Patents

Literature

40results about How to "Save punching time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

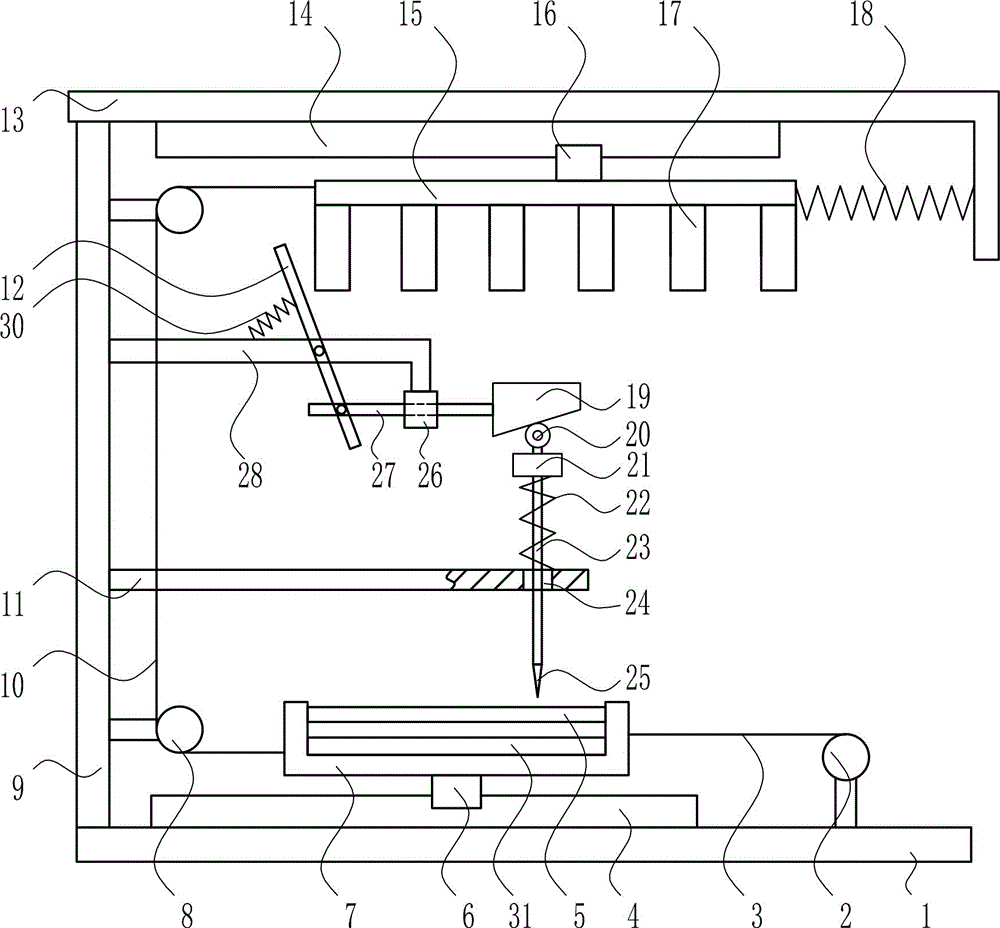

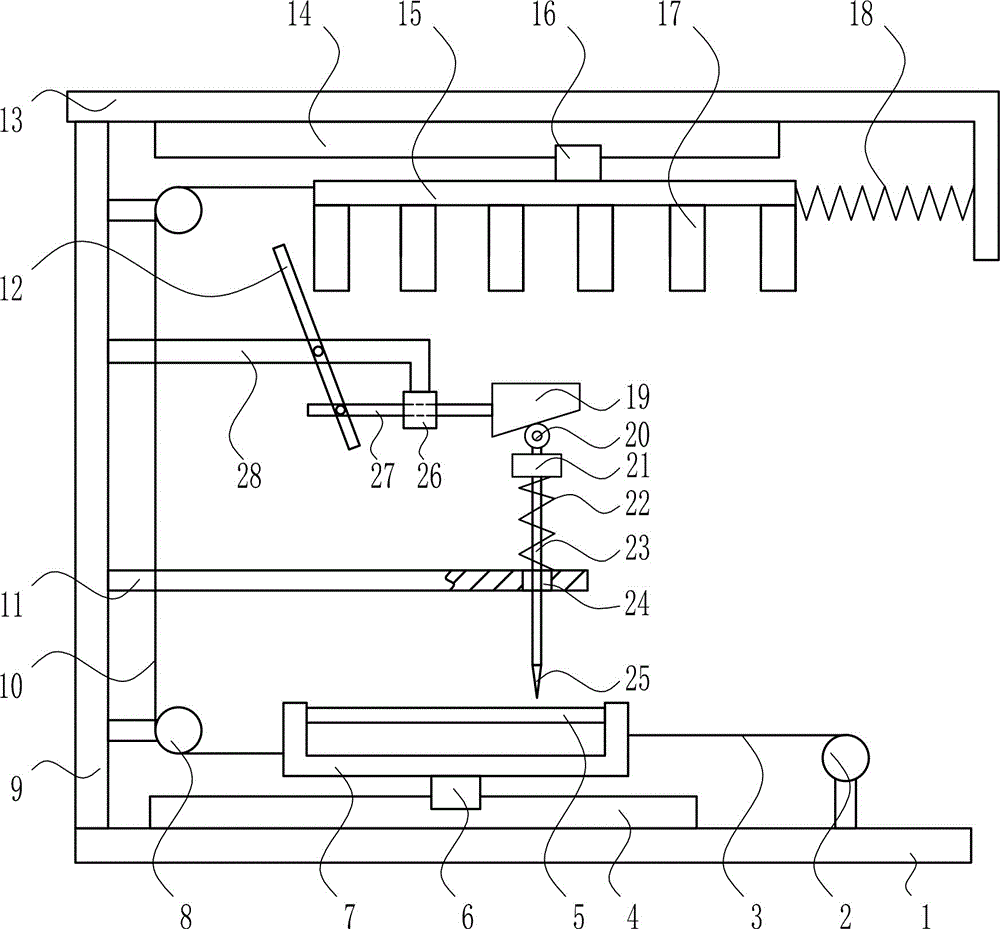

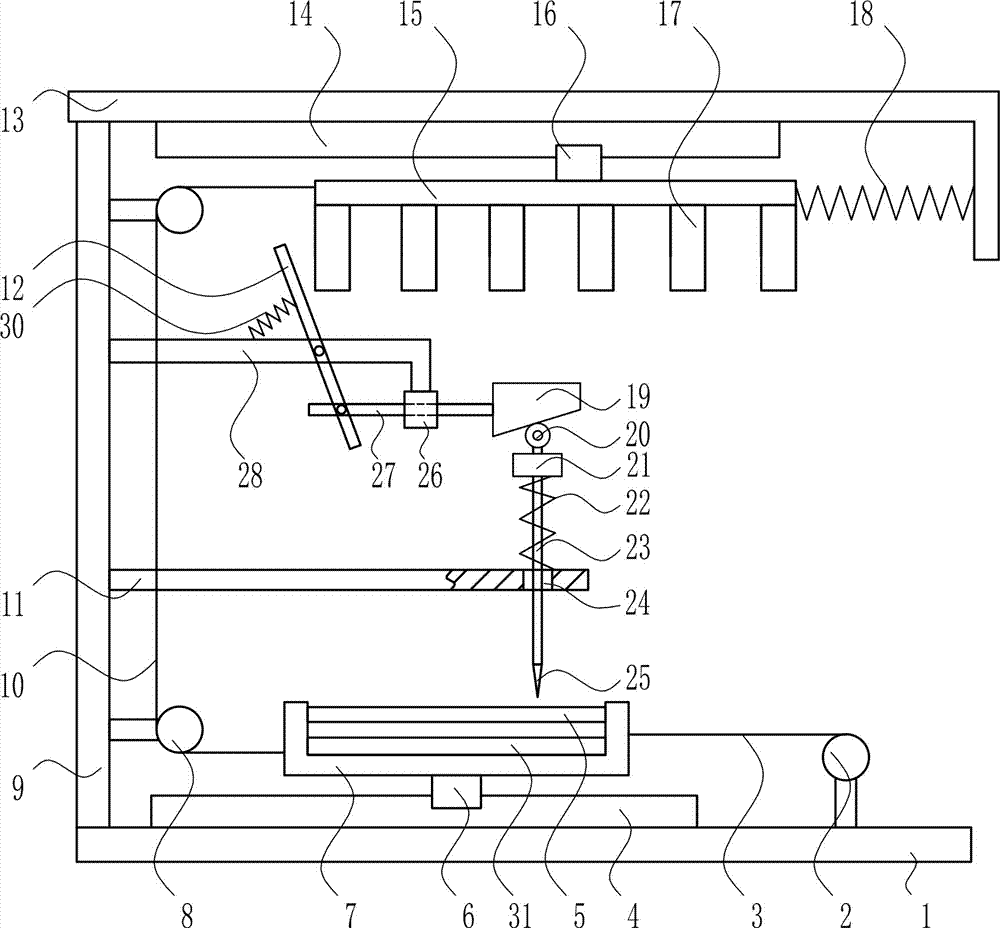

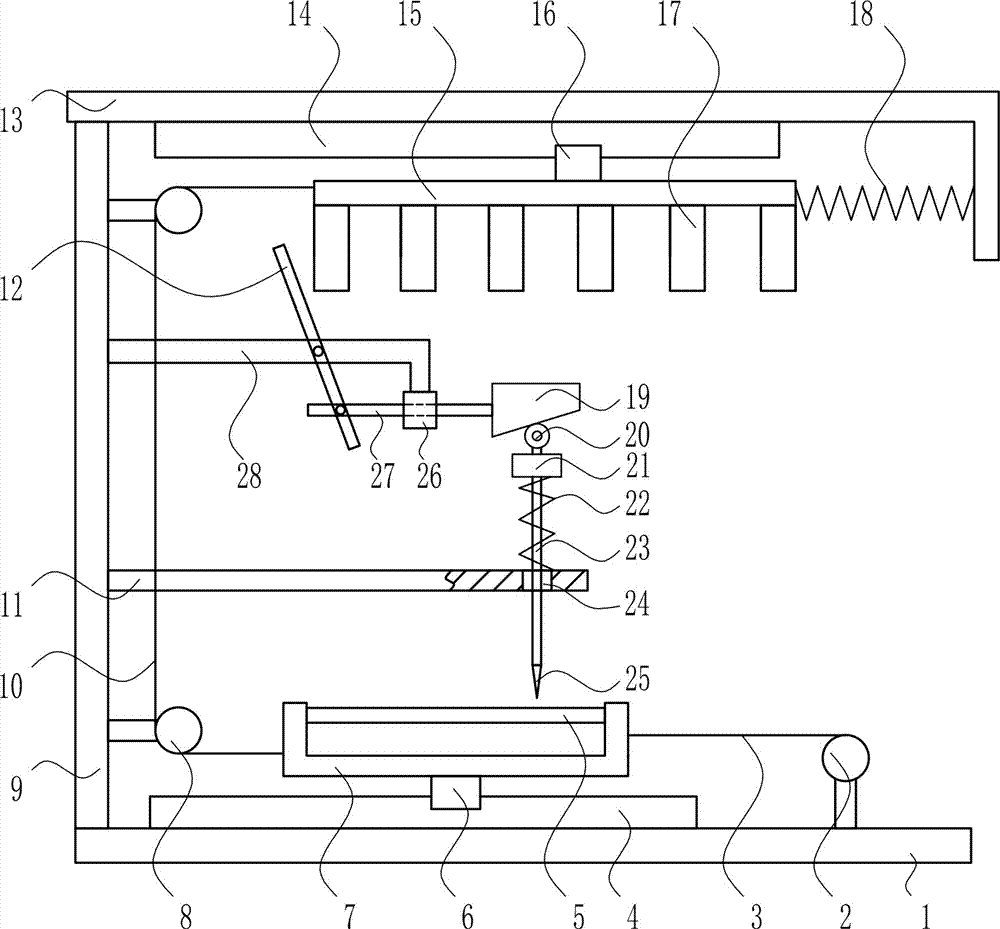

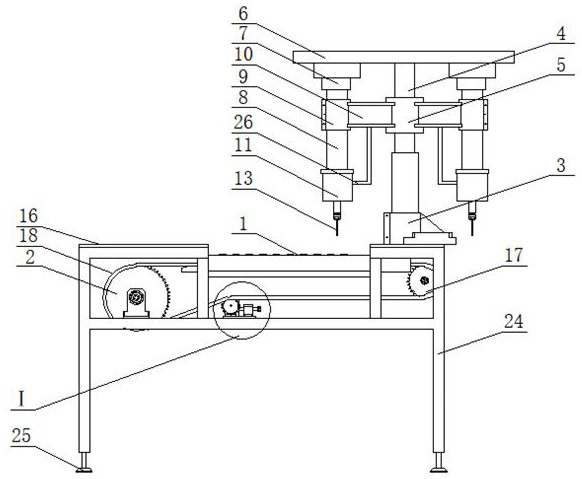

Paper perforating device for accounting teaching

InactiveCN106217477AQuick resetSave time at workMetal working apparatusPulp and paper industryMaterial Perforation

The invention relates to a paper perforating device, in particular to a paper perforating device for an accounting teaching and aims at solving the technical problems to provide the paper perforating device for the accounting teaching with small amount of labor, high working efficiency and no liability in damaging paper. For solving the technical problems, the invention provides the paper perforating device for the accounting teaching. The paper perforating device for the accounting teaching comprises a bottom plate, an electric wire winding wheel, a first stay wire, a pressure plate, a wood collection frame, a guide wheel, a left bracket, guide plates, an oscillating rod, a top plate, a first slide rail, a mobile frame, a first sliding block, pressure rods, a first spring, a wedge-shaped block, a contact rolling wheel, a stop dog, a lifting rod, a perforating drill, a sliding sleeve, a mobile rod, a connecting frame and the like; and the top of the bottom plate is sequentially provided with the left bracket from left to right. According to the paper perforating device for the accounting teaching, the effects of small amount of labor, high working efficiency and no liability in damaging paper are reached; and as the perforating drill can carry out rapid perforation on the paper, the perforating time can be reduced, the working efficiency can be improved, and the treating time can be increased.

