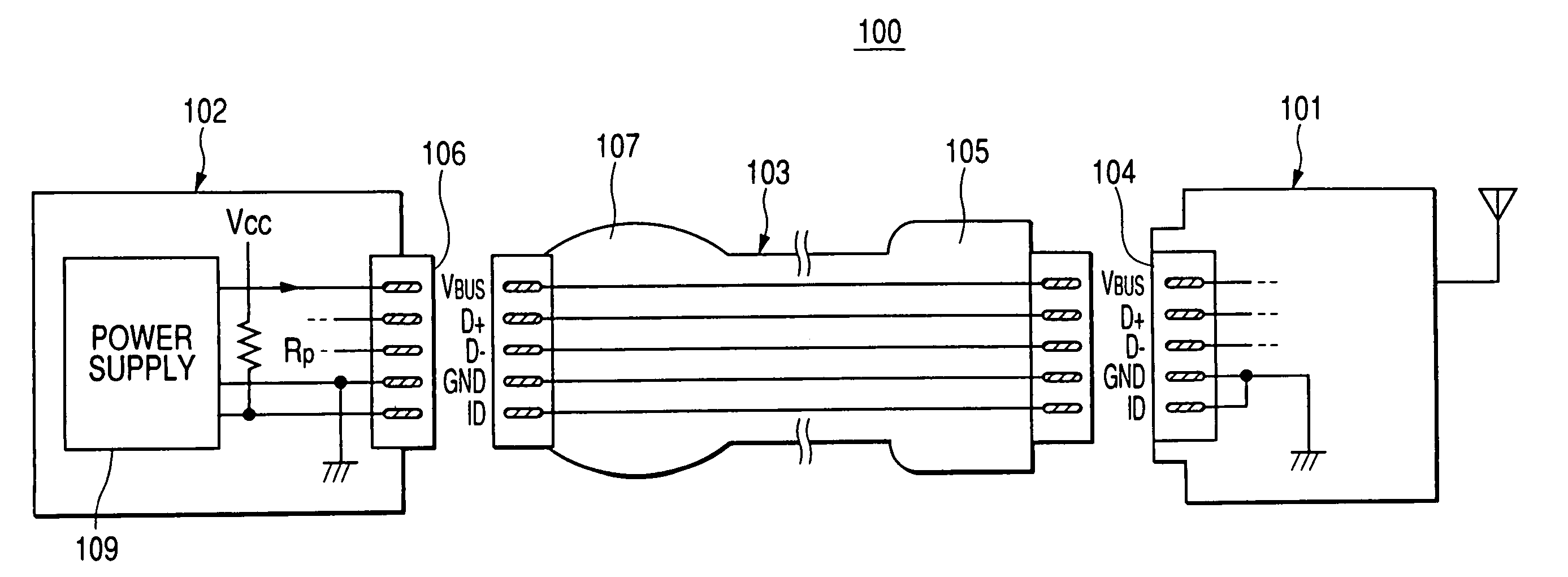

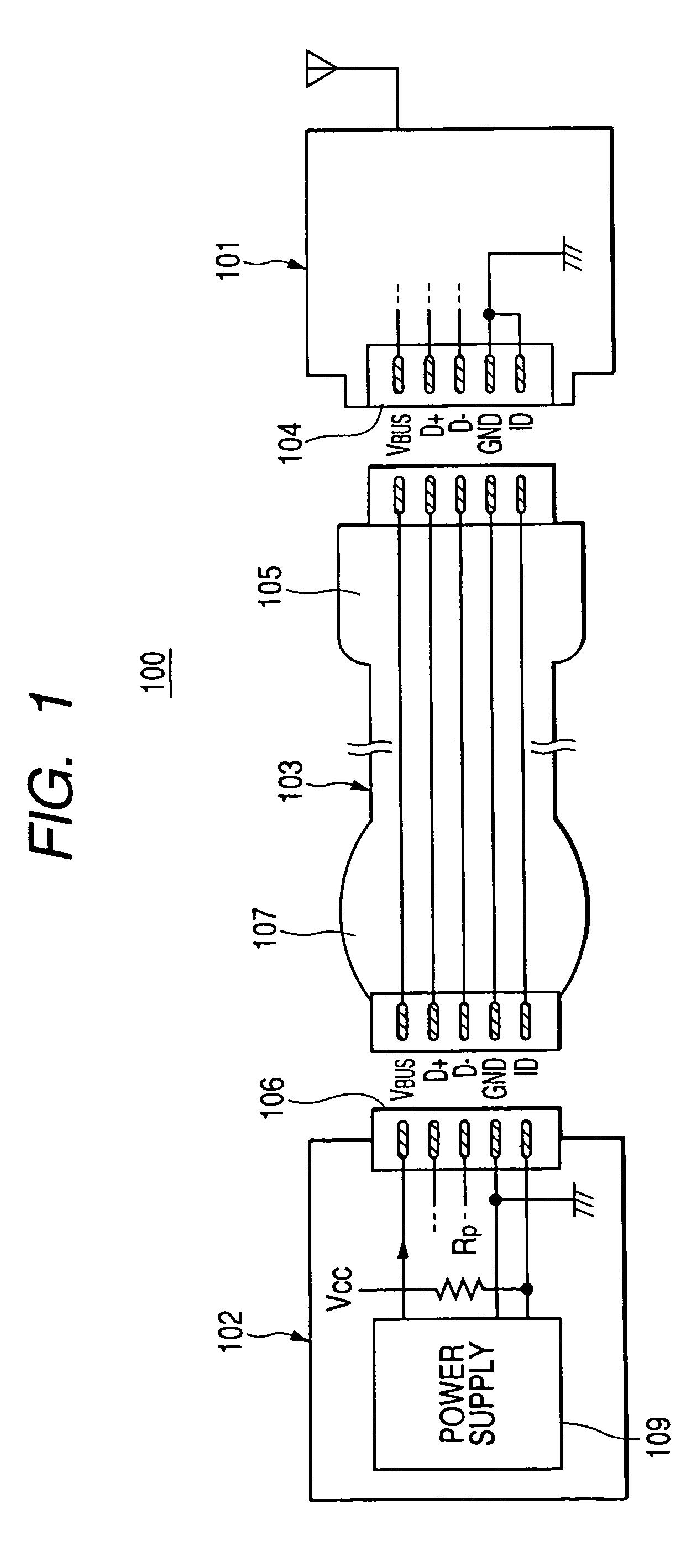

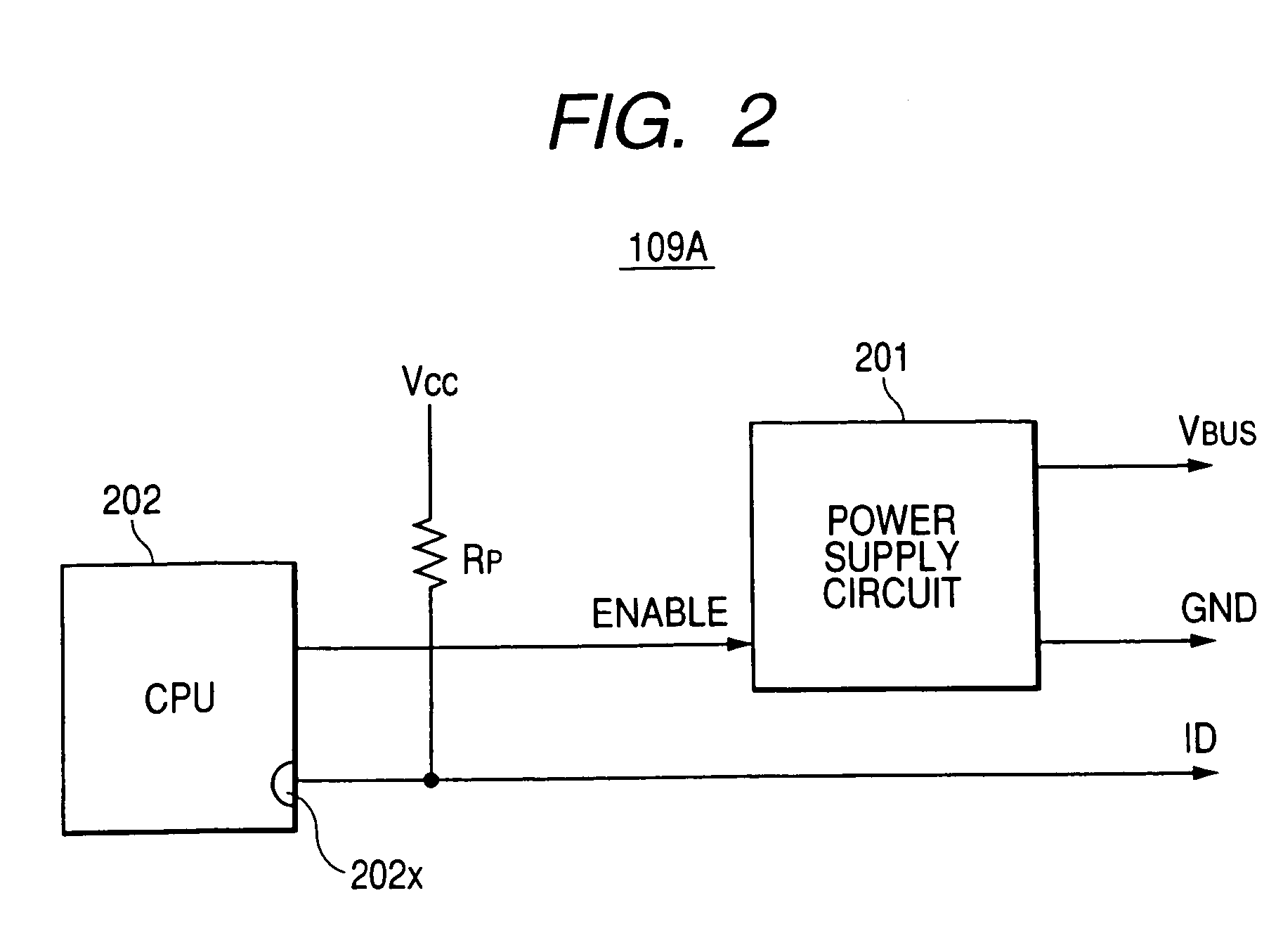

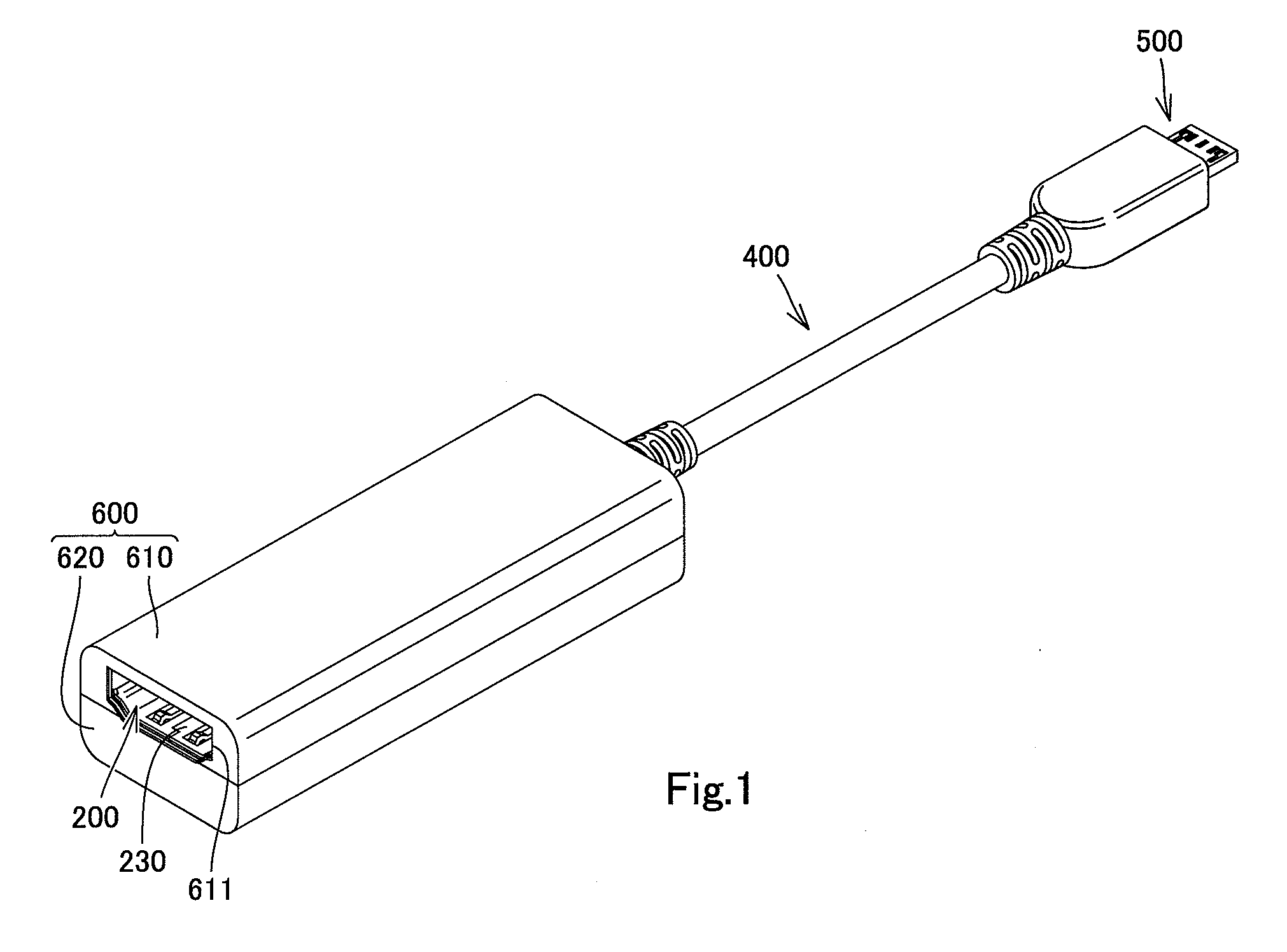

USB interface system

InactiveUS20050039060A1Easy to buildReduce in quantityTelevision system detailsVolume/mass flow measurementUSBVoltage

When a host 101 is connected to a device 102 via a USB cable 103, the ID terminal on the device 102 is short-circuited to the GND line, hence to reduce the voltage level of the ID terminal. Since power feeding means 109 starts feeding power to the VBUS terminal when detecting that the voltage level of the ID terminal turns from “H” to “L”, the power is supplied to the host 101 through the VBUS line of the USB cable 103.

Owner:TDK CORPARATION

Device that provides power to a host via a Mini-B interface upon detection of a predetermined voltage

InactiveUS7356715B2Reduce in quantitySimplify connection workTelevision system detailsVolume/mass flow measurementEngineeringUSB

