Adhesive tape blanking system for adhesive tape production and using method thereof

A technology of adhesive tape and punching table, applied in the direction of final product manufacturing, thin material processing, climate sustainability, etc., can solve the problems of cumbersome operation steps, low punching efficiency, long punching time, etc., and speed up the punching process , improve the service life and save punching time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

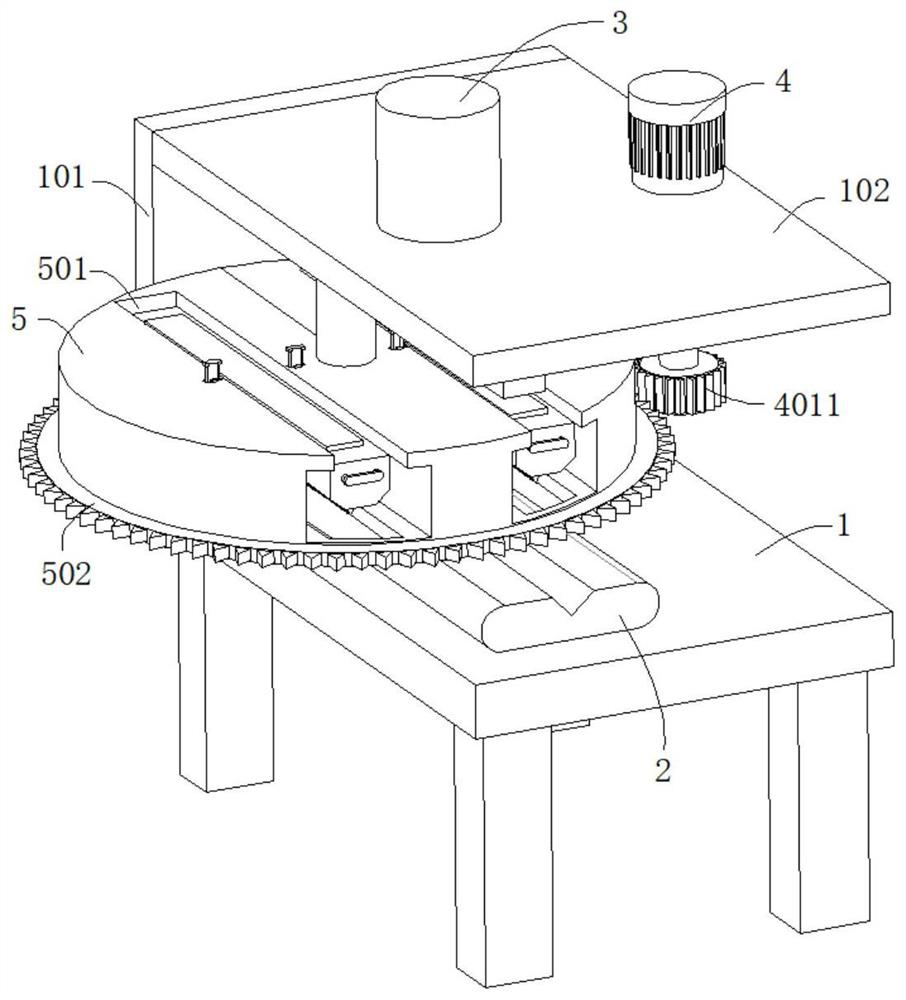

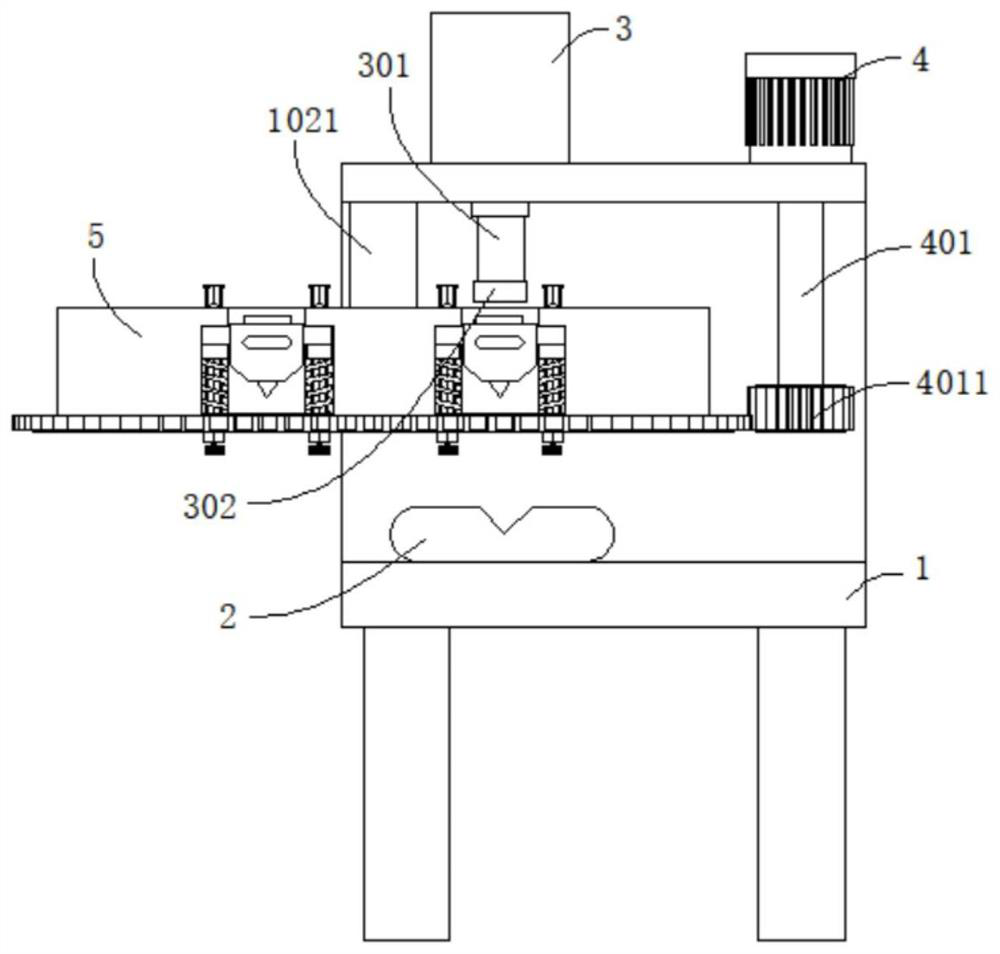

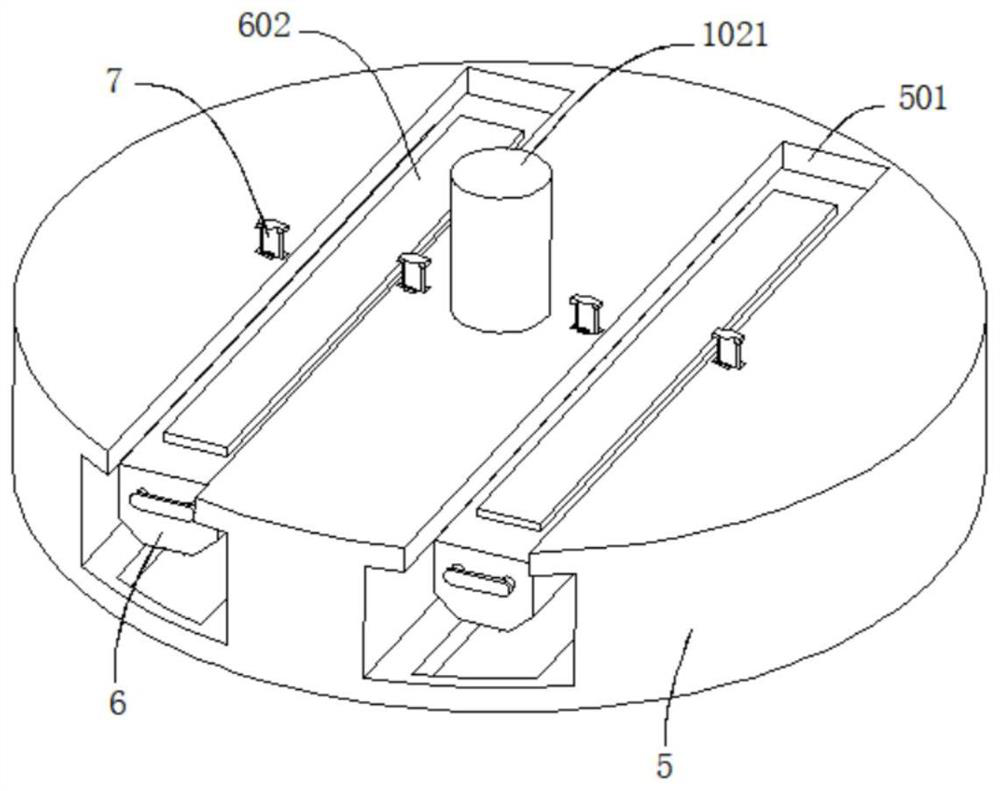

[0038] refer to Figure 1-5 , a tape punching system for adhesive tape production, comprising a workbench 1, a punching table 2 is connected to the top of the workbench 1, a connecting plate 101 is connected to the side wall of the workbench 1, and the end of the connecting plate 101 away from the workbench 1 is connected to There is a support plate 102, the top of the support plate 102 is connected with the cylinder 3 and the motor 4, the bottom of the support plate 102 is connected with the rotation column 1021 through the bearing rotation, and the end of the rotation column 1021 away from the support