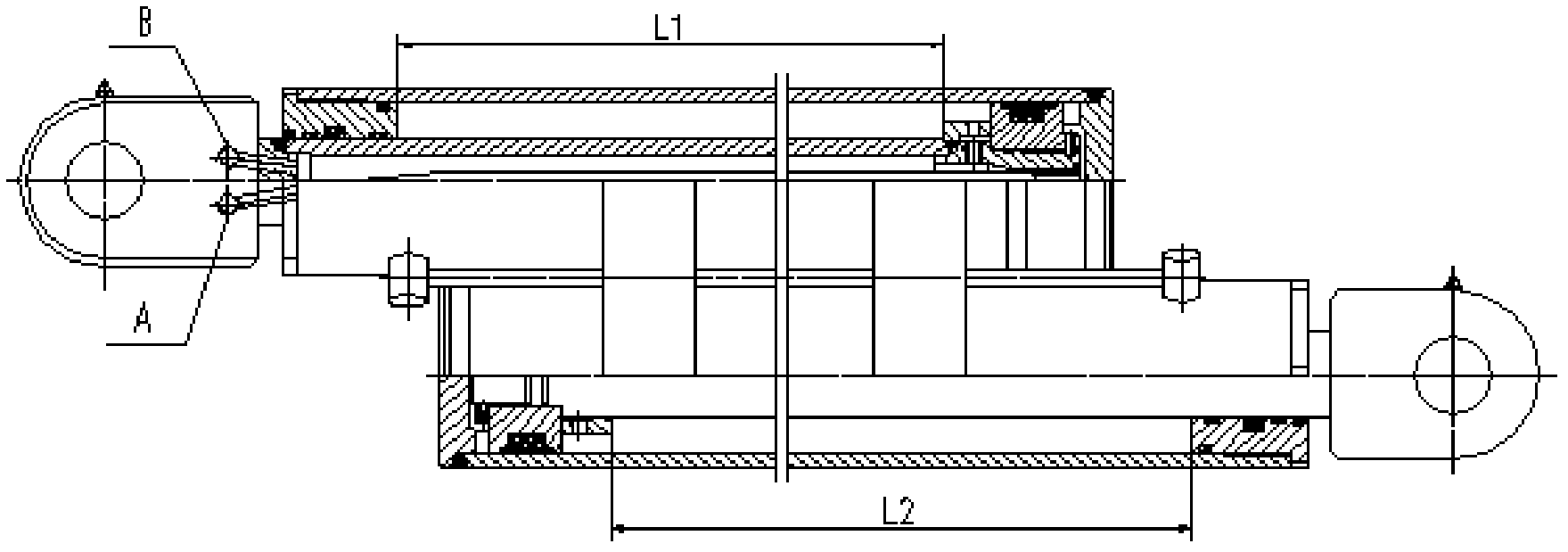

Travel valve, sequential action type combination hydraulic cylinder and hydraulic equipment

A sequential action, hydraulic cylinder technology, applied in the field of hydraulic valves and hydraulic cylinders, can solve the problems of not being able to bear multiple loads at the same time, hydraulic cylinders unable to achieve sequential control, and unable to meet complex mechanisms.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