Owner:TDK CORPARATION

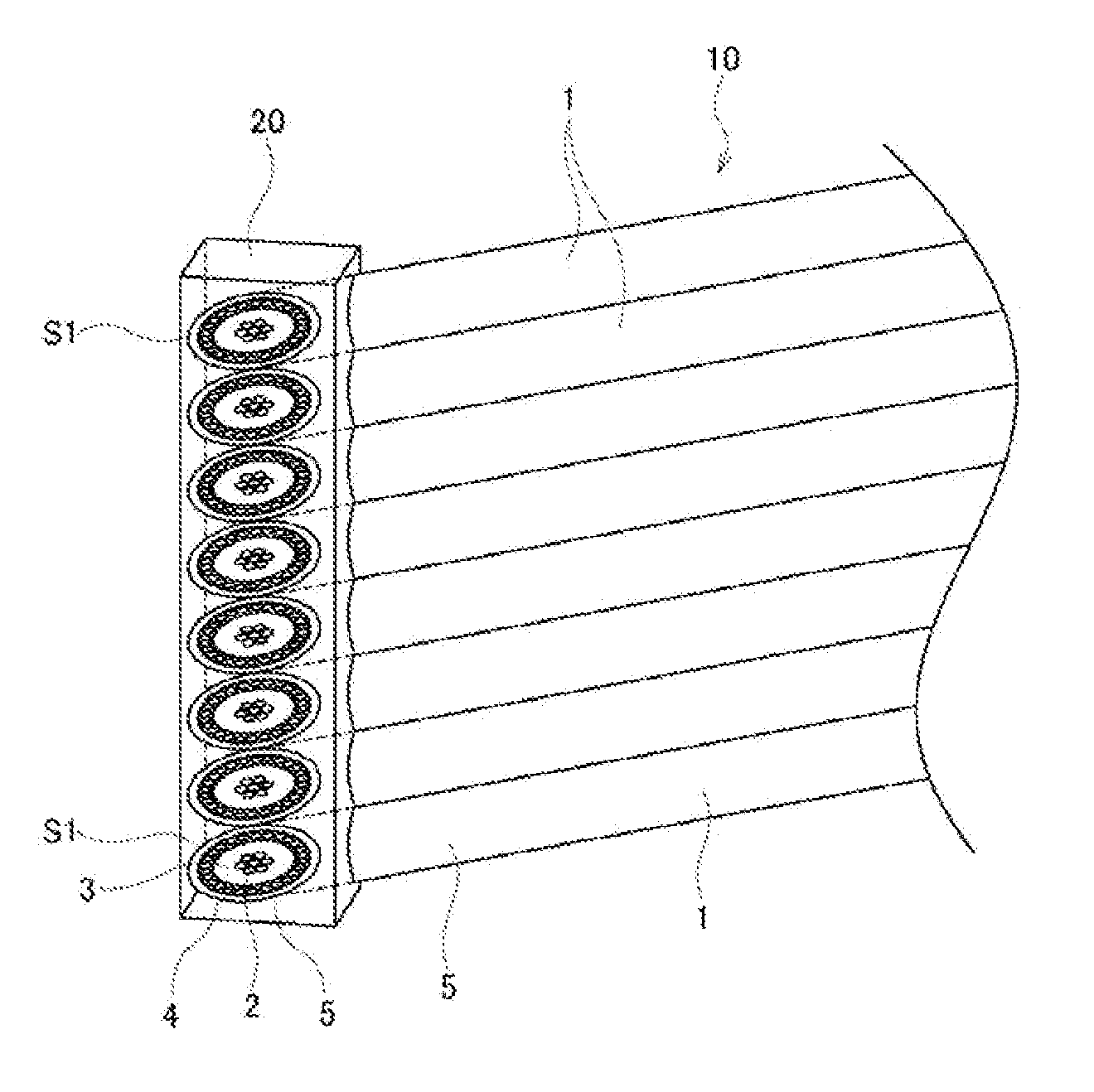

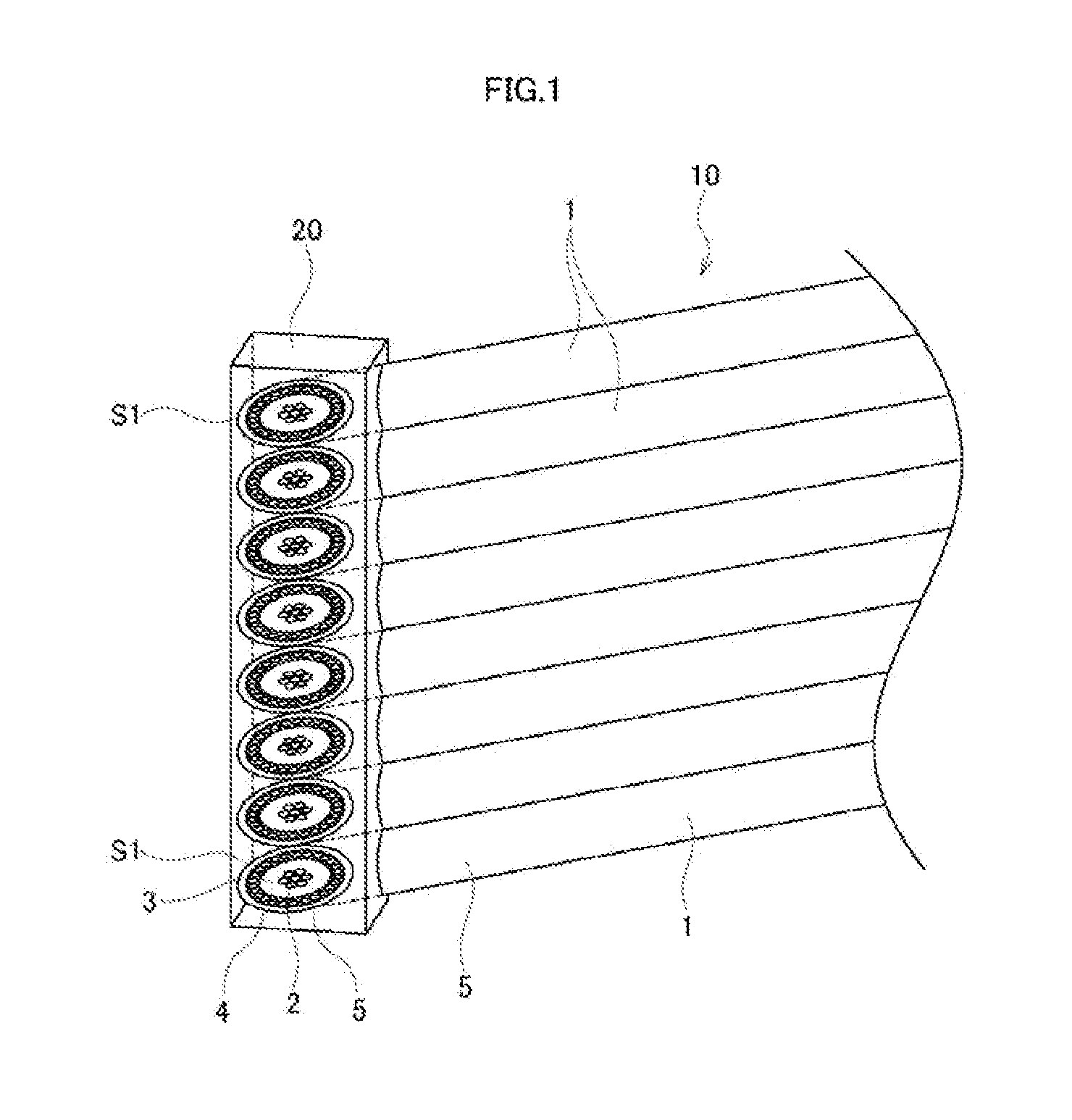

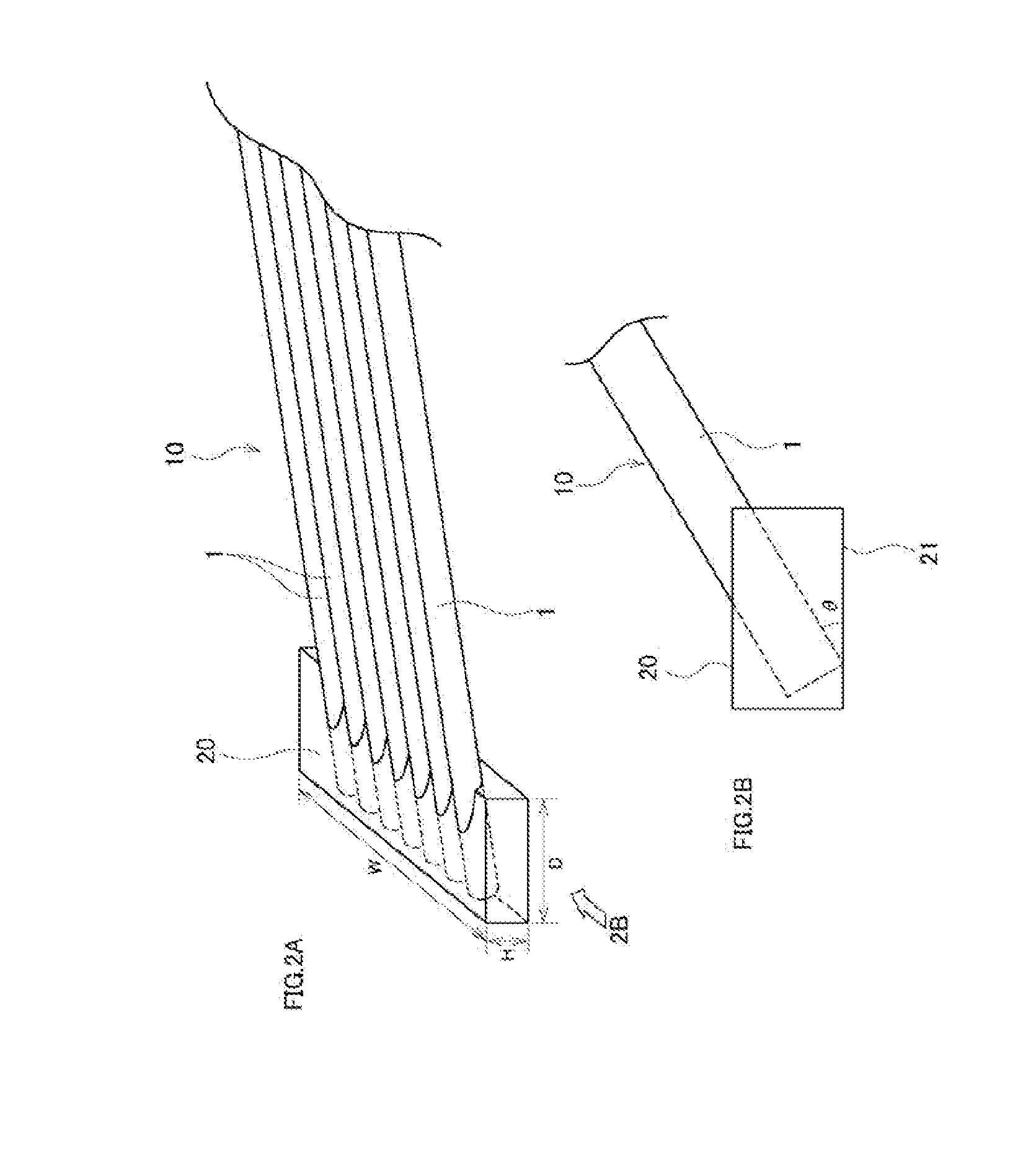

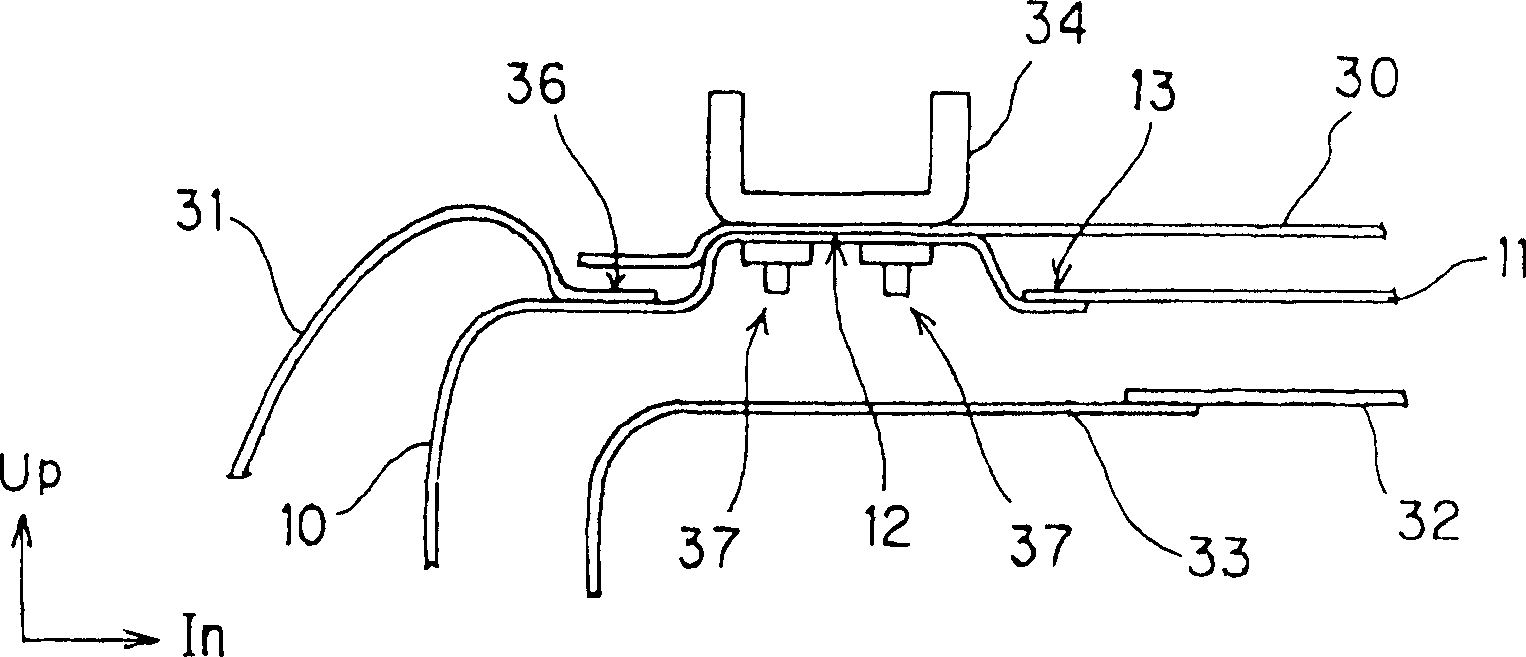

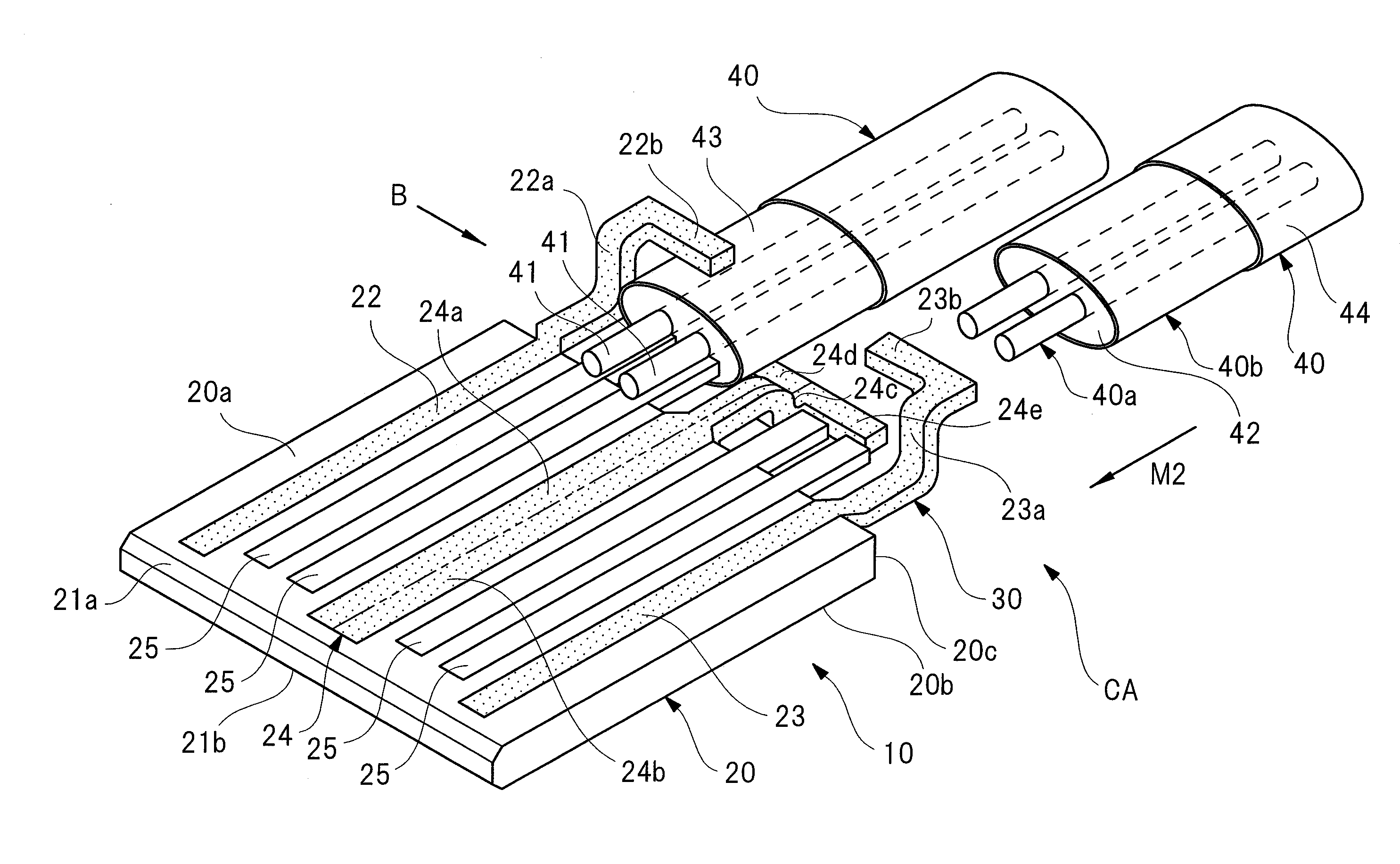

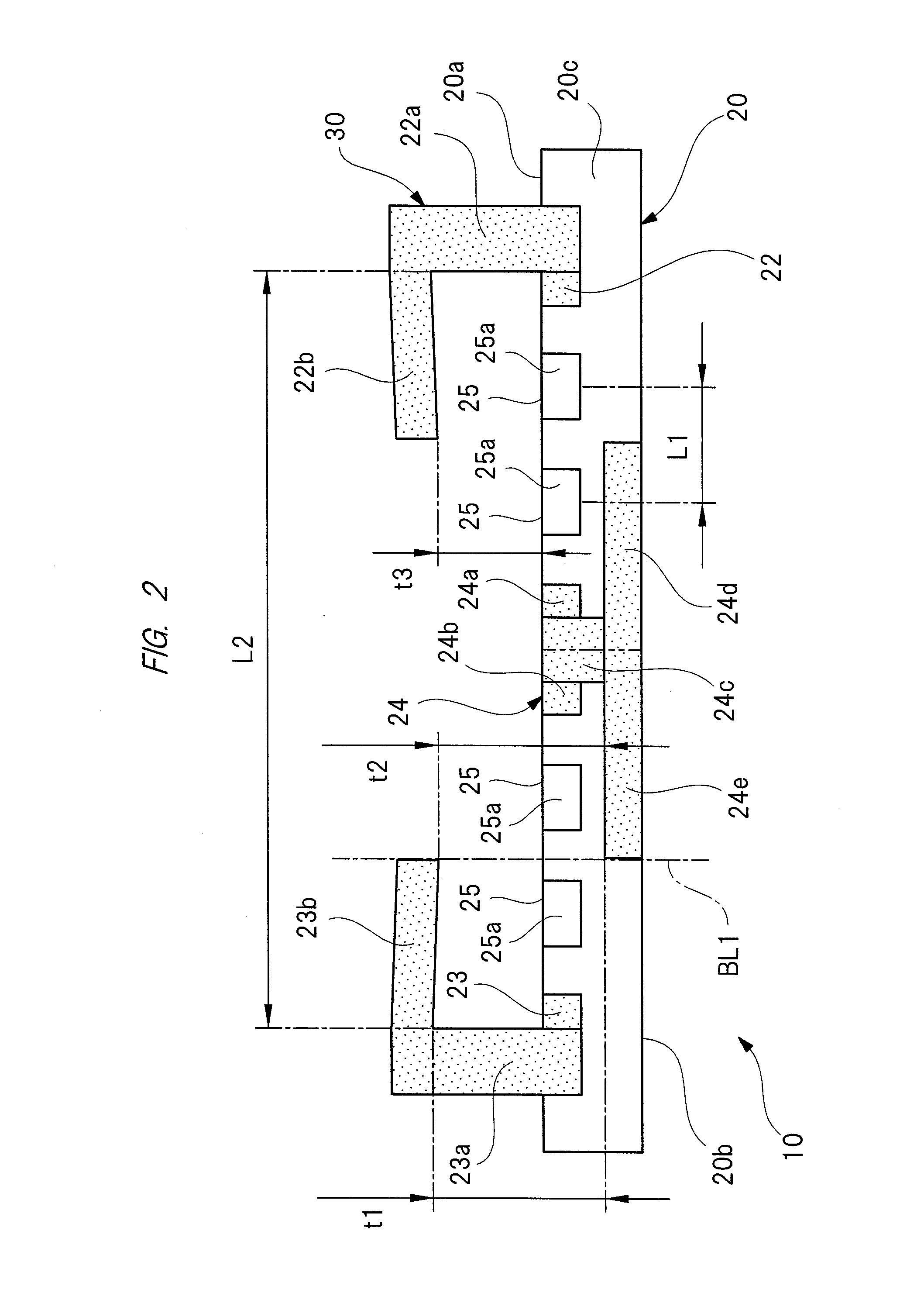

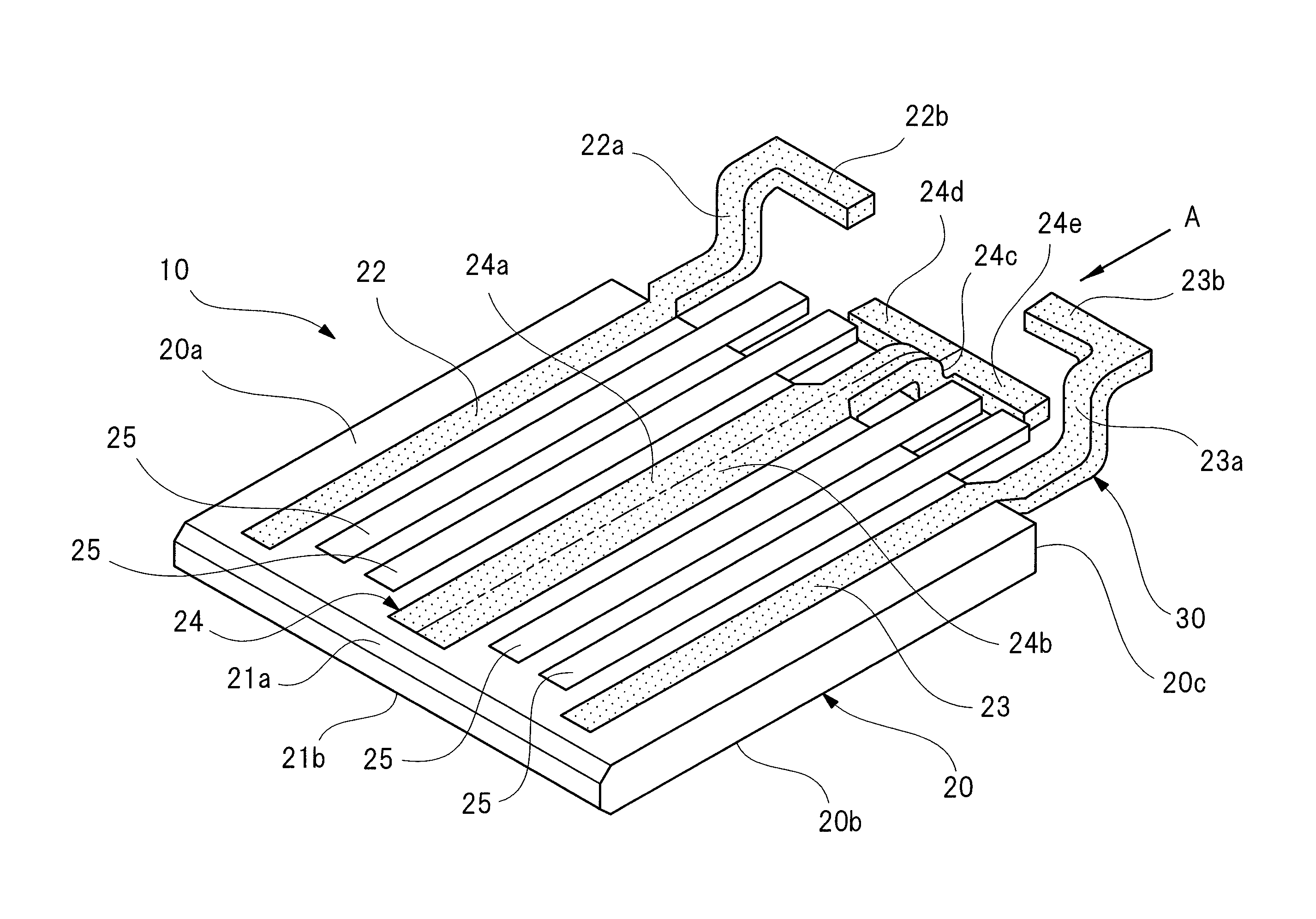

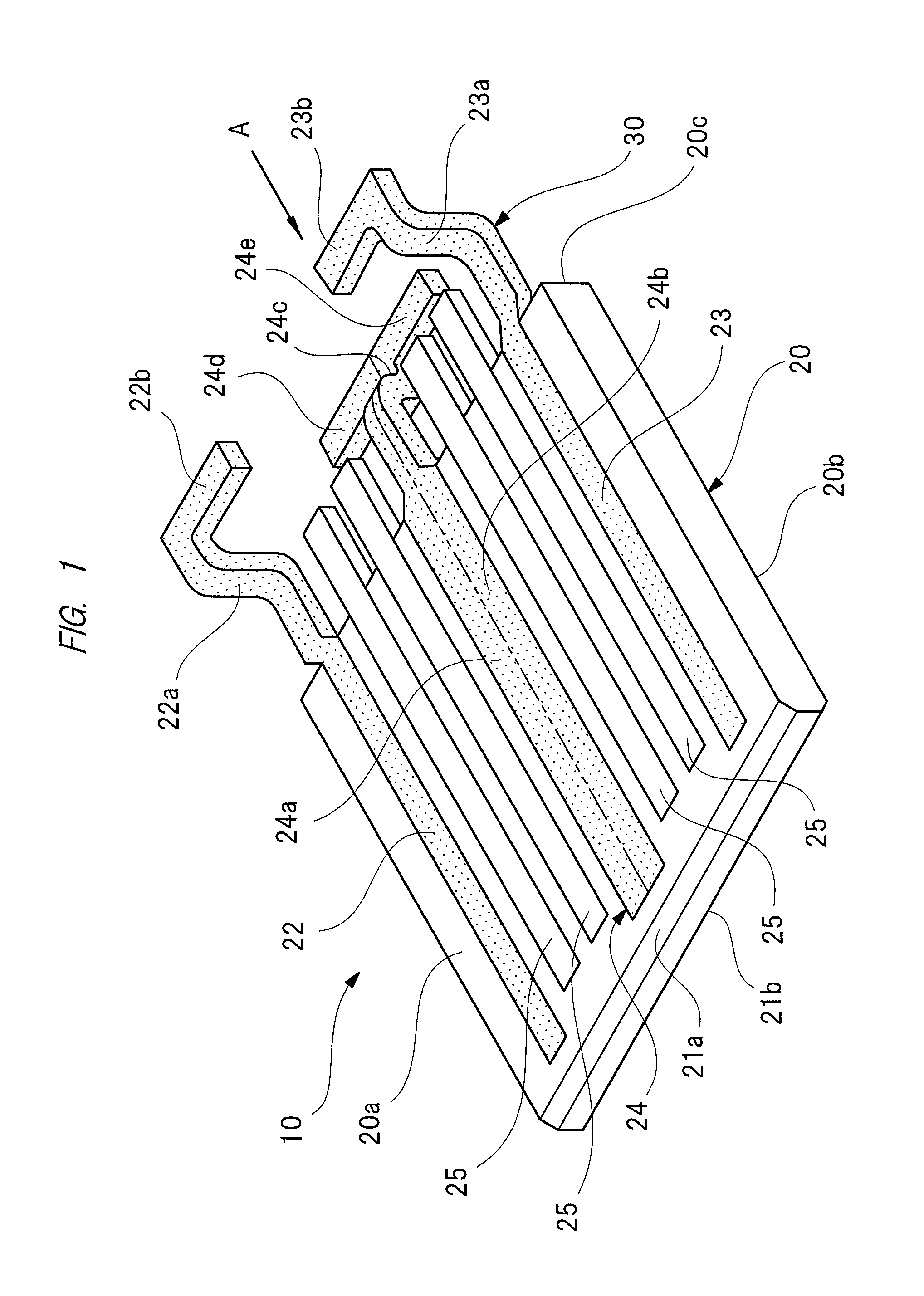

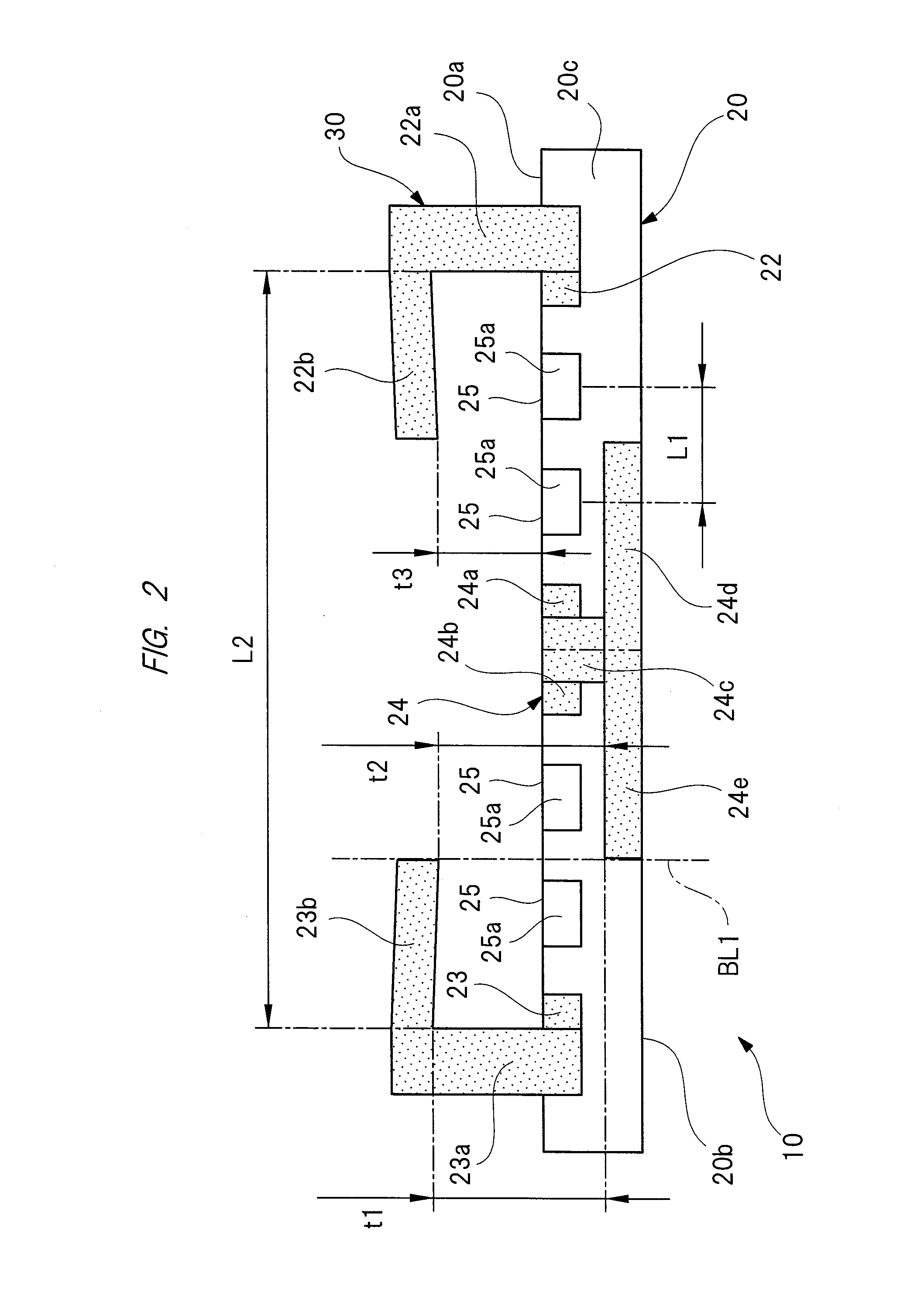

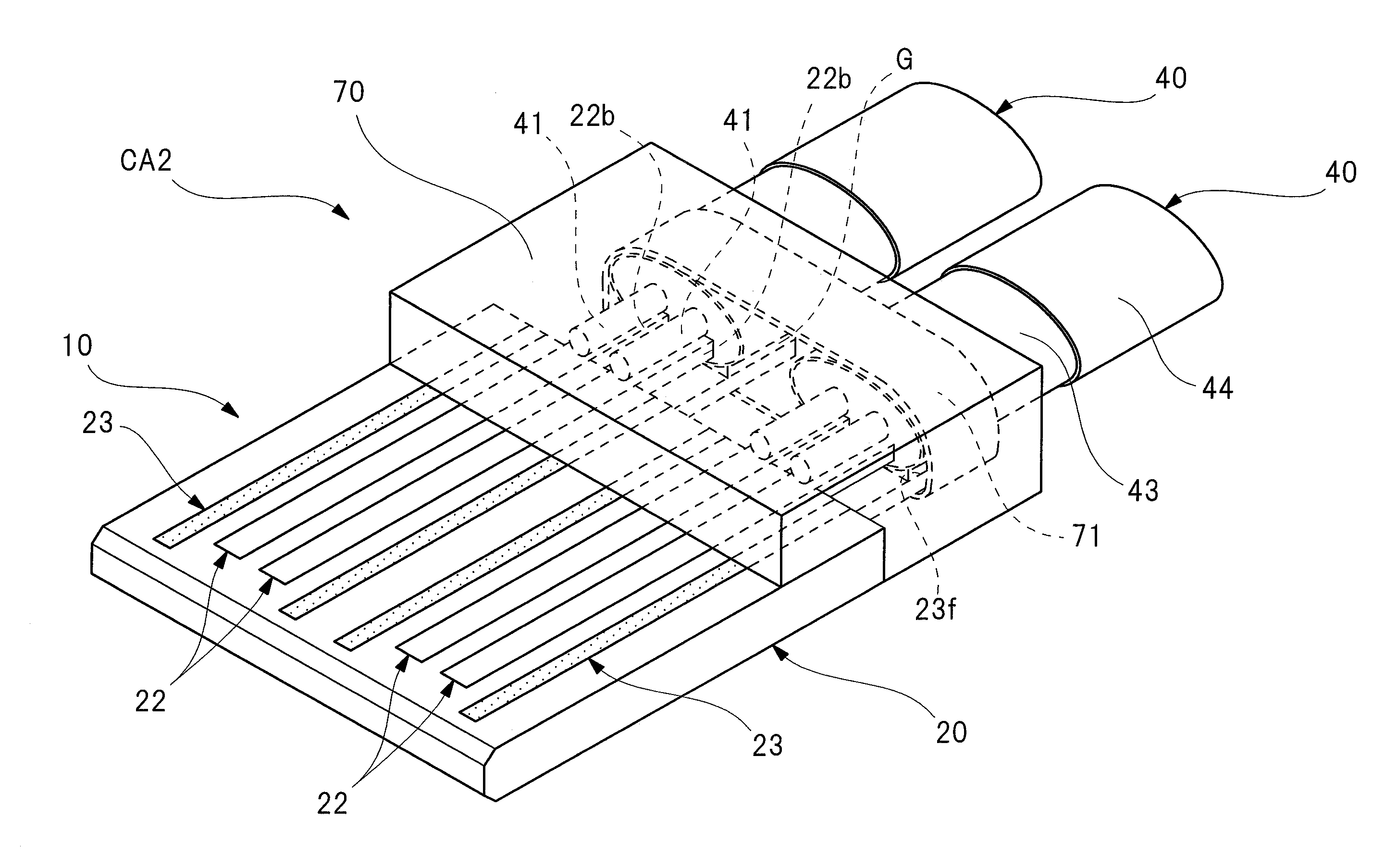

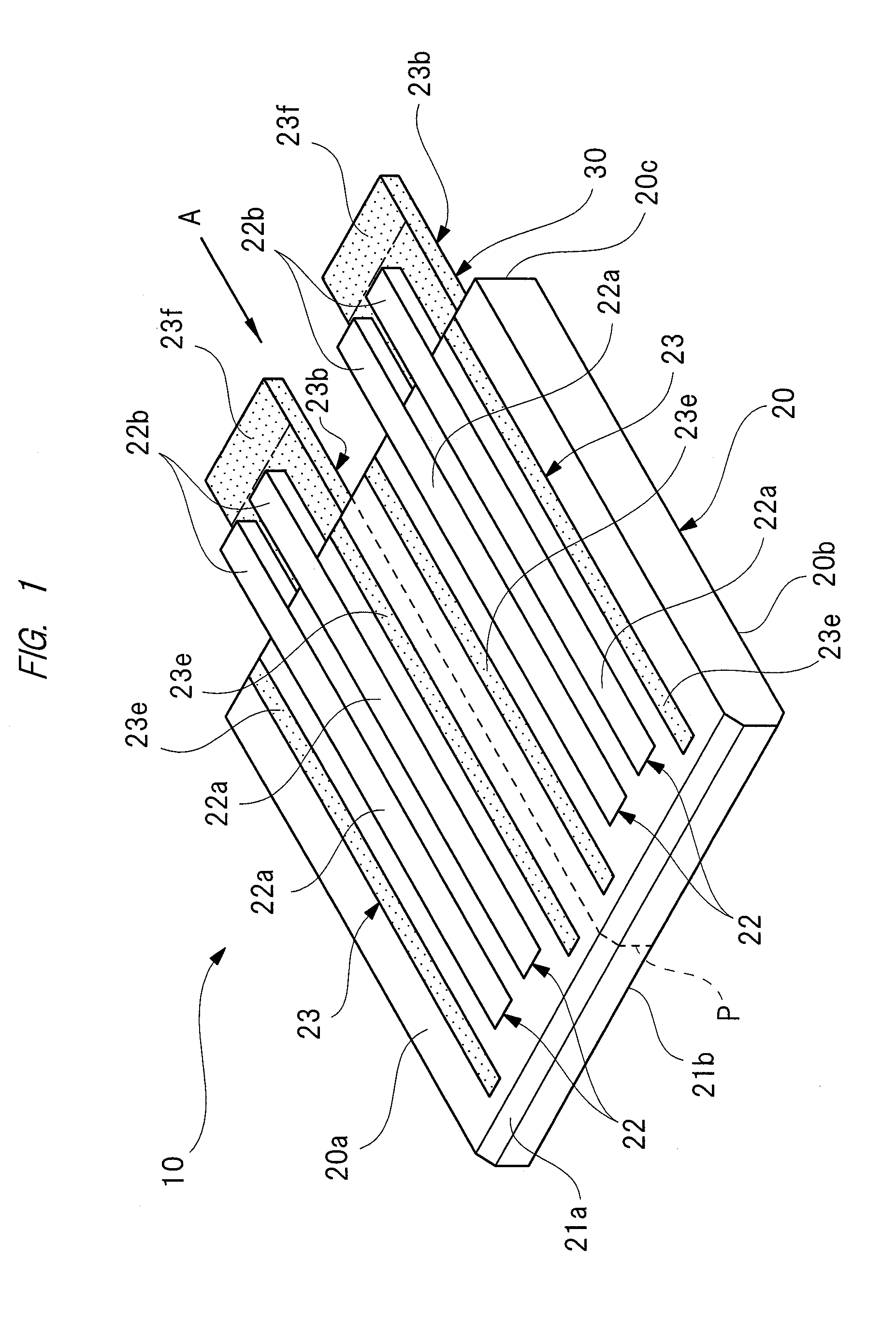

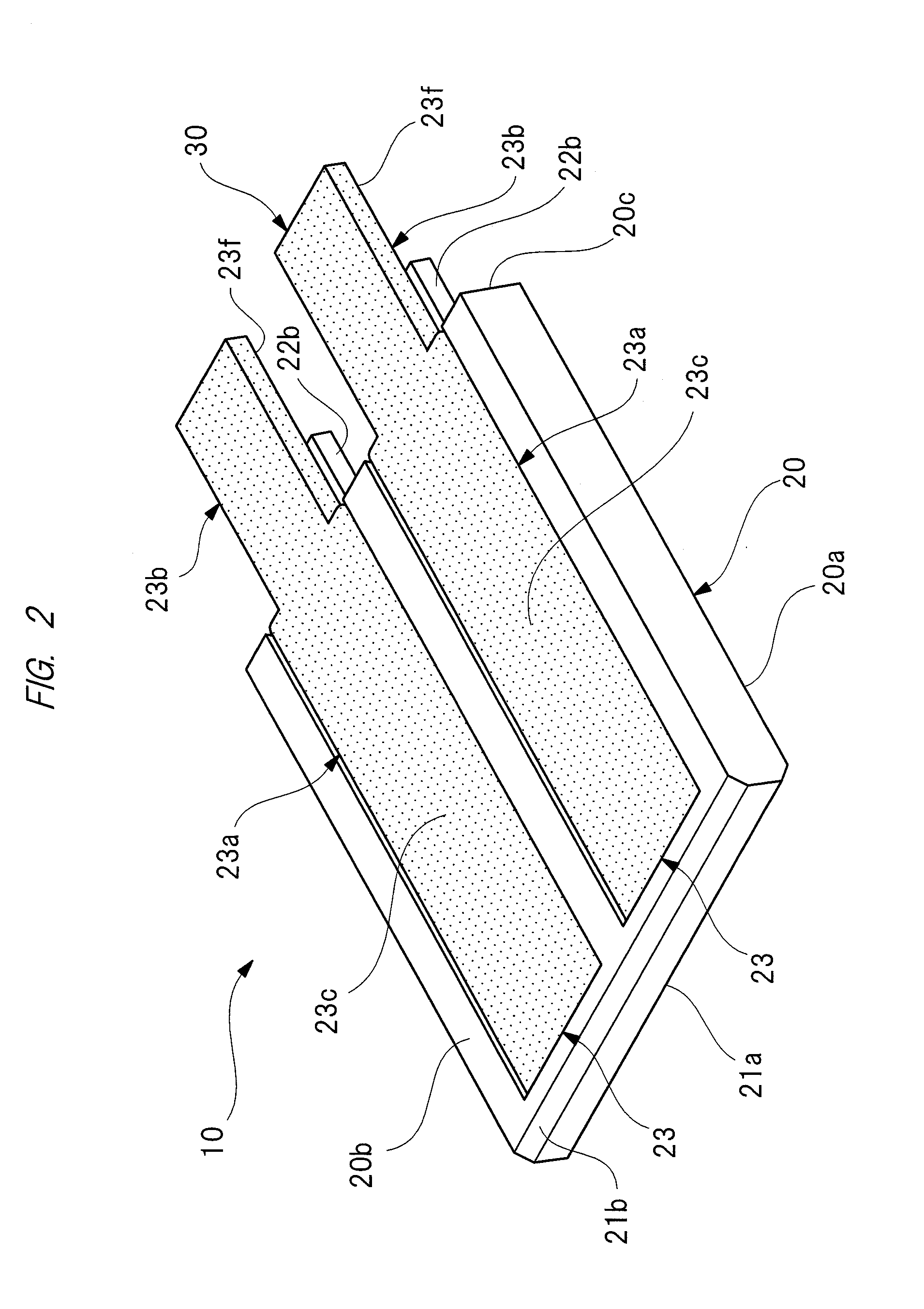

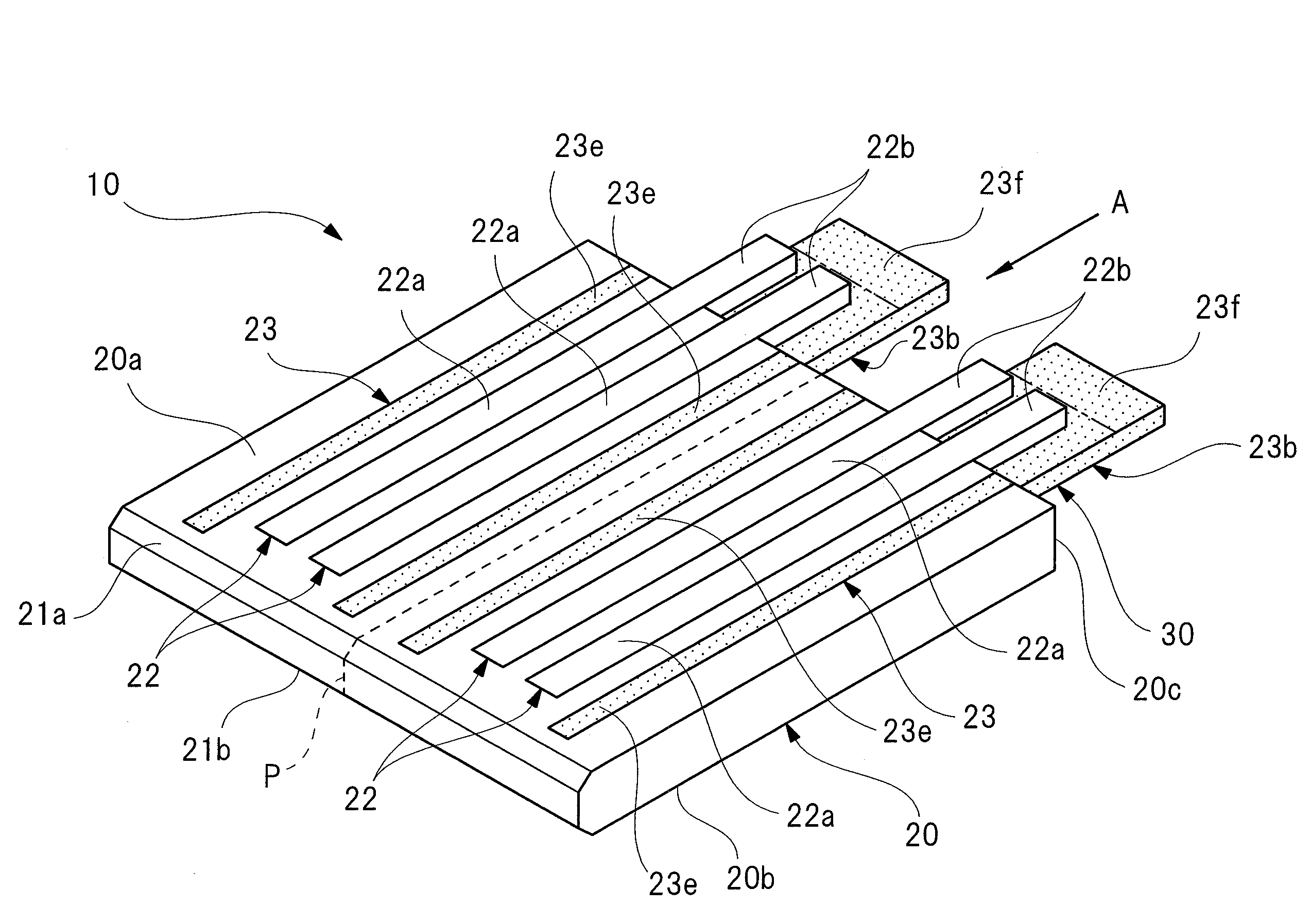

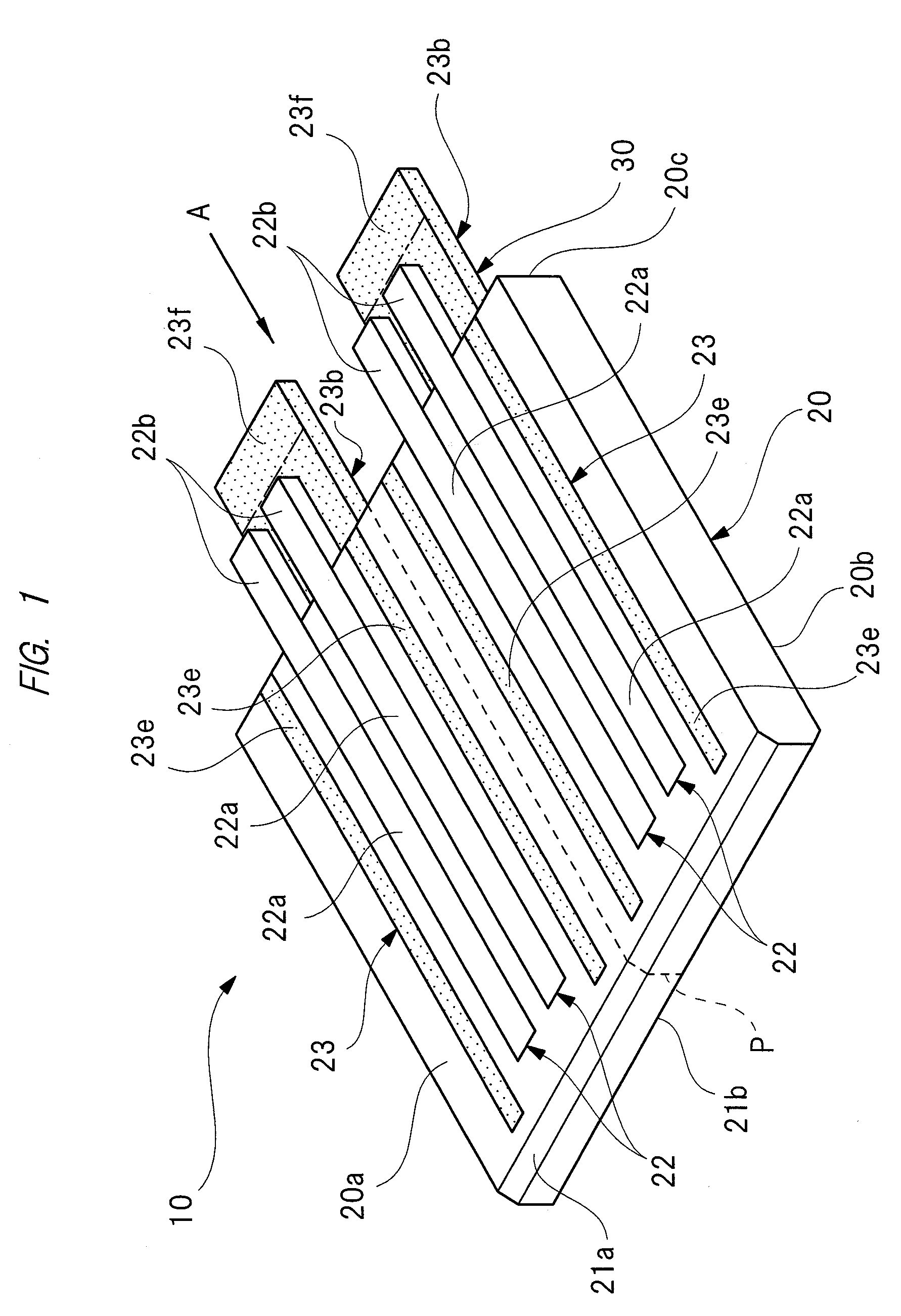

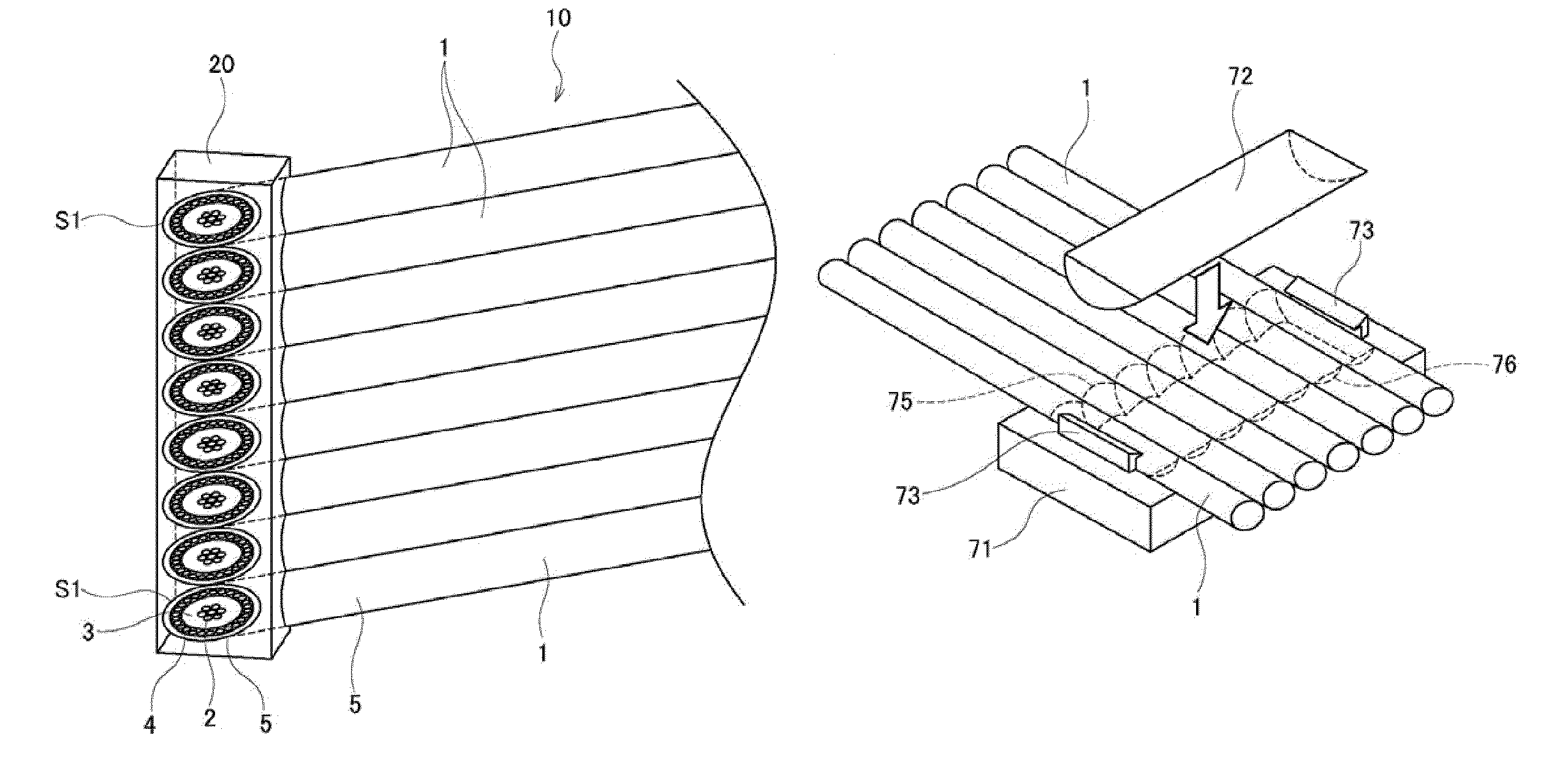

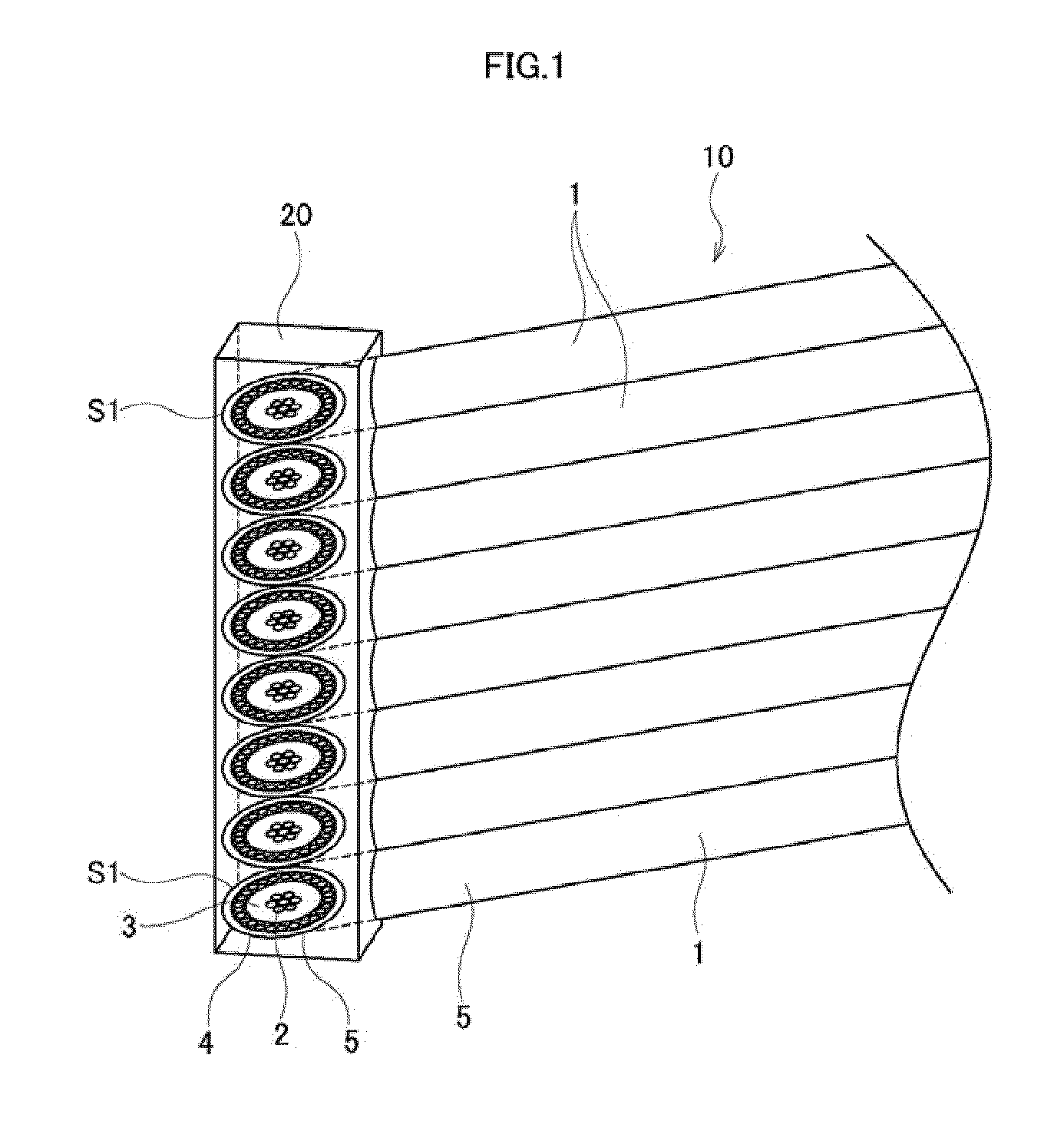

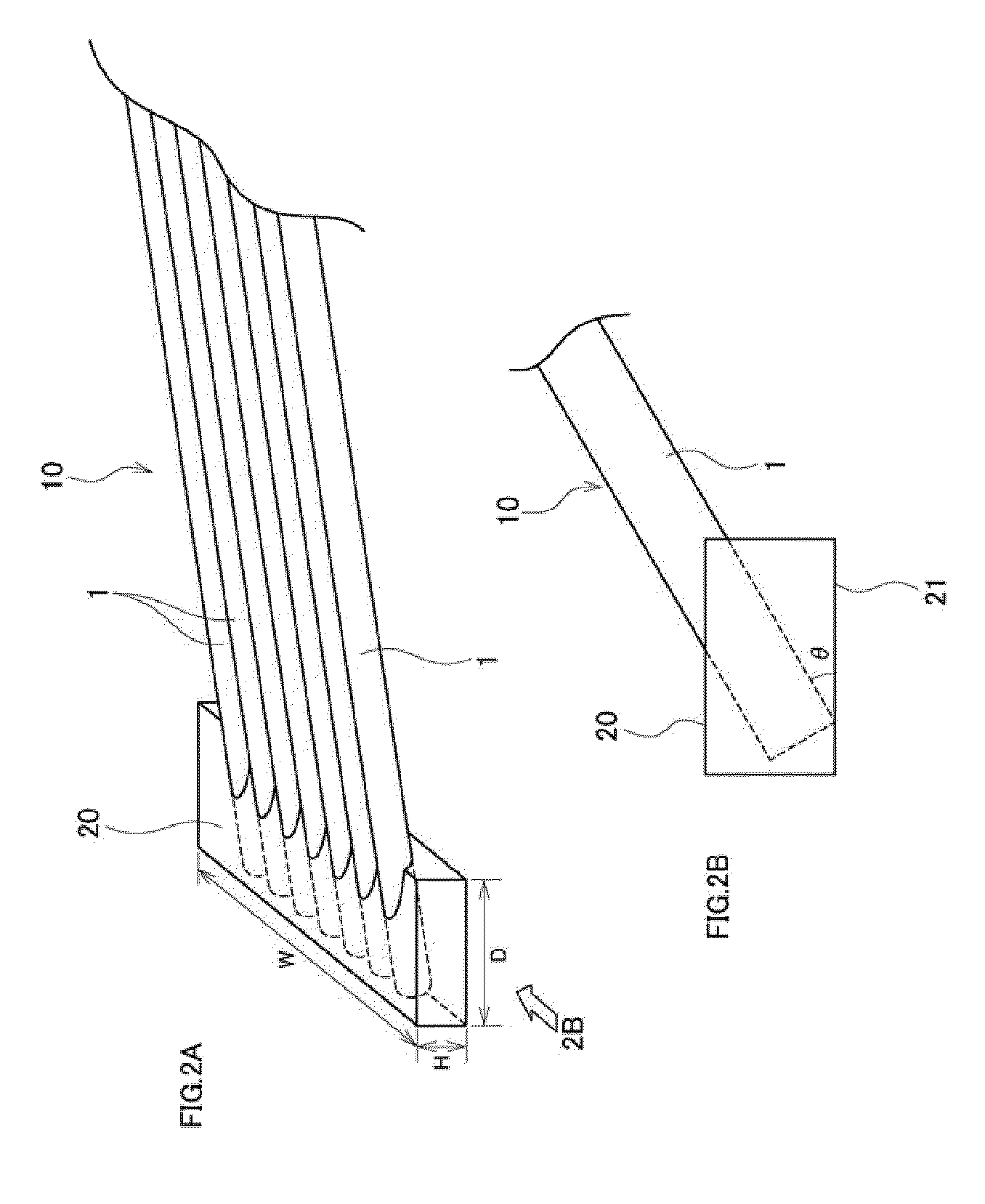

Multi-coaxial cable assembly and manufacturing method of the same

InactiveUS20090120662A1Simplify connection workReduce positioning accuracyCoupling device detailsInsulated cablesElectrical conductorCoaxial cable

A multi-coaxial cable assembly of the present invention includes a multi-coaxial cable in which a plurality of coaxial cables having insulators, external conductors, and jackets on an outer periphery of center conductors are arranged in parallel; inclined cross sections formed on the end part of the multi-coaxial cable in such a manner as exposing the center conductors and the external conductors of the coaxial cables; and a wiring board or a connector having a wiring pattern to which the center conductors and the external conductors of the coaxial cables exposed on the inclined cross sections are directly connected.

