Gloss oil spraying device for spare parts of automobiles

A technology for auto parts and spraying devices, applied in spraying devices, spray booths, etc., can solve the problems of varnish waste, adhesion in the box, varnish scattering, etc., and achieve the effect of preventing clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in further detail below by means of specific embodiments:

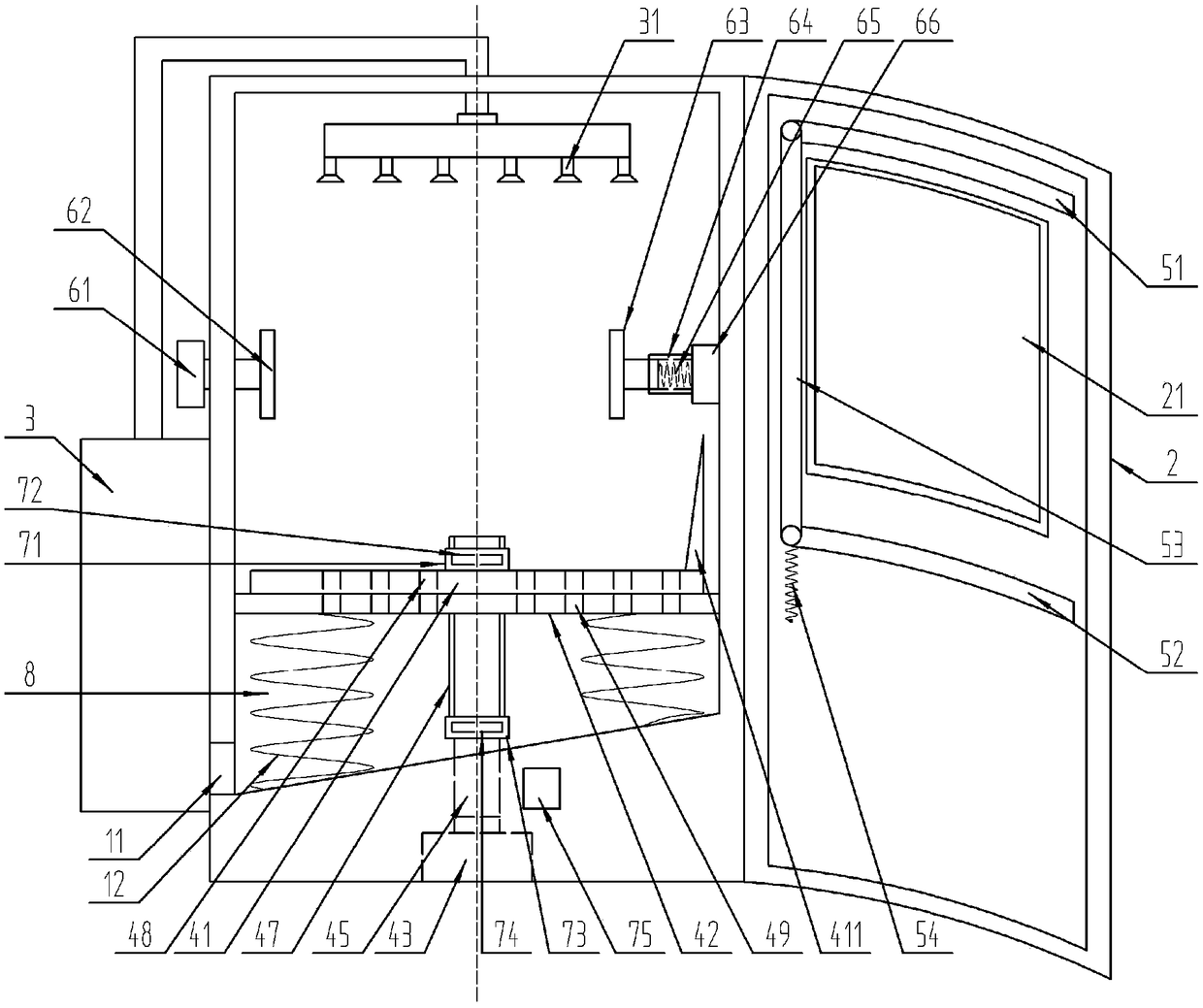

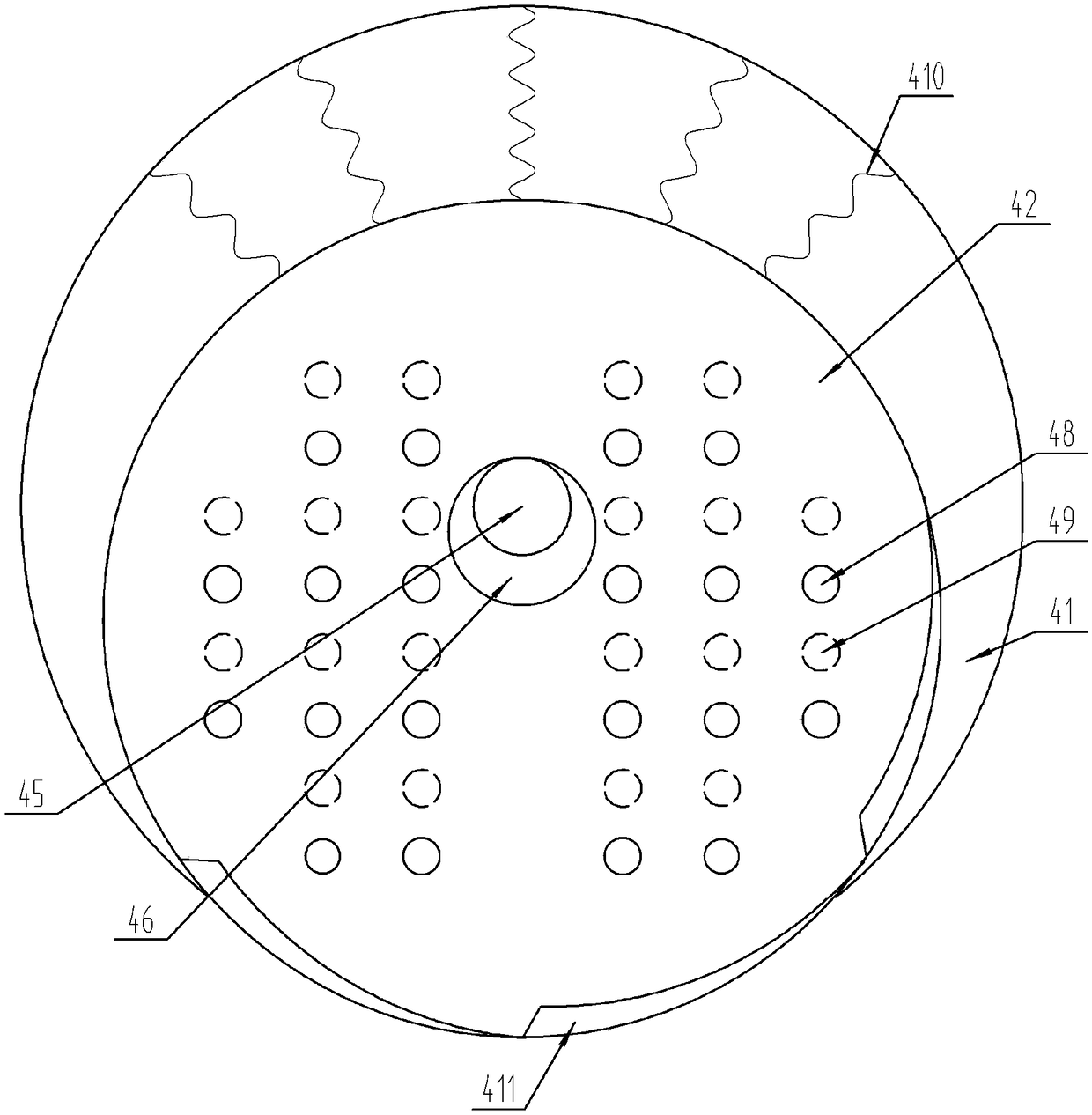

[0026] The reference signs in the accompanying drawings of the description include: recovery port 11, support compression spring 12, opening and closing door 2, observation window 21, coating mechanism 3, spray head 31, first rotating plate 41, second rotating plate 42, first motor 43. Vertical shaft 45, first rotating hole 46, protrusion 47, first leakage hole 48, second leakage hole 49, first compression spring 410, scraper 411, first chute 51, second chute 52, Scraper rod 53, extension spring 54, second motor 61, first clamping seat 62, second clamping seat 63, threaded seat 64, second compression spring 65, rotating member 66, sliding sleeve 71, iron suction 72, fixed Cover 73, electromagnet 74, switch 75, varnish recovery cavity 8.

[0027] Such as figure 1 and figure 2 As shown, the varnish spraying device for auto parts includes a box body and a paint mechanism...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com