Owner:JILIN INST OF CHEM TECH

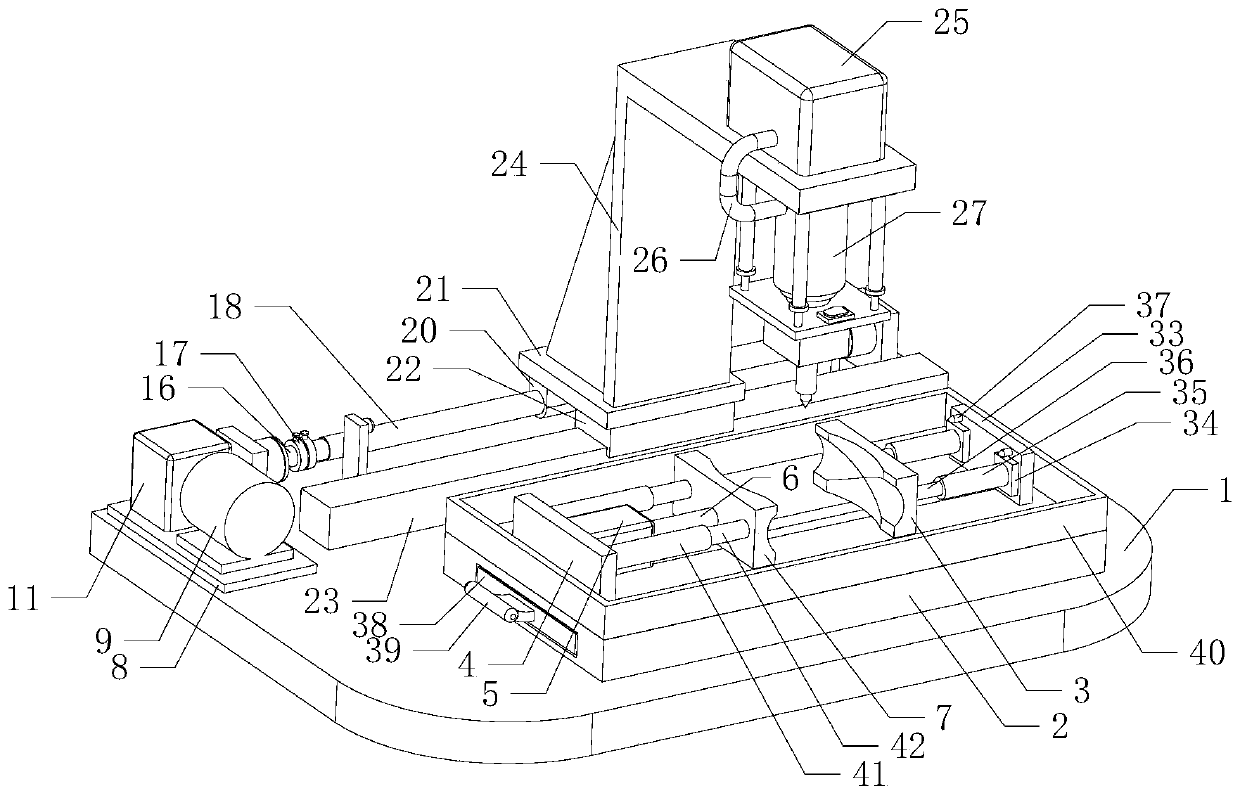

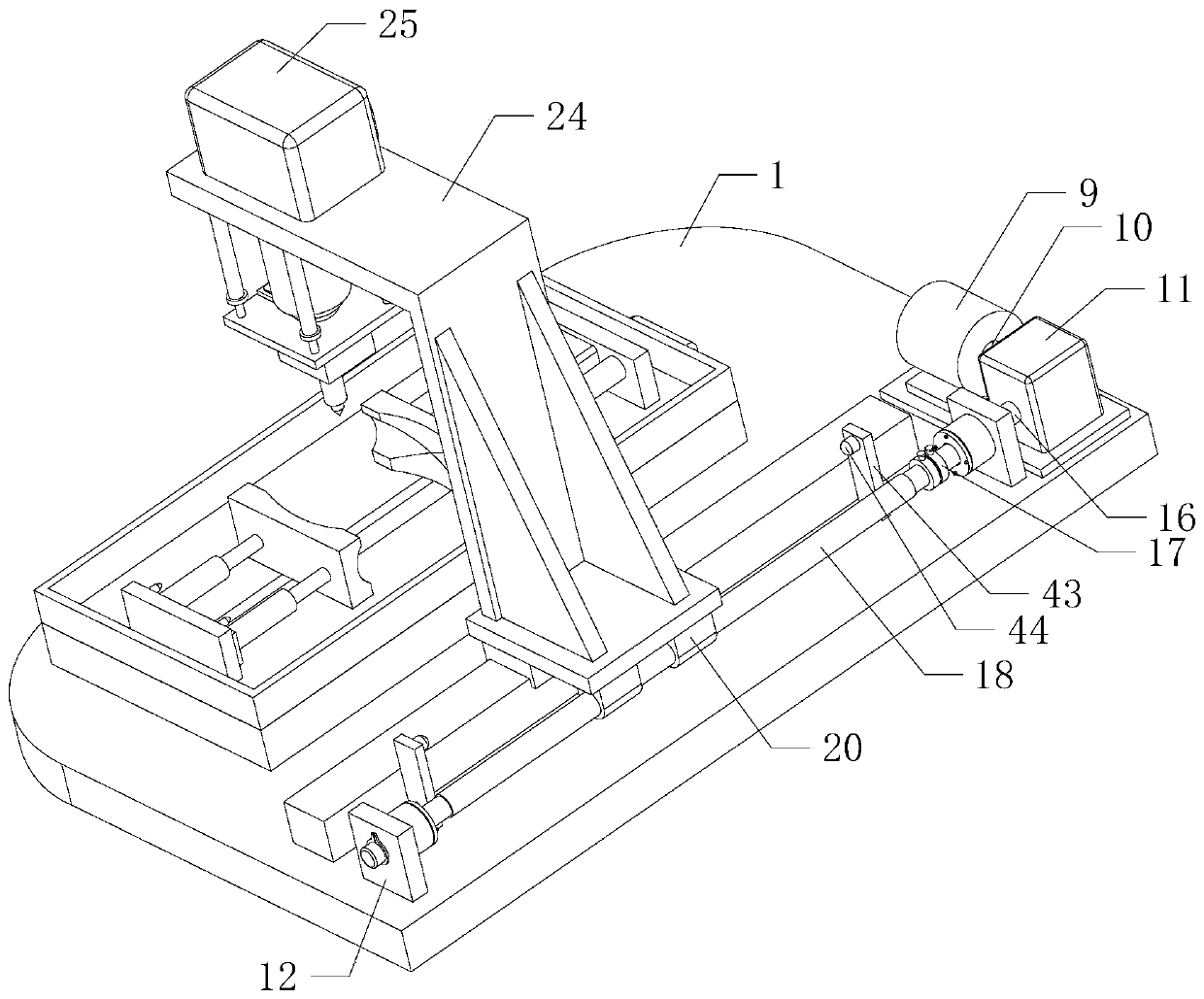

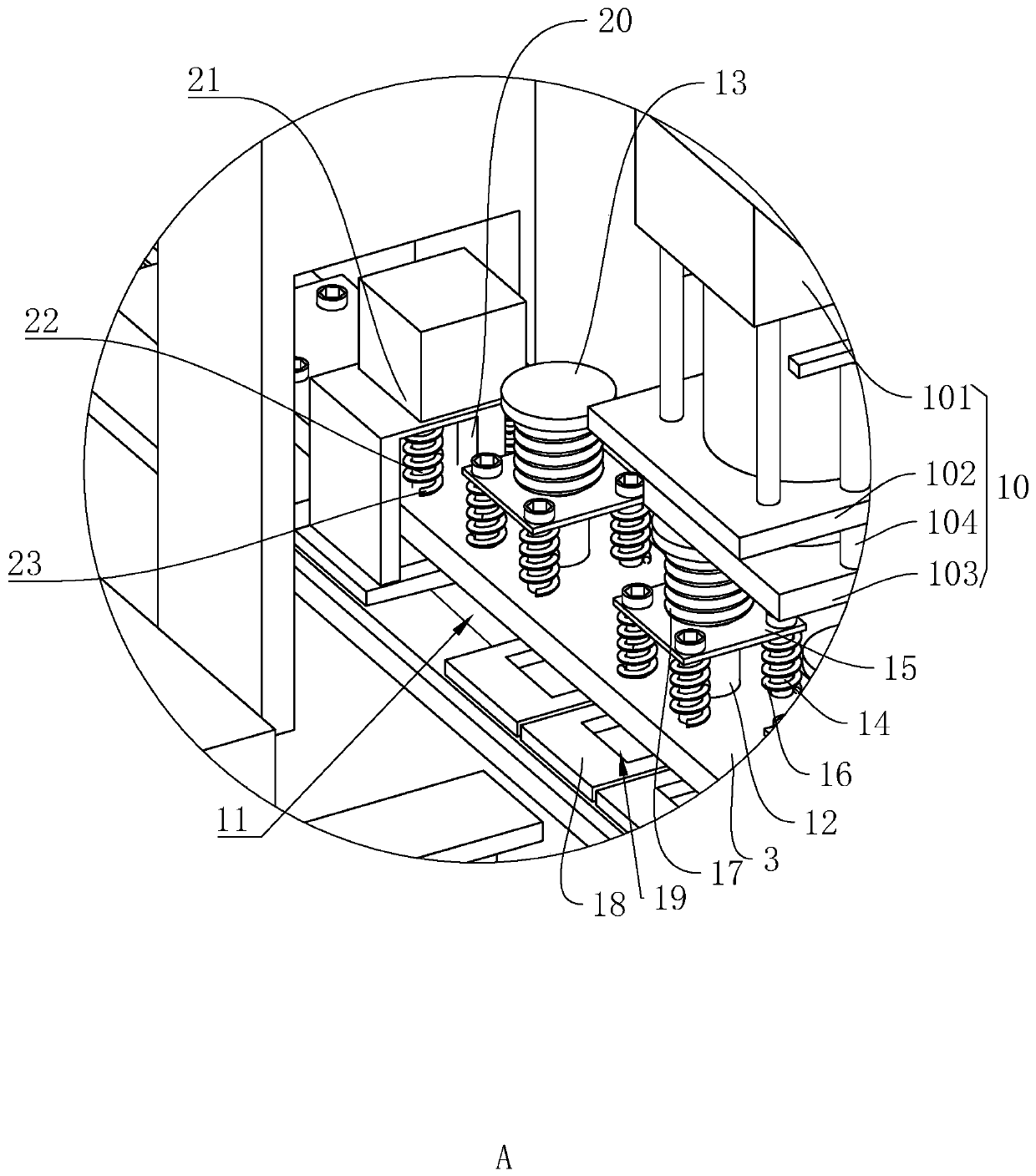

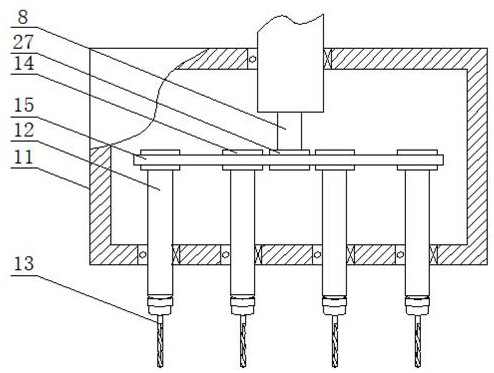

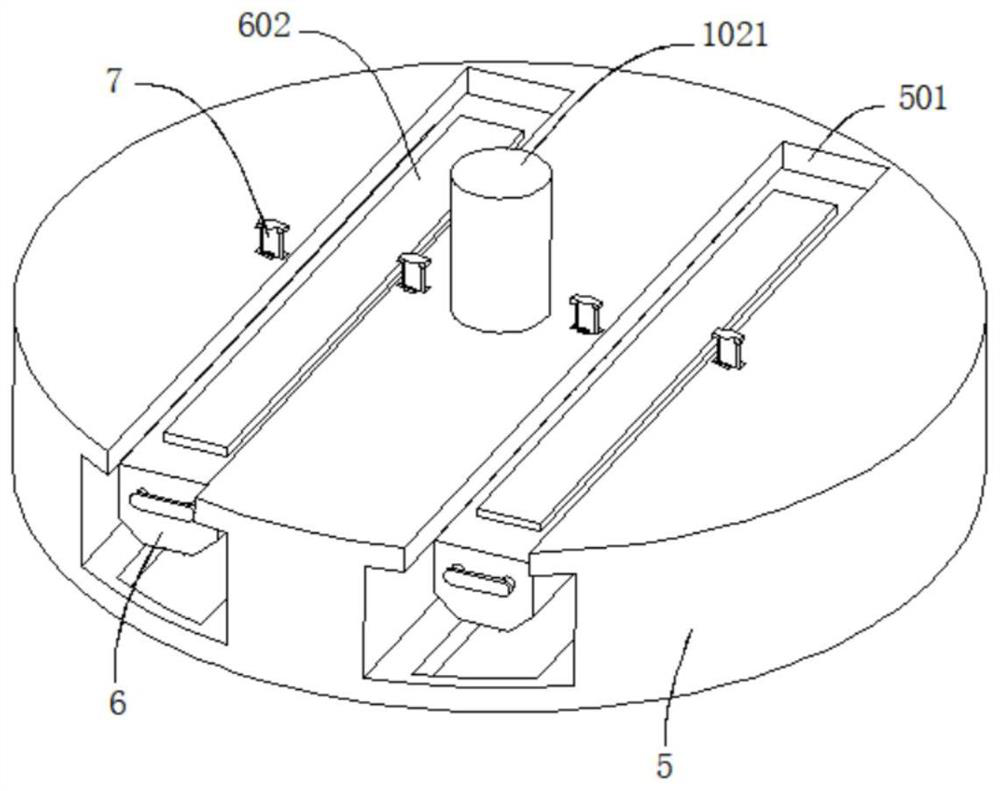

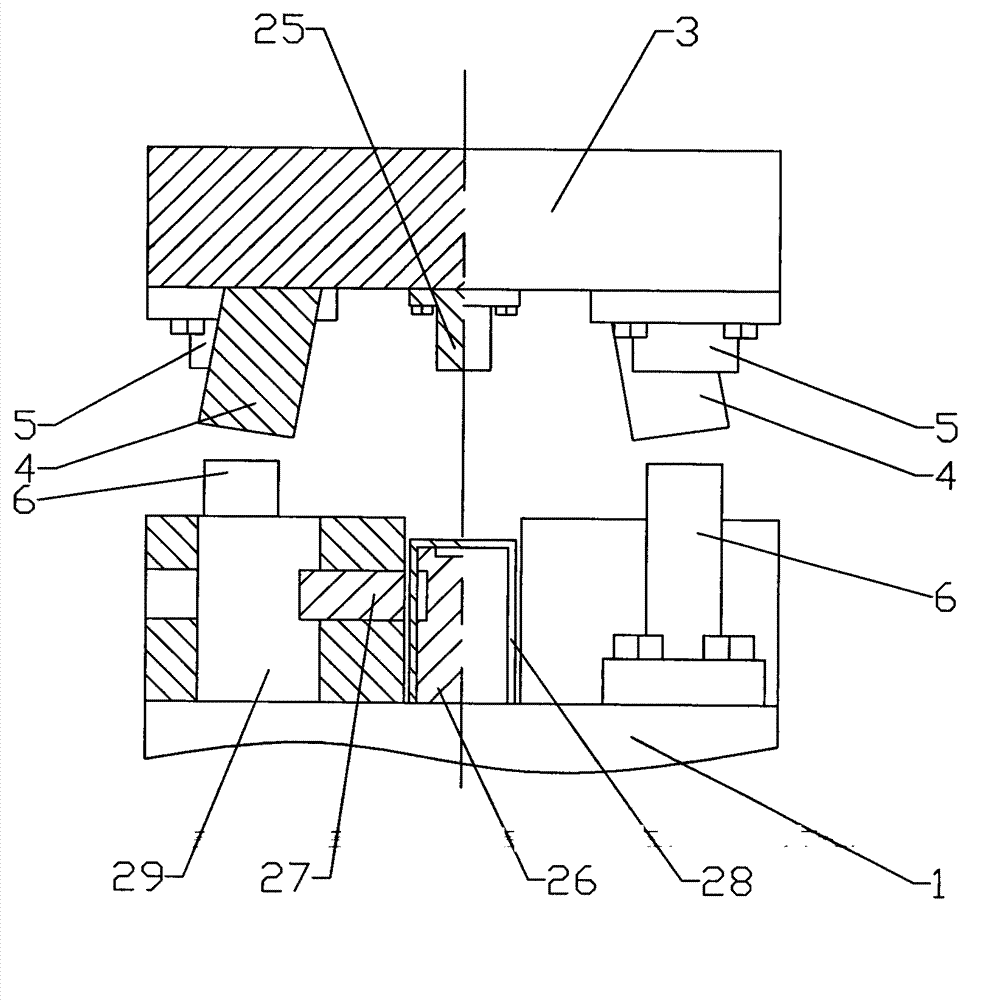

Production and machining equipment for relief butterfly valves

ActiveCN110788361AGuaranteed machining accuracyAvoid leaningPositioning apparatusBoring/drilling componentsReduction driveElectric machinery

The invention relates to the technical field of mechanical equipment, in particular to production and machining equipment for relief butterfly valves. The production and machining equipment comprisesa base, a workbench, a positioning plate, a first mounting plate, an air cylinder, a pushing rod, a clamping plate, a motor seat, a first motor, a first rotating shaft and a speed reducer, wherein thebottom end of the workbench is mounted on the front side of the top end of the base, an adjusting device is arranged on the right side of the top end of the workbench, the left end of the adjusting device is connected with the right end of the positioning plate, and the bottom end of the positioning plate is contacted with the top end of the workbench. According to the production and machining equipment for the relief butterfly valves, punching operation is carried out on the different positions on the valves, so that a punching process of the valves is effectively simplified, the punching time is shortened, the time and physical force for manually positioning the valves multiple times are saved, and the working efficiency is improved; and meanwhile, the position of a drill bit is precisely controlled, so that the position precision of a valve hole is effectively improved, the machining quality of the valves is improved, and the practicability and the reliability are improved.

Owner:SHANDONG ZHUCHENG JIANHUA VALVE MFG

Stamping device

The invention discloses a stamping device. The stamping device comprises a bottom frame, a punch press support, two parallel guide rails and a plurality of punch presses, wherein the punch press support is welded to the position above the bottom frame, the guide rails are installed on the punch press support in the length direction, and the punch presses are installed above the guide rails. Each punch press comprises an integral C-shaped punch press rack, a hydraulic cylinder vertically installed at the upper portion of the punch press rack, an upper die fixedly installed at the lower end of a hydraulic cylinder piston rod, and a lower die fixedly installed at the lower portion of the punch press rack. A transmission lead screw is arranged on the punch press support in the length direction, a punch press transverse movement device is fixedly connected to the lower portion of the punch press rack, same or different types of stamping dies can be installed on the different punch presses, the punch presses are moved to positions to be punched through the punch press transverse movement device, all workpieces to be punched are clamped and fixed through a workpiece clamp, the punch presses can act at the same time to punch the workpieces to form a plurality of holes, machining efficiency is high, and punching time is greatly shortened.

Owner:ZHEJIANG ZHONGGUANG ELECTRIC CO LTD

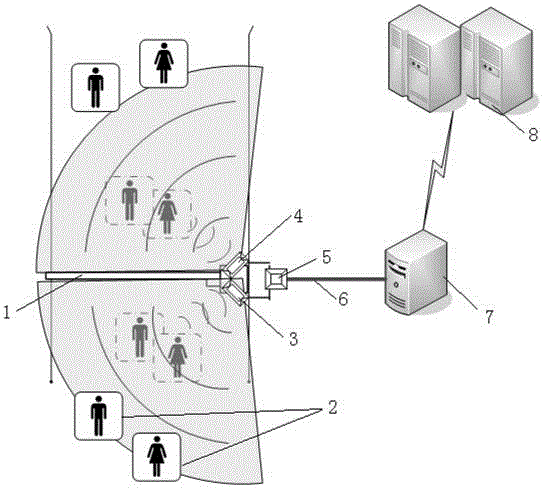

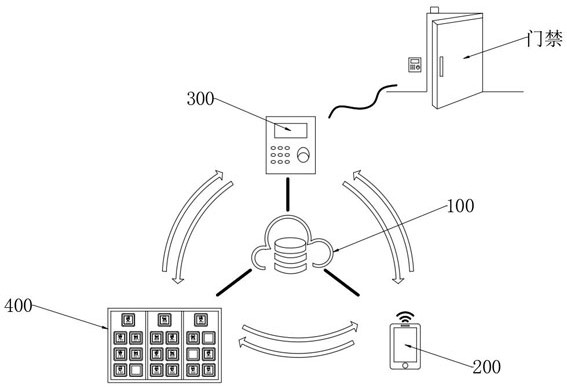

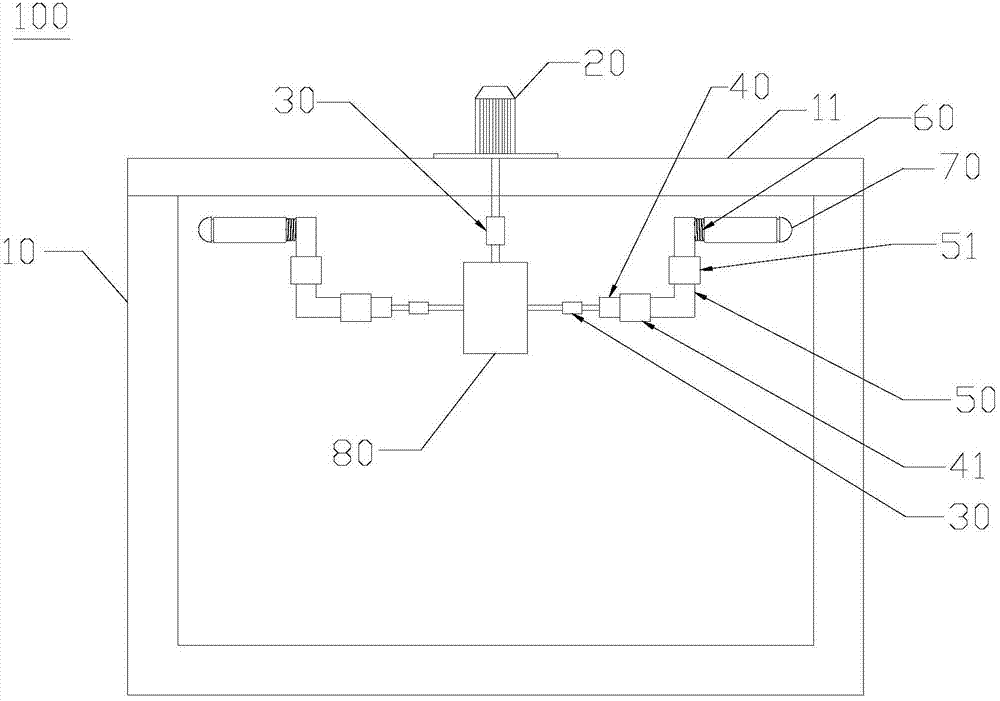

Intelligent attendance checking system and method

InactiveCN102722915ASave punching timeEliminate potential safety hazardsRegistering/indicating time of eventsRadio frequencyData transmission

The invention provides an intelligent attendance checking system, which comprises a safety door, an RFID (Radio Frequency Identification Device) card, an outer sensor, an inner sensor, a reader, a local data acquisition server and a head office server, wherein the outer sensor and the inner sensor are arranged on both sides of the safety door respectively; the RFID card is used for receiving radio-frequency information transmitted by the outer sensor and inner sensor, transmitting a corresponding frequency signal by means of energy acquired through sensing current, and transmitting the frequency signal to the local data acquiring server through a data transmission line after the frequency signal is acquired and decoded by a reader; and the head office server is used for receiving data of the local data acquiring server through a network, and performing corresponding actions. Students entering the safety door are not required swipe cards one by one, so that the potential safety hazard caused by people crowd is eliminated, and various influences caused by forgetting to swipe cards are reduced simultaneously.

Owner:遥见世纪信息有限公司

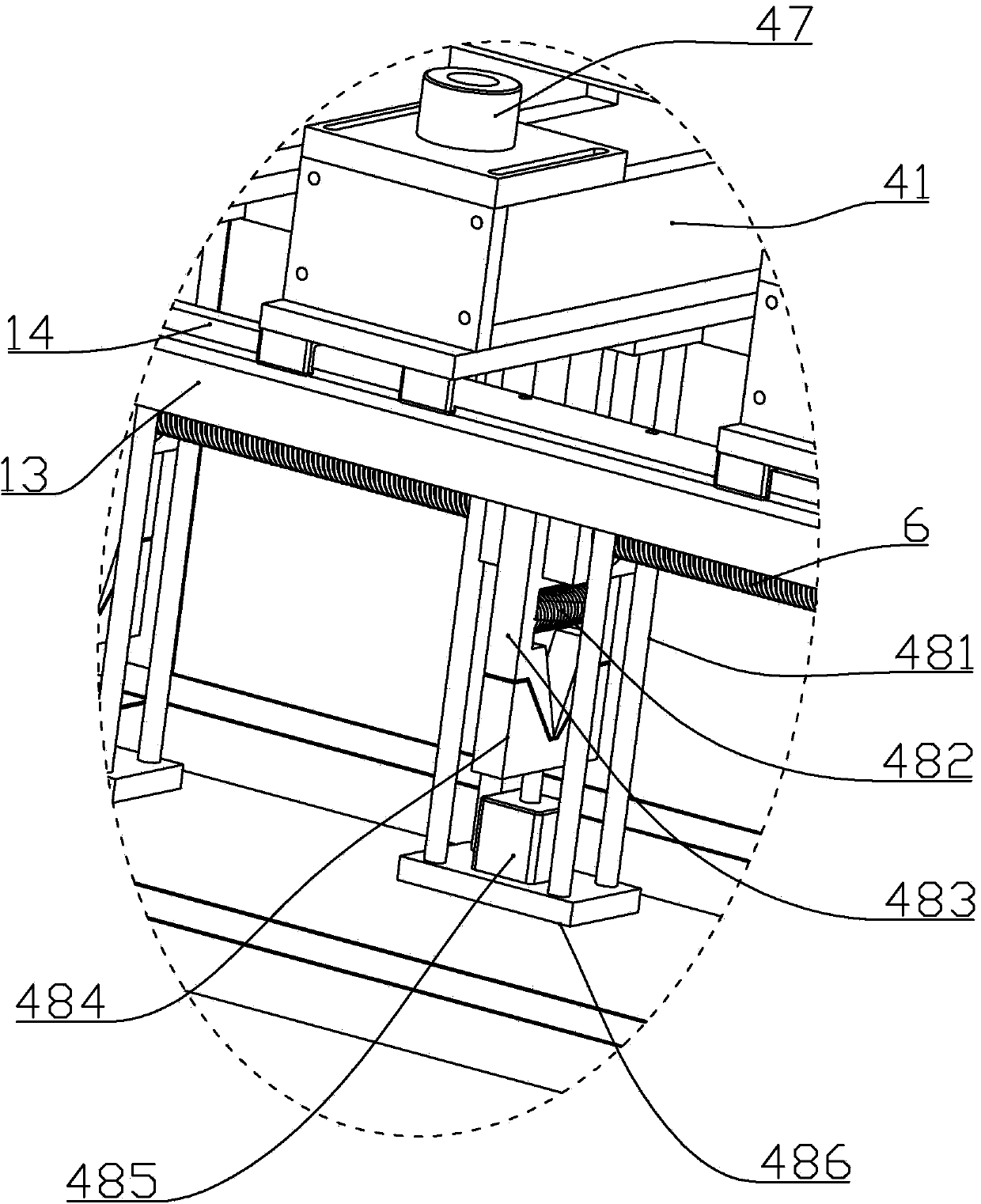

Copper bar punching and shearing machine

InactiveCN111230505ASave punching timeImprove work efficiencyOther manufacturing equipments/toolsStructural engineeringPunching shear

The invention discloses a copper bar punching and shearing machine. The copper bar punching and shearing machine comprises a base and is characterized in that a supporting plate is slidably arranged on the base, and a mold box is fixedly mounted at the end, away from the base, of the supporting plate; multiple mold heads for punching and a tools for cutting a copper bar are slidably mounted on themold box in the vertical direction, and a buffering groove for punching is formed in the end, away from the base, of the supporting plate; a console for controlling the copper bar punching and shearing machine to work is fixedly arranged on the side wall of the base, a horizontal driving part for driving the mold box to horizontally move is mounted on the base, and a gantry is mounted at the end,close to the supporting plate, of the base; and a vertical driving part for driving the mold heads to slide is mounted on the gantry, a feeding mechanism and a discharging mechanism are arranged on the two opposite side walls of the base correspondingly, and a clamping assembly for clamping a steel copper to move is arranged on the discharging mechanism. The multiple mold heads are mounted on a mold library, multiple holes of different types can be punched, different mold heads do not need to be manually replaced, the punching time is saved, and the work efficiency is improved.

