Glass melting furnace liquid level height measuring and controlling method based on machine vision

A liquid level height, glass melting furnace technology, applied in liquid level control, non-electric variable control, liquid/fluid solid measurement, etc., can solve problems such as no measurement algorithm given, no description of automatic control of glass liquid level, etc. Achieve precise measurement and control, high precision effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

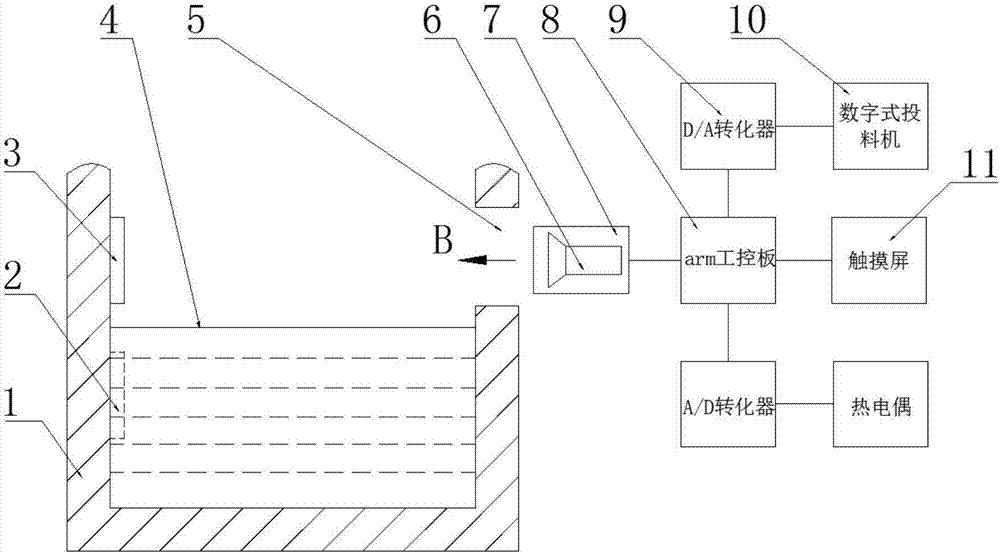

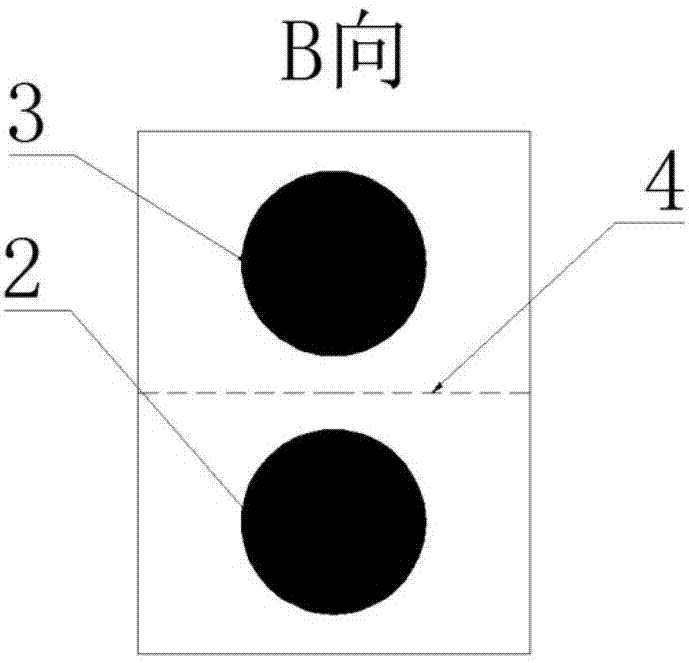

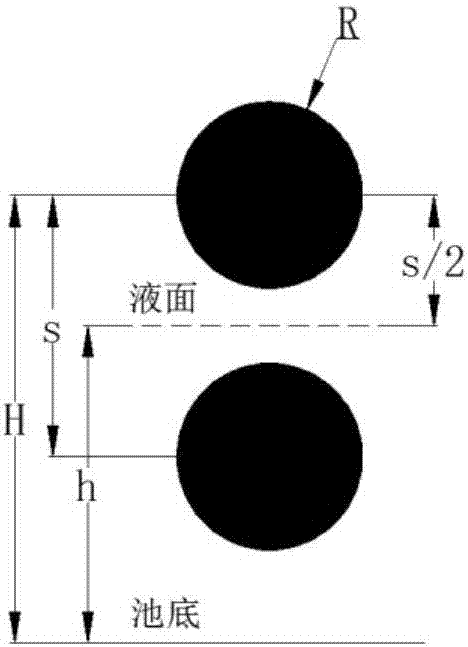

[0034] Such as figure 1 In the embodiment shown, the liquid level measurement and control system of a glass melting furnace includes: a black circular marker brick 3 , a digital camera 6 , an arm industrial control board 8 , a D / A converter 9 , a digital feeder 10 , and a touch screen 11 . The black circular marker is installed on the pool wall of the parapet 1, and a peephole 5 is opened on the opposite side of the pool wall. The digital camera 6 is installed in the camera cooling water jacket 7, and the cooling water jacket is fixed outside the peephole 5. At about 0.5m, the digital camera 6 is connected to the arm industrial control board 8 through the usb interface, and the arm industrial control board 8 is connected to the digital feeder 10 through the D / A converter 9 and connected to the touch screen 11 through the I2C bus.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com