Full-automatic adjustable paper box impressing devices

A fully automatic, crimping device technology, applied in packaging, papermaking, transportation and packaging, etc., can solve the problems of uncontrollable indentation depth, poor adjustability, and small application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

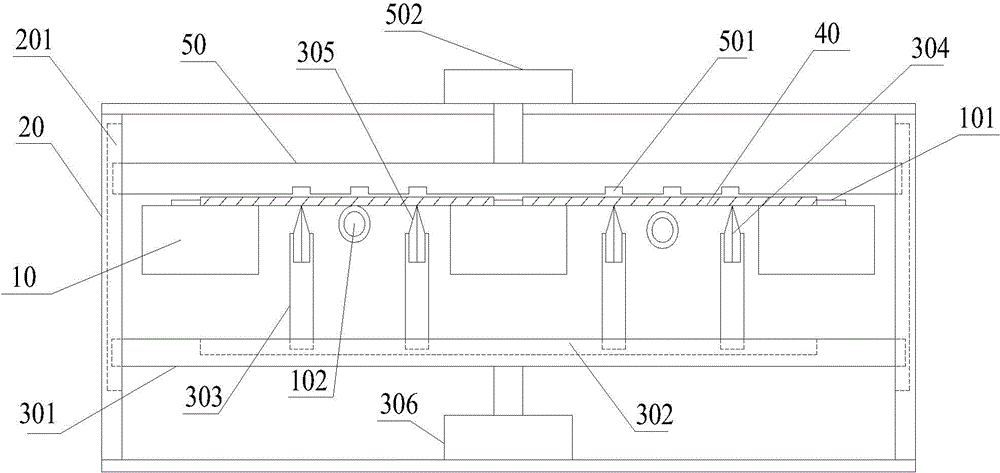

[0017] refer to figure 1 , figure 2 , the present invention proposes a fully automatic adjustable carton indentation device, comprising a conveying belt set, a frame 20 positioned on both sides of the conveying belt set, a crimping mechanism, a crimping plate 50, a controller, and a distance measuring sensor, wherein:

[0018] The conveyor belt set includes at least two conveyor belts 10 that are arranged side by side and rotate in the same direction to drive the carton cardboard 40 to move. There is a gap between the conveyor belts 10, and a support roller 102 for supporting the carton 40 is provided in the gap to prevent the carton from The cardboard is tilted during creasing; the conveyor belt 10 is provided with a stopper 101 to prevent the carton cardboard 40 from running off.

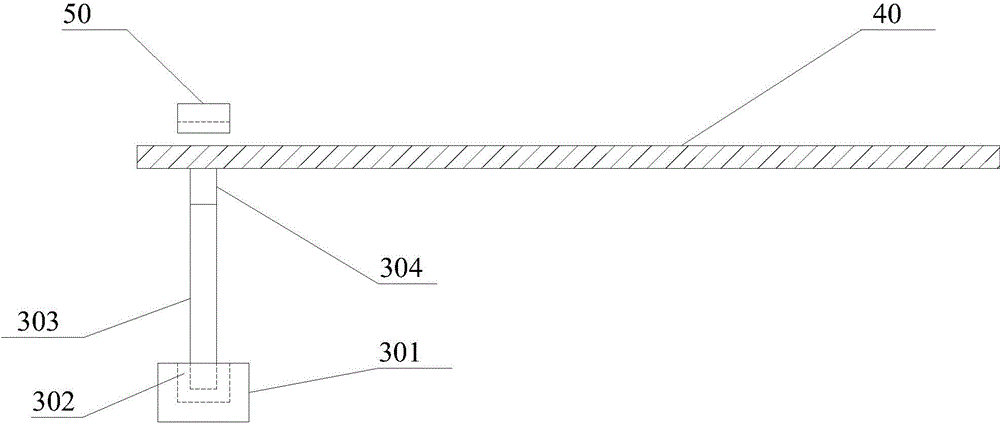

[0019] The crimping mechanism includes a mounting frame 301 and at least two crimping devices installed on the mounting frame 301. The two ends of the mounting frame 301 are installed on the fra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com