Adhesive tape joining apparatus

A sticking device and adhesive tape technology, applied in the direction of transportation and packaging, sending objects, motor vehicles, etc., can solve the problems of hindering forward movement, slowing down of sticking movement speed, dispersion, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0060] For the purpose of illustrating the present invention, although several presently considered best embodiments are shown, it should be noted that the present invention is not limited to the configurations and arrangements shown in the drawings.

[0061] Next, an embodiment of the present invention will be described with reference to the drawings.

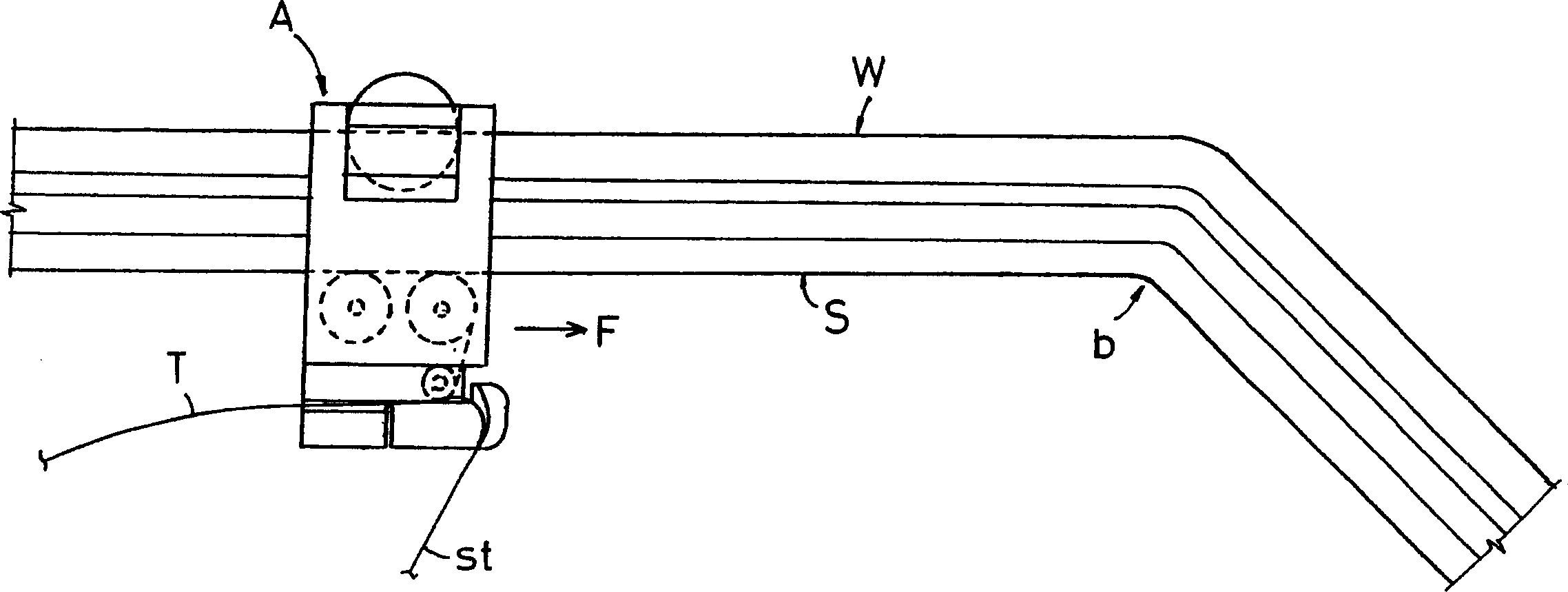

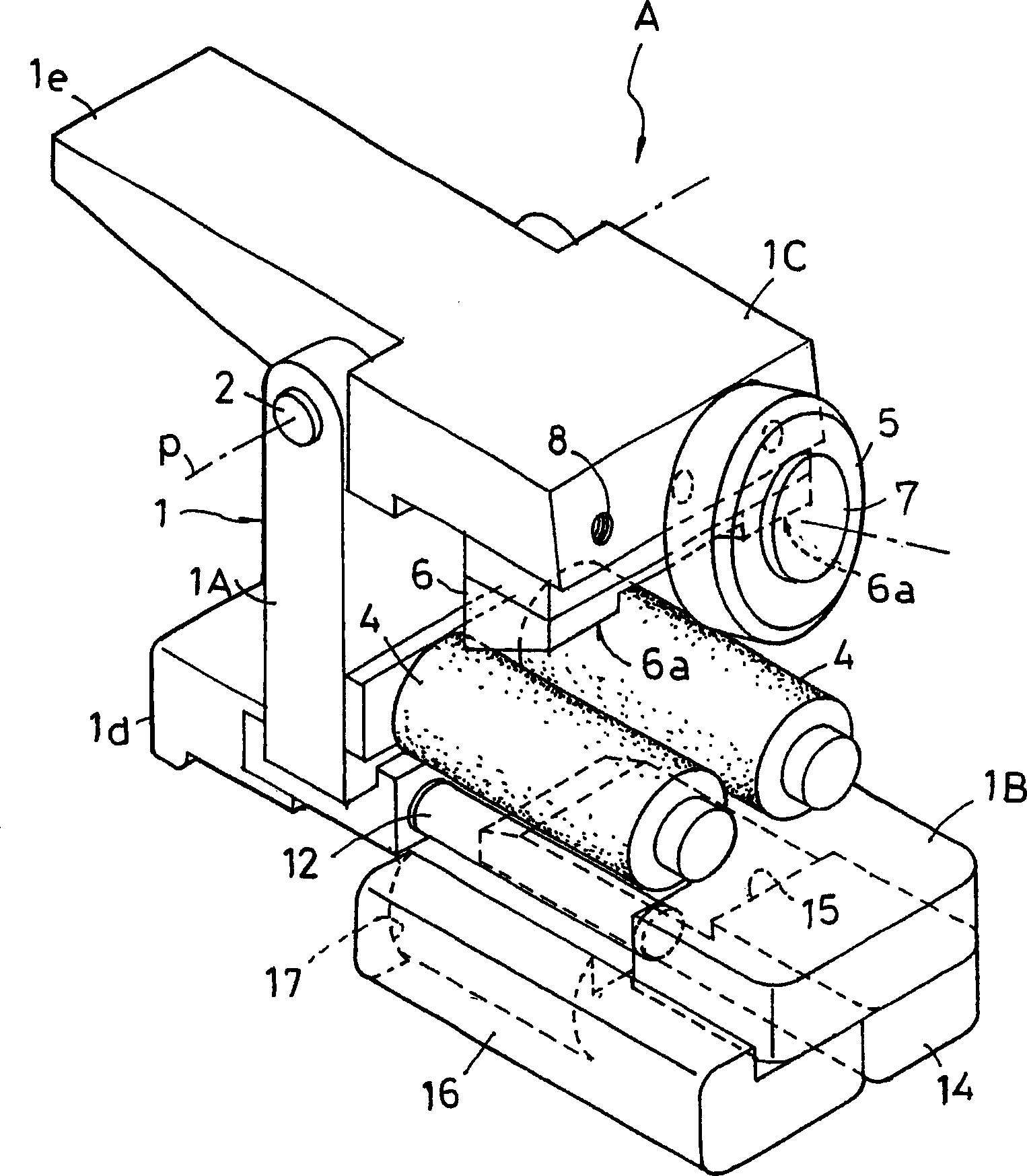

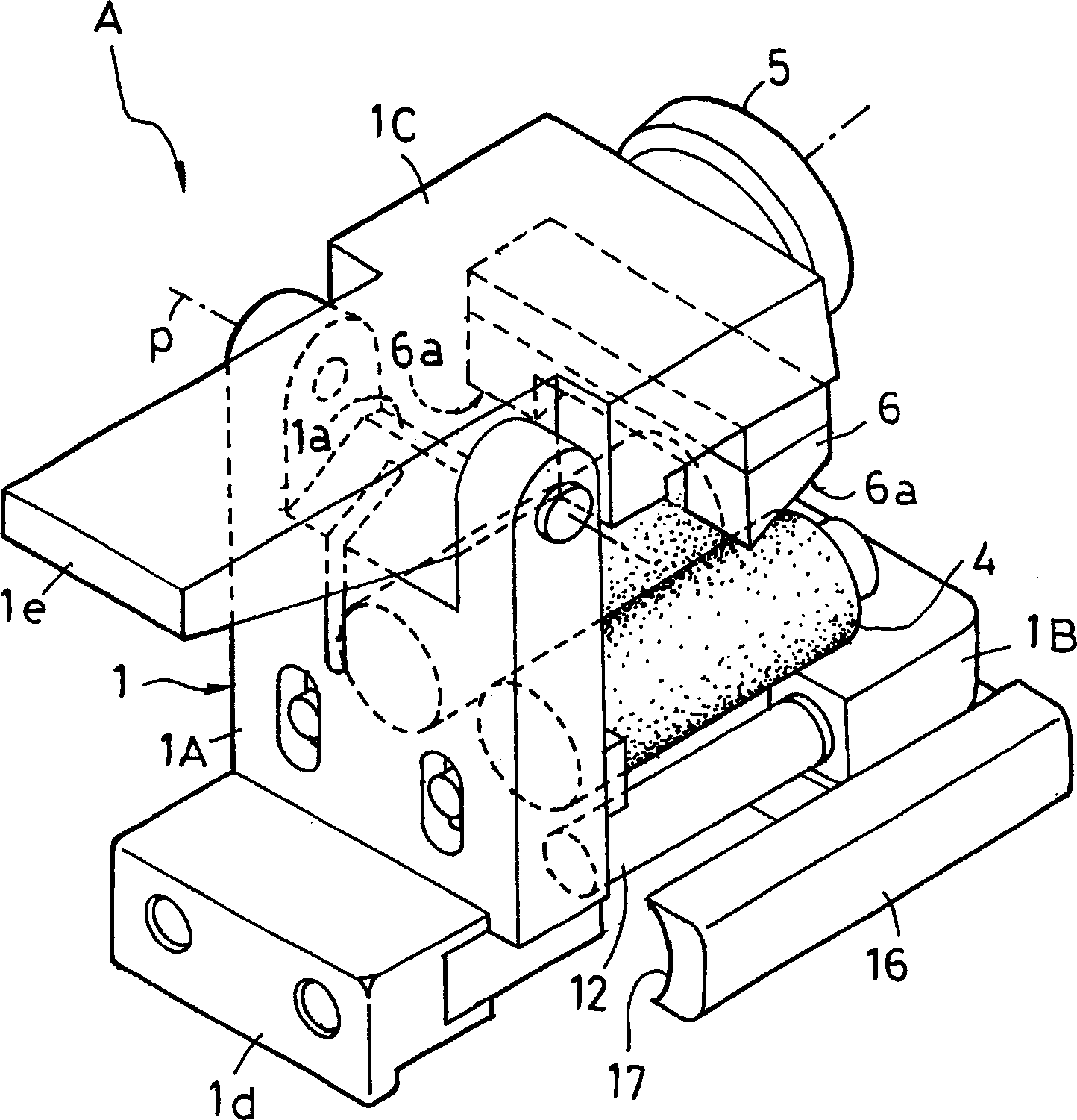

[0062] figure 1 It is a side view of the process of sticking the adhesive tape T to the curved workpiece W using the adhesive tape sticking device A of the present invention, figure 2 and image 3 A perspective view of the appearance of the adhesive tape sticking device A is shown, Figure 4 A perspective view showing an adhesive tape sticking process, Figure 5 A front view showing the pasting process.

[0063] In addition, the workpiece W of this embodiment is a door and window frame of an automobile. A black adhesive tape is pasted on the inner peripheral surface of the vehicle inner side of the door sash instead of a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com