Patents

Literature

118results about How to "Shorten travel distance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

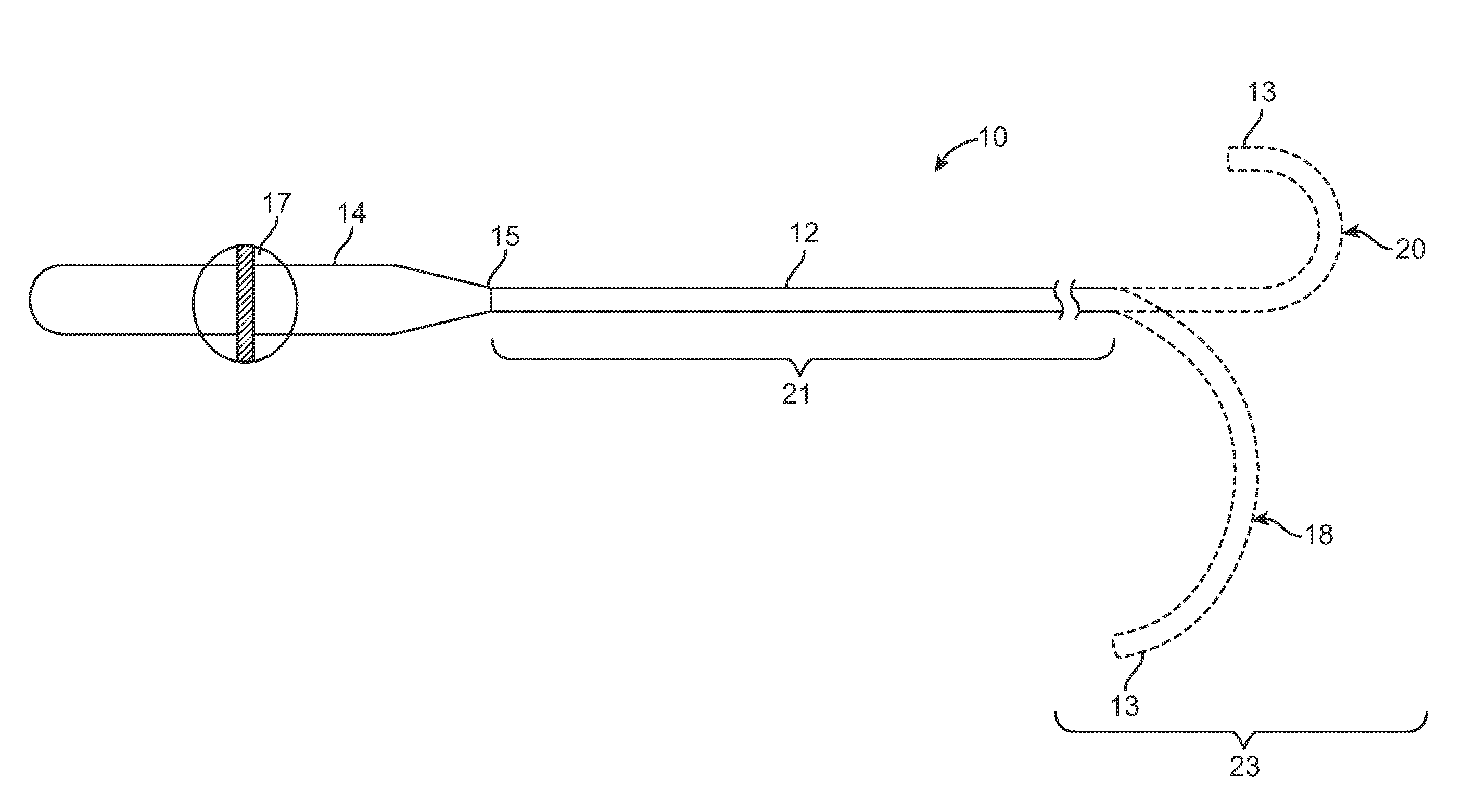

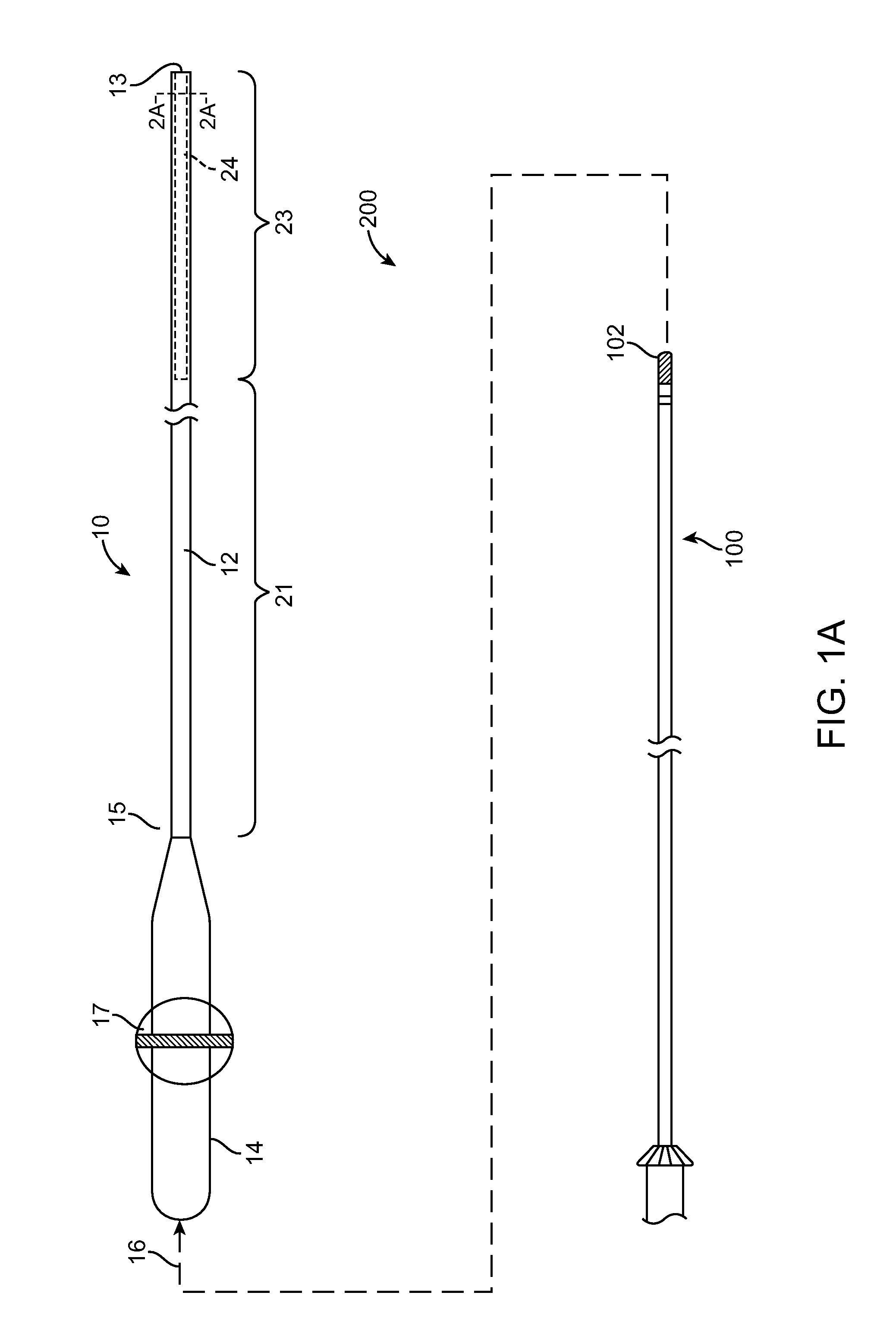

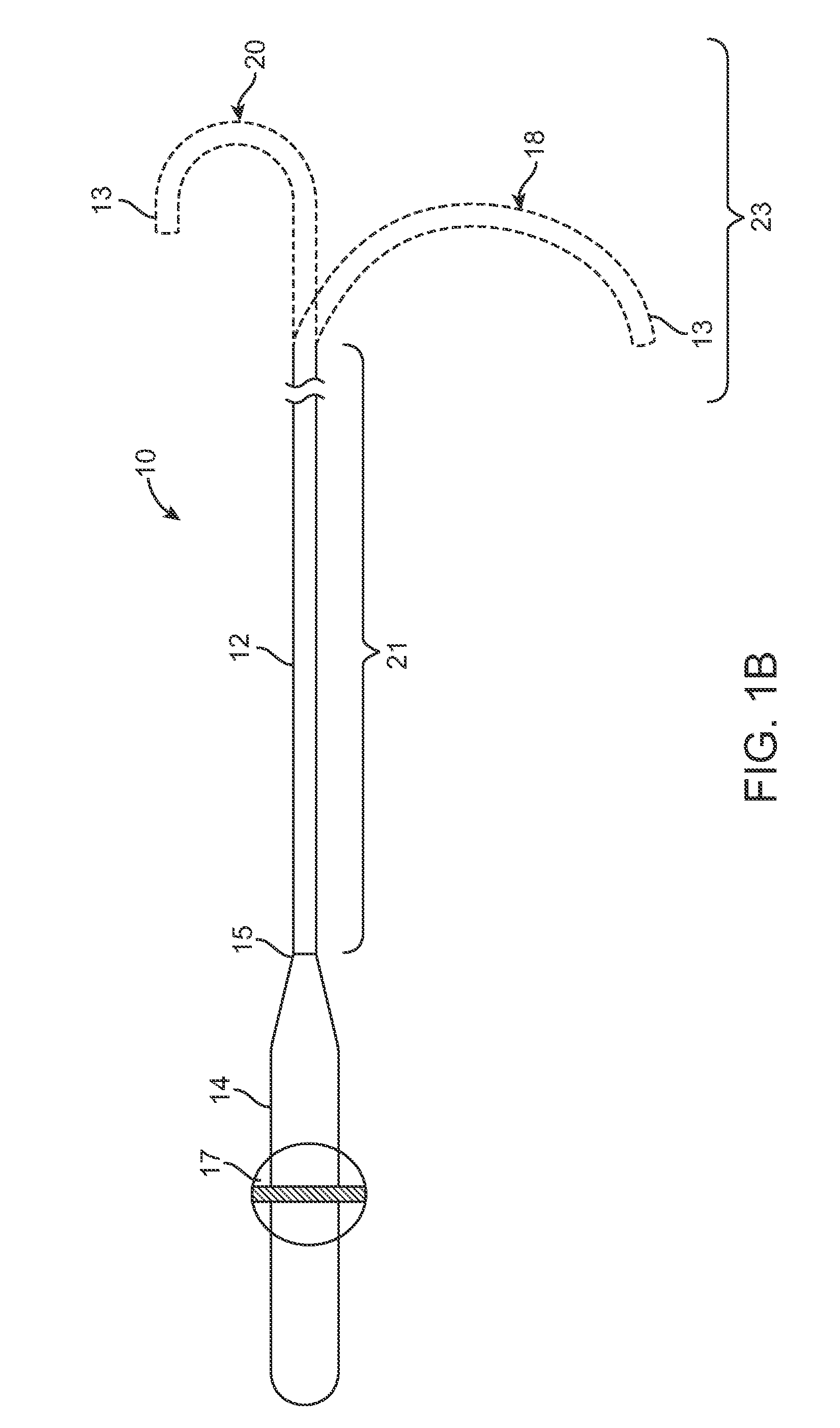

Asymmetric dual directional steerable catheter sheath

ActiveUS8500733B2Shorten travel distanceImprove usabilityMedical devicesCatheterMedicineDistal portion

A steerable catheter sheath for use in directing a catheter into a desired position is provided. The sheath includes an elongated member configured to receive the catheter therein. The distal end of the elongated member is steerable in two directions, each direction having a different bent configuration, e.g., a sharp curve in one direction and an open arching curve in the other direction. A resilient structure having different bending properties in each of its lateral sides is carried in the distal portion of the elongated member and causes the asymmetric bending. In one embodiment, the resilient structure includes a hypotube with a plurality of notches and slits in the sides. In another embodiment, the resilient structure is covered in an outer coating having different durometer portions. The sheath is particularly useful for accessing left and right pulmonary veins when a transeptal entry approach is used into the left atrium.

Owner:BOSTON SCI SCIMED INC

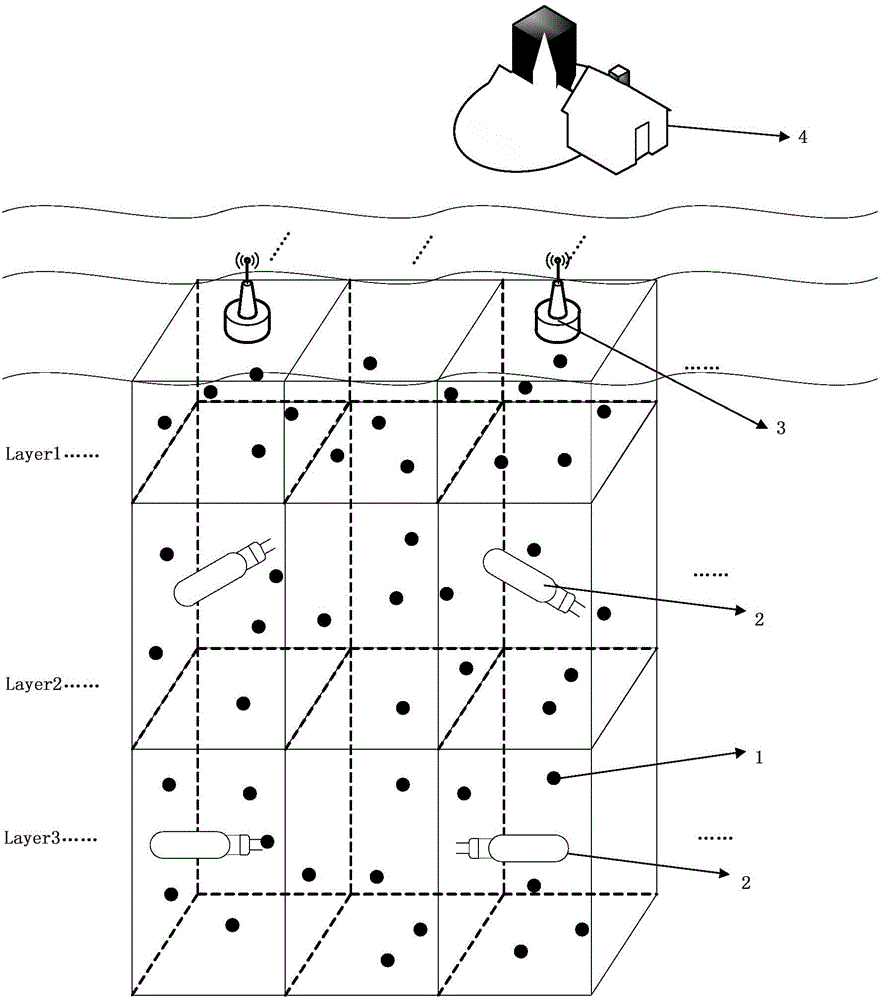

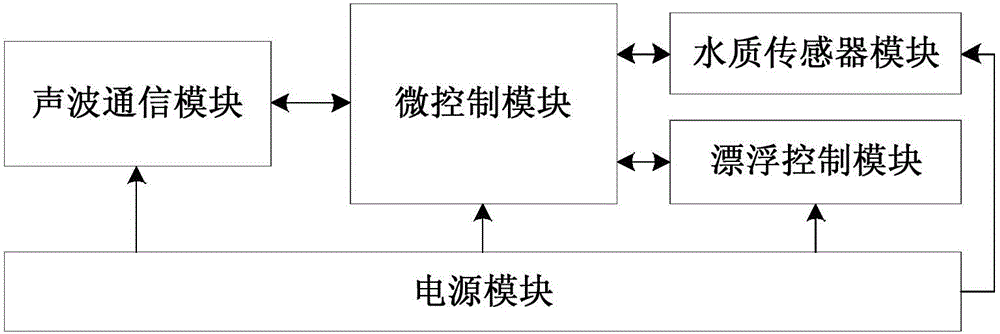

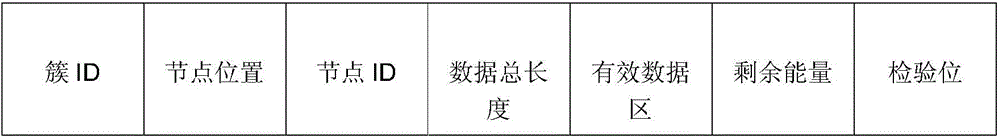

Underwater acoustic sensor networks and node deployment and networking method thereof

ActiveCN104936194AEasy to recycleExtend the working life cycleNetwork topologiesTransmissionWater qualityAcoustic wave

The invention relates to underwater acoustic sensor networks and a node deployment and networking method thereof. A target water area is covered in a hierarchical clustering manner, the networks are divided into three hierarchies, and each hierarchy is divided into multiple continuous 3D spaces; common underwater sensor nodes are uniformly distributed in different depths of the different hierarchies of the target area, sense and collect physical environment data of the surrounding, and form self-organizing clustering networks via the sound wave links; movable underwater nodes can move in the target water area, assess the water quality change of routes, and directly transmit an assessment result to water surface buoy nodes; and the water surface buoy nodes is mixed with communication modules, receive, process, gather and integrate underwater network data via the sound wave communication module, and transmit the network data to a land base station in the multi-hop manner via the radio electromagnetic wave communication module. The underwater acoustic sensor networks and the node deployment and networking method thereof can realize remote monitoring, is wide in monitoring range, high in expansibility and reliability, suitable for underwater applications, and has a good application prospect.

Owner:ZHEJIANG SCI-TECH UNIV

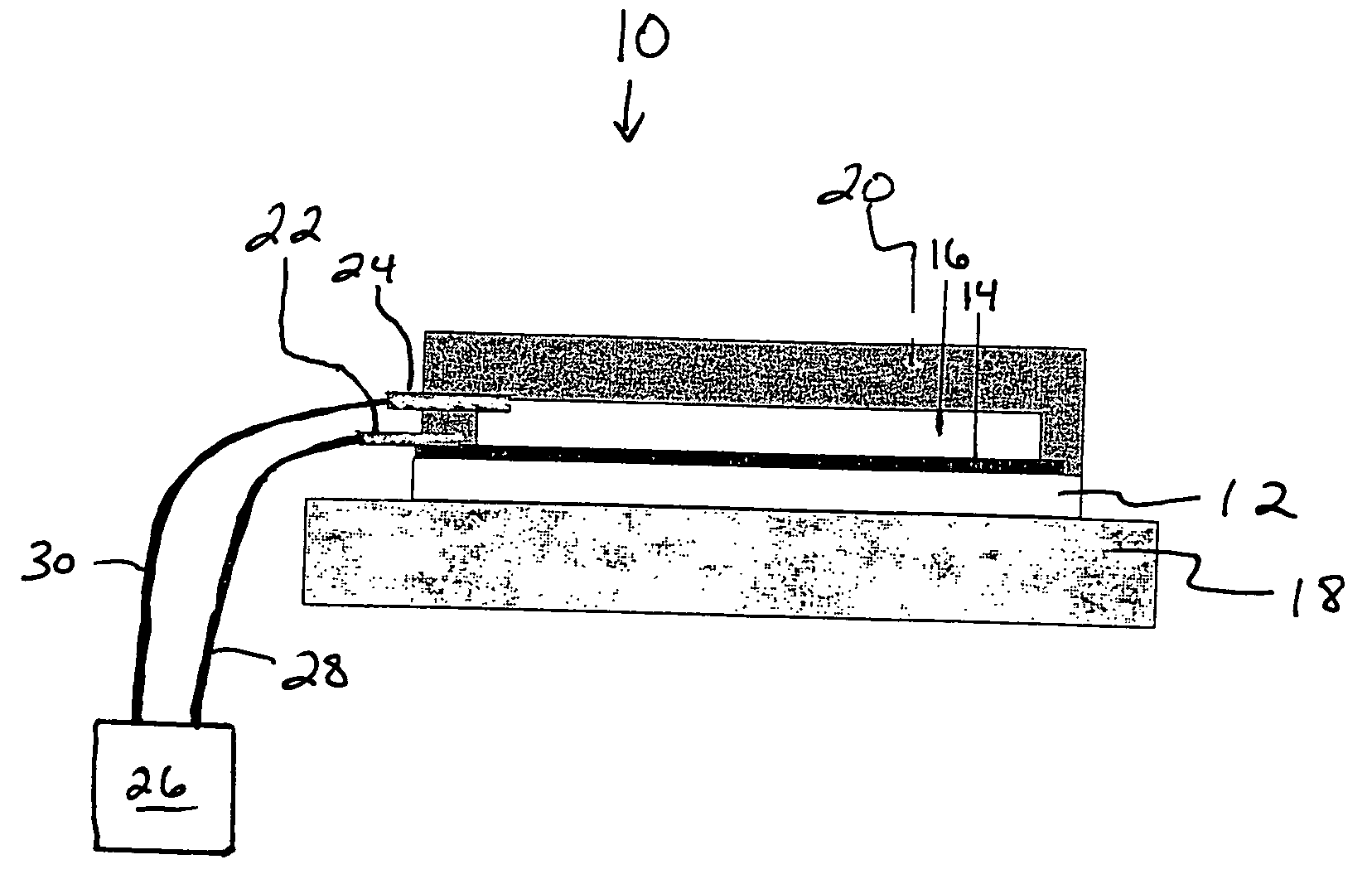

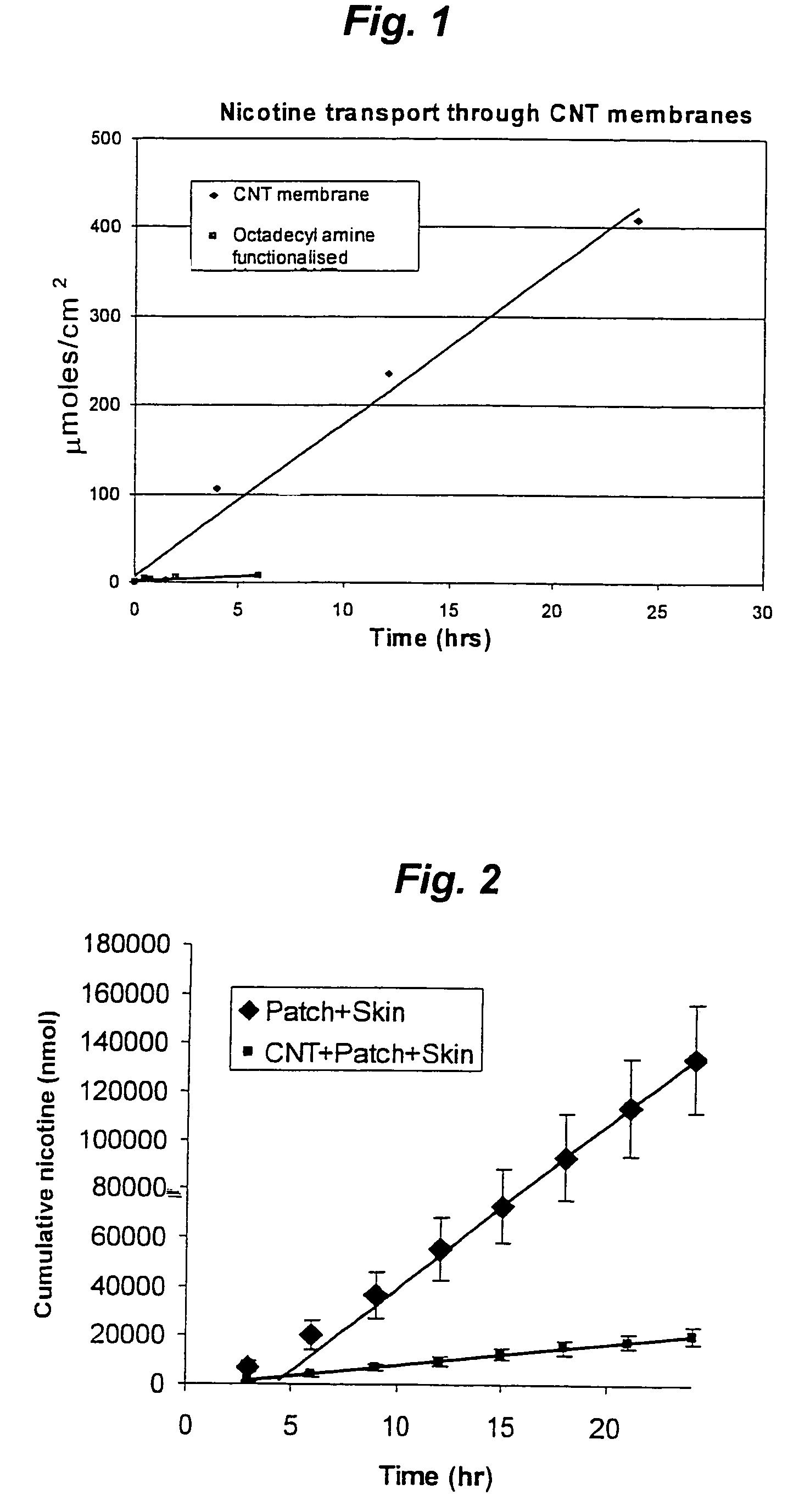

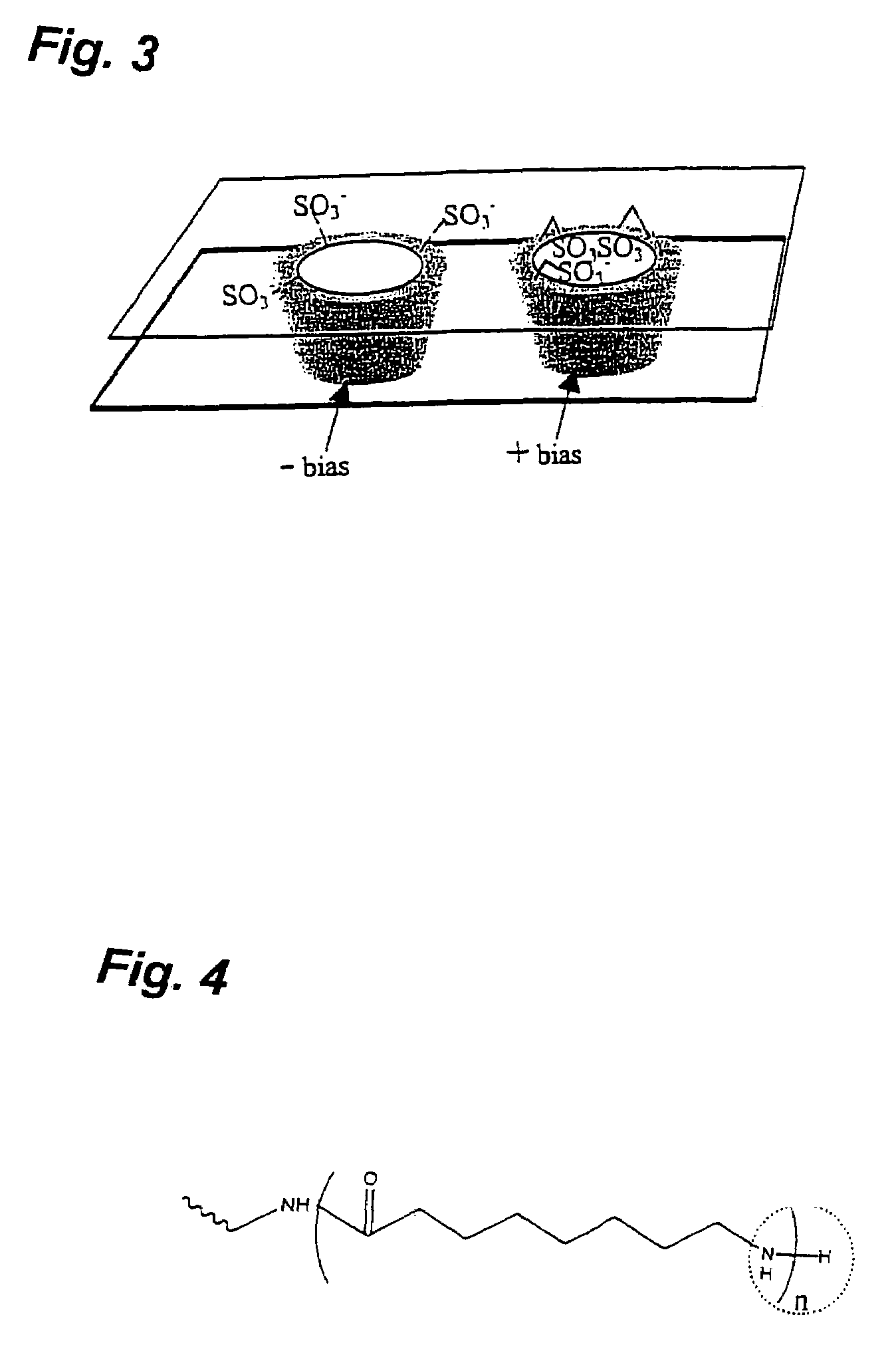

Delivery system for a composition

InactiveUS7229556B1Shorten travel distanceImprove throughputRotating receptacle mixersMembranesNanoporous membraneElectrical impulse

Devices and methods for cutaneous delivery of a composition are provided, wherein the composition is passed through an ordered nanoporous membrane in fluid communication with a reservoir. The nanoporous membrane includes a plurality of aligned hollow nanotubules coated with a continuous polymer matrix, and etched to open the plurality of hollow nanotubules and form pores. In one embodiment, the etching step oxidizes an end of the nanotubules to form carboxylate groups. The ordered nanoporous membrane further includes at least one additional functional unit bound to the carboxylate groups. The at least one additional functional unit selectively exposes or at least partially occludes the pore of an adjacent nanotubule, thereby controlling flux rate through the membrane. In one embodiment, application of an electrical impulse to the membrane causes the at least one additional functional unit to selectively expose or at least partially occlude the pore.

