Horizontal disk injecting forming unit

An injection molding machine and disc technology, which is applied in the field of disc plastic injection molding machines, can solve the problems of shortening the mold clamping cylinder piston, reducing the service life of the disc, and low production efficiency, so as to shorten the time spent and the stroke distance, and the effect of increasing productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

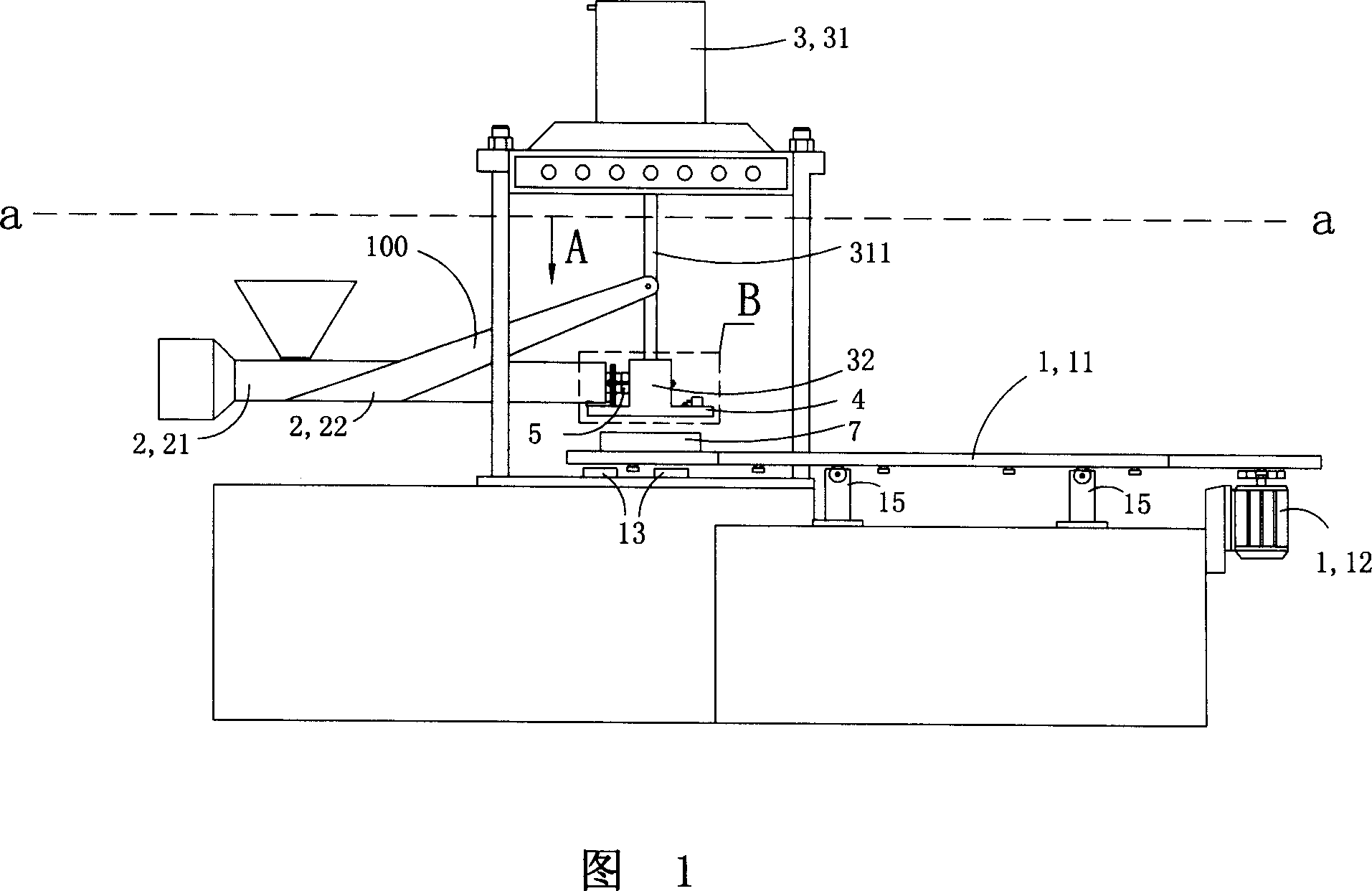

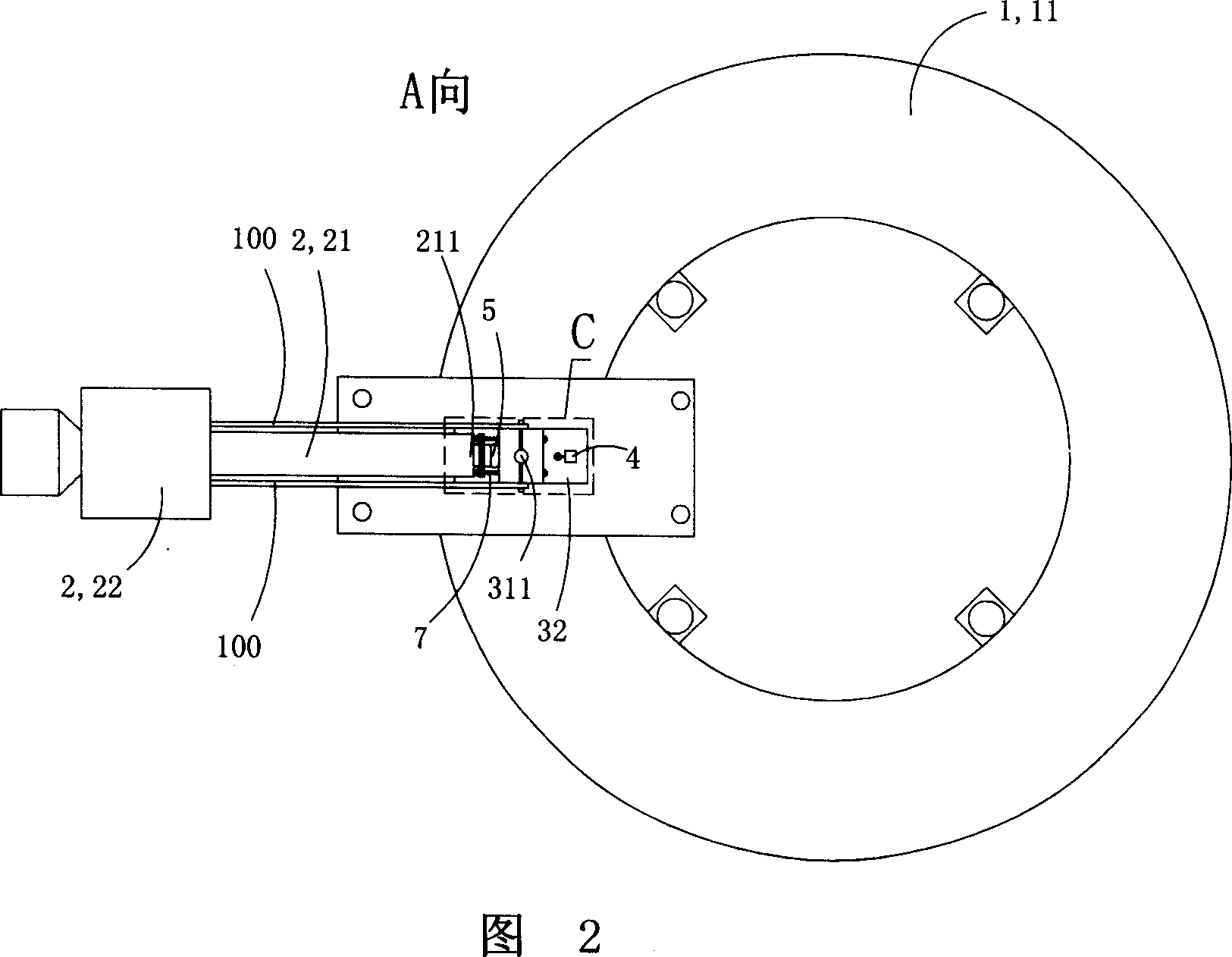

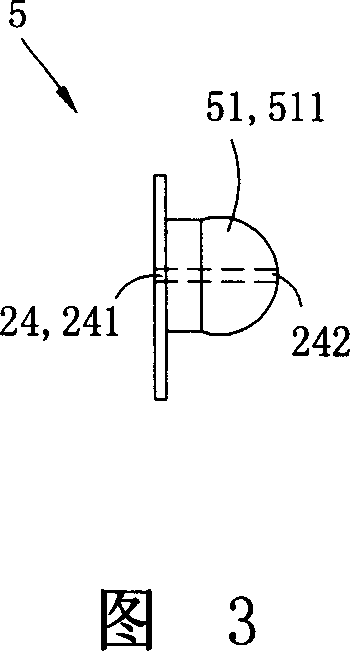

[0053] 1 to 7, the disc horizontal plastic injection molding machine of this embodiment has a turntable device 1, an injection device 2 for injecting plastic fluid into the mold, and a mold clamping device 3; the turntable device 1 includes a rotatable disc 11. The motor 12 and four fixed feet 15 that drive the rotation of the disk 11; the injection molding device 2 includes a horizontal injection molding part 21 and an injection coupling 5, and the injection coupling 5 is provided with an injection material channel 24; the mold clamping device 3 includes a mold clamping cylinder 31 and an injection head 32 arranged above the