Owner:HITACHI CABLE

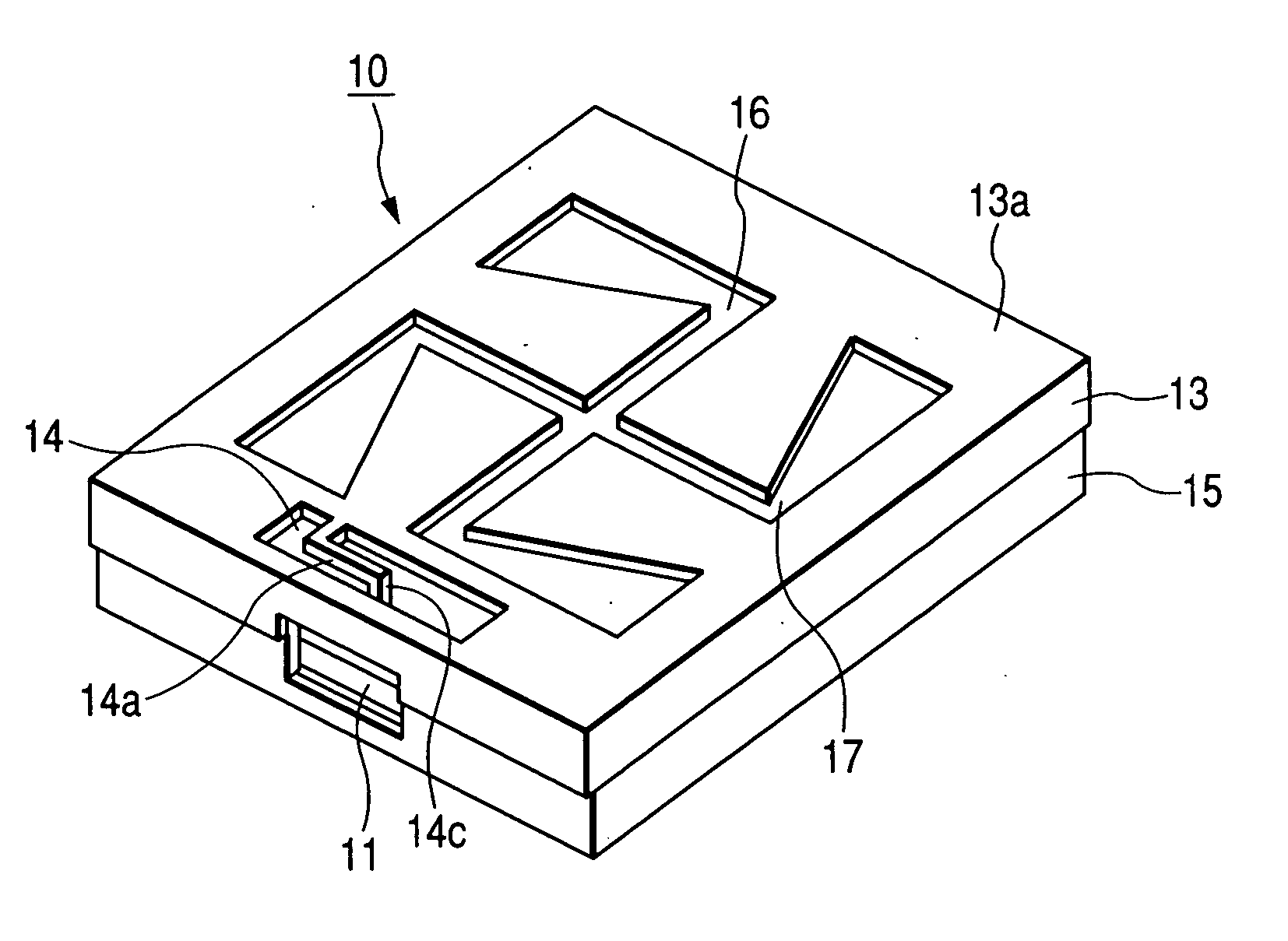

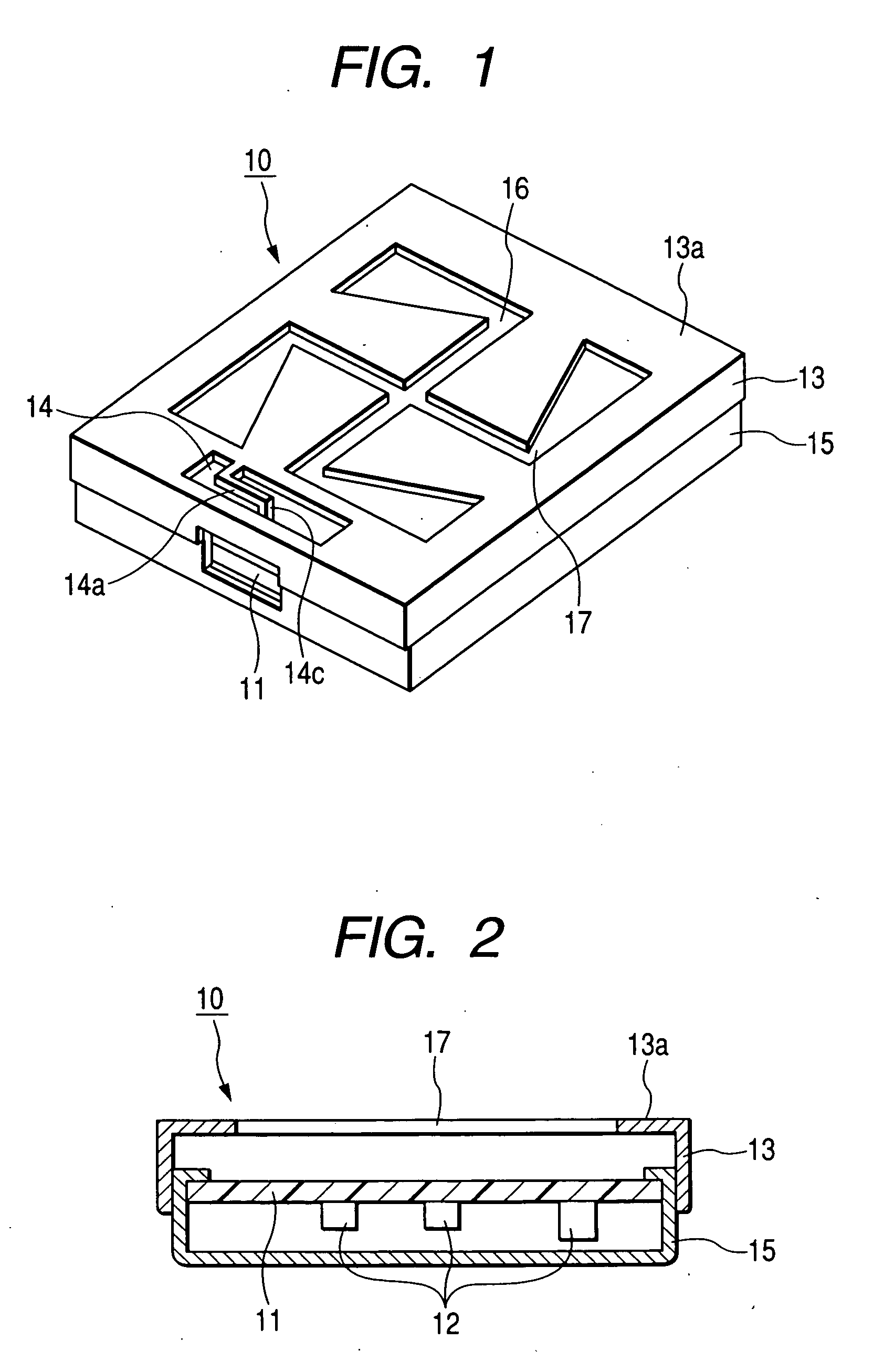

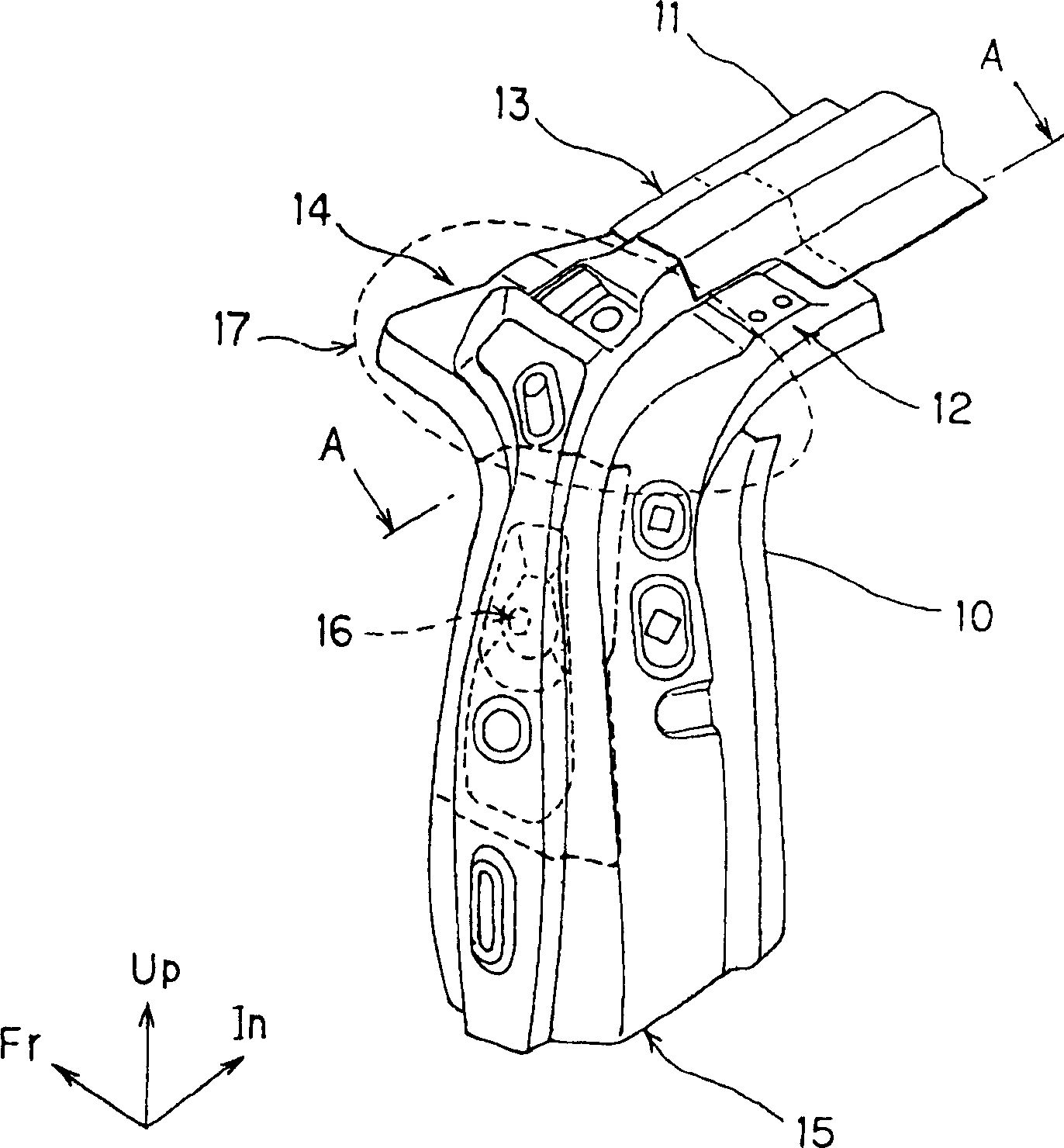

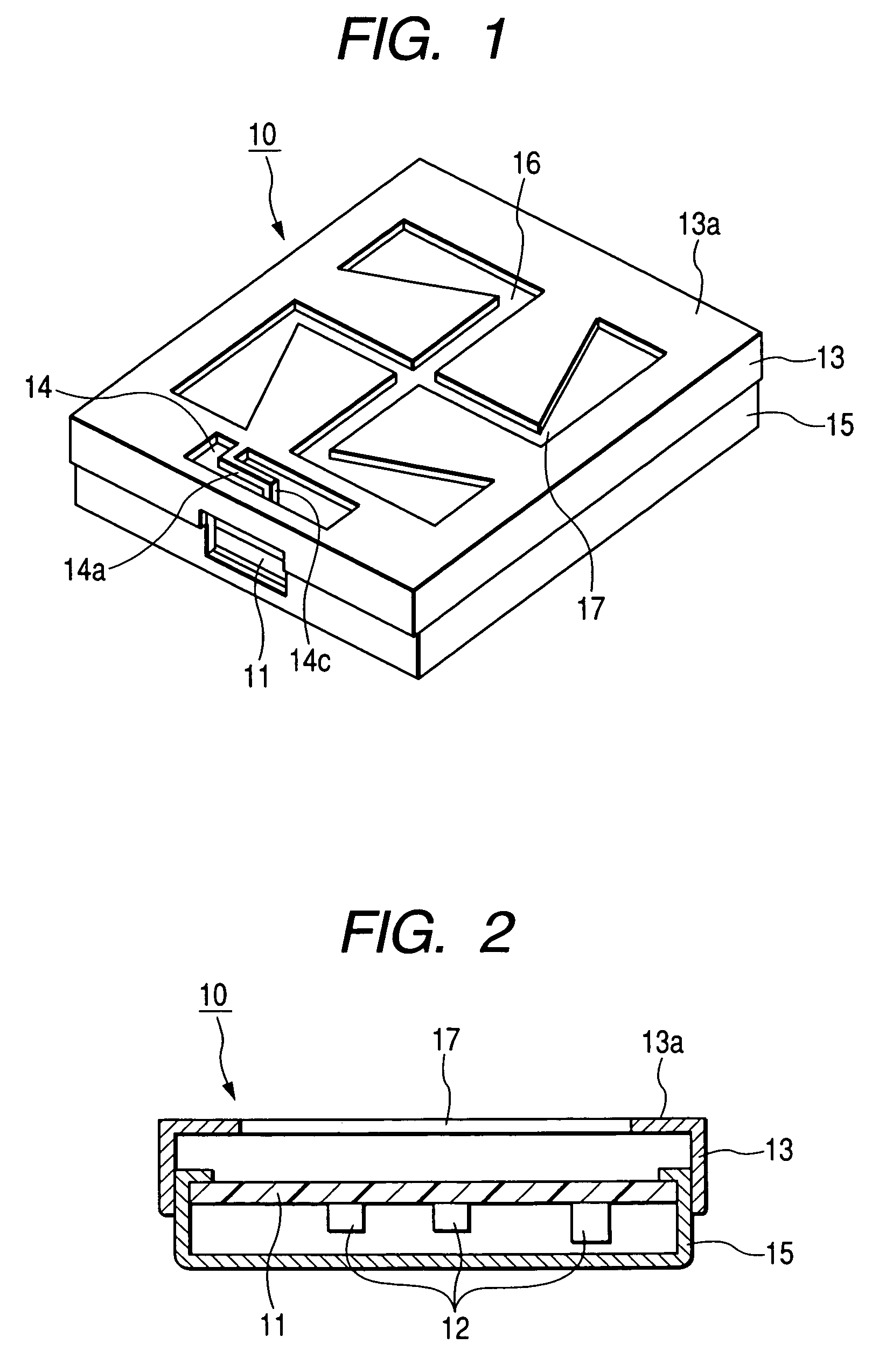

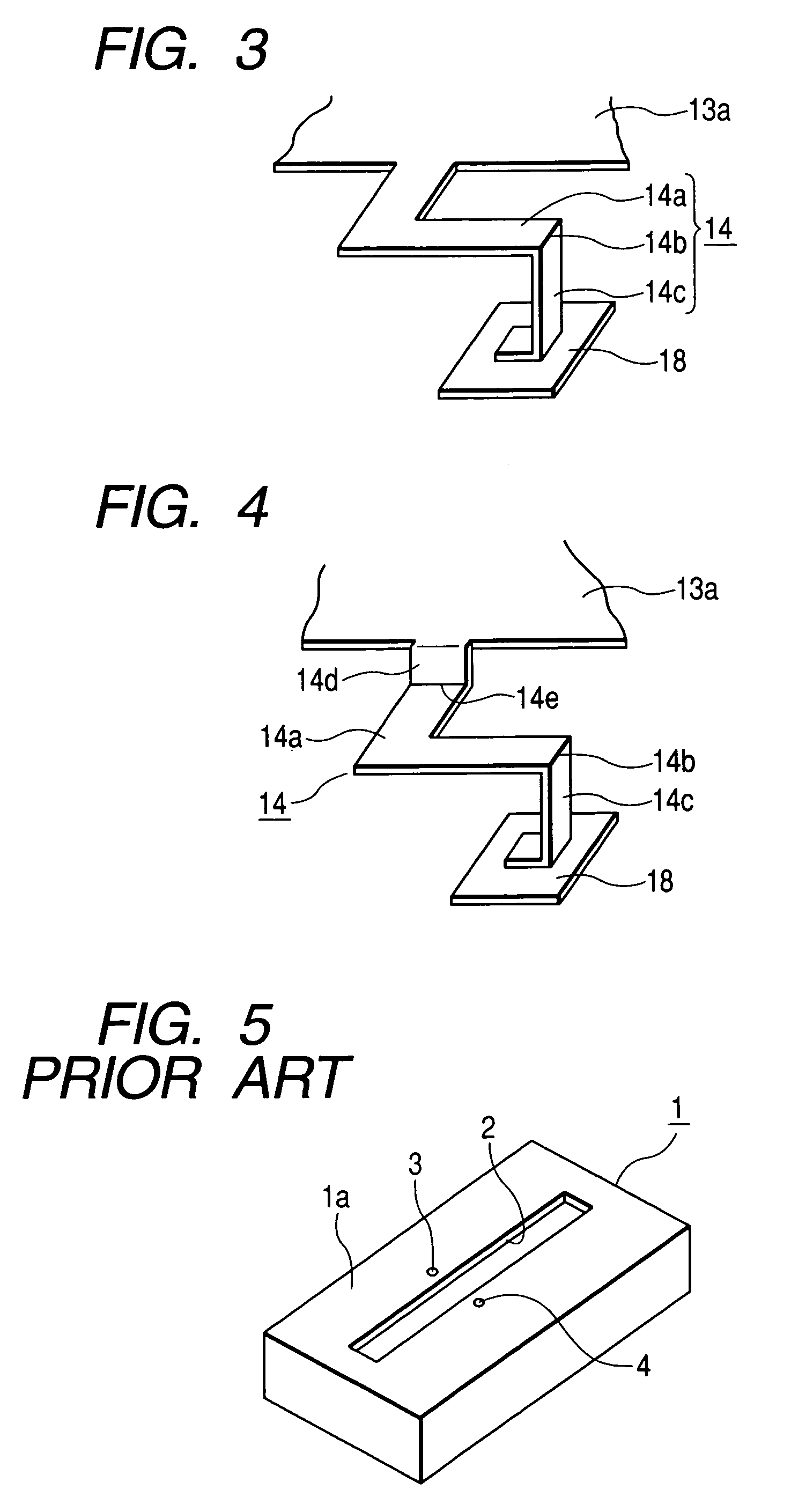

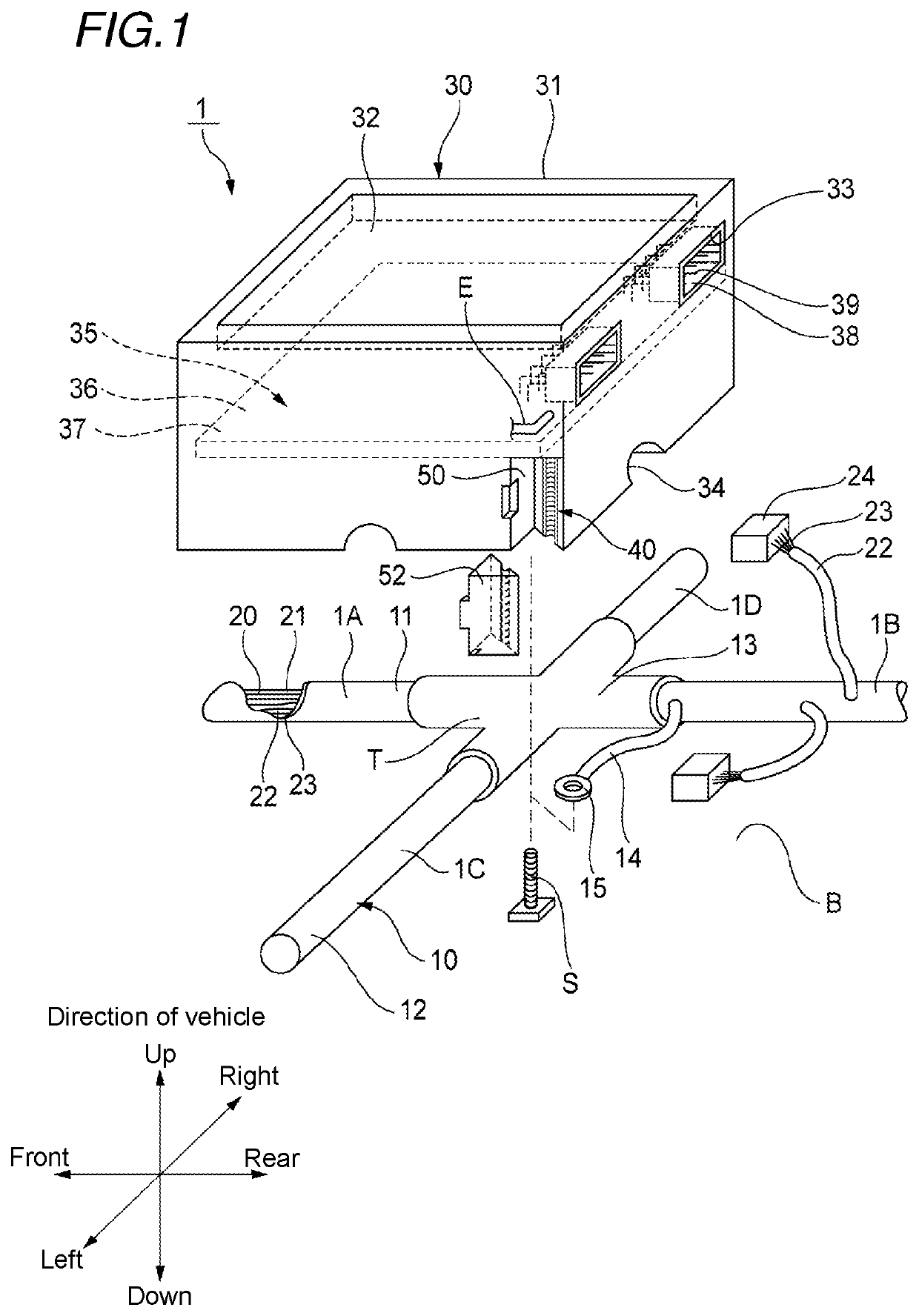

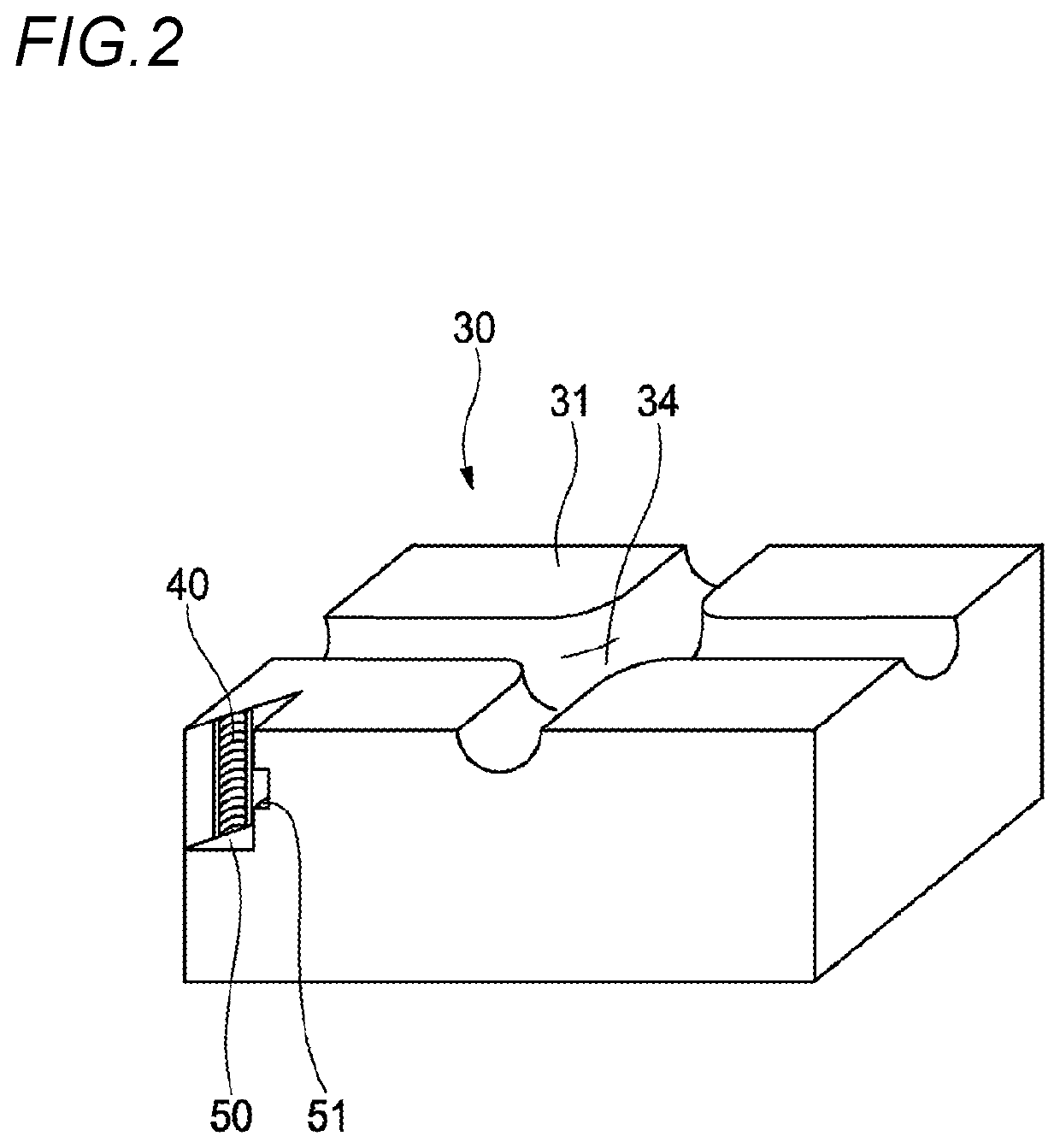

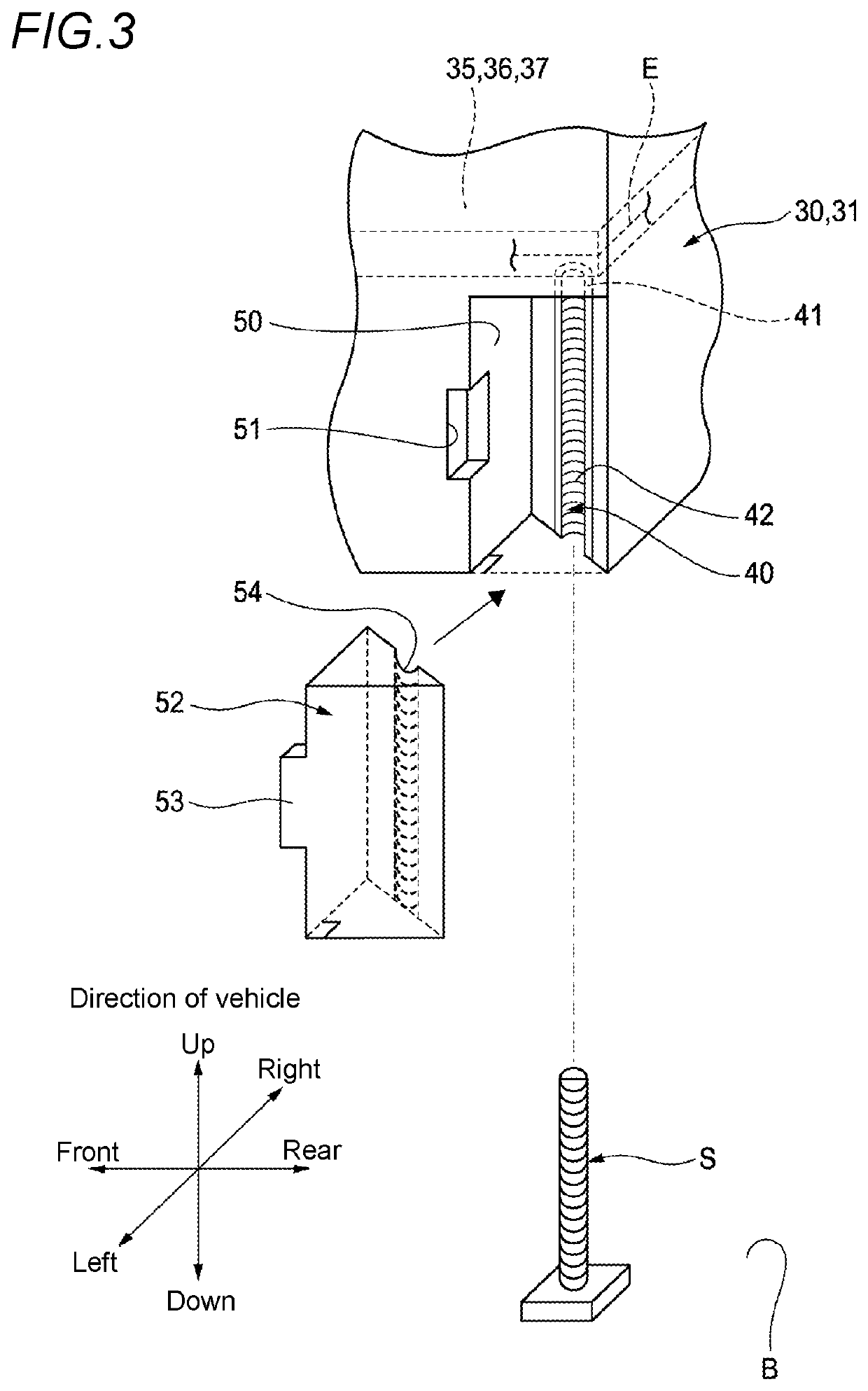

Antenna device for vehicle

InactiveUS20060077113A1Prevent solder from crackingReducing stress appliedElectrically short antennasSlot antennasEngineeringElectrical and Electronics engineering

An antenna device includes a circuit board, an upper shield case, a lower shield case, and a power feeding member. The circuit board has high frequency circuits arranged thereon. The upper shield case and the lower shield case cover the circuit board. The power feeding member extends from an upper plate of the upper shield case. Radiation slots and are formed in the upper plate. The power feeding member includes a horizontal portion, a bent portion, and a drooping portion, and a front end of the drooping portion is mounted on a land of the circuit board and soldered thereto. The horizontal portion protrudes from a base end which is continuous to the upper plate in a horizontal direction. The bent portion is formed by bending a front end of the horizontal portion at a right angle. The drooping portion extends downward from the bent portion.

Owner:ALPS ALPINE CO LTD

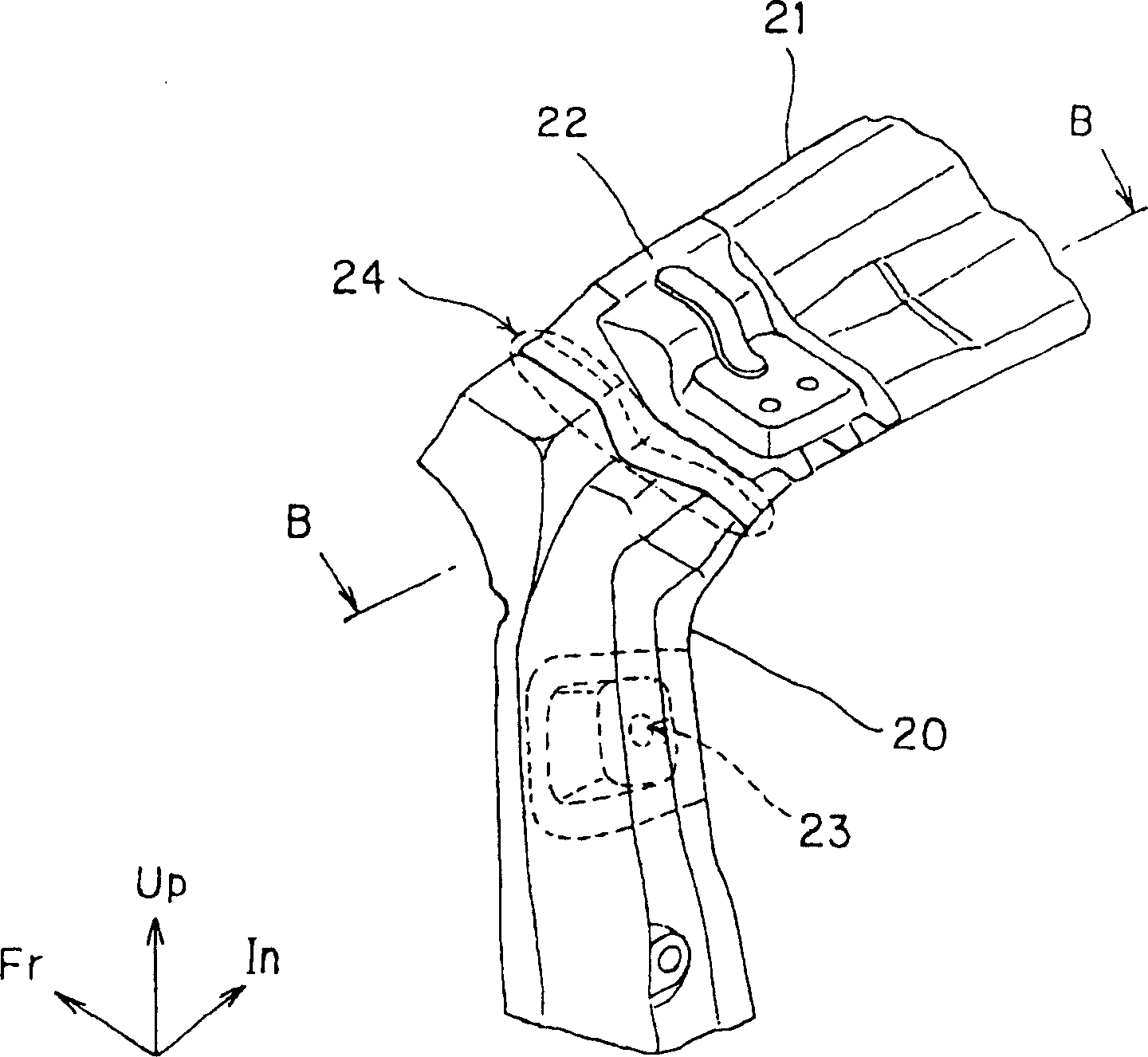

Rear body structure of vehicle

Owner:MITSUBISHI MOTORS CORP

Antenna device for vehicle

InactiveUS7388553B2Avoid Connection DefectsImprove reliabilityElectrically short antennasSlot antennasEngineeringElectrical and Electronics engineering

An antenna device includes a circuit board, an upper shield case, a lower shield case, and a power feeding member. The circuit board has high frequency circuits arranged thereon. The upper shield case and the lower shield case cover the circuit board. The power feeding member extends from an upper plate of the upper shield case. Radiation slots and are formed in the upper plate. The power feeding member includes a horizontal portion, a bent portion, and a drooping portion, and a front end of the drooping portion is mounted on a land of the circuit board and soldered thereto. The horizontal portion protrudes from a base end which is continuous to the upper plate in a horizontal direction. The bent portion is formed by bending a front end of the horizontal portion at a right angle. The drooping portion extends downward from the bent portion.

Owner:ALPS ALPINE CO LTD

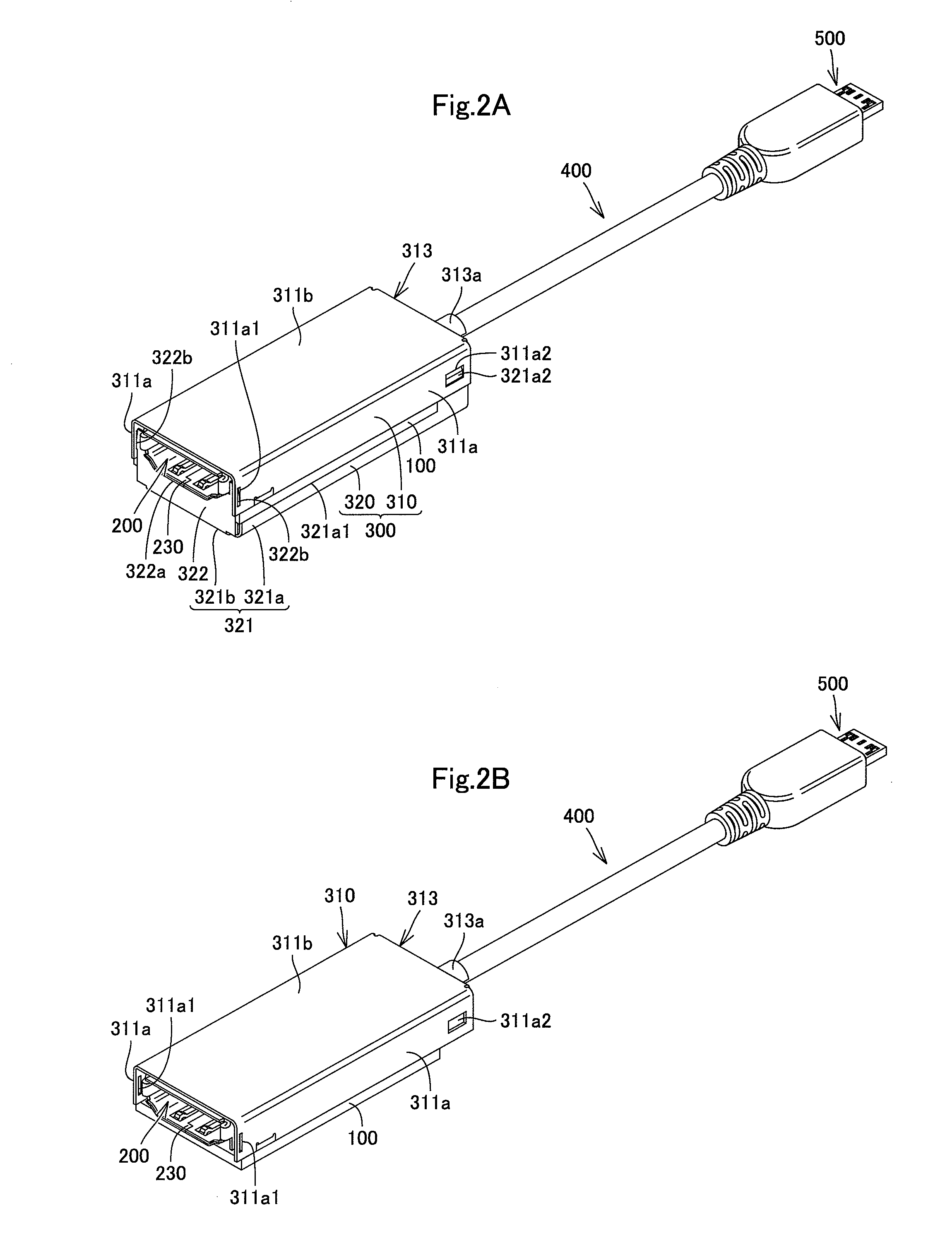

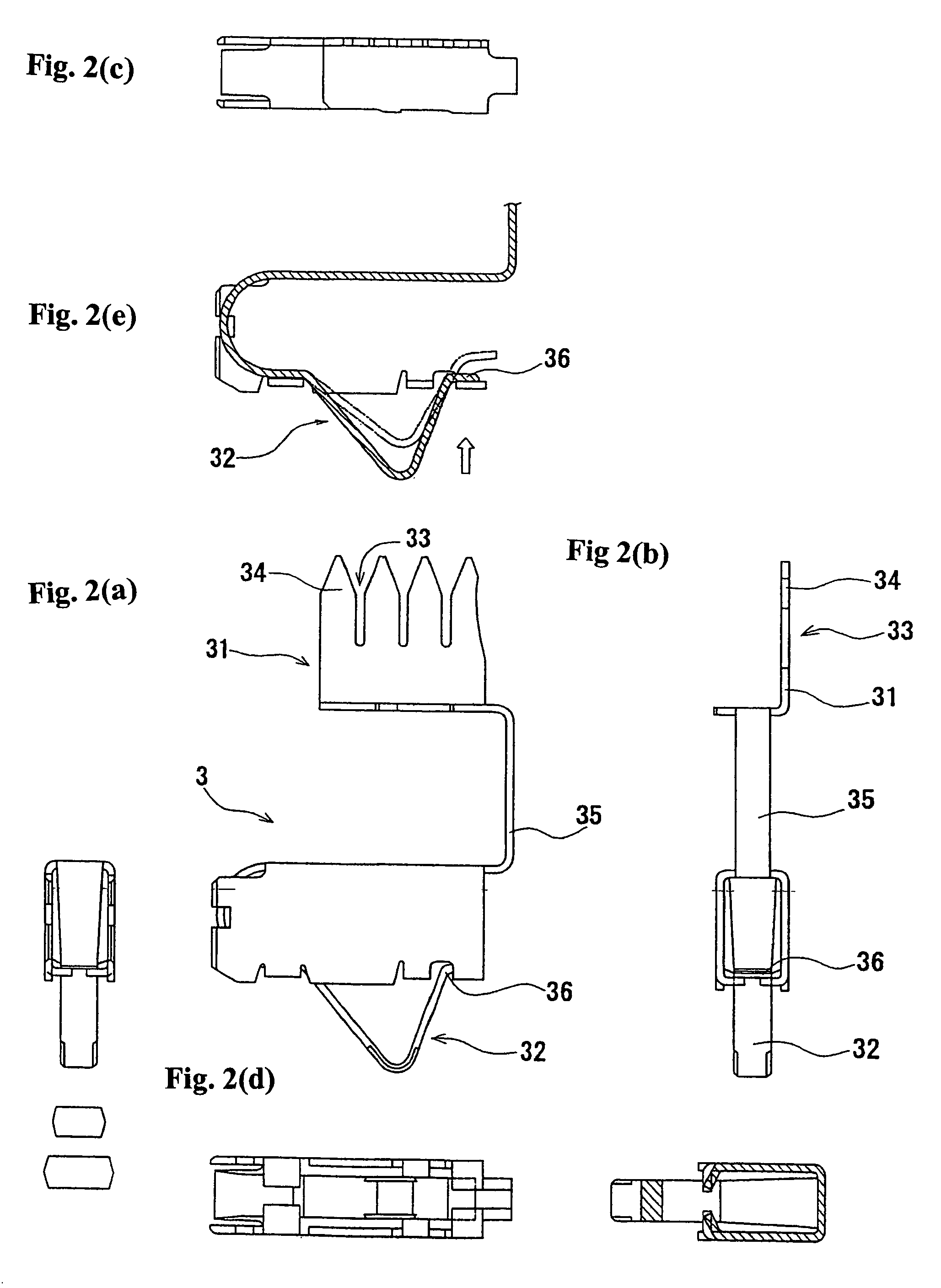

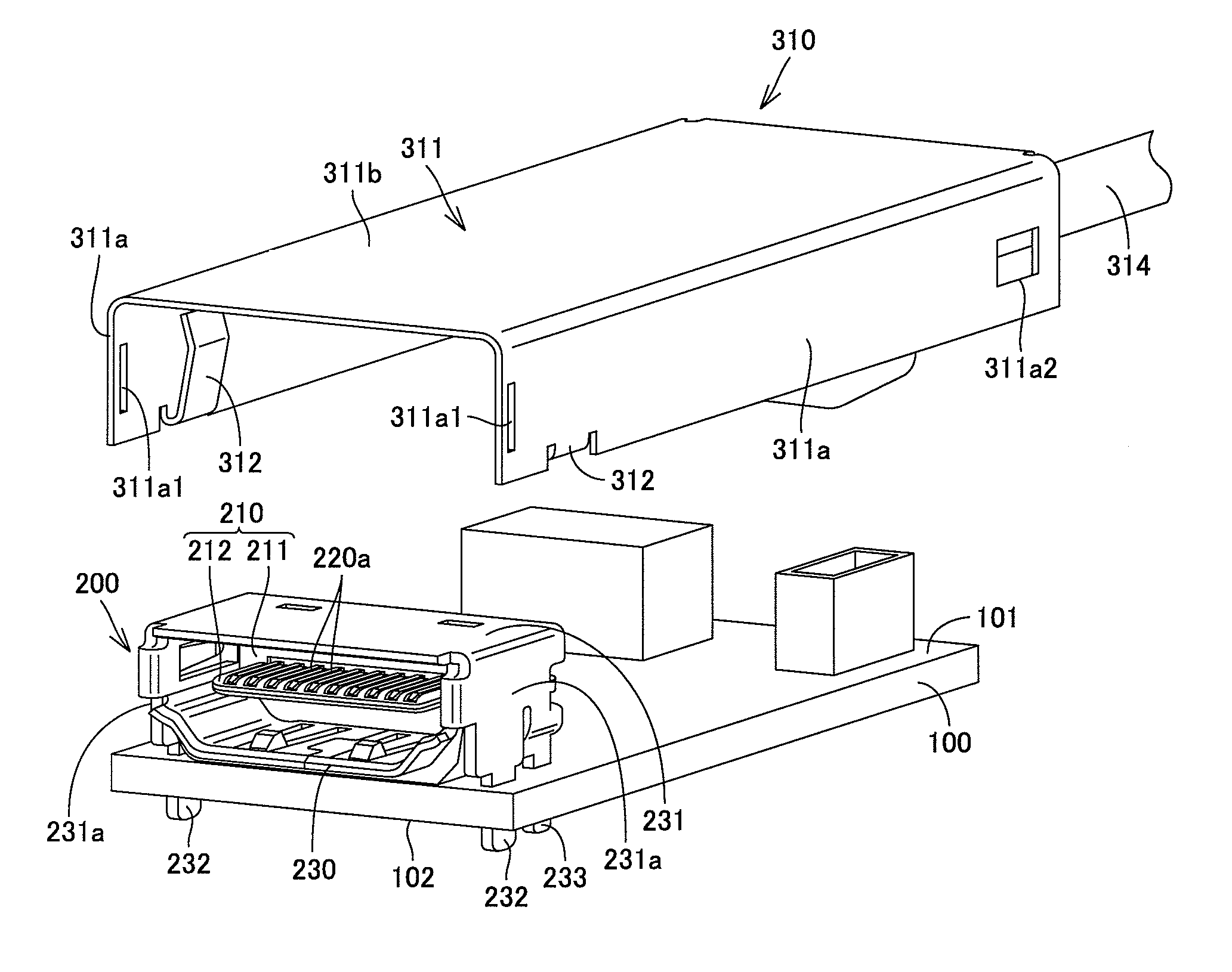

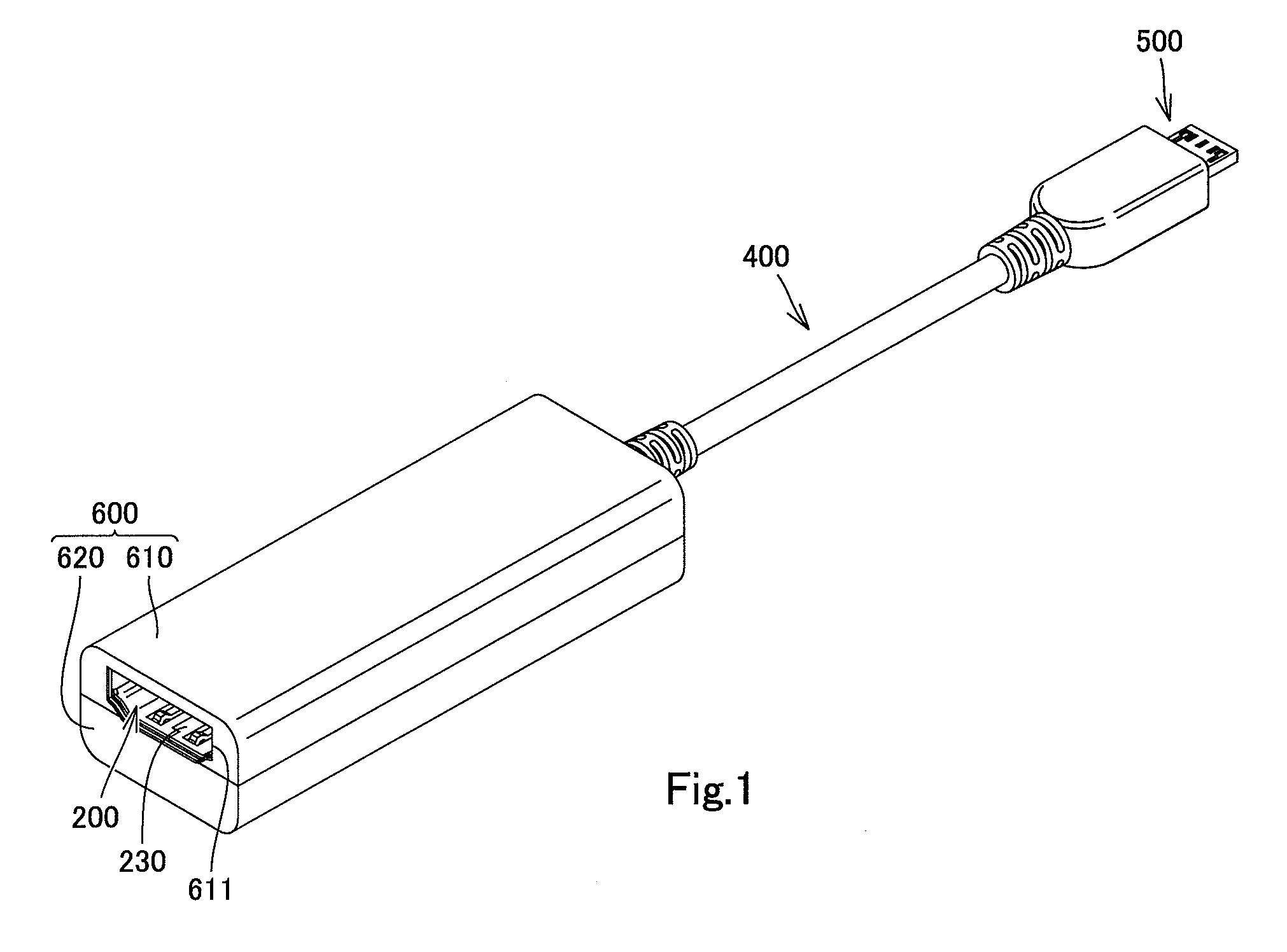

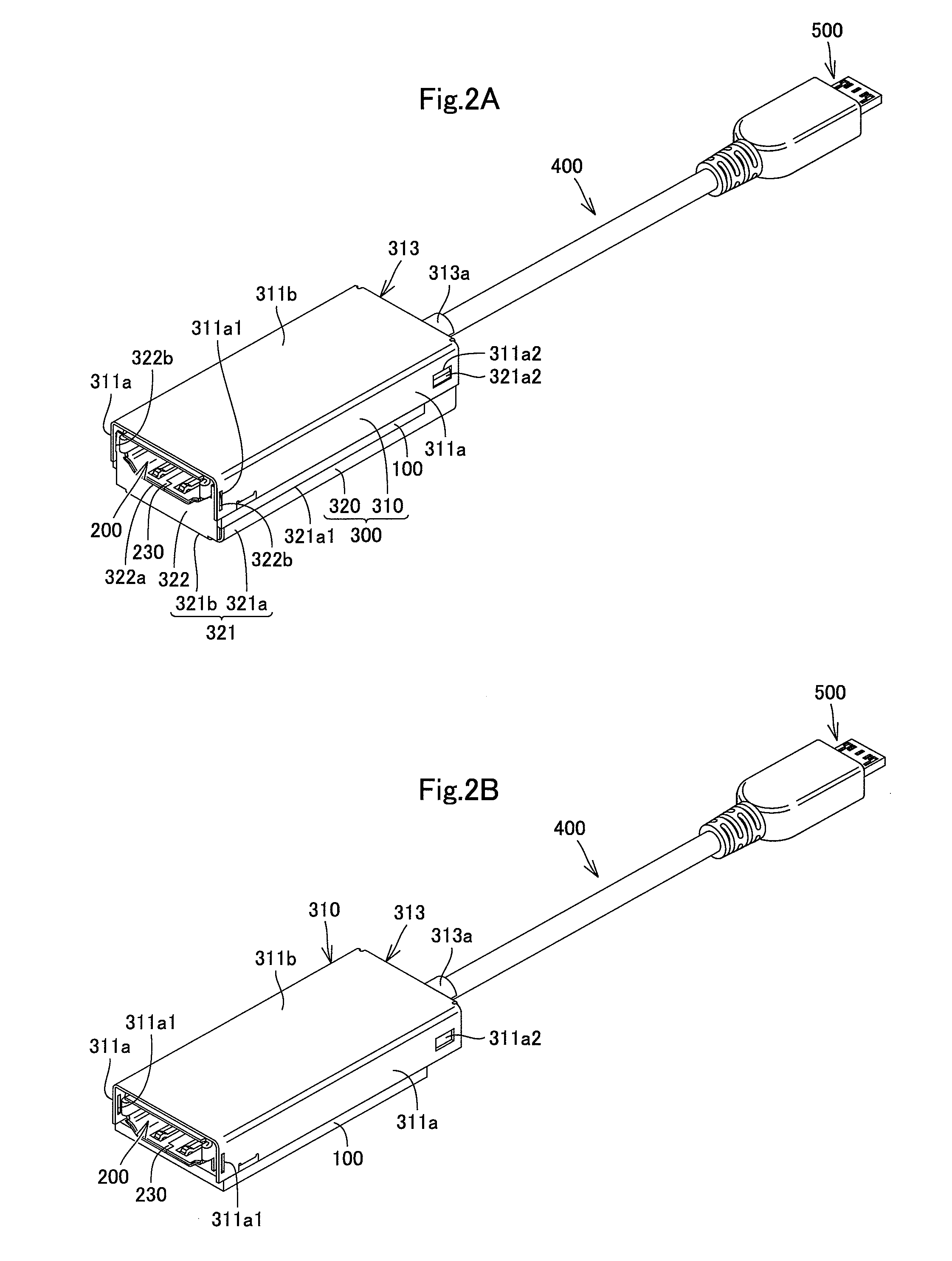

Cable connector and cable assembly, and method of manufacturing cable assembly

ActiveUS20140154927A1Easily connectableReduce number of partElectrically conductive connectionsElectric discharge tubesSignal linesGround contact

A cable connector and a cable assembly in which electrical characteristics are stabilized by suppressing elastic deformation of a cable for differential signal transmission, and besides, which are easily connectable by reducing the number of parts, and a method of manufacturing the cable assembly are provided. Respective ground contacts and respective signal line contacts positioned between the respective ground contacts through a space are provided in a connector main body. Front-side arm portions and rear-side arm portions mutually extending toward the respective signal line contacts are integrally provided with end portions of the respective ground contacts protruded from a side wall portion of the connector main body. And, under a state that respective signal line conductors are arranged in the respective signal line contacts, an outer conductor is held by the front-side arm portions and the rear-side arm portions.

