Sonoelastic coefficient calibration device for detecting residual stress of explosive through ultrasonic detection method

A technology of residual stress and ultrasonic testing, which is applied in the direction of measuring devices, force/torque/work measuring instruments, force/torque/work measuring instrument calibration/testing, etc., to prevent energy attenuation and facilitate fixation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to enable those skilled in the art to better understand the solutions of the present invention, the technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the drawings in the embodiments of the present invention.

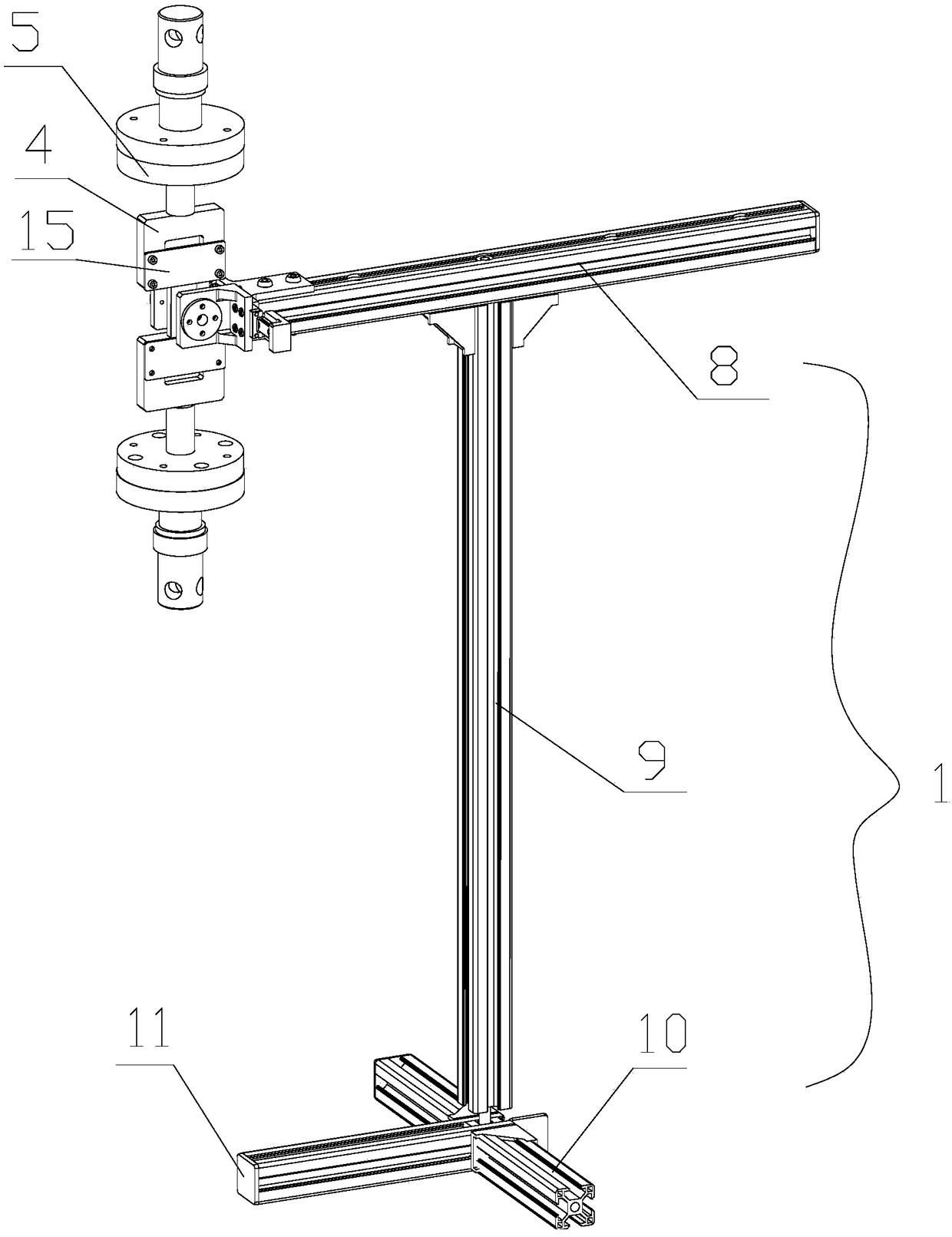

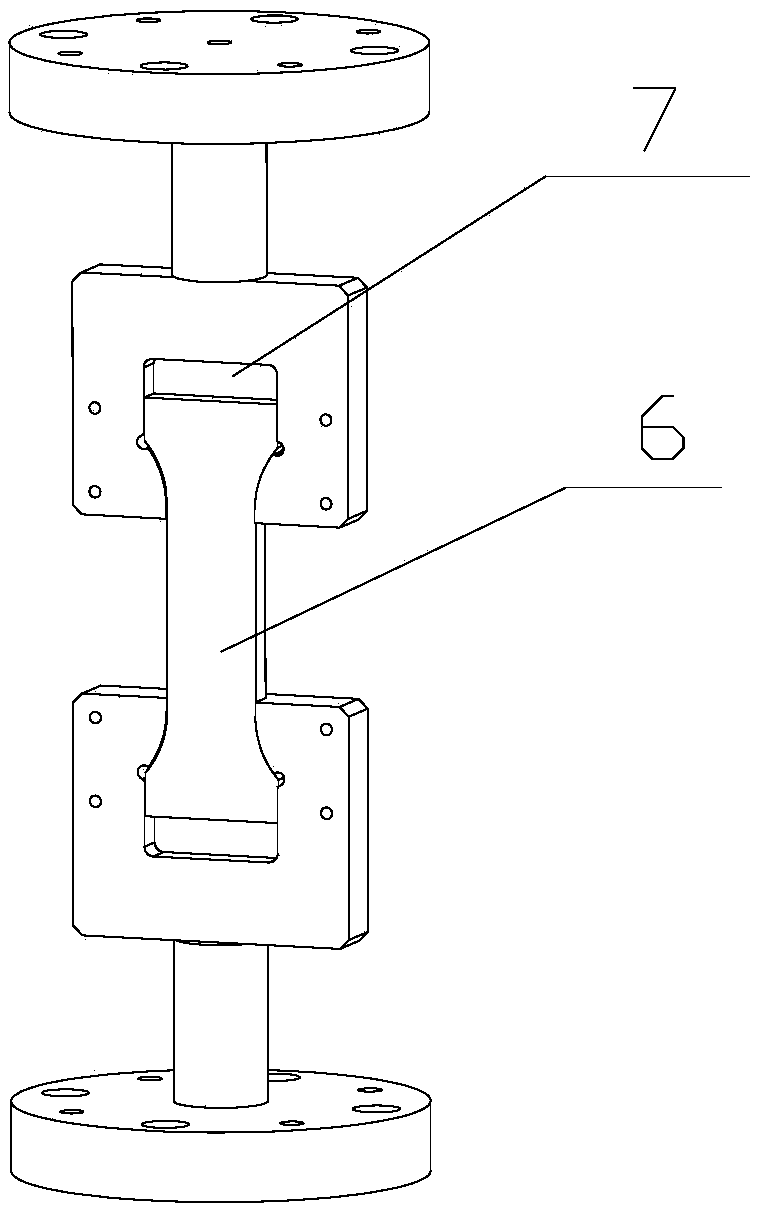

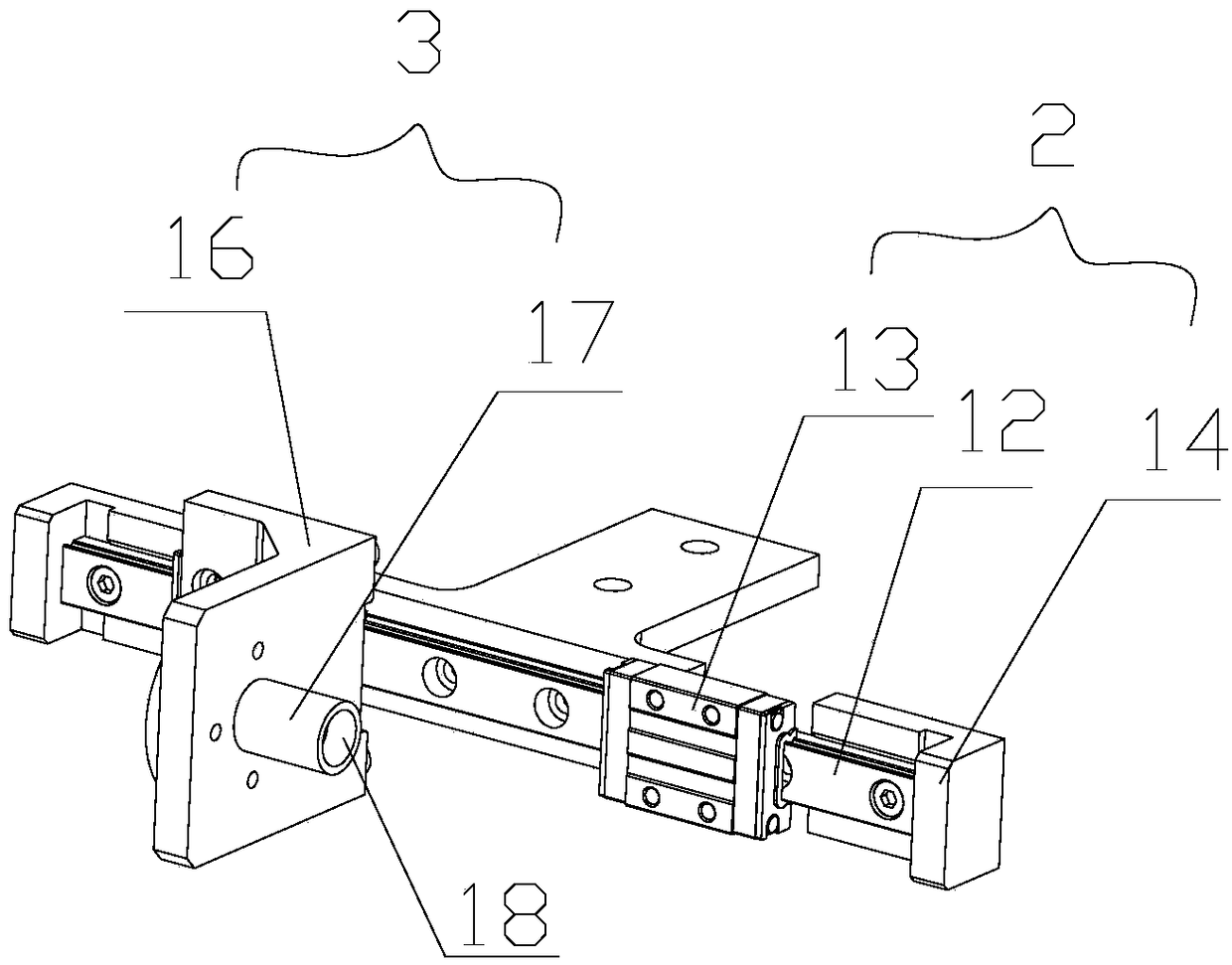

[0034] As shown in the figure, an acoustoelastic coefficient calibration device for explosive residual stress ultrasonic detection method includes a digital material testing machine and an ultrasonic stress instrument; There is a fixed groove 7 for the explosive sample 6 to snap in, the shape of the fixed groove 7 matches the shape of the explosive sample 6, the explosive jaw 4 is provided with a cover plate 15, and the tensile machine clamp 5 is connected with the tensile machine; ultrasonic stress The instrument includes a frame 1, on which a slide rail device 2 is installed, and an ultrasonic detection device 3 is fixed on the slide rail device 2; the ultrasonic detection d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com