disc 11; the mold clamping cylinder piston 311 can move up and down, and the mold clamping device 3 also includes the injection The head 32 is fixedly arranged on the lower end of the piston 311 of the clamping cylinder, and can move up and down as the piston 311 moves up and down; The feed port 331 is arranged on the side of the injection head 32, and th...

Embodiment 2

[0065] See Fig. 8 to Fig. 9, this embodiment is basically the same as Embodiment 1, the difference is that: the turntable device 1 also has a pressure-bearing tray 13 fixedly arranged relative to the mold clamping cylinder 31, two for bearing Support the elastic standoff 14 of described disc 11 and two fixed standoffs 15; The disc 11 is held up and is 2 mm to 5 mm higher than the upper surface of the pressure-bearing tray 13. When the disc 11 is pressed downward by the piston 311 of the clamping cylinder, the disc 11 and the elastic stand 14 is pressed to lower its height, so that the pressure-bearing tray 13 holds up the disc 11 .

[0066] Since the turntable device 1 of this embodiment also has a pressure-bearing tray 13 fixedly arranged relative to the clamping cylinder 31 and two elastic legs 14 for supporting the disc 11; When the disc 11 is not pressed downward by the piston 311 of the clamping cylinder, the elastic standoff 14 lifts the disc 11 and is 2 mm to 5 mm high...

Embodiment 3

[0068] See Figure 10 to Figure 15, this embodiment is basically the same as Embodiment 2, the difference is that: the left end of the injection coupling 5 is fixedly connected with the injection molding part 21, and the injection coupling 5 The right side end of the injection head 32 is movably connected, and the injection molding part 21 is also movably connected with the base 22 of the injection molding device; the injection molding part 21 can be It moves back and forth in the horizontal direction and can rotate a certain angle in the vertical direction.

[0069] The injection head 32 has two special-shaped connecting holes 35, and the special-shaped connecting hole 35 is composed of a limiting hole 351 for setting bolts and a vertically large outer and inner small hole 351 and a fixing hole for setting nuts. 352; the end of the special-shaped coupling hole 35 close to the injection coupling 5 is the limiting hole 351, and the end away from the injection coupling 5 is the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com