Owner:HITACHI METALS LTD

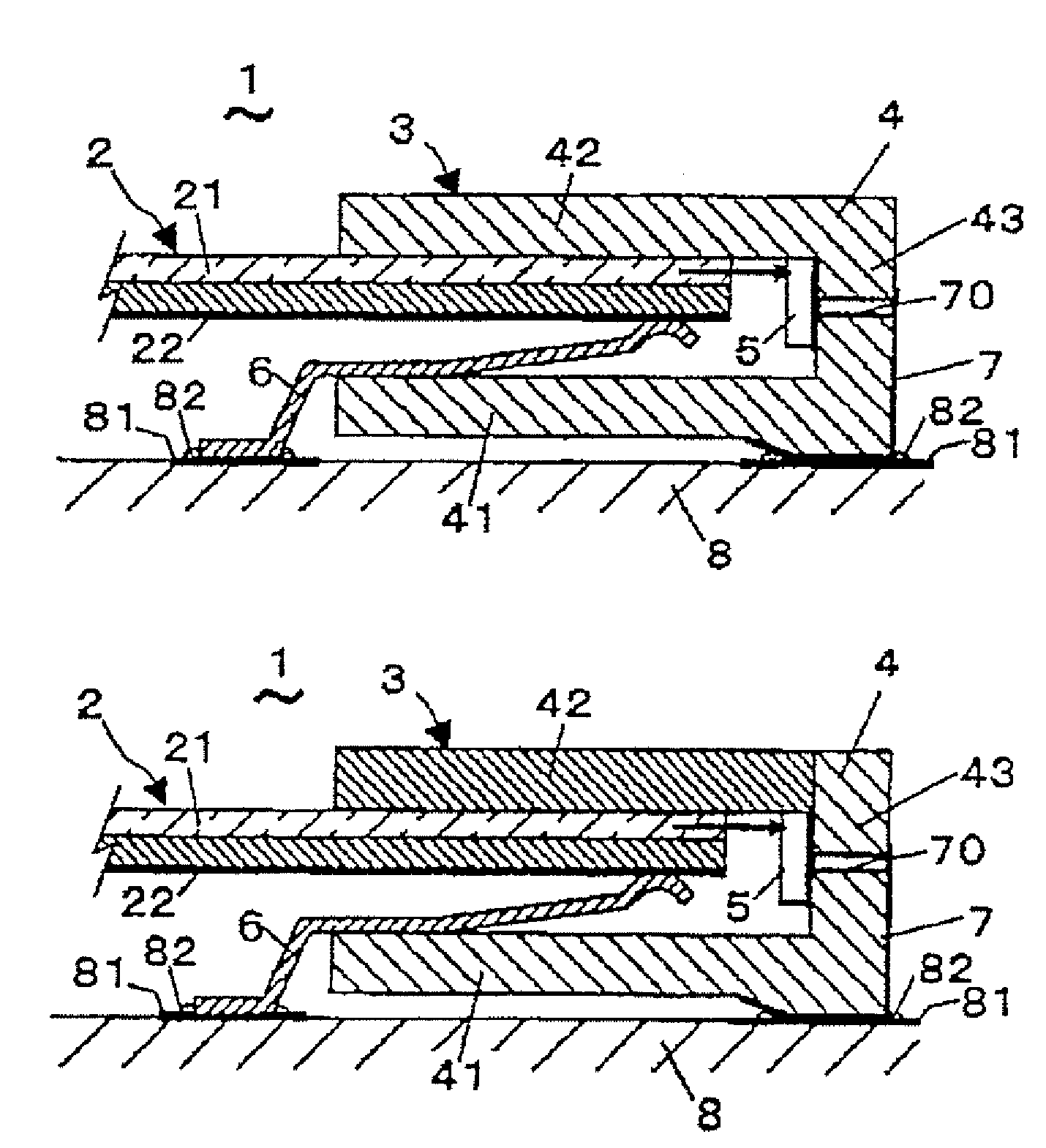

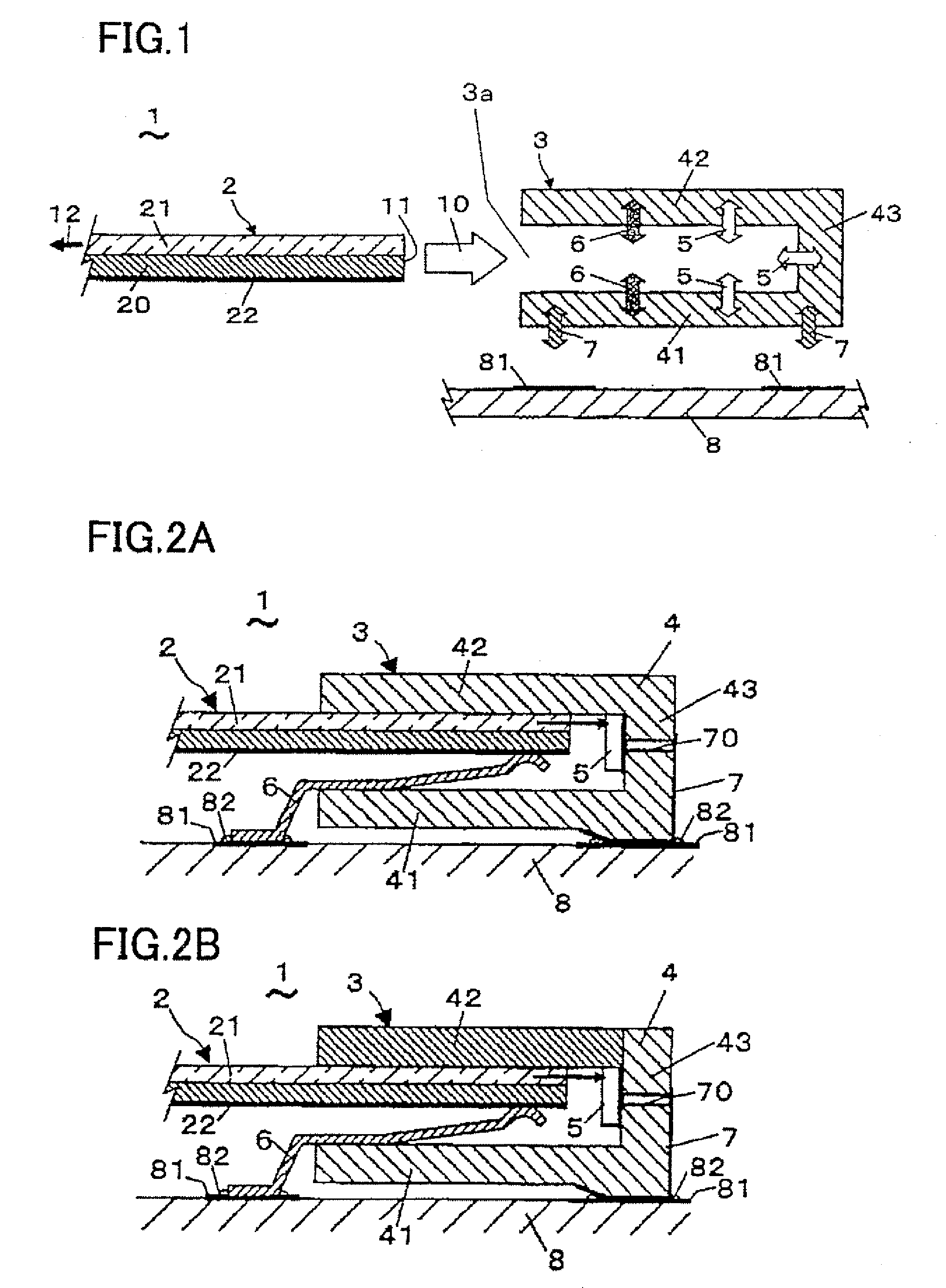

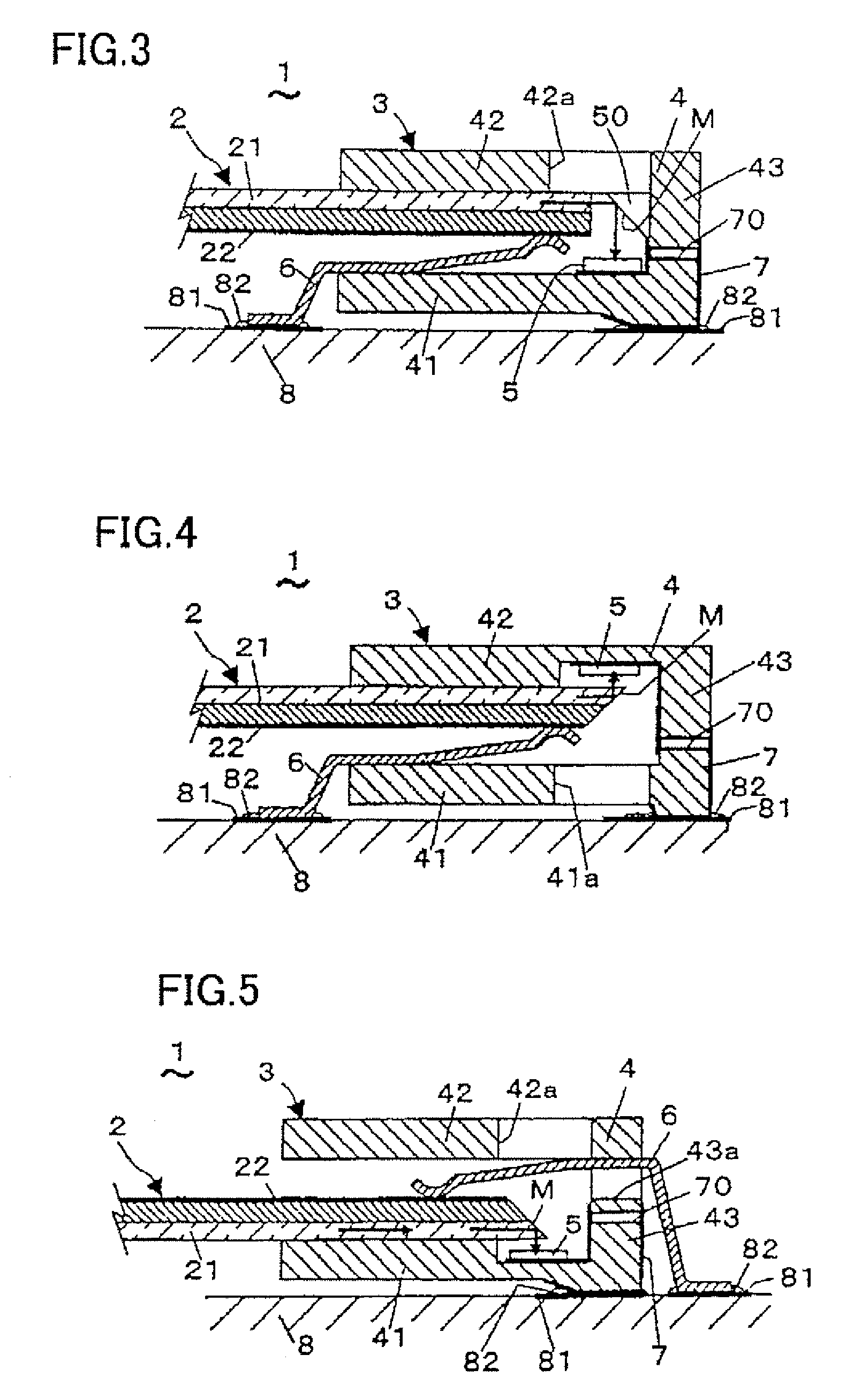

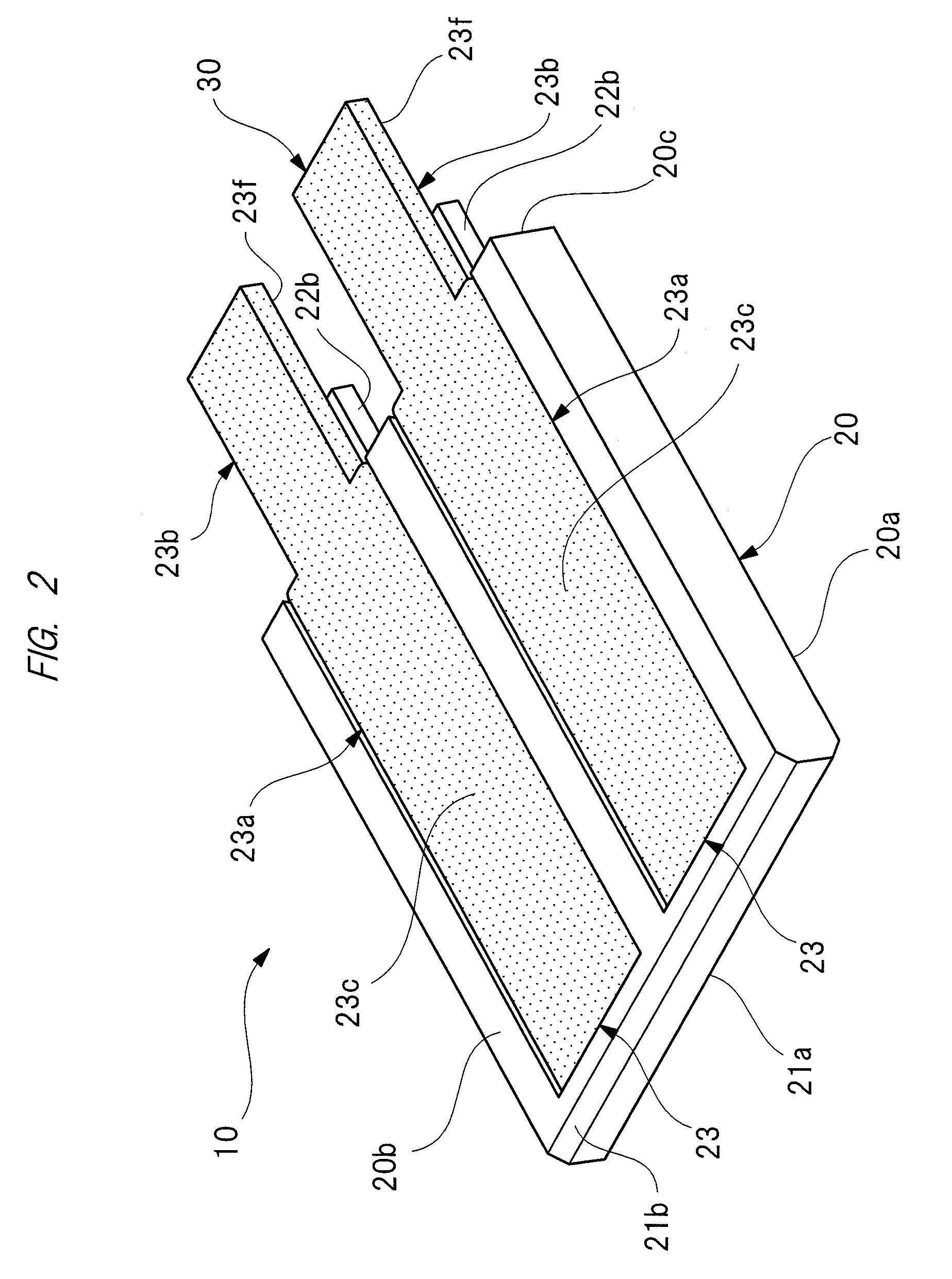

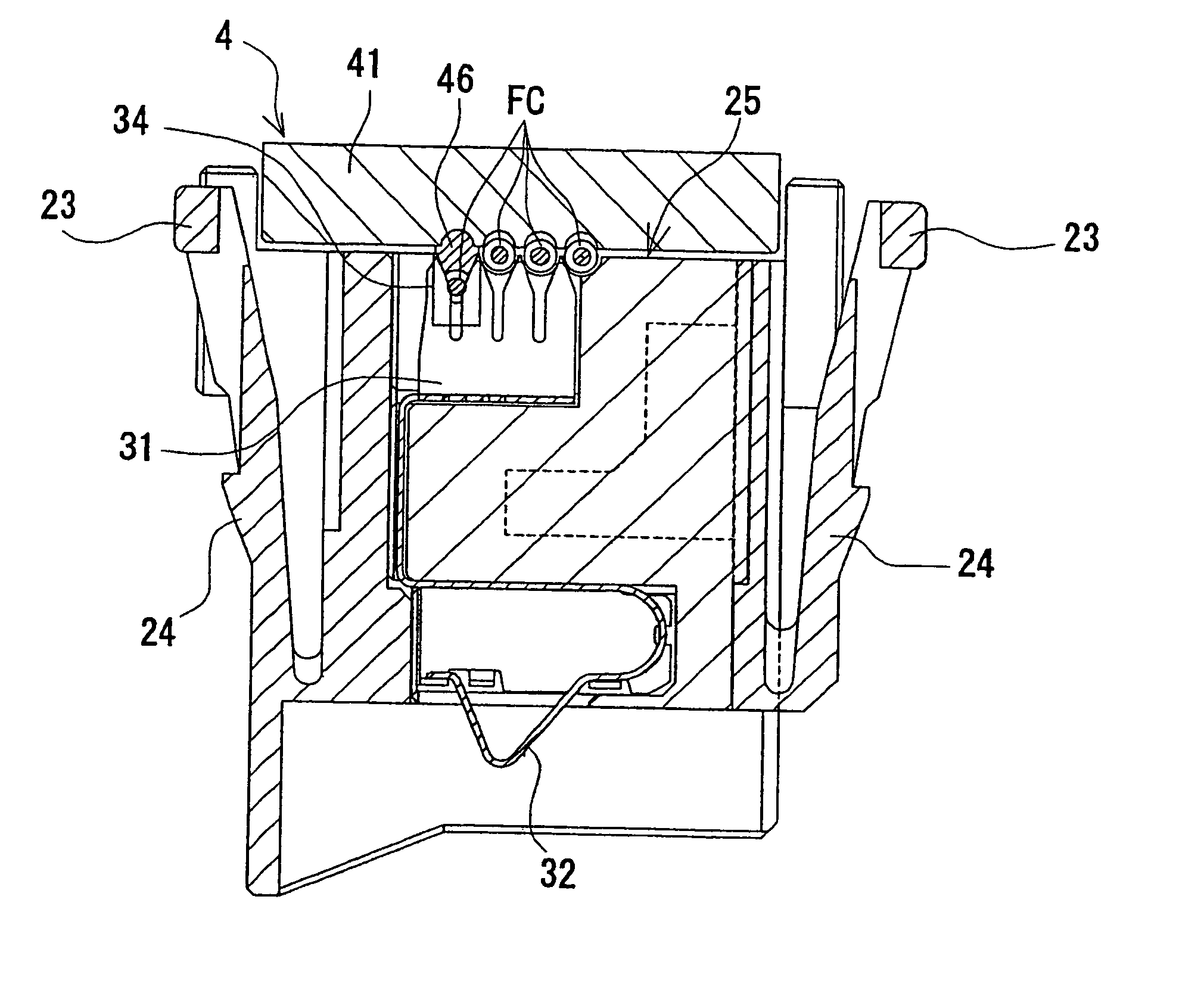

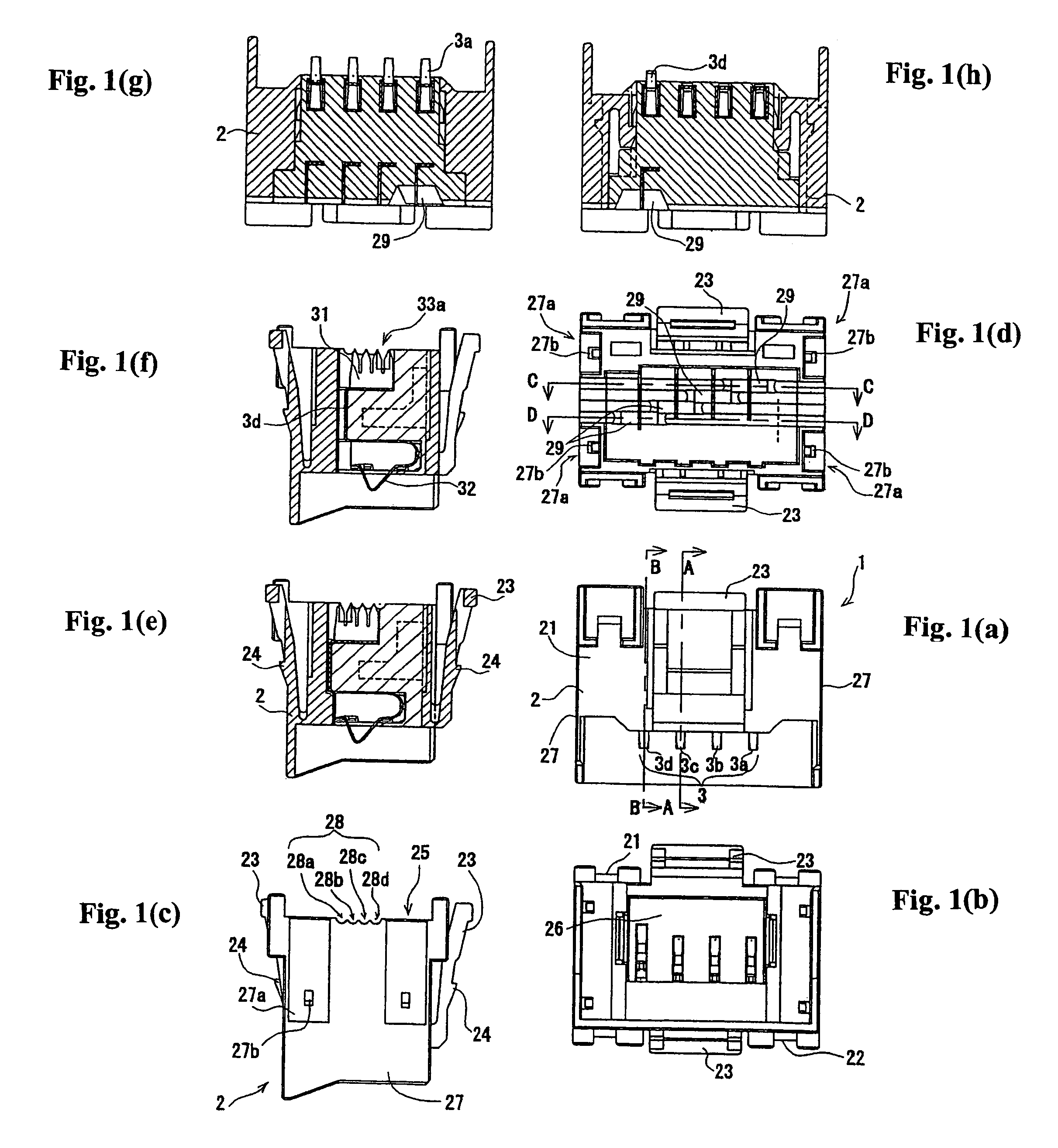

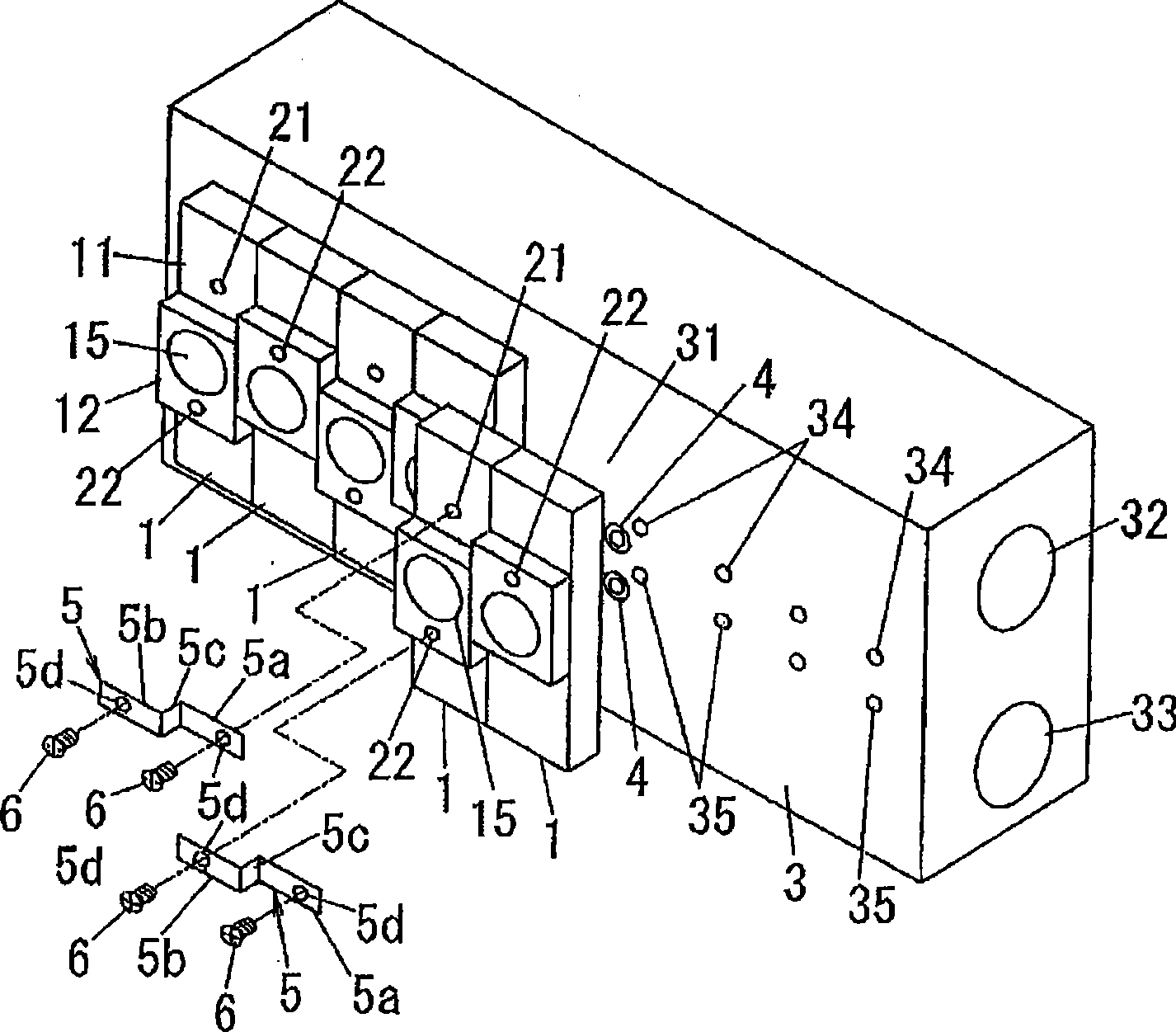

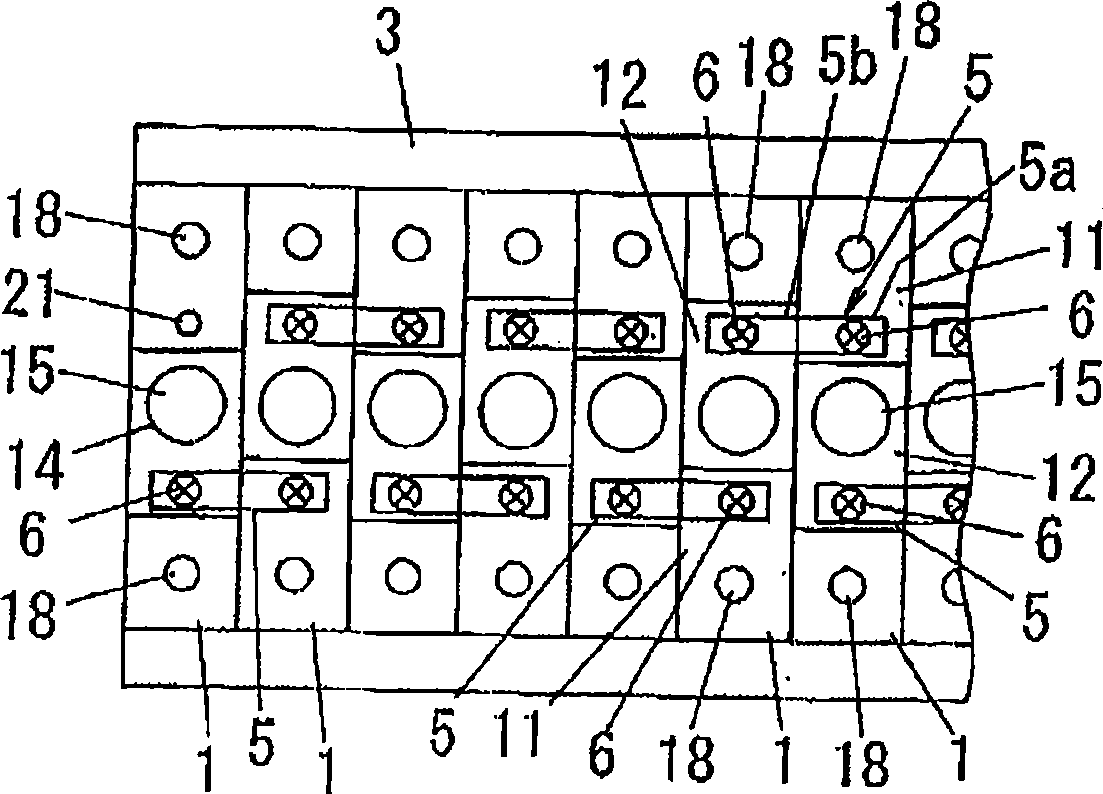

Optical and electrical compound connector

InactiveUS7458732B2Easy connection workSimplify connection workElectrically conductive connectionsCouplings bases/casesElectrical conductorLight guide

An optical and electrical compound connector, which enables to transmit and to receive light signals and electric signals of a plurality of systems and to transmit and to receive these signals with respect to other electric wiring board, is achieved with downsizing and easing connection work thereof. The optical and electrical compound connector 1 is comprised of a sheet-shaped base board 2 and a socket 3 into which this base board 2 is inserted. The sheet-shaped base board 2 is a flexible base board capable of transmission and reception of the light and electric signals, in which a light guide 21 and conductor patterns 22 extended in an insertion direction 10, are formed. The socket 3 performs the transmission and reception of the light and electric signals with the sheet-shaped base board 2 and transmits and receives the signals with an electric wiring board 8. The socket 3 comprises a connector main body 4 to which the sheet-shaped base board 2 is connected, a light-sensitive element and / or a light emitting element 5 which performs the transmission and / or reception of the light signals with the light guide 21, and contacts 6 which performs the transmission and / or reception of the electric signals with the conductor patterns 22. The connector main body 4 has a first to third walls 41 to 43 enclosing the sheet-shaped base board 2 from both sides in a thickness direction and from a front end 11 side, and the light-sensitive element and / or the light emitting element 5 and the contacts 6 are disposed on any one of these walls.