Owner:UNIV OF KENTUCKY RES FOUND

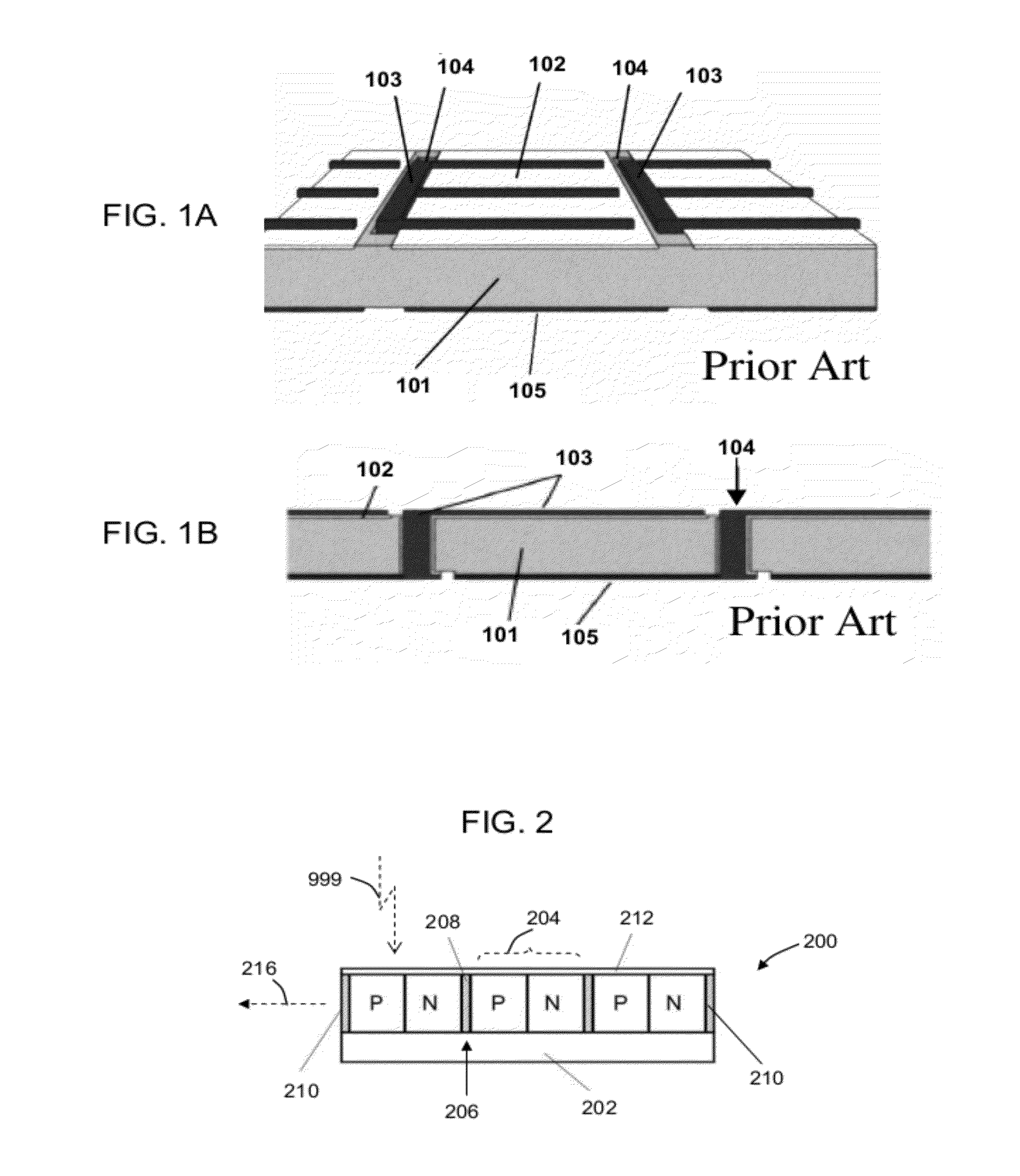

Vertical junction pv cells

InactiveUS20120152322A1Shorten travel distanceReduces and minimizes their cross-sectionPV power plantsFinal product manufactureEngineeringVoltage

A monolithic semiconductor solar cell including a semiconductor layer including a plurality of pores, wherein walls of the pores are doped, forming vertical junctions between the walls of the pores and a bulk of the semiconductor, the pores each contain a conductor which is in electrical contact with the walls of the pores, and the conductors of the pores are electrically interconnected to provide an output voltage of the solar cell. A monolithic semiconductor solar cell including a semiconductor layer including a plurality of trenches, wherein walls of the trenches are doped, forming vertical junctions between the walls of the trenches and a bulk of the semiconductor, the trenches each contain a conductor which is in electrical contact with the walls of the trenches, and the conductors of the trenches are electrically interconnected to provide an output voltage of the solar cell. Related apparatus and methods are also described.

Owner:OFEK ESHKOLOT RES & DEV +1

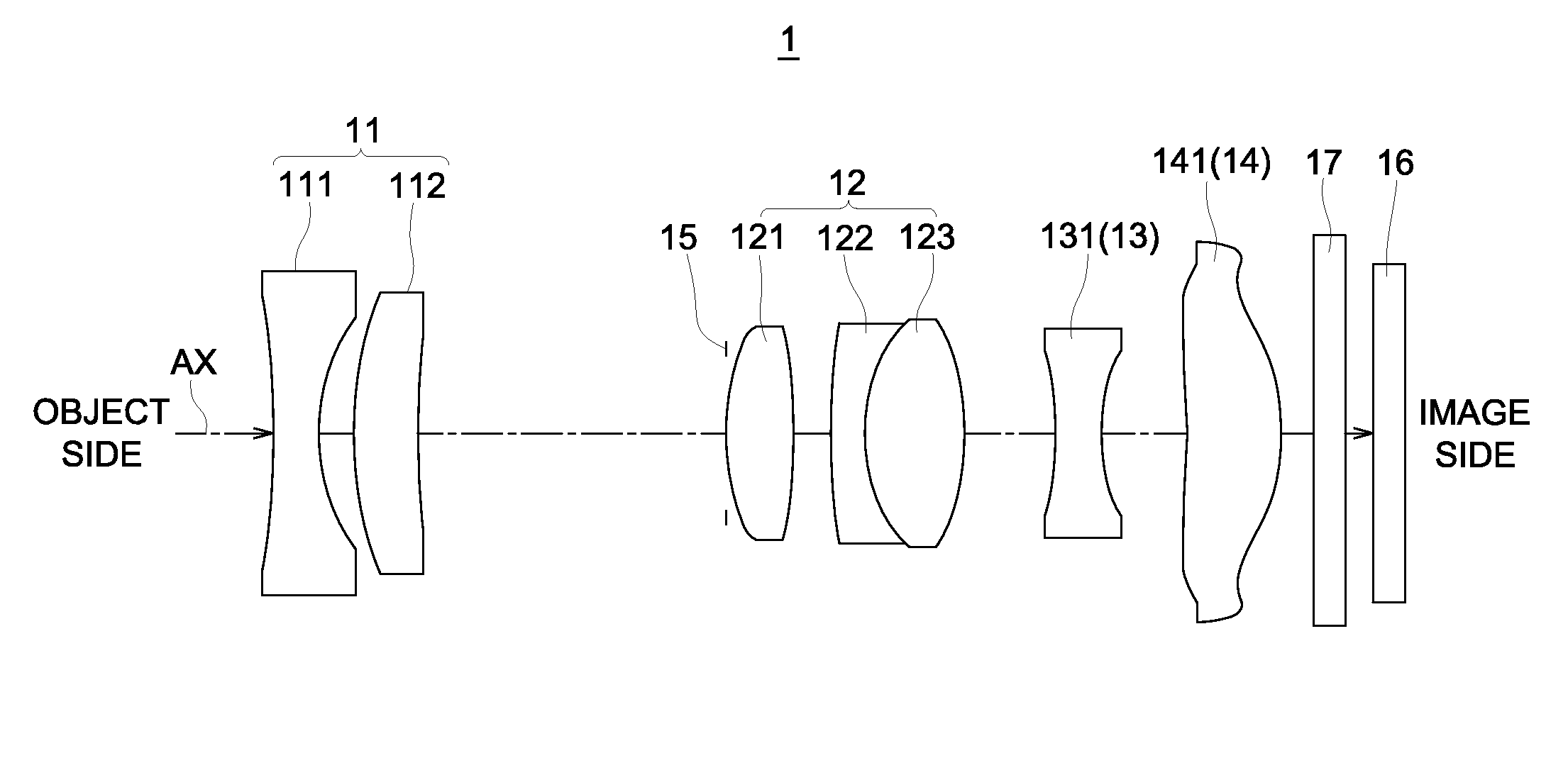

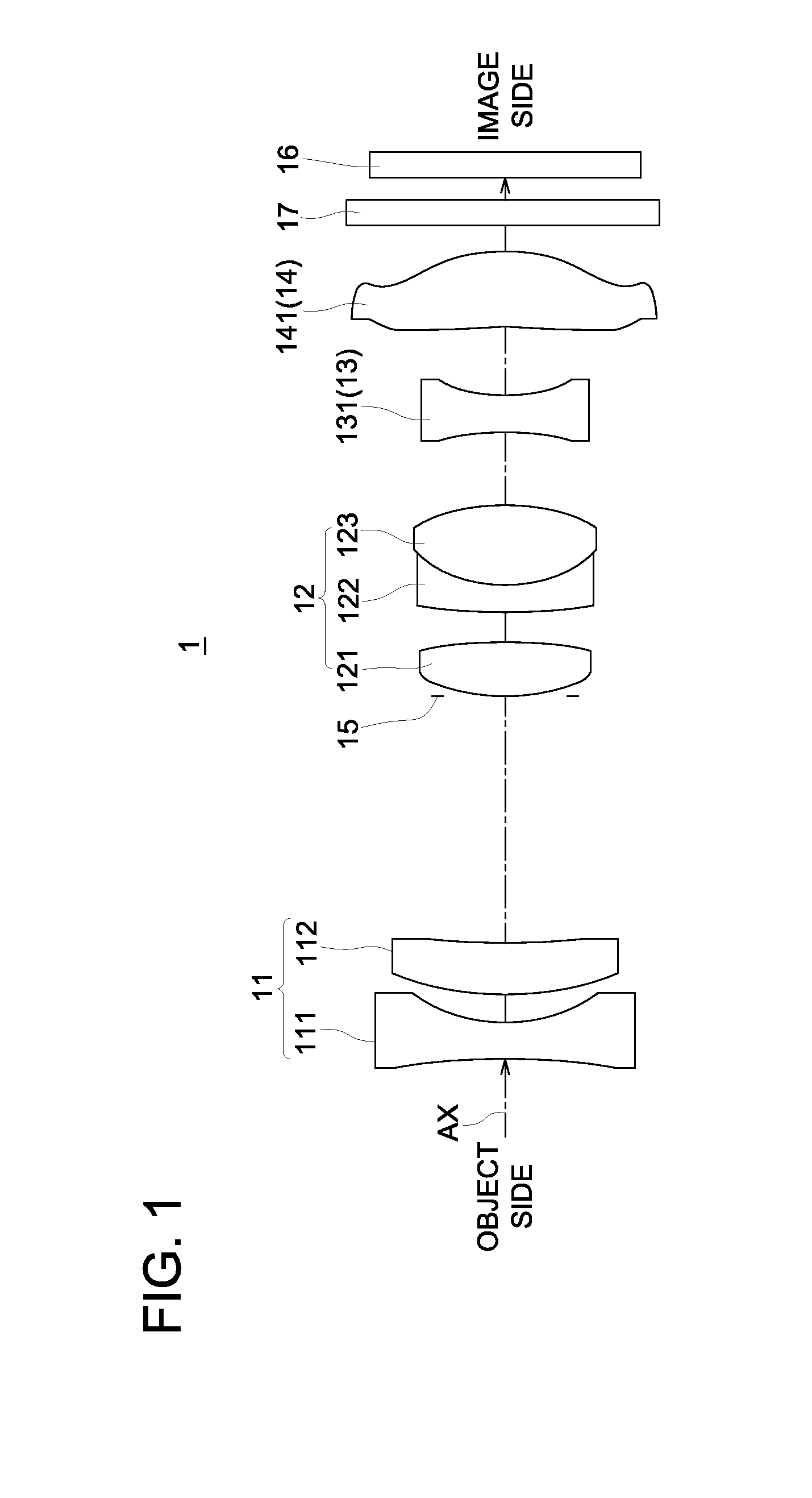

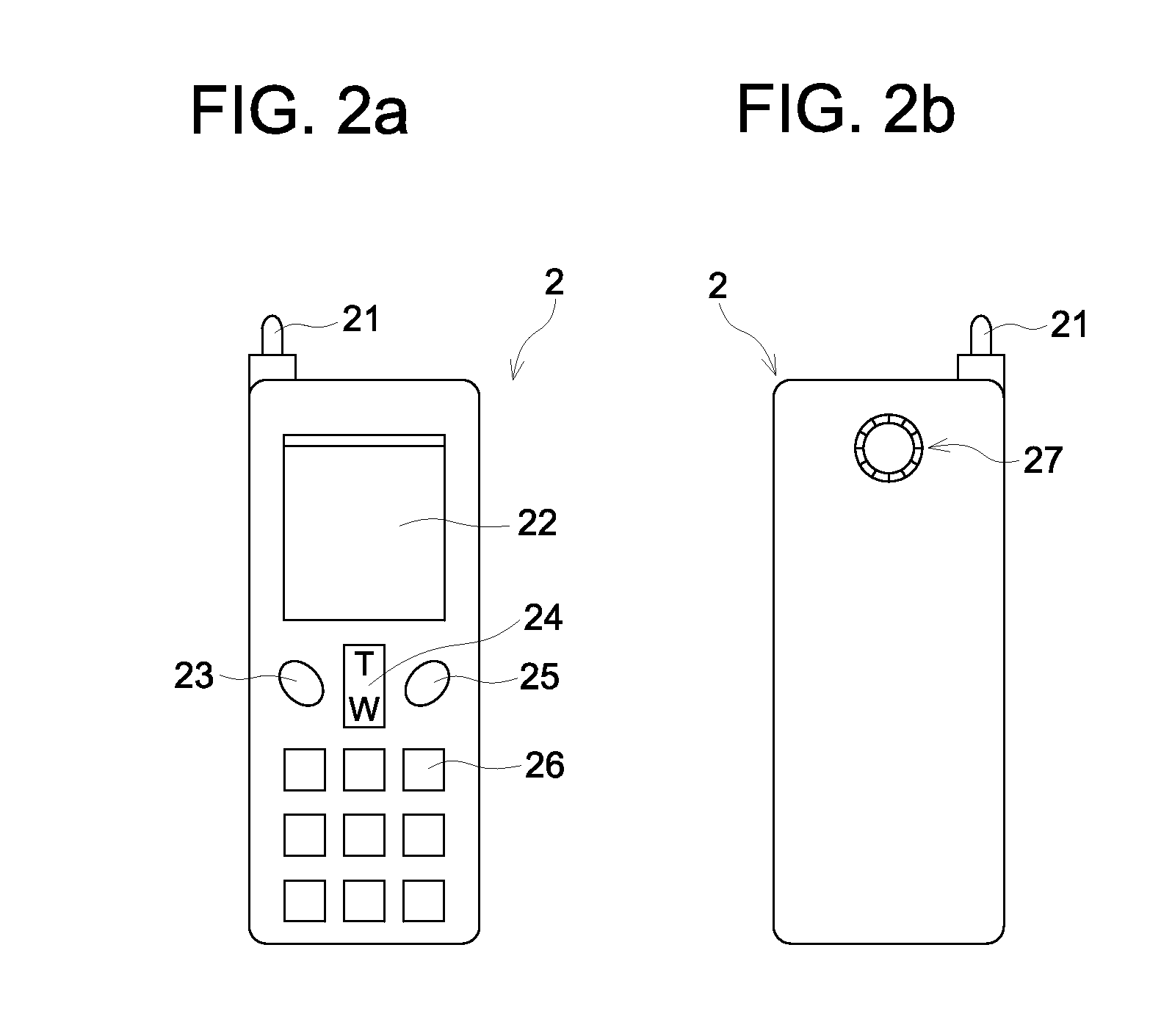

Variable-power optical system, image pickup device, and digital apparatus

ActiveUS20100045808A1Compact configurationEffective correctionTelevision system detailsColor television detailsConditional expressionOptical power

A variable-power optical system includes, in order from an object side thereof: a first lens group with a negative optical power; a second lens group with a positive optical power; a third lens group with a negative optical power; and a fourth lens group with a positive optical power. An interval between the first lens group and the second lens group decreases when a power of the variable-power optical system varies from a wide-angle end to a telephoto end. The second lens group includes at least one aspheric surface. The variable-power optical system satisfies the predetermined conditional expressions.

Owner:KONICA MINOLTA OPTO

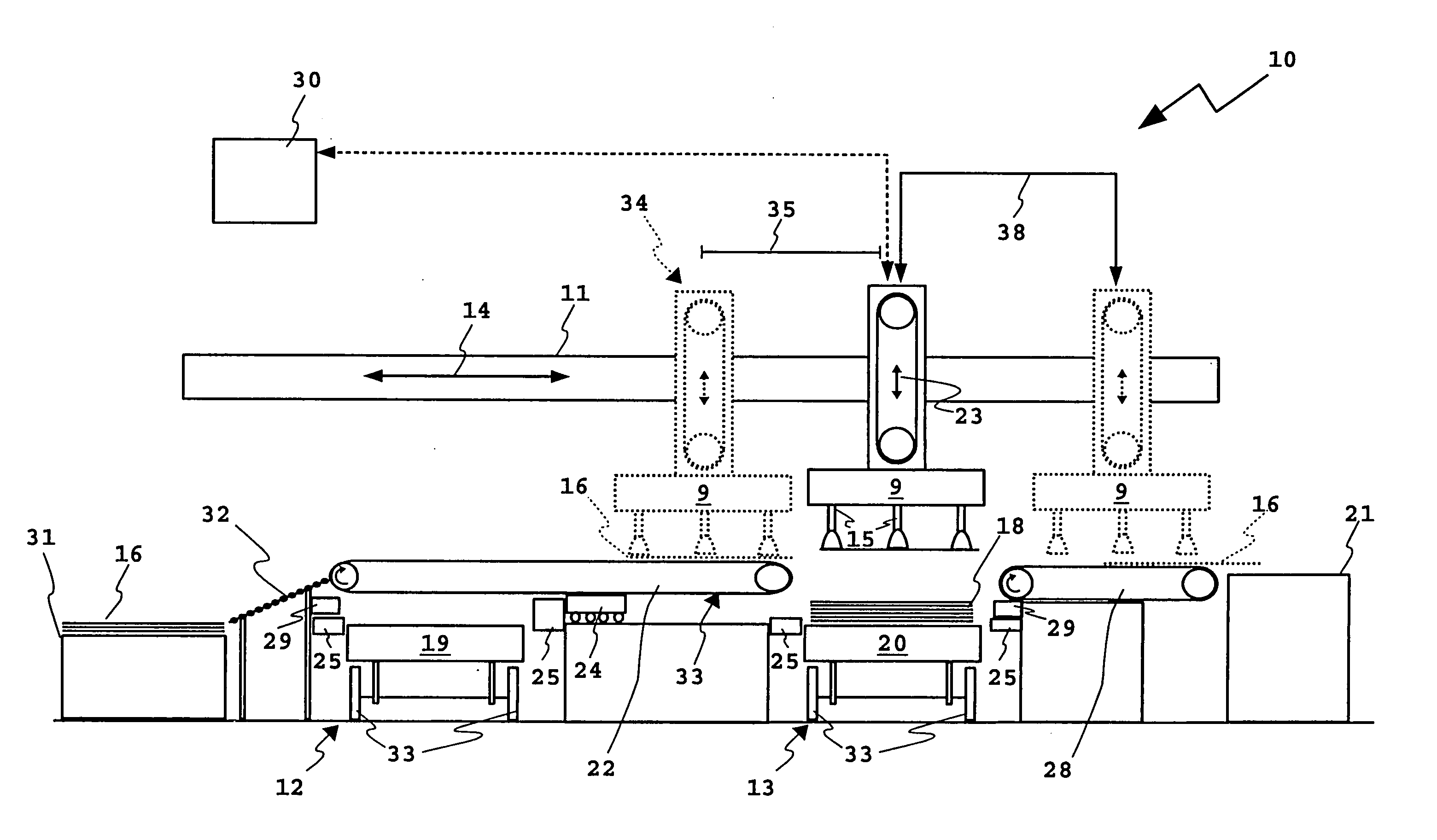

Singling device and a singling method

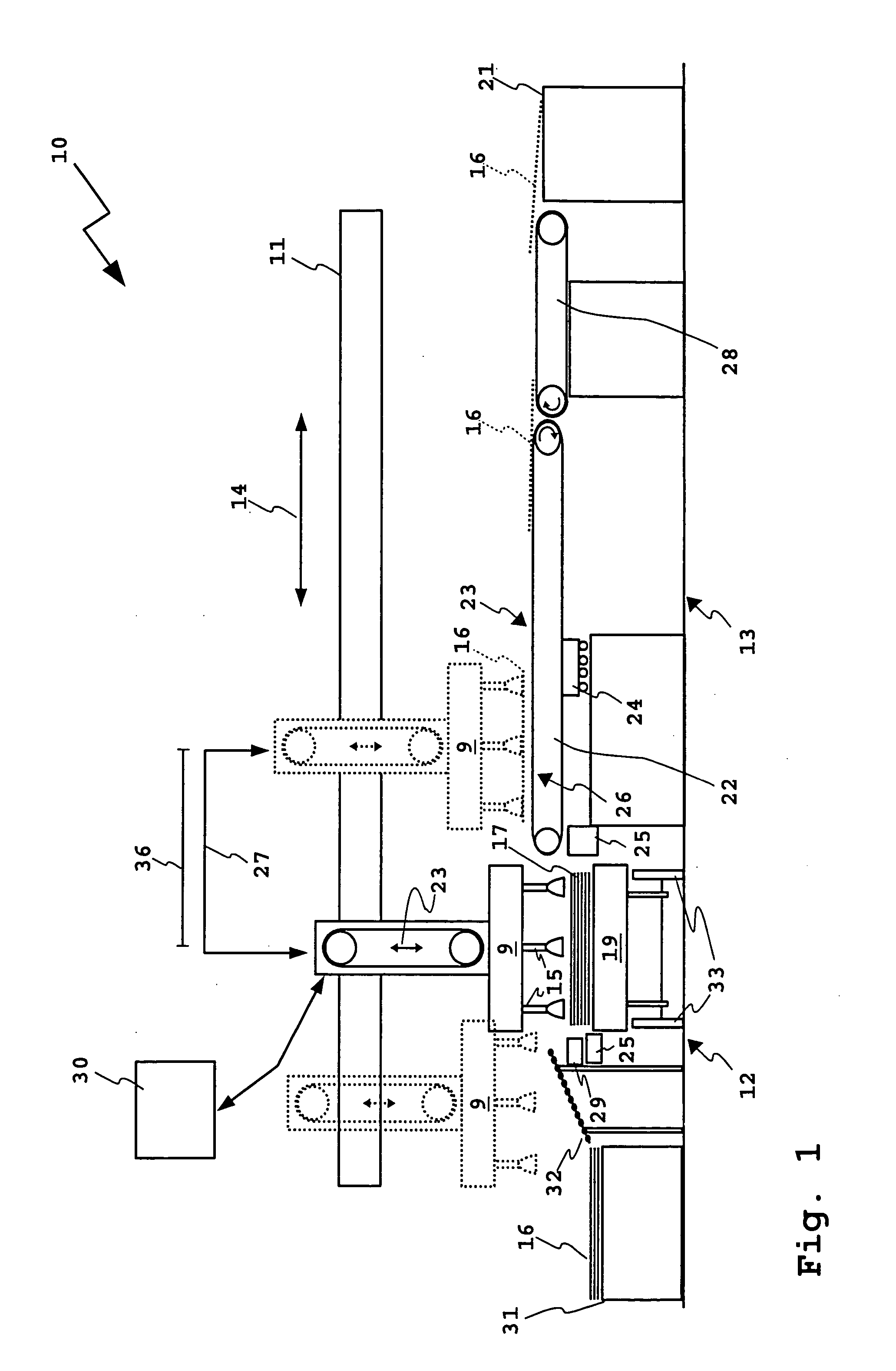

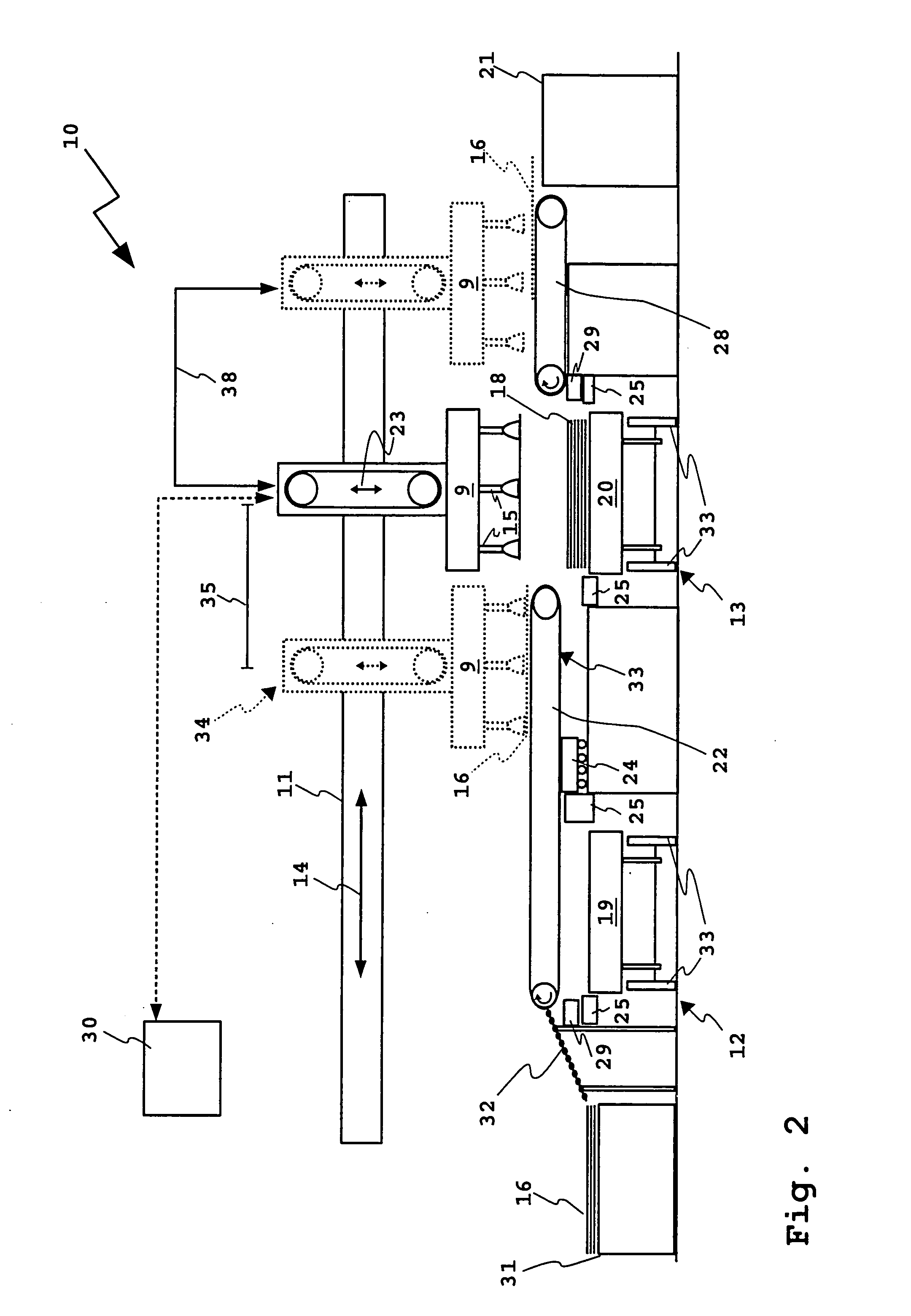

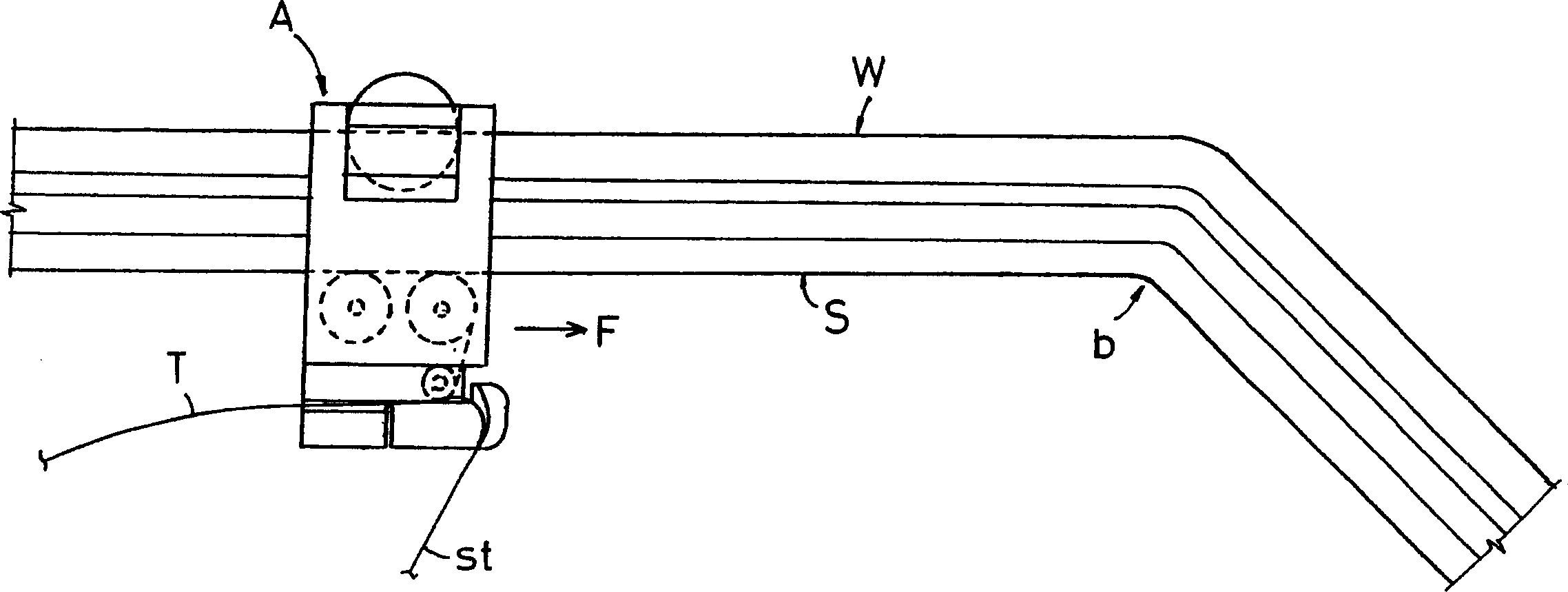

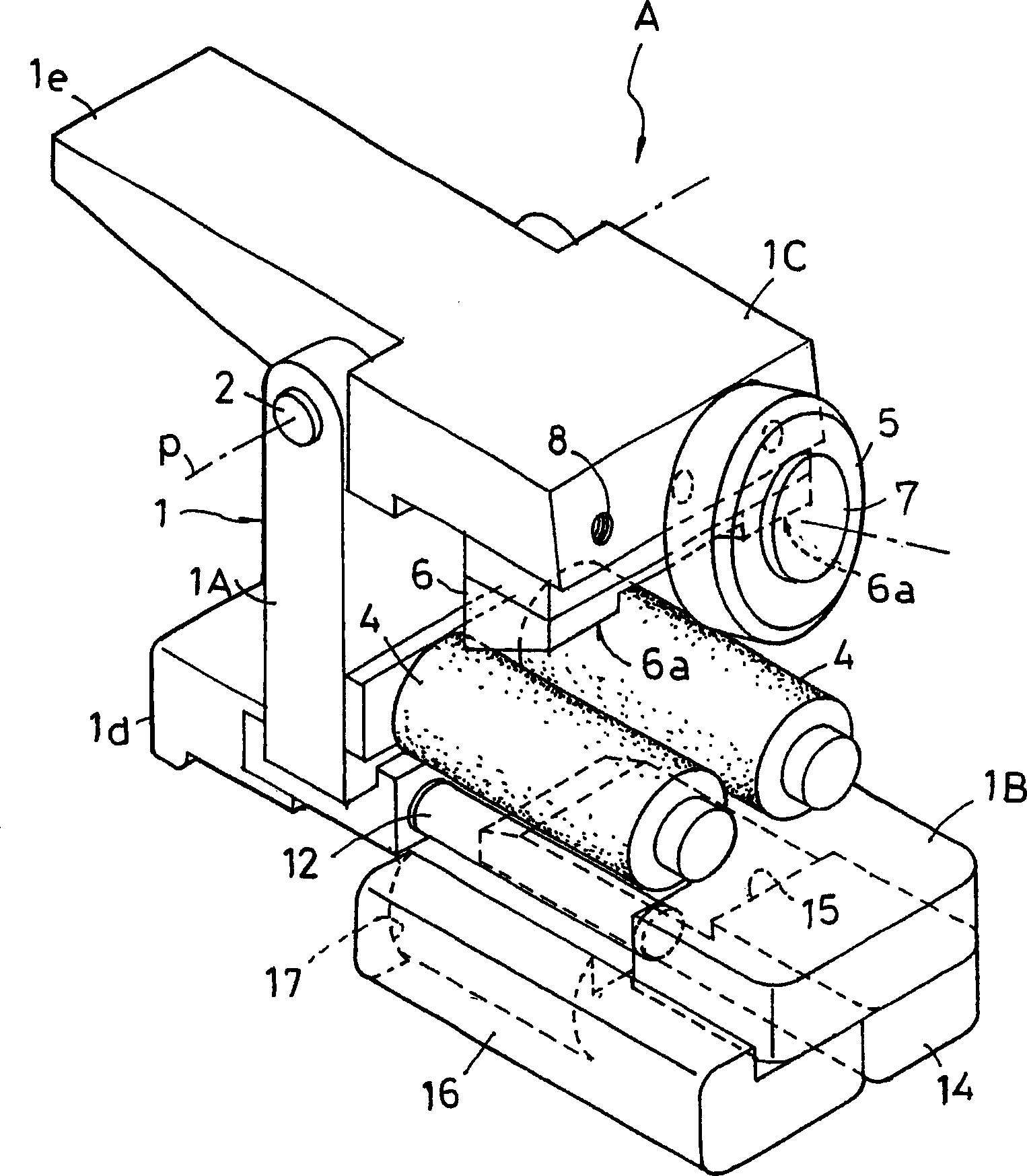

InactiveUS20040197185A1Convenience to workShorten travel distanceDe-stacking articlesConveyor partsReciprocating motionEngineering

A singling device and a singling method for singling sheet metal panels comprises two tendering positions arranged one after the other in the longitudinal direction to offer a respective sheet metal panel stack, said two tendering positions being provided with a lifting means able to be reciprocated in the longitudinal direction and for feeding the sheet metal panels in the longitudinal direction to a working site. A longitudinal conveying means is arranged between the two tendering positions, which is able to be moved in the longitudinal direction, and which terminates in a first longitudinal position moved toward the working site on the one hand in the vicinity of the first tendering position remote from the working site and on the one hand bridges over the second tendering position so that the lifting means feeds the sheet metal panels lifted from the first sheet metal panel stack onto the longitudinal conveying means which in a second longitudinal position moved away from the working site frees the second tendering position.