Owner:上海常青钣金机箱制造有限公司

Reciprocating type punching device

The invention discloses a reciprocating type punching device which comprises a rack, and a punch head and a punching seat that are arranged on the rack sequentially; a first spring is connected between the punch head and the rack; and the punching seat is slidingly connected with the rack. The reciprocating type punching device further comprises an explosive rotary plate and an intermittent pushing mechanism for pushing an explosive into the explosive rotary plate intermittently; the intermittent pushing mechanism is arranged on one side, far from the punching seat, of the punch head; the explosive rotary plate is arranged between the intermittent pushing mechanism and the punch head, and is rotationally connected with the rack; partition plates are uniformly distributed in the circumferential direction of the explosive rotary plate; a containing cavity containing the explosive is formed between every two partition plates; a flaming mouth is formed in each containing cavity; and a pushing plate is fixedly connected with one end, close to the explosive rotary plate, of the punch head, and is abutted against one partition plate. Compared with the prior art, the explosive reacts more quickly, an instant impact force of the explosive is greater, the punching time can be reduced and the punching efficiency can be improved; and a punching force of the punch head can be ensured, so that when the punch head punches a workpiece, fewer burrs are generated around the hole wall, and the polishing time is reduced.

Owner:重庆新钰立金属科技有限公司

A paper punching device for accounting teaching

InactiveCN106217477BNot easy to damageQuick punchMetal working apparatusPulp and paper industryConductor Coil

Owner:JILIN INST OF CHEM TECH

Adhesive tape blanking device for copper foil adhesive tape production

InactiveCN110640835AFlexible and convenient replacementNot susceptible to rustMetal working apparatusTool bitStructural engineering

The invention discloses an adhesive tape blanking device for copper foil adhesive tape production, and belongs to the field of blanking devices. The adhesive tape blanking device for copper foil adhesive tape production comprises a blanking table fixedly connected to the upper end of a worktable; a lifting cover plate is arranged on the upper side of the blanking table; multiple pairs of electricextension rods are fixedly connected between the lifting cover plate and the worktable; a through hole is drilled in the center of the lifting cover plate from top to bottom; a cylinder is connected to the center of the upper end surface of the lifting cover plate; a power output end of the cylinder penetrates through the through hole, and is fixedly connected with a lifting block; a storage groove matched with the lifting block is drilled in the lower end of the lifting cover plate; a protective groove is drilled in the lower end of the lifting block; a pair of chutes is drilled in the innerside wall of the protective groove; and a tool bit module is arranged in the protective groove. According to the adhesive tape blanking device for copper foil adhesive tape production, the tool bit module can be conveniently and flexibly replaced, the tool bit can be reversely inserted in the protective groove in an idle state to be protected from being rusted by the external environment, and higher safety achieve is achieved.

Owner:湖北富和冠电子材料有限公司

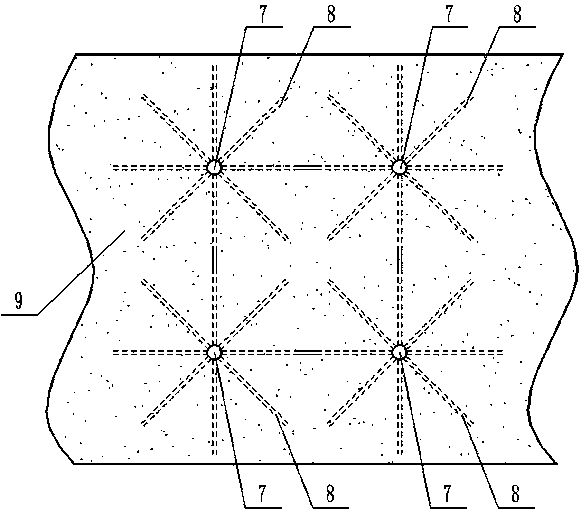

High-pressure oriented perforating permeability-increasing method and device

InactiveCN108952795ACollapse will not causeEasy extractionFluid removalGas removalEngineeringHigh pressure water

The invention discloses a high-pressure oriented perforating permeability-increasing method and device. The high-pressure oriented perforating permeability-increasing device comprises a high-pressurehydraulic pump, a high-pressure rubber tube, a high-pressure rotating joint, a drilling rig, a high-pressure water jet drilling rod and a high-pressure water jet nozzle. The high-pressure oriented perforating permeability-increasing method and device have the following beneficial effects that a coal seam is subjected to permeability increasing through the oriented perforating permeability-increasing method, a permeability-increasing part formed through the permeability-increasing method is actinoid, collapse of a coal seam roof can be avoided, and safety is improved; the permeability-increasing area is wide, the drilling density is low, and the permeability-increasing efficiency can be effectively improved; and the permeability-increasing method is simple and easy to operate, and the permeability-increasing device is simple and easy to transform.