Owner:MATSUSHITA ELECTRIC WORKS LTD

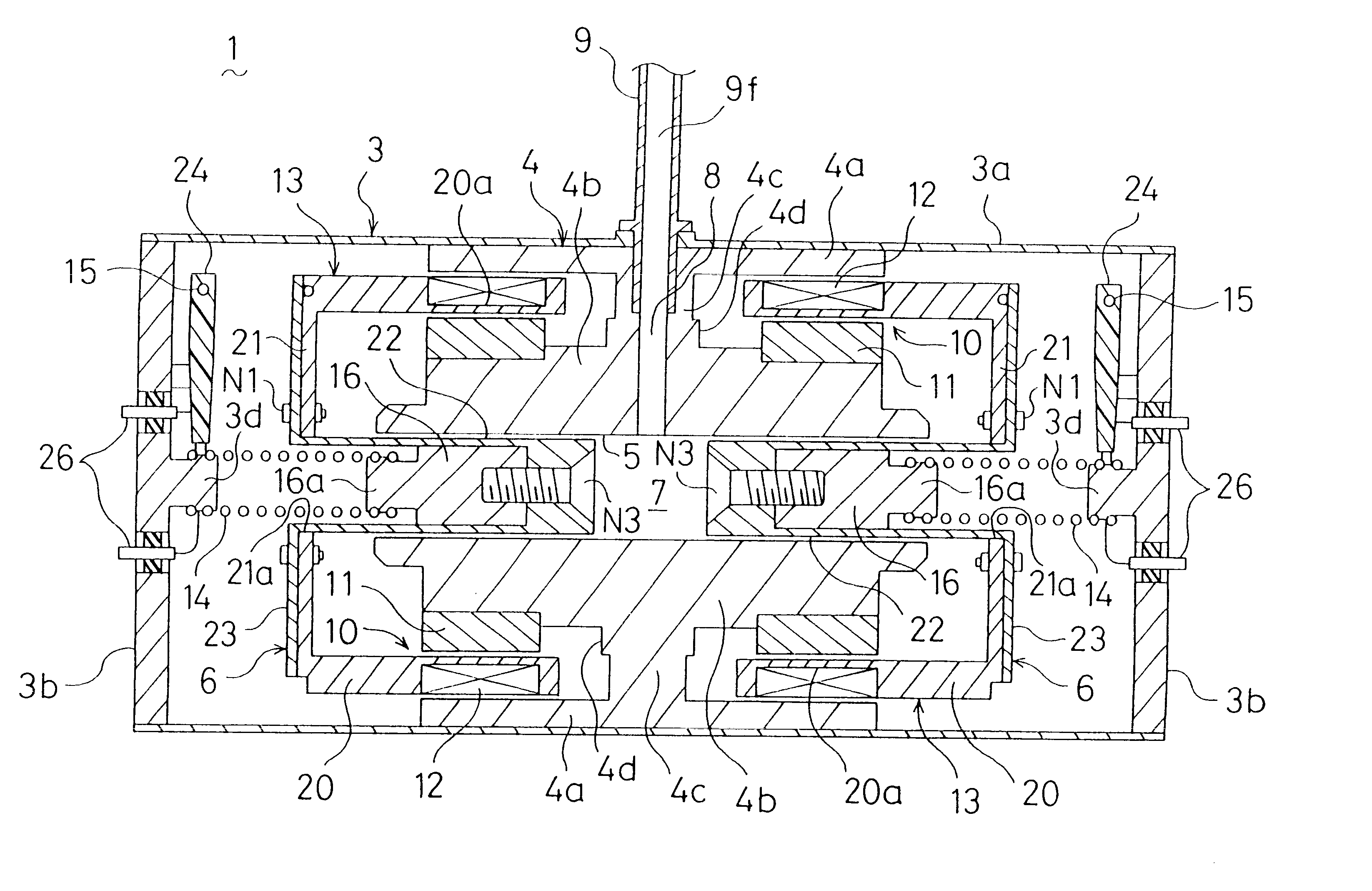

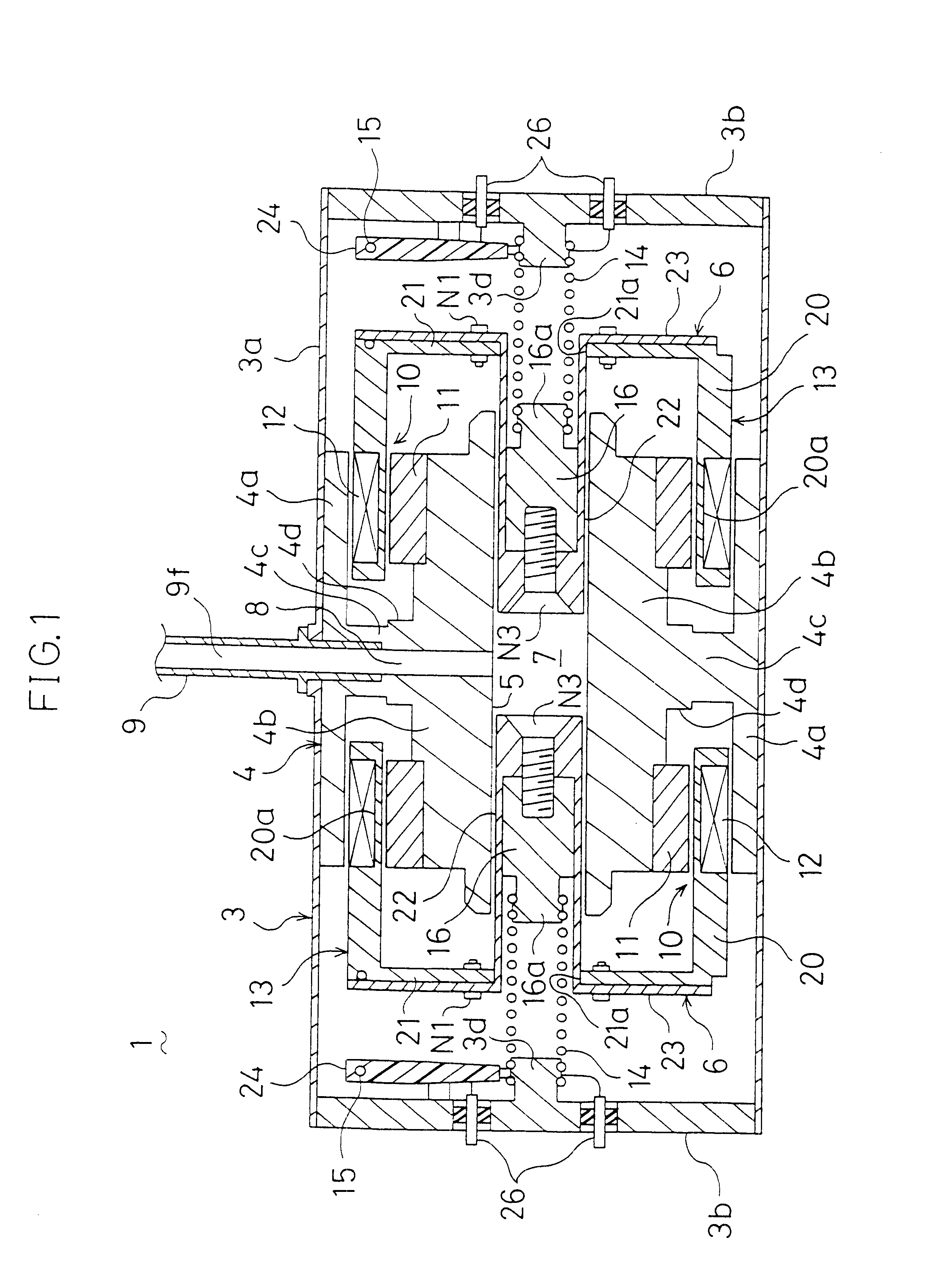

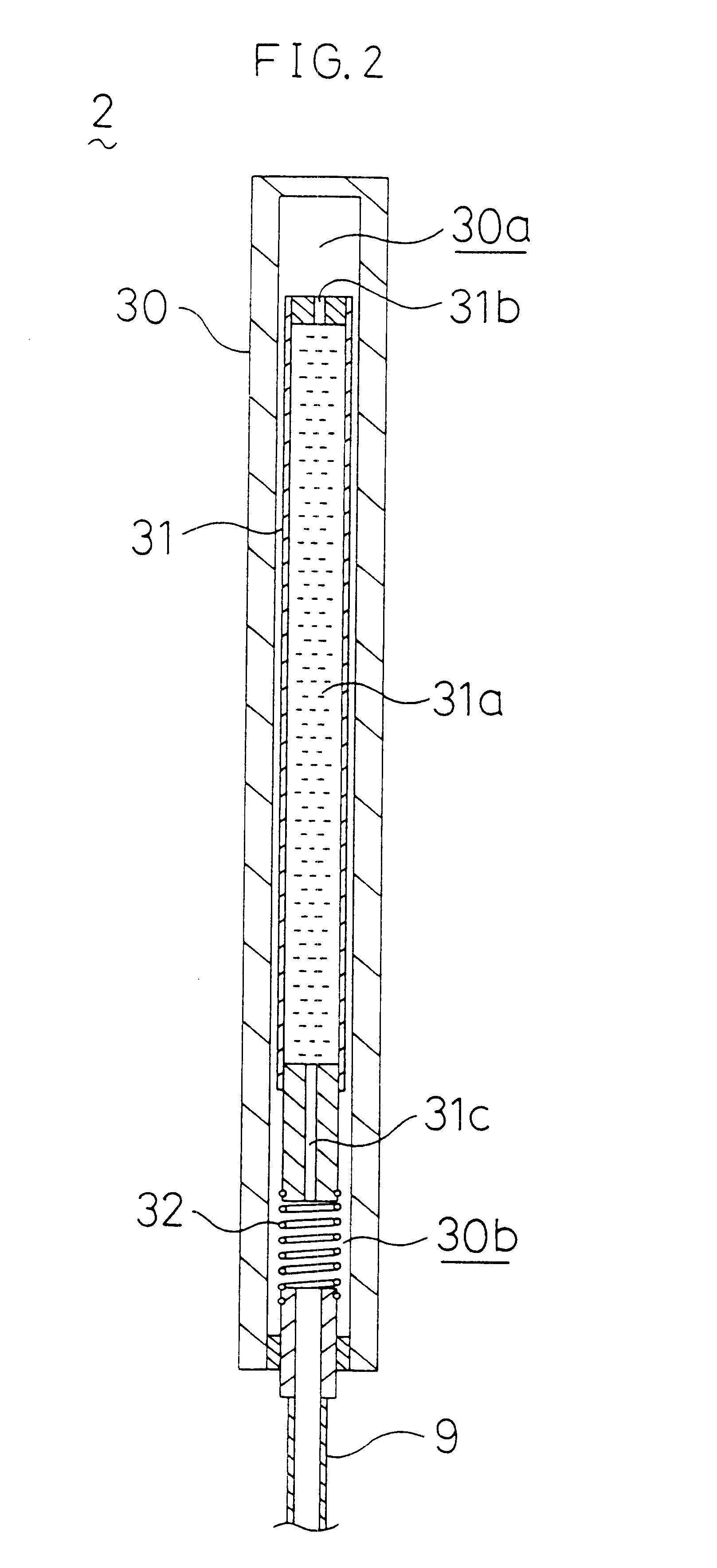

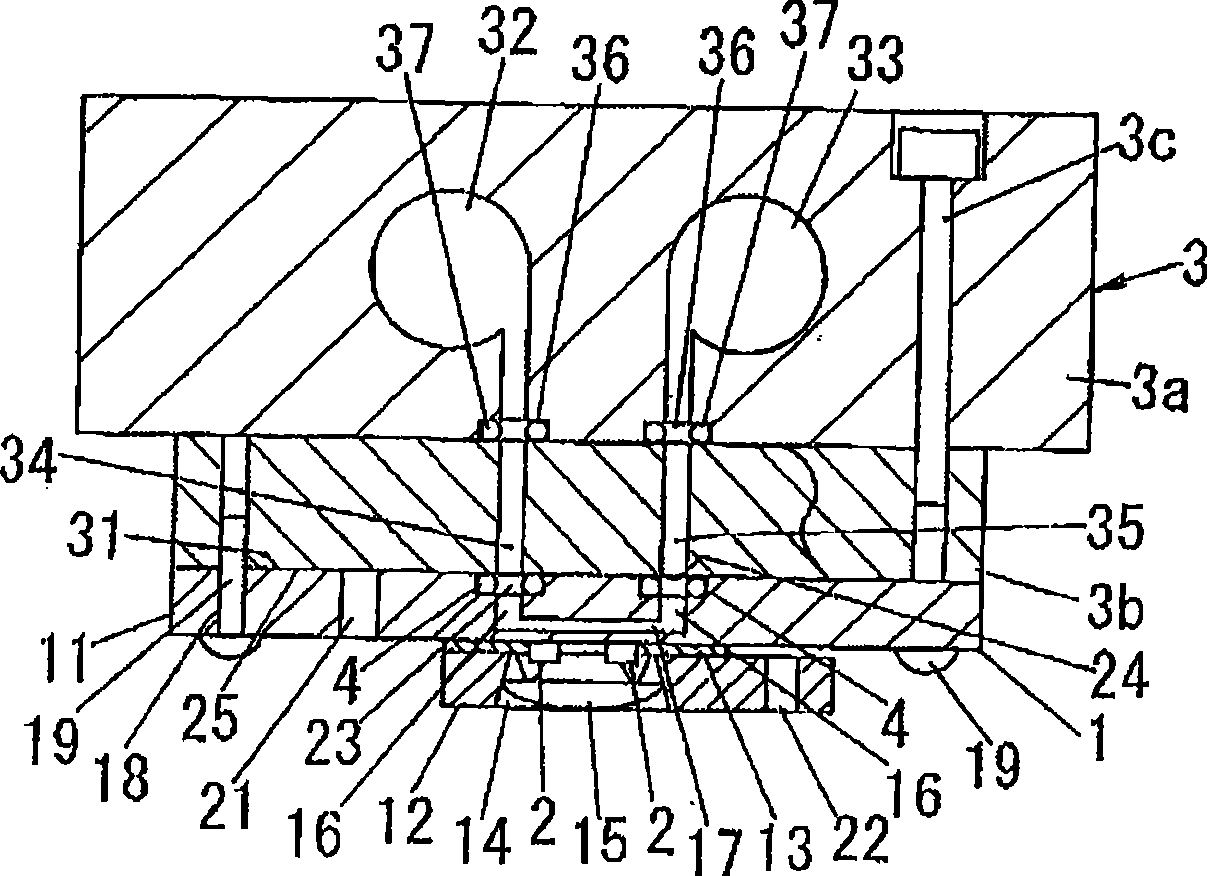

Stirling refrigerating machine

InactiveUS6460347B1Improve reliabilitySmall sealing areaPositive displacement pump componentsCompression machinesEngineeringFlange

Insertion holes (3c, 4e) into which a connection pipe (9) are inserted are formed from a casing (3) to a cylinder (4). The connection pipe (9) has a flange (9a) formed on the outer periphery at a set distance from the end of the connection pipe (9). With the flange (9a) in contact with the wall outer surface of the casing (3), the end part of the connection pipe (9) is inserted into the insertion holes (3c, 4e). Between the flange (9a) and the wall outer surface of the casing (3), an O-ring (01) is fit so as to surround an internal passage (9f) of the connection pipe (9). Another O-ring (02) is fit between the end part of the connection pipe (9) and the insertion hole (4e) of the cylinder (4).

Owner:SUMITOMO HEAVY IND LTD

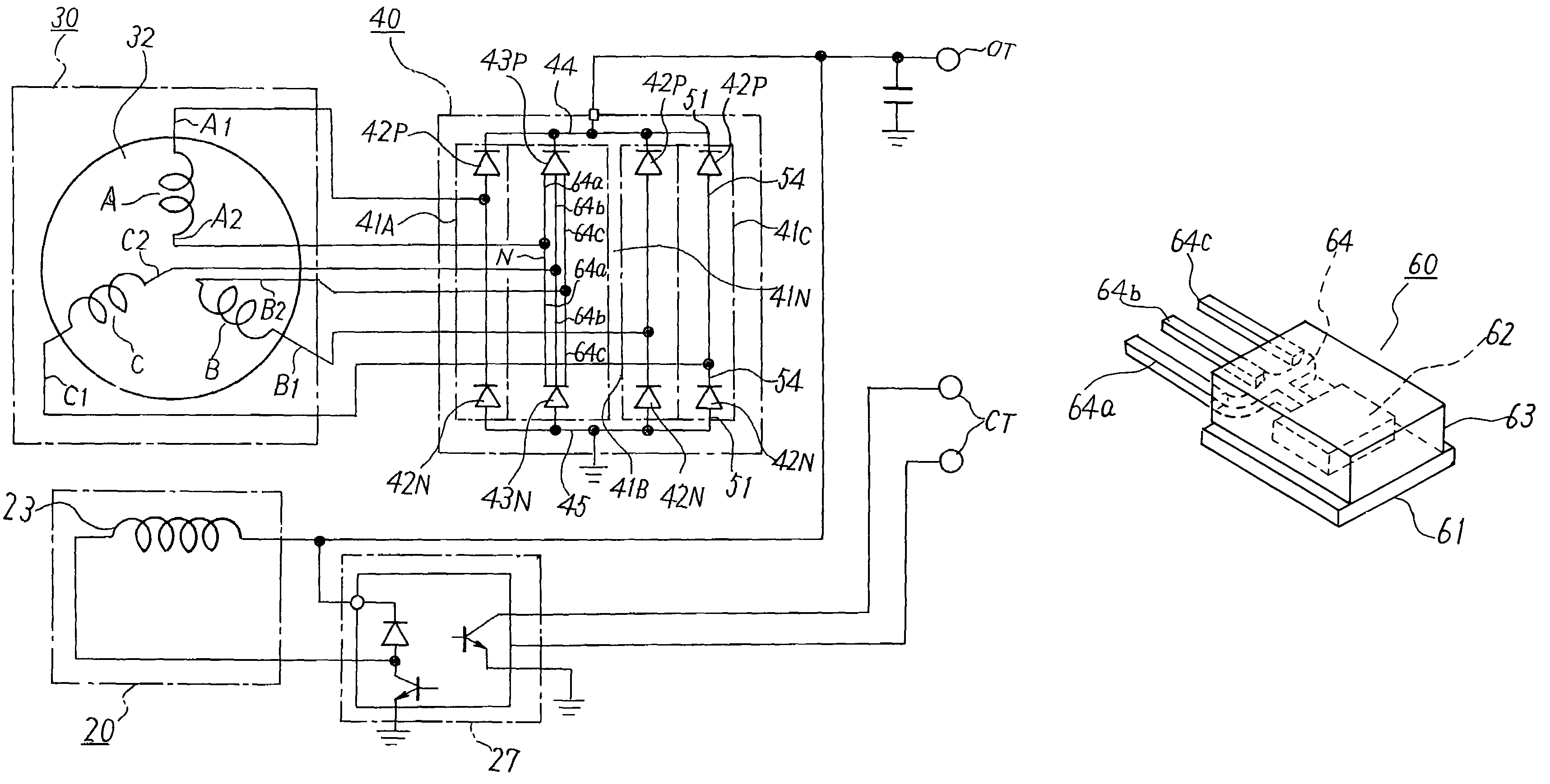

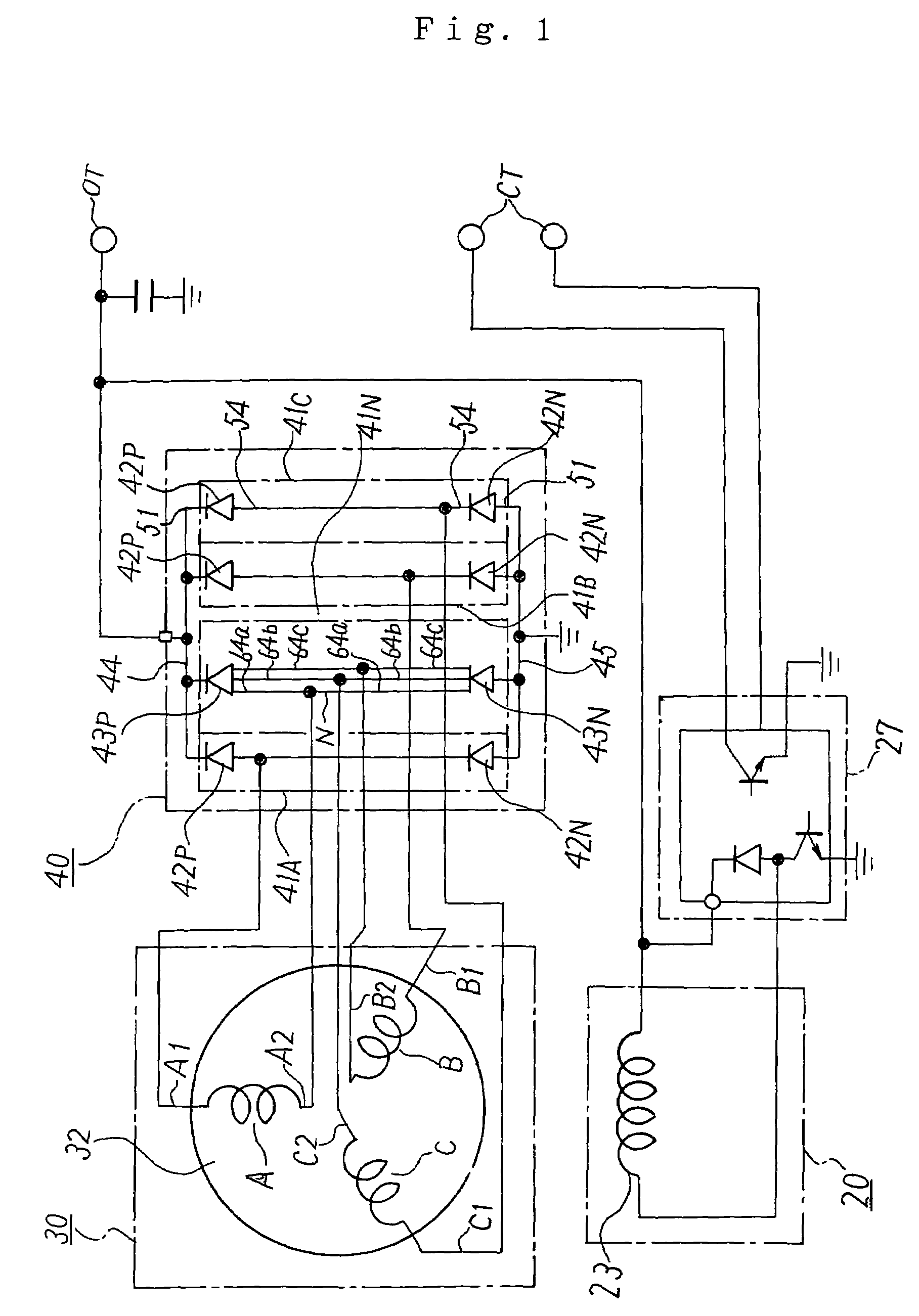

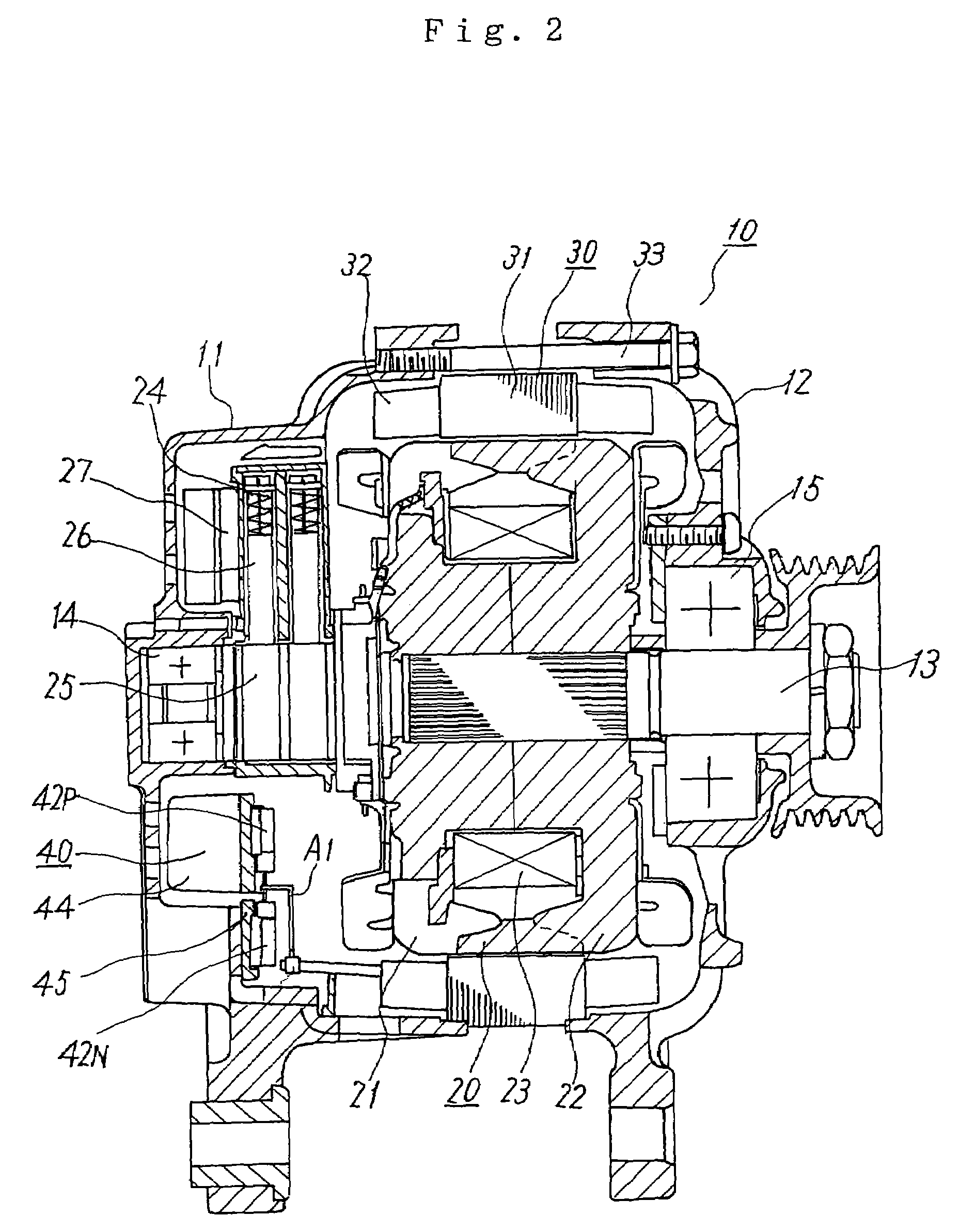

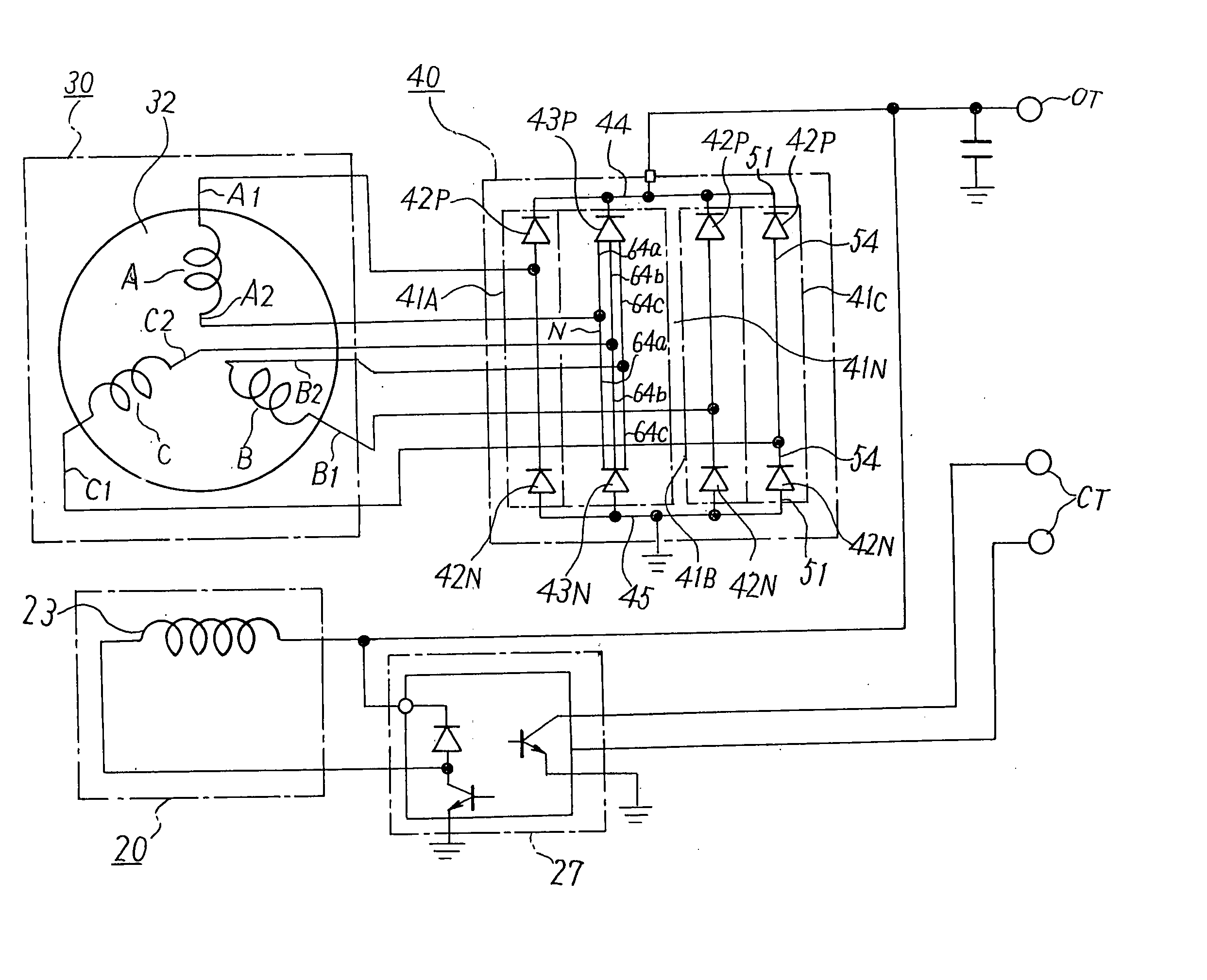

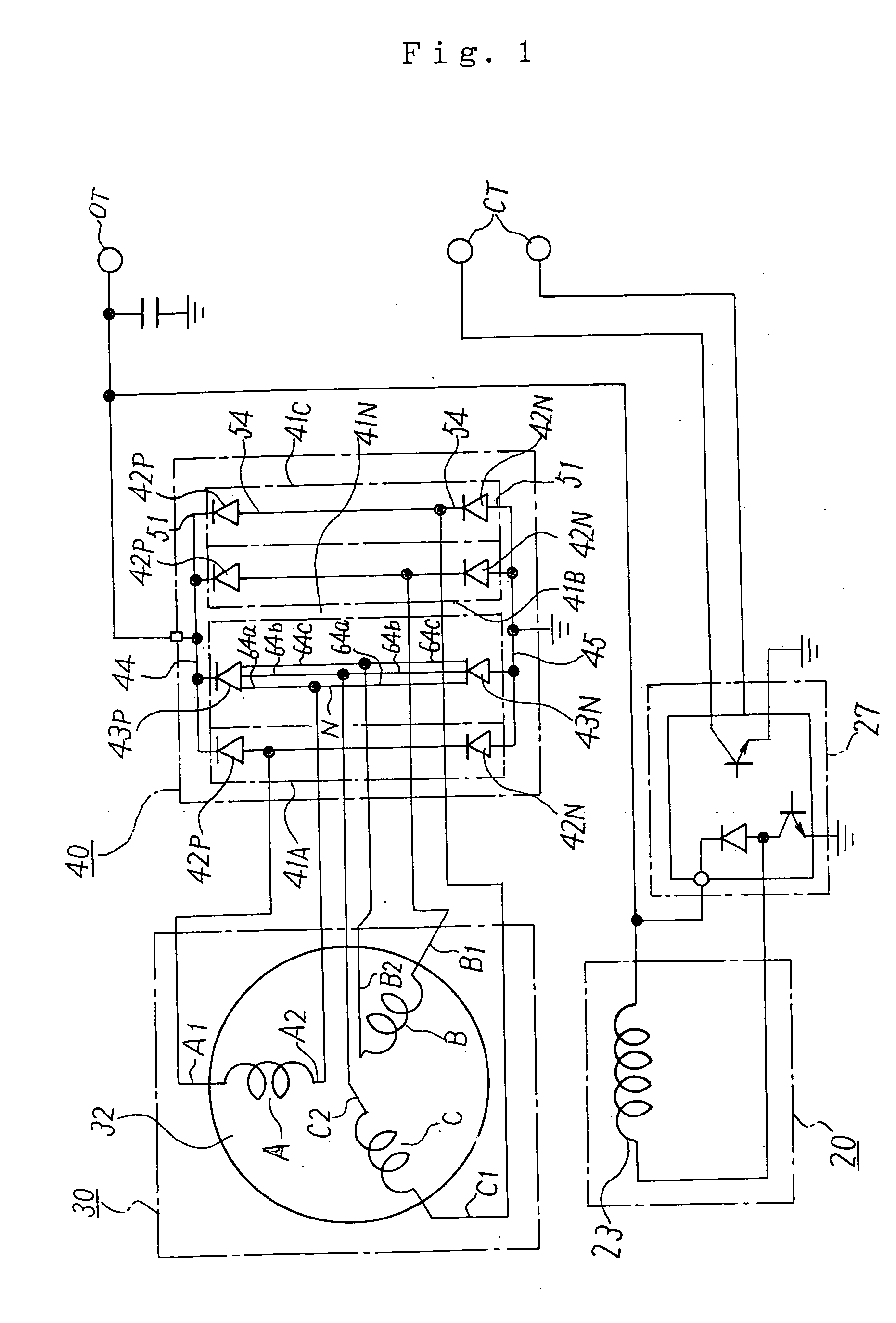

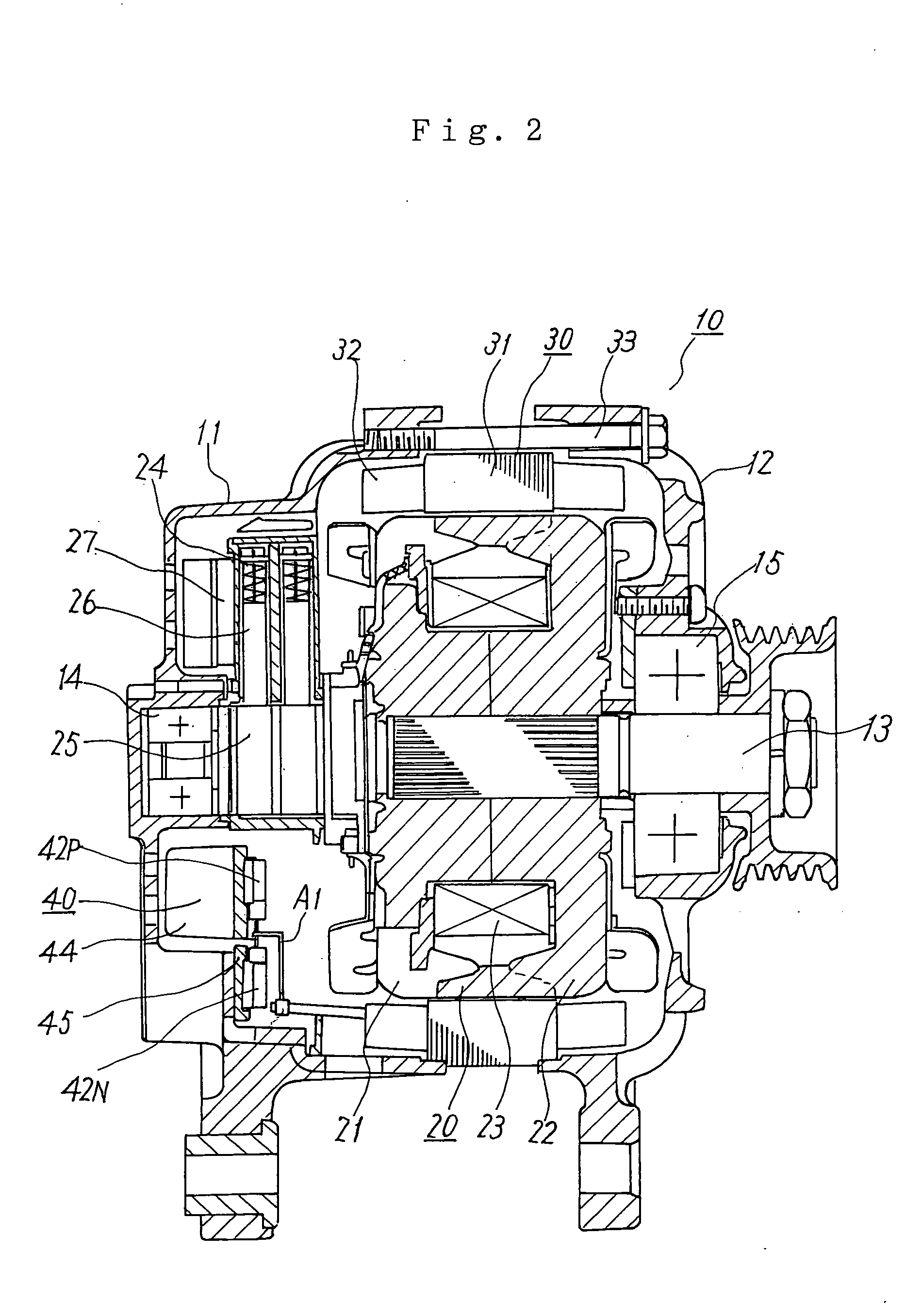

Three-phase ac generator for vehicle

InactiveUS7109687B2Simplify workSimplify connection workSynchronous generatorsMagnetic circuitElectricityThree-phase

A neutral point diode having three connecting terminals electrically commonly connected to each other is used in a type for connecting each generating coil of a three-phase alternating current electric generator for a vehicle in a Y-shape connection. The coil terminal of a neutral point side of each generating coil is connected to each of the three connecting terminals of this neutral point diode. A diode having two connecting terminals electrically commonly connected to each other is used in a type for connecting each generating coil in a Δ-shape connection. The coil terminals of two adjacent generating coils are connected to the respective two connecting terminals of this diode. In both the types, one coil terminal is connected to one connecting terminal and a connecting work is simplified.

Owner:MITSUBISHI ELECTRIC CORP

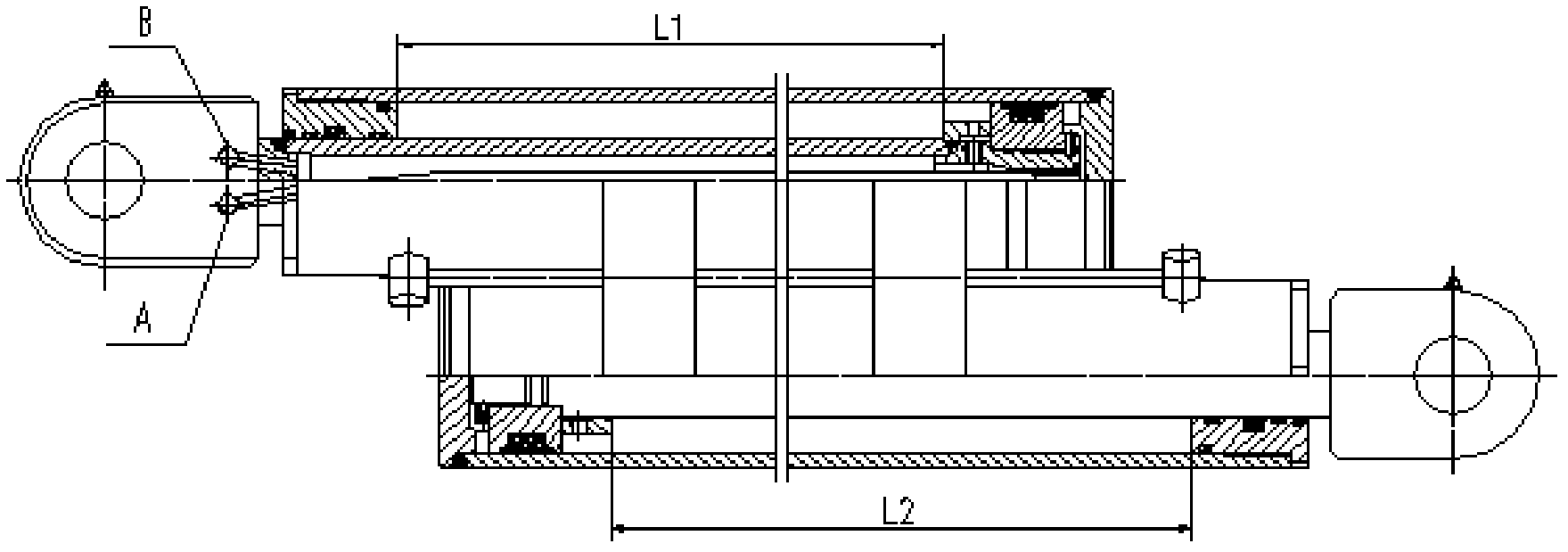

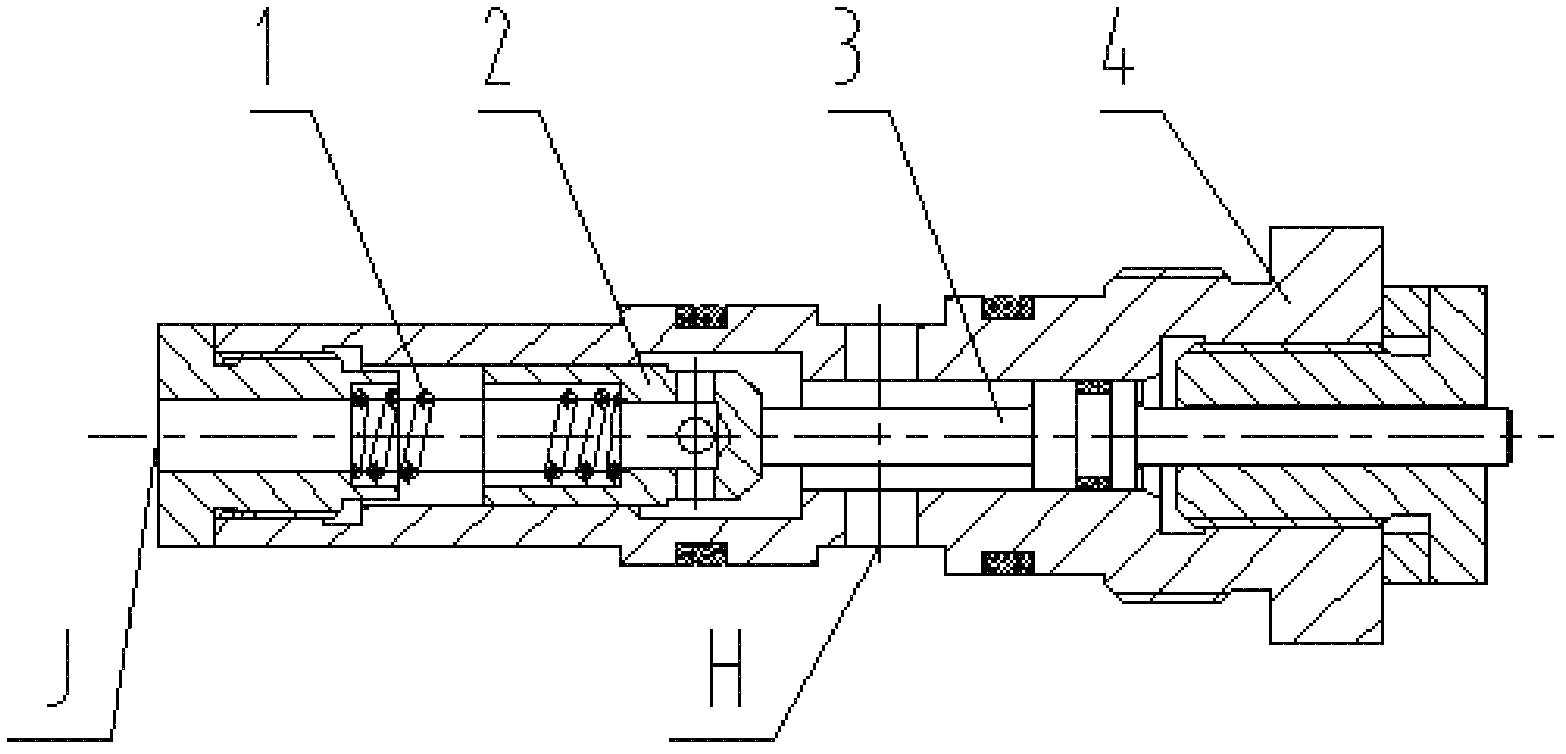

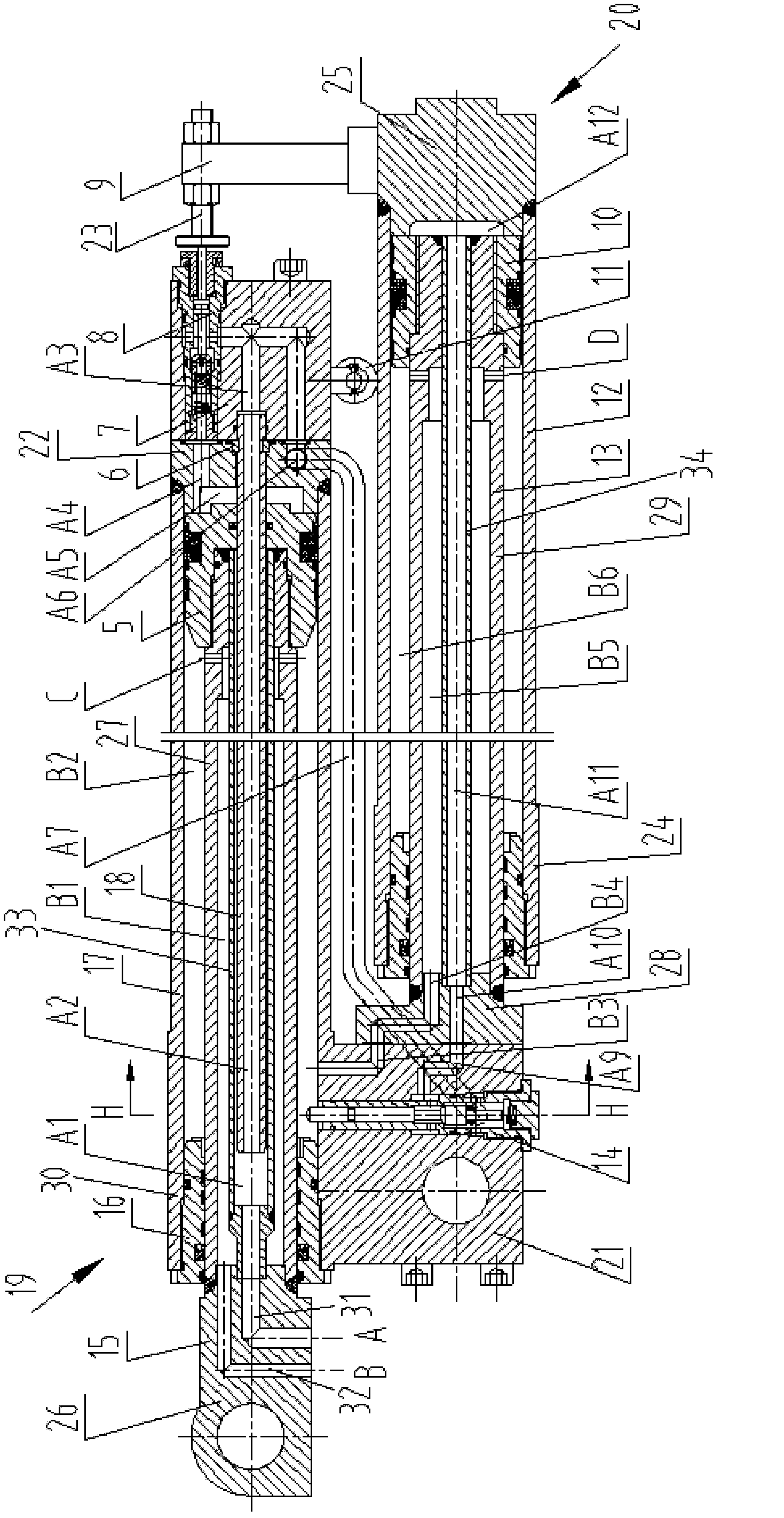

Travel valve, sequential action type combination hydraulic cylinder and hydraulic equipment

ActiveCN102518617AReasonable structureHigh working reliabilityServomotor componentsHydraulic cylinderHydraulic equipment

The invention discloses a travel valve, which comprises a valve body (4), a valve spool (2), a spring (1) and an ejector rod (3), wherein a forward oil port (H) and a reverse oil port (J) are formed on the valve body (4), the valve spool and the spring are arranged in a valve cavity of the valve body to form a one-way valve, the ejector rod can slide in the valve body so as to eject the valve spool and enable the forward oil port and the reverse oil port to be communicated to each other. The invention discloses a sequential action type combination hydraulic cylinder, which comprises two travel valves. The ejector rods of the two travel valves can be driven mechanically so that the sequential action type combination hydraulic cylinder can act sequentially. Besides, the invention further discloses hydraulic equipment, which comprises the sequential action type combination hydraulic cylinder. The sequential action type combination hydraulic cylinder is controlled by the two travel valves, so that each hydraulic cylinder unit of the combination hydraulic cylinder can act sequentially accurately and the requirements of complicated mechanisms can be met. The sequential action type combination hydraulic cylinder is reasonable in structure, reliable in working and convenient in mounting and demounting and has excellent work reliability.

Owner:HUNAN TELI HYDRAULIC

Cable connector and cable assembly, and method of manufacturing cable assembly

ActiveUS8900007B2Suppression of deformationReduce the number of partsElectrically conductive connectionsCoupling device engaging/disengagingGround contactElectrical conductor

A cable connector and a cable assembly in which electrical characteristics are stabilized by suppressing elastic deformation of a cable for differential signal transmission, and besides, which are easily connectable by reducing the number of parts, and a method of manufacturing the cable assembly are provided. Respective ground contacts and respective signal line contacts positioned between the respective ground contacts through a space are provided in a connector main body. Front-side arm portions and rear-side arm portions mutually extending toward the respective signal line contacts are integrally provided with end portions of the respective ground contacts protruded from a side wall portion of the connector main body. And, under a state that respective signal line conductors are arranged in the respective signal line contacts, an outer conductor is held by the front-side arm portions and the rear-side arm portions.