Owner:SCHULER AUTOMATION

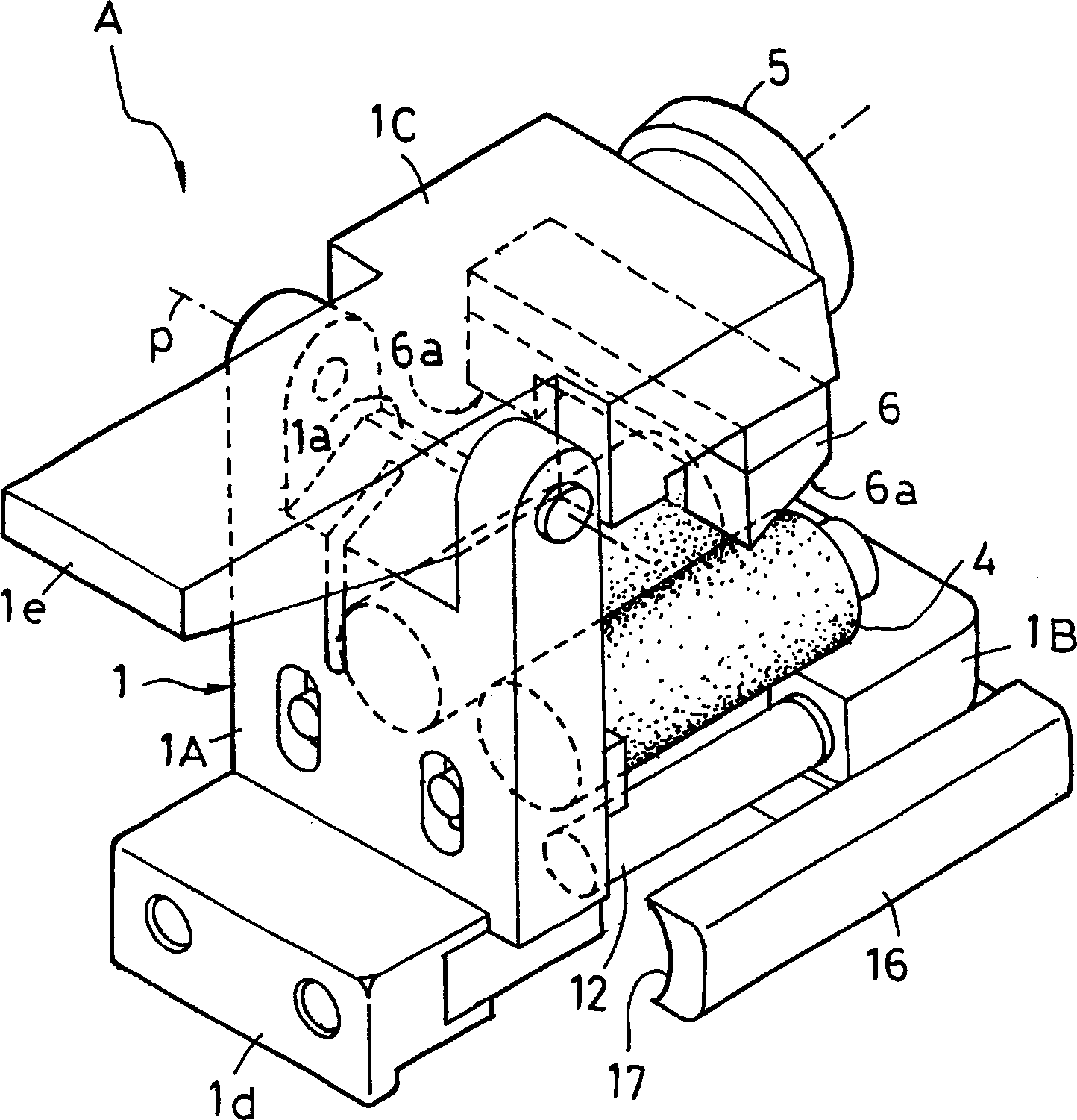

Adhesive tape joining apparatus

InactiveCN1840455APaste firmlySuppresses attached dustVehiclesArticle deliveryAdhesive beltEngineering

A main body to be moved and operated along a workpiece includes a joining roller which elastically presses the supplied adhesive tape against a tape joining face of the workpiece, guide members which determine the position of the main body and maintain the posture of the main body with respect to the workpiece being engaged with the outer face of the workpiece at the opposite side of the tape joining face, a separator guide which is arranged to be opposed to a tape supply roller, and a tape guide which is arranged in the vicinity of the side where the adhesive tape is reeled out toward the separator guide. On the separator guide, a separator guide face is formed, which guides a separator separated from the adhesive tape into a direction different from an adhesive tape joining direction.

Owner:NITTO DENKO CORP

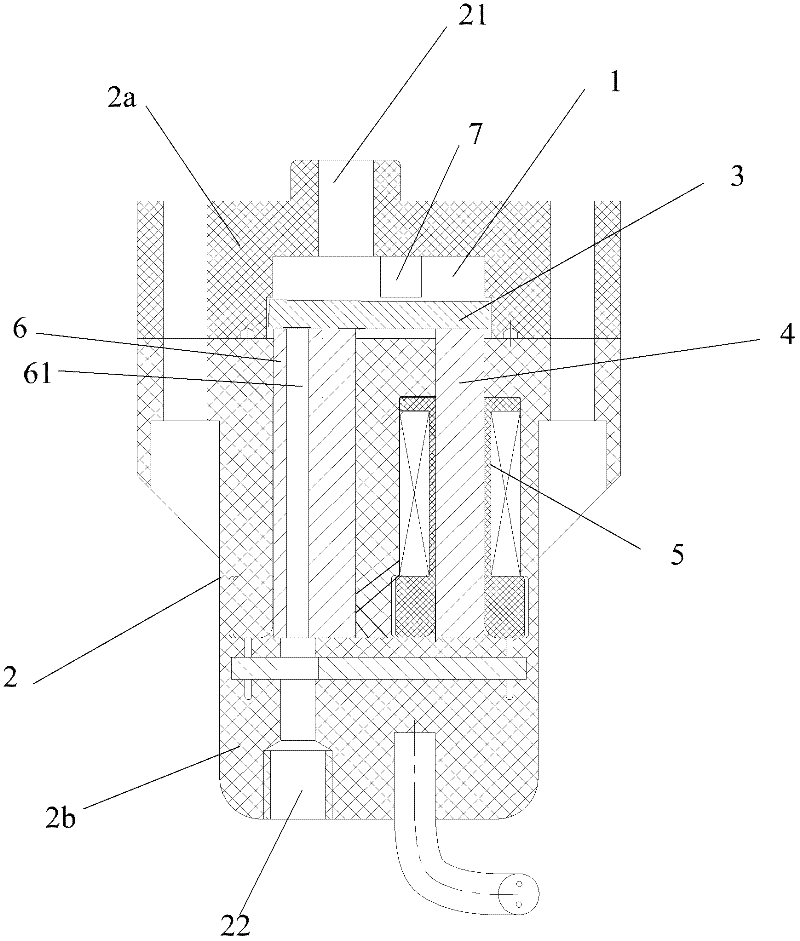

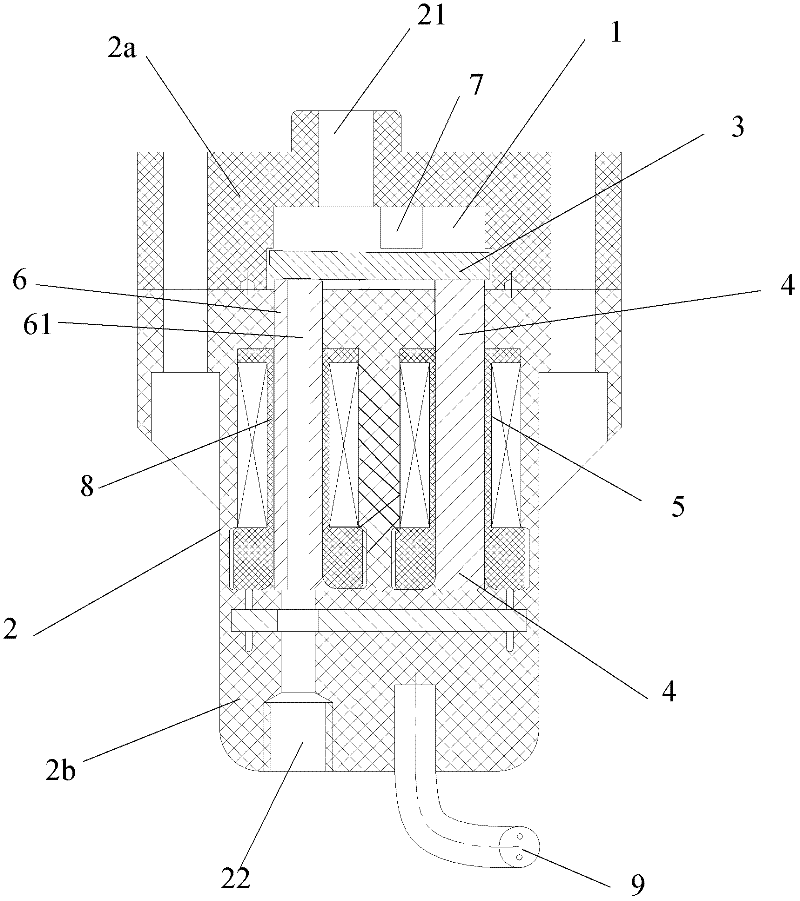

Electromagnetic valve and electromagnetic valve system

ActiveCN102518859AReduce travel distanceSmall magnetic resistanceOperating means/releasing devices for valvesMultiple way valvesEngineeringElectromagnetic valve

The invention provides an electromagnetic valve and an electromagnetic valve system. The electromagnetic valve comprises a valve body provided with a valve chamber. A medium inlet communicated with the valve chamber is arranged at one end of the valve body and a medium outlet communicated with the valve chamber is arranged at the other end of the valve body. The electromagnetic valve further comprises a movable piece of the valve and a first iron core fixed at one end of the medium outlet of the valve body and wound with a first coil. A first pillar extending to the valve chamber is arranged at one end of the medium outlet of the valve body. The first pillar is provided with a through hole communicated respectively with the medium outlet and the valve chamber. The movable piece of the valve is located in the valve chamber and presses the first pillar under the effect of medium pressure difference between inside and outside of the valve chamber, forms a seal pair with the first pillar and a gap is formed between the movable piece and the first iron core. The first coil under electrified state generates an electromagnetic force that makes the movable piece of the valve rotate along a pivot so that one end of the movable piece of the valve is attracted away from the first pillar and the other end is adsorbed on the first iron core. The electromagnetic valve and the electromagnetic valve system provided by the invention improve the working frequency and the service life of the electromagnetic valve.

Owner:HEFEI MEIYA OPTOELECTRONICS TECH

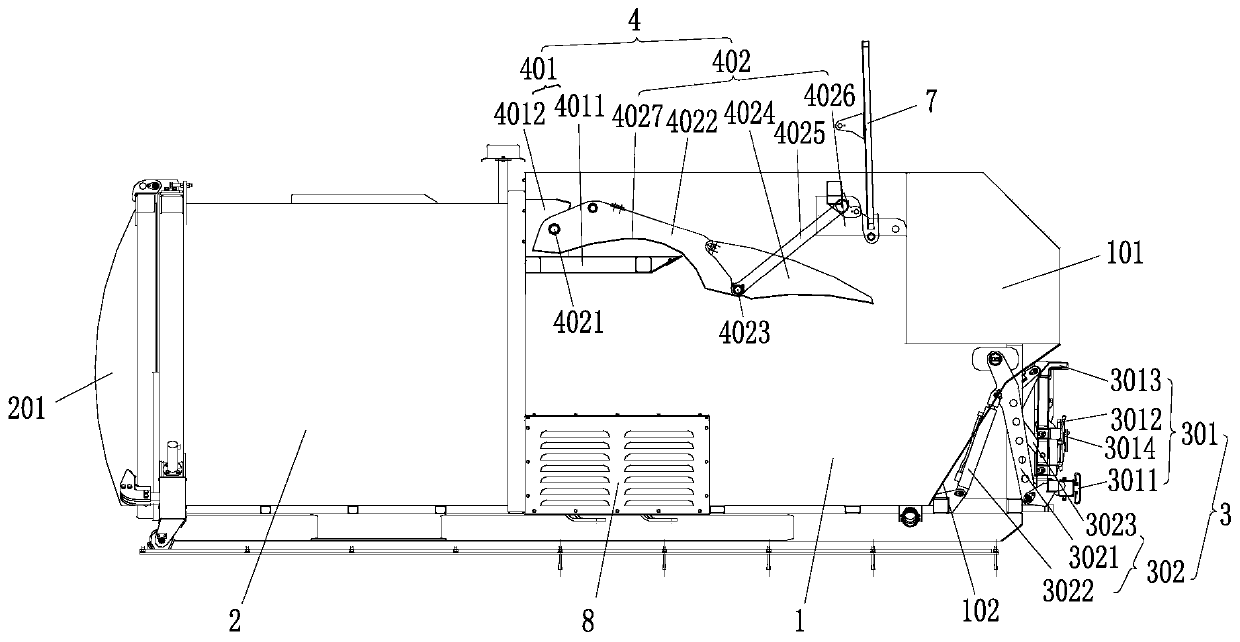

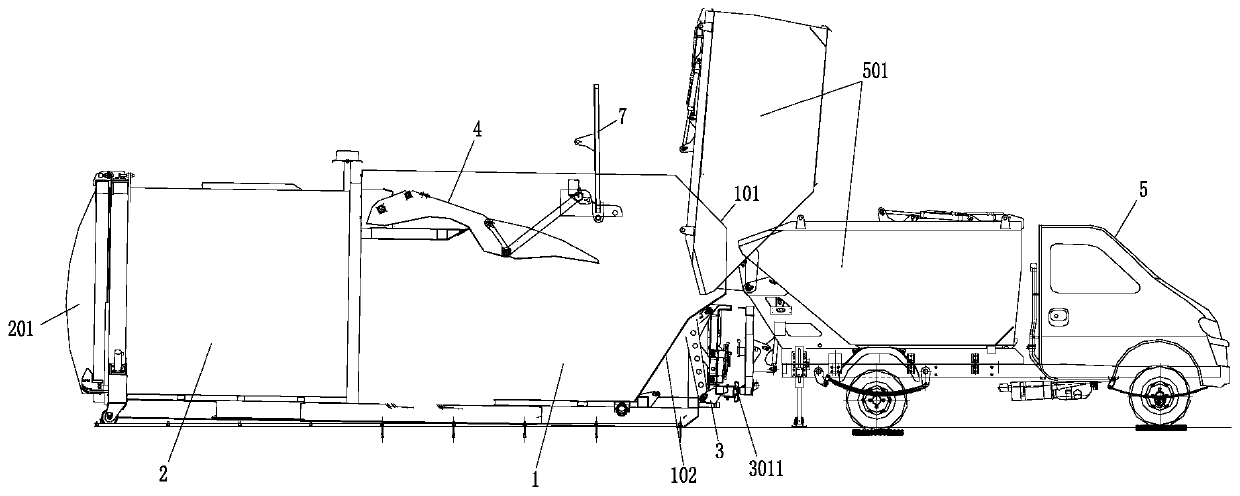

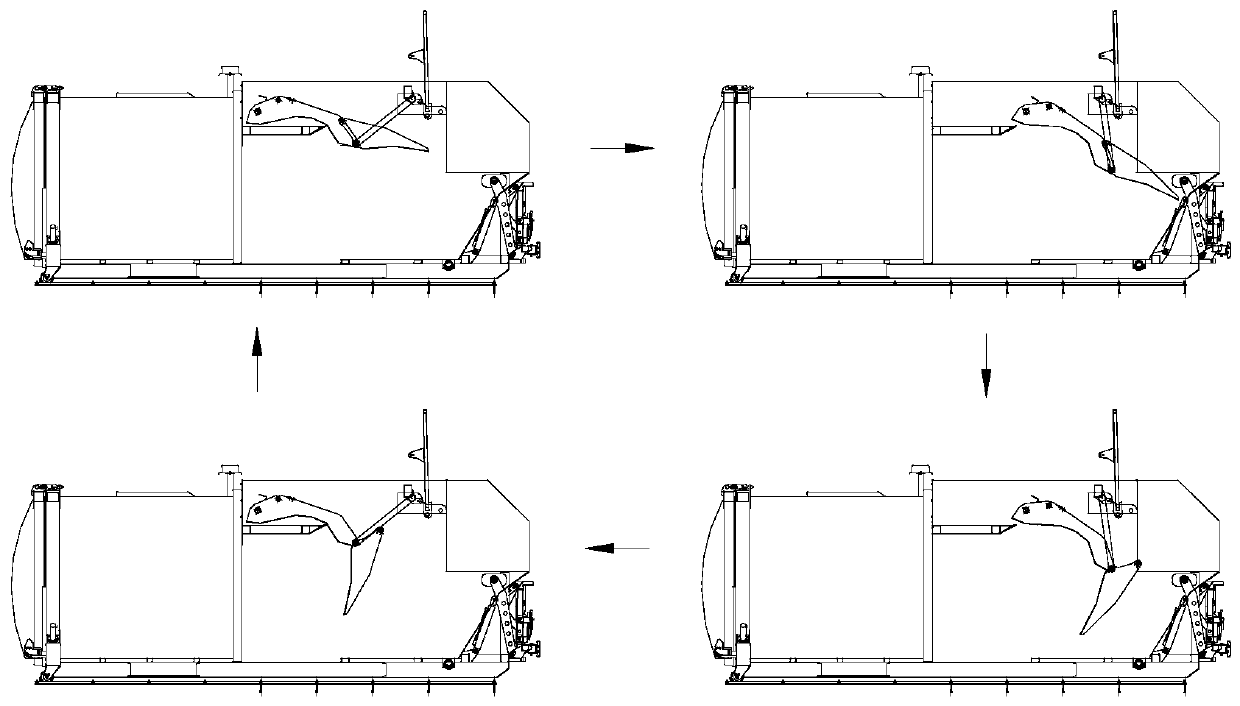

Movable garbage compression device

ActiveCN111573084APrevent leakageAvoid corrosionWaste collection and transferRefuse vehiclesStructural engineeringMechanical engineering

The invention discloses a movable garbage compression device. The movable garbage compression device comprises a compression bin used for compressing garbage entering the equipment inwards and a garbage can connected with the output end of the compression bin and used for receiving the garbage output by the compression bin and storing the garbage, wherein a discharging opening used for dischargingthe garbage and a discharging door covering the discharging opening in a sealing manner are arranged at the end, away from the compression bin, of the garbage can; a feeding opening used for feedingthe garbage is formed in the end, away from the garbage can, of the compression bin; the height of the wall body of the feeding side of the feeding opening is matched with the discharging height of abutt joint discharging vehicle so that a discharging box of the butt joint discharging vehicle can be overturned into the feeding opening to conduct direct butt joint discharging; a can overturning mechanism used for hooking the garbage can and overturning the garbage can to the position of the feeding opening to dump the garbage is further arranged outside the wall body of the feeding side of thefeeding opening; the can overturning mechanism is further used for serving as anti-collision limiting of the butt joint discharging vehicle; and a pressing filling mechanism used for pushing and pressing the garbage entering the compression bin from the upper portion is arranged at the upper portion of an inner cavity of the compression bin.

Owner:ZOOMLION ENVIRONMENTAL IND CO LTD

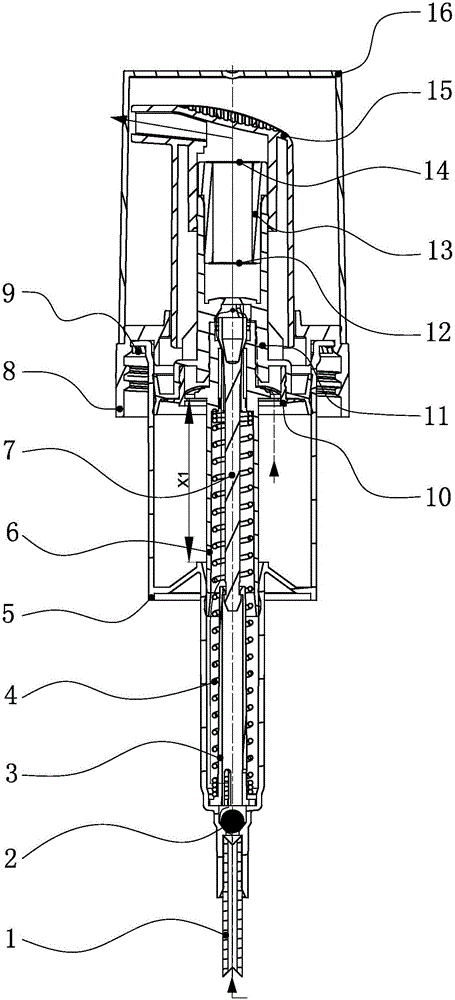

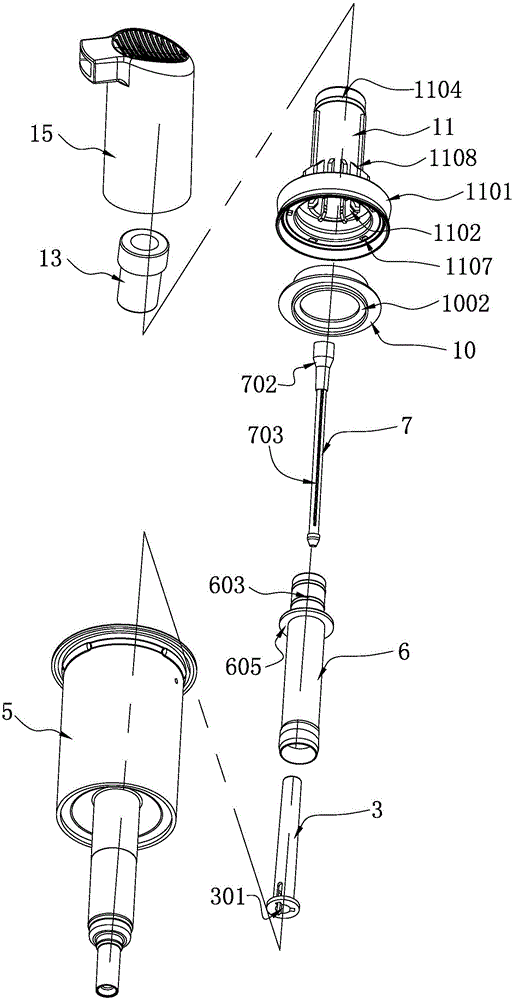

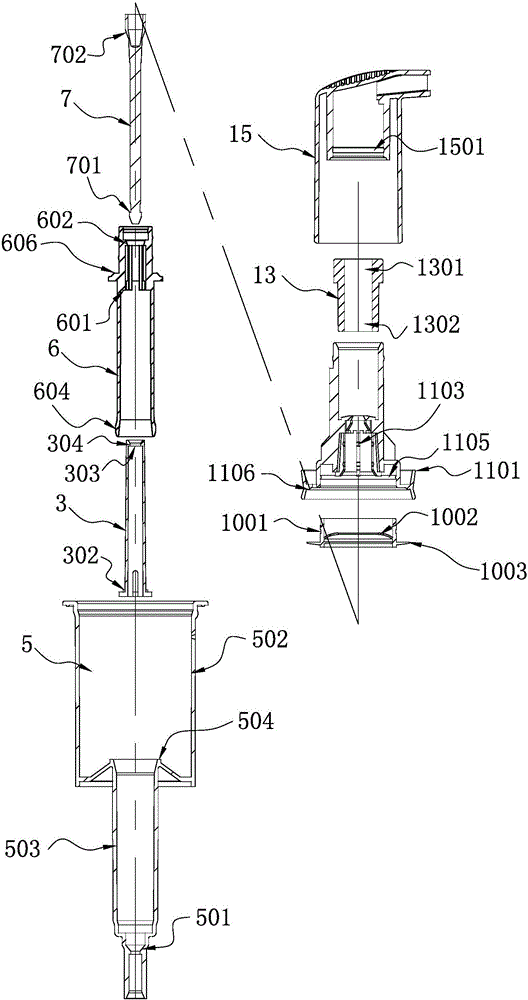

Press-type foam pump and discharge rate control method thereof

ActiveCN105923253AMeet the requirements of ejection volumeImprove interoperabilityClosuresSingle-unit apparatusEngineeringDischarge rate

The invention relates to a press-type foam pump and a discharge rate control method thereof and aims to solve the technical problems that conventional like products are inconvenient in discharge rate changing and controlling, and need to be further improved in structural design. The press-type foam pump is mainly characterized in that an outwardly protruding convex clasp ring and a tapered limit opening are respectively formed at the nesting parts between a valve rod and a pump body, downward movement of a piston driven by a duckbill is the stroke that a limit ring at the external diameter of the valve rod moves downwards to be propped against the limit opening of the pump body, the limit opening of the pump body is provided with a cylindrical glue site protruding toward the interior of the pump body, and the cylindrical glue site is subjected to integral injection molding with the limit opening and the pump body. Therefore, the discharge rate of the foam pump is changed only by changing the structure of the limit opening in the pump body on the basis of not changing the integral structure of the foam pump, that is, the discharge rate of the foam pump is controlled by controlling the downward movement of the piston via the length of the cylindrical glue site. Accordingly, sharing of product parts and the university of automatic assembly equipment are effectively improved, the production efficiency is improved, energy consumption is reduced, and the production cost is lowered.

