Electromagnetic valve and electromagnetic valve system

A solenoid valve and valve cavity technology, applied in the direction of lift valve, valve detail, multi-way valve, etc., can solve the problem of low operating frequency of the electromagnetic valve, achieve the effect of reducing the travel distance, increasing the operating frequency, and shortening the closing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 3

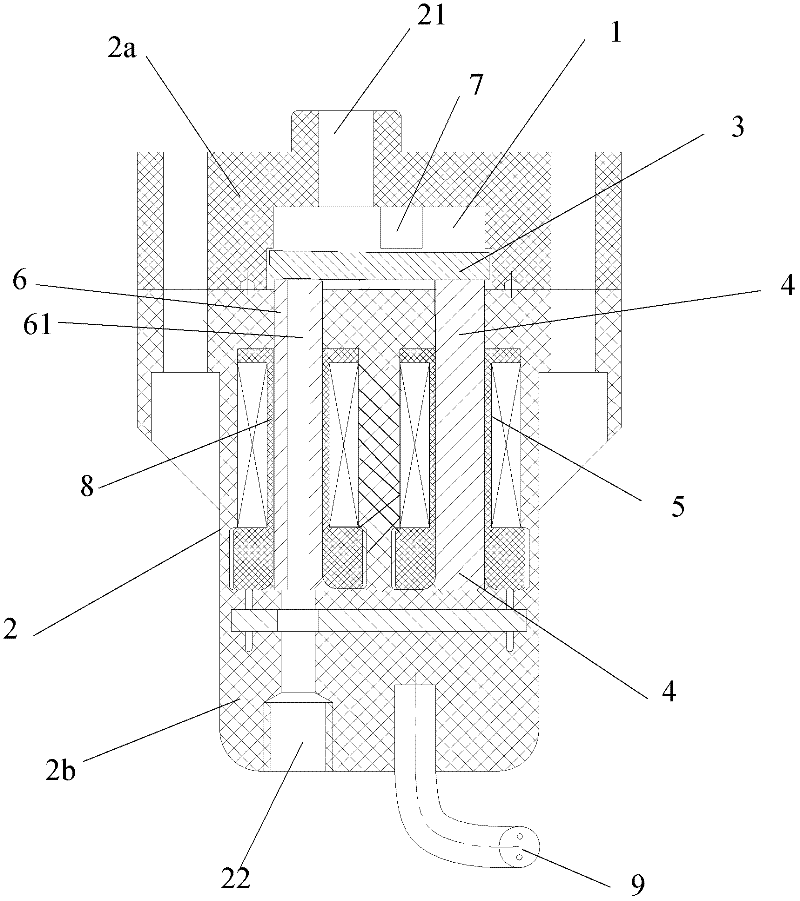

[0086] Among them, the present invention also provides a solenoid valve embodiment 3. In this embodiment, the first pillar of the solenoid valve is also an iron core wound with a second coil. This embodiment is different from the solenoid valve embodiment 2. The difference is that the circuit connection structures of the first coil and the second coil are different.

[0087] see Figure 5 , shows a schematic diagram of the circuit connection inside the solenoid valve in Embodiment 3.

[0088] The second coil 8 is connected in parallel with the two ends of the first coil 5 after being connected in series with the forward current blocking diode 82 .

[0089] After the first coil 5 and the second coil 8 are connected in parallel, they can be directly connected to an external power source. Preferably, the switch pulse control circuit 200 can also be connected through the built-in switch 300, and the external power supply can be connected through the switch pulse control circuit ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com