Owner:HENAN POLYTECHNIC UNIV

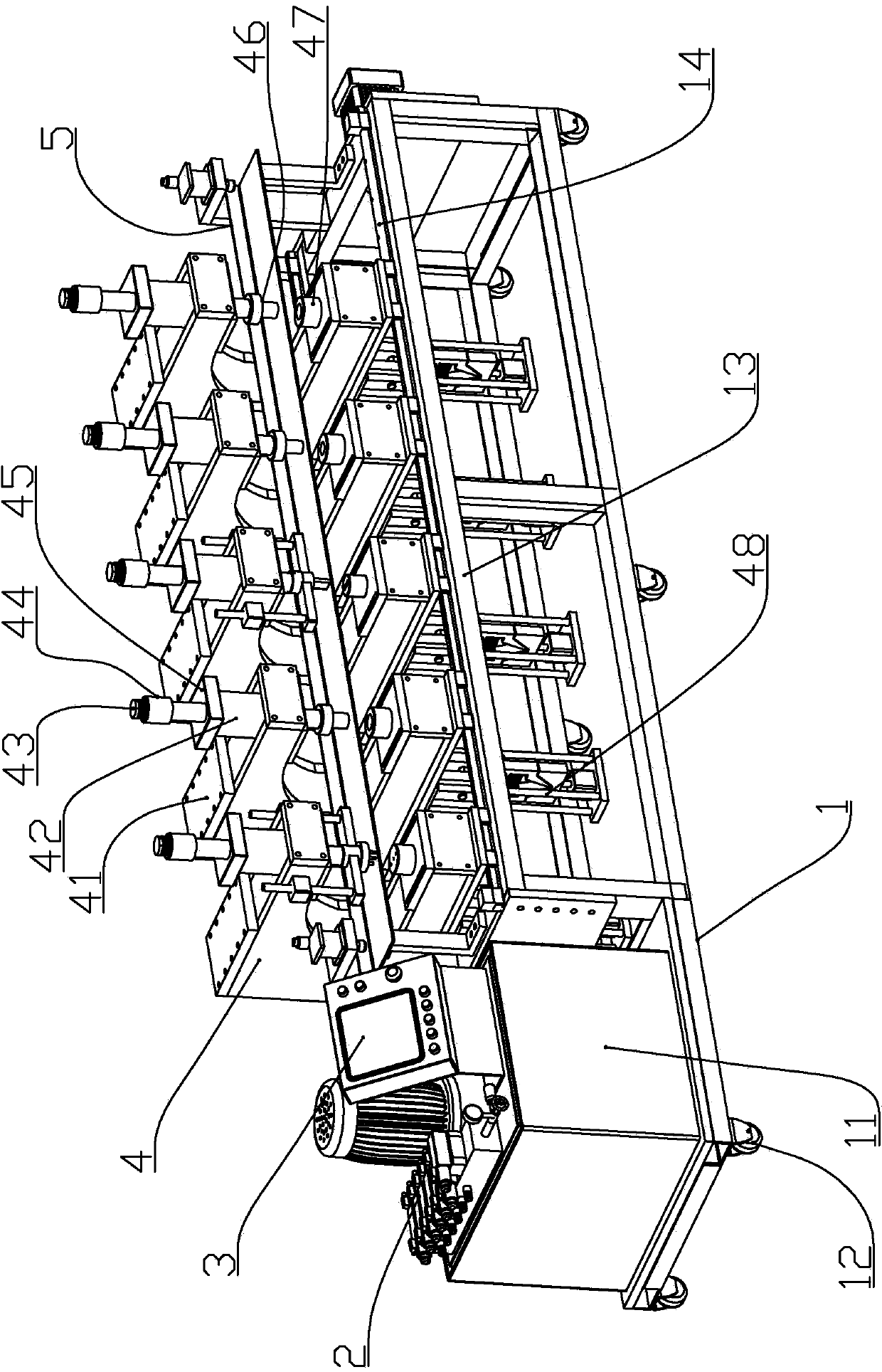

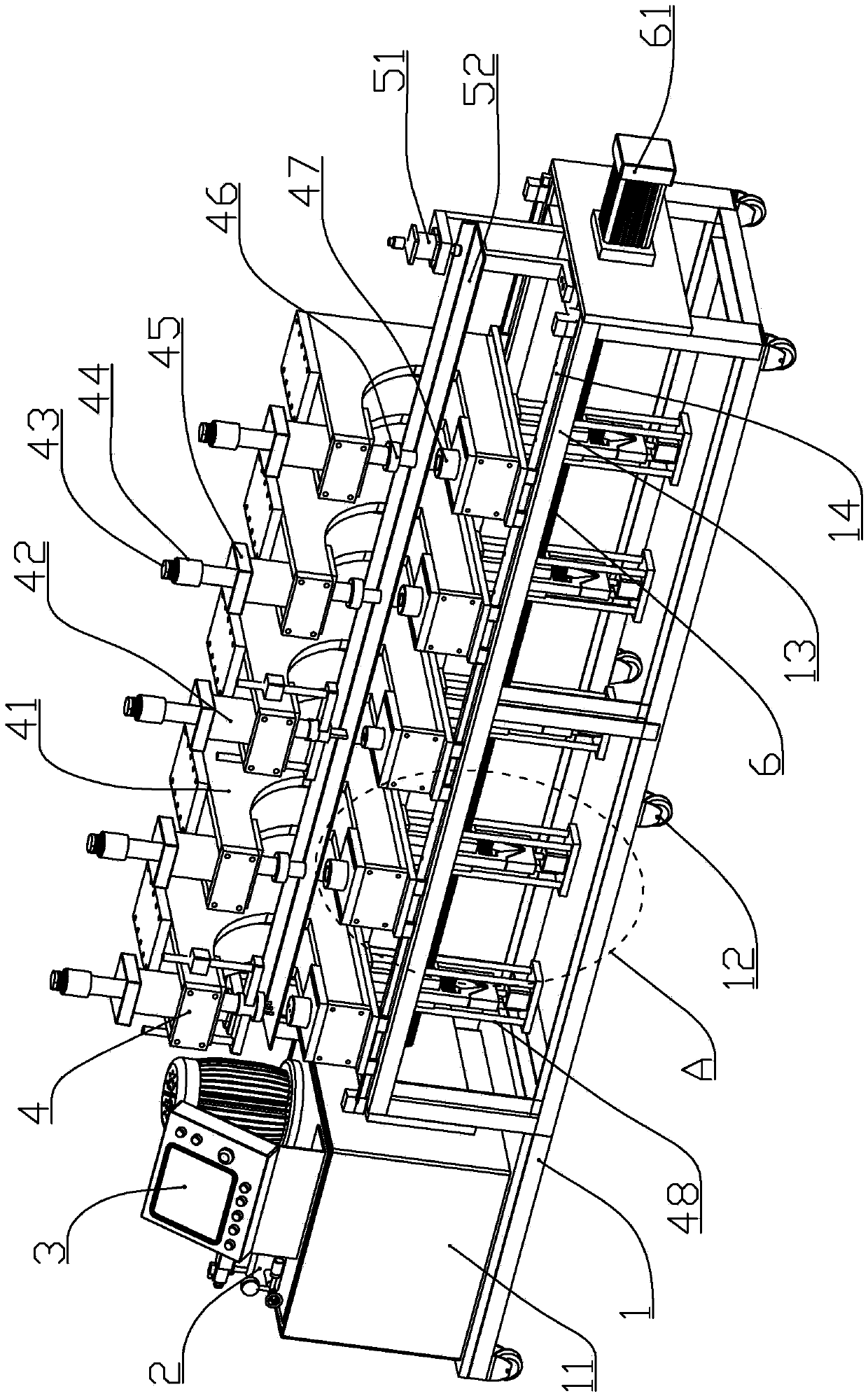

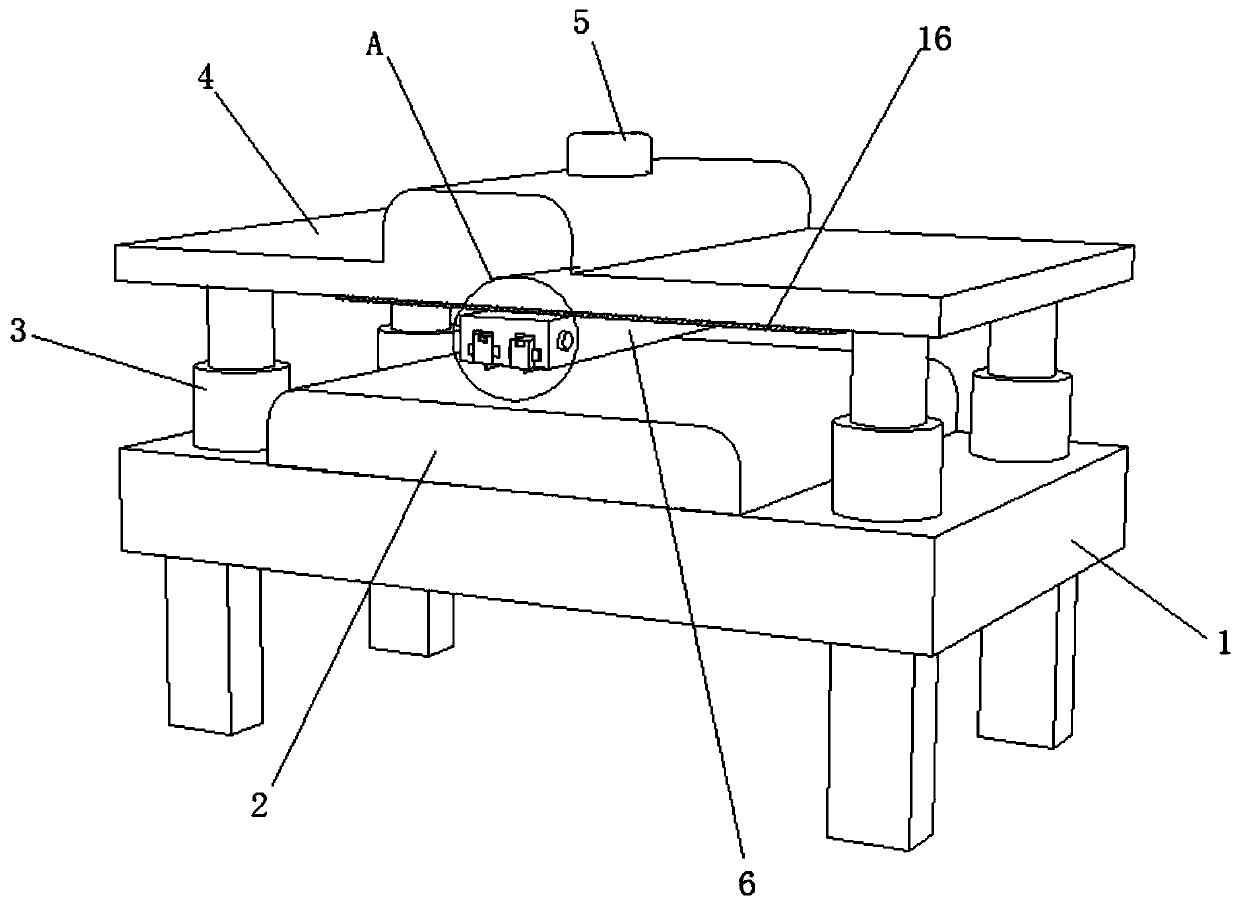

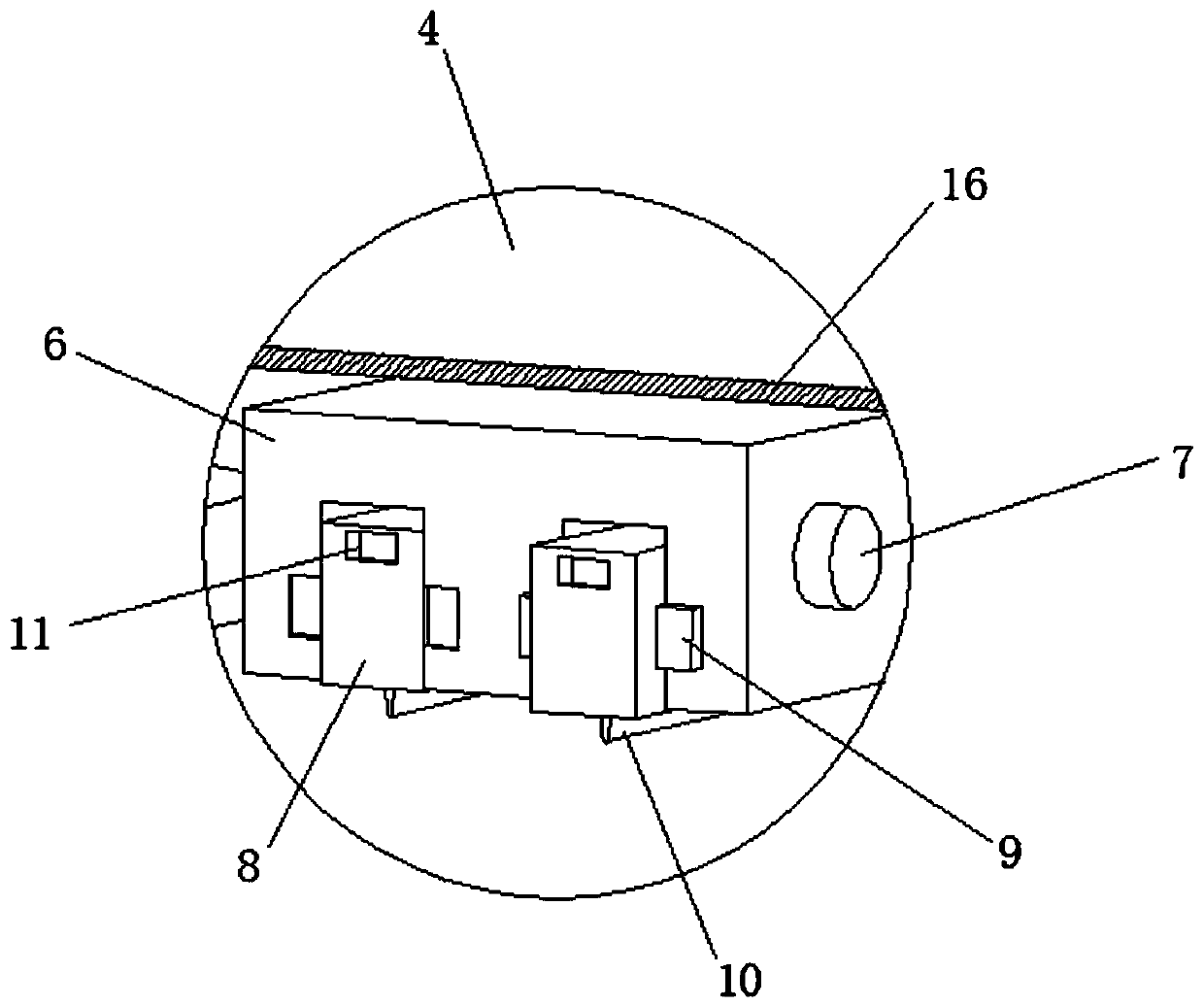

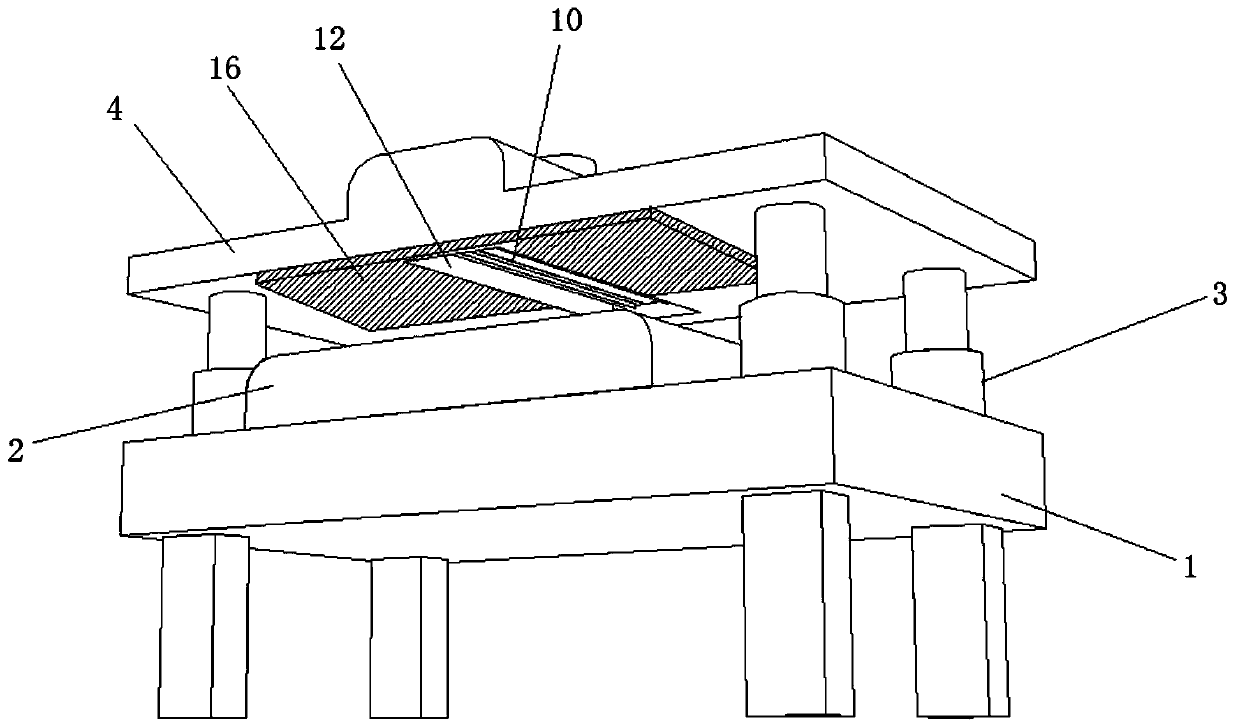

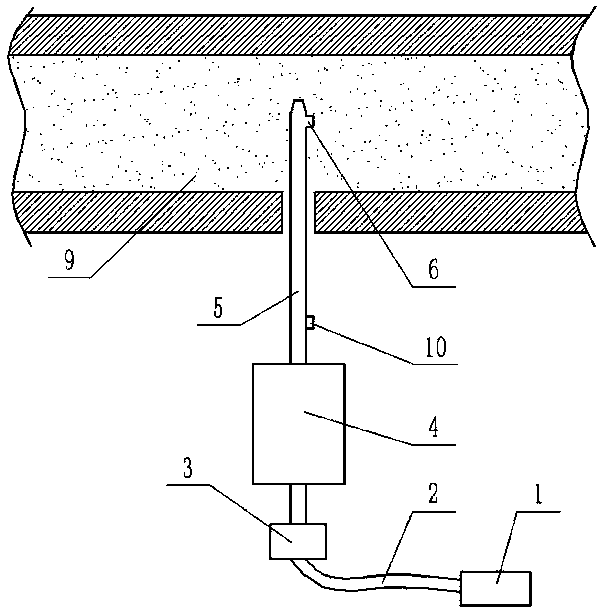

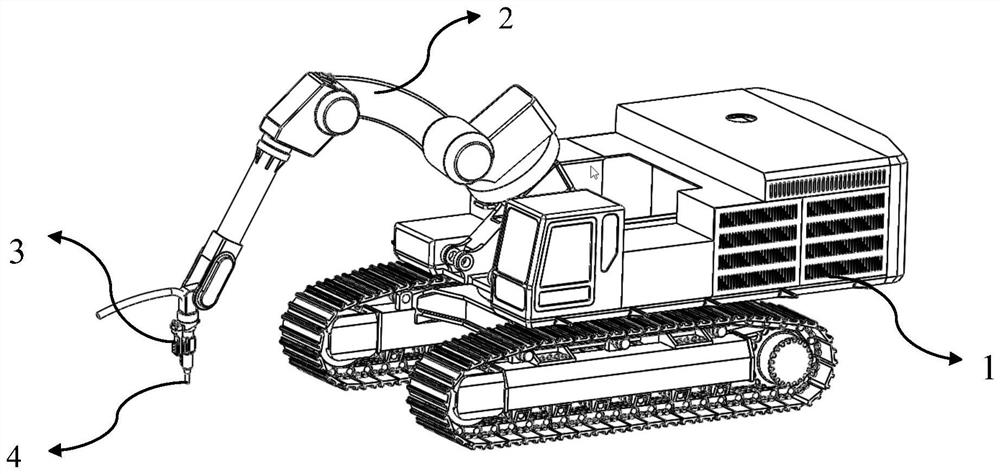

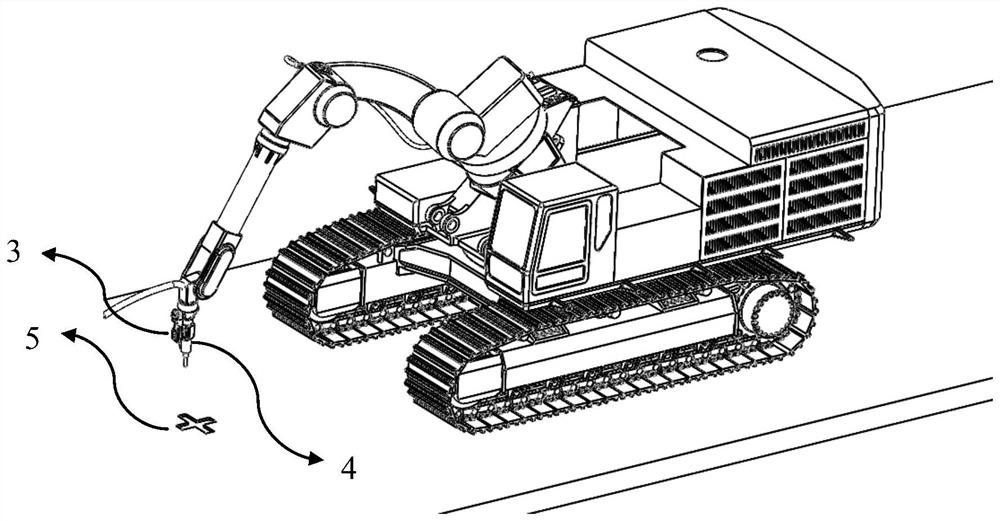

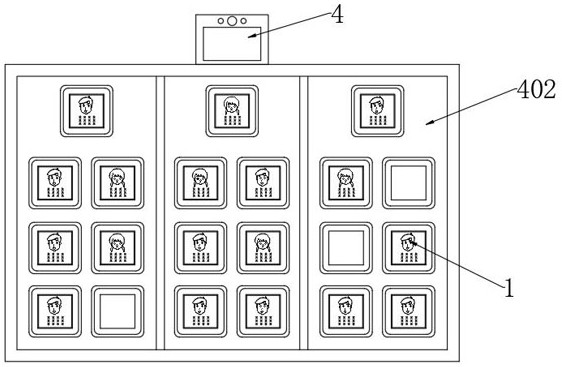

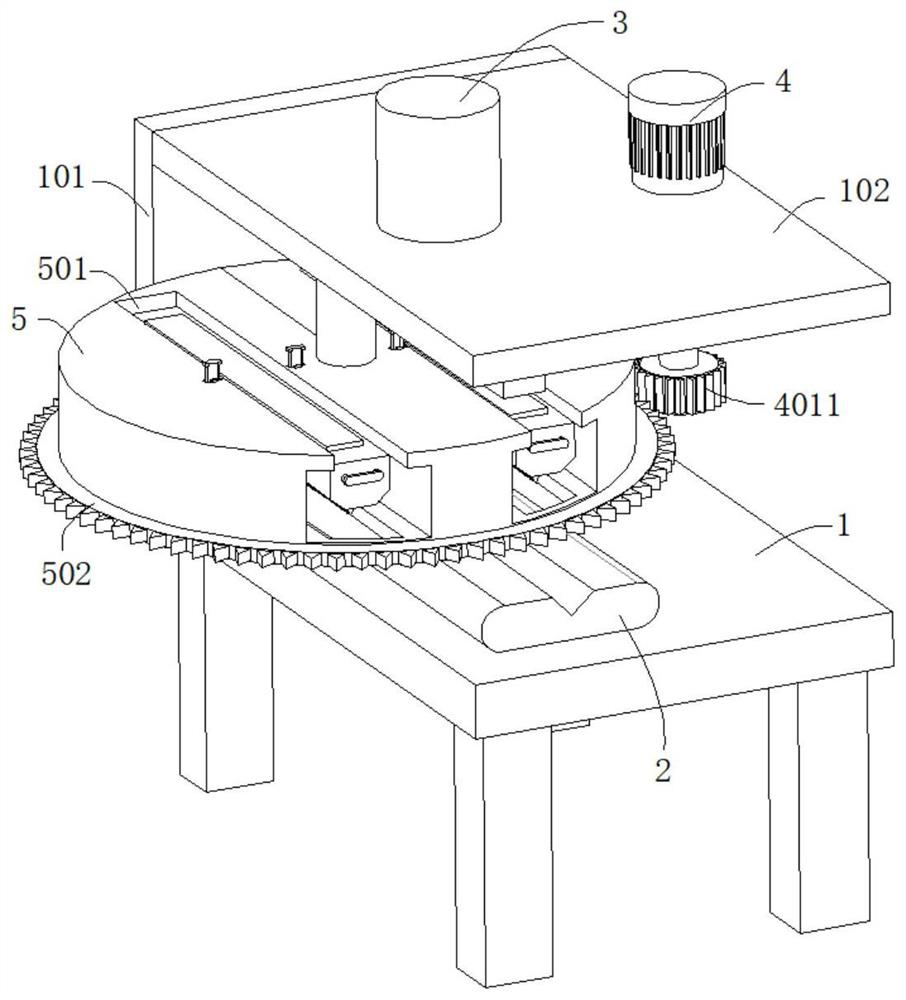

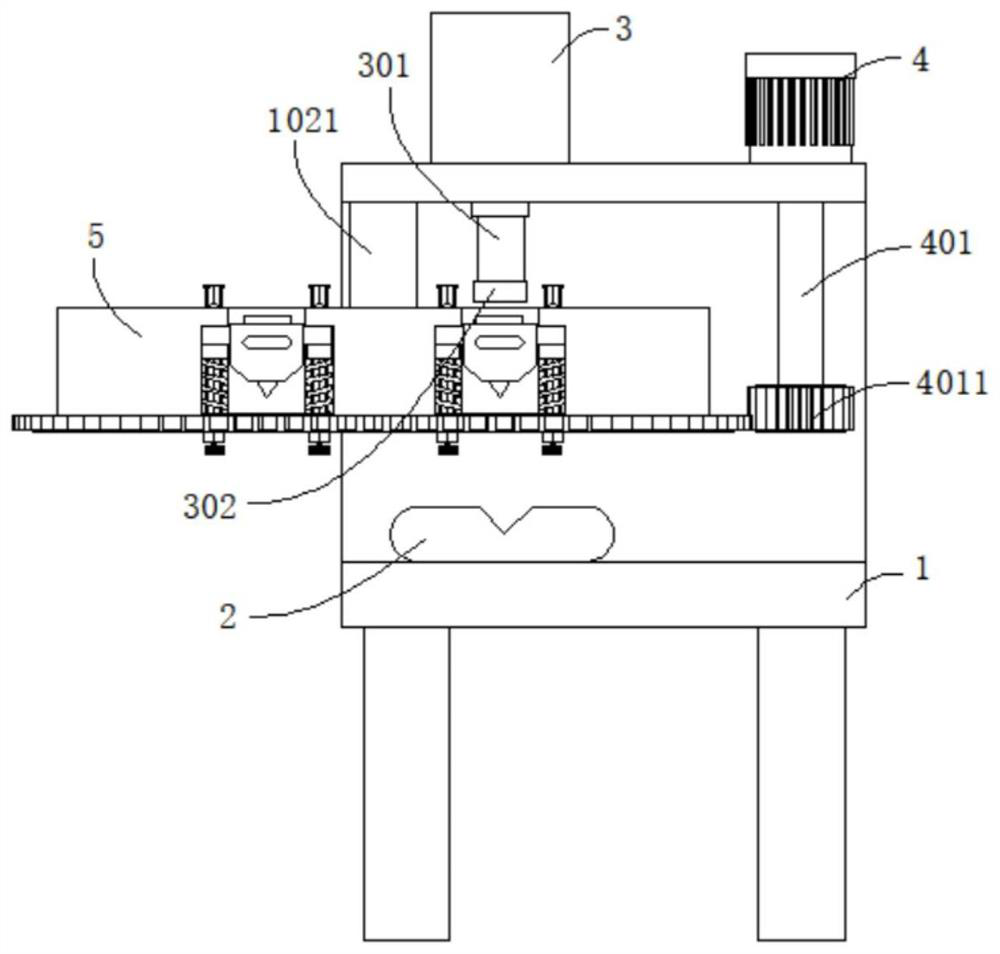

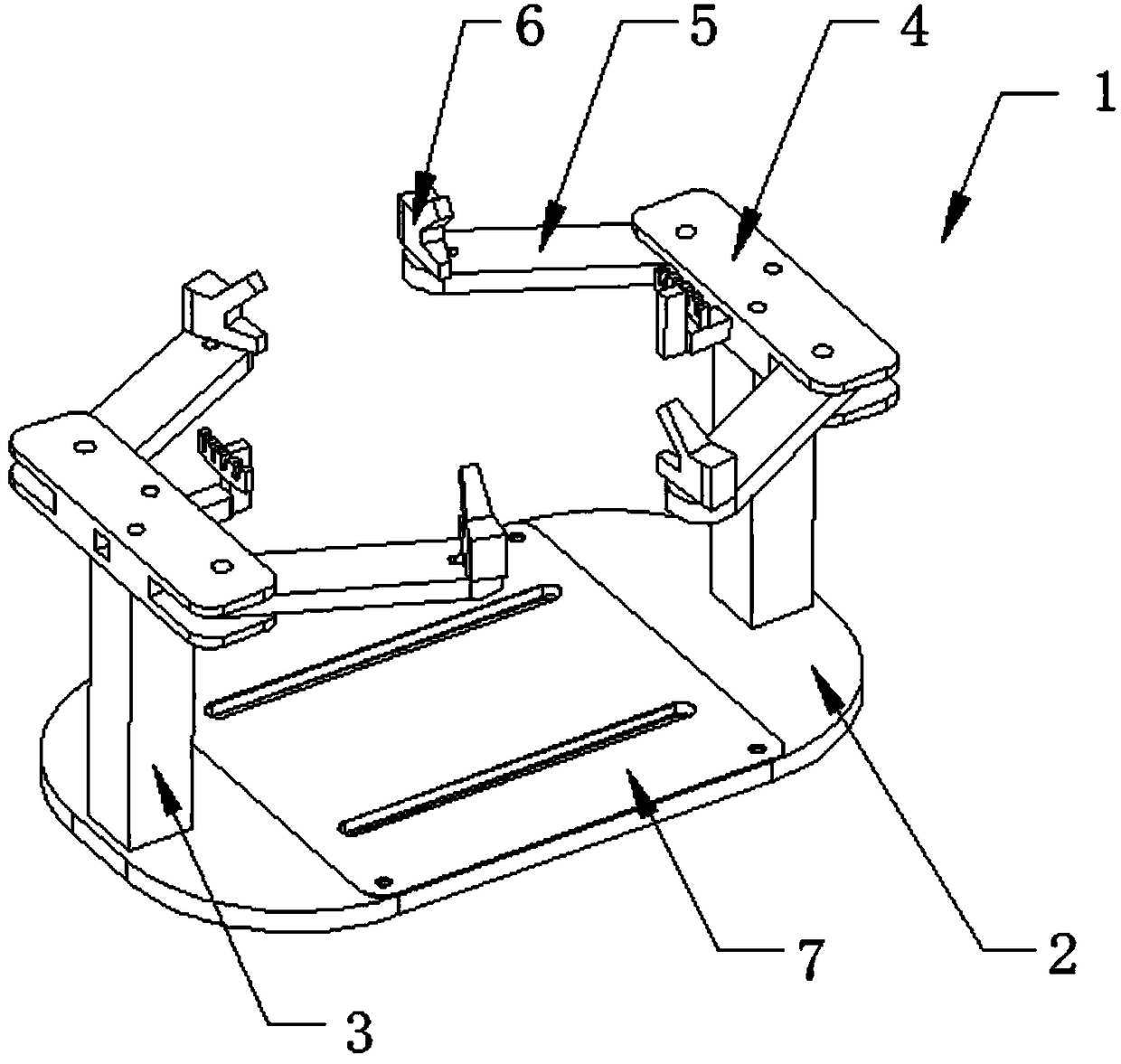

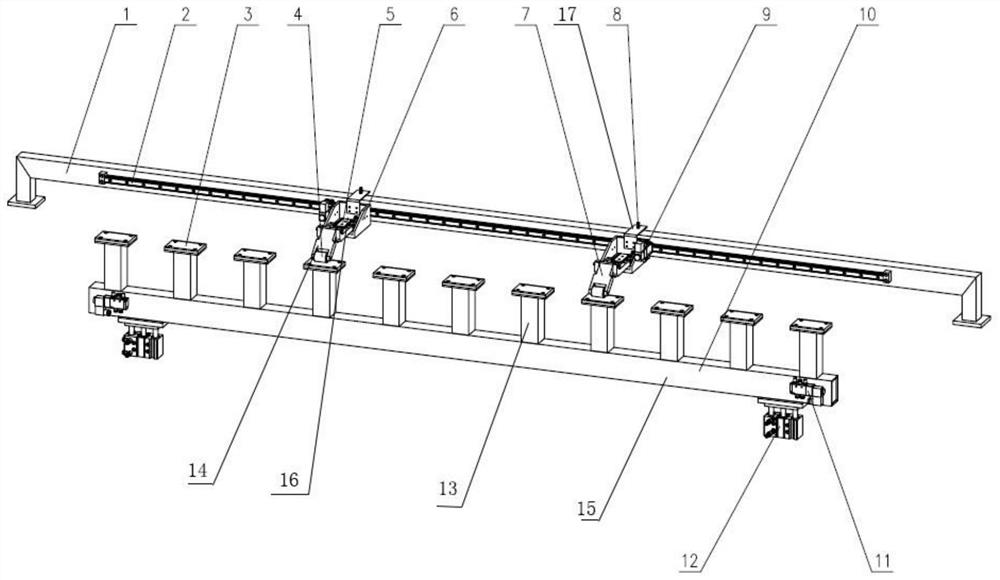

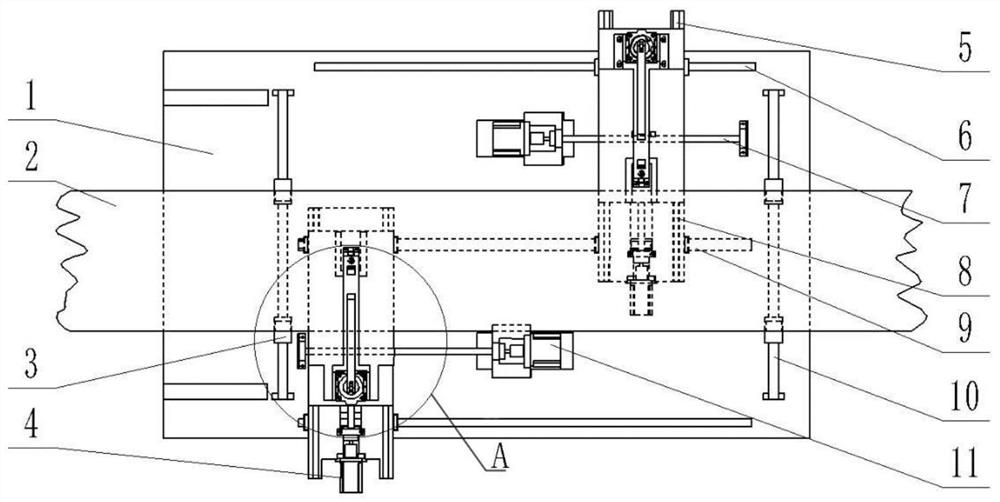

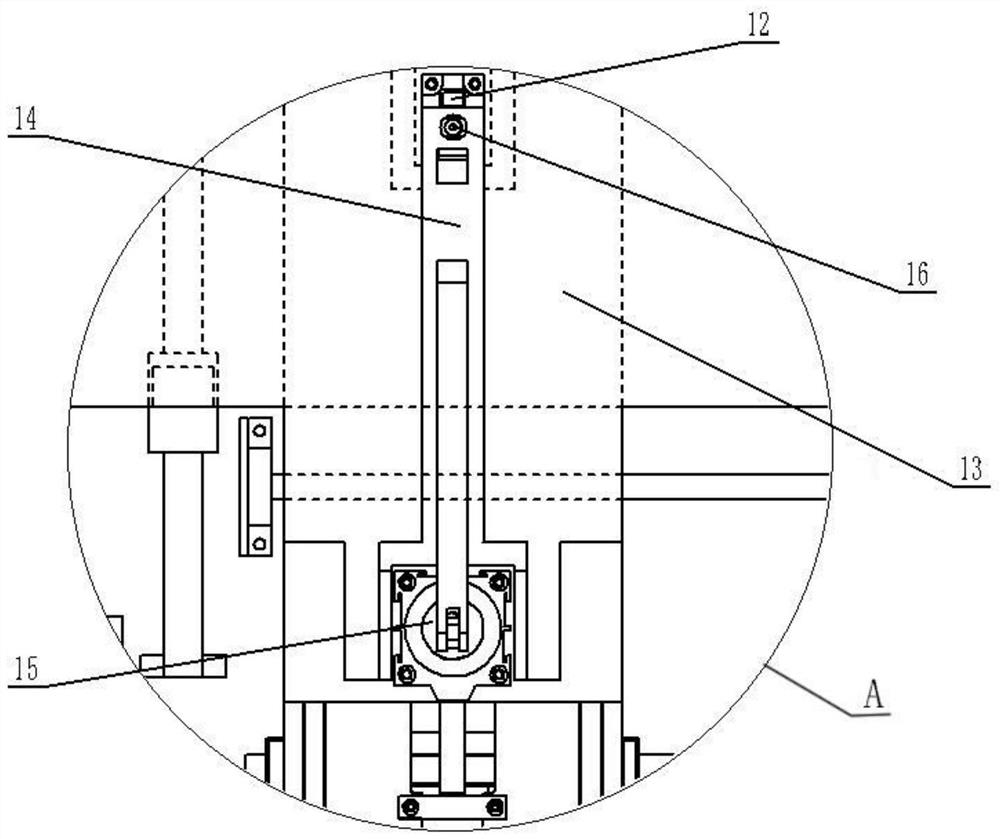

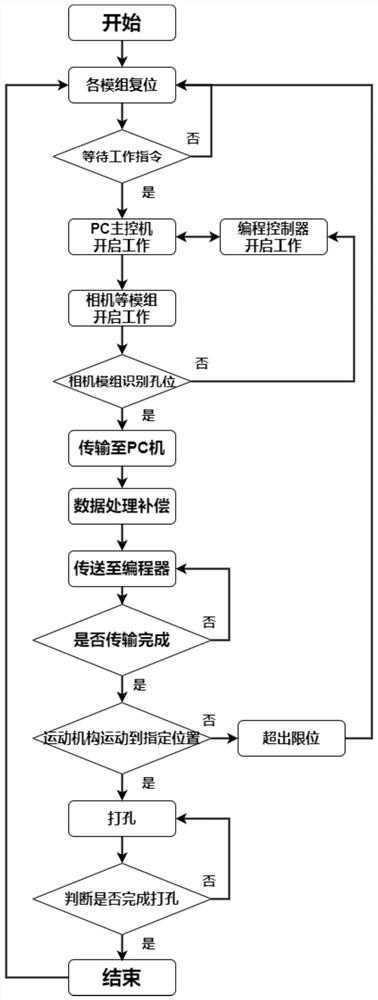

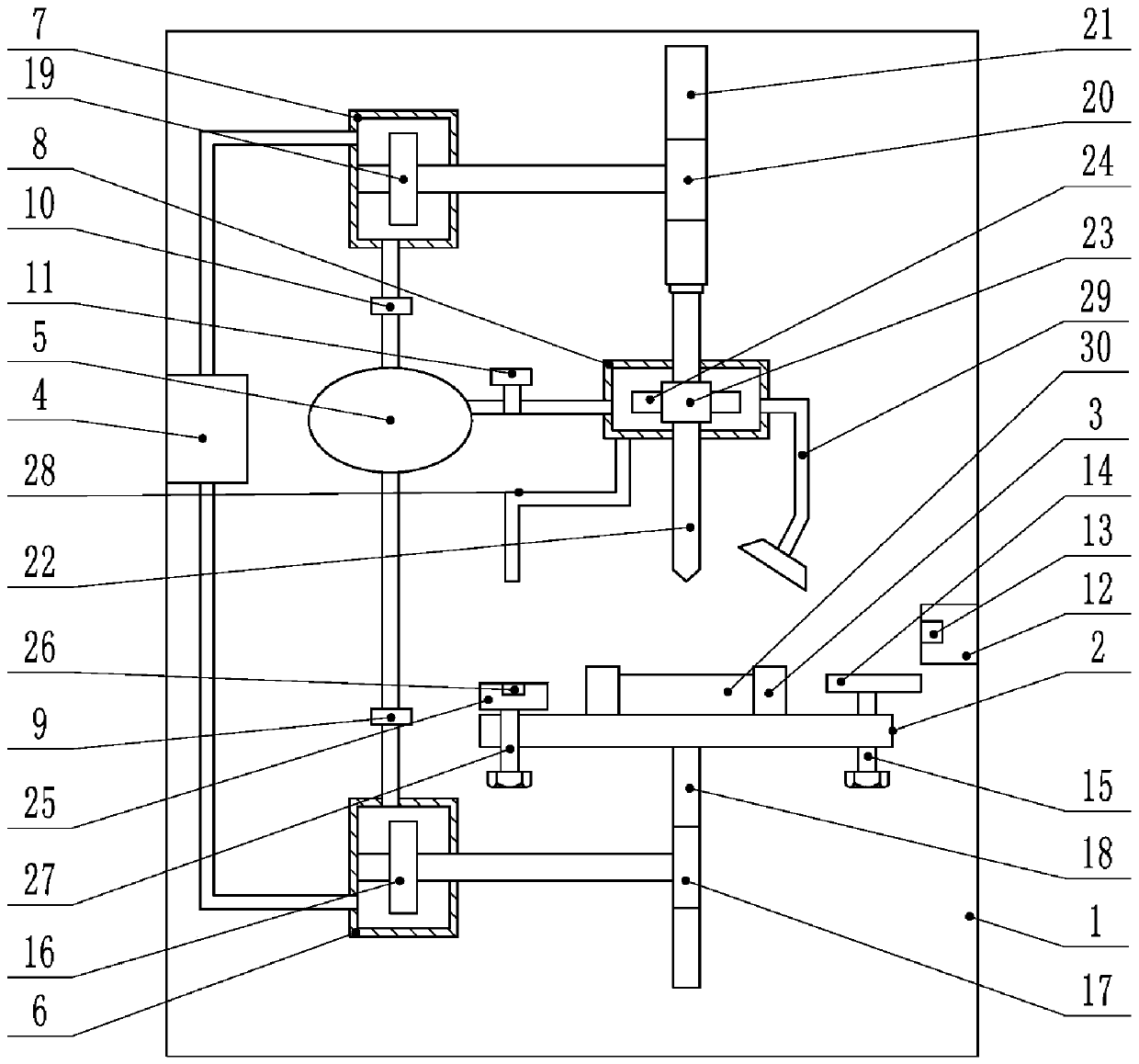

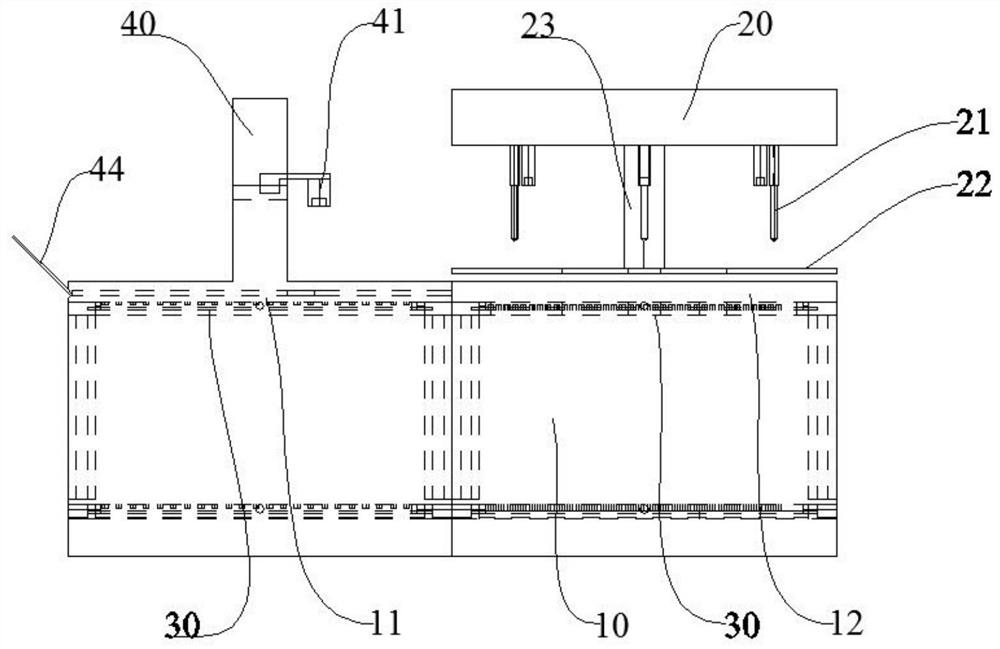

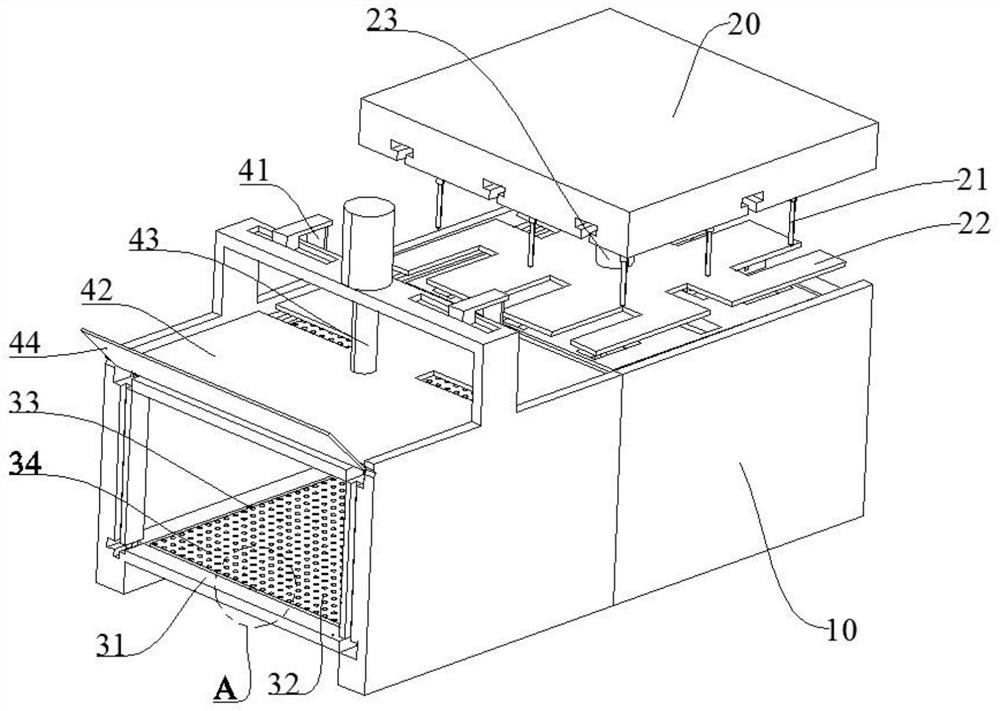

GIL leg installation punching method and punching robot

PendingCN111993434ASave punching timeImprove efficiencyProgramme-controlled manipulatorOther workshop equipmentControl engineeringWorkspace

The invention discloses a GIL leg installation punching method and a punching robot. The GIL leg installation punching method mainly replaces manual punching with the punching robot and comprises thecore steps of manual marking and punching by the punching robot. The punching robot mainly comprises a multi-mode walking chassis vehicle 1, a multi-joint robot 2 mounted on the multi-mode walking chassis vehicle 1, an industrial vision system 3 fixed on the arm of the multi-joint robot 2, and a drilling machine 4 fixed at the end of an arm of the multi-joint robot. Workers mark the hardened ground in a GIL tunnel and determine the position of an expansion bolt hole, according to GIL construction drawings. The punching robot moves to the working area, the industrial vision system 3 takes photos and positions, and the multi-joint robot 2 intelligently positions according to information provided by the industrial vision system 3, and the drilling machine 4 on the multi-joint robot 2 completes punching. Compared with manual drilling, time is greatly saved, the labor intensity is reduced, the efficiency is improved, the punching method and the punching robot are particularly suitable for GIL installation and construction, and are novel and creative.

Owner:郑州弗曼智能设备科技有限公司 +1

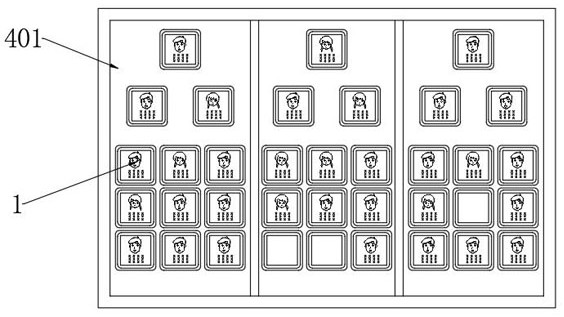

Novel attendance management system and use method thereof

InactiveCN112785744AQuick understandingEasy to understandRegistering/indicating time of eventsSensing radiation from moving bodiesSplit screenManagement system