Owner:ZHEJIANG Z&Z IND CO LTD

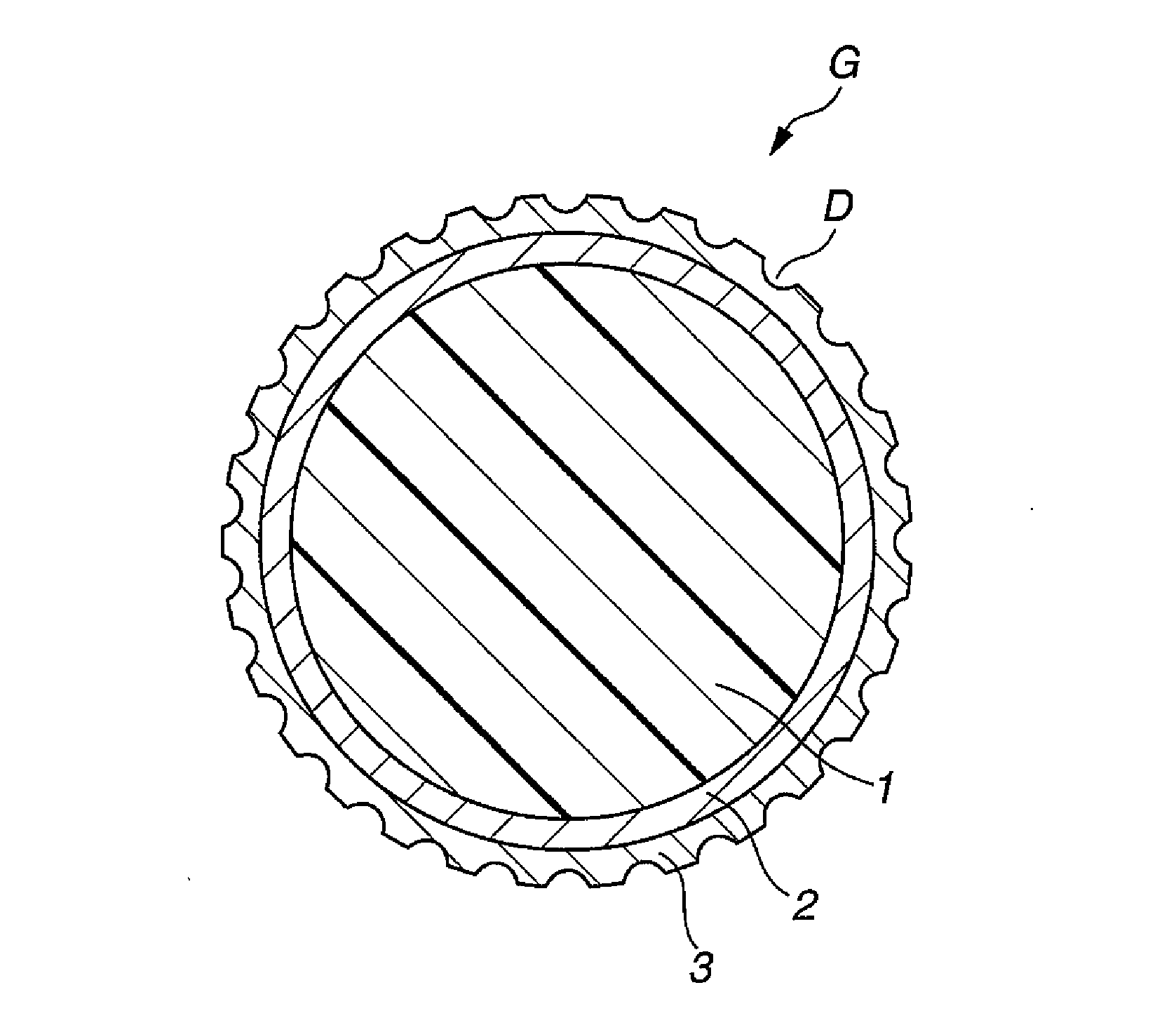

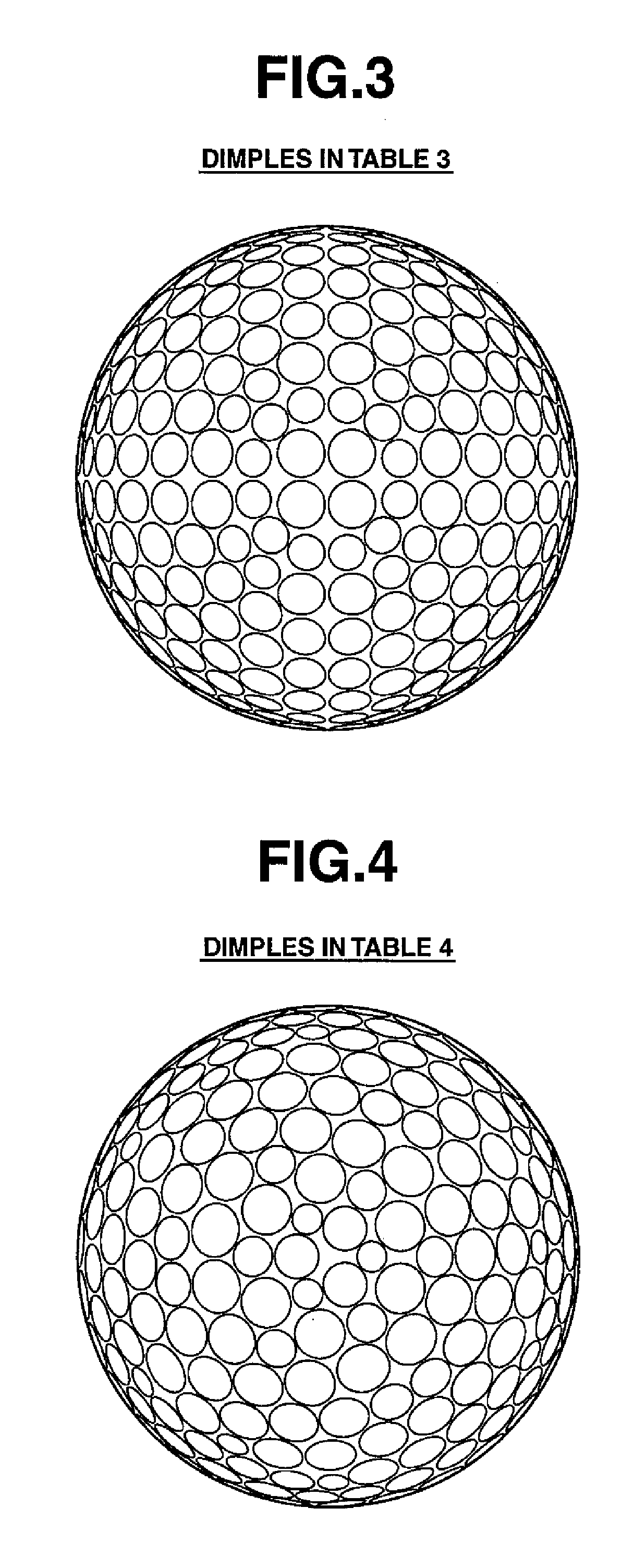

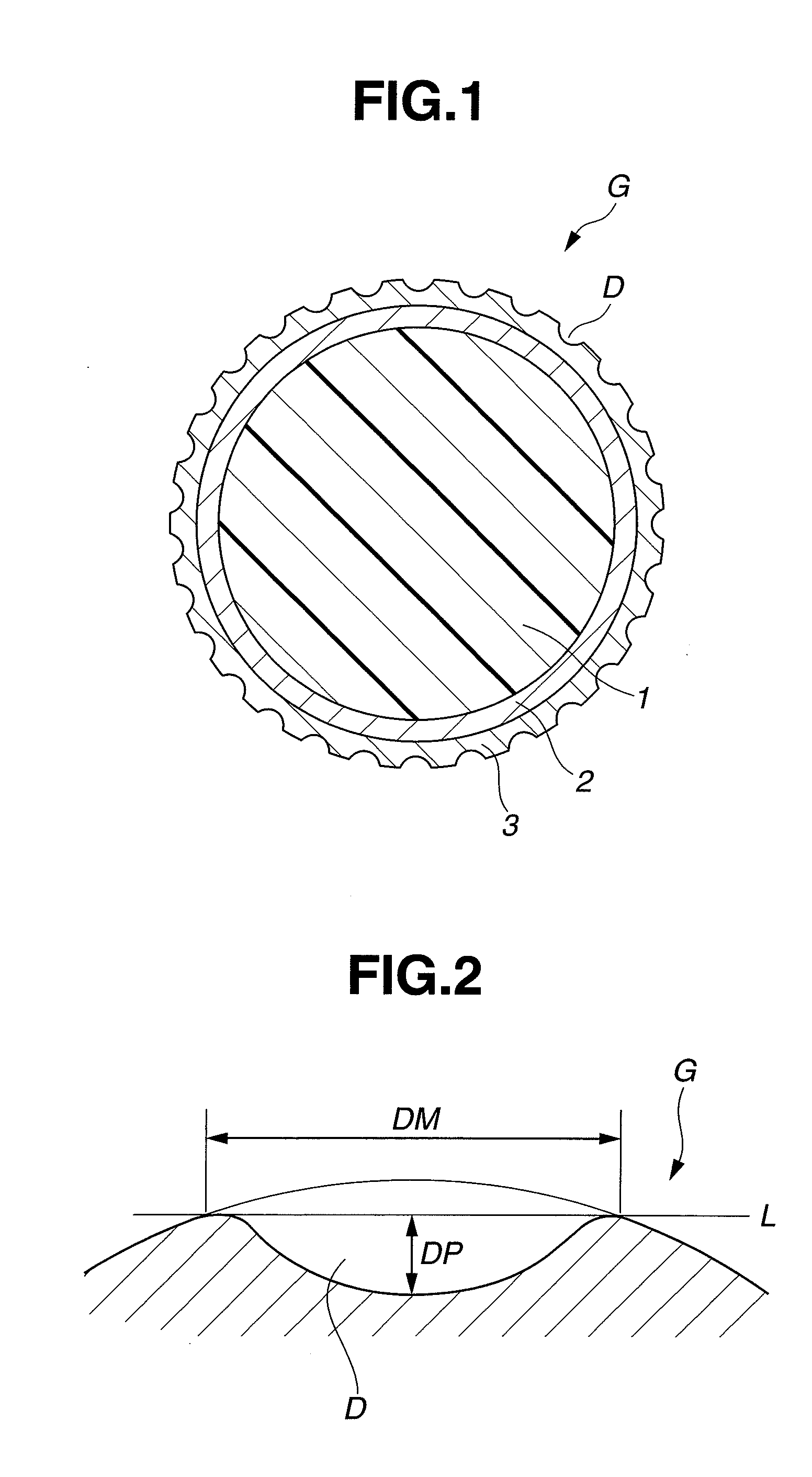

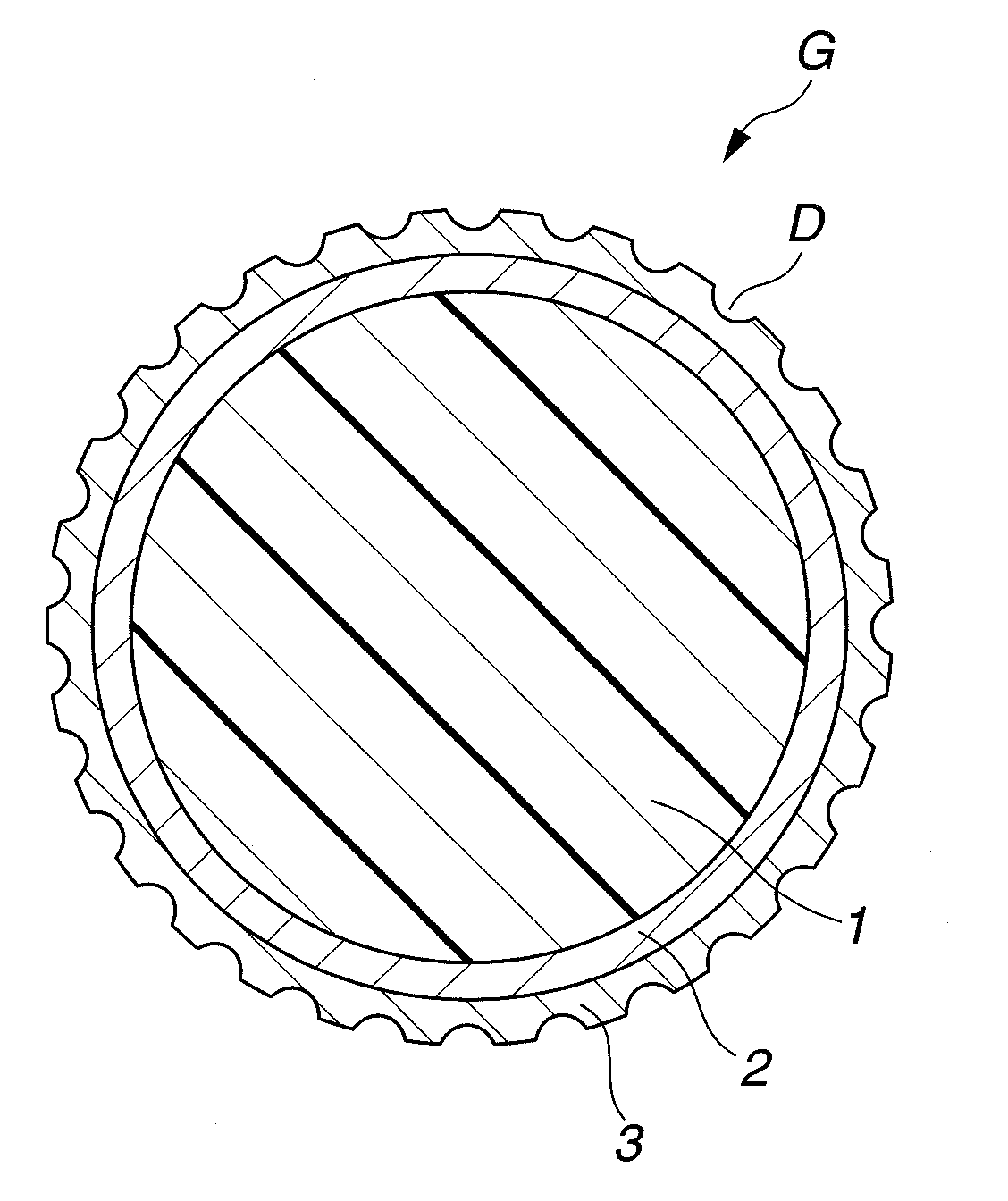

Multi-piece solid golf ball

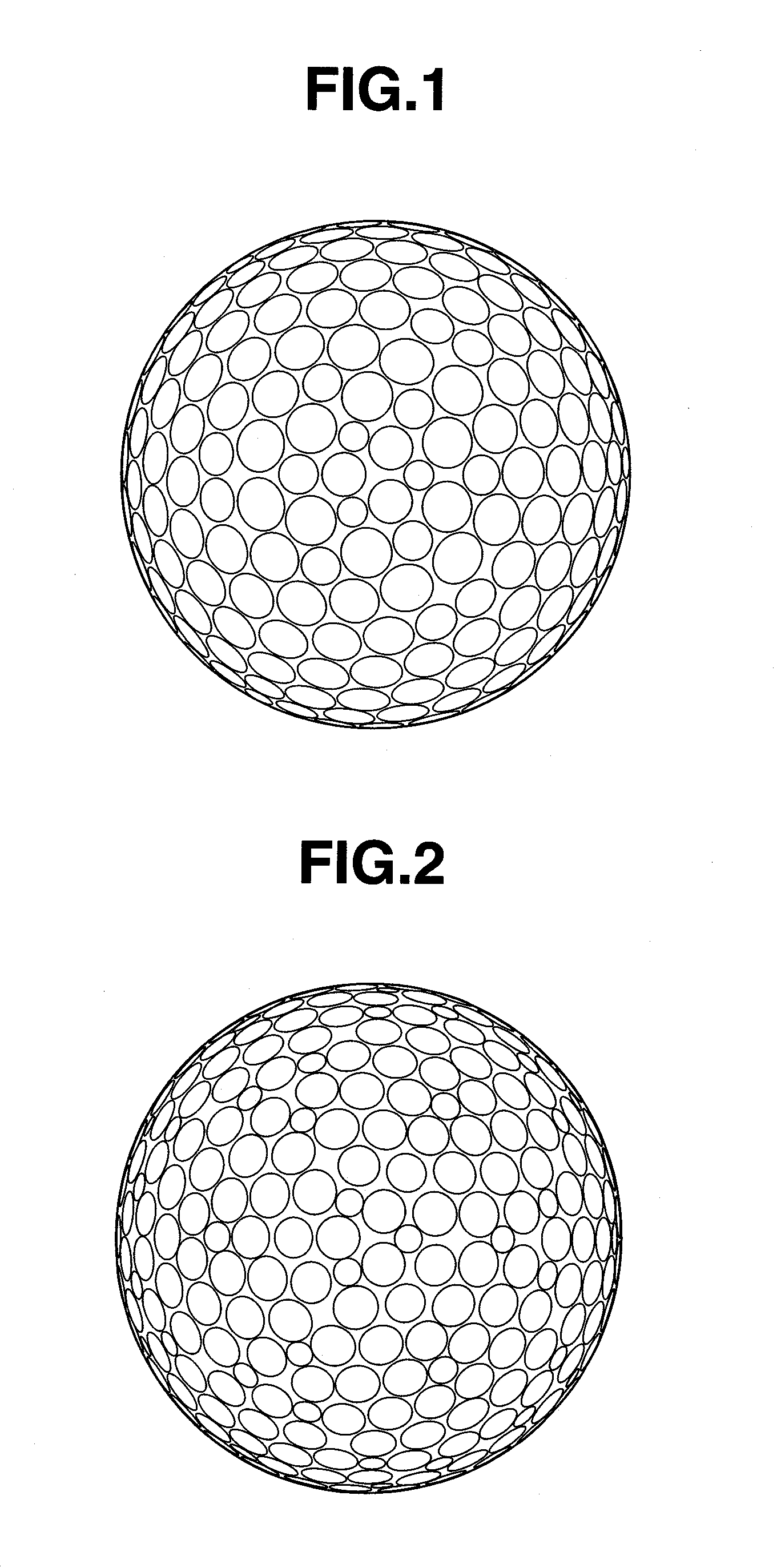

InactiveUS20130196790A1Specific deflection ratio therebetweenShorten travel distanceGolf ballsSolid ballsStructural engineeringGolf Ball

The invention provides a multi-piece solid golf ball having a solid core, an inner cover layer and an outer cover layer, which outer cover layer has numerous dimples on a surface thereof. The ball is characterized both in that the core and the inner cover layer are formed so as to have a specific deflection ratio therebetween, and also by the combination of an inner cover layer formed to a specific material hardness and thickness, an outer cover layer formed to a specific material hardness, and dimples which satisfy specific conditions. This multi-piece solid golf ball is able to substantially reduce the distance traveled by the ball when struck at a high head speed, while at the same time holding down the decrease in distance when struck at a low head speed.

Owner:BRIDGESTONE SPORTS

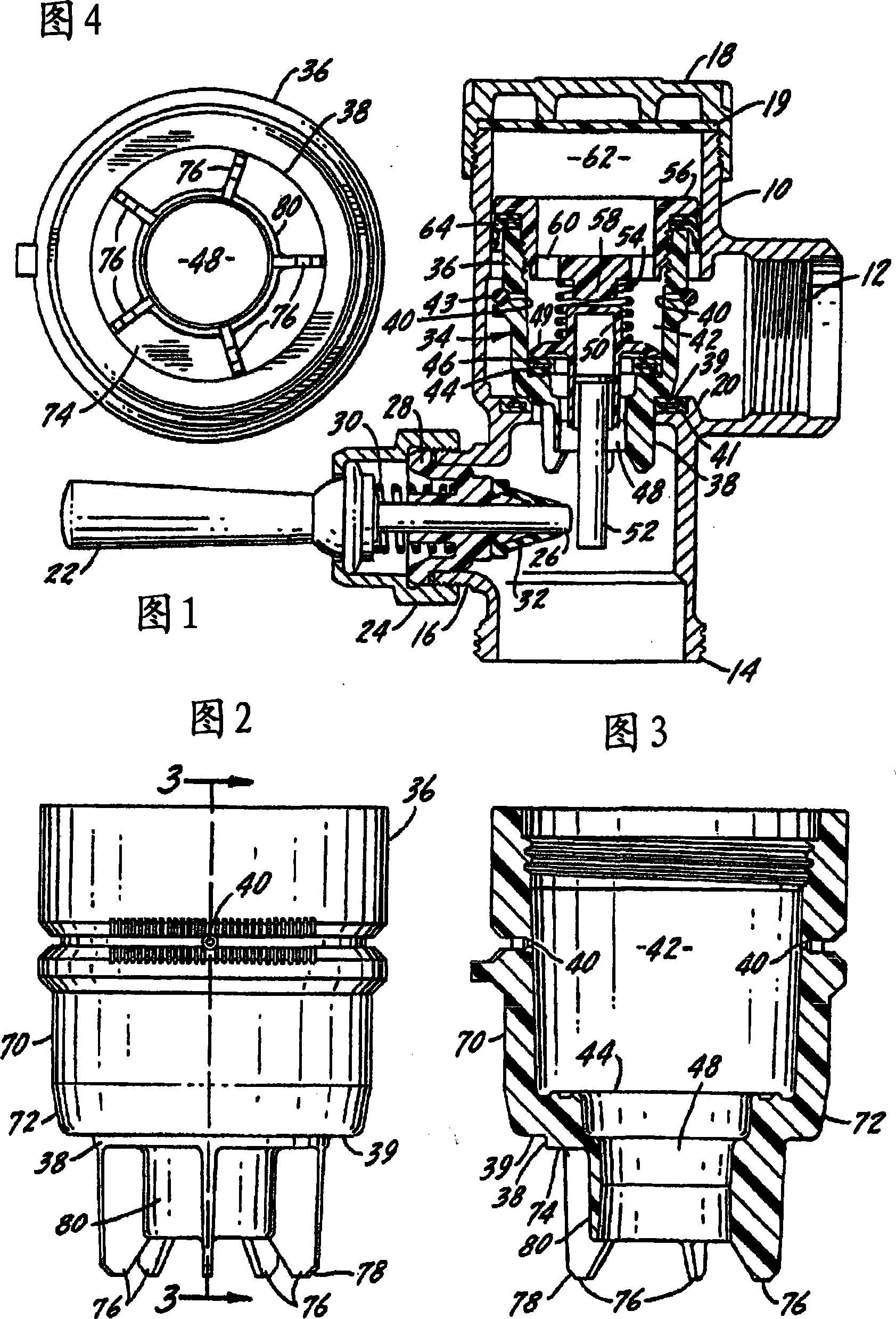

Dual bypass for piston-type flushometer

InactiveCN101089303AReduce the importance of angular orientationReduce the effect of back pressureOperating means/releasing devices for valvesFlushing devicesControl flowPiston

Owner:SLOAN VALVE COMPANY

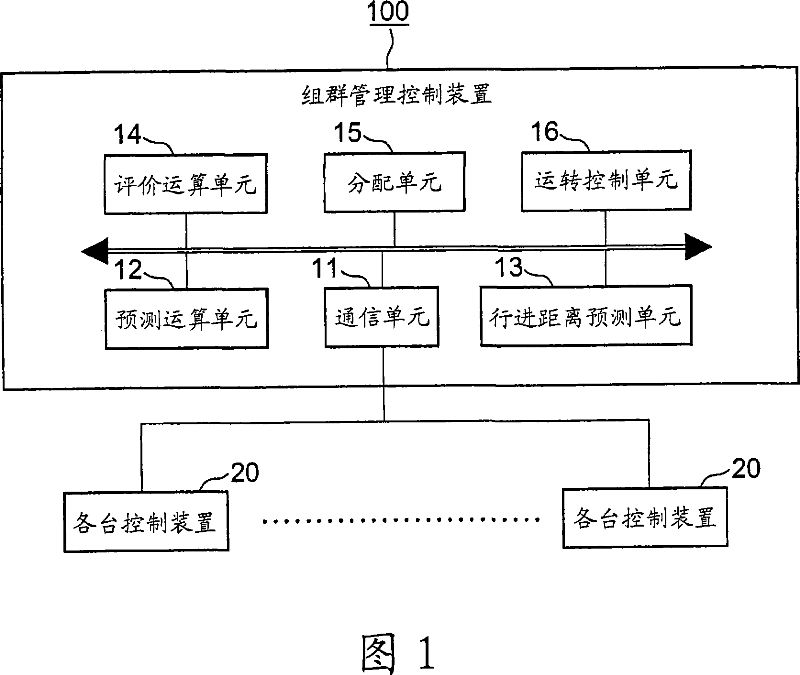

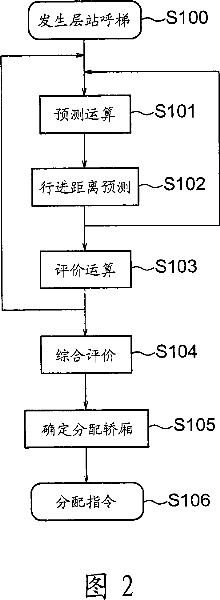

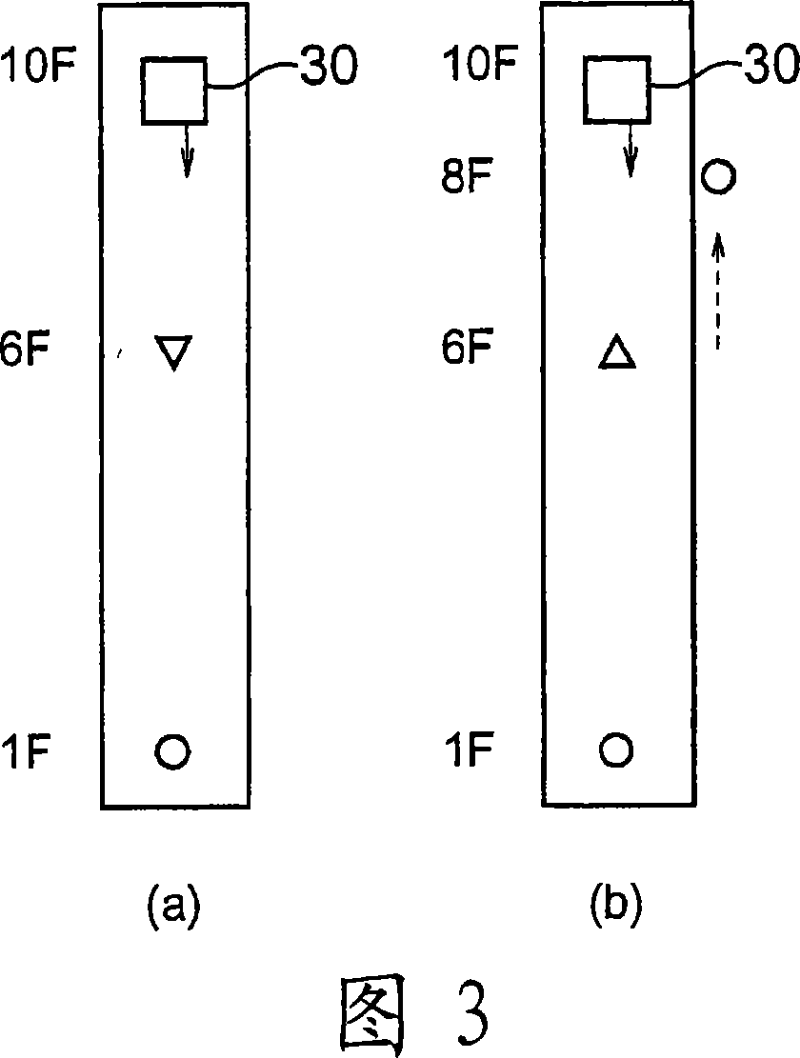

Elevator group management and control apparatus

An elevator management and control apparatus for operating elevators efficiently. The elevator management and control apparatus has estimation and calculation means for estimating the time until arrival of each car from a current position at a floor where a landing call is produced; travel distance estimation means for estimating the distance of travel along which each car travels from the current position until it stops after responding to every call allocated to it; evaluation and calculation means for calculating a waiting time for a landing call based on the time until arrival which is estimated by the estimation and calculation means, calculating a waiting time evaluation by using a first evaluation function in which the waiting time is used as an evaluation index, and calculating a travel distance evaluation by using a second evaluation function in which the travel distance calculated by the travel distance estimation means is used as an evaluation index; and allocation means for performing calculation of a comprehensive evaluation function for each car including at least the waiting time evaluation and the travel distance evaluation, and allocating a car having the minimum value of the comprehensive evaluation function to the landing call.

Owner:MITSUBISHI ELECTRIC CORP

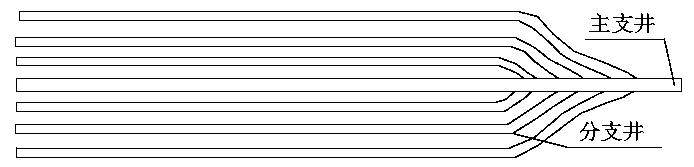

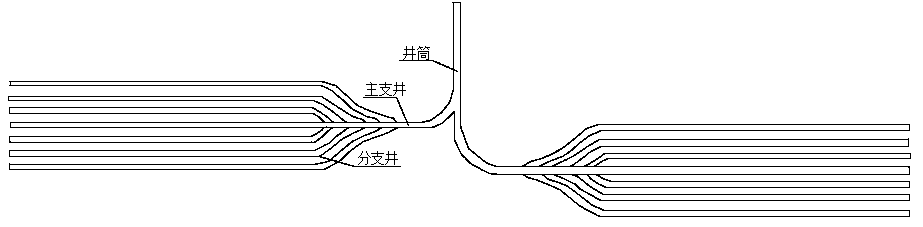

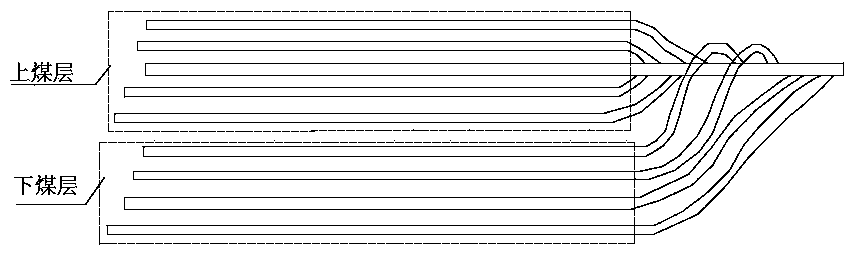

Ground area stripe coal mine gas outburst elimination technique

InactiveCN108643960AReduce the amount of drilling workShorten construction timeFluid removalGas removalCoalCoal mine methane

The invention provides a ground area stripe coal mine gas outburst elimination technique. The ground area stripe coal mine gas outburst elimination technique comprises the following steps that a branch arrangement mode is optimized; a well location of a vertical well is optimized; a deflection point is optimized; a branch parameter is optimized; a reservoir modification technology is optimized; well drilling and deflecting are carried out; drilling of a main branch section is completed, and a coal rock core is observed; drilling of branches is completed; main branch hydraulic jetting fracturing is completed; and drainage and mining is started according to a drainage and mining design. The ground area stripe coal mine gas outburst elimination technique has the beneficial effects that the development cost of ground coal bed gas can be reduced, a gas extraction period can be shortened, the aim that coal seam gas-bearing capacity is quickly reduced is realized, and a great promoting function of improving coal mine production and accelerating rapid development of the coal industry is achieved.

