Drilling device for auto parts

A technology for auto parts and punching devices, applied in positioning devices, metal processing machinery parts, boring/drilling and other directions, can solve the problem of inability to ensure the same force applied by workers, low punching efficiency, and large difference in depth, etc. problems, to achieve the effect of shortening the punching time, reducing the time of idling operation, and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described in detail below through specific implementations:

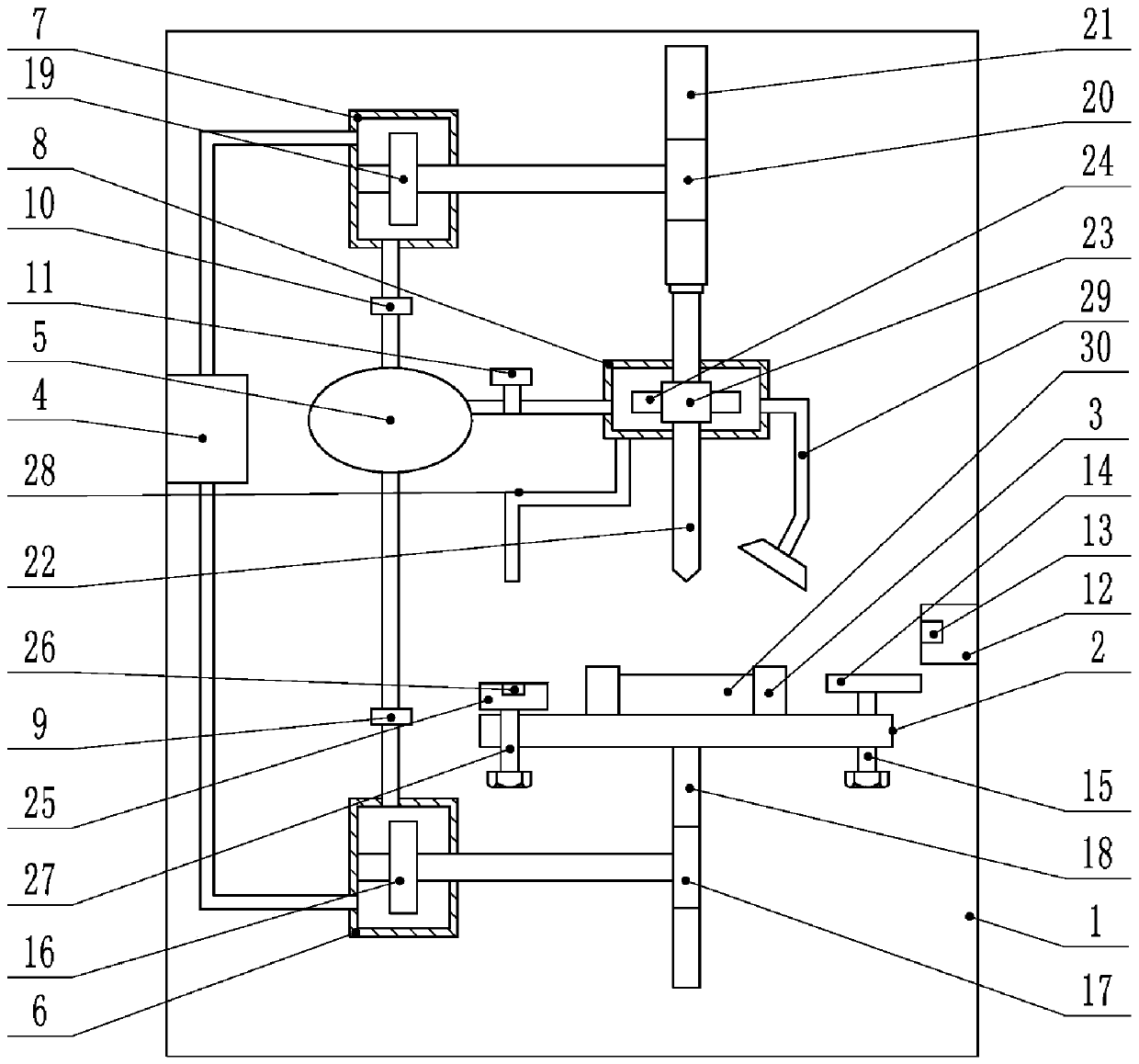

[0022] The reference signs in the drawings of the specification include: frame 1, workbench 2, fasteners 3, air supply box 4, air bag 5, first air chamber 6, second air chamber 7, third air chamber 8, first One-way valve 9, second one-way valve 10, valve 11, third slider 12, second touch switch 13, second slider 14, second screw 15, first turbine 16, first gear 17, first A rack 18, a second turbine 19, a second gear 20, a second rack 21, a perforated column 22, a spline sleeve 23, a third turbine 24, a first slider 25, a first touch switch 26, a first A screw 27, a support rod 28, an exhaust pipe 29, and parts 30.

[0023] This embodiment is basically as attached figure 1 Shown:

[0024] The punching device for automobile parts includes a frame 1, a workbench 2 is slidably connected to the frame 1, and a fastener 3 for clamping parts 30 is provided on the workbench 2; the fra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com