Owner:HITACHI METALS LTD

Cable connector and cable assembly, and method of manufacturing cable assembly

InactiveUS20140154928A1Suppression of deformationReduce the number of partsElectric discharge tubesCoupling device engaging/disengagingGround contactElectrical conductor

Provided is a cable connector, a cable assembly, and a method of manufacturing the cable assembly, in which electric characteristics are stabilized by suppressing elastic deformation of a cable for differential signal transmission, and besides, which is easily connectable by reducing the number of parts. In a ground contact, an outer-conductor adhering portion which is protruded from a side wall portion of a connector main body and which is adhered with an outer conductor by a conductive adhesive is provided. In this manner, elastic deformation of a cable for differential signal transmission is suppressed, so that electric characteristics can be stabilized. Also, connecting work between the outer conductor and the ground contact can be simplified as reducing the number of parts. Further, the cable for differential signal transmission is not exposed to a high temperature of soldering or others, and therefore, thermal deformation thereof does not occur, either.

Owner:HITACHI METALS LTD

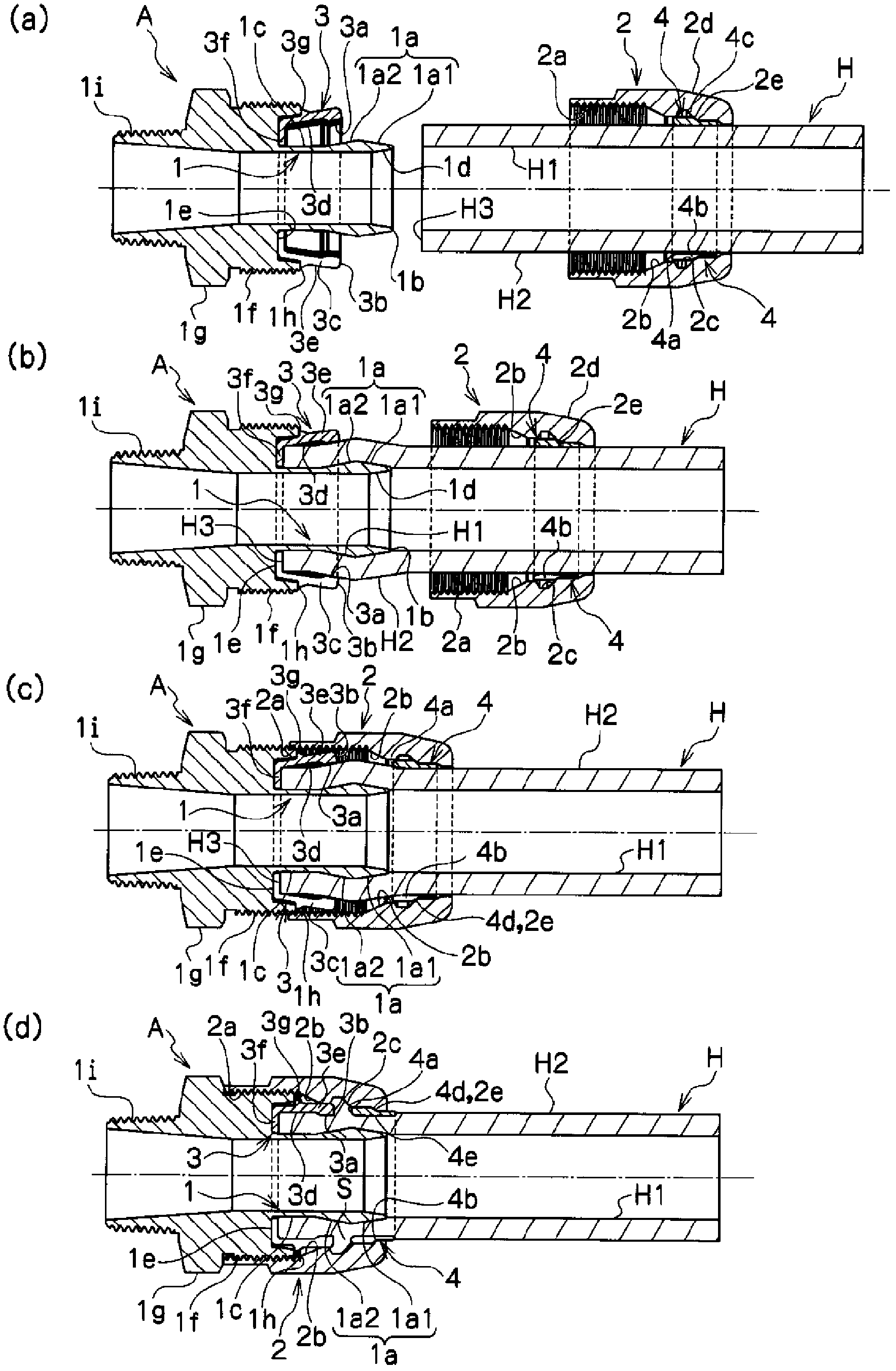

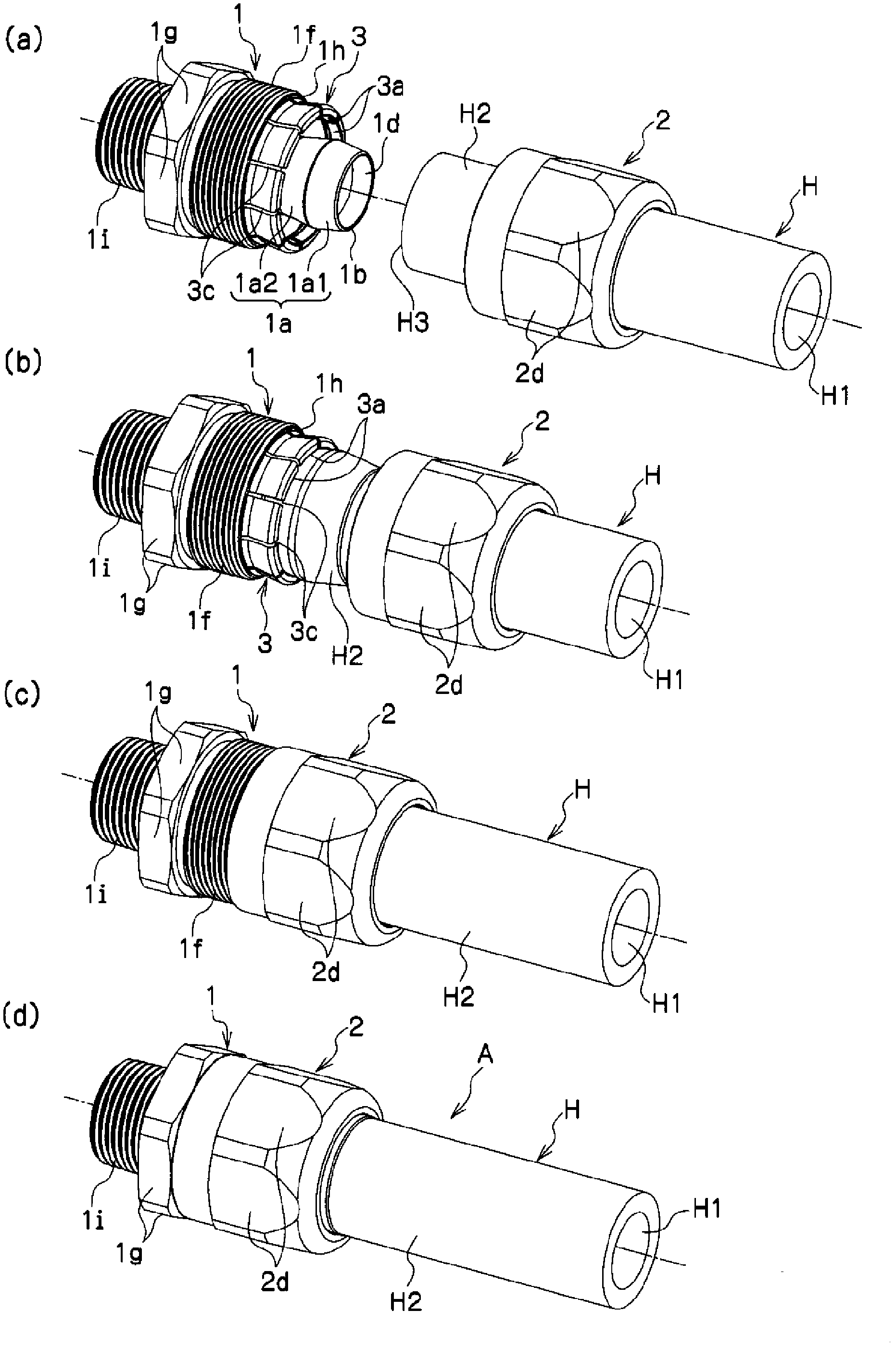

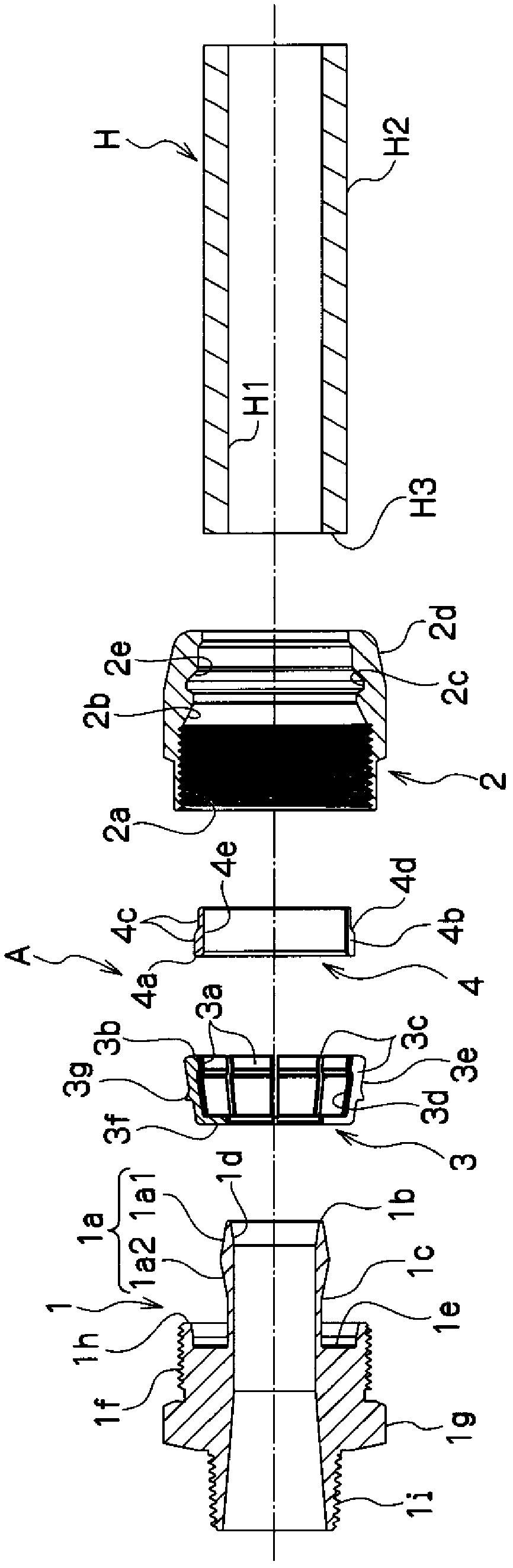

Hose joint

InactiveCN102575801AImprove sealingHigh strengthHose connectionsUltimate tensile strengthBiomedical engineering

Provided is a hose joint by which an insertion position of a front end of a hose is stabilized to thereby enhance the sealing efficiency and a disconnecting strength between the outer surface of a nipple and the hose. When the hose (H) is inserted, the inner diameter of an inlet portion (3a) of an expandable and contractible sleeve (3) opposed to a decreasing diameter portion (1a2) is set to be larger than the outer diameter of the hose (H) which is inserted along the decreasing diameter portion (1a2) of a bulged portion (1a), whereby the front end of the hose (H) is smoothly introduced between the expandable and contractible sleeve (3) and the decreasing diameter portion (1a2) without causing the front end of the hose to butt against the inlet portion (3a) of the expandable and contractible sleeve (3) and can be inserted to a predetermined position. Thereafter, when pressed by a pressing surface portion (2b) in accordance with the axial movement of a fastening tool (2), the inner diameter of the inlet portion (3a) of the expandable and contractible sleeve (3) is set to be smaller than the outer diameter of the hose (H) inserted along the decreasing diameter portion (1a2) of the bulged portion (1a), whereby the hose (H) is held between the inlet portion (3a) of the expandable and contractible sleeve (3) and the decreasing diameter portion (1a2) of the nipple (1).

Owner:TOYOX CO LTD

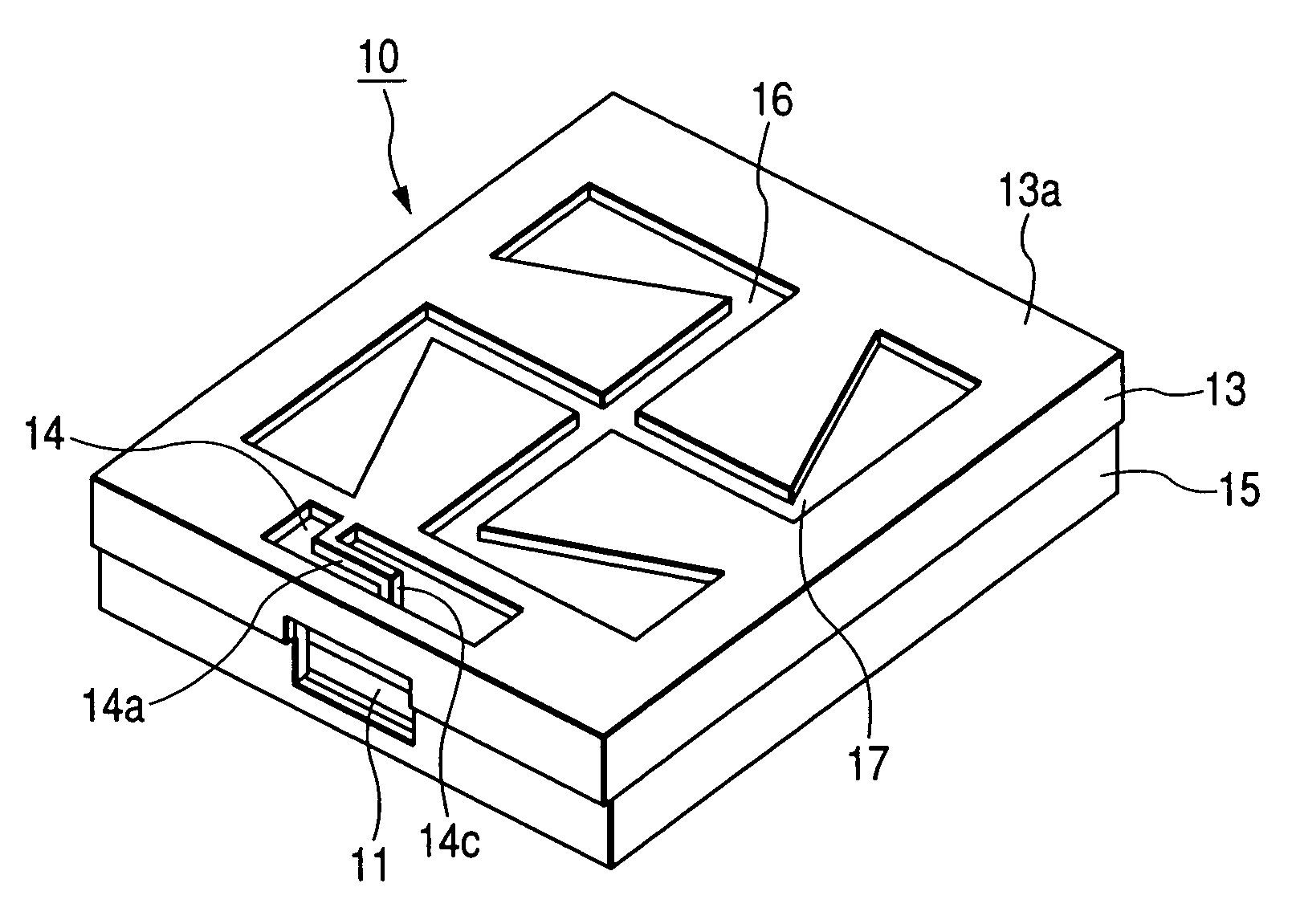

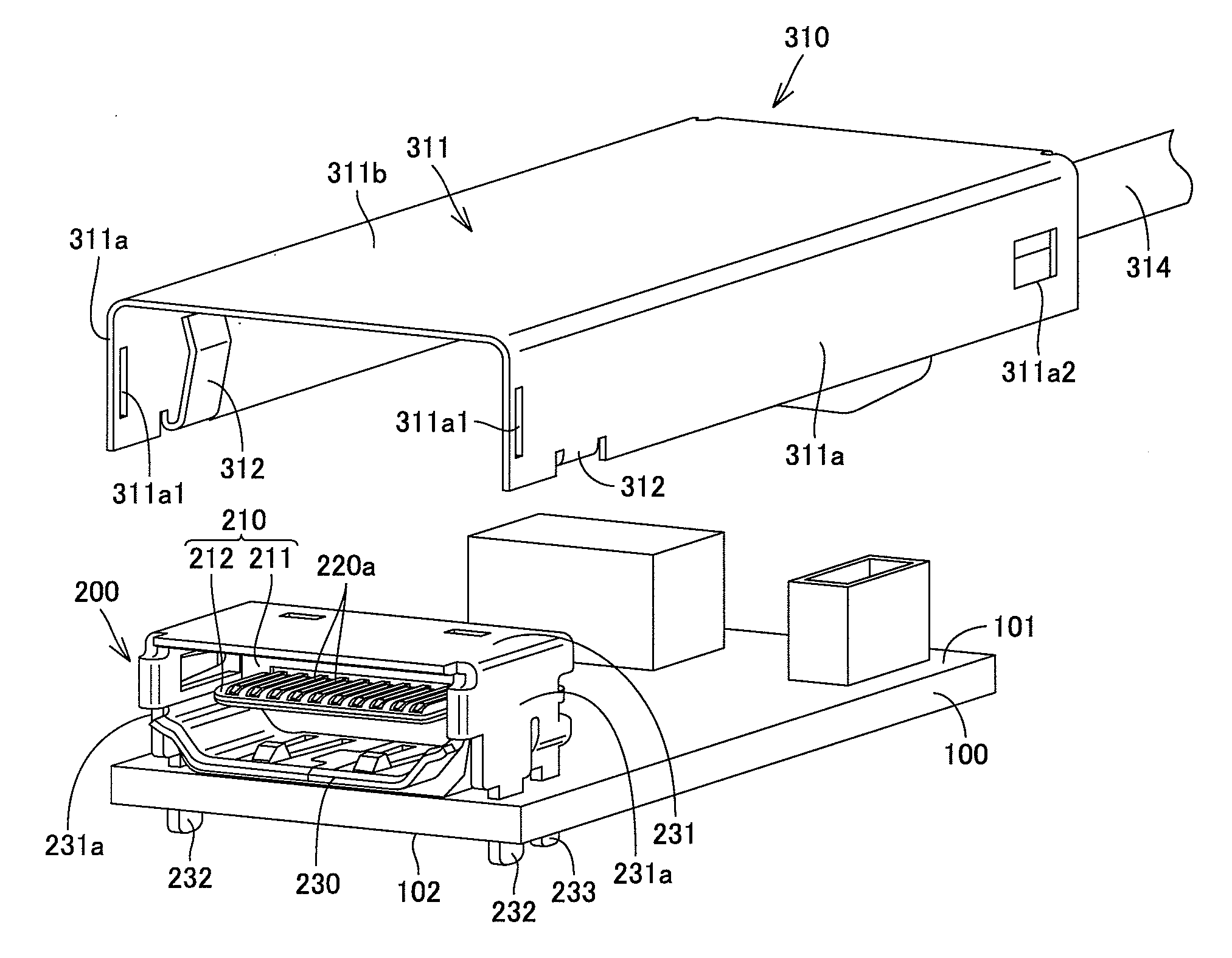

Shield cover, shield case, and circuit board module

InactiveUS20110085317A1Low costSimplify connection workMagnetic/electric field screeningCoupling device detailsElectronic componentMetal

The invention provides a shield cover adapted to cover at least a first electronic component mounted on a first surface of a circuit board. The first electronic component has a metal shell or has a ground / earth terminal on a lateral surface thereof. The shield cover has a contact portion being elastically contactable with a lateral surface of the metal shell or the ground / earth terminal of the first electronic component.

Owner:HOSIDEN CORP

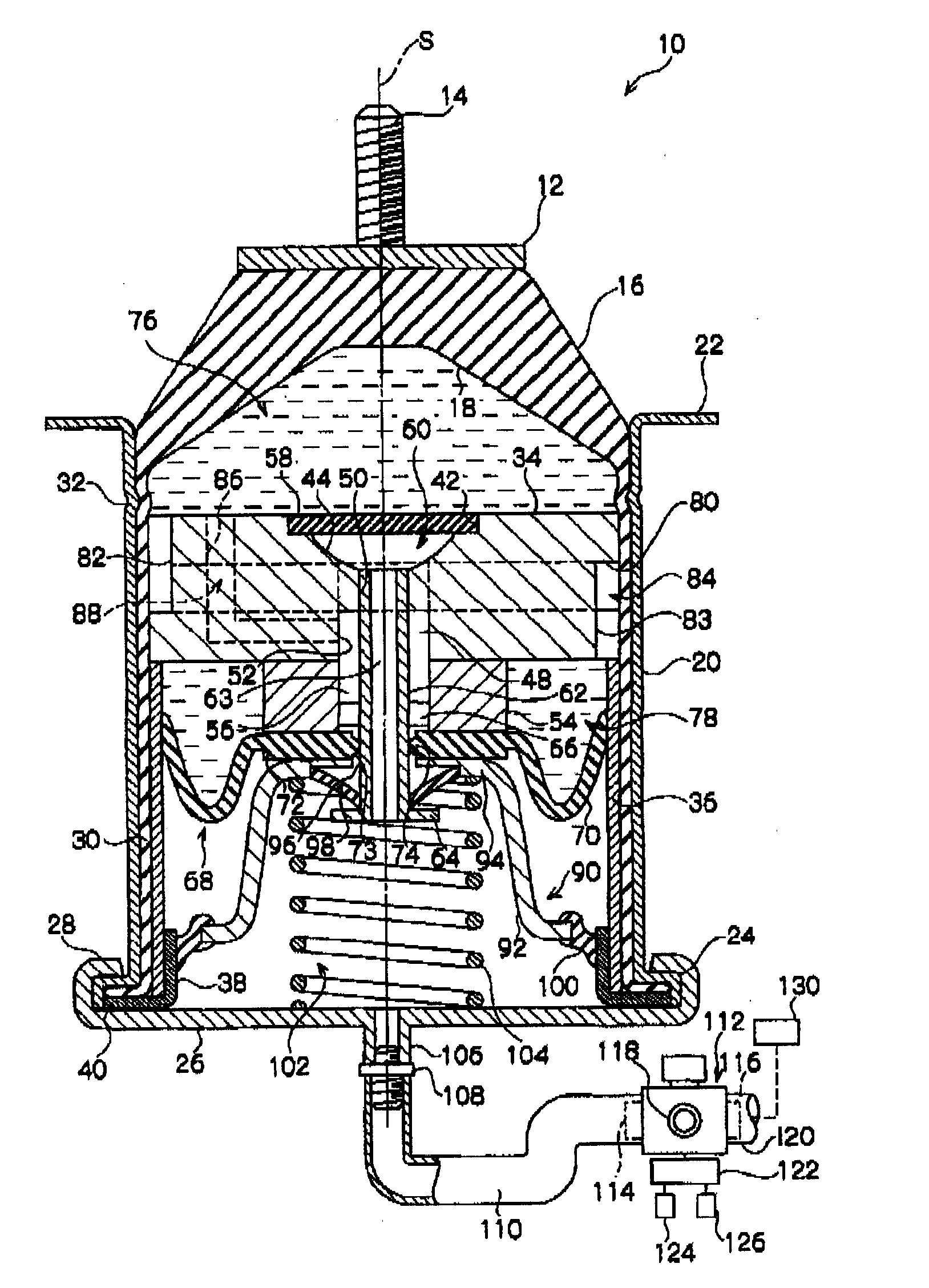

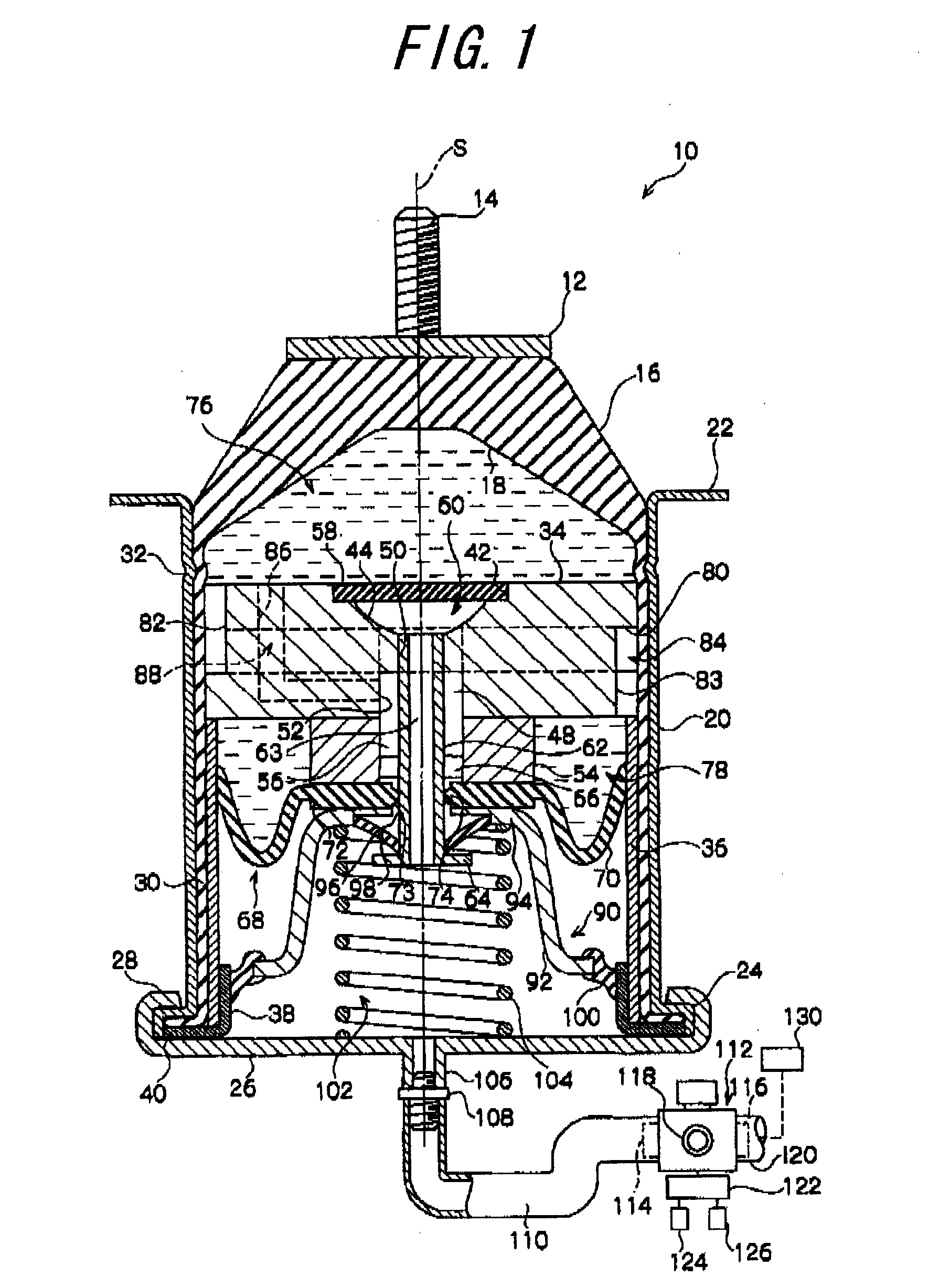

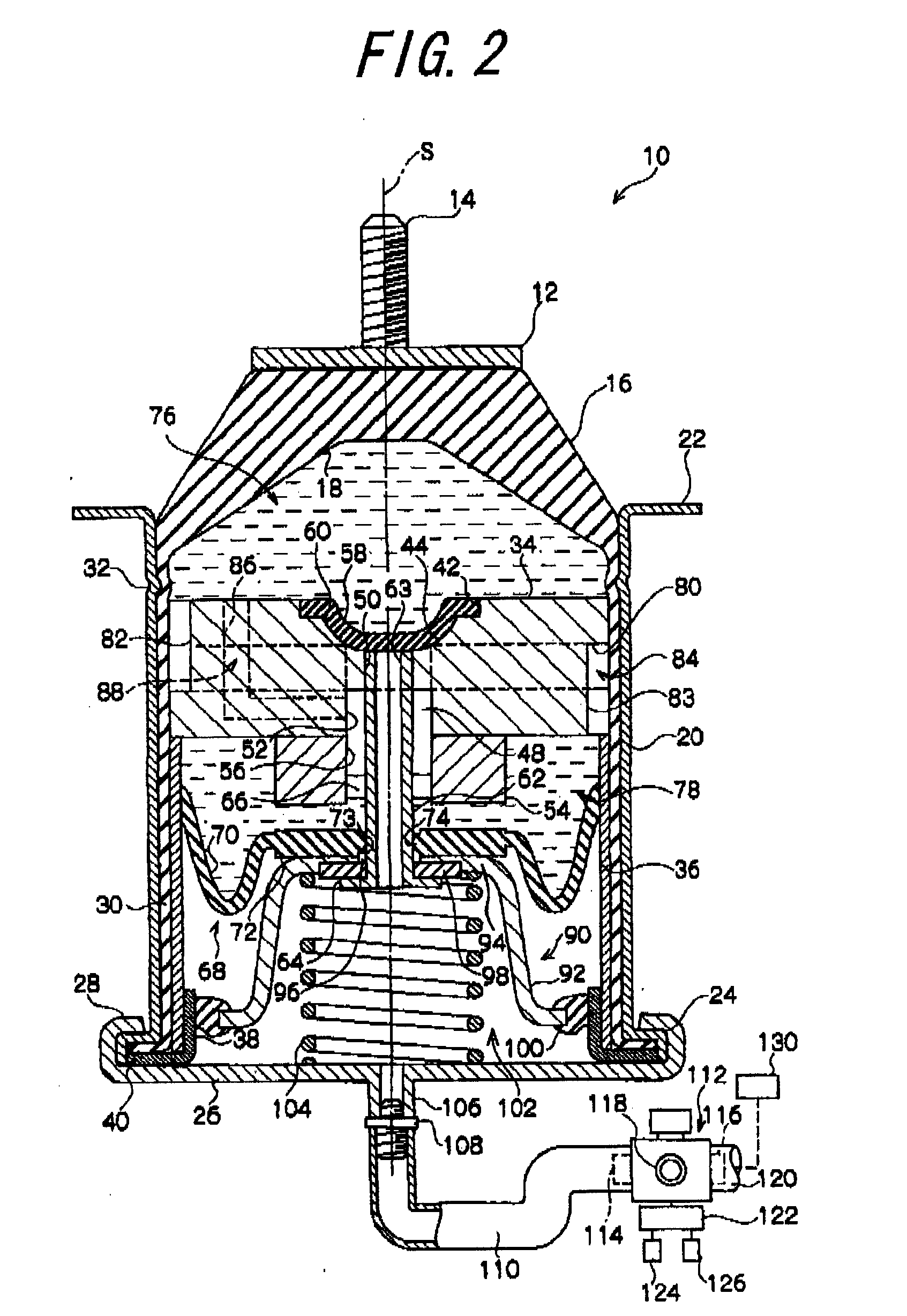

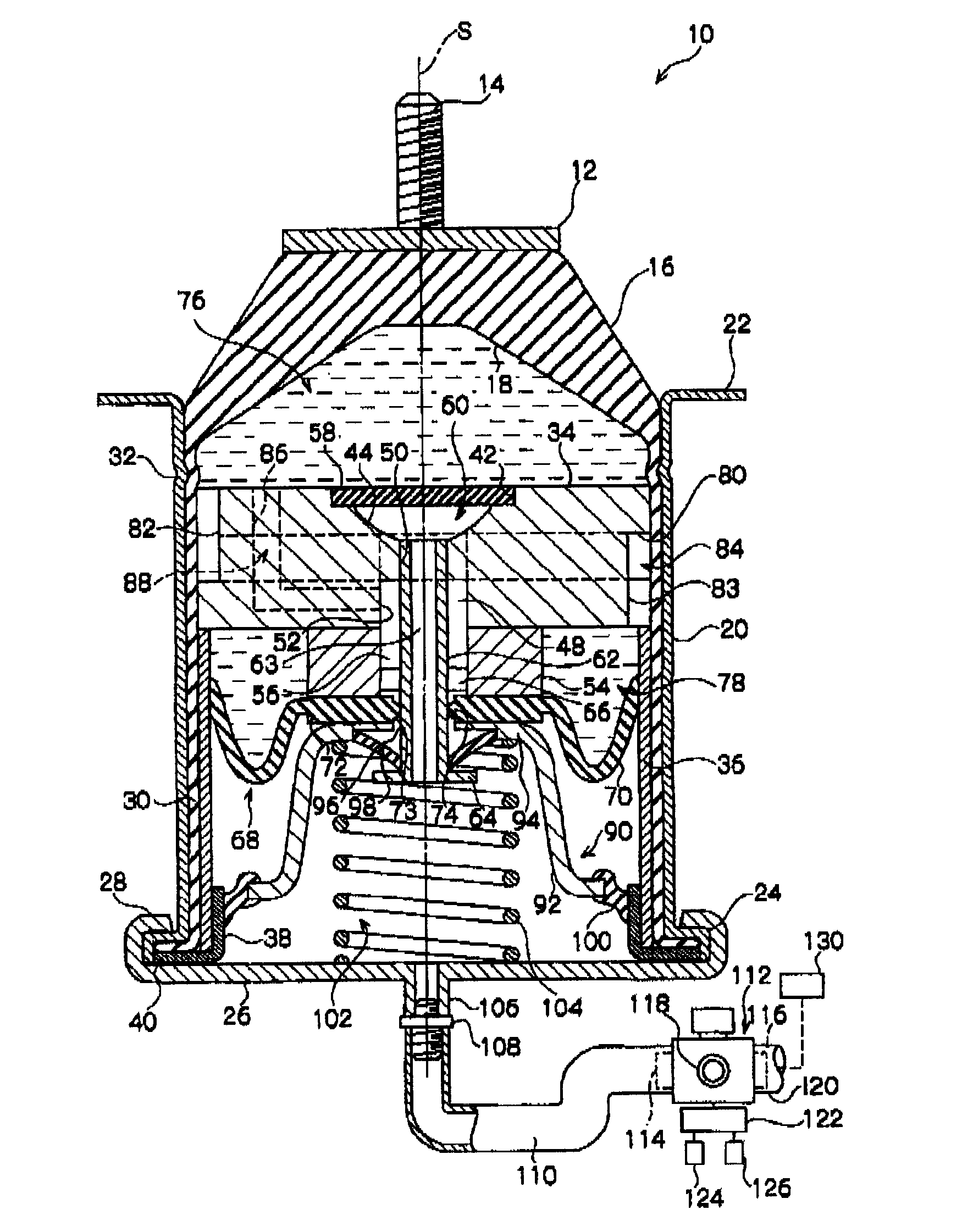

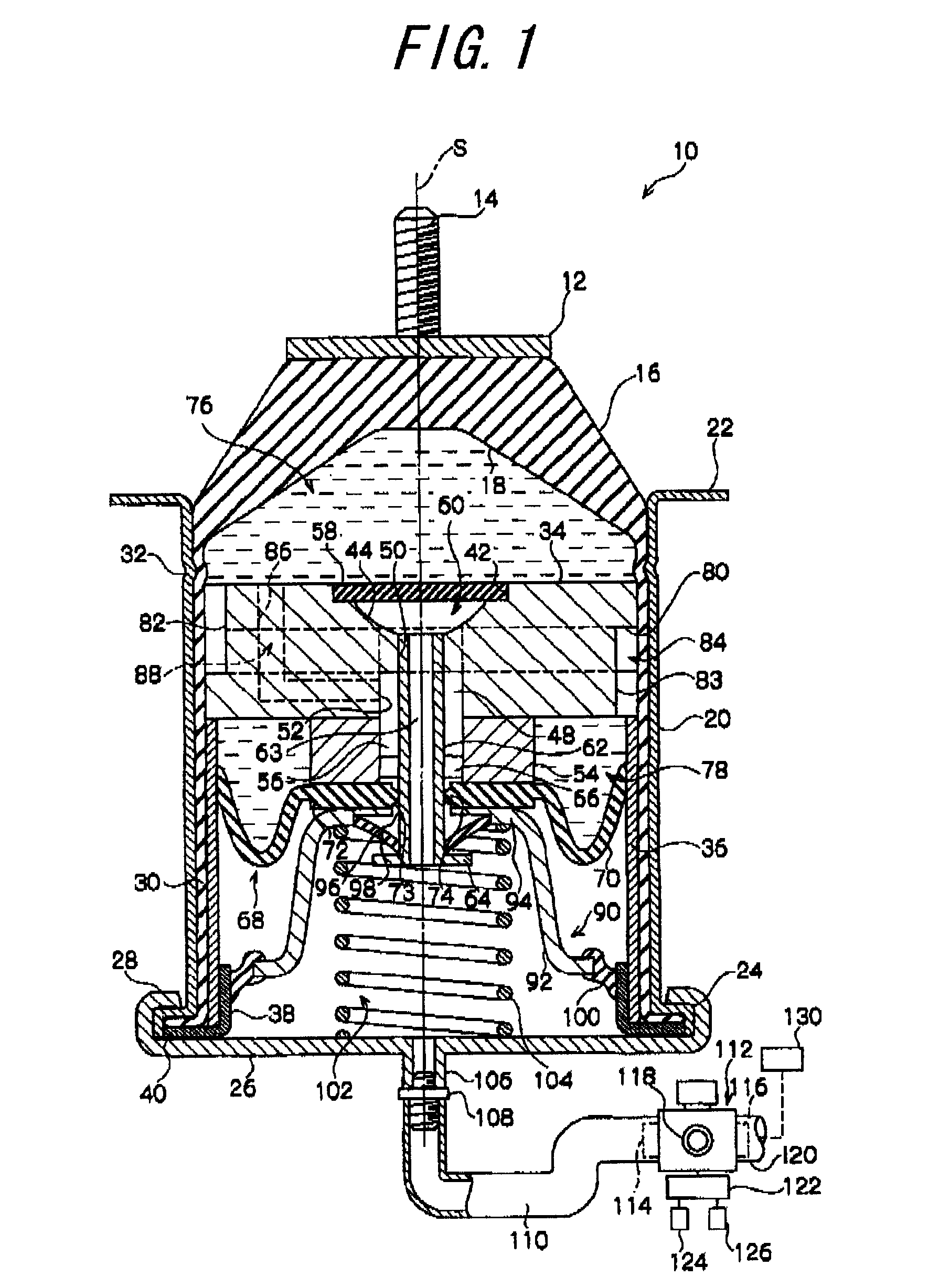

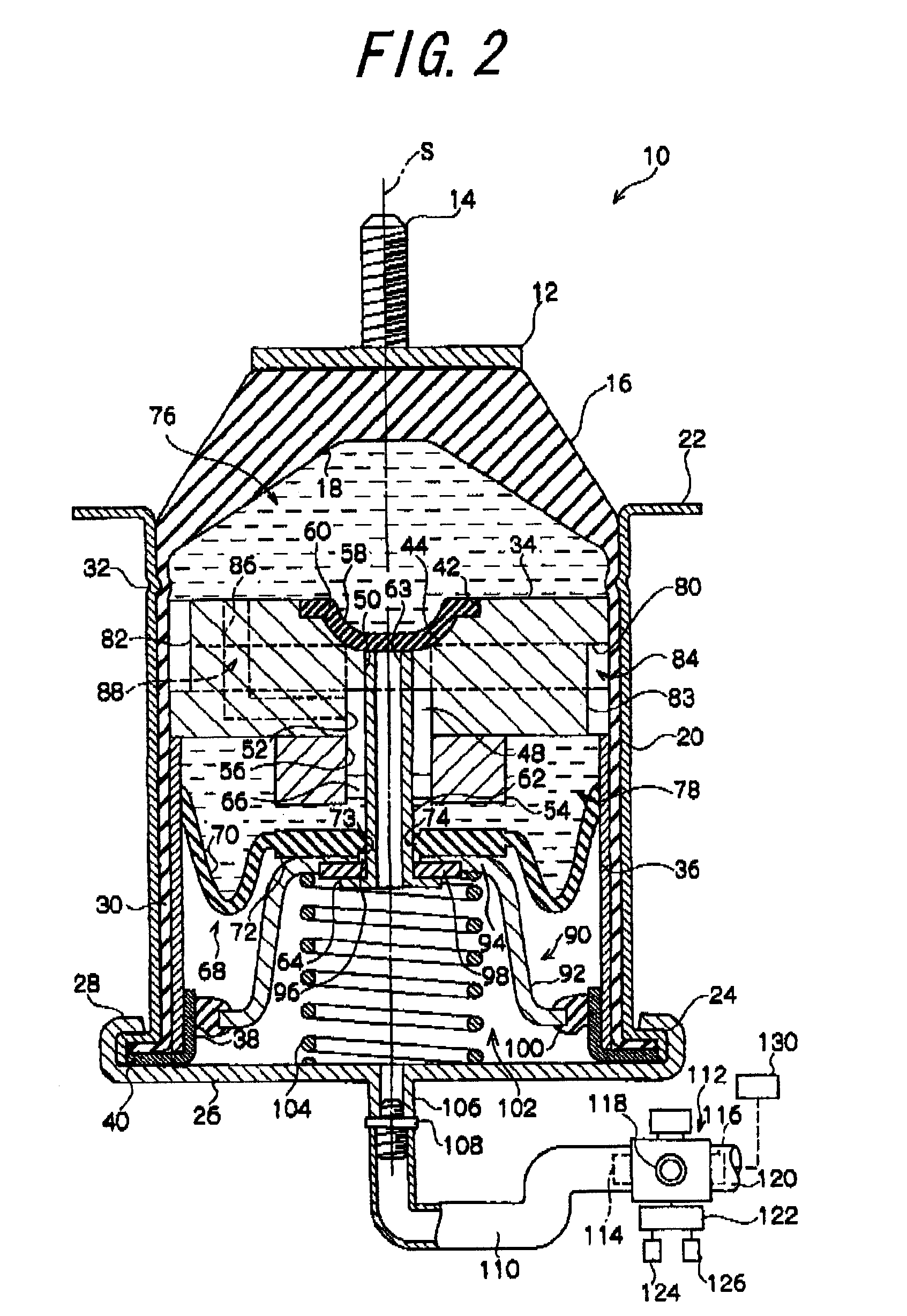

Vibration isolator

InactiveUS20100219570A1Simple structureSimplify connection workMachine framesLiquid springsWorking pressureEngineering

A vibration isolator (10) enabling simplification of a passage structure for connecting a negative pressure chamber in which a membrane is used as a partition wall and a valve chamber of a valve mechanism for opening and closing a second restriction passage to an operating pressure supply source, and simplification of connection of the negative pressure chamber and the valve chamber of the valve mechanism to the operating pressure supply source. The inner passage (63) of a communication tube (62) on the inner peripheral side of an outer cylinder member (20) communicates the negative pressure chamber (60) with the valve chamber (102). A pipe connection part (106) and a supply / discharge pipe (110) communicate the valve chamber (102) with the supply / discharge port (114) of a switching valve (112) on the outside of the vibration isolator (10). The switching valve (112) selectively communicates the supply / discharge port (114) to either an intake manifold (130) as the negative pressure supply source, or an atmosphere space. The negative pressure chamber (60) communicates with the valve chamber (102) through the communication tube (62) on the inner peripheral side of the outer cylinder member (20). Thus, either of a negative pressure and an atmospheric pressure, which is same as a pressure in the valve chamber (102), can be supplied into the negative pressure chamber (60), by supplying either of the negative pressure and the atmospheric pressure into the valve chamber (102) through the supply / discharge pipe (110) and the pipe connection part (106).