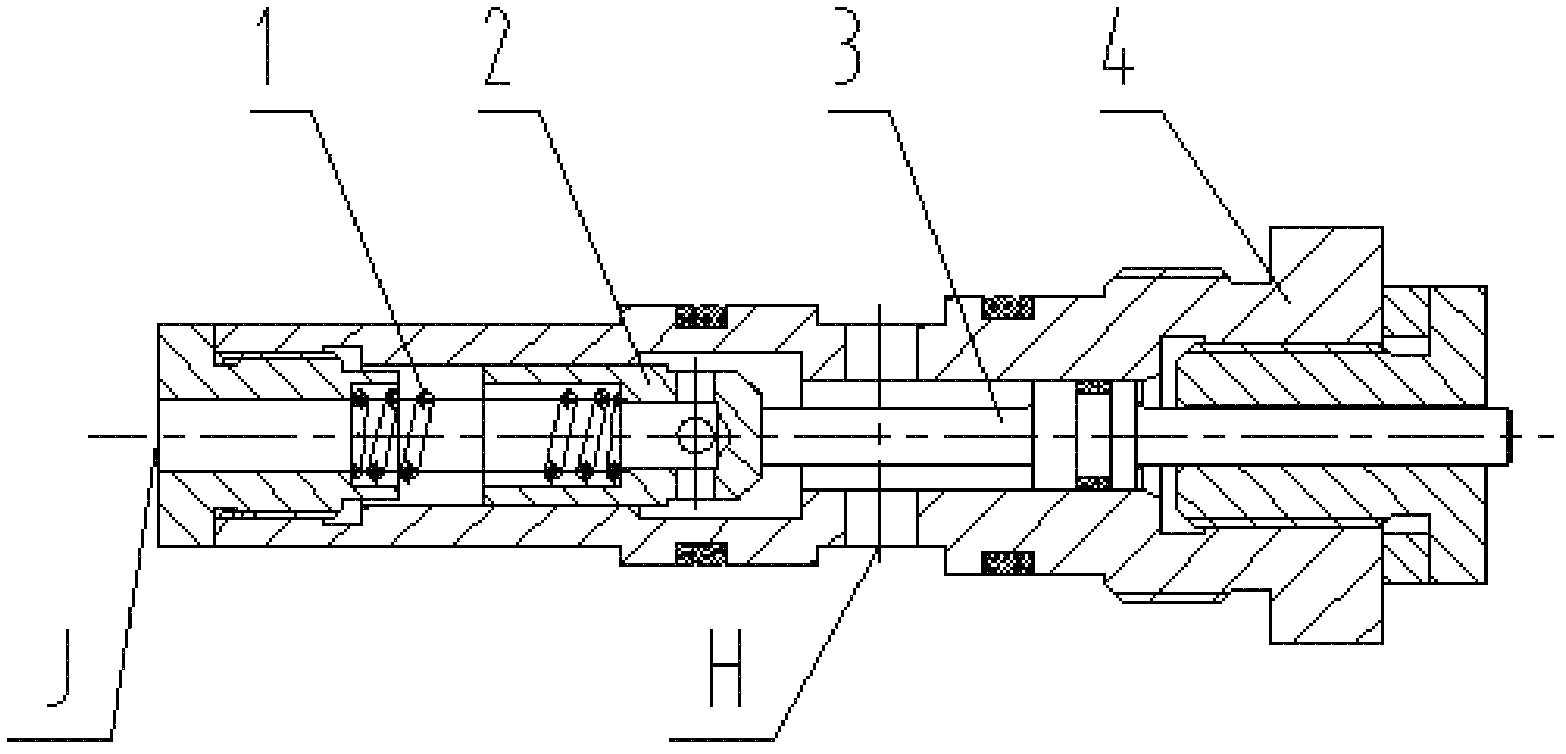

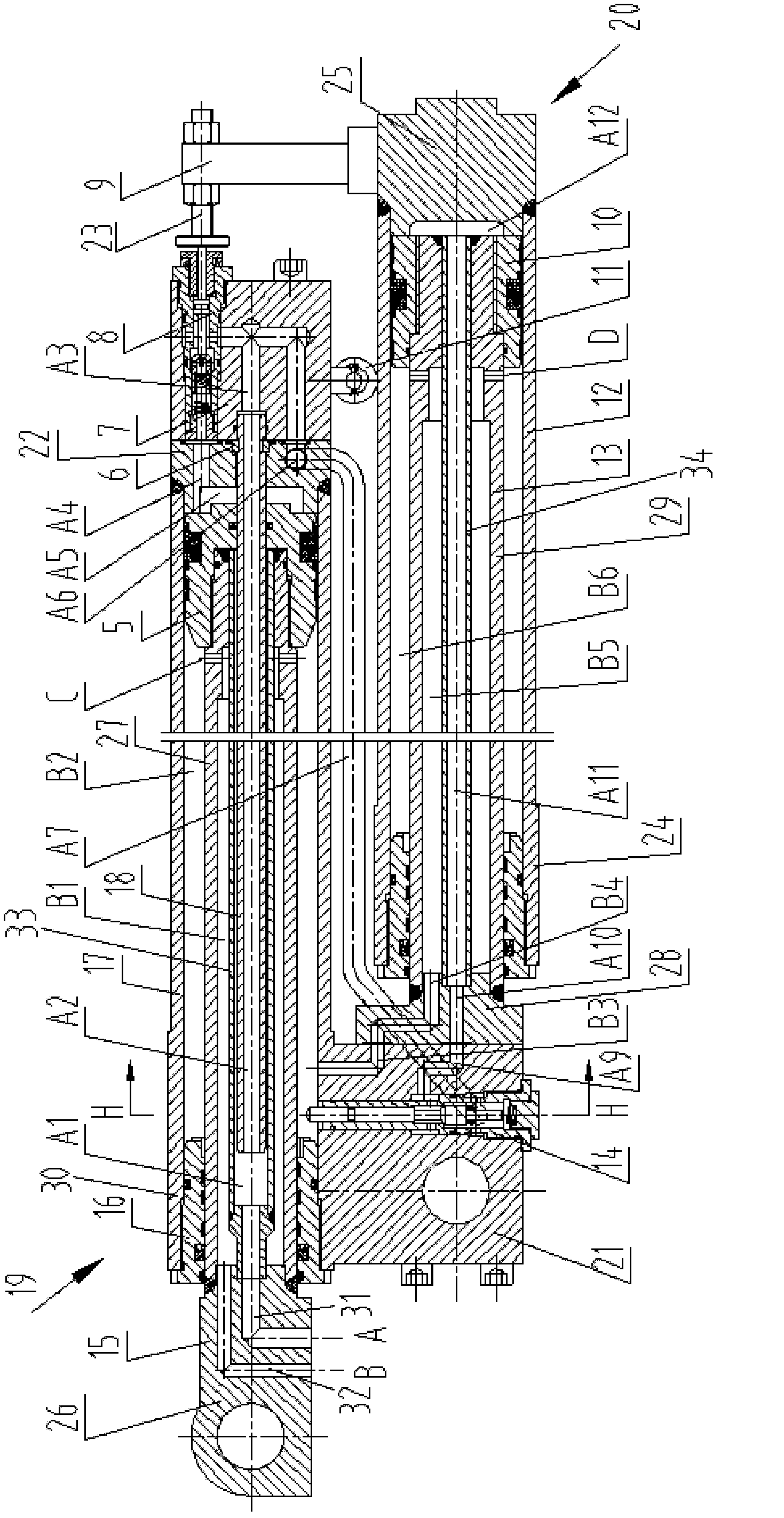

[0062] The specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. It should be understood that the specific embodiments described here are only used to illustrate and explain the present invention, and the protection scope of the present invention is not limited to the following specific embodiments. .

[0063] First of all, it needs to be explained that in the following description, the "head" of the piston rod refers to the part of the piston rod of the hydraulic cylinder that is exposed outside the cylinder in the retracted state under normal circumstances, while the "cylinder head" It refers to the part relatively close to the head of the piston rod when the piston rod is retracted, the "tail of cylinder body" refers to the part of the cylinder body opposite to the "head of cylinder body", and the outer end of the piston refers to the opposite The part close to the "cylinder head", the inner end of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com