All-product-specification cigarette sorting machine

A sorter and rule technology, applied in sorting, conveyor, conveyor objects and other directions, can solve the problems of long travel distance, fast conveyor belt transmission speed, longer distance of cigarettes, etc., to achieve shorter travel distance, The effect of improving sorting efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

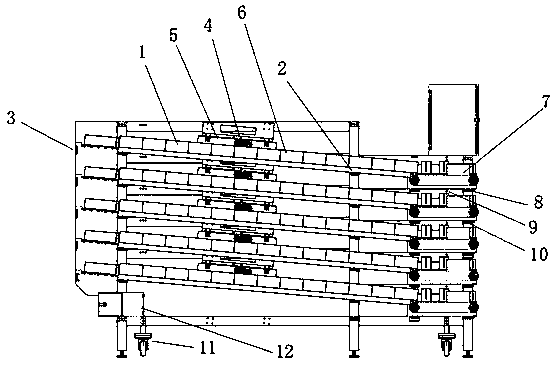

[0017] Such as figure 1 As shown, the present invention provides a sorting machine for all kinds of ruled cigarettes, including a material buffer mechanism, a tobacco bin width adjustment mechanism, a sorting module and a universal wheel moving mechanism. The material buffer mechanism includes a bottom fluent strip slide rail 1, a The smoke sensor 2 and the cargo display screen 3 are provided with several sets of bottom fluent bar slide rails 1, and several sets of bottom fluent bar slide rails 1 are uniformly and obliquely distributed on the sorter frame, and the upper end of the bottom fluent bar slide rail 1 is installed There is a display screen 3 for the storage space, and a smoke sensor 2 is installed at the end of the fluent slide rail 1 on the bottom; 4. It is fixedly installed in the middle of the bottom surface of the tobacco chamber width adjustment mechanism. The side fluent strip slide rail 6 is installed on both sides of the bottom surface fluent strip slide rail...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com