The invention discloses a novel attendance management system and a use method thereof, and belongs to the field of attendance. The novel attendance management system comprises an attendance management system, the attendance management system comprises a mobile phone APP system, a fingerprint punch-card machine and an attendance display screen which are mutually connected. According to the scheme, a management layer can visually, quickly and conveniently know the attendance condition of employees through the attendance display screen, the main screen of the display screen is used by high-level managers, and the split screens are used by middle-level managers, so that the managers at all levels can quickly and visually know the attendance condition of the employees, and time and energy are effectively saved; a display board on the attendance display screen is connected with a mobile phone of an employee, one person has one board, management is convenient, the display board adopts a magnetic adsorption connection mode and can be flexibly transferred along with the change of the duty, the fingerprint attendance punch card is connected with an access control system, the card punching time is saved, and meanwhile the anti-theft effect can be achieved; and in addition, the card punching mode can be flexibly selected according to the epidemic situation, and the epidemic prevention work is effectively improved.

Owner:浙江望东君文化传媒有限公司

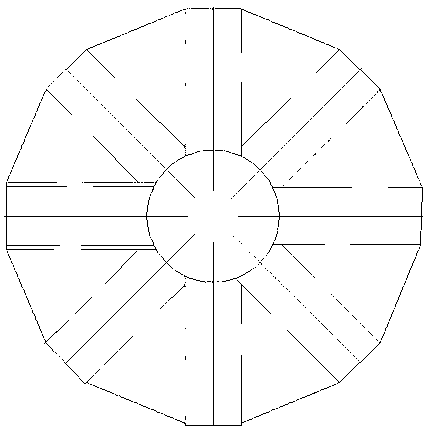

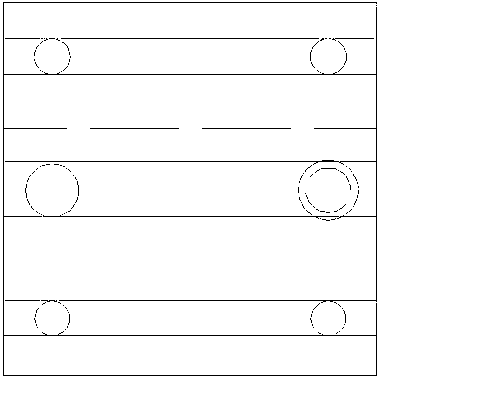

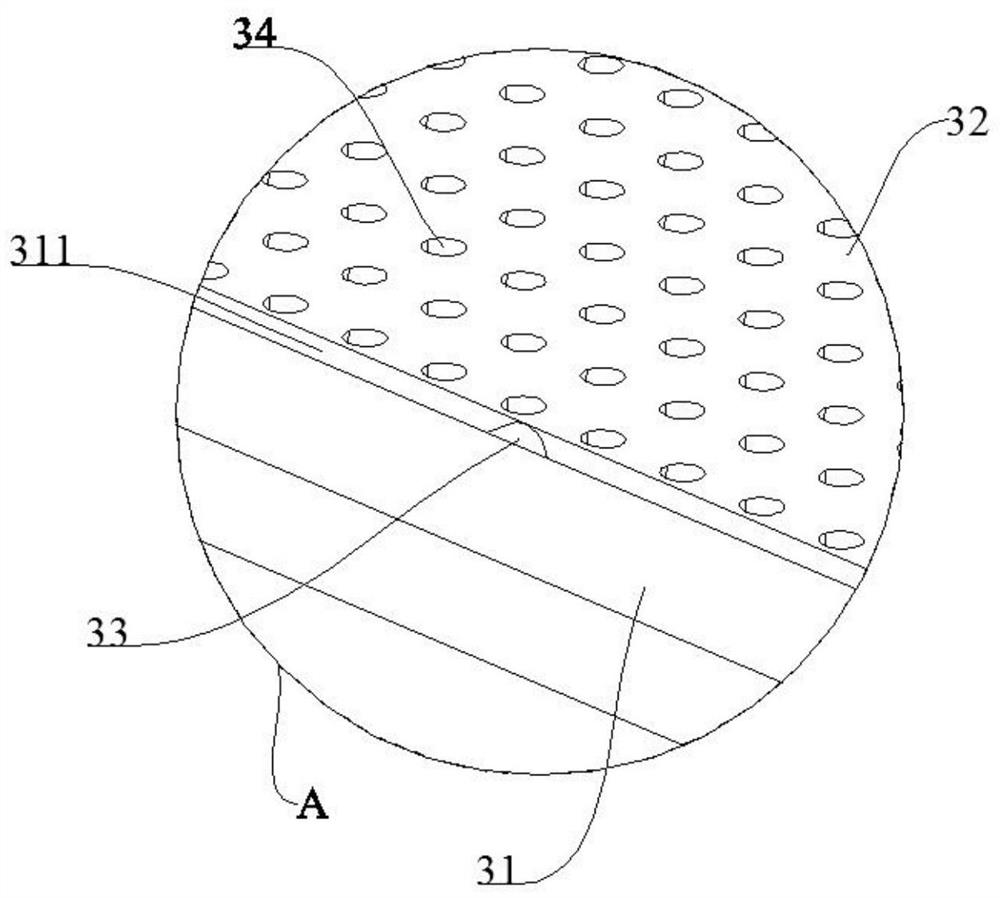

Constant punching device

The invention relates to a constant punching device, and belongs to the technical field of pipe or bar punching and machining. According to the technical scheme, the constant punching device comprises a constant puncher and a positioning bolt (7); the constant puncher is a polygonal prism body (5); a workpiece manhole (1) is arranged on the end face of the polygonal prism body; a plurality of working holes (3) are arranged on the lateral face of the polygonal prism body; a positioning screw (2) is further arranged on the lateral face of the polygonal prism body; the positioning screw is matched with the positioning bolt; and the working holes, the positioning screw and the workpiece manhole are communicated. The constant punching device provided by the invention has the beneficial effects in that after the pipe or the bar which has the constant internal diameter and the constant external diameter and needs to be punched is fixedly arranged on the constant punching device, the pipe or the bar is directly punched without measuring the size in use; and furthermore, no sliding excursion is generated, so that a punching position is accurate; the convenience in use can be realized; the labor intensity is reduced; the effect of the labor efficiency is improved; the constant punching device is applicable to generally punching in scale; the punching precision can be improved; the position measurement cannot be carried out; and the labor intensity is reduced.

Owner:BAODING TIANWEI GRP CO LTD

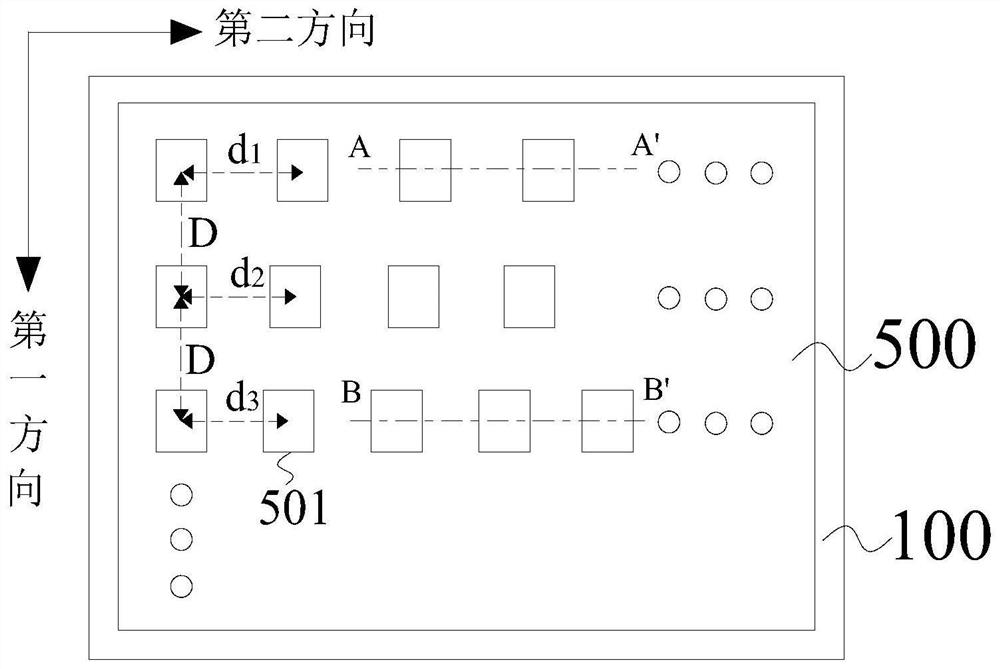

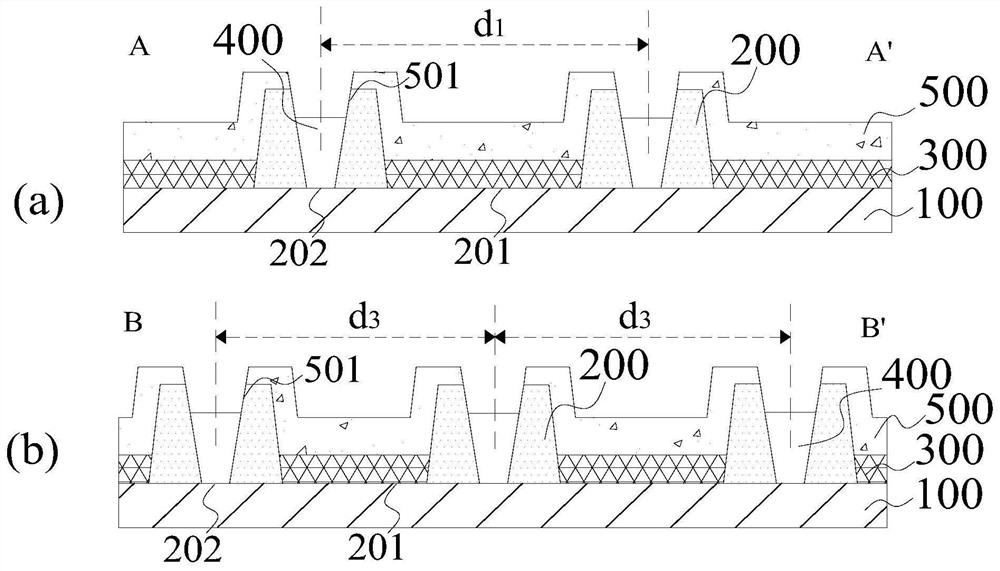

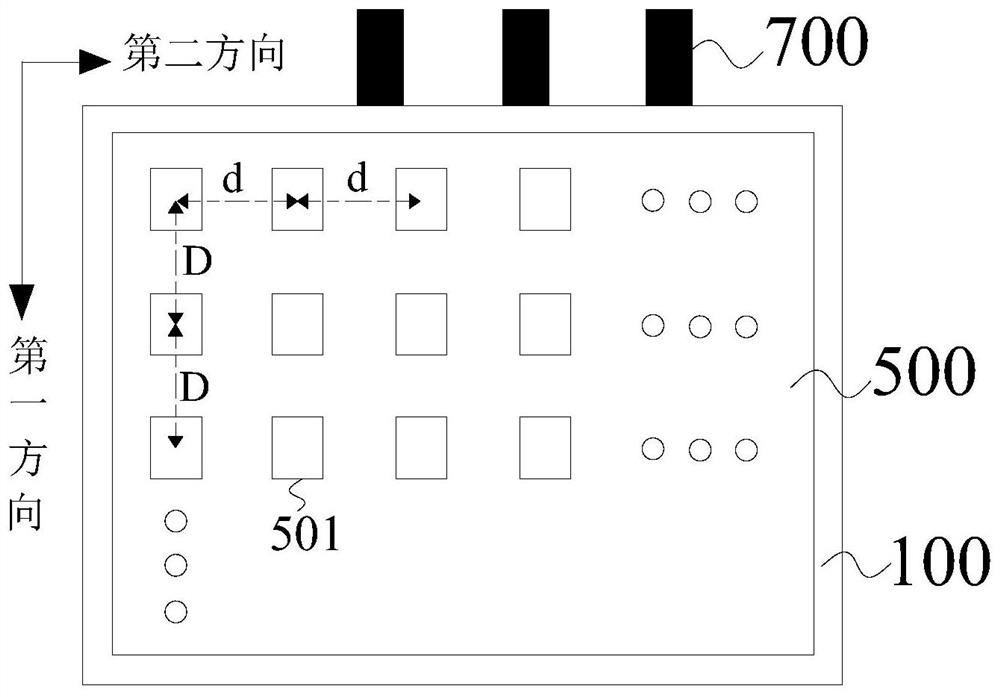

Display backboard, display panel and display device

PendingCN111653685AImprove brightness uniformityImprove display qualitySolid-state devicesSemiconductor/solid-state device manufacturingDisplay deviceEngineering

