Stamping device

A punching equipment and punching technology, applied in the field of punching equipment, can solve the problems of low punching efficiency, unfavorable plate processing, and time-consuming, etc., and achieve the effect of high processing efficiency and reduction of punching time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] A detailed description will be given below of specific embodiments of the present invention according to the accompanying drawings.

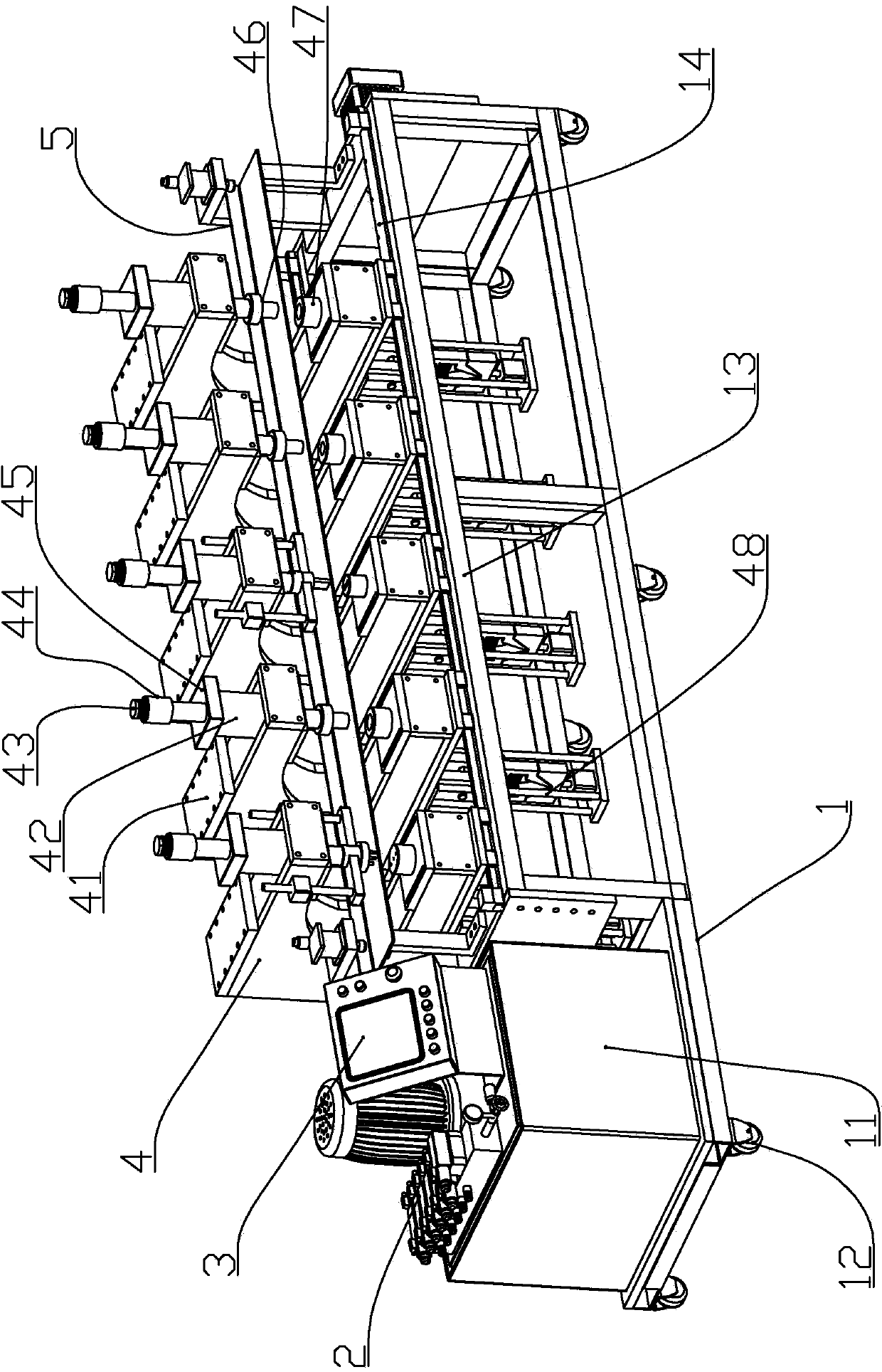

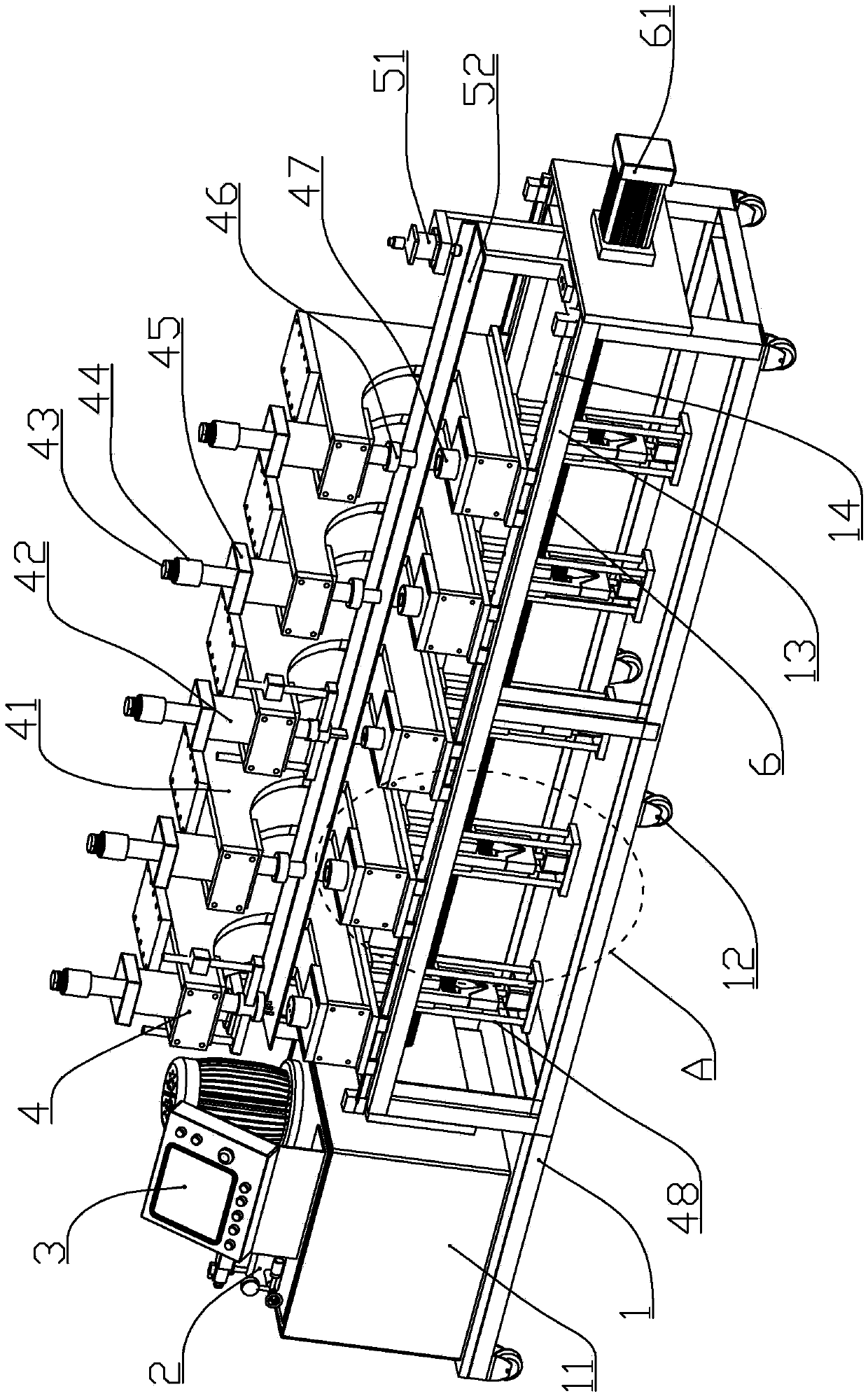

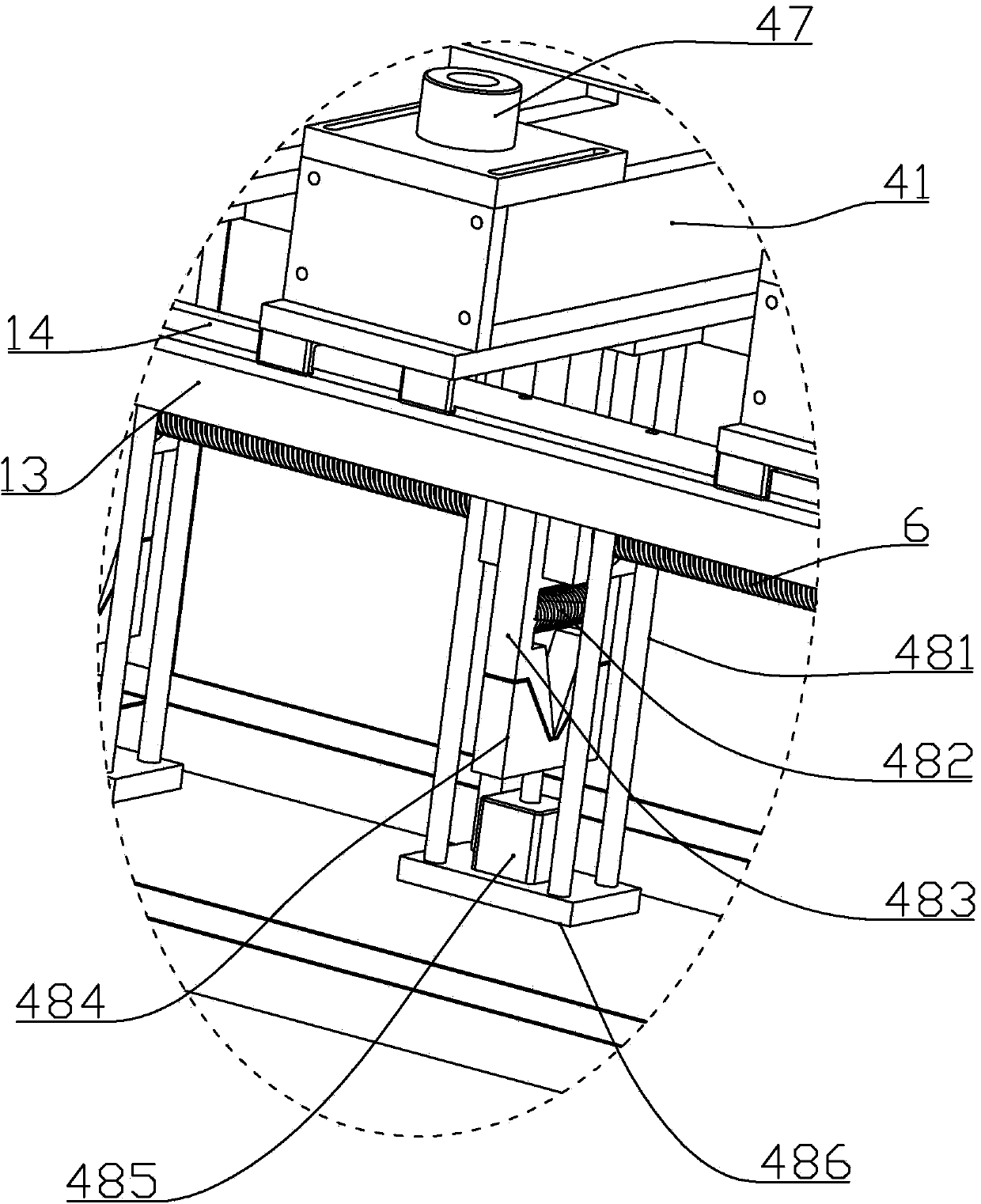

[0017] according to Figure 1 to Figure 5 As shown, a kind of stamping equipment described in this embodiment includes a chassis 1, a punch bracket 13 welded on the bottom chassis, two parallel guide rails 14 arranged along the length direction above the punch bracket, and A plurality of punch presses 4 installed above the guide rail; the punch press includes a C-shaped punch frame 41 as a whole, a double-piston rod hydraulic cylinder 42 vertically installed on the upper part of the punch frame, fixedly mounted on the hydraulic cylinder piston The upper mold 46 at the lower end of the rod, and the lower mold 47 fixedly installed on the lower part of the punch frame and matched with the upper mold; the upper end of the piston rod of the hydraulic cylinder is threadedly connected with an adjusting nut 44, and the upper part of the hydraulic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com