Owner:PROSPIRA CORP

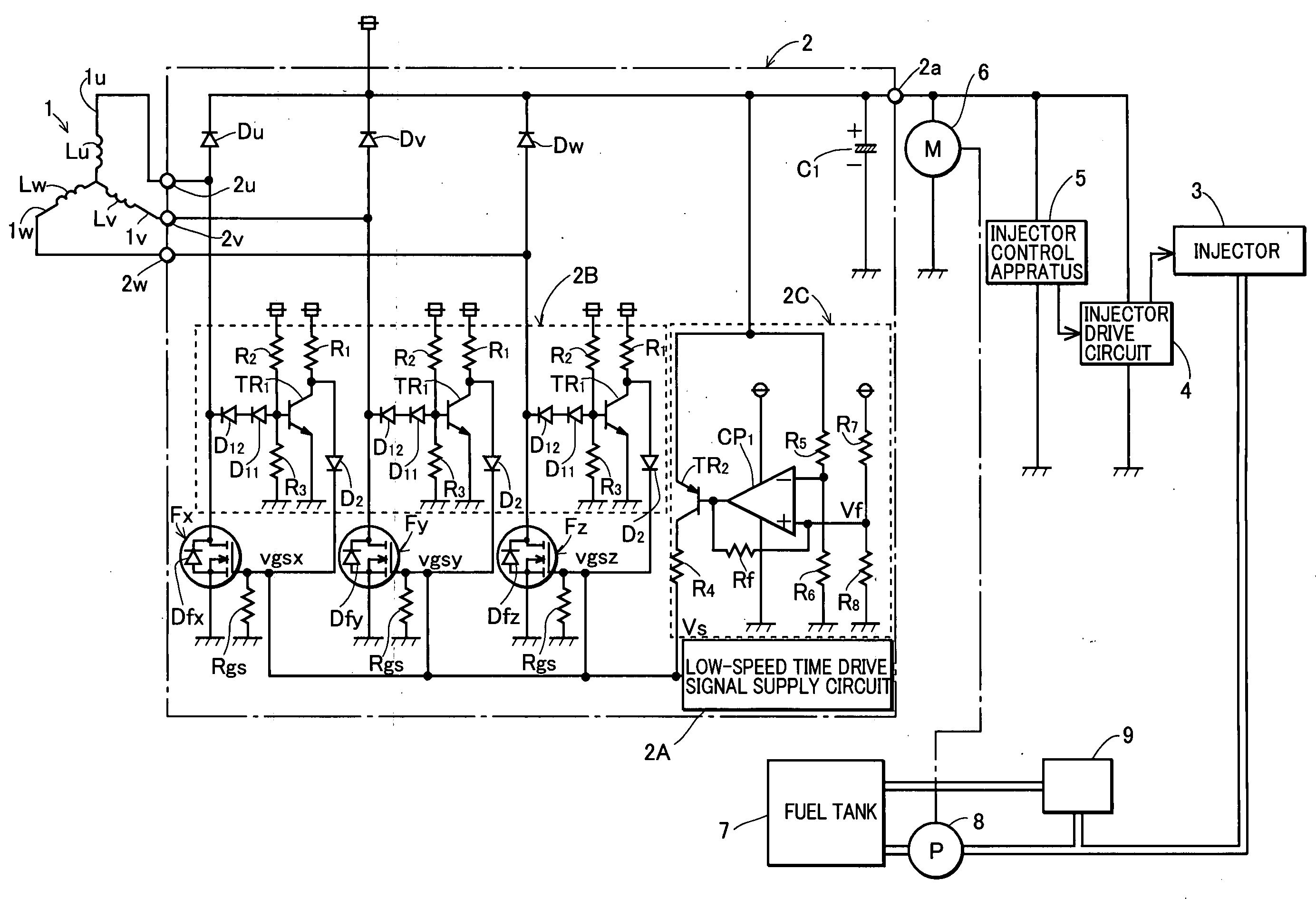

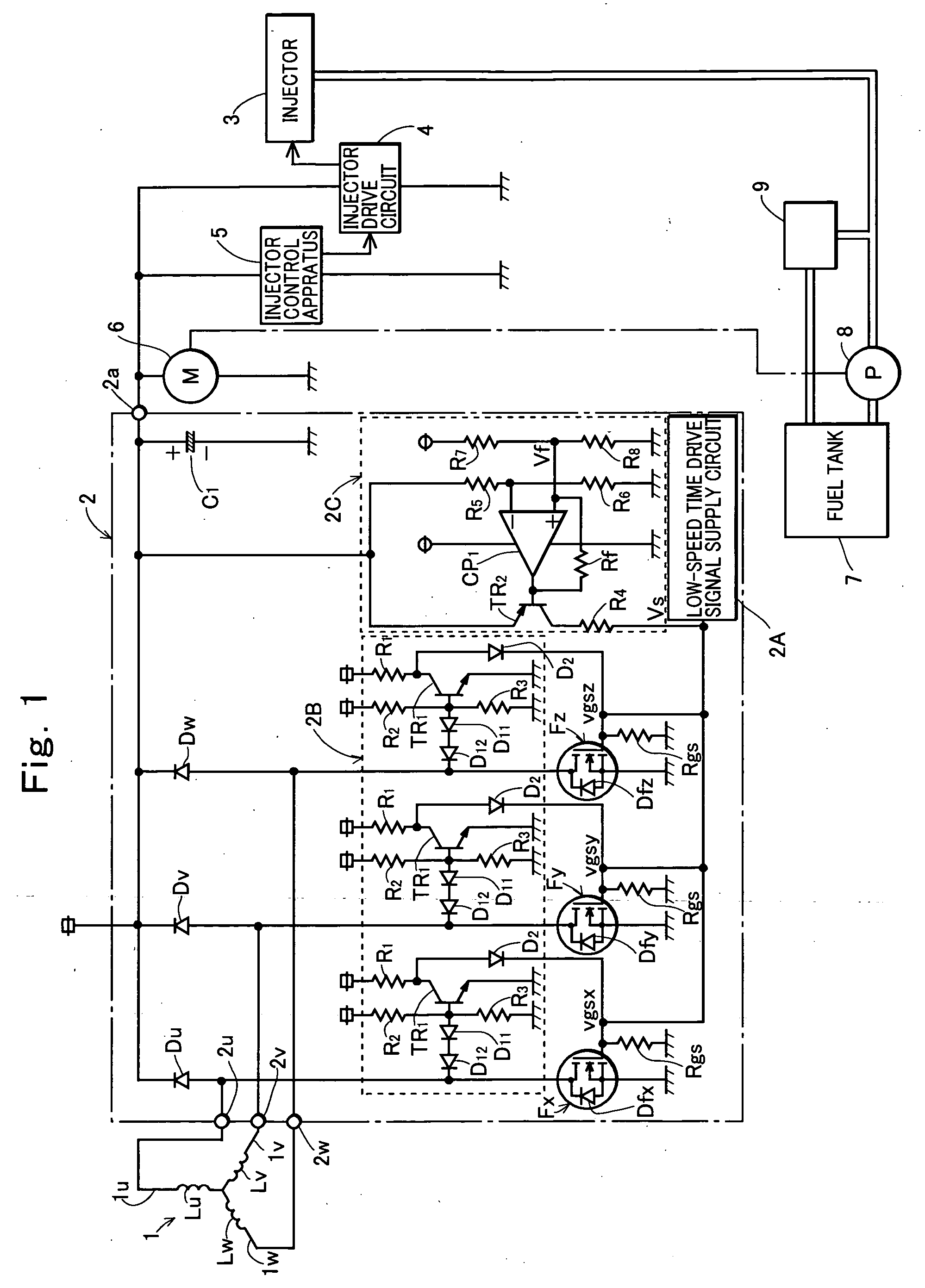

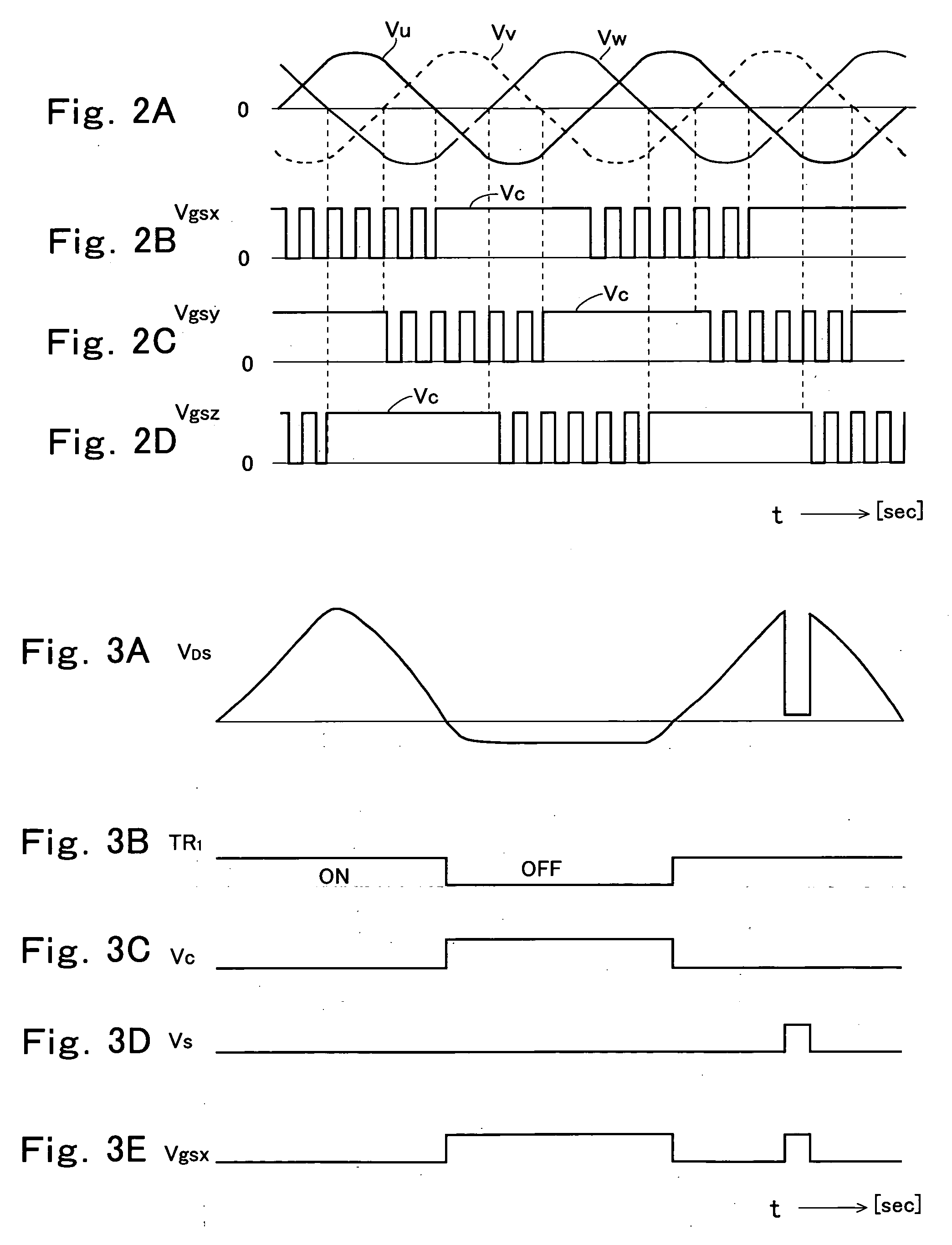

Power supply apparatus for fuel injection apparatus

ActiveUS20060103237A1Reduce output voltageIncrease the output voltageDc network circuit arrangementsElectrical controlMOSFETFull wave

A power supply apparatus comprised of a bridge circuit made up of rectification diodes and MOSFETs for rectifying an output of a generator through a full-wave rectifier circuit comprised of rectification diodes and parasitic diodes of the MOSFETs and obtaining a supply voltage of a fuel injection apparatus, the power supply apparatus being comprised of an FET control section which turns ON / OFF the MOSFETs to step up the output voltage of the generator and a transistor provided for each MOSFET, which is set in an ON-state for a period during which a reverse voltage is applied to a parasitic diode of each MOSFET and set in an OFF-state for a period during which a forward voltage is applied to the parasitic diode of each MOSFET, wherein a control voltage for turning ON the MOSFET is given between the gate and source of the corresponding MOSFET for a period during which each transistor is in an OFF-state.

Owner:MAHLE INT GMBH

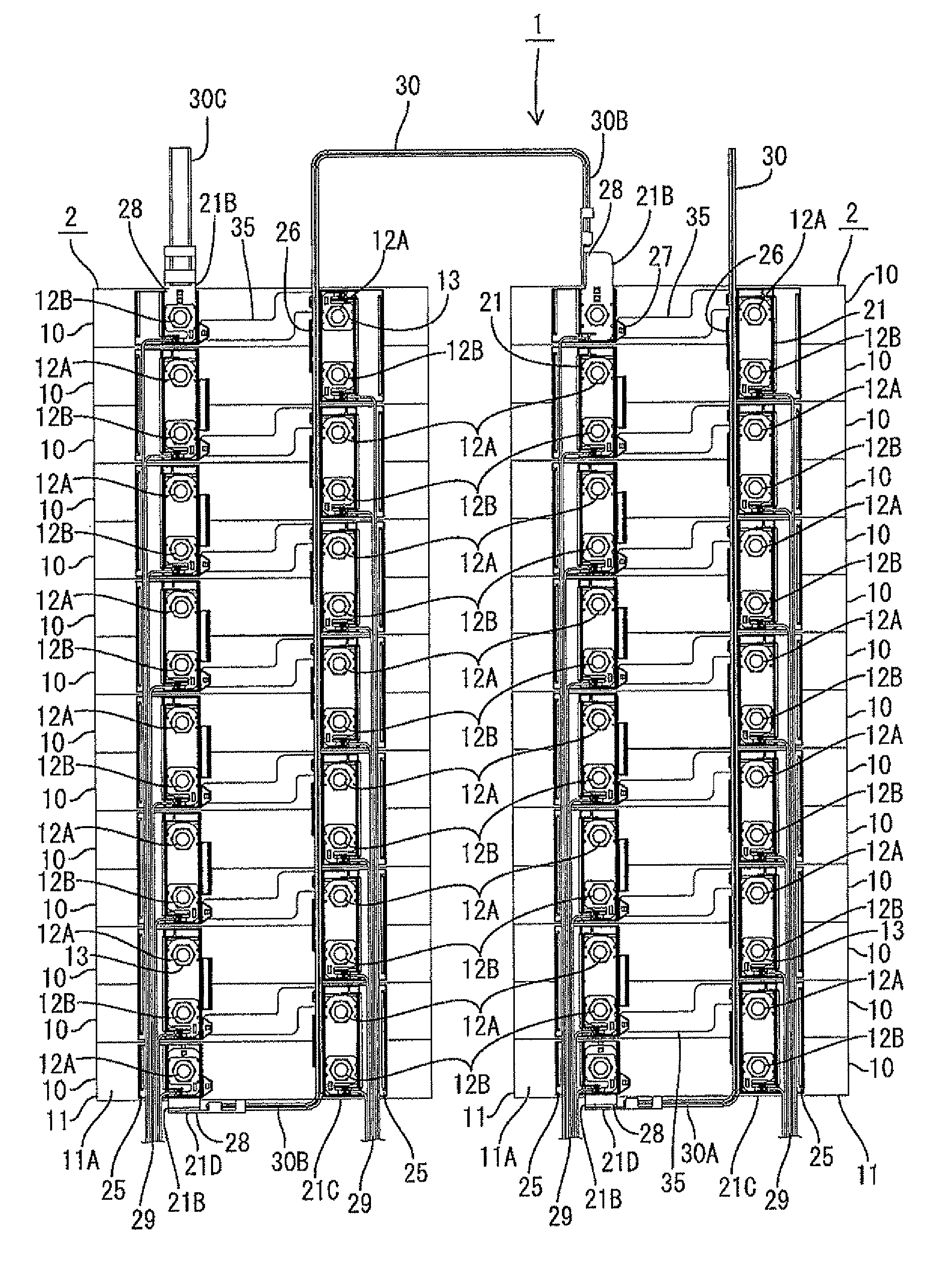

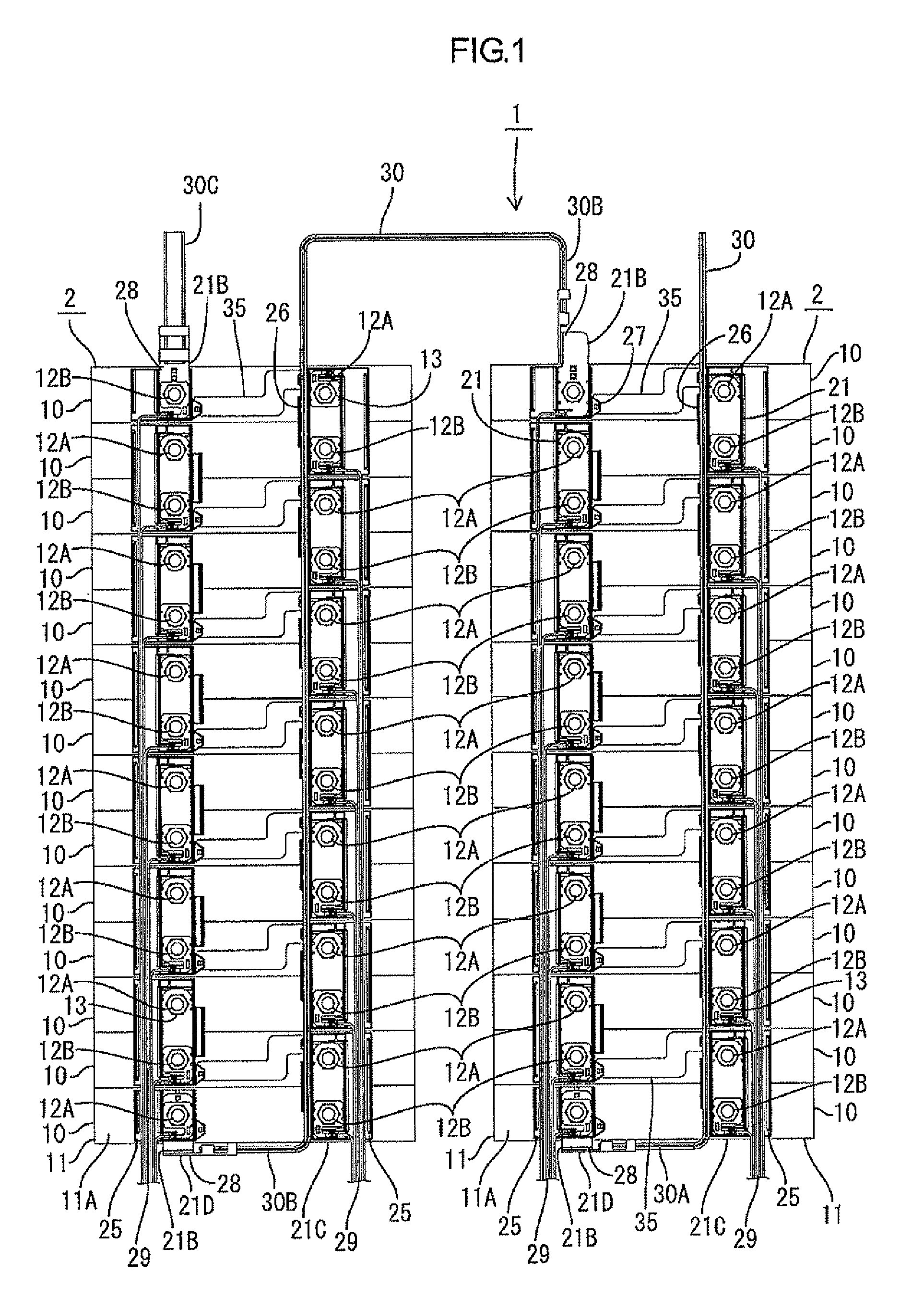

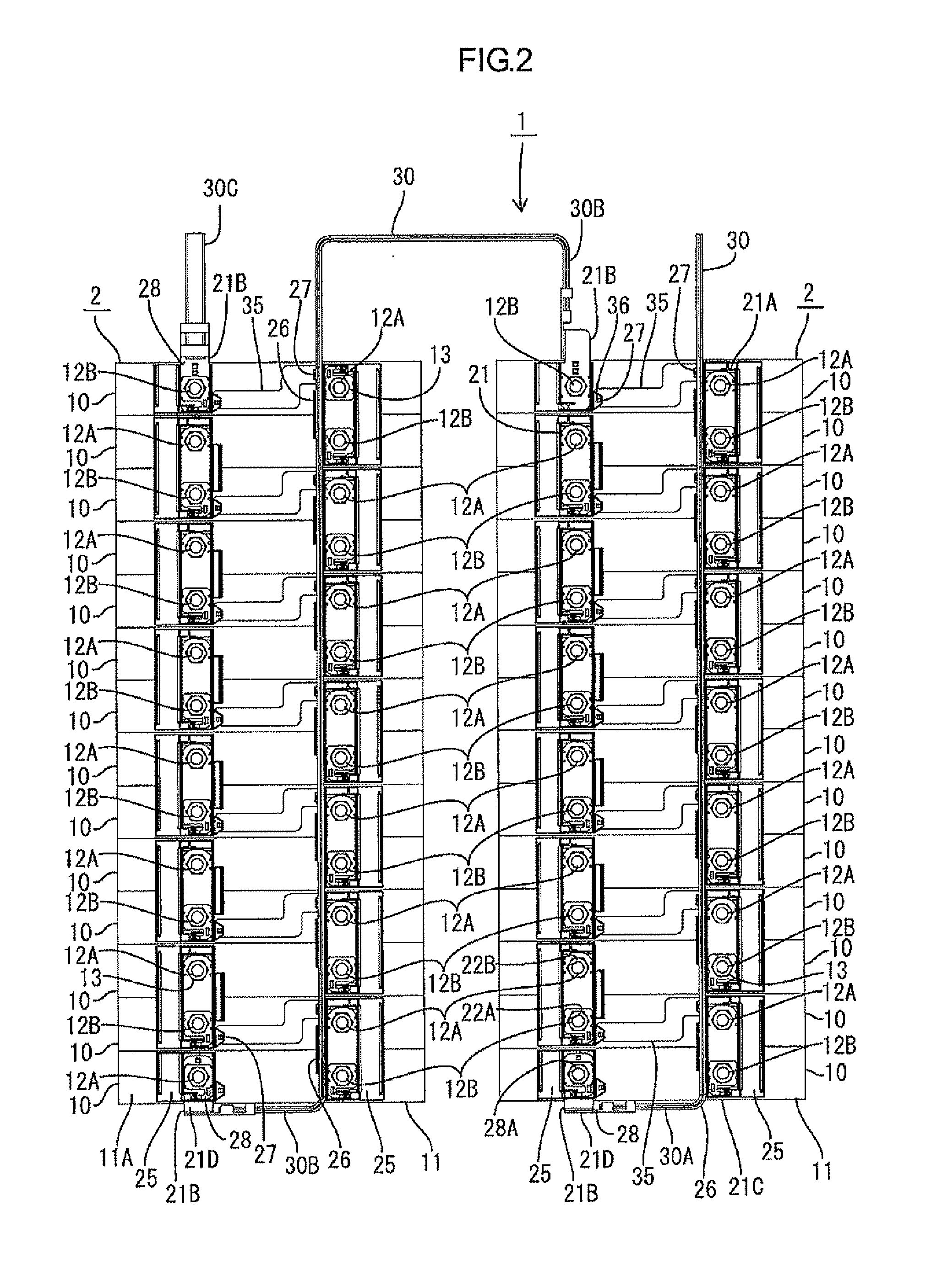

Battery connecting assembly

InactiveUS8998646B2Simplify connection workEasy connection workElectric discharge tubesSecondary cellsElectrical conductorElectric wire

Owner:AUTONETWORKS TECH LTD +2

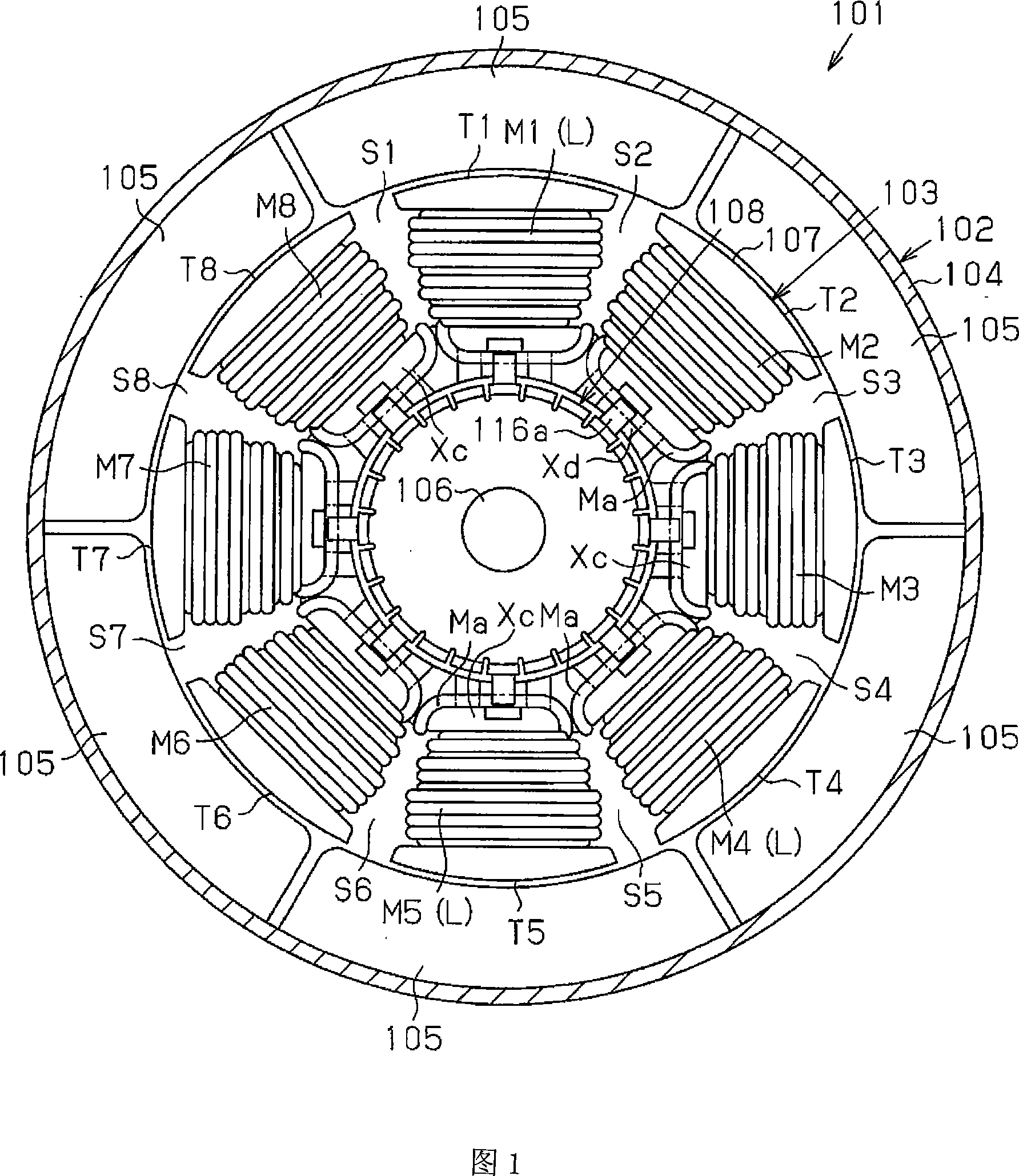

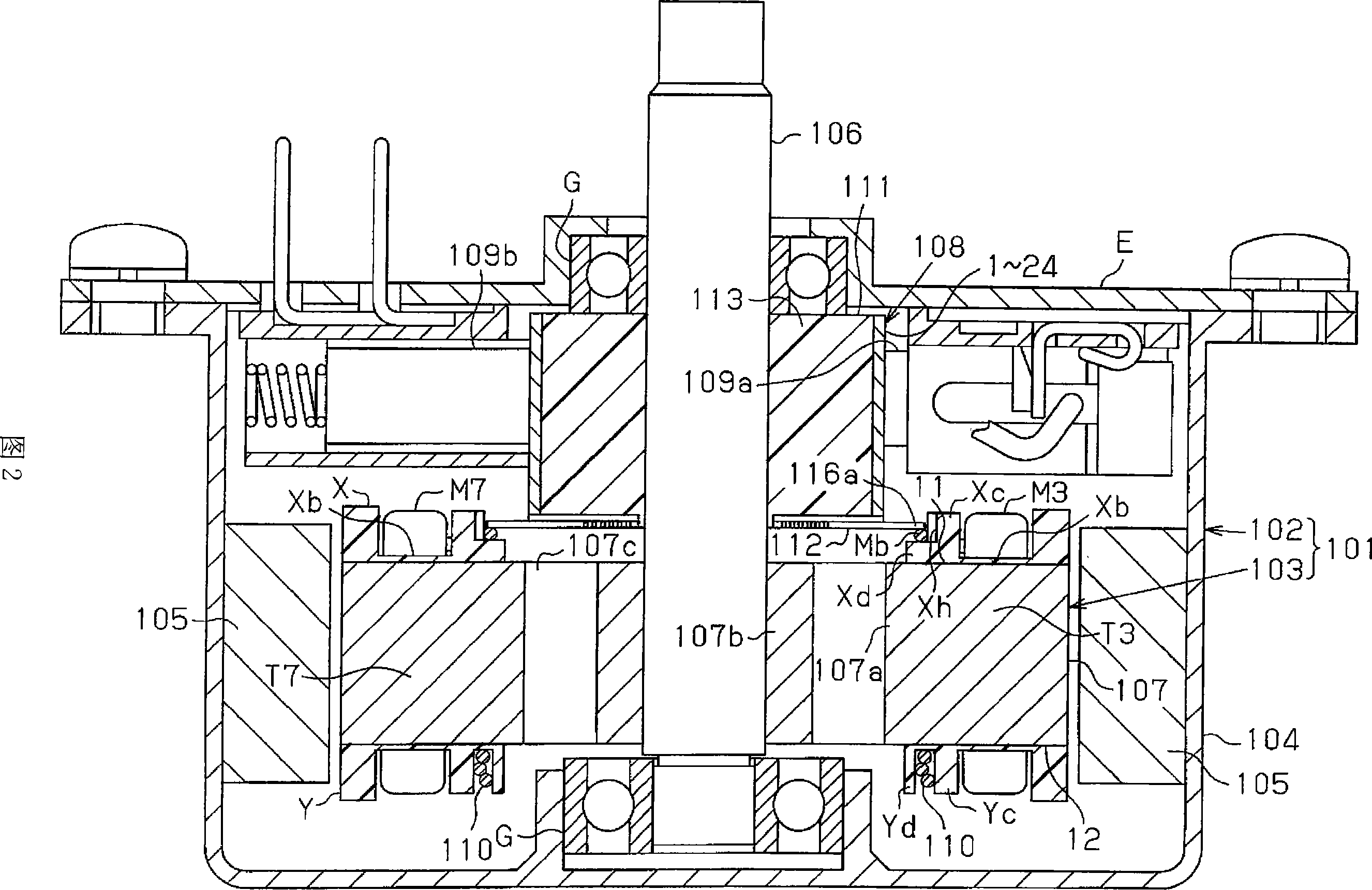

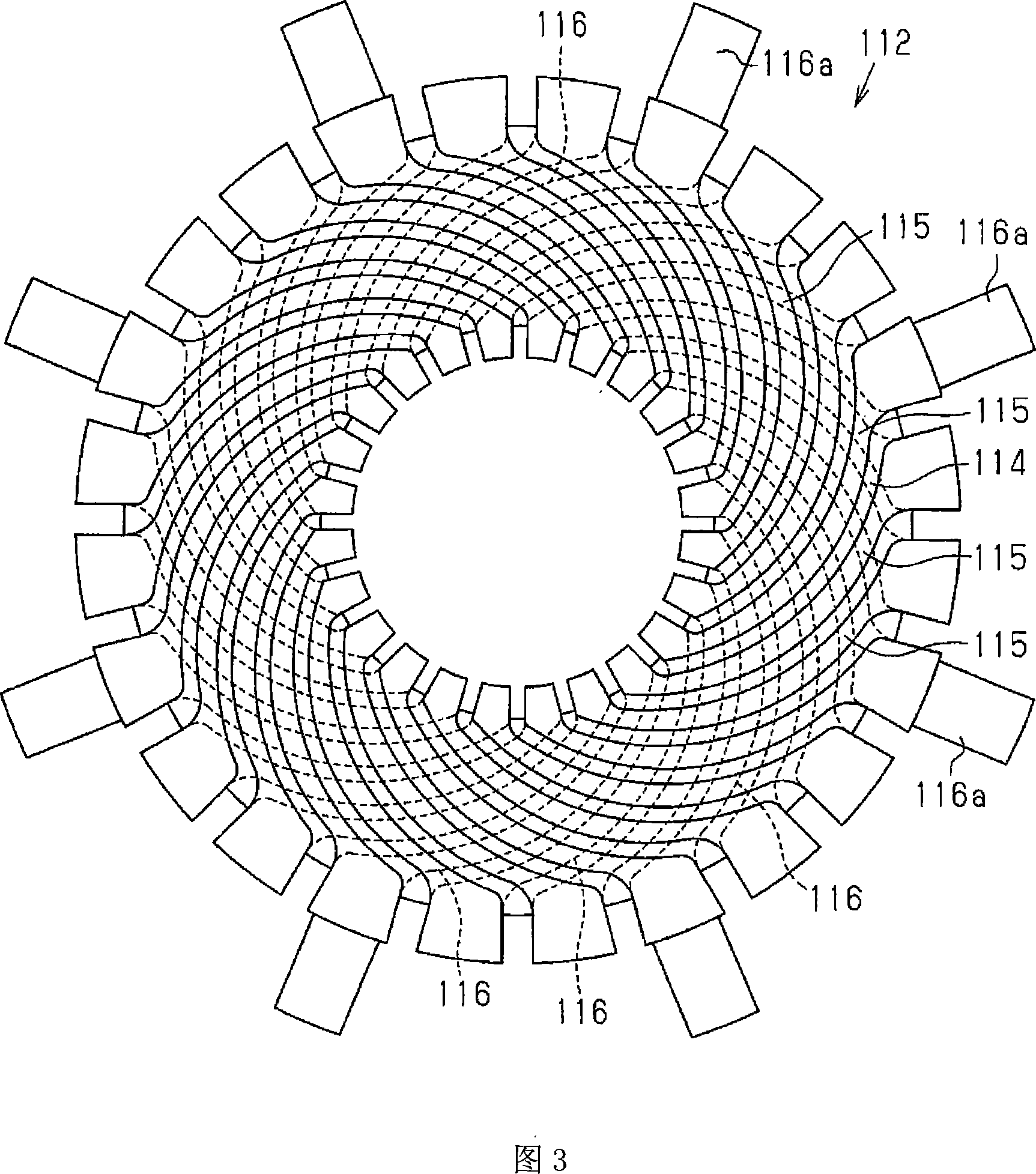

Armature, rotating electric machine, DC motor, and brushless motor

InactiveCN101032064AAvoid damageSimplify connection workMagnetic circuit stationary partsDC commutatorBrushless motorsElectric machine

Owner:ASMO CO LTD

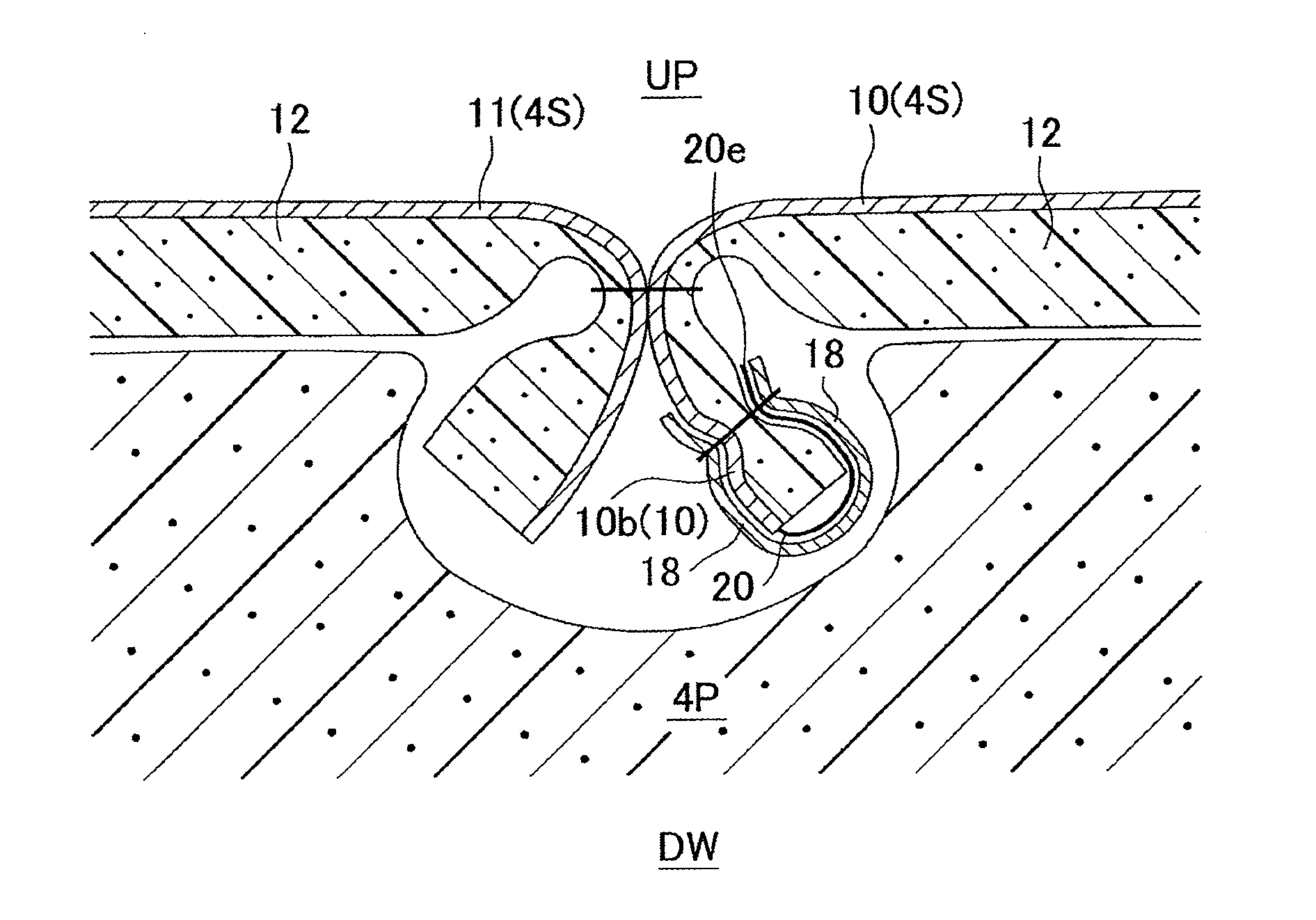

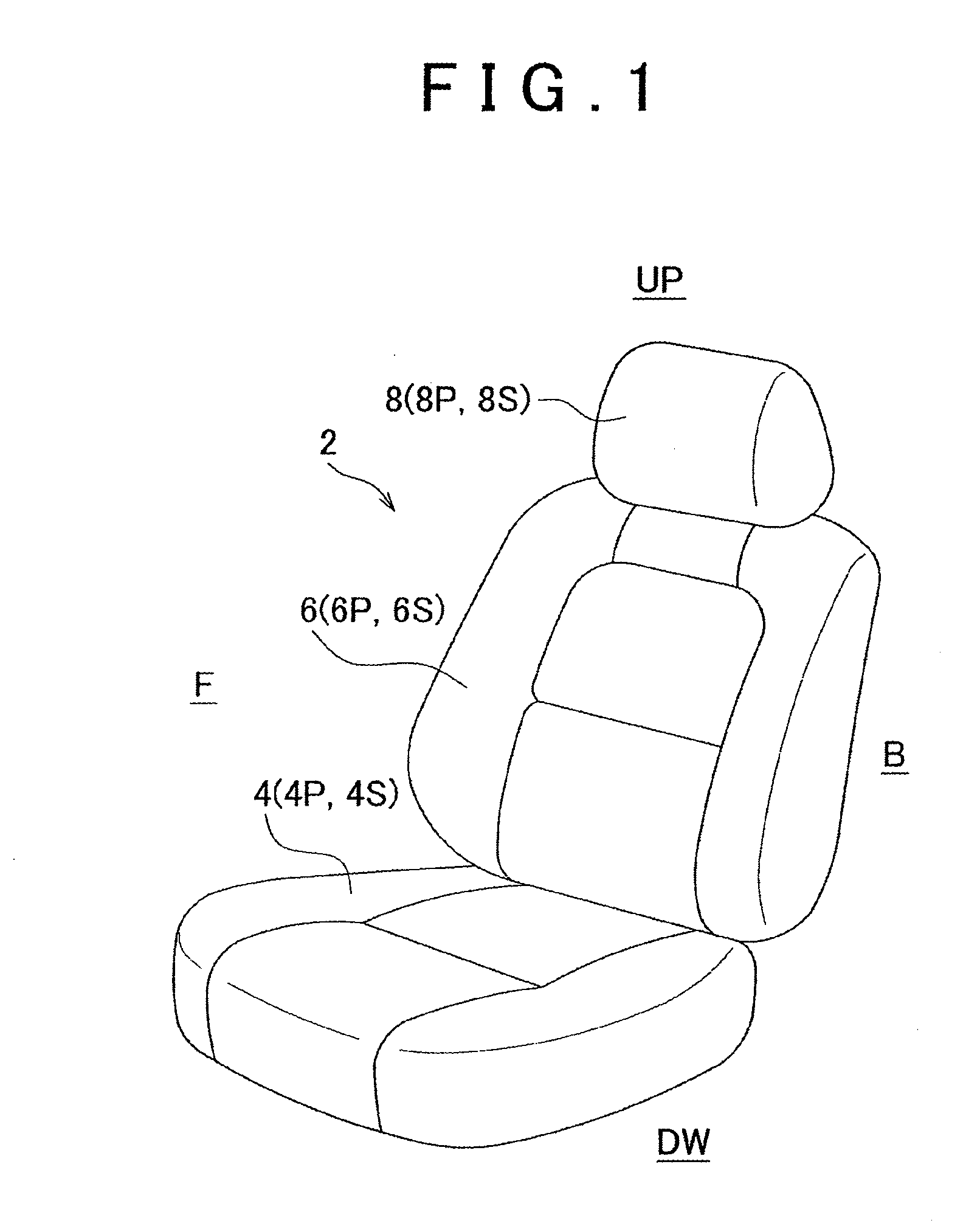

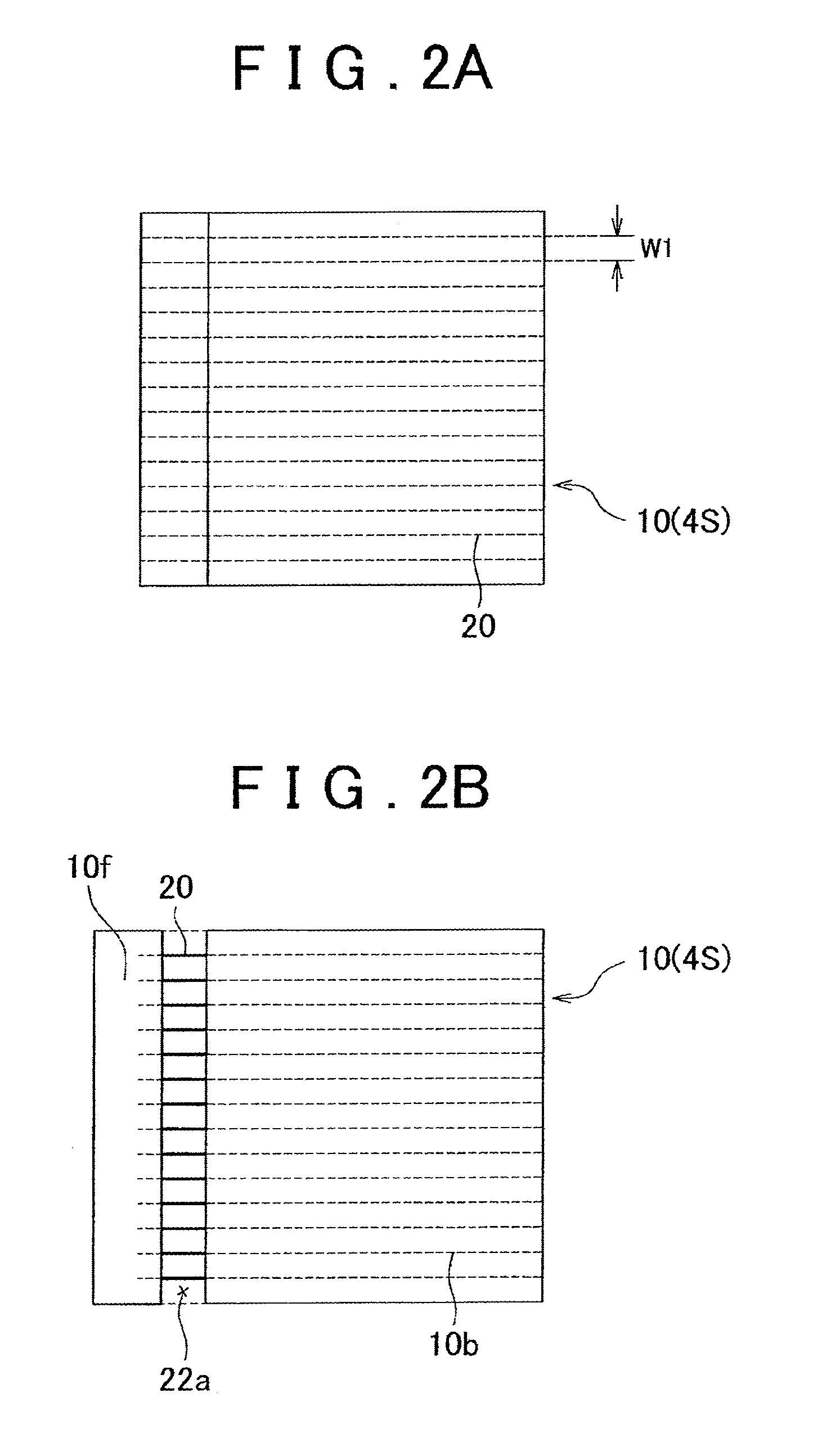

Skin material of vehicle interior equipment and manufacturing method for the same

ActiveUS20120285008A1Simplify connection workFirmly connectedVehicle seatsContact member manufacturingFiberElectric power

A manufacturing method for a skin material of a vehicle interior equipment includes exposing a conductive wire material by removing a main fiber material from a first fabric material formed of the conductive wire material and the main fiber material that is weaker than the conductive wire material and electrically connecting a conductive member, which is used to supply electric power to the conductive wire material, to the exposed portion of the conductive wire material.