The invention provides a display backboard, a display panel and a display device. The display backboard comprises: a substrate; a pixel defining layer arranged on one side of the substrate and provided with a plurality of first openings and a plurality of second openings; anode layers disposed in the first openings; auxiliary cathodes disposed in the second openings; and a light-emitting layer which covers the pixel defining layer and the anode and is provided with a plurality of laser openings, wherein the orthographic projections of the laser openings on the substrate partially coincide withthe orthographic projections of the auxiliary cathodes on the substrate, the distance between every two adjacent laser holes in the second direction is gradually decreased in the first direction, andthe second direction and the first direction are arranged in a crossed mode. According to the display backboard provided by the invention, the longitudinal density of the plurality of laser holes which are formed in the light-emitting layer and used for connecting the auxiliary cathode and the cathode is gradually increased, so that the punching time of laser punching can be shortened, the yieldcan be improved, and meanwhile, the brightness uniformity and the display quality of the display backboard can also be improved.

Owner:BOE TECH GRP CO LTD +1

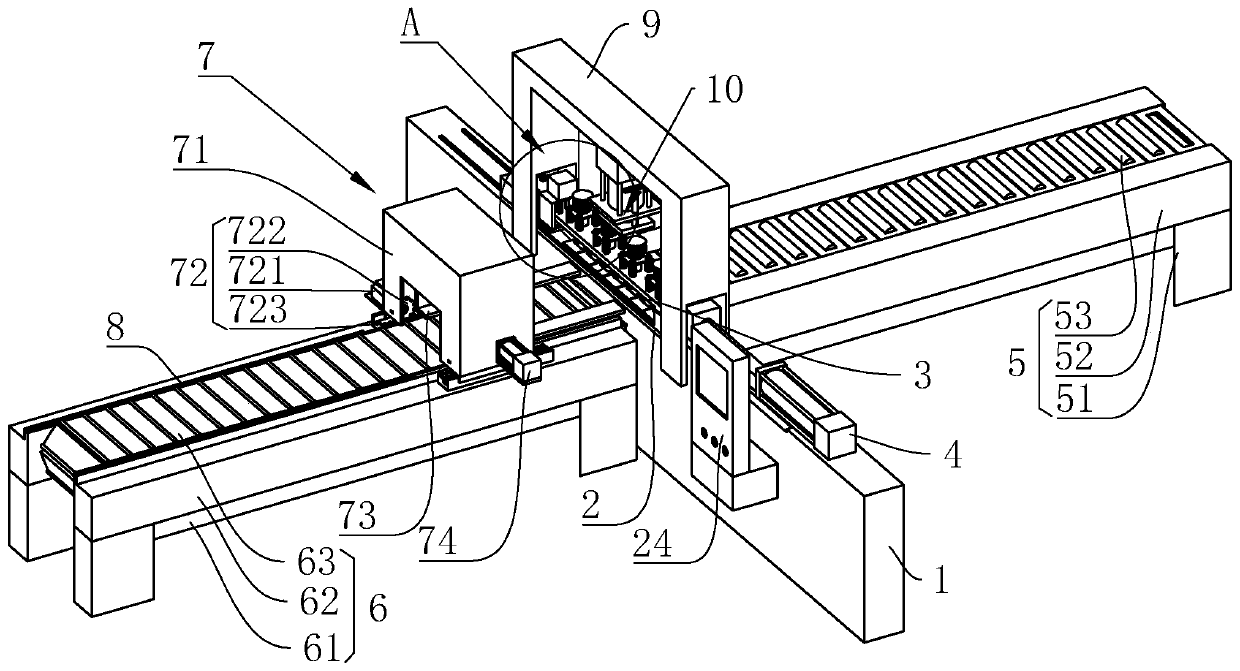

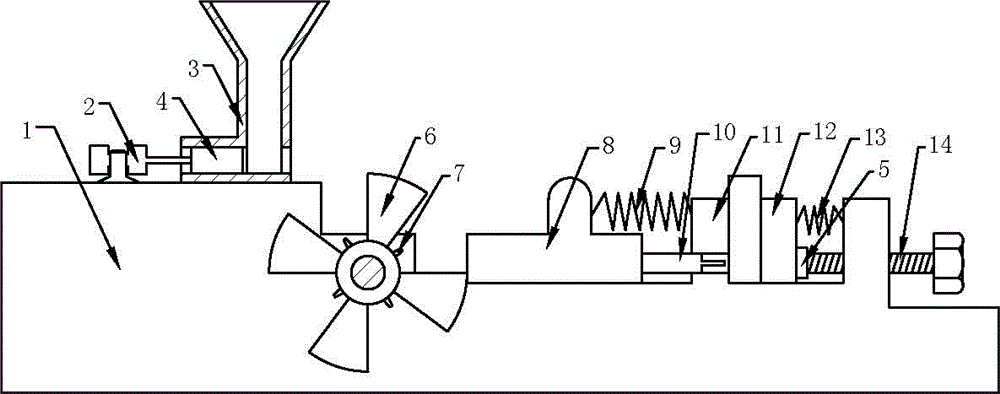

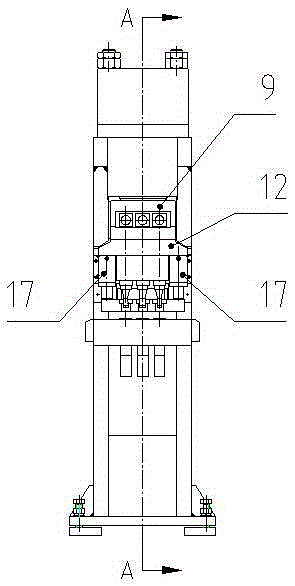

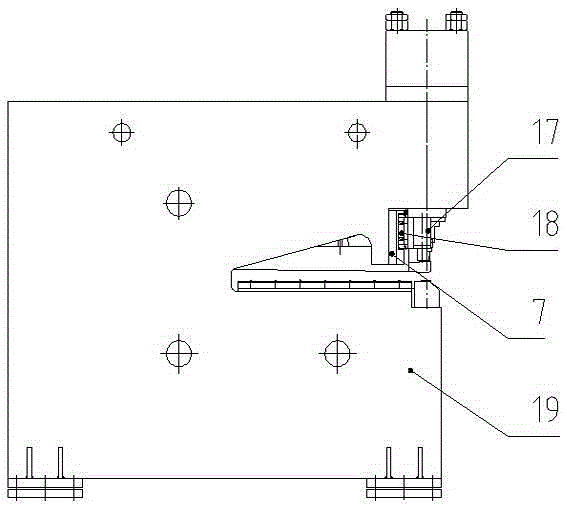

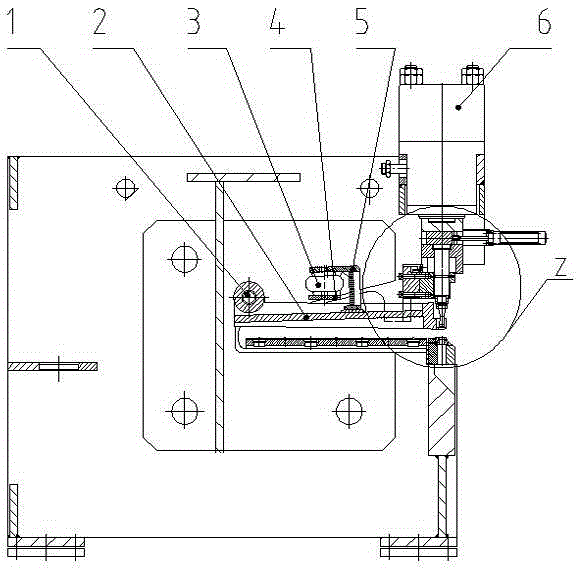

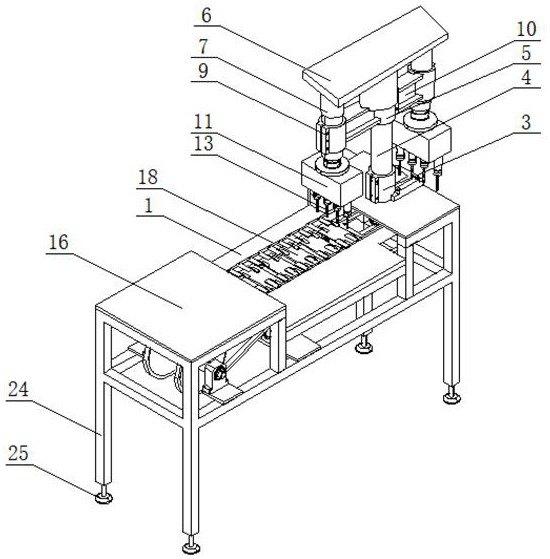

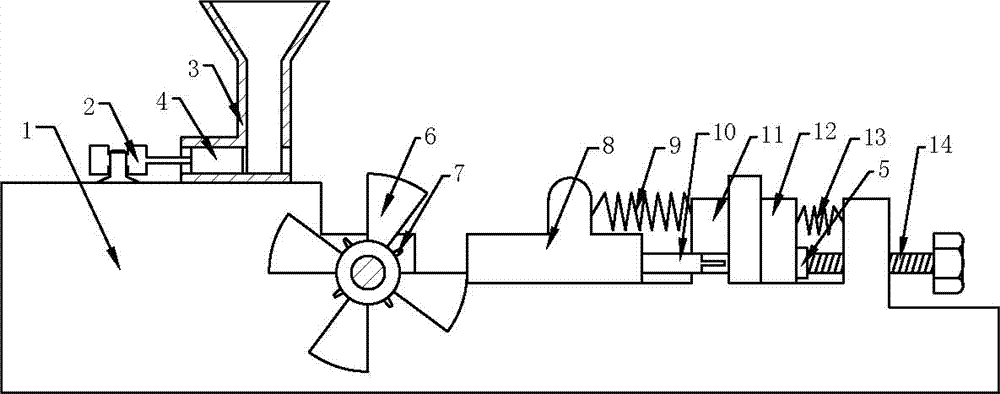

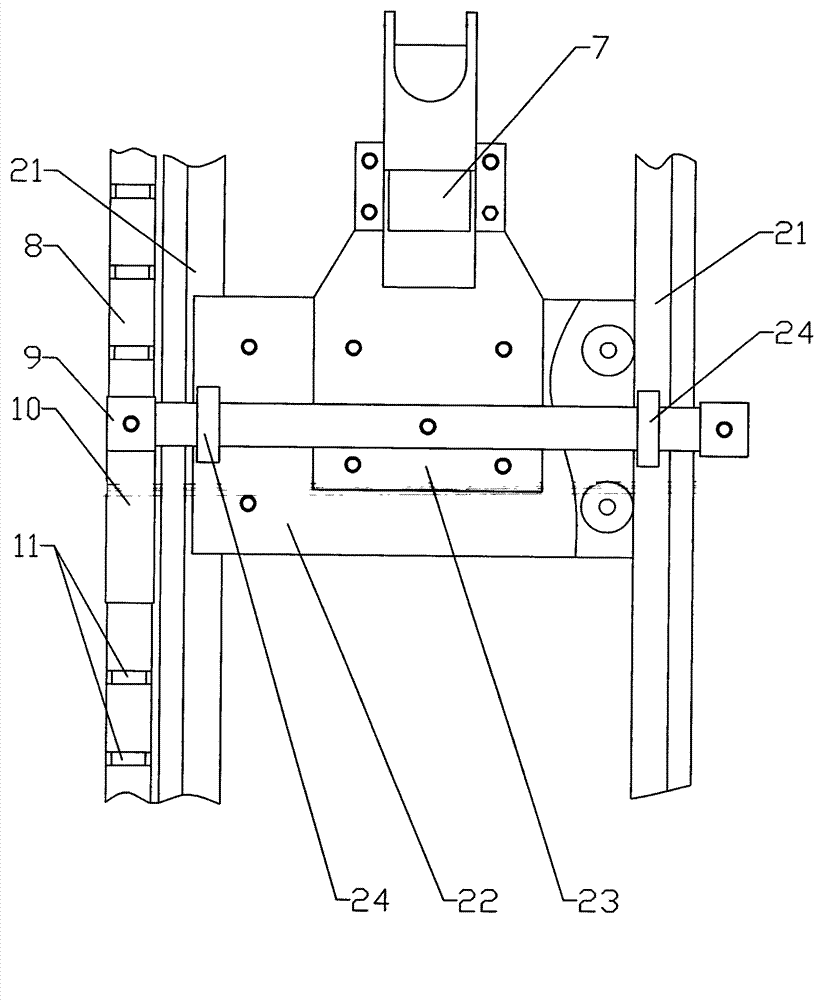

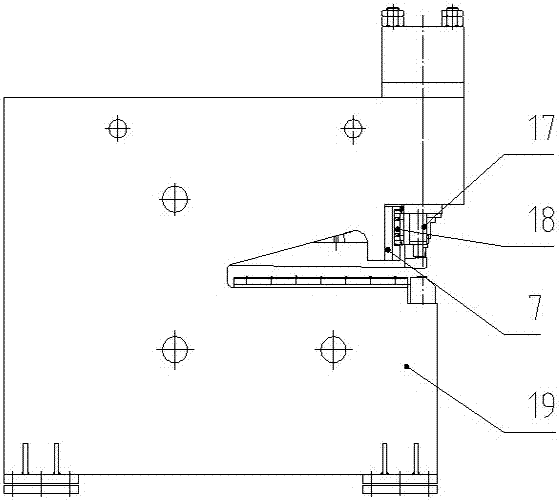

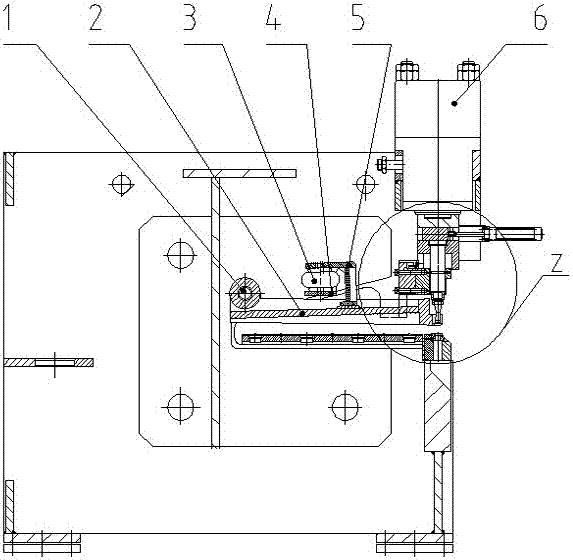

Numerical control hydraulic punching machine with follow-up material-pressing device

ActiveCN105382092ASave punching timeIncrease productivityShaping toolsPerforating toolsNumerical controlPunching

The invention discloses a numerical control hydraulic punching machine with a follow-up material-pressing device. The numerical control hydraulic punching machine comprises a machine body, a punching oil cylinder, the follow-up material-pressing device, a punching head and a female die. The follow-up material-pressing device comprises a material-pressing frame and two one-way material-pressing oil cylinders. The material-pressing frame is rotatably installed on the machine body through an installing shaft. The one-way material-pressing oil cylinders are fixedly installed on the machine body through a guide base plate and fixed to a piston rod of the punching oil cylinder through a pressing head and a punching head rod base. The two one-way material-pressing oil cylinders are distributed on the two sides of a punching head rod guide base. The lower portions of piston rods of the one-way material-pressing oil cylinders are attached to the material-pressing frame tightly. The piston rod of the punching oil cylinder can drive the one-way material-pressing oil cylinders to move downwards. The punching head rod guide base is installed on the guide base plate. The punching head is fixedly installed on a punching head rod through a locking nut. The punching head rod is installed in the punching head rod base. The material-pressing frame is further provided with a material-pressing frame re-rising structure.

Owner:JINAN EVERSHINING CNC MACHINE

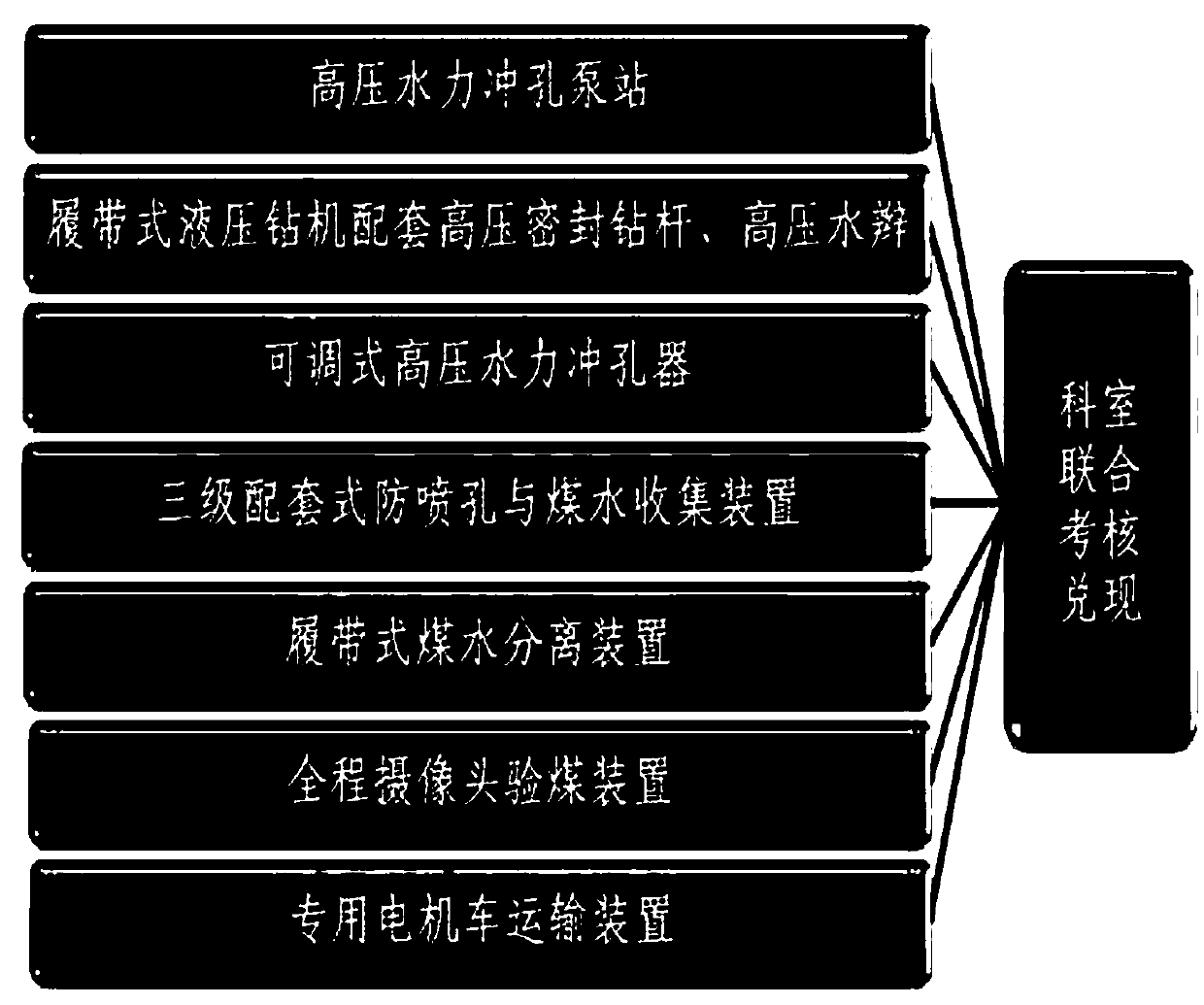

Drilling, punching, screening and transporting integrated gas treatment method

InactiveCN110985111ASafe punching water pressureImprove punching effectLiquid/gas jet drillingMachines/enginesCoal waterPunching

The invention belongs to the field of coal mining, and particularly relates to a drilling, punching, screening and transporting integrated gas treatment method. The drilling, punching, screening and transporting integrated gas treatment method comprises the steps of optimization of a high-pressure hydraulic power punching pump station, optimization of a crawler-type hydraulic drilling machine, optimization of a hydraulic puncher, optimization of a blowout control hole and a coal water collecting device and optimization of a crawler-type coal-water separating device. After the new procedures are carried out, the trouble that coal water generated by punching flows disorderly and coal-water separation is hard is solved thoroughly, and more importantly, single-hole metering can be achieved, the amount of coal punched out of one hole by a worker in one shift and the number of settled wage are clear at a glance, and the enthusiasm of the worker for hydraulic punching is greatly improved. Manual coal clearing, coal loading, coal transporting and other links are reduced, the coal water generated by punching is directly loaded into a tramcar through a coal-water separating device, pulverized coal of the current shift can be directly carried away, cost input is reduced, and the on-site quality standardization level is improved.