plate 102 is connected with the working block 5, the working block 5 Two installation grooves 501 are dug in the outer wall, and the cutter head assembly is movably connected in the installation groove 501. The output end of the cylinder 3 passes through the support plate 102 and is connected with the driving rod 301. The outer wall of the driving rod 301 is connected with a pre...

Embodiment 2

[0043] refer to Figure 3-10 , a tape blanking system for adhesive tape production, which is basically the same as that of Embodiment 1. Further, a positioning rod 7 is slidably connected in the installation groove 501, and the outer wall of the sliding block 603 and the moving plate 5012 is dug to match the positioning rod 7. The positioning rod 7 is slidably connected in the through hole, and the positioning rod 7 is placed in the inner ring of the first elastic element 5011 .

[0044] The top and the bottom of the positioning rod 7 are respectively connected with a top plate 701 and a bottom plate 702, the bottom plate 702 is offset against the bottom wall of the working block 5, and the outer walls of the working block 5, the moving plate 5012 and the sliding block 603 are all excavated with movable grooves matching the top plate 701 8.

[0045] Positioning rod 7 internal thread is connected with screw rod 11, and screw rod 11 outer wall is connected with knob 111, and on...

Embodiment 3

[0050] refer to Figure 1-10 , a tape blanking system for adhesive tape production, which is basically the same as that of Embodiment 2. Further, the outer wall of the positioning rod 7 is connected with a guide bar 9, and the outer wall of the working block 5 and the moving plate 5012 is dug with a guide bar 9. Guide groove 10; prevent positioning rod 7 from rotating with the rotation of screw rod 11, and improve the practicability of the device.

[0051] When in use, put the copper foil tape on the upper end surface of the punching table 2, then control the operation of the cylinder 3, so that the output end of the cylinder 3 drives the pressure plate 302 to move down through the drive rod 301, so that the pressure plate 302 exerts force on the cutter head assembly, and the knife The head mounting seat 6 is forced to drive the sliding block 603 to slide outside the positioning rod 7, the first elastic element 5011 is compressed, the cutter head mounting seat 6 drives the cut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com