Owner:HENAN INST OF ENG

Golf ball

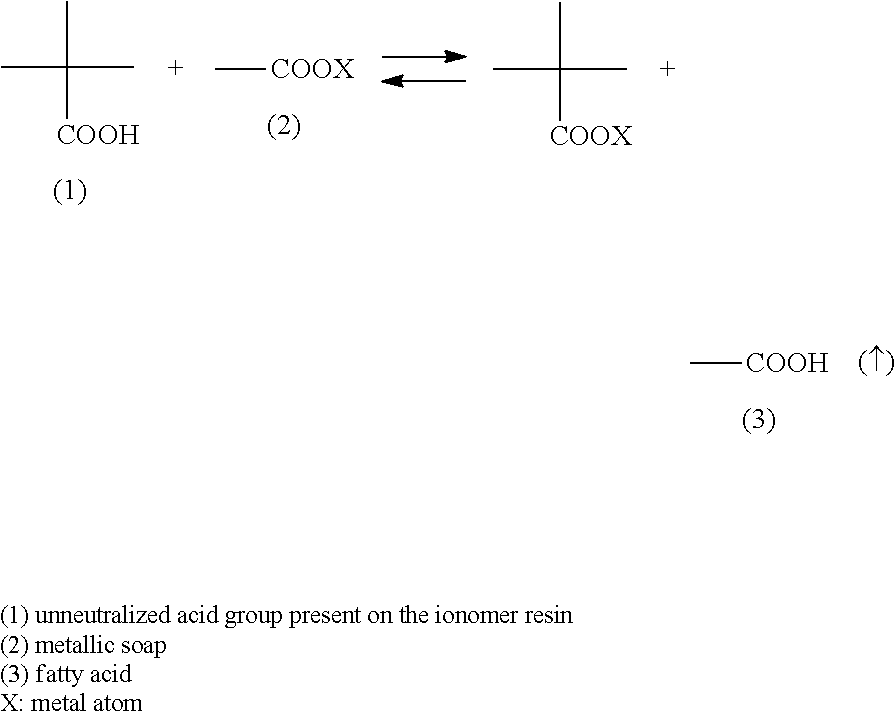

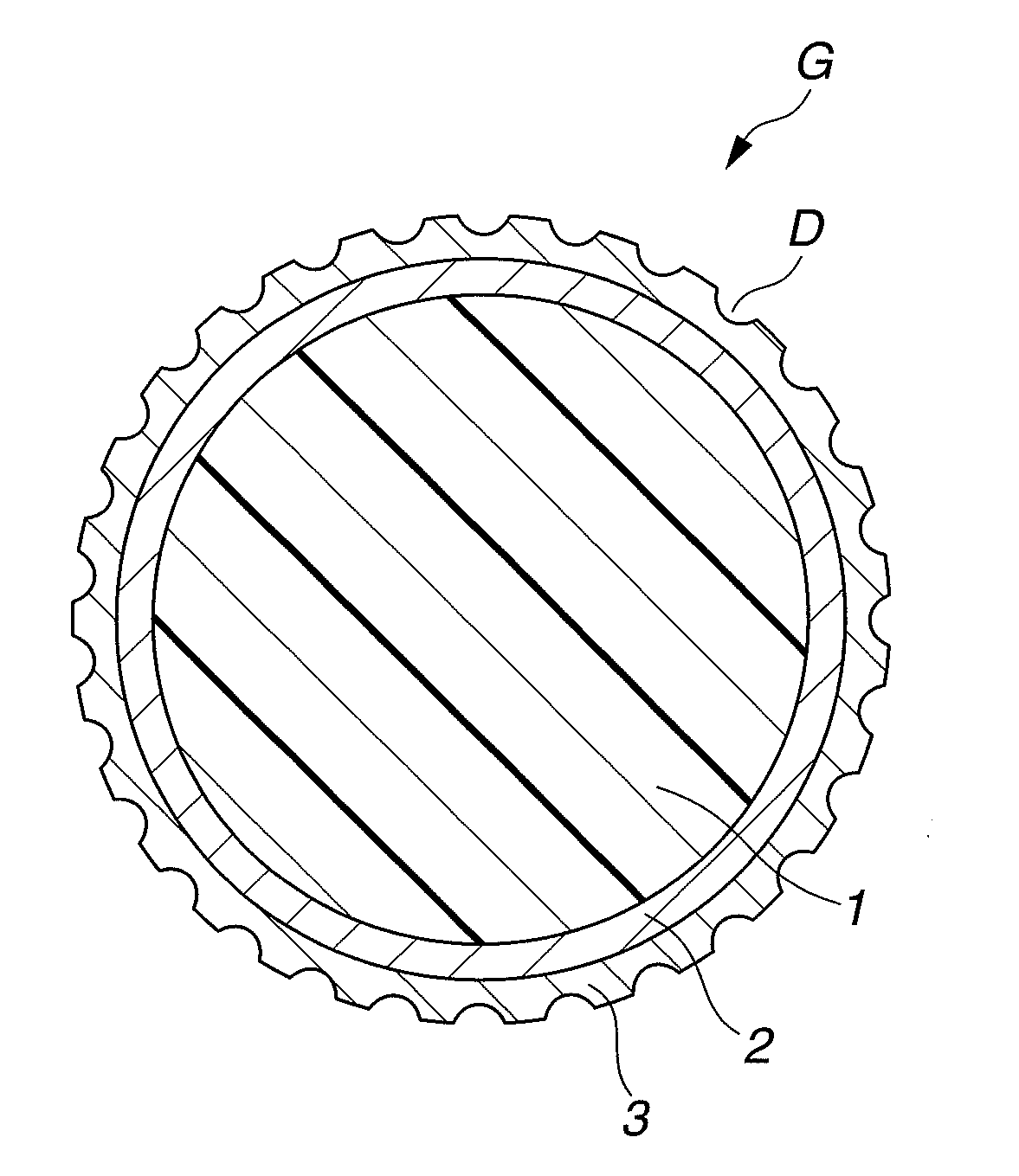

ActiveUS20110098131A1Increase distanceReduced spin rateGolf ballsSolid ballsEngineeringInorganic filler

The invention provides a golf ball having a core, at least one intermediate layer encasing the core, and a cover. The intermediate layer is formed primarily of a specific ionomer resin composition that has been highly neutralized, and the cover is formed primarily of an ionomer resin composition containing a specific amount of a granular inorganic filler. The golf ball has an excellent durability to repeated impact and a good flight performance.

Owner:BRIDGESTONE SPORTS

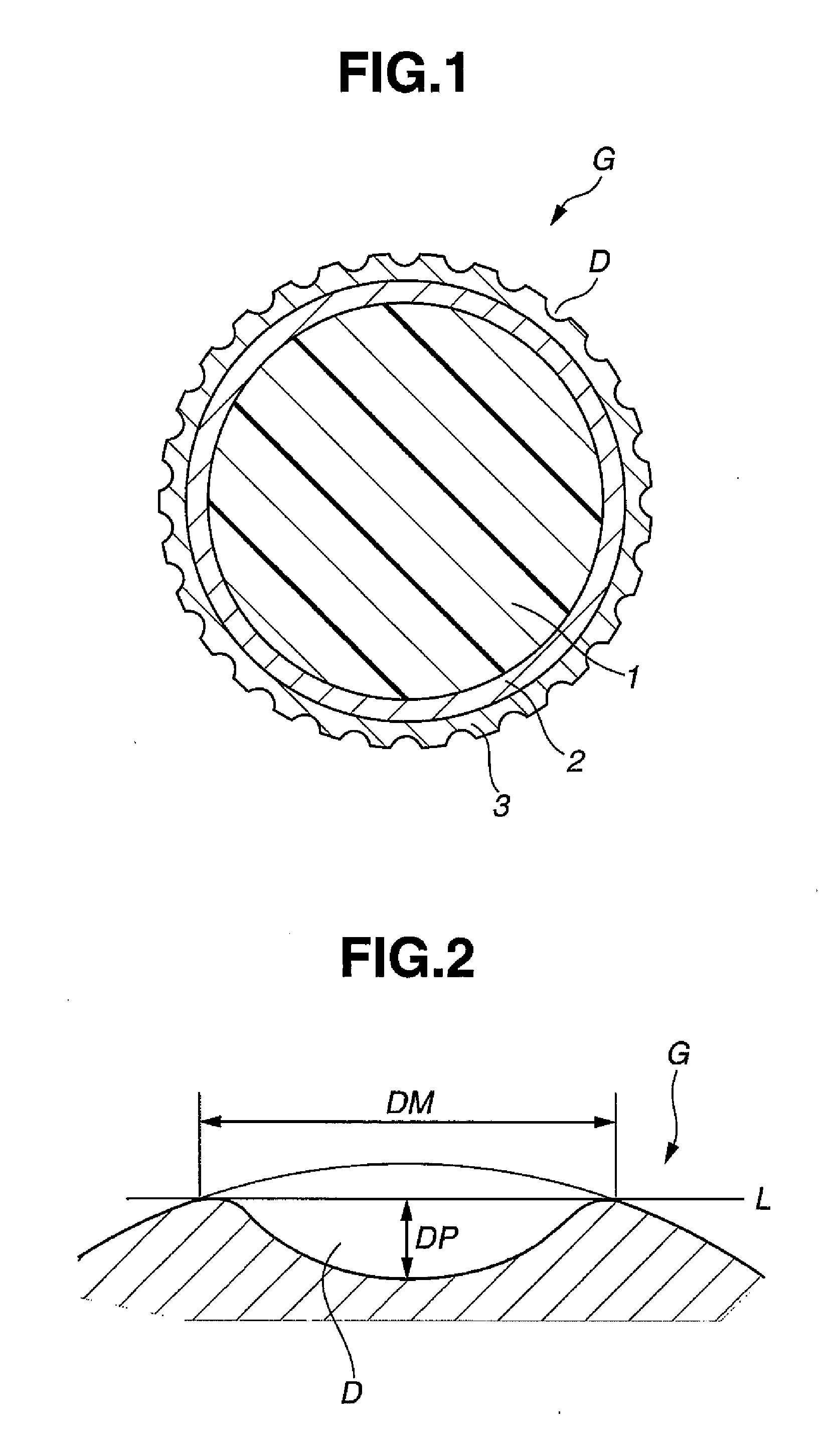

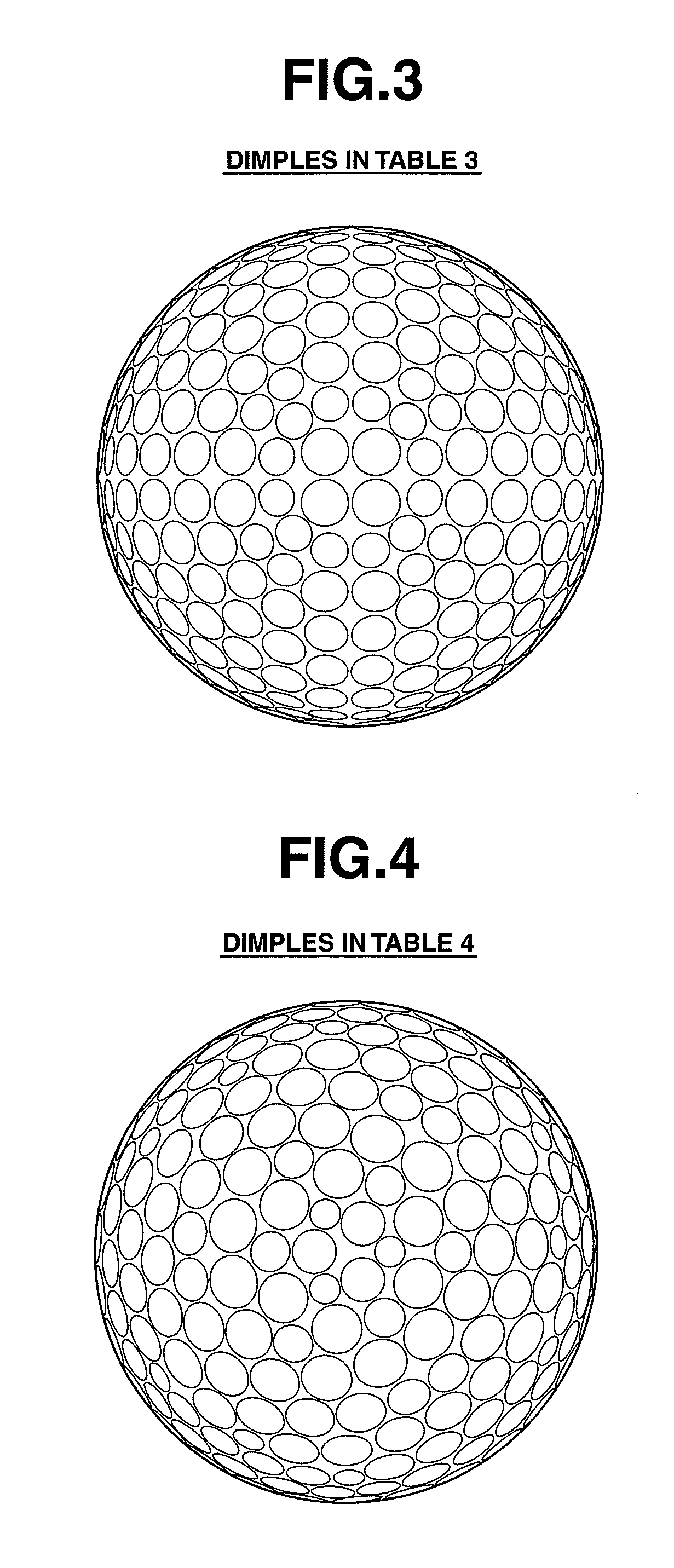

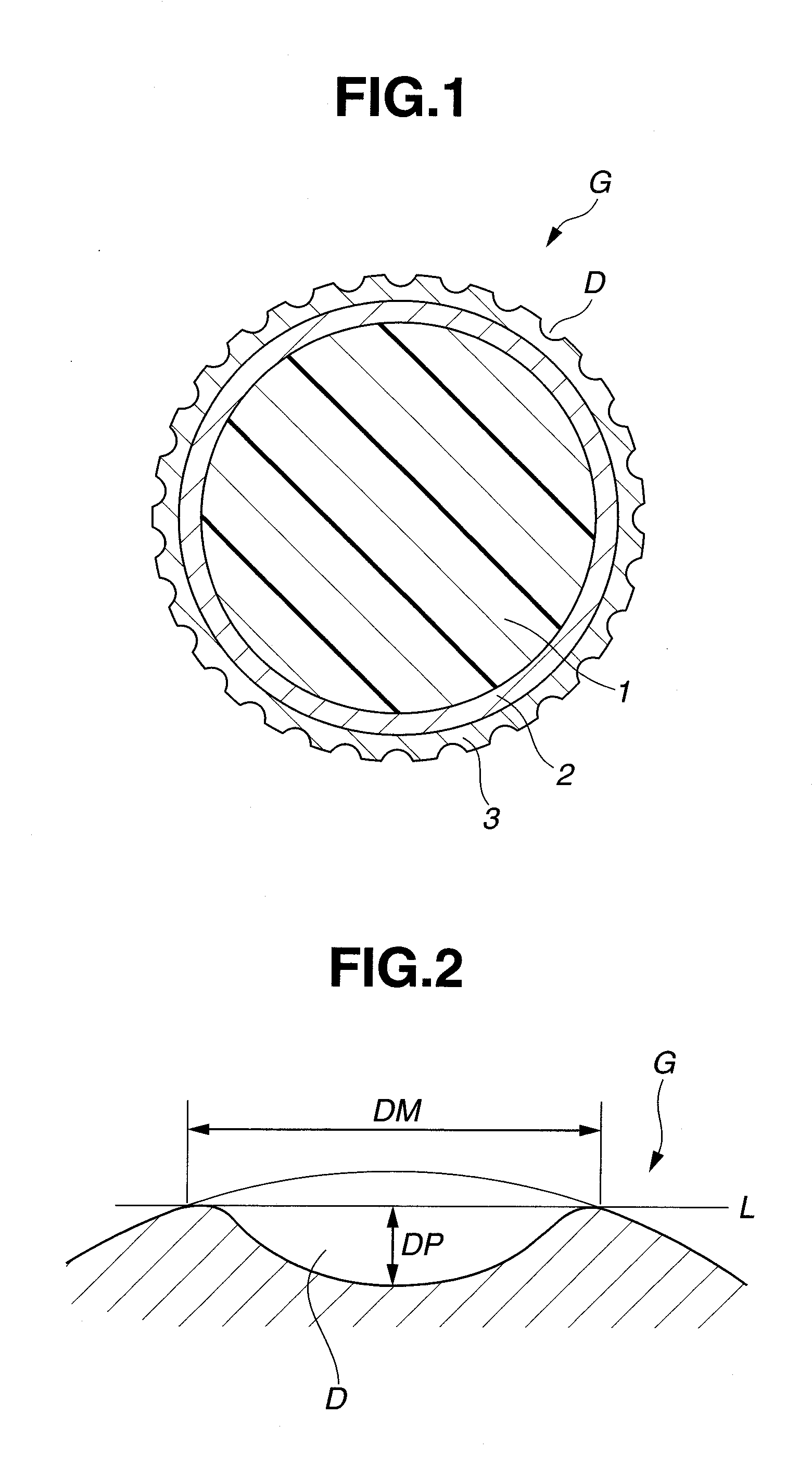

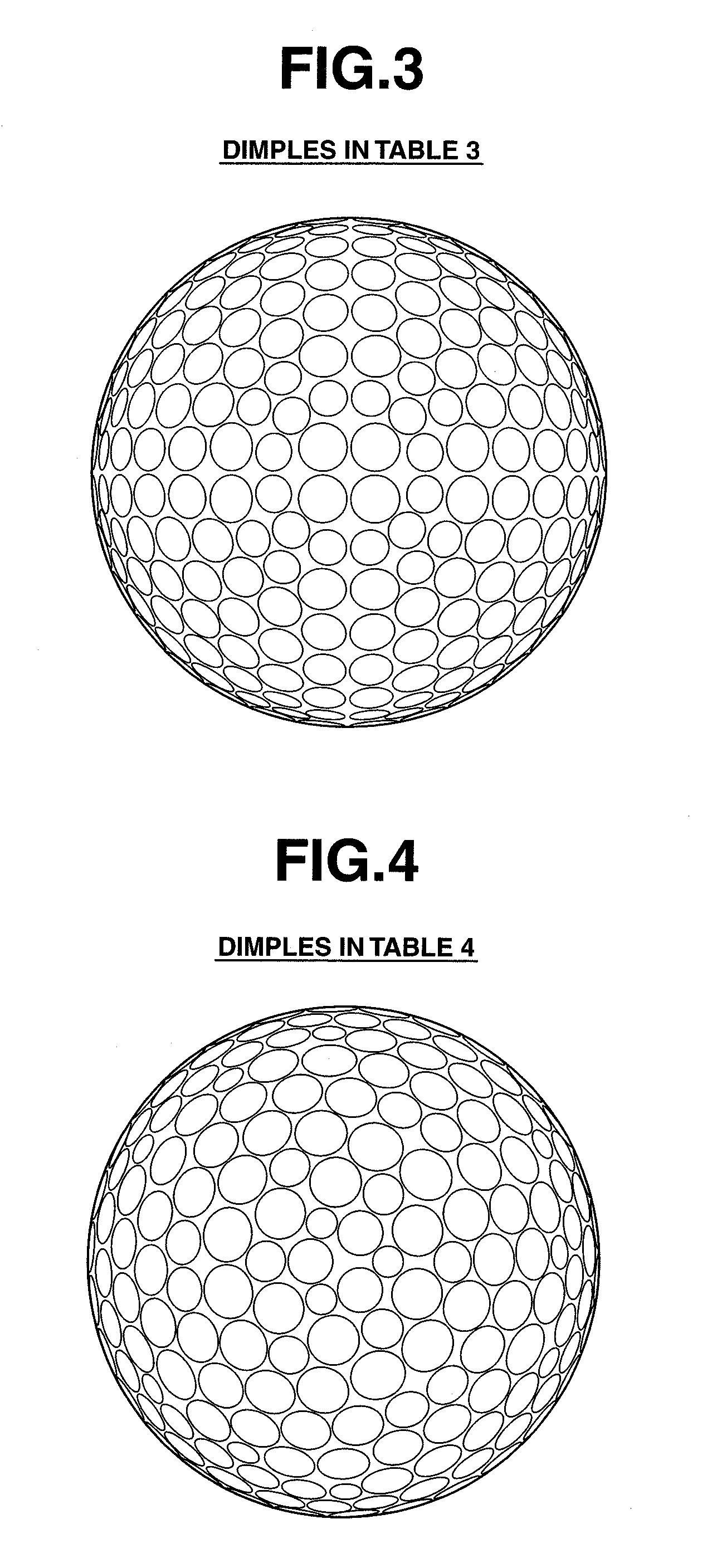

Multi-piece solid golf ball

InactiveUS20110250987A1Shorten travel distanceReduce distanceGolf ballsSolid ballsEngineeringGolf Ball

The invention provides a multi-piece solid golf ball having a solid core, an inner cover layer and an outer cover layer, which outer cover layer has a plurality of dimples on a surface thereof. The value obtained by subtracting a material hardness (Shore D) of the outer cover layer from a material hardness (Shore D) of the inner cover layer is greater than −5 and less than +5. The dimples number at least 250 and not more than 500, have a surface coverage (SR) of at least 70% and a volume ratio (VR) of at least 1.0%, are of at least three types of mutually differing dimple diameter (DM) and / or dimple depth (DP), and have an average depth of at least about 0.18 mm and a diameter-to-depth ratio (DM / DP) of not more than about 23. The ball has a coefficient of lift CL at a Reynolds number of 70,000 and a spin rate of 2,000 rpm which is maintained at 60% or more of the coefficient of lift CL at a Reynolds number of 80,000 and a spin rate of 2,000. This multi-piece solid golf ball is able to substantially reduce the distance traveled by the ball when struck at a high HS, while at the same time holding down the reduction in distance when struck at a low HS.

Owner:BRIDGESTONE SPORTS

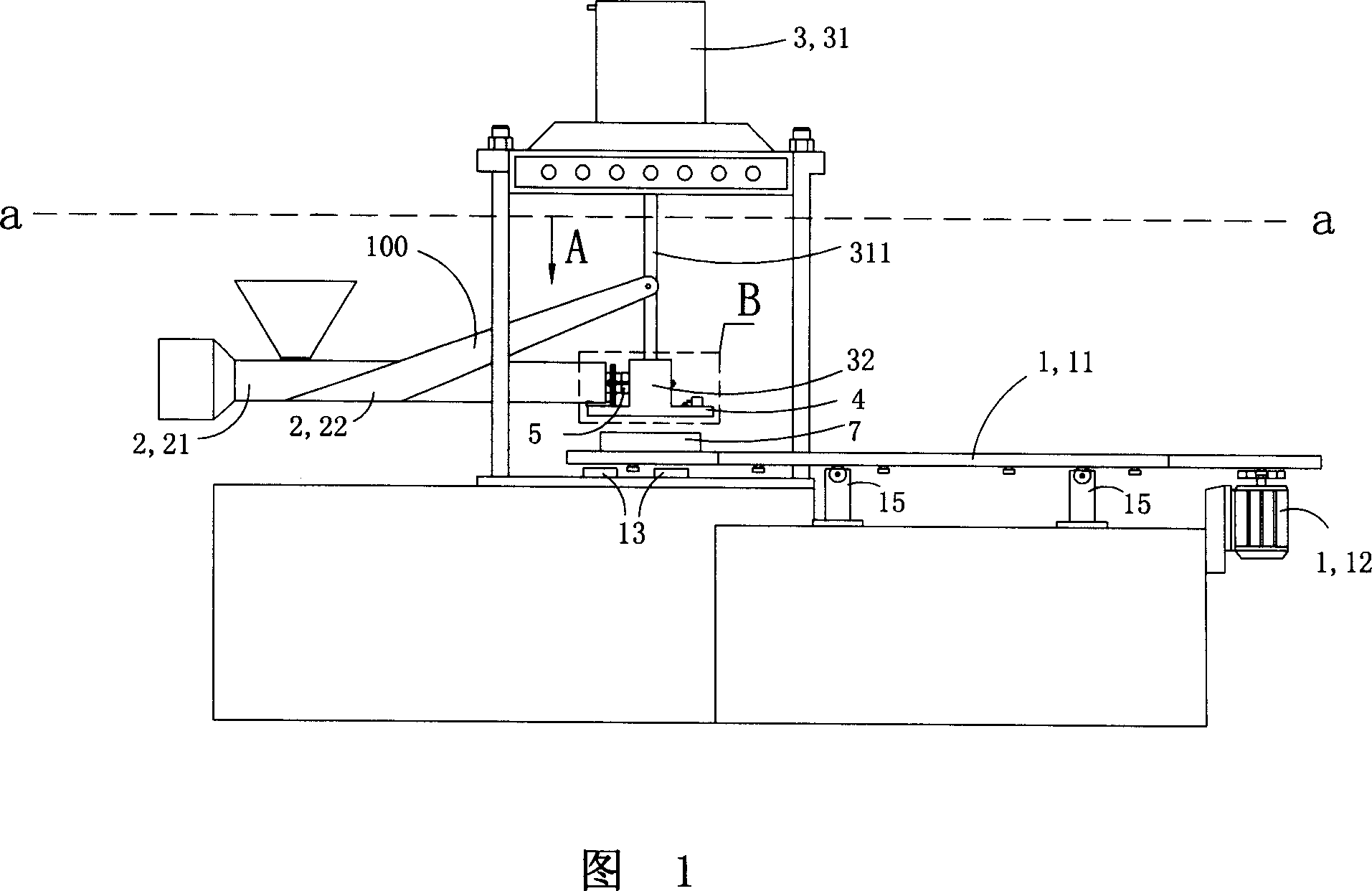

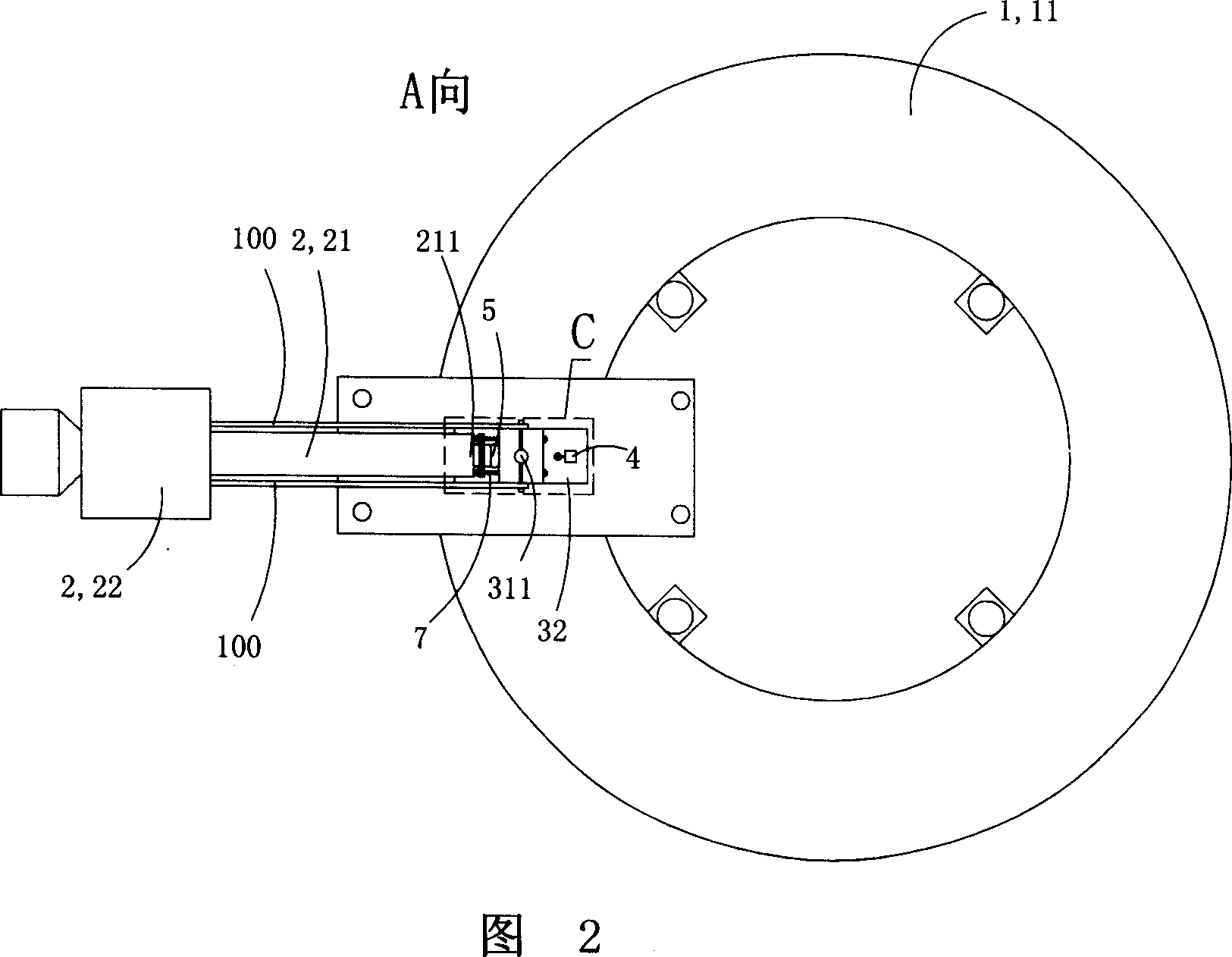

Horizontal disk injecting forming unit

A horizontal disc type injection moulding machine is composed of a rotary disc unit, a injection moulding unit and a mould closing unit. Said injection moulding unit consists of a horizontal injection part and an injection jointer for allowing the fused plastic fluid to flow through it. Said mould closing unit comprises and mould closing cylinder with piston moving up and down, and an injection head fixed to the lower end of said piston for injecting the fused plastic fluid into moulding cavity of mould.