Owner:苏三星

Straight down type voice diaphragm punching die

InactiveCN104301855ASave punching processSave punching timeElectrical transducersPunchingEngineering

The invention relates to punching dies, in particular to a straight down type voice diaphragm punching die used for punching voice diaphragms. The straight down type voice diaphragm punching die comprises an upper knife edge and a lower knife edge corresponding to the upper knife edge, the lower knife edge is an annular column and is hollow, a voice diaphragm to be punched is arranged at the upper end of the lower knife edge, and the edge of the voice diaphragm to be punched is folded inwards and perpendicularly to form a locating ring attached to the exterior outline of the lower knife edge. By the adoption of the structure, the voice diaphragm directly falls off from the hollow portion of the lower knife edge after being punched by the straight down type voice diaphragm punching die, so that it is avoided that the voice diaphragm is fetched after an ejection spring ejects a locating die core. The voice diaphragm directly falls off after being punched, and then the next voice diaphragm to be punched can be placed to be punched continuously, so that the punching processes are reduced, punching time is shortened, and punching efficiency is improved.

Owner:BESTAR HLDG

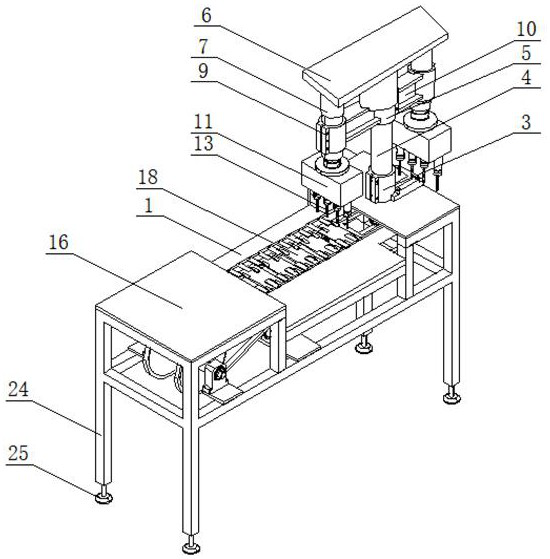

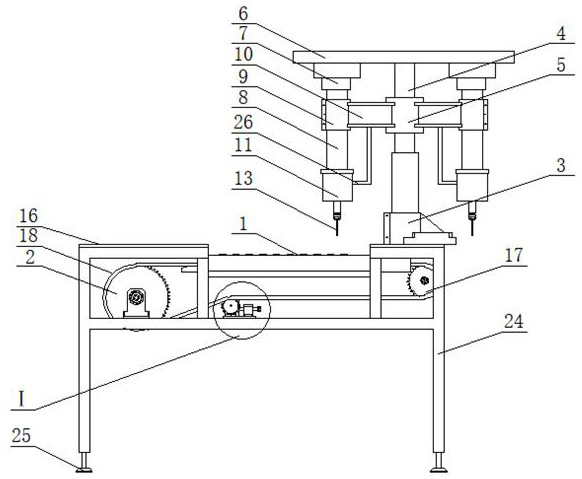

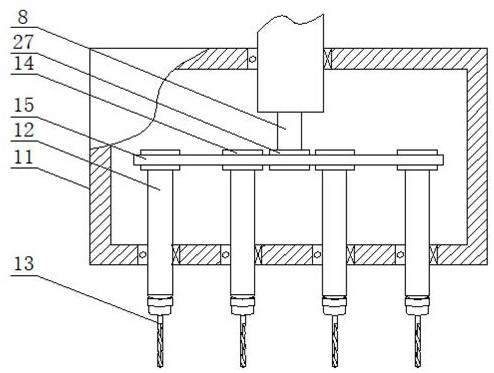

Aluminum alloy plate machining and drilling device

ActiveCN113894322ASimple structureEasy to useLarge fixed membersDriving apparatusElectric machineryEngineering

The invention provides an aluminum alloy plate machining and drilling device, and mainly relates to the field of plate machining and drilling equipment. The aluminum alloy plate machining and drilling device comprises a workbench, a transmission device is arranged on the workbench, a telescopic rod is rotatably mounted at one side of the top surface of the workbench through a bearing seat with a locking device, the periphery of the telescopic rod is provided with a first connecting sleeve in a sleeved manner, a transverse plate is mounted at the top end of the telescopic rod, and driving motors are mounted at two sides of the bottom surface of the transverse plate. The beneficial effects of the device are that the structure is simple, the usage is convenient, porous operation can be conducted on one plate at the same time through the arrangement of multiple drill bits, the drilling time is saved, the drilling operation efficiency is improved, two drill bit sets are arranged, when one drill bit set breaks down, the other drill bit set can be rapidly replaced for operation, the downtime is shortened, the continuity of the drilling operation is ensured, the operation efficiency is further improved, and convenience is brought to the drilling operation of the plates.

Owner:烟台智诚铝业科技有限公司

Adhesive tape blanking system for adhesive tape production and using method thereof

ActiveCN112960453ASave punching timeSpeed up the blanking processFinal product manufactureArticle deliveryTool bitAdhesive belt

The invention discloses an adhesive tape blanking system for adhesive tape production and a using method thereof, and belongs to the technical field of adhesive tape production. The adhesive tape blanking system for adhesive tape production comprises a workbench, the top of the workbench is connected with a blanking table, the side wall of the workbench is connected with a connecting plate, the end, away from the workbench, of the connecting plate is connected with a supporting plate, the top of the supporting plate is connected with an air cylinder and a motor, the bottom of the supporting plate is rotationally connected with a rotating column through a bearing, the end, away from the supporting plate, of the rotating column is connected with a working block, two mounting grooves are formed in the outer wall of the working block, tool bit assemblies are movably connected into the mounting grooves, the output end of the air cylinder penetrates through the supporting plate and is connected with a driving rod, the outer wall of the driving rod is connected with a pressing plate, the pressing plate movably abuts against the tool bit assemblies, and the output end of the motor is connected with a rotating shaft. The tool bit assemblies can be conveniently and rapidly replaced, the blanking time is saved, the blanking process is accelerated, and the working efficiency of adhesive tape production is improved.

Owner:SHANGHAI RENHONG PRECISION MACHINERY

Bilateral frame positioning and punching device

PendingCN107378266AEliminates unwanted effects of uneven bottom surfacesEliminate the adverse effects of unevennessLaser beam welding apparatusLaser transmitterStructural engineering

The invention relates to a bilateral frame positioning and punching device which is used for punching two sides of a frame. The device comprises a driving part, a double-output-shaft steering box and two groups of punching mechanisms, the driving part is fixed on a positioning platform of the frame, an output end of the driving part is fixedly connected with an input end of the double-output-shaft steering box, two output ends of the double-output-shaft steering box are fixedly connected with the punching mechanisms, each group of punching mechanisms comprise cross rods, vertical rods and laser transmitters, the output ends of the double-output-shaft steering box are fixedly connected with the cross rods, the cross rods are fixed with the vertical rods, the vertical rods are fixed with the laser transmitters, and one side of the frame is punched by the laser transmitters. According to the positioning and punching device, the punching mechanisms are simultaneously driven, so that two sides of the frame are punched in a laser manner, manual carrying of the frame or movement of a machining device is avoided, adverse effects of unevenness of the bottom surface of the frame are eliminated, concentricity of two holes in two sides of the frame can be completely ensured, and production efficiency and punching quality are improved.

Owner:湖北天明粮油设备有限公司

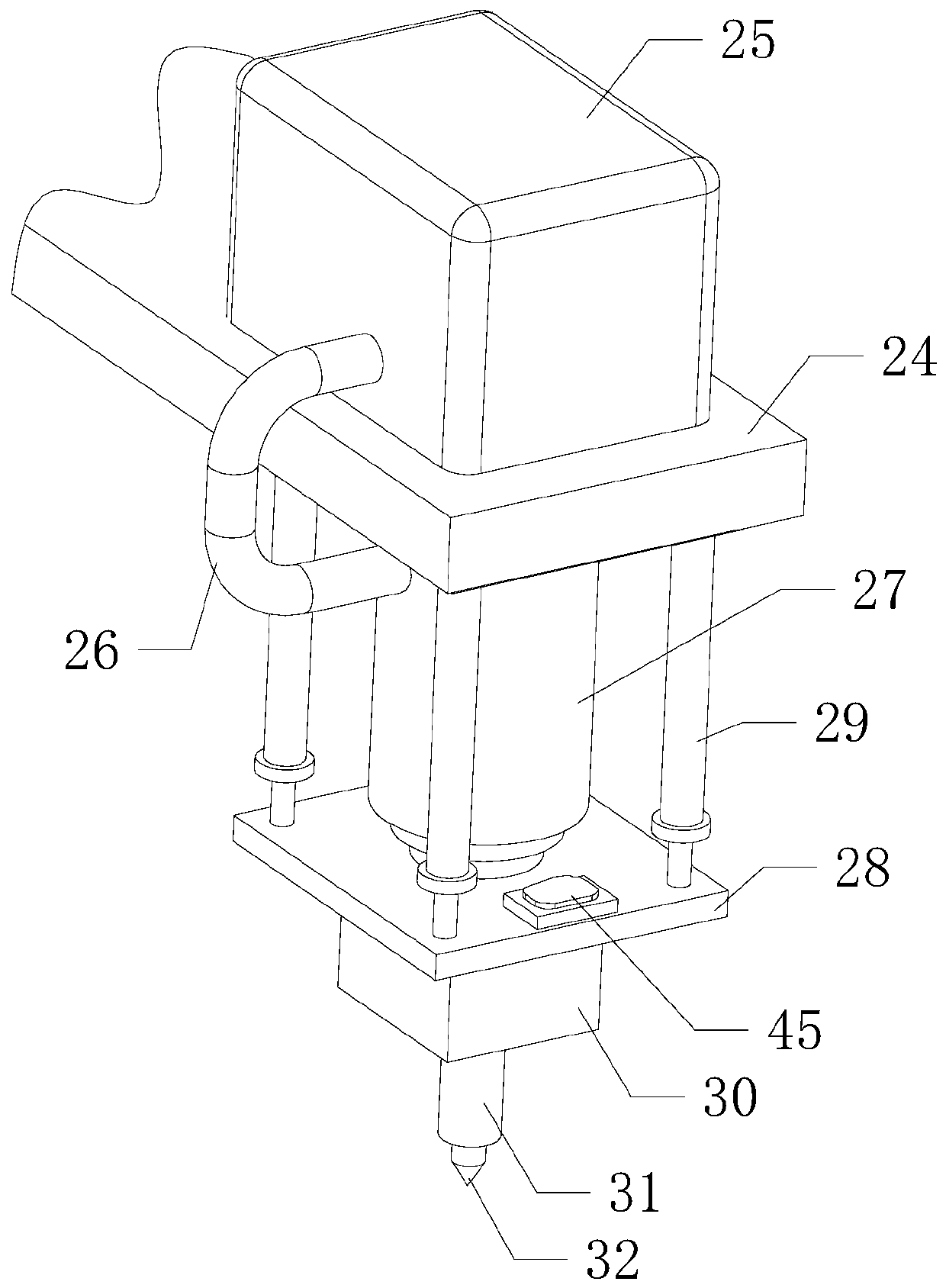

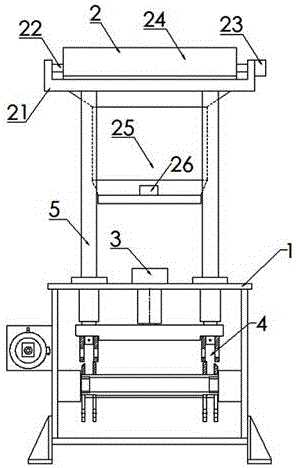

Cutting device with moving head

InactiveCN106625818AEasy to operateGuaranteed uptimeMetal working apparatusEngineeringMechanical engineering

The invention discloses a cutting device with a moving head. The cutting device is composed of a workbench (1) and a moving press head component (2), wherein an oil cylinder device (3) is arranged on the workbench (1), and the oil cylinder device (3) drives the moving press head component (2) to press downwards to cut materials on the workbench (1). The cutting device is characterized in that the moving press head component (2) is composed of an upper press plate (21), a lead screw (22) arranged at the top end of the upper press plate (21), a servo motor II (23) connected to the lead screw (22), a moving head slide rail (24) arranged on the lead screw (22), the moving head (25) connected to the moving head slide rail (24) and a sensor (26) arranged on the moving head (25); and the moving head (25) is controlled to move left and right through the servo motor II (23). According to the cutting device disclosed by the invention, one-time material feeding and many-time cutting are realized, thus the production efficiency is greatly increased.

Owner:YANCHENG CITY LONG XIANG MACHINERY MFG PLANT

Fixing device for perforating of bread board

InactiveCN109277842ASimple structureGood effectPositioning apparatusMetal-working holdersComputer engineering

The invention discloses a fixing device for perforating of a bread board. The fixing device comprises a base which is transversely arranged, a bottom sheet is laid on the top of the base, two clampinggrooves are formed in the top of the bottom sheet, a supporting rod is arranged at each of the two ends of the top of the base, a cross beam is arranged at the top of each of the two supporting rods,the two ends of each cross beam are each provided with a stretching arm, a connecting rod is installed in the middle of each cross beam, one end of each connecting rod is provided with a perforatingseat supporting rod, a perforating seat is arranged on one side of each perforating seat supporting rod, and several limiting grooves are formed in each perforating seat. Two supporting sheets with the same size are directly inserted into the two clamping grooves in the base of the fixing device by a user, the bread board needing to be perforated is flatly placed on the mutually-parallel supporting sheets, concave openings in fixing heads are just clamped on the bread board by moving the stretching arms, perforating machine heads are sequentially placed into the limiting grooves, and a perforating machine is pushed to perform perforating on the bread board.

Owner:季德贵

Reciprocating punching device

The invention discloses a reciprocating type punching device which comprises a rack, and a punch head and a punching seat that are arranged on the rack sequentially; a first spring is connected between the punch head and the rack; and the punching seat is slidingly connected with the rack. The reciprocating type punching device further comprises an explosive rotary plate and an intermittent pushing mechanism for pushing an explosive into the explosive rotary plate intermittently; the intermittent pushing mechanism is arranged on one side, far from the punching seat, of the punch head; the explosive rotary plate is arranged between the intermittent pushing mechanism and the punch head, and is rotationally connected with the rack; partition plates are uniformly distributed in the circumferential direction of the explosive rotary plate; a containing cavity containing the explosive is formed between every two partition plates; a flaming mouth is formed in each containing cavity; and a pushing plate is fixedly connected with one end, close to the explosive rotary plate, of the punch head, and is abutted against one partition plate. Compared with the prior art, the explosive reacts more quickly, an instant impact force of the explosive is greater, the punching time can be reduced and the punching efficiency can be improved; and a punching force of the punch head can be ensured, so that when the punch head punches a workpiece, fewer burrs are generated around the hole wall, and the polishing time is reduced.

