Tool for measuring height of tooth edge

A tool and high-level technology, applied in the field of measurement, can solve the problems of long measurement time, cumbersome operation, self-explosion of the windshield, etc., and achieve the effect of convenient and fast measurement, low measurement cost and good measurement effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] The present invention will be described in further detail below in conjunction with the accompanying drawings.

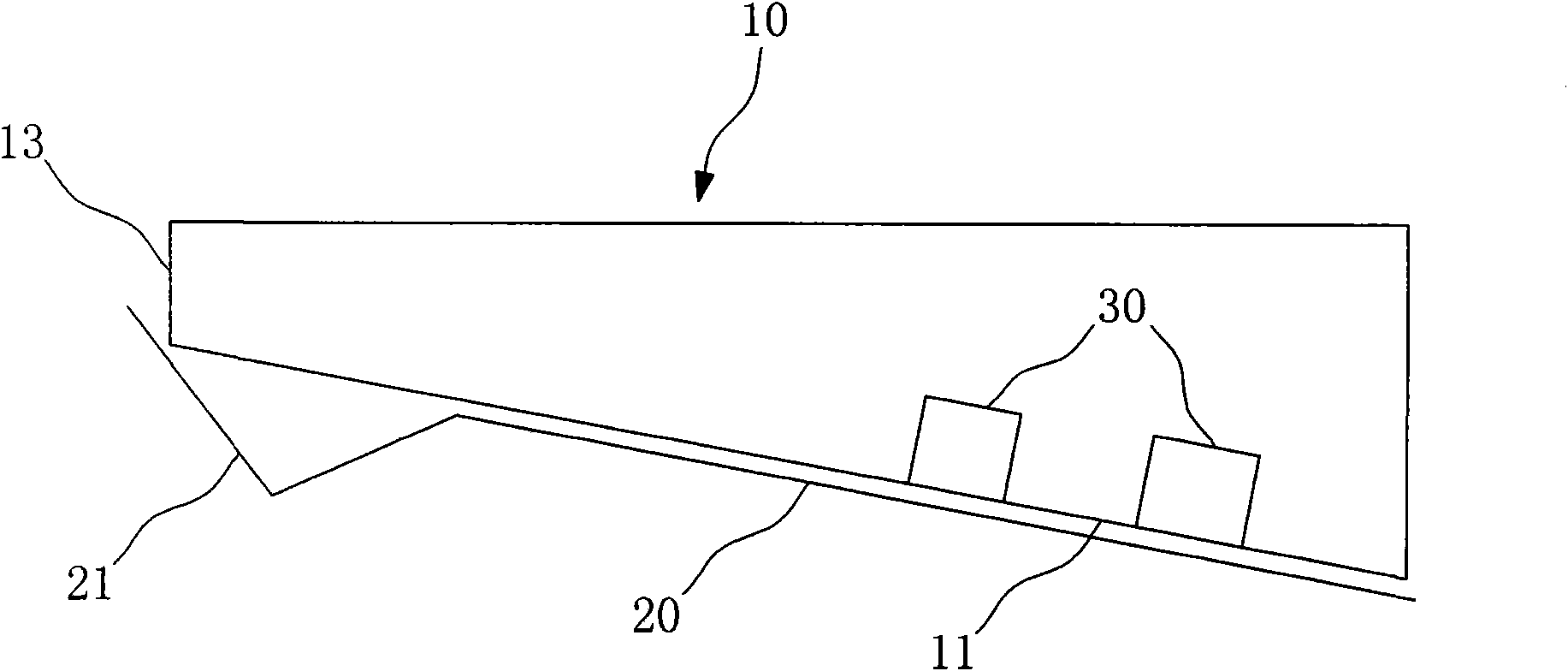

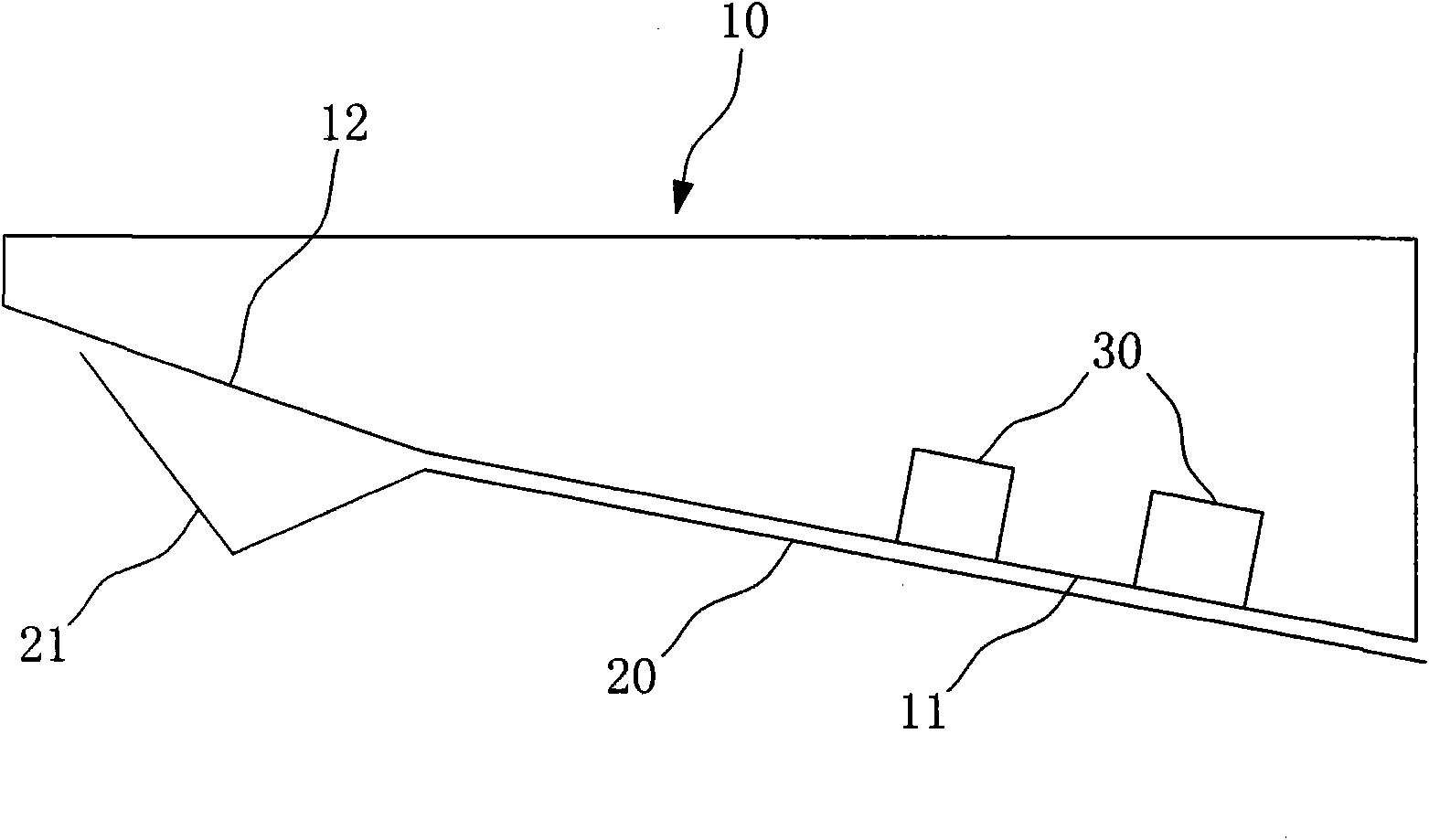

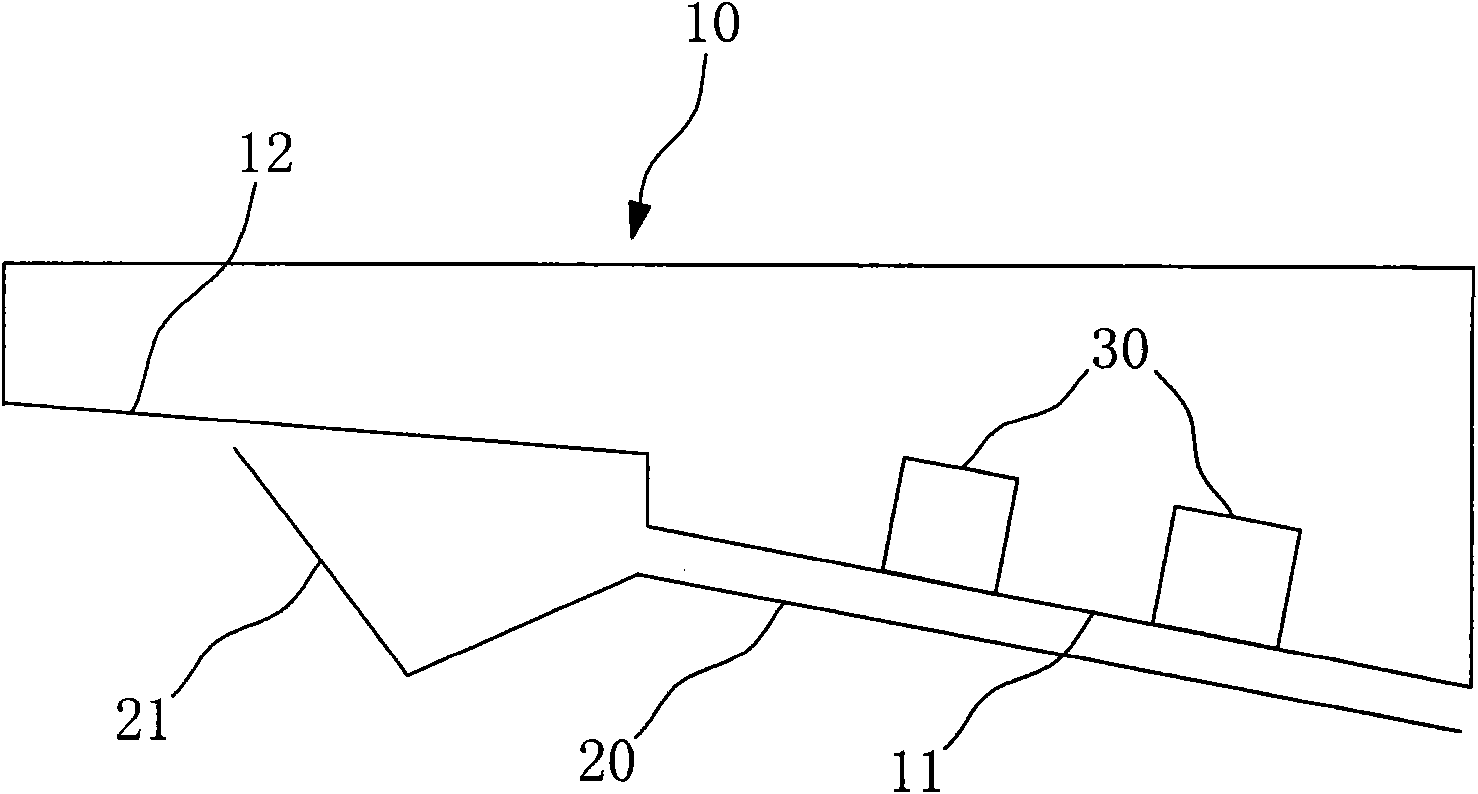

[0009] Such as Figure 1~5 As shown, the tool 10 is provided with a positioning reference plane 11, and the slope of the positioning reference plane 11 coincides with the slope of the plane 20 of the sheet metal where the tooth edge 21 is located.

[0010] As a preferred version of the present invention, such as figure 1 As shown, the tool 10 is provided with an end surface 13 on the side of the positioning reference surface 11 facing the windshield, and the end surface 13 is provided with a scale line for measuring the height of the tooth edge 21 .

[0011] The end face 13 can be an inclined plane or a vertical plane. When the scale line is set on the end face 13, if the installation height of the windshield glass is marked at the same time, then when the end face 13 is close to the sheet metal edge 21, not only the topmost distance between the end face 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com