Owner:金孝禹

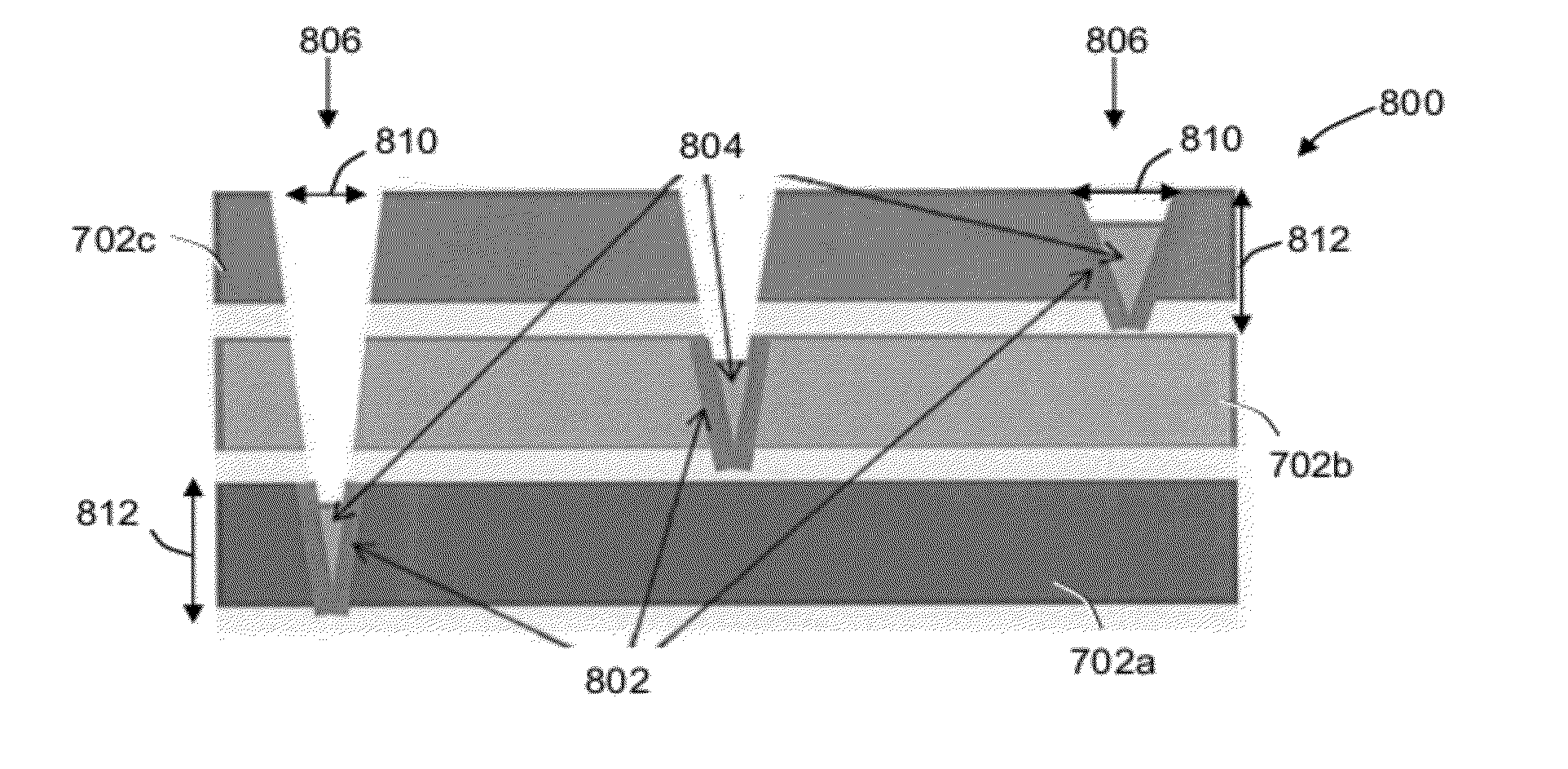

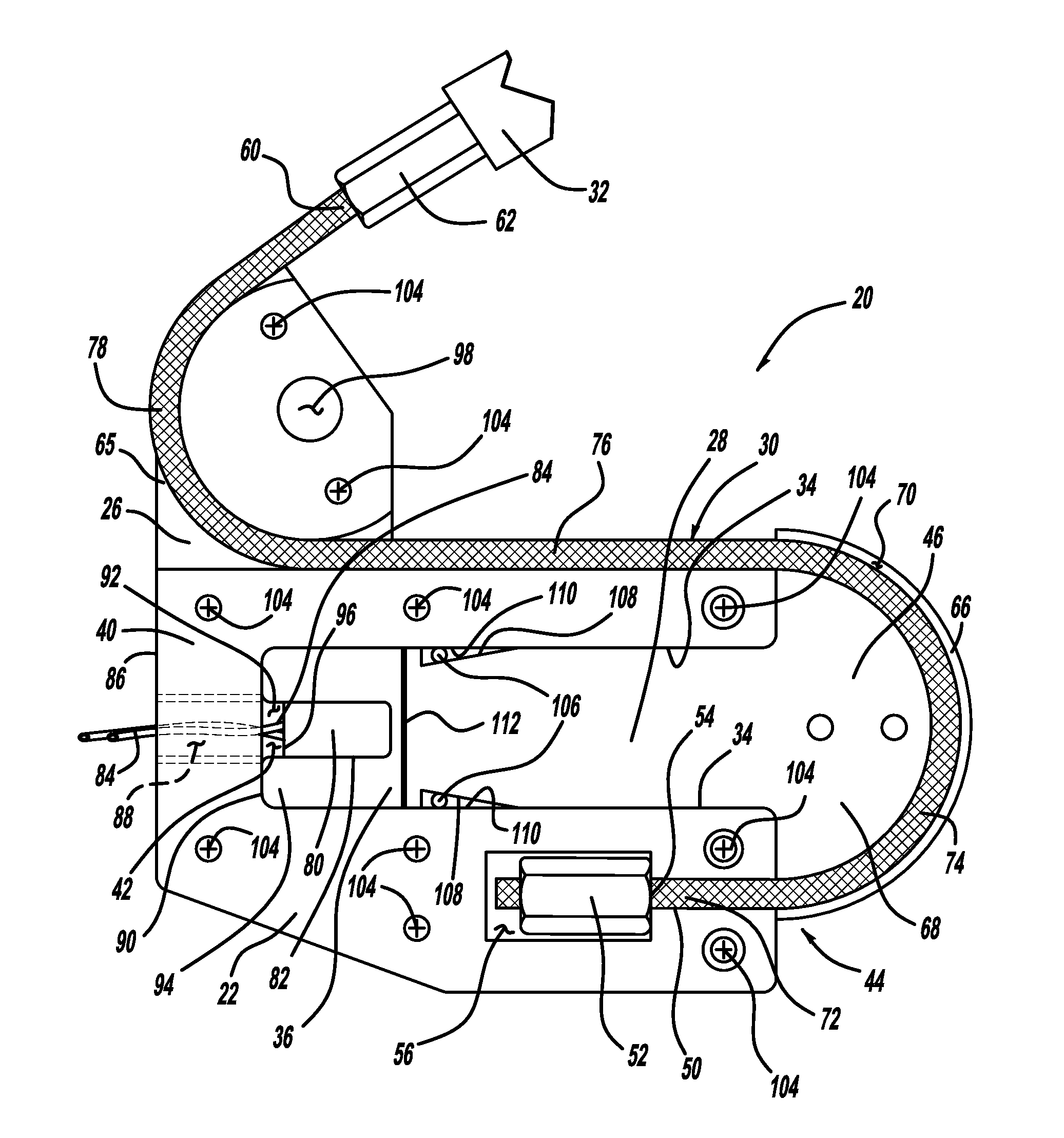

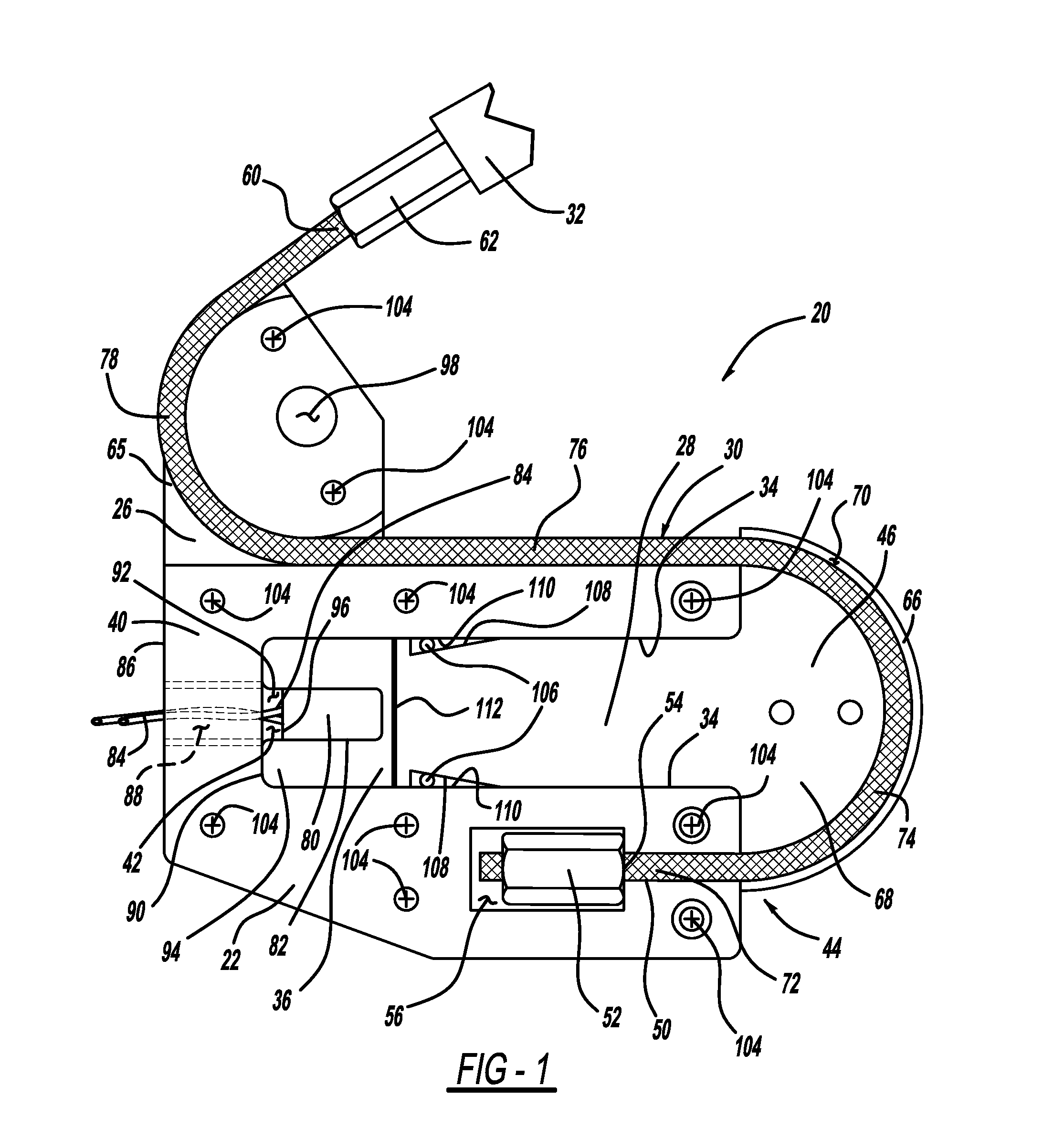

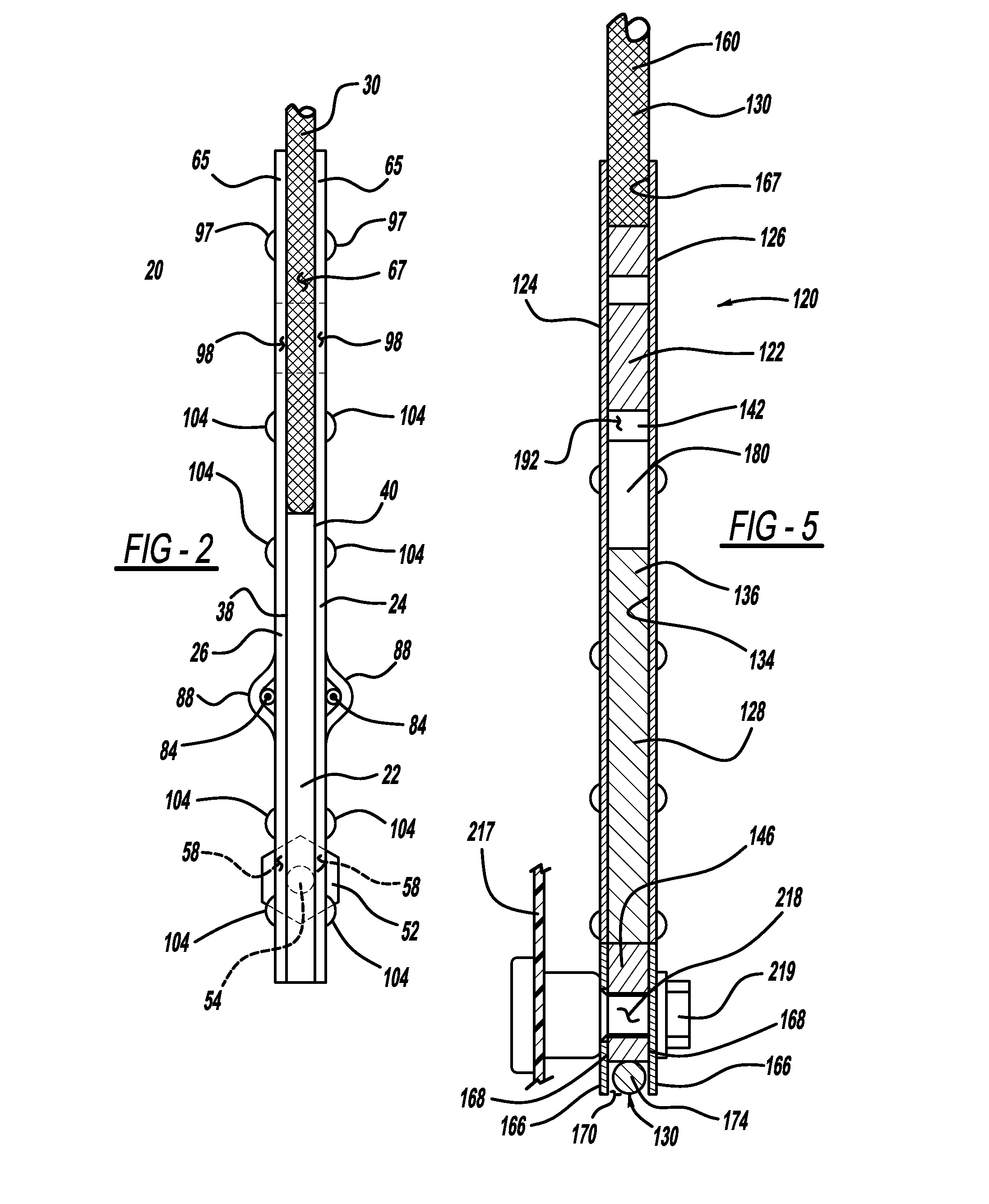

Thin Linear Seatbelt Pretensioner

ActiveUS20120119478A1Reduce leakage pathShorten travel distanceSafety beltsBelt retractorsEngineeringGas generator

A linear pretensioner for use as part of a motor vehicle occupant belt restraint system mountable to vehicle structure and coupled with a belt restraint system component. The pretensioner includes at least one base plate having a slot and at least one closure plate fixedly attached to the base plate. The closure plate(s) and the slot of the base plate(s) form a cavity having an open end. A piston plate has a piston tail slidably disposed within the cavity and a piston head extending from the open end. A cable is coupled with the piston plate, the base plate(s), and / or the closure plate(s). The piston plate, the slot of the base plate(s), and the closure plate(s) cooperate to form an expanding chamber that enlarges when pressurized by a gas generator, which drives the piston plate and the base plate relative to each other to exert tension on the cable.

Owner:AUTOLIV ASP INC

Multi-piece solid golf ball

InactiveUS20110250989A1Shorten travel distanceReduce distanceGolf ballsSolid ballsEngineeringGolf Ball

The invention provides a multi-piece solid golf ball having a solid core, an inner cover layer and an outer cover layer, which outer cover layer has a plurality of dimples on a surface thereof. The inner cover layer has a thickness of from 0.8 to 3.0 mm and a material hardness (Shore D) of from 50 to 80, the outer cover layer has a material hardness (Shore D) of from 35 to 60, and the material hardness (Shore D) of the inner cover layer is higher than the material hardness (Shore D) of the outer cover layer. The dimples number at least 250 and not more than 500, have a surface coverage (SR) of at least 70% and a volume ratio (VR) of at least 1.0%, are of at least three types of mutually differing dimple diameter (DM) and / or dimple depth (DP), and have an average depth of at least about 0.18 mm and a diameter-to-depth ratio (DM / DP) of not more than about 23. The ball has a coefficient of lift CL at a Reynolds number of 70,000 and a spin rate of 2,000 rpm which is maintained at 60% or more of the coefficient of lift CL at a Reynolds number of 80,000 and a spin rate of 2,000. This multi-piece solid golf ball is able to substantially reduce the distance traveled by the ball when struck at a high HS, while at the same time holding down the reduction in distance when struck at a low HS.

Owner:BRIDGESTONE SPORTS

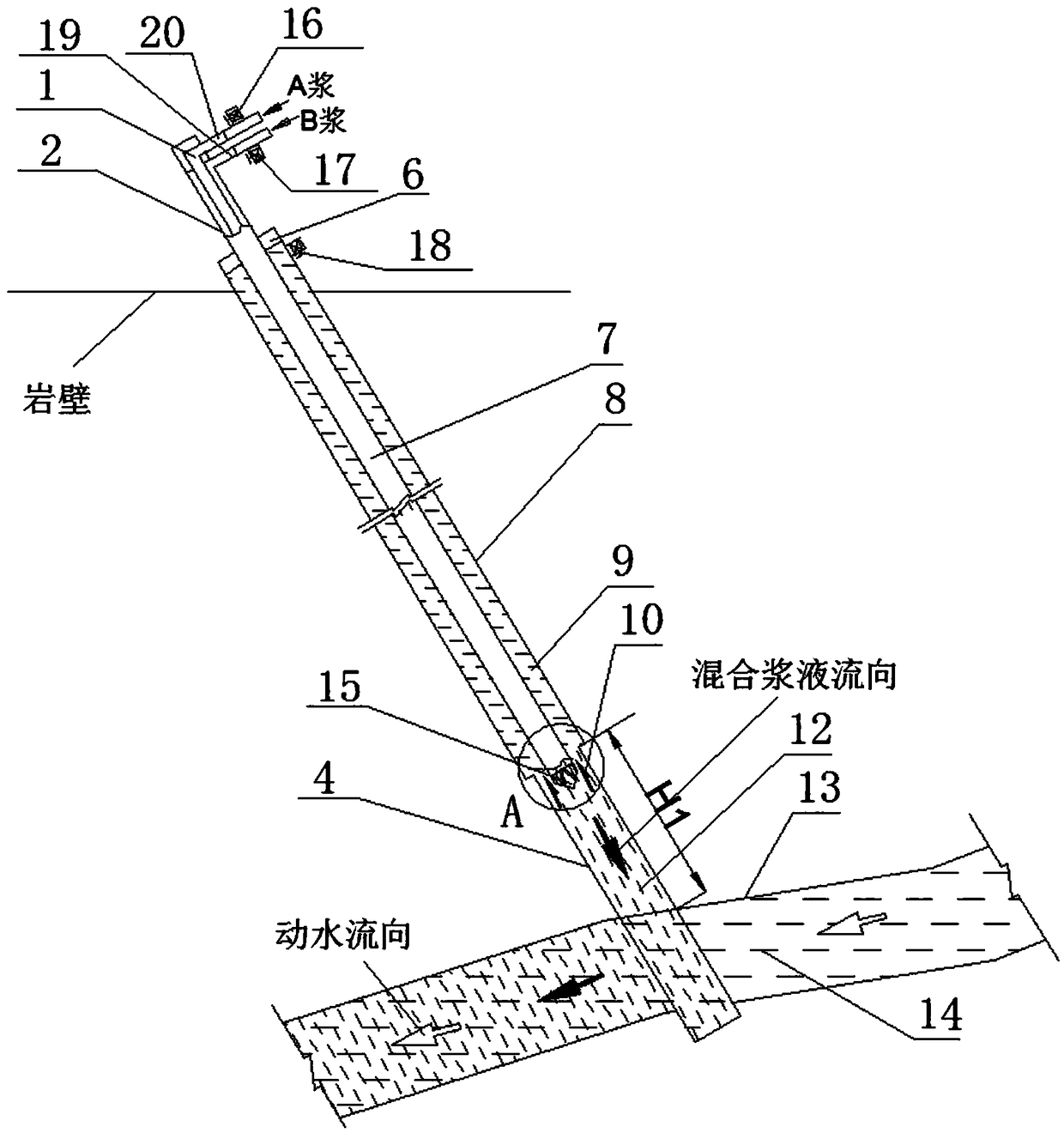

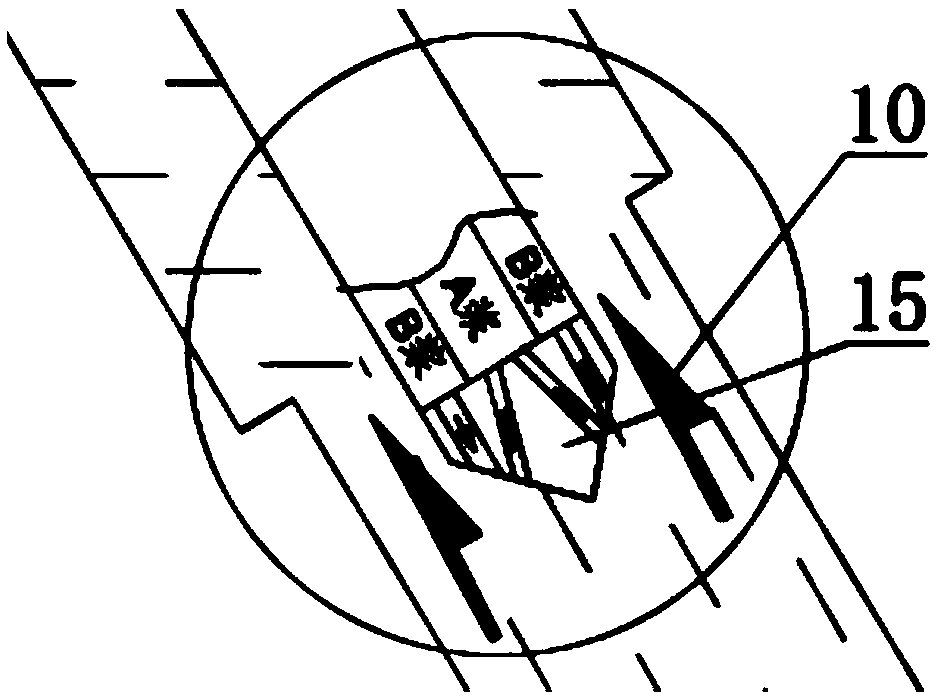

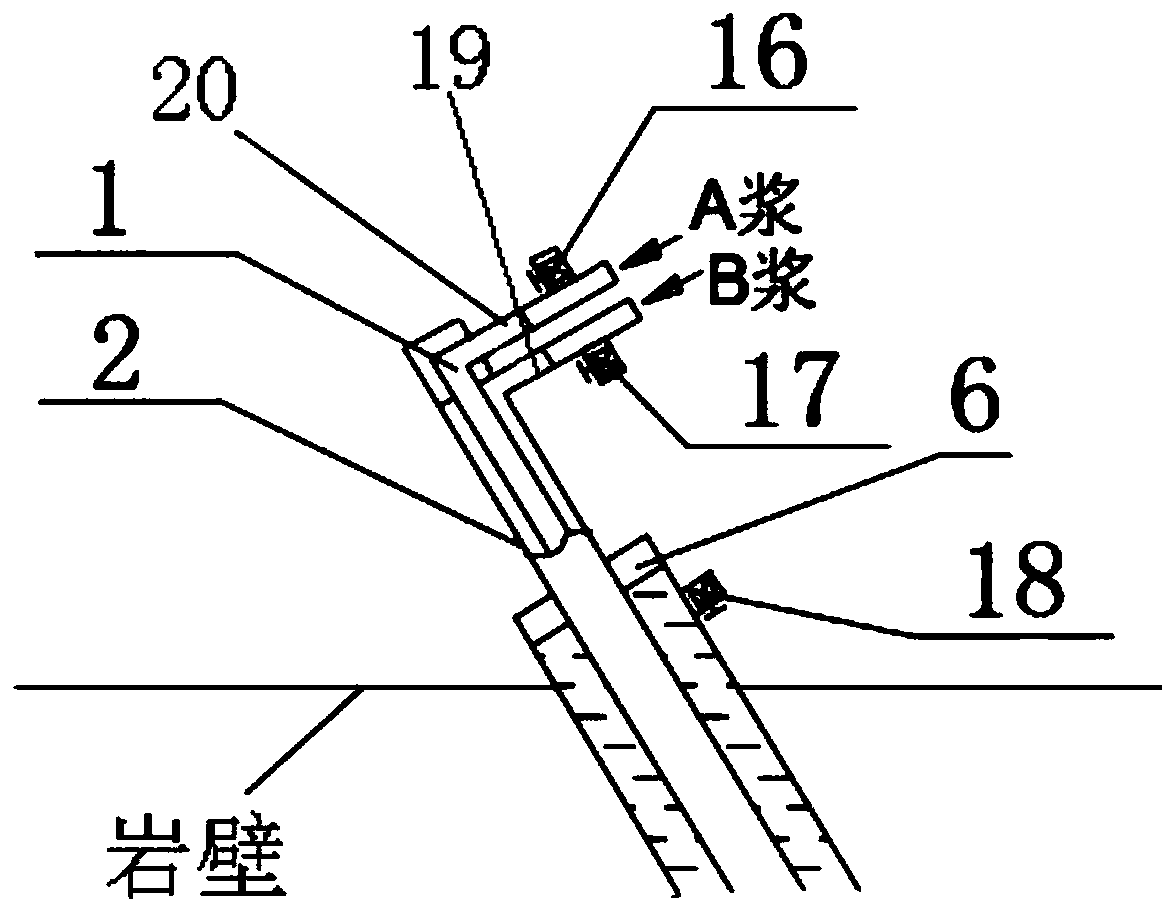

Double-liquid grouting method utilizing water column to stop grout in ultra-deep borehole under mine

ActiveCN109403914AEliminate backflow into the casing and seal the disadvantages of blocking the casingSolve shrinkageSealing/packingWater flowSlurry

This invention relates to a double-liquid grouting method utilizing a water column to stop grout in an ultra-deep borehole under a mine and belongs to the field of prevention and control of mine waterhazard. The double-liquid grouting method comprises a step of constructing a water-stopping and grouting drilled hole according to design parameters, a step of judging the exact position of a water storing and guiding channel, a step of estimating the water flow area of the water storing and guiding channel, a step of calculating the designed depth position of the bottom end of a second-stage aperture casing in the drilled hole, a step of lowering the second-stage aperture casing and sealing, a step of connecting and lowering a double-grout grouting pipe, a step of installing a sealing device, a step of performing grouting and water stopping after installation is completed and a step of detaching the double-grout grouting pipe and the sealing device after grouting is completed. The double-liquid grouting method effectively solves the difficult problems of diameter shrinkage and hole wall collapse in the water-sensitive formation section of the drilled hole, the transporting and movingdistance of mixed grout is greatly shortened, and the purpose of injecting double-grout mixed grout into the drilled hole below the mine shaft of any depth, and quickly plugging the water storing andguiding channel for realizing grouting can be achieved and water stopping.

Owner:SHANDONG JIAOTONG UNIV

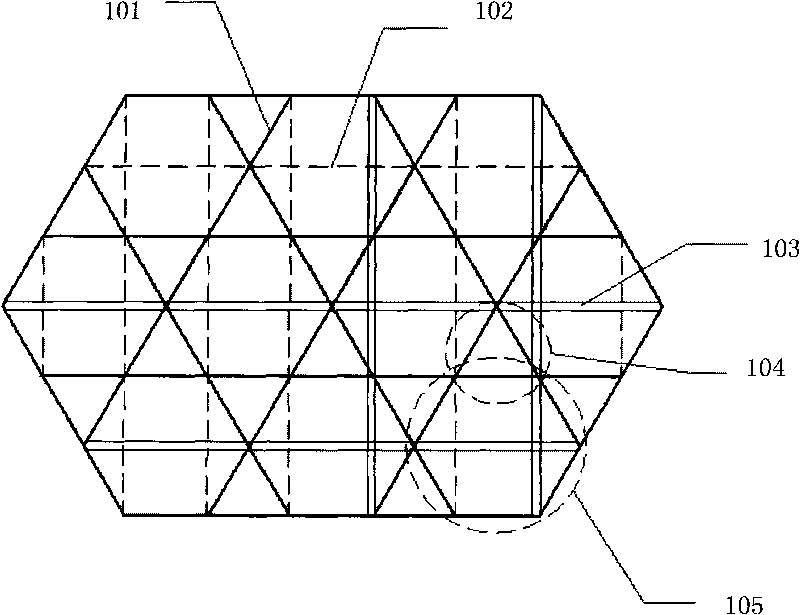

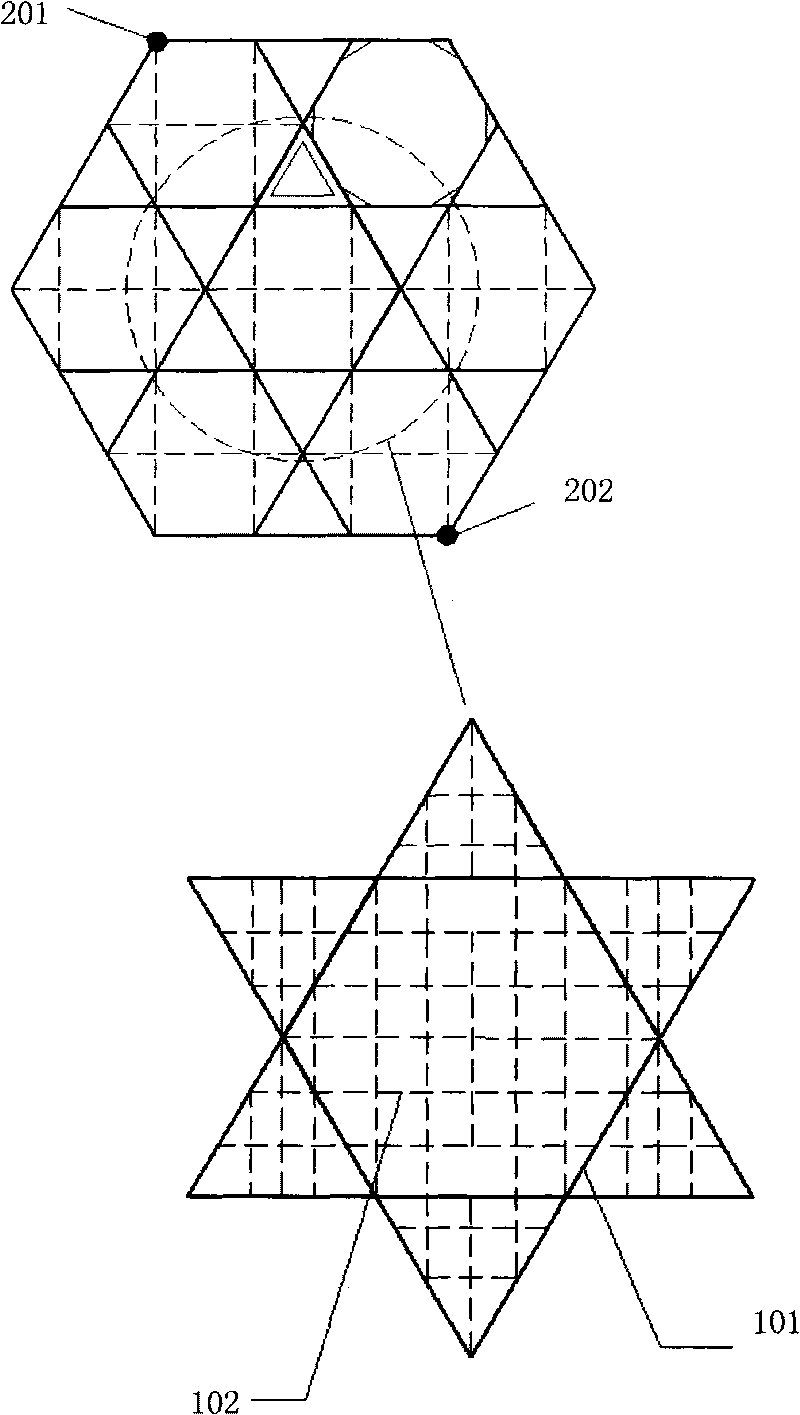

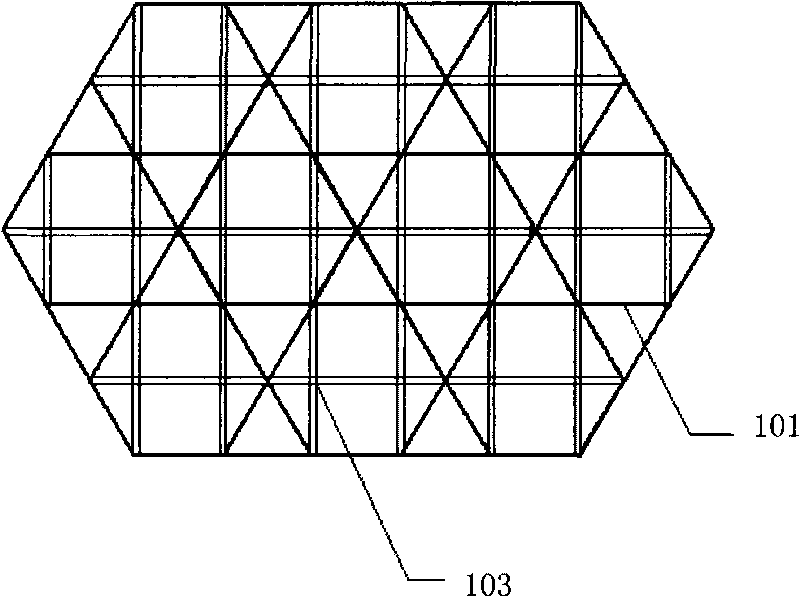

Road system of hexagon added with triangle

The invention relates to an urban road system and a corresponding underground railway system, aiming at providing a scheme which can not only improve traffic efficiency of an urban road network and reduce energy consumption of urban traffic, but also improve urban structure and urban livable value. The technical scheme comprises the essential that in the whole or part of the urban area, a road network is structured according to the way of forming a net structure of hexagon added with triangle. Compared with a traditional rectangle city, the road of the hexagon added with the triangle can reduce at least 18.4 percent of road distance, and enable the road in each area inside the road network to be closed relatively, thereby enhancing traffic speed on an urban main road, and effectively improving traffic efficiency and urban traffic structure.