Owner:重庆新钰立金属科技有限公司

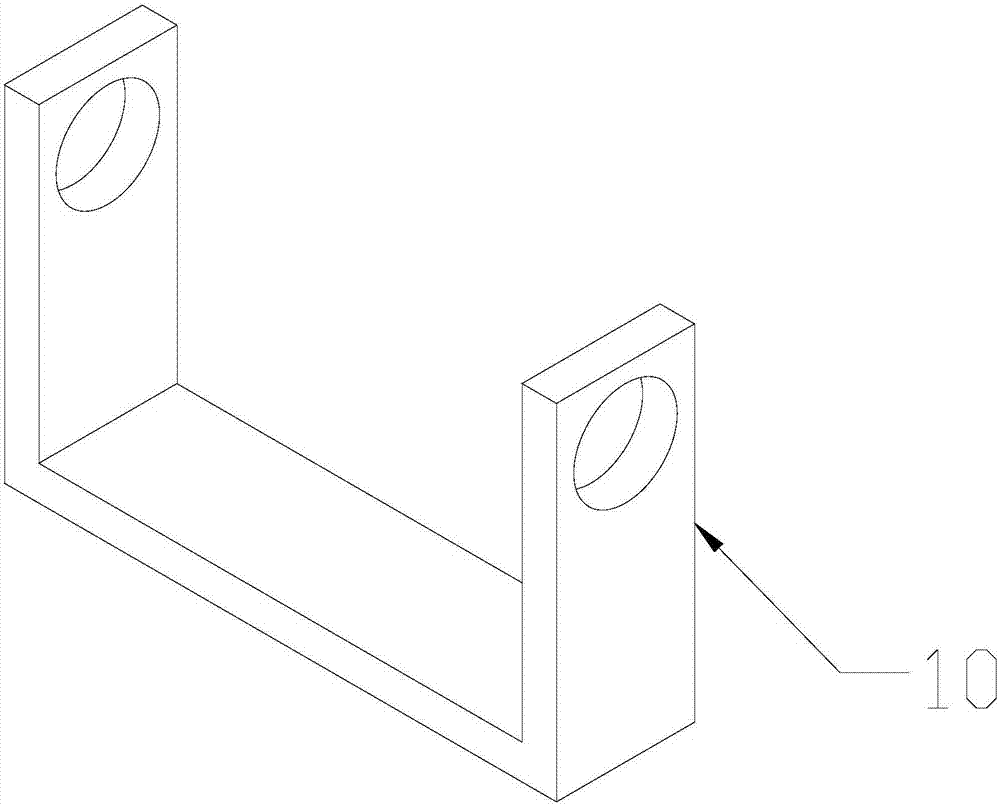

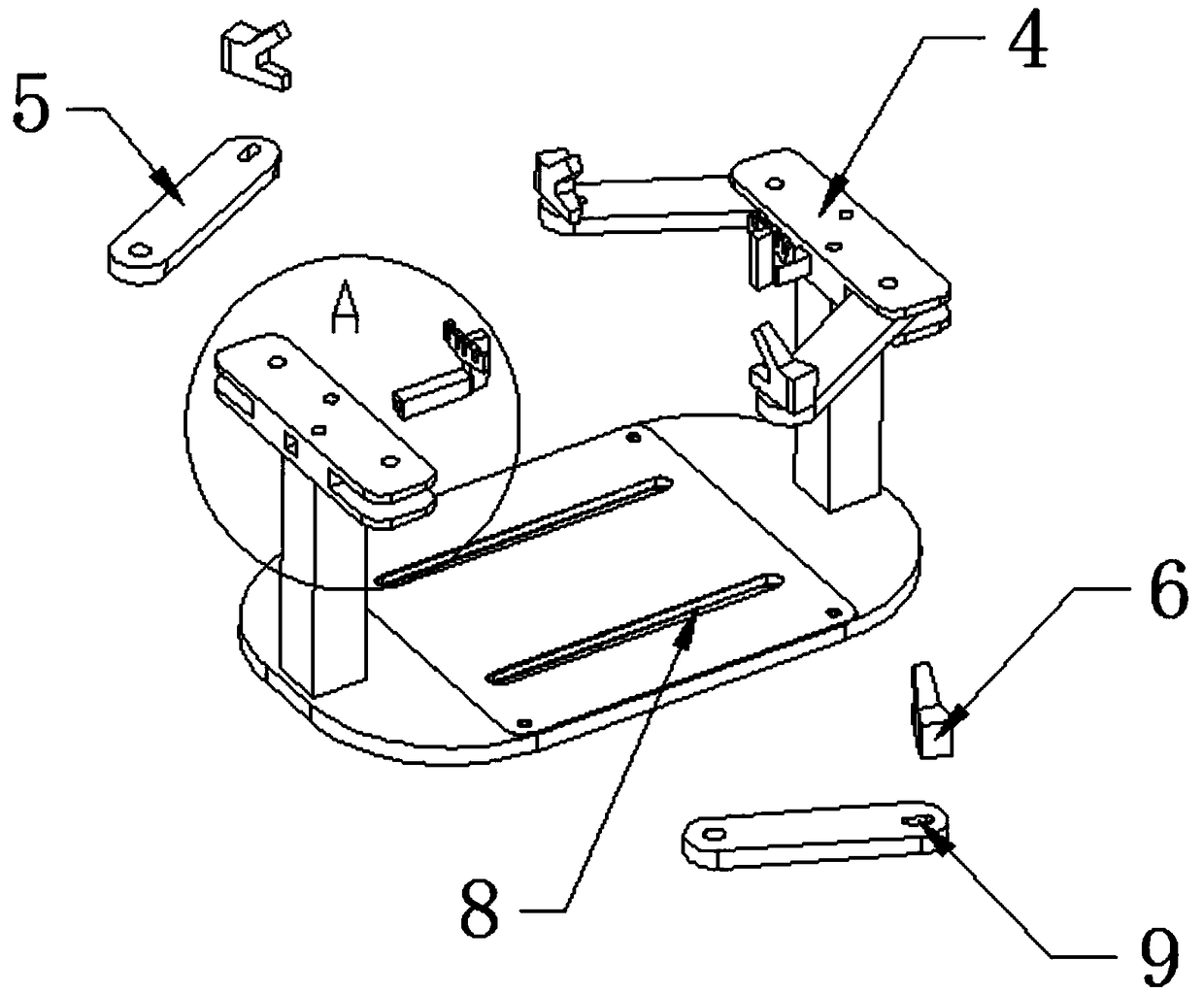

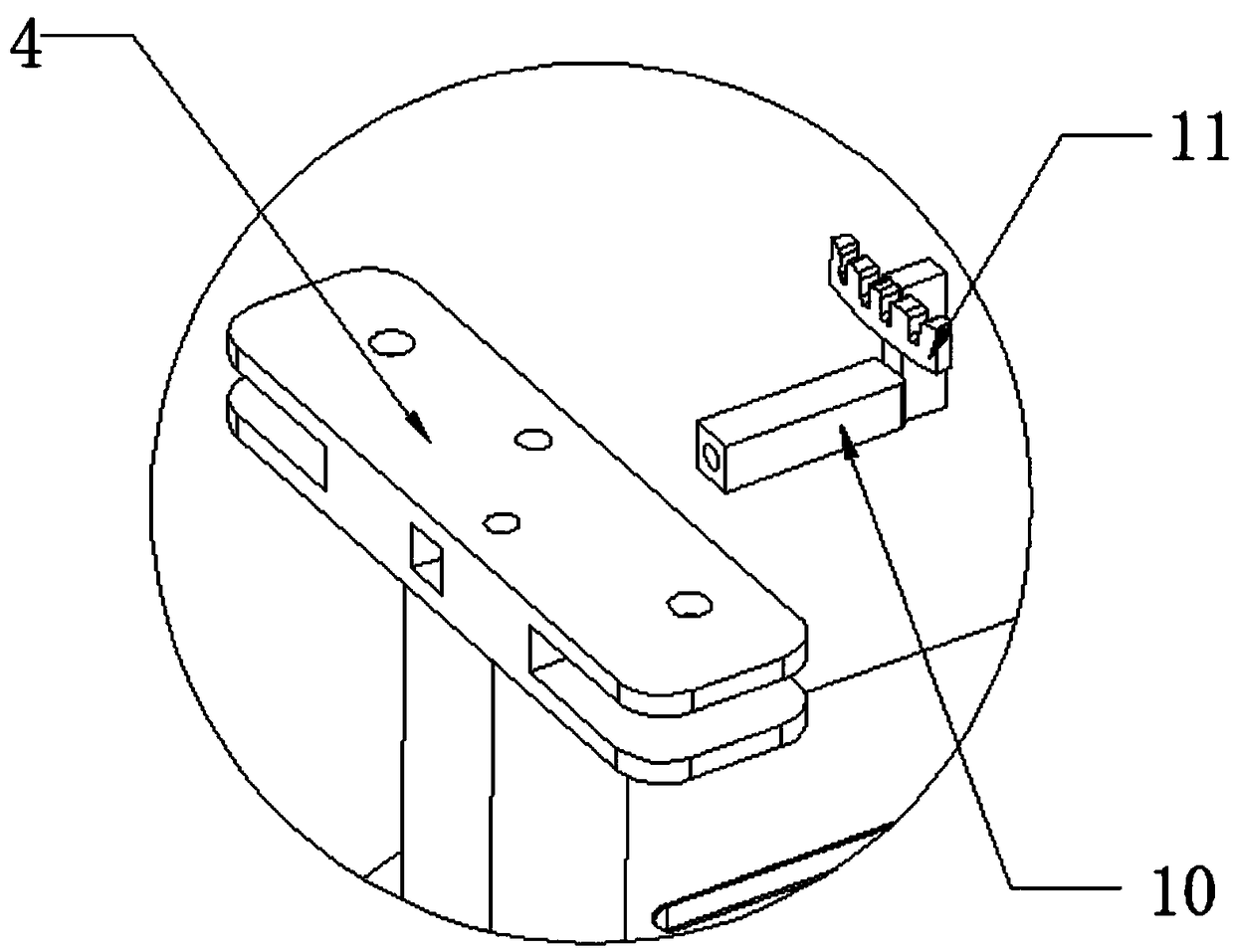

Clamping device for glass plate laser drilling machine

InactiveCN112589293AImprove drilling efficiencyHighly consistentWelding/cutting auxillary devicesAuxillary welding devicesEngineeringMechanical engineering

The invention discloses a clamping device for a glass plate laser drilling machine, and belongs to the technical field of glass plate deep processing auxiliary equipment. The clamping device comprisesa supporting cross beam, a plurality of first clamping device bodies and a plurality of second clamping device bodies, one end of each first clamping device body is detachably and fixedly connected with the supporting cross beam, the other end of each first clamping device body abuts against one side of a glass plate, the second clamping device bodies are arranged on the other side of the glass plate, one side of each second clamping device body abuts against the other side of the glass plate, and the other end of the first clamping device body is matched with one side of the second clampingdevice body in a clamping manner to clamp the glass plate. During drilling, the glass plate is jacked up and clamped, the height of the lower surface of the glass plate is kept consistent, the positioning accuracy of a visual system can be guaranteed, and the drilling efficiency and the drilling precision are effectively improved.

Owner:CHINA TRIUMPH INT ENG

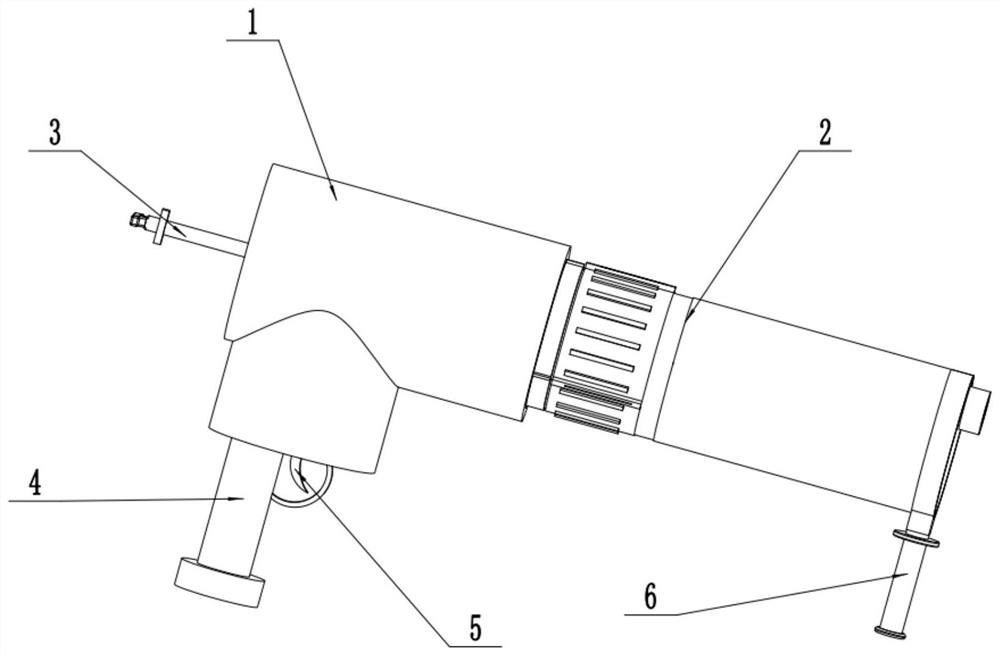

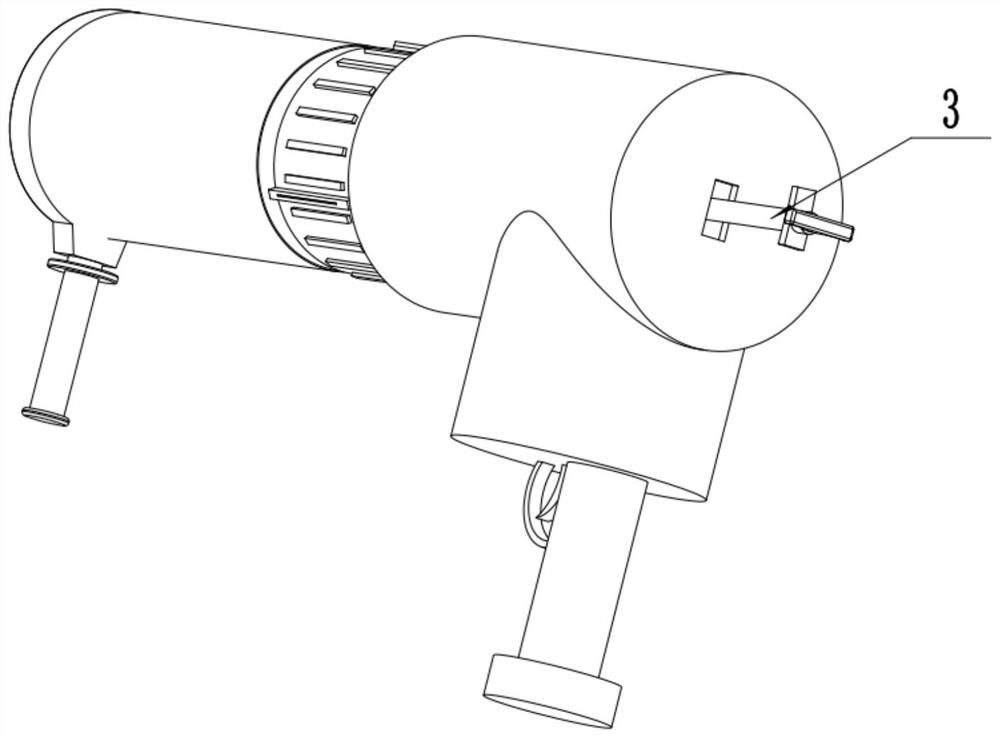

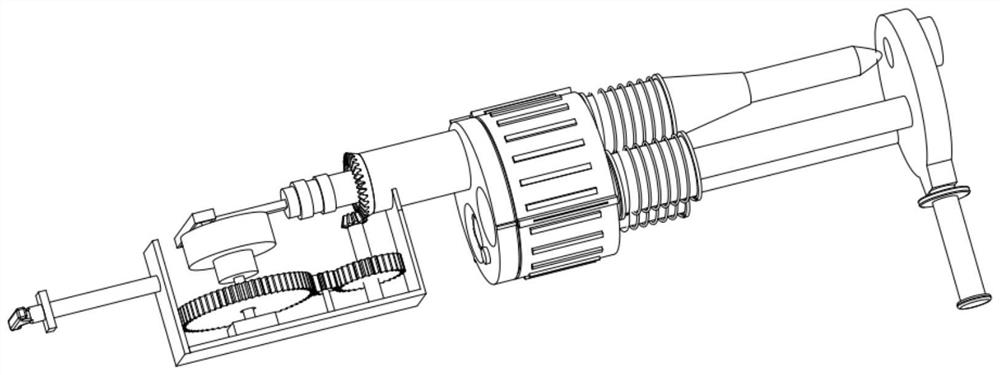

A device for installing expansion screws

ActiveCN112171581BEasy to useImprove securityMetal-working hand toolsStone-like material working toolsClassical mechanicsStructural engineering

A device for installing expansion screws, comprising a transmission mechanism, a drill bit mechanism, a push-pull handle, a main grip, a switch, and a secondary grip structure, characterized in that: the transmission mechanism and the drill bit mechanism are rotated and installed to realize switching between different drill bit functions; Rotate and install the cylindrical part of the structure and the drill mechanism, hold the auxiliary handle structure with the other hand to maintain the stability of the machine, and adjust the angle of the auxiliary handle structure to facilitate the use of the machine; the main handle is provided under the casing of the transmission mechanism , There is a switch under the casing of the transmission mechanism, and the operation of the transmission mechanism is controlled by the switch; the push-pull handle is installed outside the casing of the transmission mechanism, and the push-pull handle is rotated and installed behind the U-shaped iron plate. The push-pull handle is used to push and fix U-shaped iron plate.

Owner:邯郸市大润紧固件制造有限公司

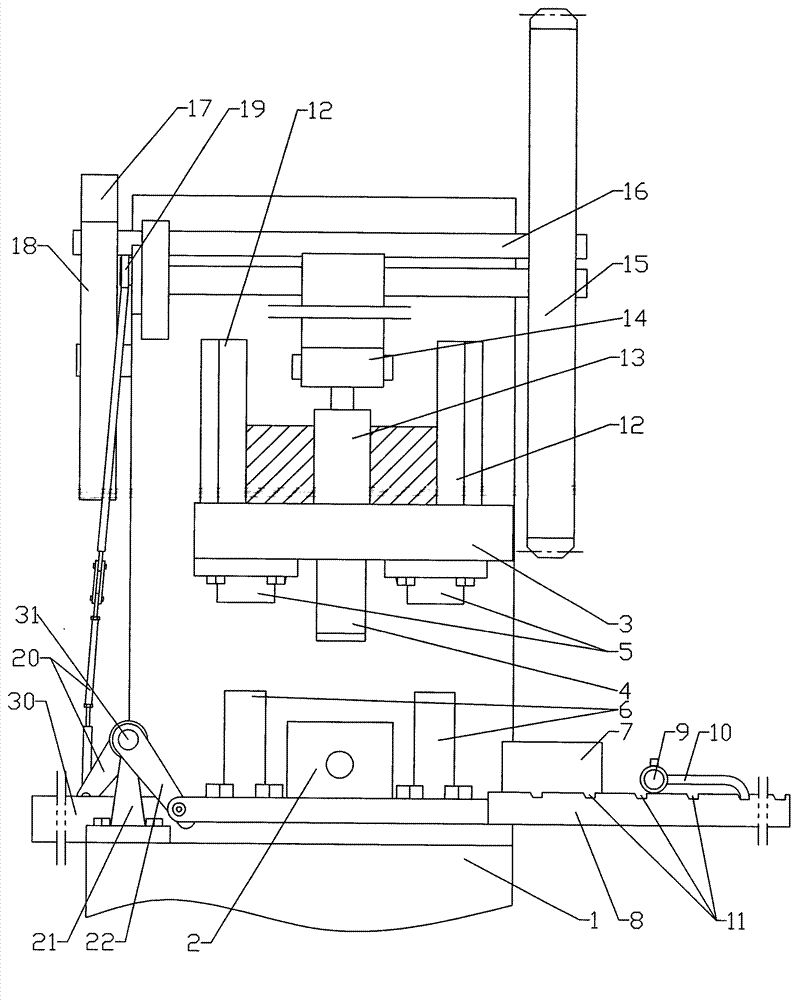

Full-automatic PCB punching equipment based on machine vision and punching method

PendingCN113799195ASave punching timeNarrow down the difference rangeMetal working apparatusMachine visionEngineering

The invention provides full-automatic PCB punching equipment based on machine vision and a punching method, and relates to the field of punching equipment. According to the full-automatic PCB punching equipment based on machine vision and the punching method, a bottom plate is included, a PCB is arranged at the top end of the bottom plate, a platform moving track is fixedly connected to the top end of the bottom plate, and two limiting stopper fixing plates are fixedly connected to the top end of the bottom plate. A camera module can identify strip-shaped information in the PCB through imprinting information of the PCB, the number information and the relative position information of plate-shaped holes stored on a PC main control computer are called out, so that multi-channel one-time punching is realized, the punching time can be effectively shortened, the image data on the PCB are collected, the original point of a gray-scale printing circular hole is taken as the center, a circular image with the maximum diameter of 5 mm is reserved, high exposure processing needs to be performed on the other part of the image, so that repeated automatic punching is realized through the PC main control computer, and the difference value range between the punched area and the non-punched area is continuously reduced.

Owner:GUANGXI UNIVERSITY OF TECHNOLOGY

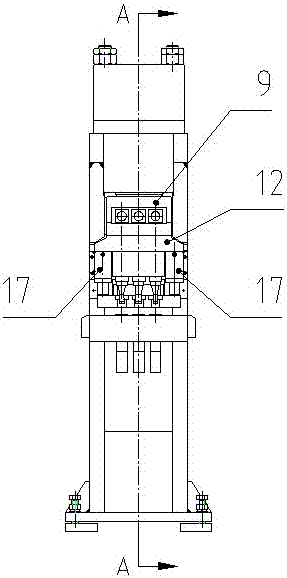

Main pipe punching device for radiator

InactiveCN102962320AImprove punching accuracySave punching timeShaping toolsPerforating toolsPunchingEngineering

The invention relates to a main pipe punching device for a radiator, which comprises a rack, wherein the rack is provided with a lower die, an upper die is correspondingly arranged right above the lower die, a working table is arranged on one side of the lower die, a feed device is arranged on the other side of the lower die, and the main pipe punching device for the radiator is characterized in that the upper die is connected with an eccentric mechanism which is connected with a power device in a drive way. The main pipe punching device for the radiator has the following advantages that: 1, three surfaces can be punched at the same time and the punching precision is high; 2, the punching time is saved and the working efficiency is improved; and 3, the main pipe punching device for the radiator is simple in structure and convenient to use, and automated operation is implemented.

Owner:QINGZHOU SHENGHONG IND & TRADE

Drilling device for auto parts

ActiveCN108620626BAvoid punching effectsImprove accuracyPositioning apparatusMaintainance and safety accessoriesGear wheelEngineering

The invention relates to the technical field of automobile part processing and discloses a perforating device for automobile parts. The perforating device for automobile parts comprises a rack, wherein a worktable is slidably connected to the rack and an air supply box is fixedly connected to the rack; a first air chamber and a second air chamber communicate to the air supply box; a first worm wheel is rotatably connected to the first air chamber; a first gear is coaxially connected to the first worm wheel; a first rack is engaged to the first gear; a second worm wheel is rotatably connected in the second air chamber; a second gear is coaxially connected to the second worm wheel; a second rack is engaged to the second gear; a perforating pile is rotatably connected to the second rack; a spline sleeve sleeves the perforating pile; a third air chamber communicating to the first and second air chambers is fixedly connected to the rack; a third worm wheel is connected to the spline sleevein a sleeving manner; an adjusting mechanism is arranged on the worktable; a first touch switch for closing the air supply box is mounted on the adjusting mechanism; and a supporting rod leaning against the first touch switch is arranged on the third air chamber. The perforating device for automobile parts provided by the invention can adjust the perforating depth and improves the perforating efficiency.

Owner:宁波隆锐机械制造有限公司

A CNC hydraulic punching machine with a follow-up pressing device

ActiveCN105382092BSave punching timeIncrease productivityShaping toolsPerforating toolsNumerical controlPunching

Owner:JINAN EVERSHINING CNC MACHINE

Punching device

InactiveCN113815045ASave punching timeImprove punching efficiencyCircuit board tools positioningMetal working apparatusPunchingStructural engineering

The invention relates to the technical field of circuit board manufacturing, and provides a punching device. The punching device comprises a rack, a punching mechanism and at least two workbenches, wherein the rack is provided with a feeding position and a punching position; the punching mechanism is arranged above the punching position; the at least two workbenches are used for bearing core boards; and the at least two workbenches can circularly move between the feeding position and the punching position, so that the punching mechanism is used for punching the core boards on the workbenches moved to the punching position. According to the punching device, after the core boards are positioned to one of the workbenches, the workbench can be moved to the punching position firstly, then the core boards on the workbenches are directly punched through the punching mechanism, the positions of the core boards do not need to be adjusted before punching, the punching precision is high, the punching time of the punching device is shortened, the waiting time is shortened, and the punching efficiency is improved.

Owner:KINWONG ELECTRONIC TECH (ZHUHAI) CO LTD

A kind of aluminum alloy plate processing punching device

ActiveCN113894322BSimple structureEasy to useLarge fixed membersDriving apparatusPunchingElectric machinery

The invention provides an aluminum alloy plate processing and punching device, which mainly relates to the field of plate processing and punching equipment. A punching device for processing aluminum alloy plates, including a workbench, on which a transmission device is arranged, and a telescopic rod is installed on one side of the top surface of the workbench through a bearing seat with a locking device, and the telescopic rod The first connecting sleeve is set on the outer periphery, a horizontal plate is installed on the top of the telescopic rod, and transmission motors are installed on both sides of the bottom surface of the horizontal plate. The beneficial effect of the present invention is that: the present invention is simple in structure, easy to use, by setting a plurality of drill bits, can carry out the drilling work on a plate at the same time, save the drilling time, improve the drilling efficiency, and by setting two sets of drill bit groups , when one group of drill bit fails, another group of drilling group can be replaced quickly, which shortens the downtime, ensures the continuity of drilling operation, further improves the operation efficiency, and brings convenience to the plate drilling operation .

Owner:烟台智诚铝业科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com