Owner:TOYOTA BOSHOKU KK

Cable connector and cable assembly, and method of manufacturing cable assembly

InactiveUS8979576B2Suppression of deformationReduce the number of partsCoupling device engaging/disengagingCoupling device detailsGround contactElectrical conductor

Provided is a cable connector, a cable assembly, and a method of manufacturing the cable assembly, in which electric characteristics are stabilized by suppressing elastic deformation of a cable for differential signal transmission, and besides, which is easily connectable by reducing the number of parts. In a ground contact, an outer-conductor adhering portion which is protruded from a side wall portion of a connector main body and which is adhered with an outer conductor by a conductive adhesive is provided. In this manner, elastic deformation of a cable for differential signal transmission is suppressed, so that electric characteristics can be stabilized. Also, connecting work between the outer conductor and the ground contact can be simplified as reducing the number of parts. Further, the cable for differential signal transmission is not exposed to a high temperature of soldering or others, and therefore, thermal deformation thereof does not occur, either.

Owner:HITACHI METALS LTD

Three-phase ac generator for vehicle

InactiveUS20050082930A1Simplify workSimplify connection workSynchronous generatorsMagnetic circuitElectricityEngineering

A neutral point diode having three connecting terminals electrically commonly connected to each other is used in a type for connecting each generating coil of a three-phase alternating current electric generator for a vehicle in a Y-shape connection. The coil terminal of a neutral point side of each generating coil is connected to each of the three connecting terminals of this neutral point diode. A diode having two connecting terminals electrically commonly connected to each other is used in a type for connecting each generating coil in a A-shape connection. The coil terminals of two adjacent generating coils are connected to the respective two connecting terminals of this diode. In both the types, one coil terminal is connected to one connecting terminal and a connecting work is simplified.

Owner:MITSUBISHI ELECTRIC CORP

Connector structure

InactiveUS7163415B2Simplify connection workSimplify workCoupling contact membersContact members penetrating/cutting insulation/cable strandsEngineeringElectric wire

A contact construction requiring minimum space above a connector allowing installation of a connection cable on a circuit board in a layout direction of contacts that provides increased freedom in wiring / board design. A bottom surface of the housing forms a mounting surface of the circuit board while a top surface forms a cable layout surface for laying out the connection cable in the surface direction of the circuit board. A bottom end of a terminal in the housing protrudes toward the circuit board side to form a contact part to connect with the circuit board, and the top end forms a connection part to connect with the connection cable. A plurality of terminals is provided in a row in the housing, a plurality of wires is laid out on the cable layout surface in the circuit board direction, ensuring each connection cable is electrically connected to the desired terminal.

Owner:SMK CORP

Vibration isolator

InactiveUS8006965B2Simple structureSimplify connection workMachine framesLiquid springsEngineeringAtmospheric pressure

A vibration isolator having an inner passage of a communication tube that communicates the negative pressure chamber with the valve chamber. A pipe connection part and a supply / discharge pipe communicate the valve chamber with the supply / discharge port of a switching valve on the outside of the vibration isolator. The switching valve selectively communicates the supply / discharge port to either an intake manifold as the negative pressure supply source, or an atmosphere space. The negative pressure chamber communicates with the valve chamber through the communication tube on the inner peripheral side of the outer cylinder member. Thus, either of a negative pressure and an atmospheric pressure, which is same as a pressure in the valve chamber, can be supplied into the negative pressure chamber, by supplying either of the negative pressure and the atmospheric pressure into the valve chamber through the supply / discharge pipe and the pipe connection part.

Owner:PROSPIRA CORP

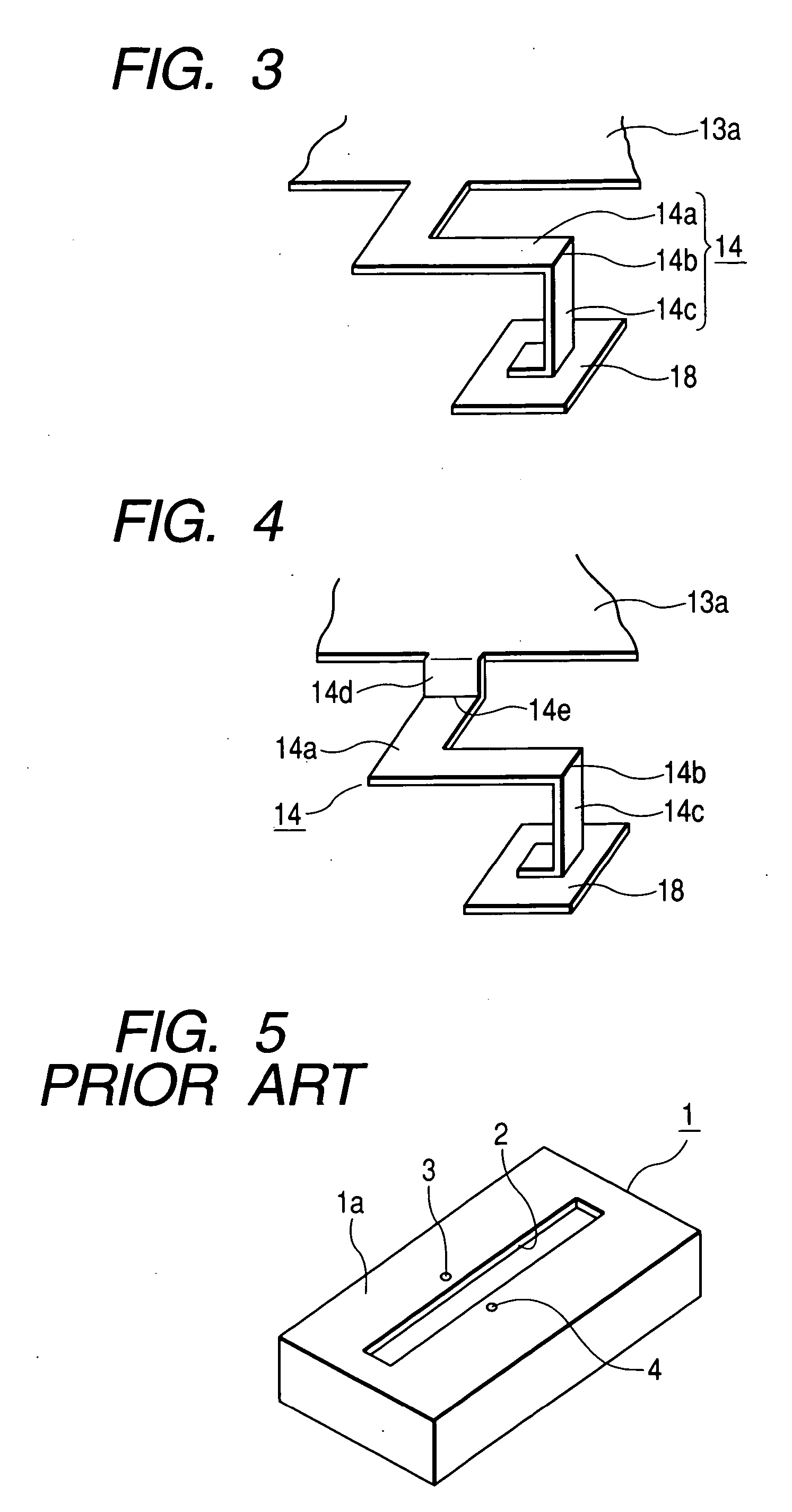

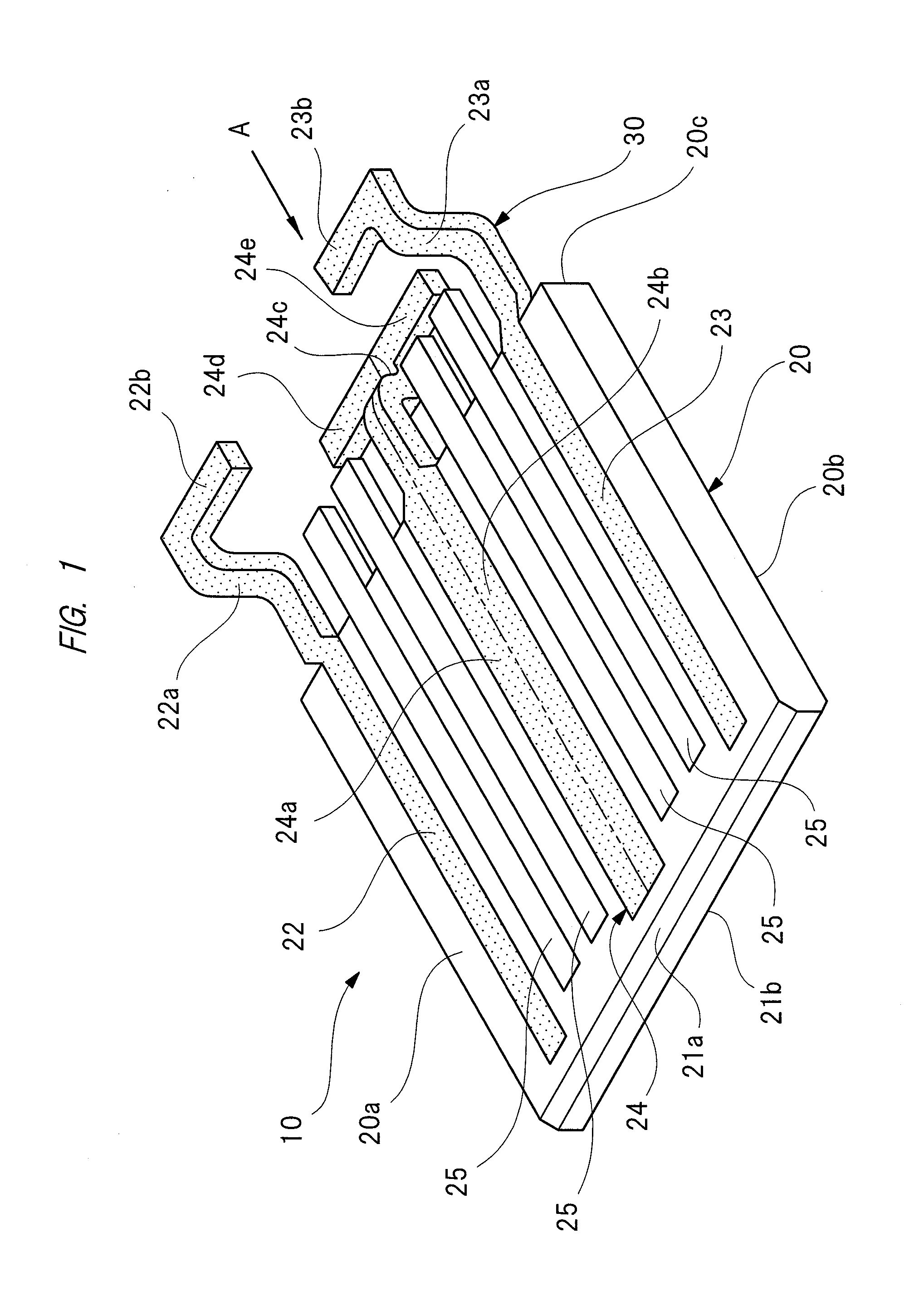

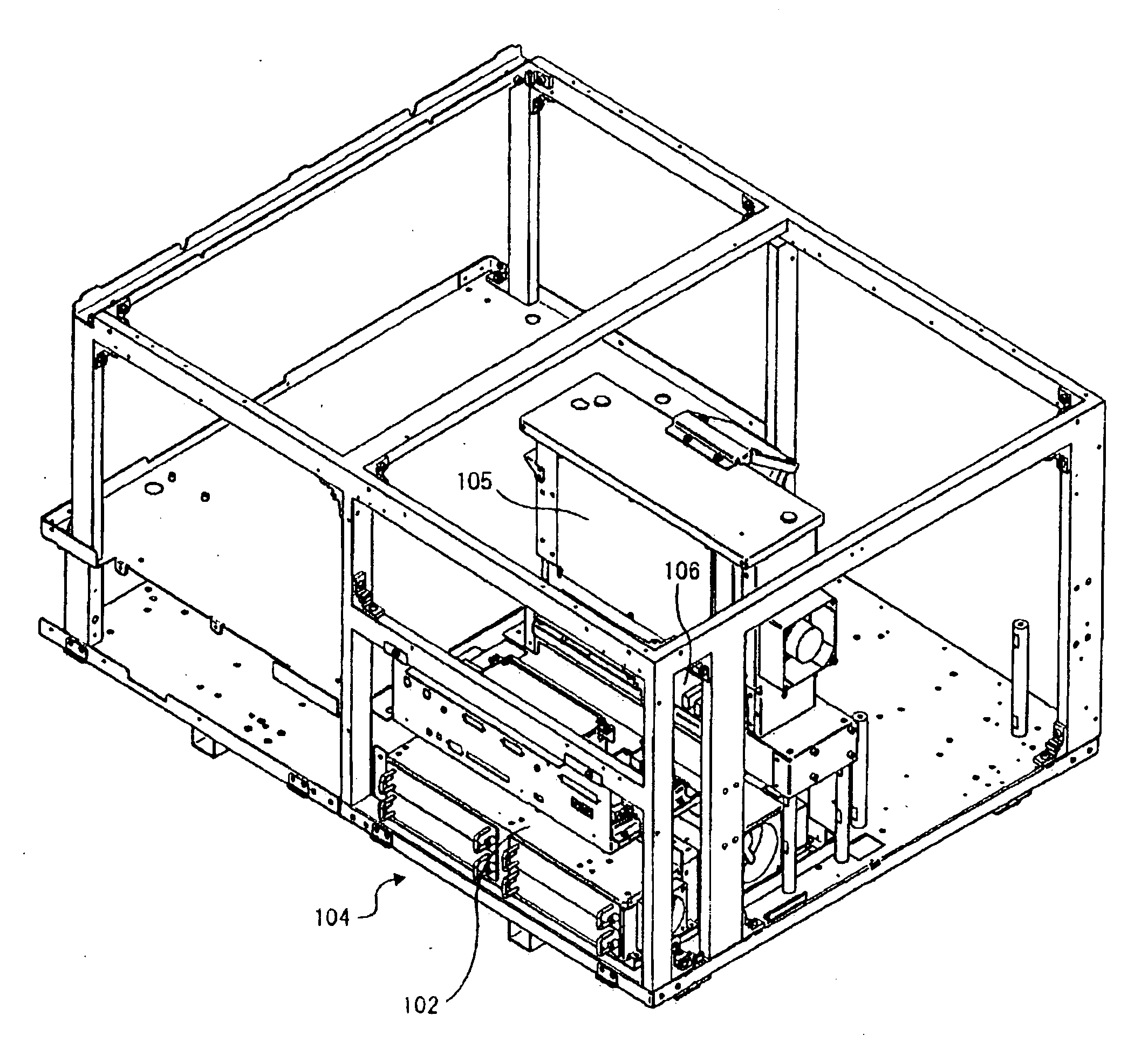

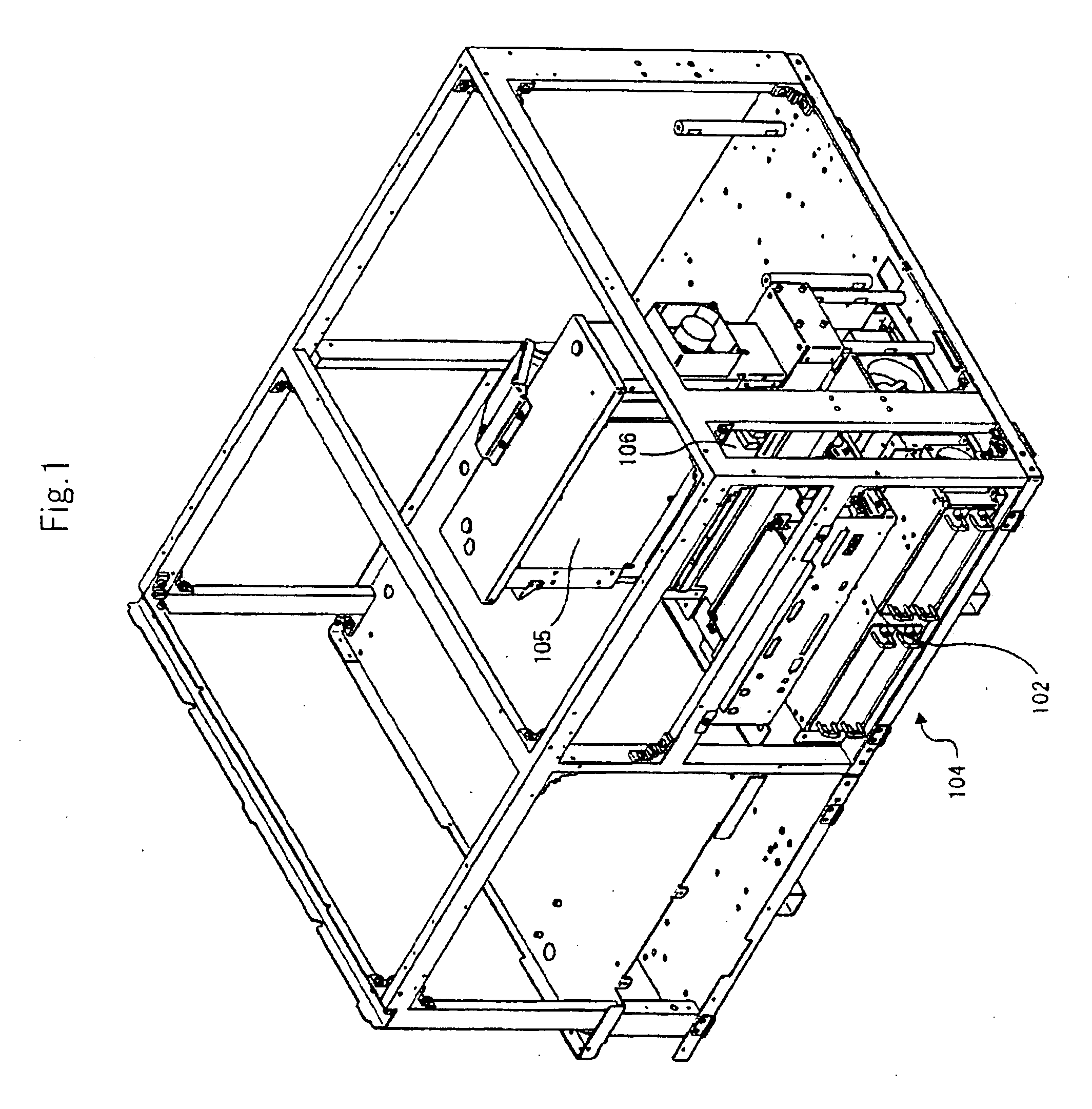

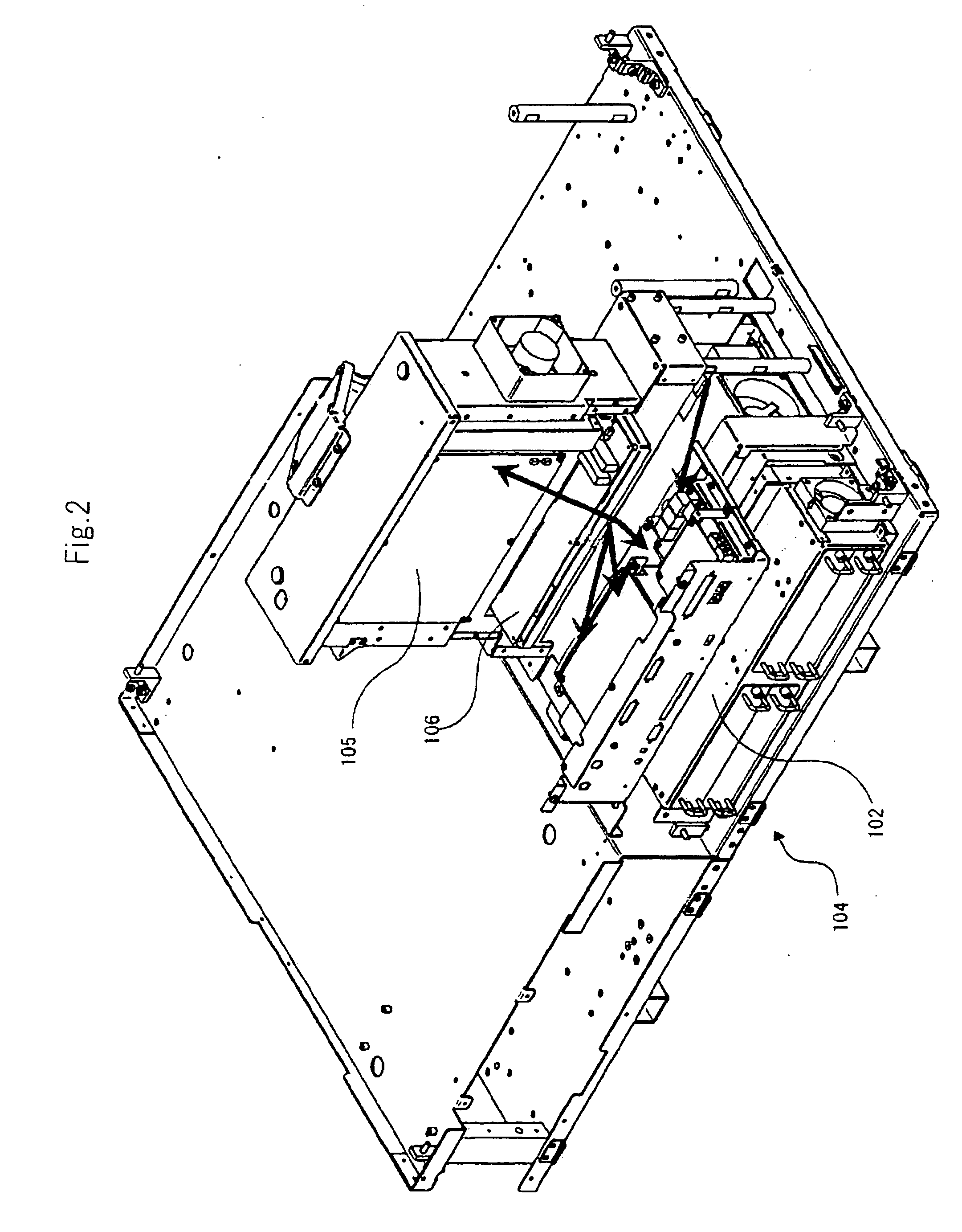

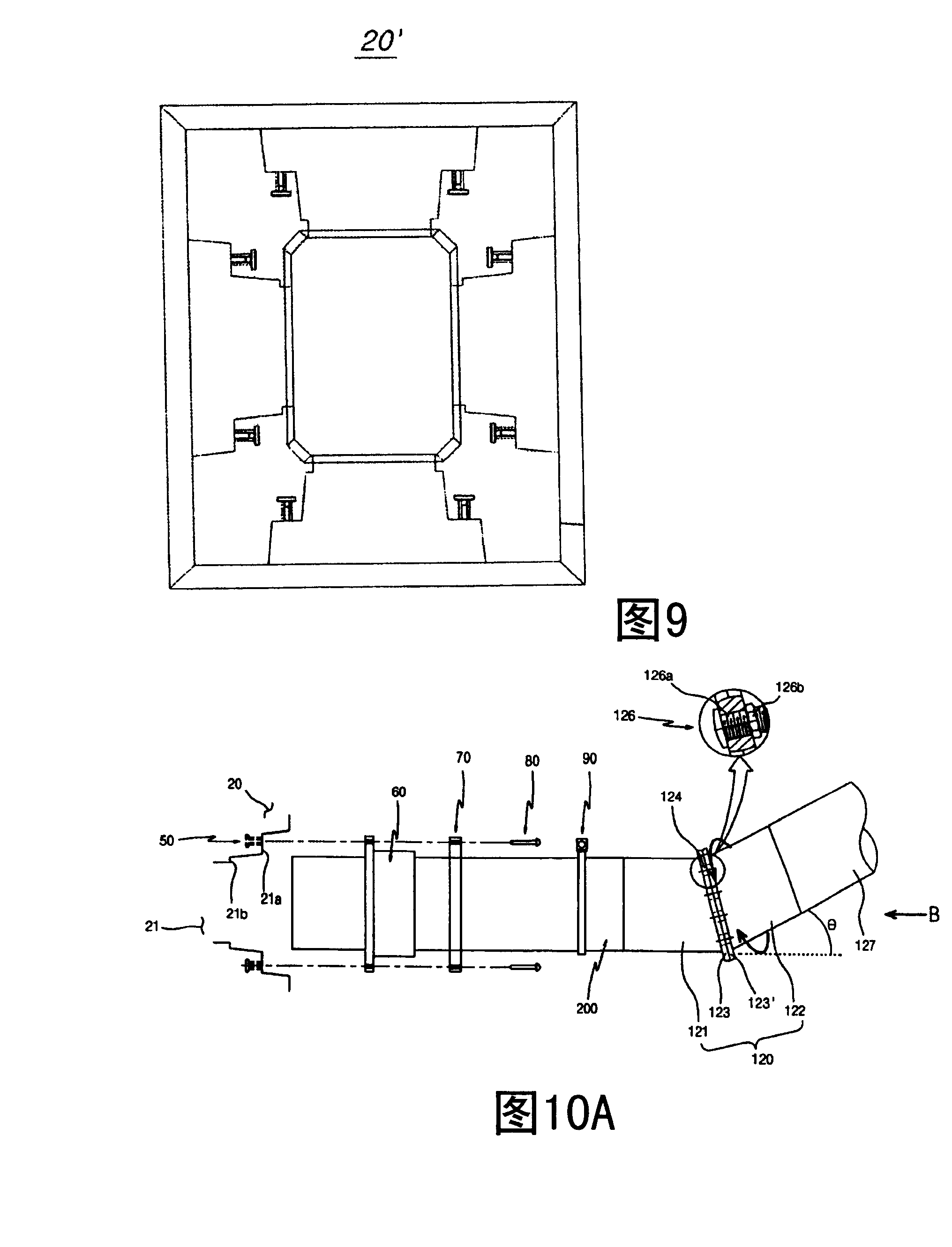

Projector and unit for projector

InactiveUS20110211315A1Improve usabilitySimplify connection workProjectorsElectrical apparatus casings/cabinets/drawersMetalElectrical and Electronics engineering

A projector includes: a mounting unit for mounting optional unit (2) having an extension function section, connection substrate (7), and cable (6) for electrically connecting the extension function section and connection substrate (7); mother substrate (31) having connector (31a) to which terminal (7a) is electrically connected; Z-shaped guide metal fitting (40) located on the mounting unit and configured to movably guide terminal (7a) to connector (31a); and a case having mother substrate (31) located therein. One side face of the case has an opening for inserting / removing optional unit (2) into / from the case, and a side panel for covering the opening being removably located in the opening. When optional unit (2) is inserted into the case from the opening, connection substrate (7) is guided by Z-shaped guide metal filling (40), and optional unit (2) functions when terminal (7a) is electrically connected to connector (31a).

Owner:NEC DISPLAY SOLUTIONS LTD

Multi-coaxial cable assembly and manufacturing method of the same

InactiveUS7696436B2Simplify connection workReduce positioning accuracyElectrically conductive connectionsCoupling device detailsCoaxial cableElectrical conductor

The multi-coaxial cable assembly includes a multi-coaxial cable in which a plurality of coaxial cables having insulators, external conductors, and jackets on an outer periphery of center conductors are arranged in parallel; inclined cross sections formed on the end part of the multi-coaxial cable in such a manner as exposing the center conductors and the external conductors of the coaxial cables; and a wiring board or a connector having a wiring pattern to which the center conductors and the external conductors of the coaxial cables exposed on the inclined cross sections are directly connected.

Owner:HITACHI CABLE

Package and semiconductor device

InactiveCN101364580AReduced luminous efficiencyImprove heat radiation abilitySemiconductor/solid-state device detailsSolid-state devicesNon symmetricEngineering

A package has a base substrate that is a metal plate electrically connected to one electrode of a UV-ray light emitting diode and a cover substrate that is a metal plate electrically connected to the other electrode and that is stacked on the base substrate. A plurality of packages are mounted on a header such that center lines of the base substrates extending in their widthwise directions are aligned to each other. The cover substrates are arranged asymmetrical with respect to the longitudinal center line of the base substrates so as to traverse the center line. When mounted on the header, the packages are arranged such that positions of the cover substrates are staggered with respect to the center line. Moreover, the base substrate of one of the adjacent packages and the cover substrate of the other adjacent package are connected together by a connection plate fastened to the base substrates and the cover substrate by connection screws.

Owner:PANASONIC INDAL DEVICES SUNX

Shield cover, shield case, and circuit board module

InactiveUS8503191B2Reduce the overall heightSimplify connection workMagnetic/electric field screeningCoupling device detailsEngineeringElectronic component

The invention provides a shield cover adapted to cover at least a first electronic component mounted on a first surface of a circuit board. The first electronic component has a metal shell or has a ground / earth terminal on a lateral surface thereof. The shield cover has a contact portion being elastically contactable with a lateral surface of the metal shell or the ground / earth terminal of the first electronic component.

Owner:HOSIDEN CORP

Wire harness

ActiveUS10741978B2Improve wiring efficiencySimplify workCoupling contact membersCouplings bases/casesElectrical conductorElectrical connection

Owner:YAZAKI CORP

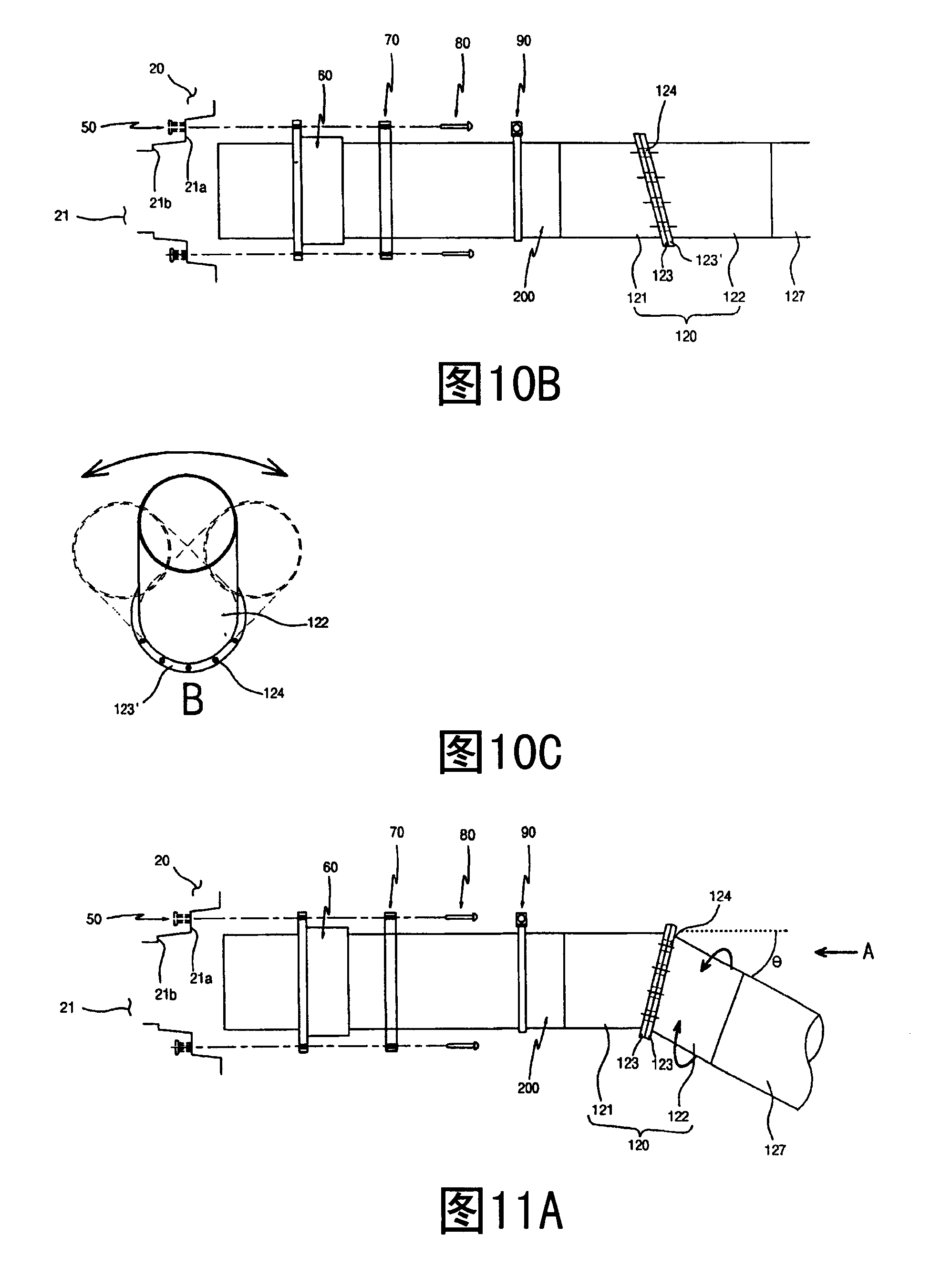

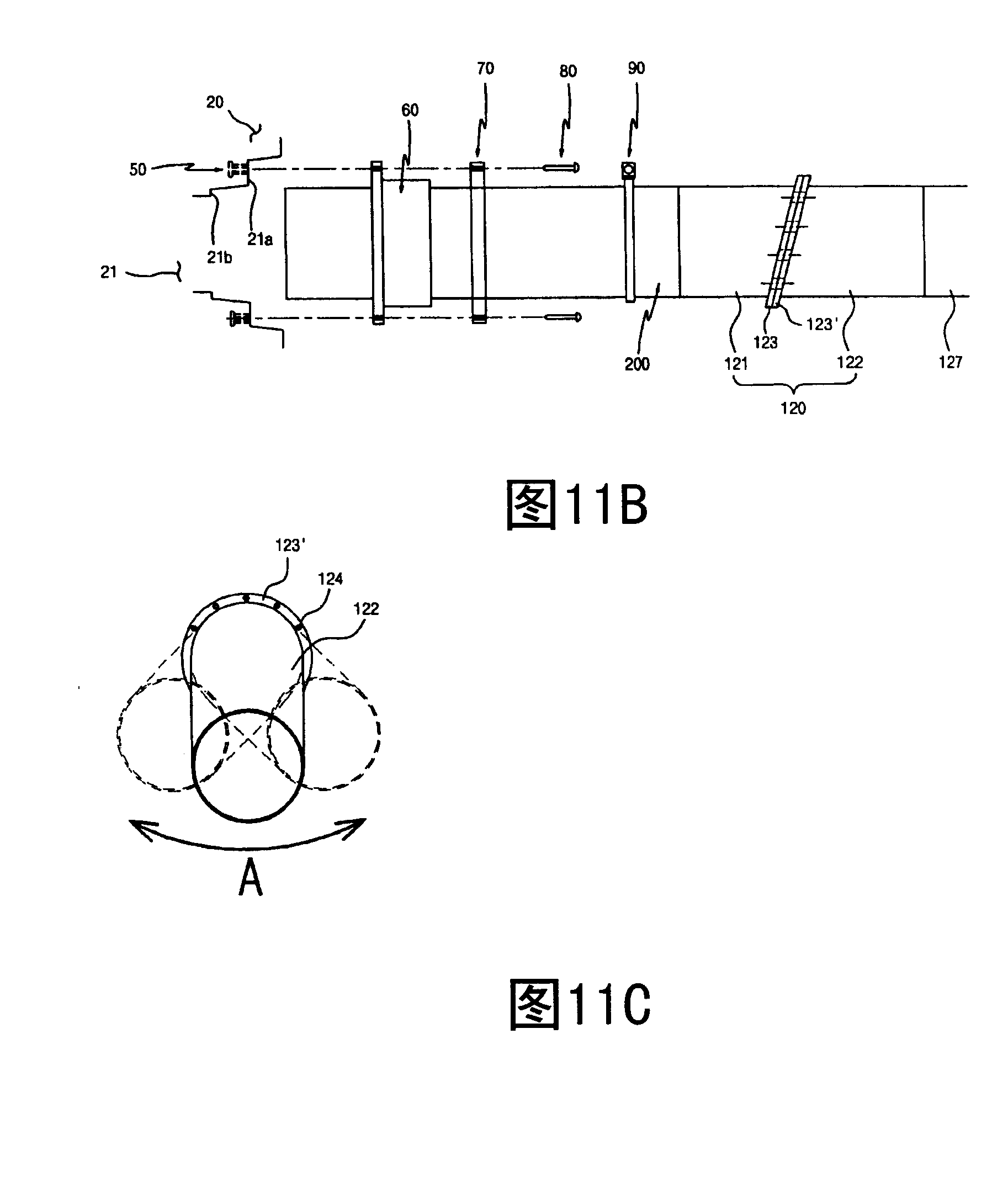

Pipeline direction changeable combine structure for manhole with pipe

InactiveCN101225915ASimplify connection workLow costSewerage structuresSewer pipelinesCouplingOperability

The invention provides a direction changeable manhole-pipe coupling structure, with high durability to bear the external force and increased operability, to prevent the pipe from moving and leaking. The direction changeable manhole-pipe coupling structure comprises a pipe, a pipeline connection opening; a fixing device under the ladder portion; a rubber pad with a connection part; a connecting device; and a flange portion composed of a left flange connected to the pipe and provided with an incline plane inclined downward in the longitudinal direction, a right flange and a coupling part.

Owner:赵周晔

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com