Owner:任立乔

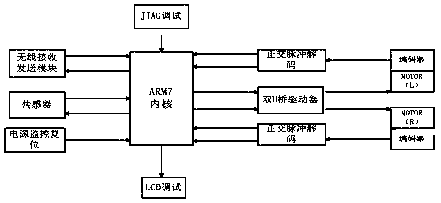

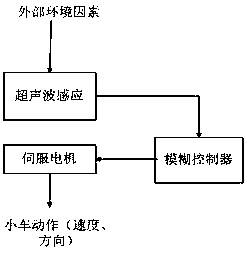

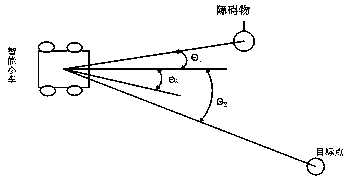

Automatic guiding obstacle avoidance robot trolley in modern logistics and control method thereof

InactiveCN108427415AShorten travel distanceReduce travel timePosition/course control in two dimensionsVehiclesElectricityWireless transceiver

The invention relates to an automatic guiding obstacle avoidance robot trolley in modern logistics. The trolley comprises a robot trolley body; an ultrasonic detecting device is installed on the robottrolley body and comprises a plurality of ultrasonic sensors, and each ultrasonic sensor is electrically connected with a fuzzy controller; a controller is installed on the robot trolley body and electrically connected with the ultrasonic sensors through a wireless transceiver module separately, and the controller is electrically connected with the fuzzy controllers separately; the controller iselectrically connected with servo motors on wheels of the robot trolley body through double H bridge drivers separately; an encoder is connected with all the servo motors; an orthogonal pulse decoderis connected with the encoder and the controller separately; a power monitoring reset is installed at the top of the trolley body. The travel distance of the trolley can be shortened, and therefore the travel time is shortened; the designed fuzzy controllers can improve the stability of a system and reduce errors. By using the ultrasonic sensors, obtained external information is high in accuracy,and the trolley is easy to implement.

Owner:UNIV OF JINAN

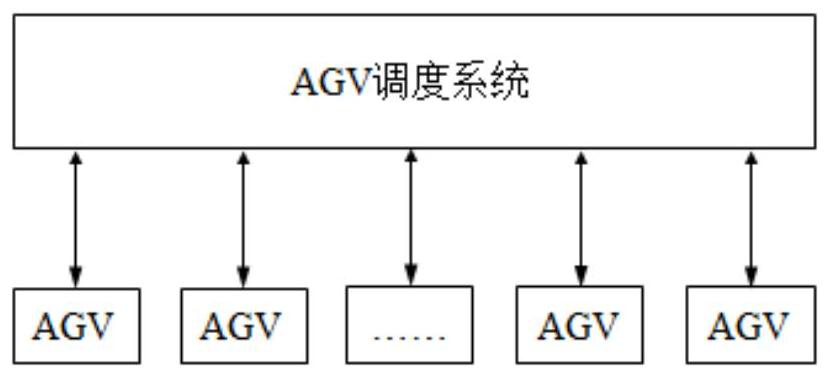

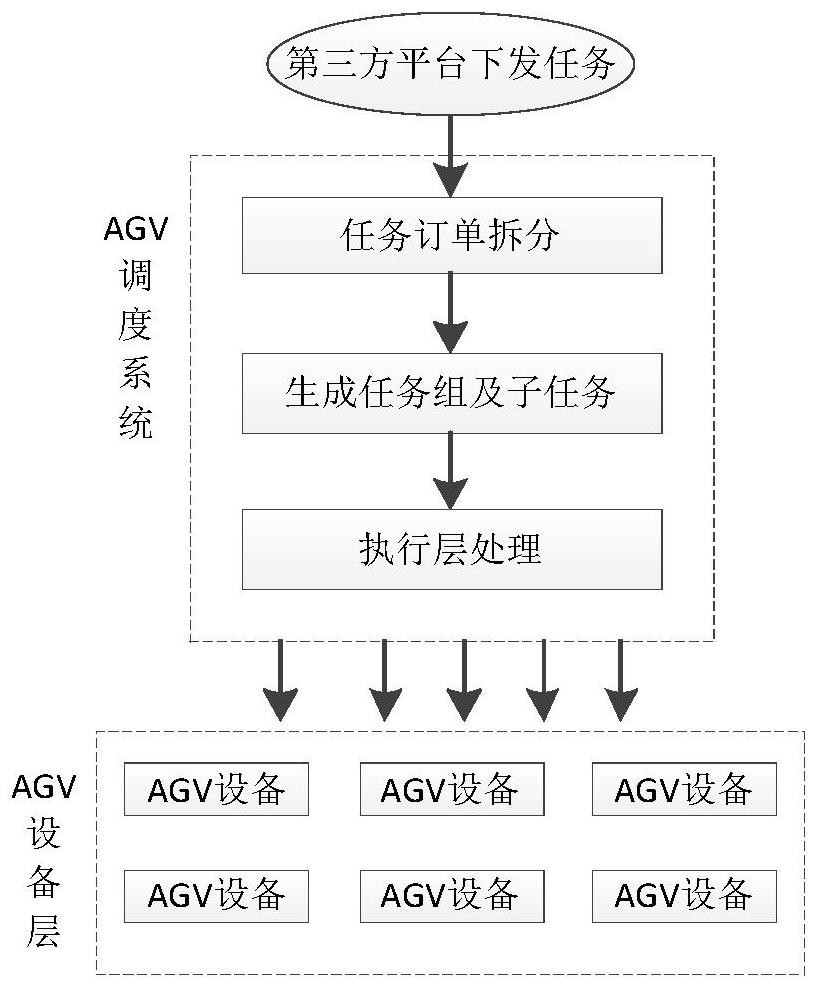

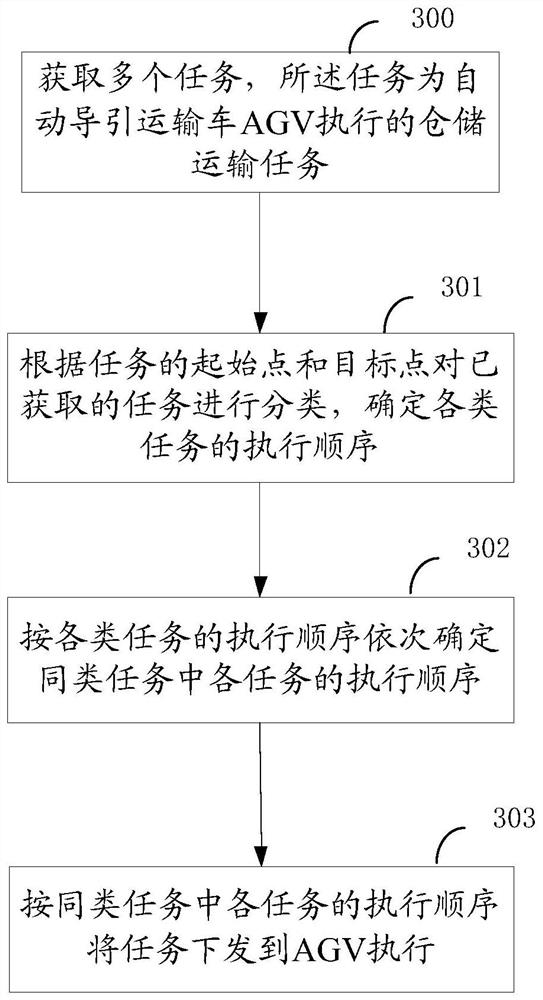

Task scheduling method, device and equipment

PendingCN112184053AImprove robustnessImprove acceleration performanceResourcesLogisticsAutomated guided vehicleOperating system

The invention discloses a task scheduling method, a task scheduling device and task scheduling equipment. The method can associatively consider tasks belonging to the same execution area, reduce pathreciprocation, shorten the total task execution time and improve the operation efficiency of a system. The method comprises the following steps: acquiring a plurality of tasks, wherein the tasks are storage and transportation tasks executed by an automated guided vehicle AGV; classifying the obtained tasks according to the starting points and the target points of the tasks, and determining an execution sequence of each type of tasks; sequentially determining the execution sequence of each task in the same kind of tasks according to the execution sequence of each kind of tasks; and issuing thetasks to the AGV for execution according to the execution sequence of the tasks in the same kind of tasks.

Owner:ゼジャンハーレイテクノロジーカンパニーリミテッド

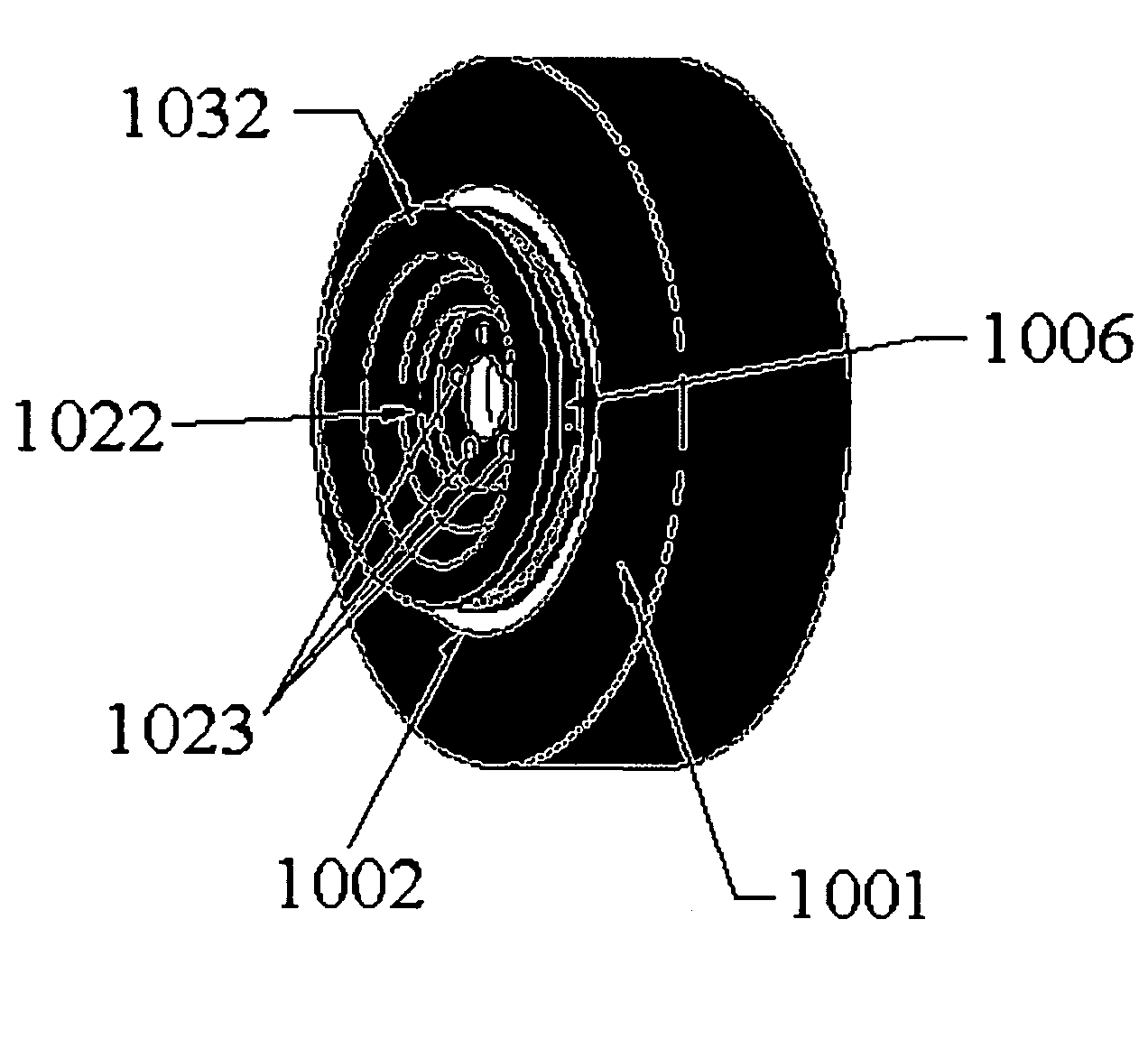

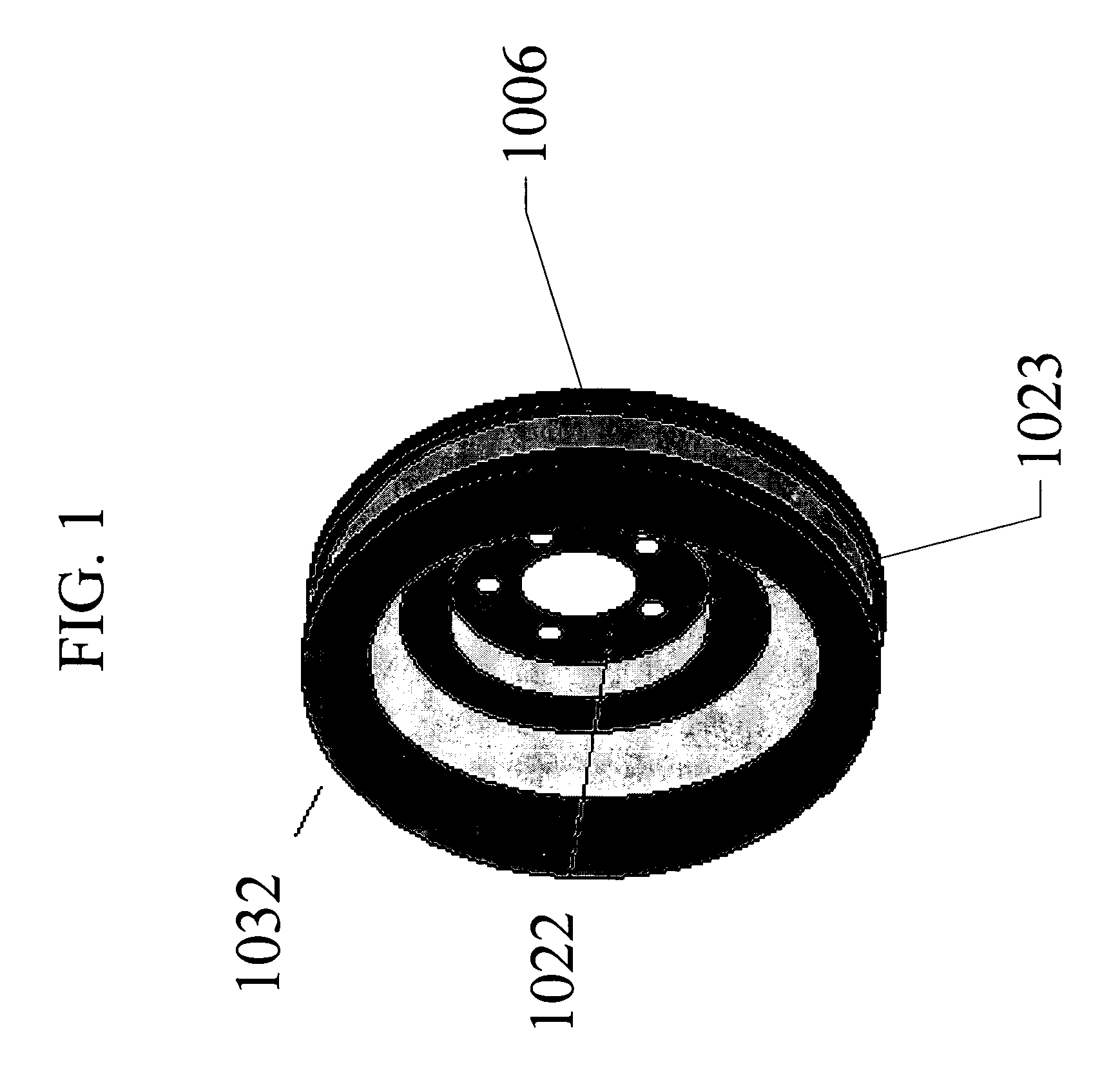

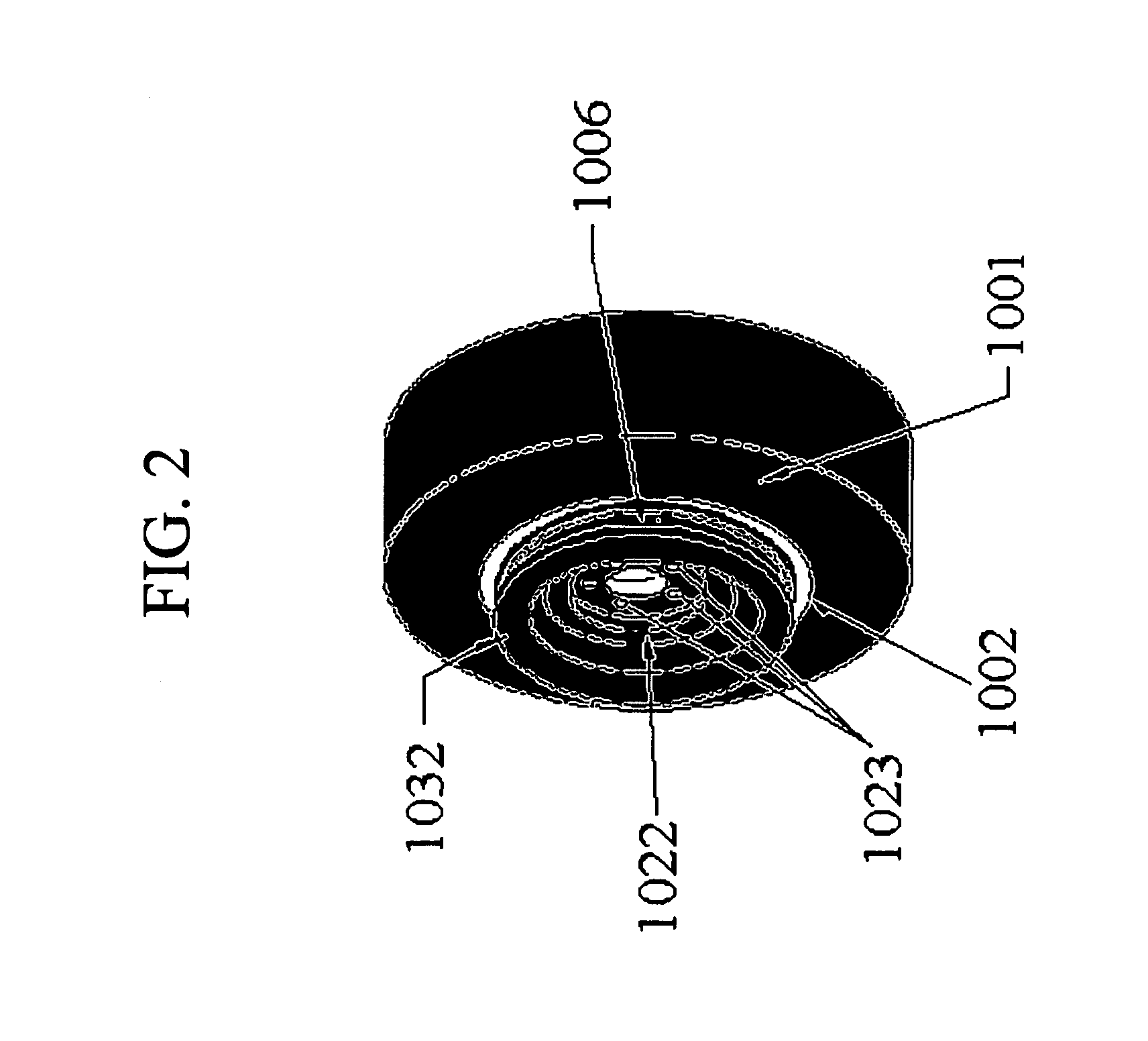

Tire winch, tire winch kit and method

A tire winch, tire winch kit, and method of pulling an object. The tire winch includes a spool having a substantially cylindrical hub dimensioned to accept and wind a cable thereabout, and a means for attaching the spool to a tire such that the rotation of the tire causes the spool to rotate. The kit includes a winding spool, an unwinding spool and a means for attaching one of the spools to the tire. The method includes the steps of attaching the winch to a drive wheel of a vehicle, winding a flexible member around the hub of the winch, attaching the free end of the member to an object, and driving away from the object to unwind the member from the winch and, thereby, pull the object a distance that is less than the distance traveled by the vehicle.

Owner:VAN COR DALE E

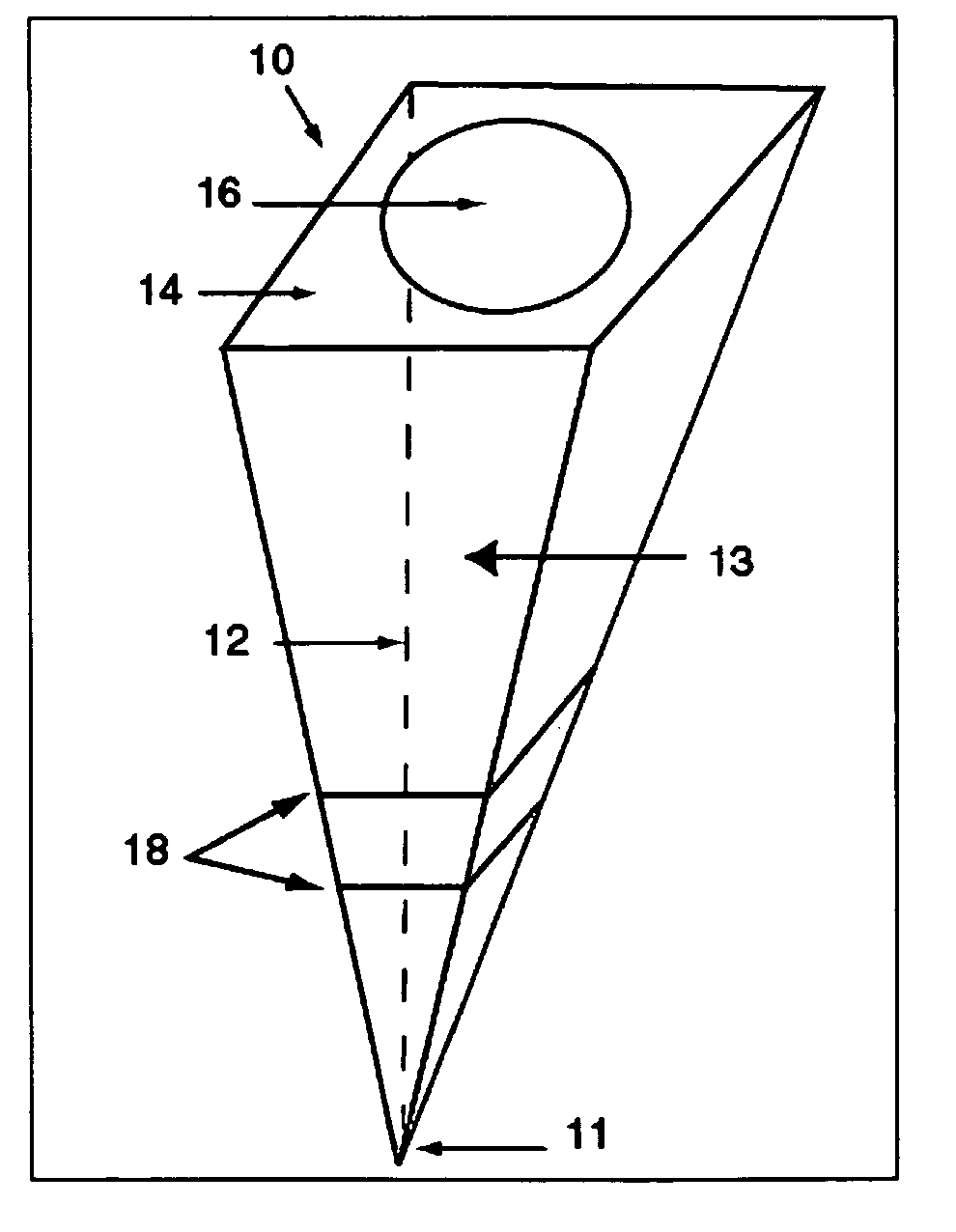

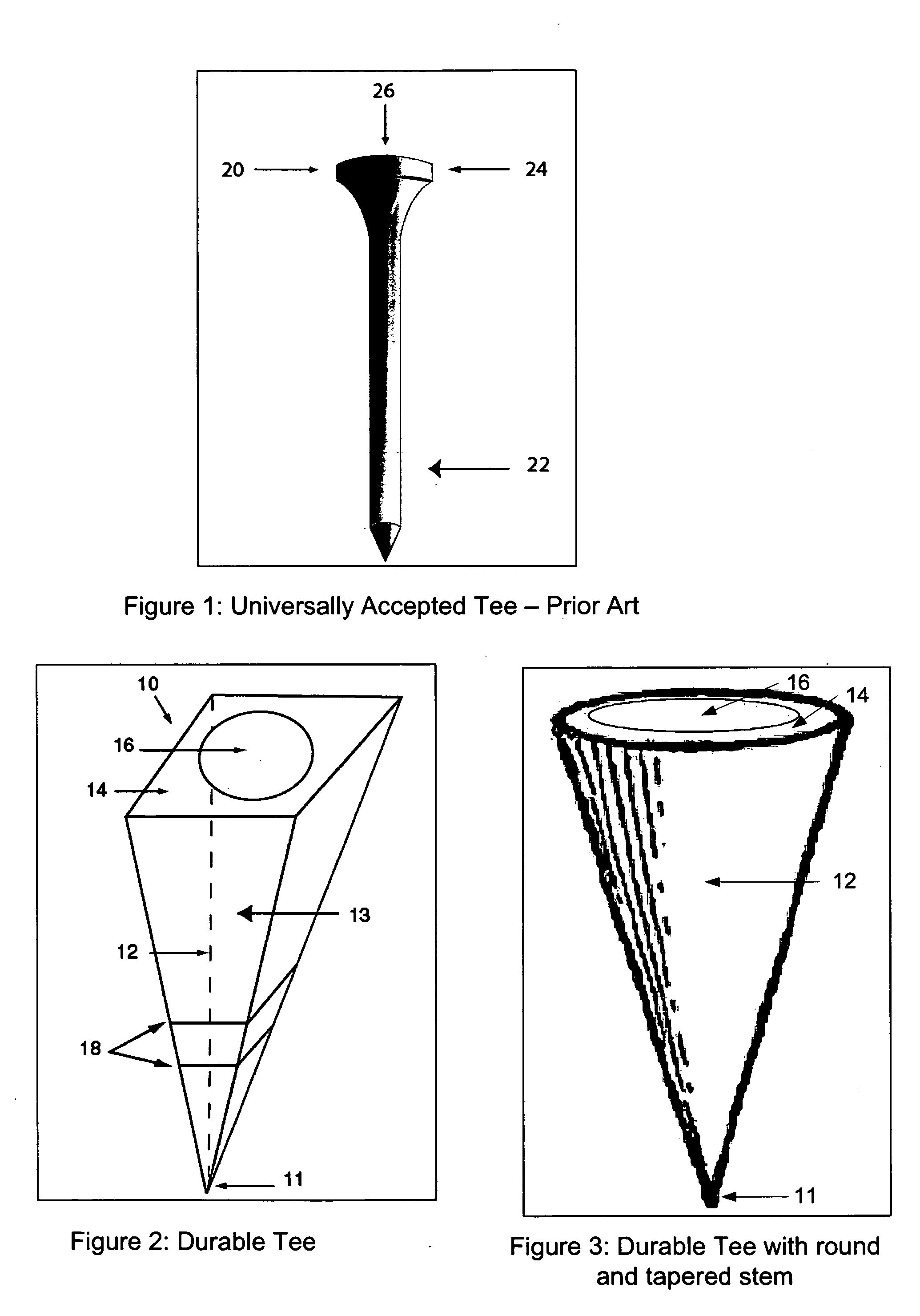

Durable golf tee

A golf tee designed to be strong and durable without relying on synthetic materials to be so. The golf tee is designed with an evenly tapered stem along the entire length, or a majority of the length, of the tee and tapers to a sufficient dimension so as to be easily inserted into the ground and includes a top surface with a depression to accept and retain a golf ball. The evenly tapered stem adds bulk and strength to the tee and reduces stress to the tee during a tee shot, providing longevity.

Owner:BRETON GERARD A

Computer radiating system

InactiveCN104571423AShorten travel distanceSpeed up the cycleDigital data processing detailsWater dischargeWater flow

The invention relates to a computer radiating system which comprises a case. The case comprises a casing and a radiating assembly. The radiating assembly comprises a water channel, a water feeding pipe, a water tank, a water discharging pipe, a water flow adjusting assembly, a cooling plate and a fin group. The water discharging pipe and the water flow adjusting assembly are arranged on two sides of the water tank. The water flow adjusting assembly comprises a round water pipe and a partition plate. The partition plate is arranged in the water pipe, the middle axis of the water pipe is located on the plane of the partition plate, one side of the partition plate is connected with the pipe wall of the water pipe in a sealing mode, a gap is formed between the other side of the partition plate and the pipe wall of the water pipe, a water inlet and a water outlet are arranged in the water pipe on two sides of the partition plate, the water inlet is connected with the water feeding pipe, and the water outlet is communicated with a cooling cavity. The computer radiating system adopts the waterfall type water cooling mode to conduct heat exchange in the case, improves the computer radiating speed, omits a fan, reduces noise, omits air ports, and achieves a good dustproof effect.

Owner:HUANGGANG POLYTECHNIC COLLEGE

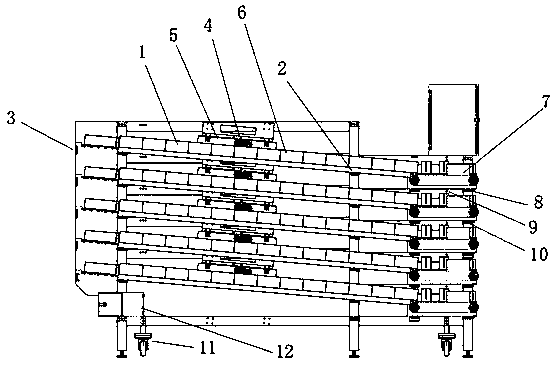

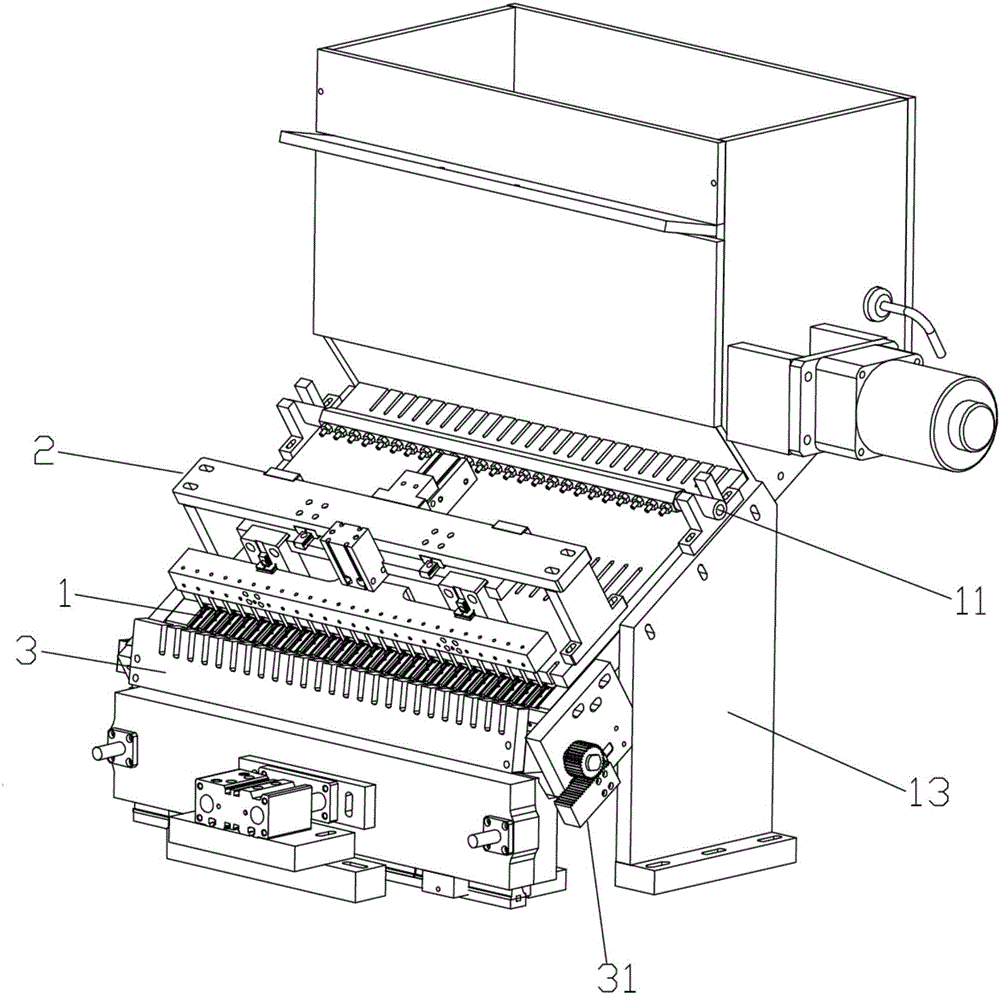

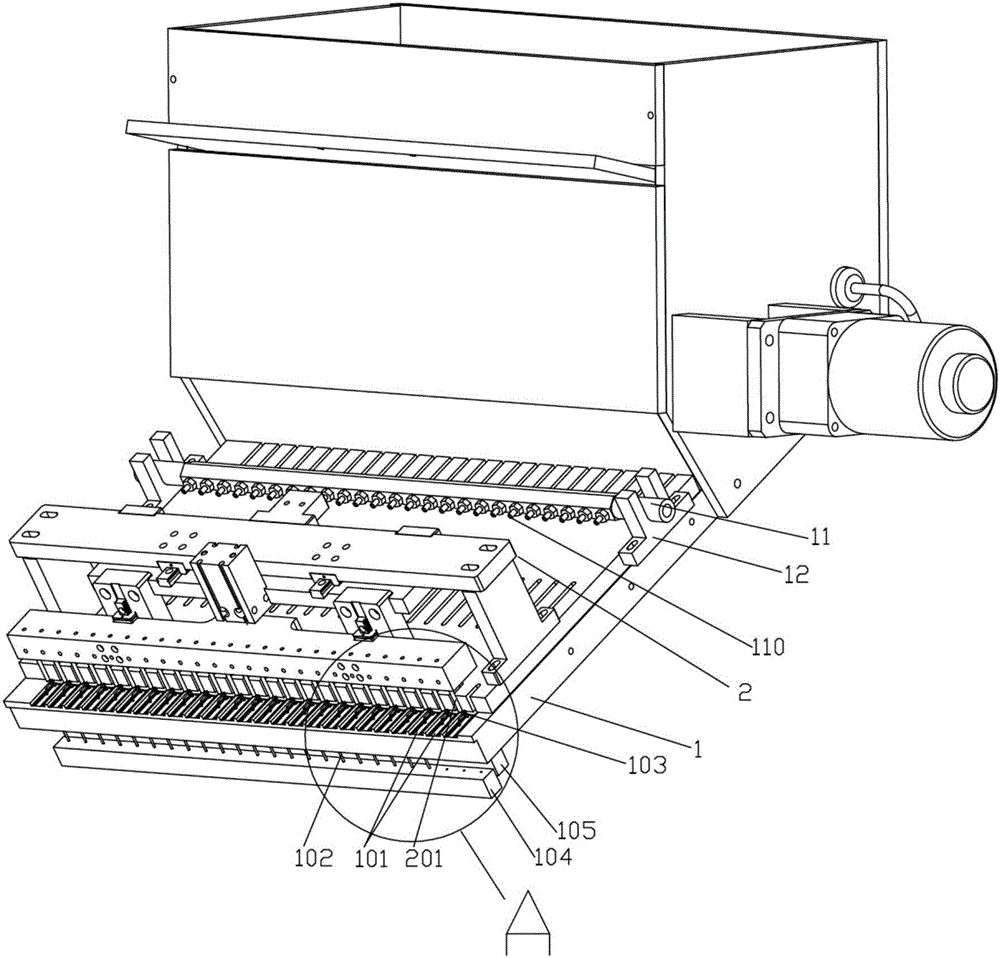

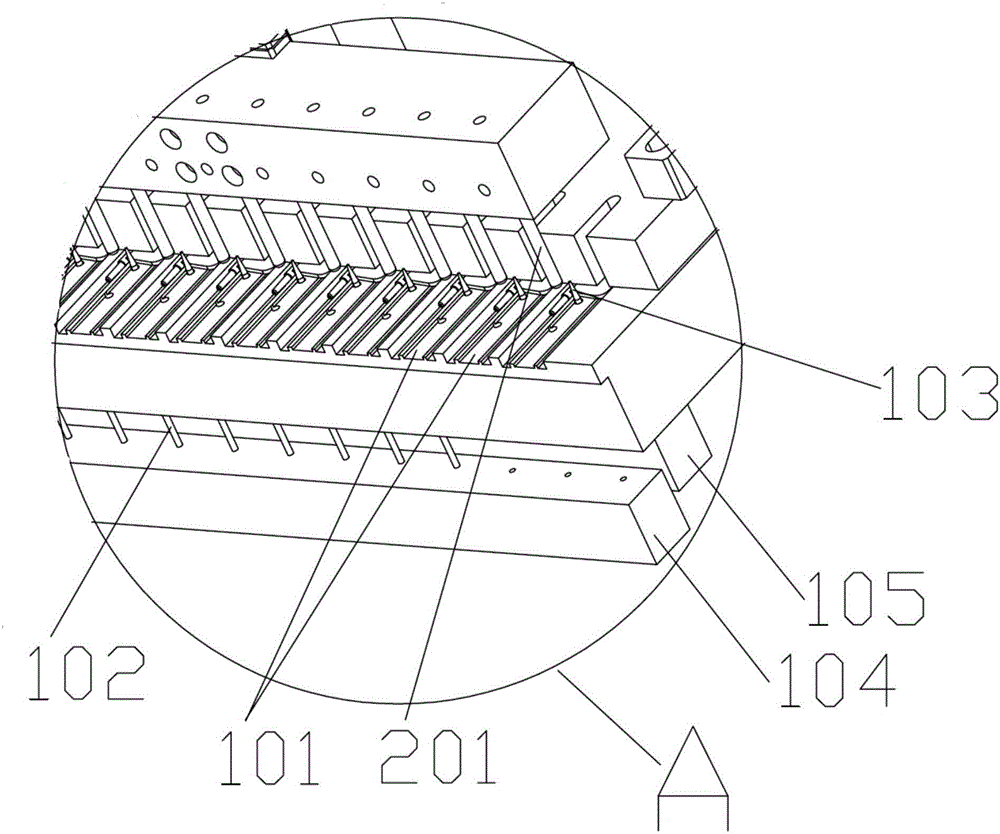

All-product-specification cigarette sorting machine

PendingCN108722887AShorten travel distanceImprove sorting efficiencyConveyorsSortingAlloyEngineering

The invention discloses an all-product-specification cigarette sorting machine which comprises a material buffering-storage mechanism, a cigarette bin width adjusting mechanism, a sorting module and auniversal wheel moving mechanism. The material buffering-storage mechanism comprises bottom aluminum alloy slide rails, cigarette lacking sensors and goods station display screens, wherein the bottomaluminum alloy slide rails are evenly and obliquely distributed on a sorting machine frame, the goods station display screens are mounted at the upper ends of the bottom aluminum alloy slide rails, and the cigarette lacking sensors are mounted at the tail ends of the bottom aluminum alloy slide rails. The cigarette bin width adjusting mechanism comprises double-shaft motors, width adjusting baffles and side aluminum alloy slide rails. The sorting module comprises sorting belts, counting points, cigarette blocking mechanisms and blocking mechanisms, wherein the sorting belts are mounted at thetail ends of the bottom aluminum alloy slide rails and are in transmission connection with the motors through rolling shafts, and the counting points are arranged on the sorting belts. Cigarettes inthe sorting machine transversely move instead of moving longitudinally in the prior art, the travel distance is shortened, and the sorting efficiency is improved; and sorting bins can be adjusted in width and height, so that the sorting machine is suitable for cigarettes of various specifications.

Owner:武汉泛征科技有限公司

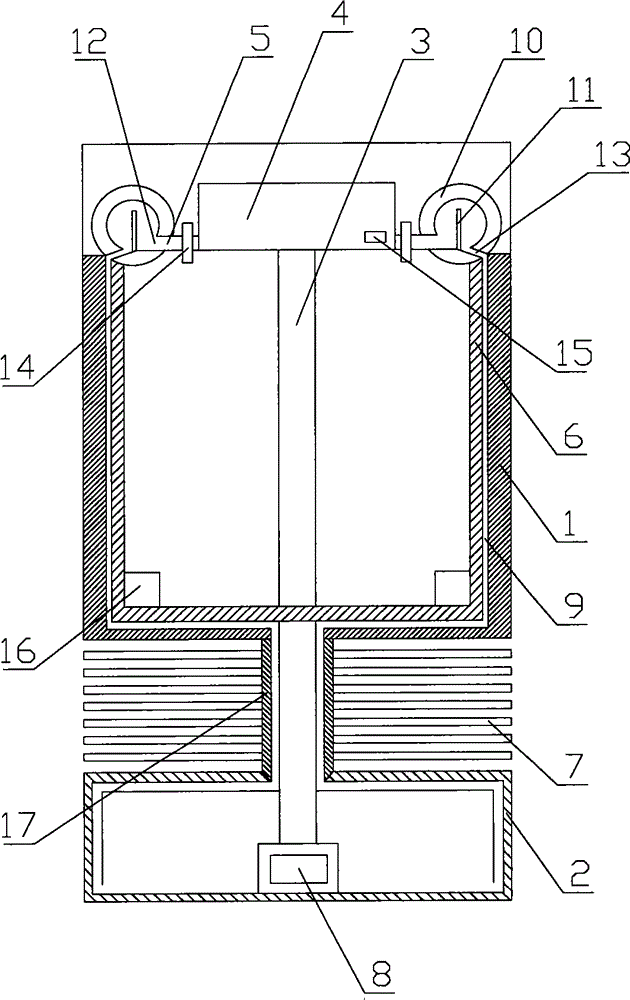

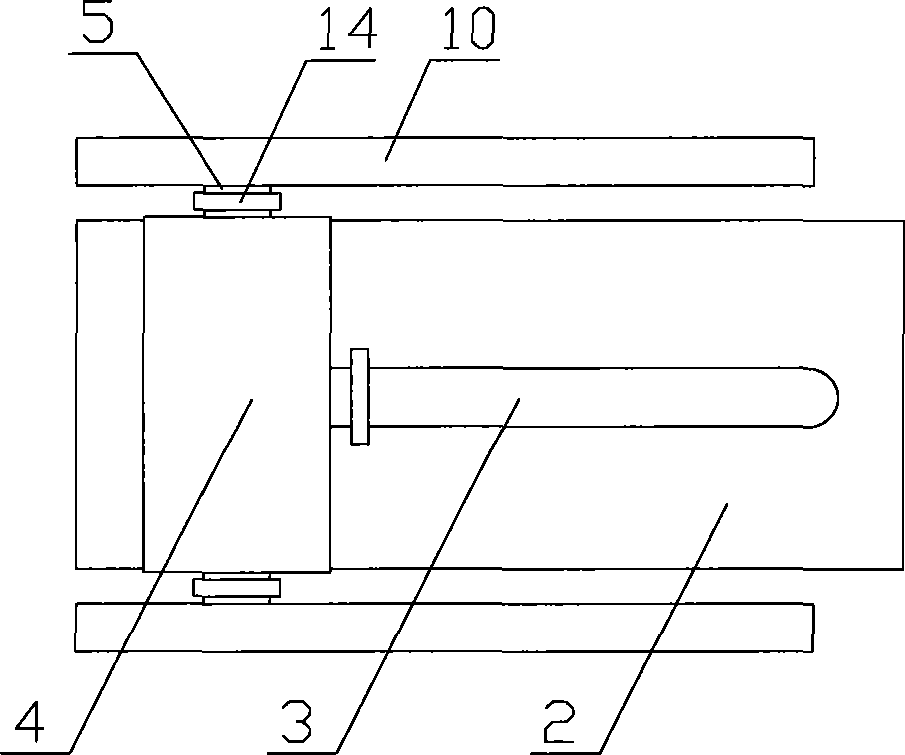

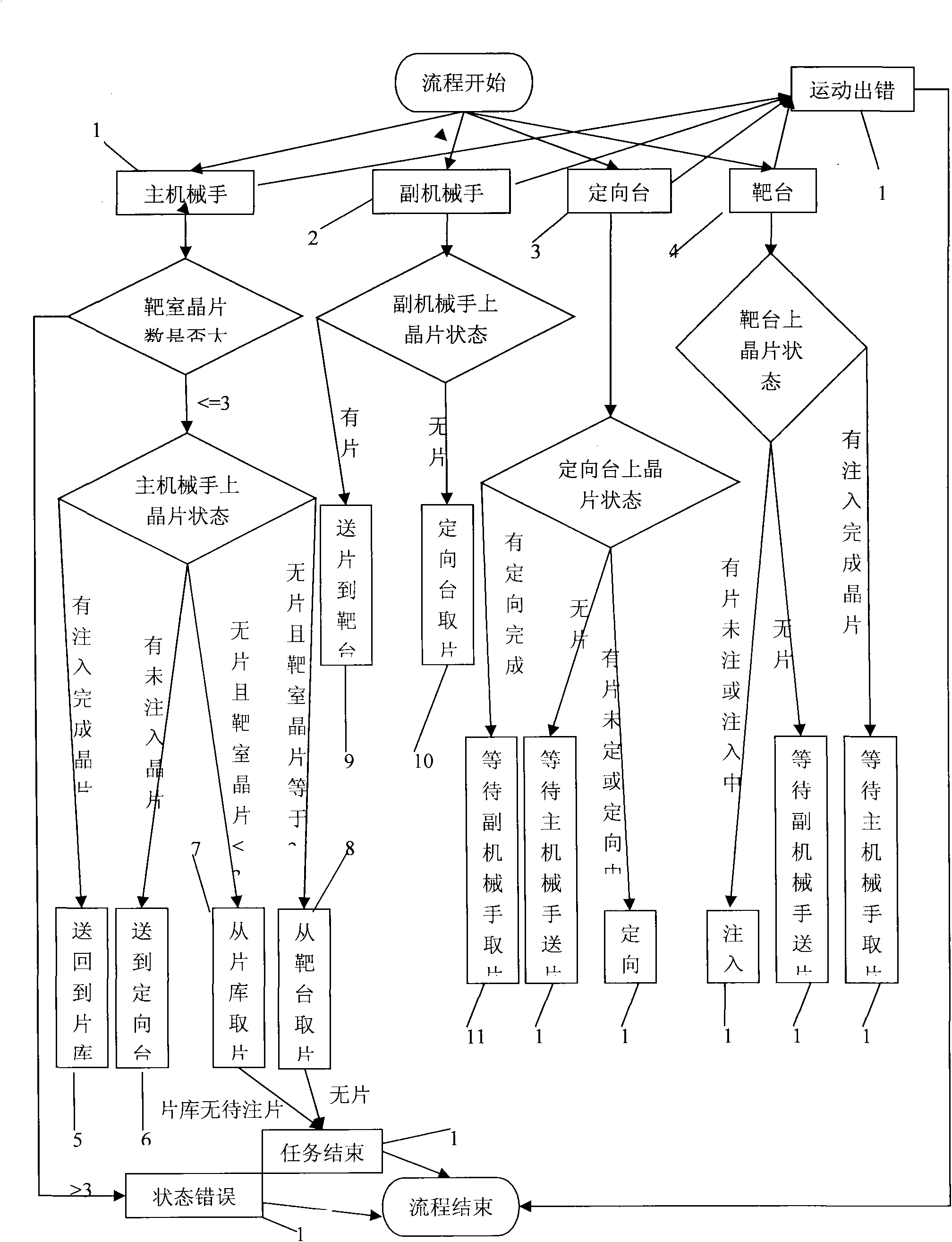

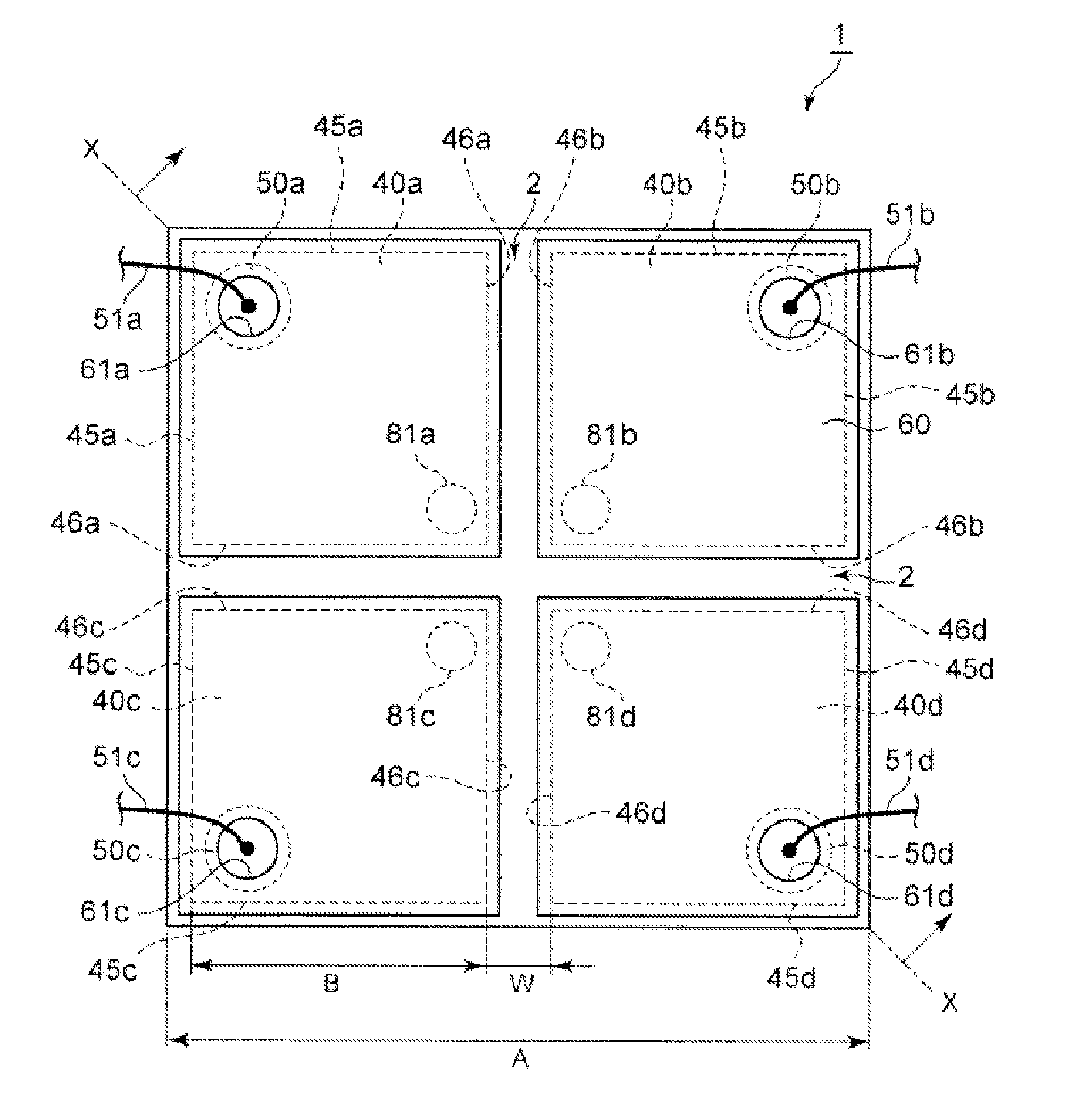

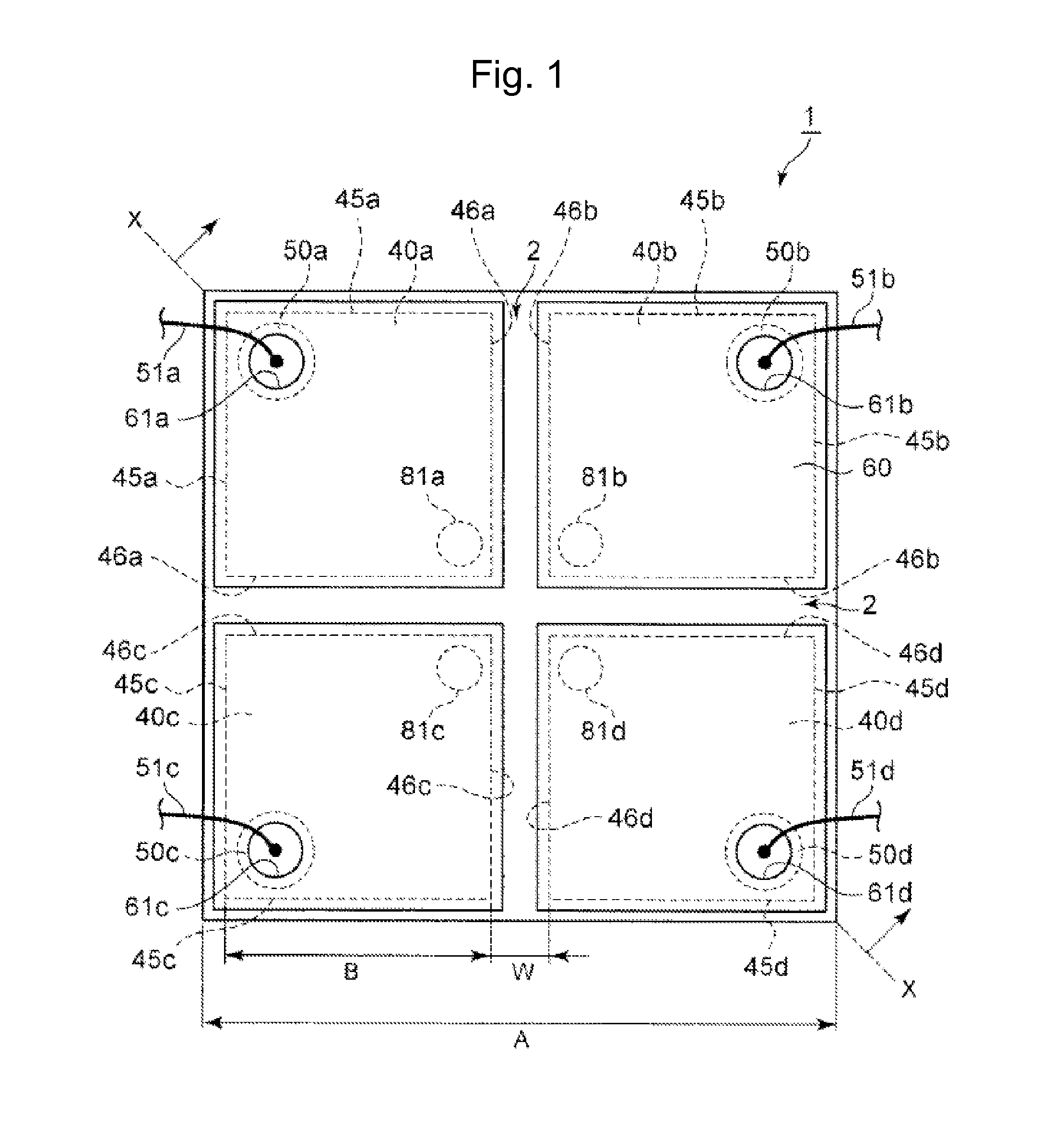

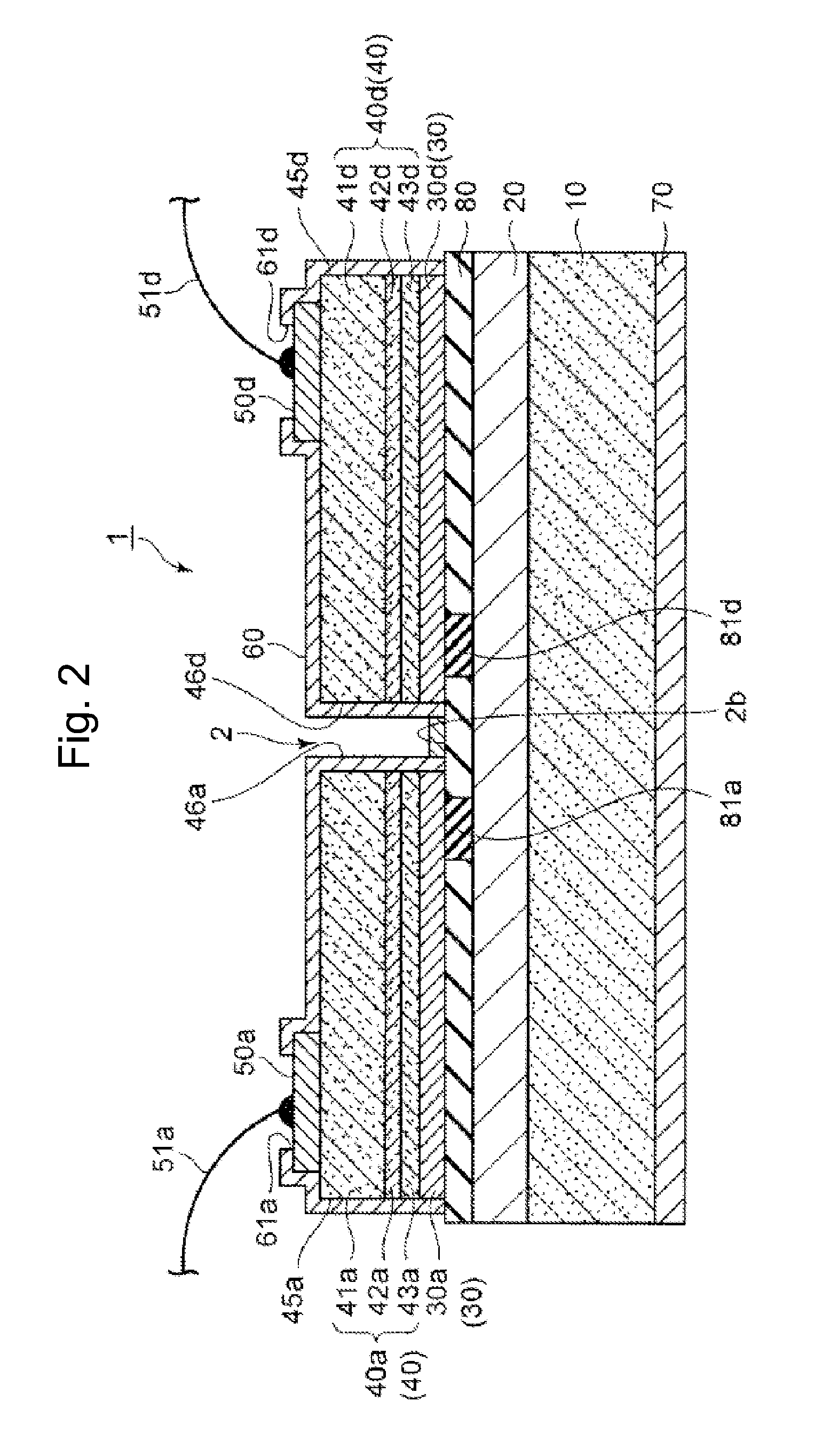

Method for improving wafer transmission efficiency of target chamber

ActiveCN102867768AAvoid timing confusionImprove stabilitySemiconductor/solid-state device manufacturingConveyor partsEngineeringMotion error

The invention discloses a method for improving the wafer transmission efficiency of a target chamber. According to the method, four functional modules are included, namely, a primary manipulator (1), a secondary manipulator (2), an orientation platform (3) and a target platform (4), furthermore a plurality of sub-modules for feeding back a wafer to a wafer warehouse (5), conveying the wafer to the orientation platform (6), taking the wafer from the wafer warehouse (7), taking the wafer from the target platform (8), showing state error (17) and ending the task (19) are arranged under the primary manipulator (1); two sub-modules for conveying the wafer to the target platform (9) and taking the wafer from the orientation platform (10) are further arranged under the secondary manipulator (2); three sub-modules for waiting for the secondary manipulator to take the wafer (11), waiting for the secondary manipulator to convey the wafer (12) and for orientation (13) are further arranged under the orientation platform; and each large module is provided with a motion error module (18). The method is characterized in that the primary manipulator (1), the secondary manipulator (2), the orientation platform (3) and the target platform (4) execute respective internal events and are coordinated and allocated by an upper module uniformly, so that the internal disorder of programs and procedures is prevented, the programs and the procedures are simpler and clearer; with the adoption of the method, three wafers can be conveyed inside the target chamber at the same time, so that the utilization rate of the manipulator is improved to the maximum extent, the ideal time is shortened, and the transmission efficiency is improved.

Owner:BEIJING SHUOKE ZHONGKEXIN ELECTRONICS EQUIP CO LTD

Intravenous needle wing panel feeding device

InactiveCN106219198AAvoid the phenomenon of staying in the groove Ⅰ of the main plate of the needle handleNeat finishConveyorsLoading/unloadingIntravenous needlesEngineering

The invention provides an intravenous needle wing panel feeding device. The intravenous needle wing panel feeding device comprises a needle handle main plate which is used for conveying an intravenous needle wing panel, a material pushing assembly which is used for pushing the intravenous needle wing panel and a feeding seat which is used for rotating, guiding and conveying the intravenous needle wing panel; the material pushing assembly can push the intravenous needle wing panel which is conveyed to the bottom end of the needle handle main plate along the needle handle main plate to leave the needle handle main plate; the feeding seat is used for receiving the intravenous needle wing panel which is conveyed downwards from the needle handle main plate; a plurality of grooves I which are used for conveying intravenous needle wing panels are formed in the needle handle main plate; a first ejector pin and a second ejector pin are arranged at the bottom end of each groove I side by side. Due to the adoption of the technical scheme, the material pushing assembly and two groups of ejector pins which are arranged at the bottom end of the needle handle main plate are matched mutually to work, so that the phenomenon that quite a few intravenous needle wing panels stay in the grooves I of the needle handle main plate caused by the factors that the self weight of each intravenous needle wing panel is light and the like is avoided; clean, accurate and high-efficiency conveying of the intravenous needle wing panels are effectively ensured.

Owner:梁启明

Semiconductor light emitting element

ActiveUS20120161183A1Reduce warpageLight extraction efficiencySolid-state devicesSemiconductor/solid-state device manufacturingActive layer

A semiconductor light emitting element comprises a semiconductor laminate including a p-type semiconductor layer, an active layer and an n-type semiconductor layer which are sequentially laminated; and a conductive support substrate joined to the p-type semiconductor layer side of the semiconductor laminate. The semiconductor laminate is divided into at least two semiconductor regions by a trench penetrating the p-type semiconductor layer, the active layer and the n-type semiconductor layer.

Owner:NICHIA CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com